NbTi/Cu superconducting composite pipe and preparation method thereof

A composite tube and superconducting technology, which is applied in the manufacture/processing of superconductor devices, superconductor components, etc., can solve the problems of no superconductor size, niobium-titanium alloy content control, etc., and achieve industrial production, simple operation, and technological process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

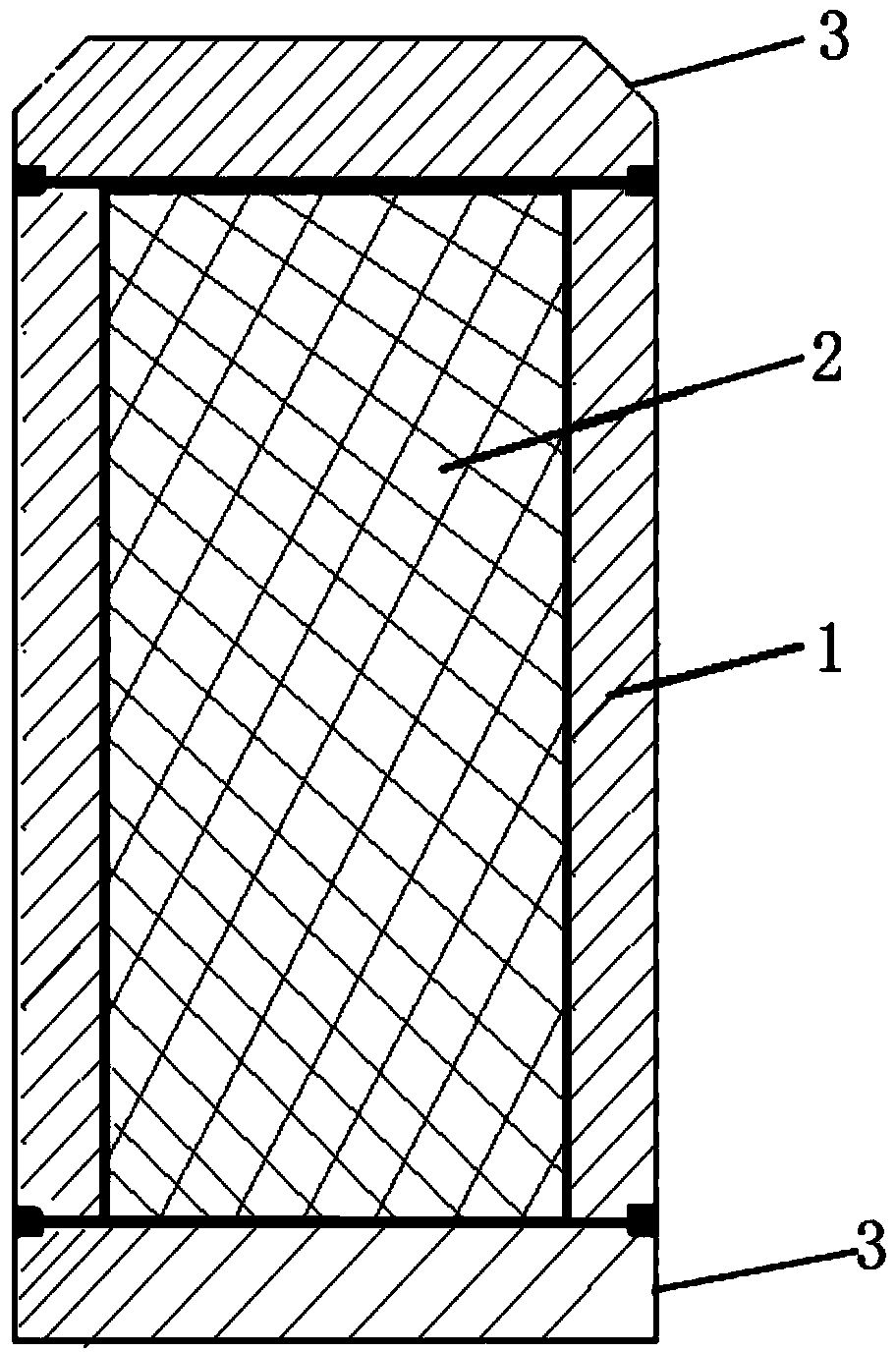

[0052] Step 1. Press the NbTi alloy ingot 2 into the oxygen-free copper tube 1, assemble it into a NbTi / Cu composite ingot, make the NbTi alloy ingot 2 and the oxygen-free copper tube 1 interfere fit, and seal and weld the composite ingot with the oxygen-free copper cover plate 3 both ends. Wherein, the Nb content in the NbTi alloy ingot 2 is 45%, the rest is Ti, and the ratio of the cross-sectional area of the oxygen-free copper tube 1 to the NbTi alloy ingot 2 is 0.5:1;

[0053] Step 2. The NbTi / Cu composite ingot assembled in step 1 is hot-extruded to become a NbTi / Cu composite rod. The hot-extrusion temperature is 500° C., and the extrusion ratio is 9:1;

[0054] Step 3, cold drawing the NbTi / Cu composite rod prepared in step 2, the deformation of the cold drawing pass is 15%, so that its diameter is 20mm;

[0055] Step 4, performing aging heat treatment on the composite rod treated in step 3, the aging heat treatment temperature is 350°C, and the aging heat treatment t...

Embodiment 2

[0060] Step 1. Press the NbTi alloy ingot 2 into the oxygen-free copper tube 1, assemble it into a NbTi / Cu composite ingot, make the NbTi alloy ingot 2 and the oxygen-free copper tube 1 interfere fit, and seal and weld the composite ingot with the oxygen-free copper cover plate 3 both ends. Wherein, the Nb content in the NbTi alloy ingot 2 is 48%, the rest is Ti, and the ratio of the cross-sectional area of the oxygen-free copper tube 1 to the NbTi alloy ingot 2 is 0.8:1;

[0061] Step 2. The NbTi / Cu composite ingot assembled in step 1 is hot-extruded to become a NbTi / Cu composite rod. The hot-extrusion temperature is 580° C., and the extrusion ratio is 11:1;

[0062] Step 3, cold drawing the NbTi / Cu composite rod prepared in step 2, the deformation of the cold drawing pass is 17%, making its diameter 17mm;

[0063] Step 4, performing aging heat treatment on the composite rod treated in step 3, the aging heat treatment temperature is 370°C, and the aging heat treatment time...

Embodiment 3

[0068] Step 1. Press the NbTi alloy ingot 2 into the oxygen-free copper tube 1, assemble it into a NbTi / Cu composite ingot, make the NbTi alloy ingot 2 and the oxygen-free copper tube 1 interfere fit, and seal and weld the composite ingot with the oxygen-free copper cover plate 3 both ends. Wherein, the Nb content in the NbTi alloy ingot 2 is 47%, the rest is Ti, and the ratio of the cross-sectional area of the oxygen-free copper tube 1 to the NbTi alloy ingot 2 is 0.6:1;

[0069] Step 2. The NbTi / Cu composite ingot assembled in step 1 is hot-extruded to become a NbTi / Cu composite rod. The hot-extrusion temperature is 550° C., and the extrusion ratio is 10:1;

[0070] Step 3, cold drawing the NbTi / Cu composite rod prepared in step 2, the deformation of the cold drawing pass is 13%, making its diameter 13mm;

[0071] Step 4, performing aging heat treatment on the composite rod treated in step 3, the aging heat treatment temperature is 390°C, and the aging heat treatment time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com