Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Change stickiness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly type insulated dope for cold rolling non-oriented silicon steel and preparation method for coat thereof

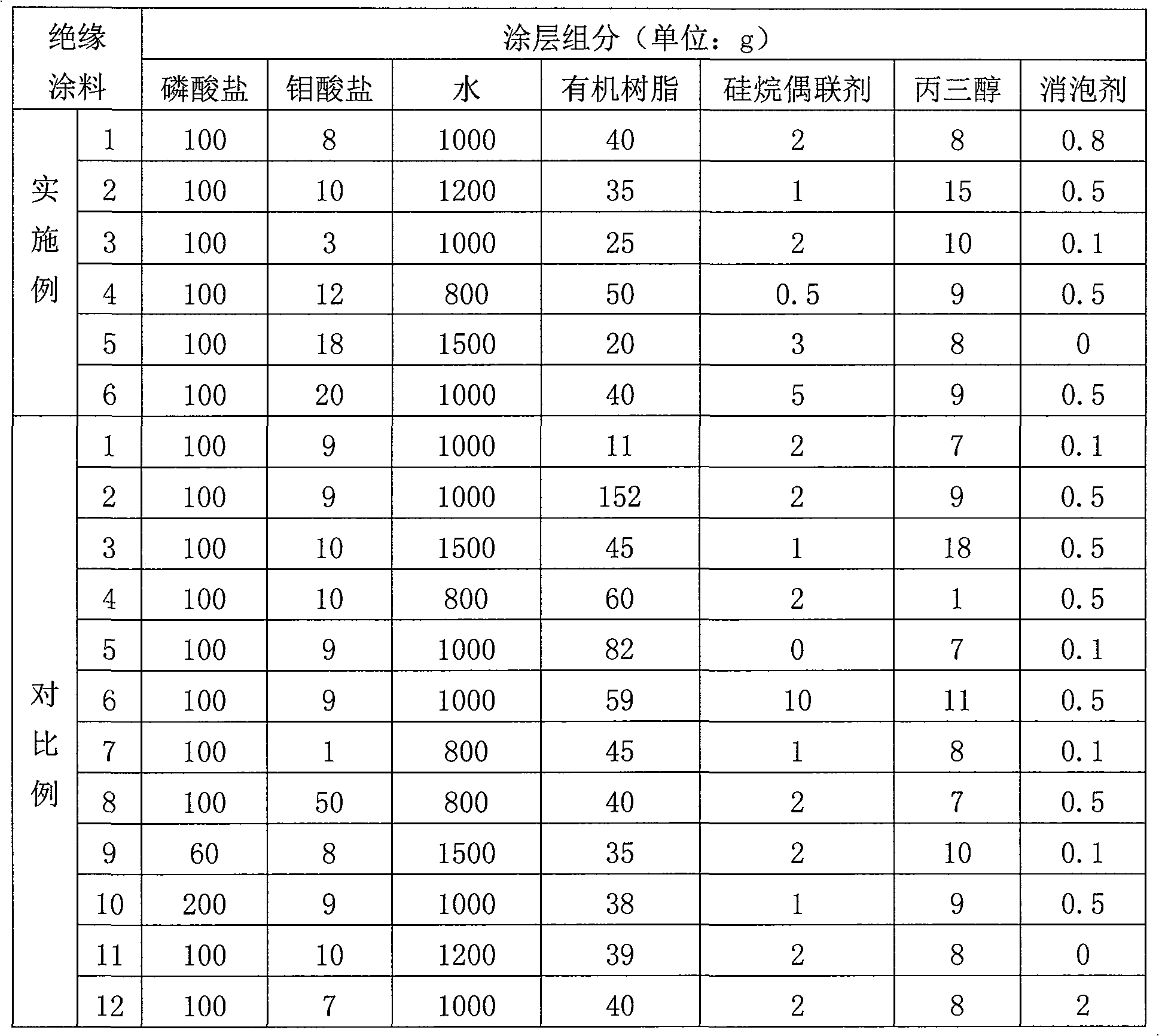

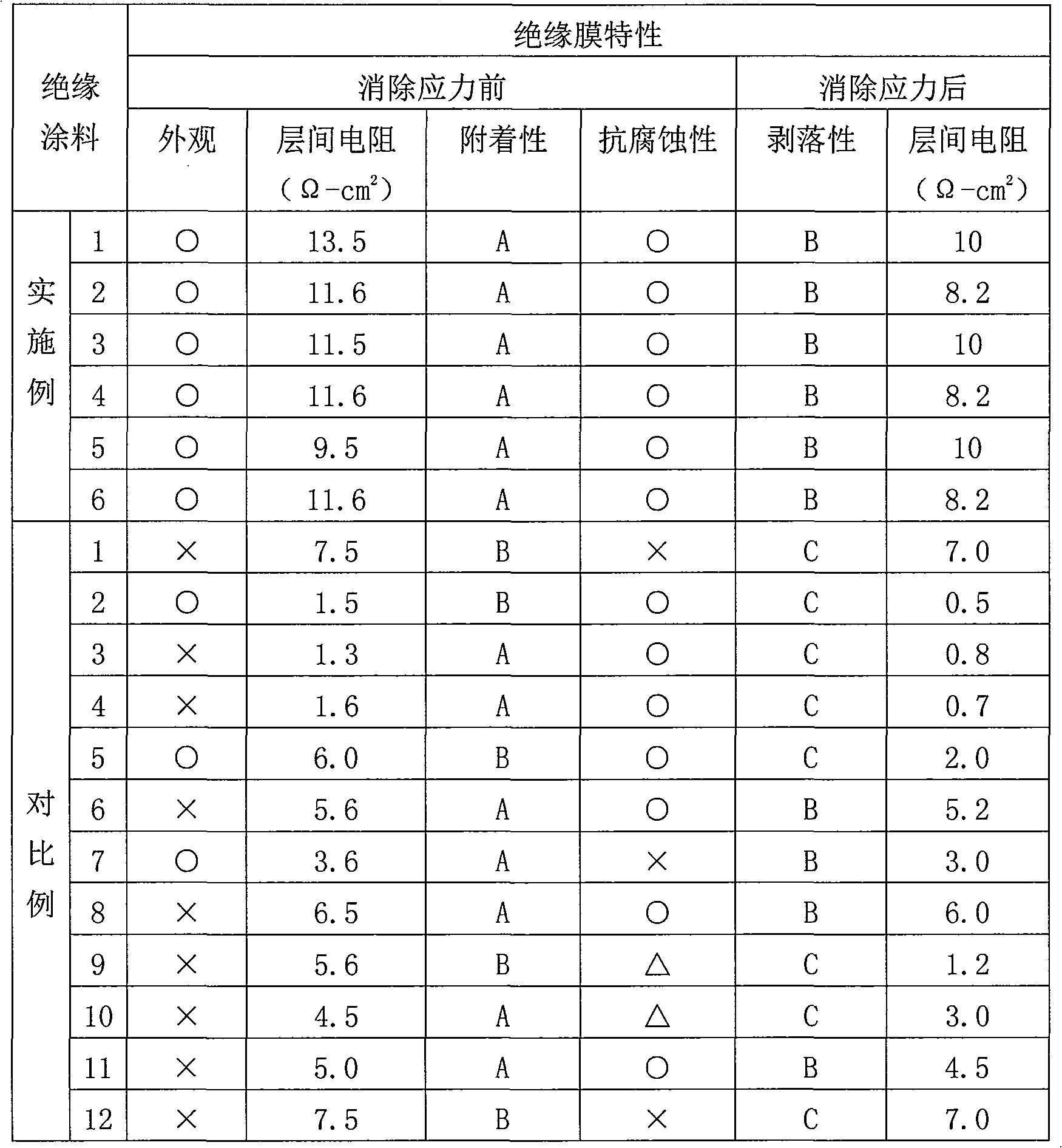

The invention relates to an environment-friendly insulating coating for cold-rolled non-oriented silicon steel and a preparation method thereof. The components of the insulating coating include: phosphate, molybdate, water, organic resin, silane coupling agent, and glycerol; the above-mentioned The weight ratio of each component is: phosphate 100, molybdate 3-20, water 800-1500, organic resin 20-50, silane coupling agent 0.5-5, glycerol 8-15. The steps of the coating preparation method are: (1) coating insulating paint on the surface of cold-rolled non-oriented silicon steel; (2) baking and drying, the baking temperature is 150-300 ° C; 600°C, the sintering time is 30-90 seconds; (4) Finished product. The insulating paint of the invention does not contain harmful elements, and the coating has good insulating performance, good adhesion and corrosion resistance, good punching and shearing processability and weldability, and can withstand heat resistance of stress-relieving annealing. The method of the invention is simple to operate, and the coating prepared by the method has good punching and shearing processability and weldability, and can withstand heat resistance of stress-relieving annealing.

Owner:武钢集团有限公司

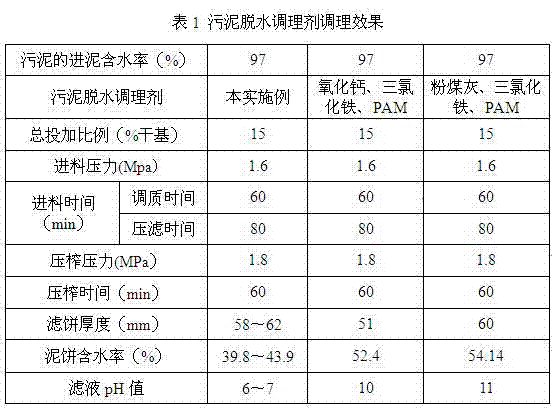

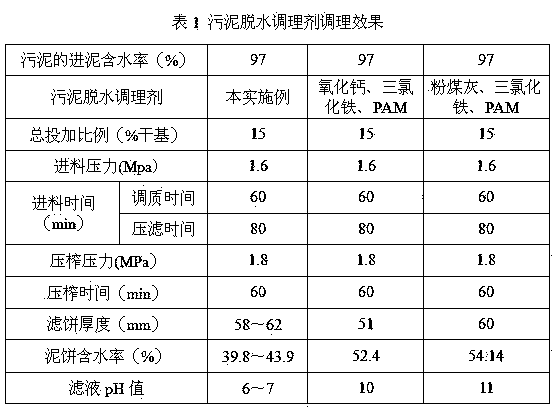

Compound type sludge dewatering conditioner and application method thereof

ActiveCN103113013AChange surface chargeEfficient dehydrationSludge treatment by de-watering/drying/thickeningChemical industryActive agent

The invention provides a compound type sludge dewatering conditioner which comprises the following components in parts by weight: 3-6 parts of ferric trichloride, 3-6 parts of calcium oxide, 1-2 parts of magnesium oxide, 1-4 parts of surfactant and 1-2 parts of sulfuric acid. The compound type sludge dewatering conditioner provided by the invention can realize efficient dewatering of sludge, the conditioning technology is simple and quick, the dosage of the conditioner is small, the moisture content of the dewatered sludge is reduced to below 45%, the pH value is 6-7, foul smell and the problem of capacity increase are avoided, and sludge reduction can be realized; and the compound type sludge dewatering conditioner has good environmental benefits, is favorable for subsequent sludge resource utilization, can be widely applied to the sewage and sludge treatment of the industries such as chemical industry, municipal affairs and the like, and is particularly suitable for treating the domestic sludge of urban sewage plant.

Owner:SHENZHEN WATER GRP CO LTD

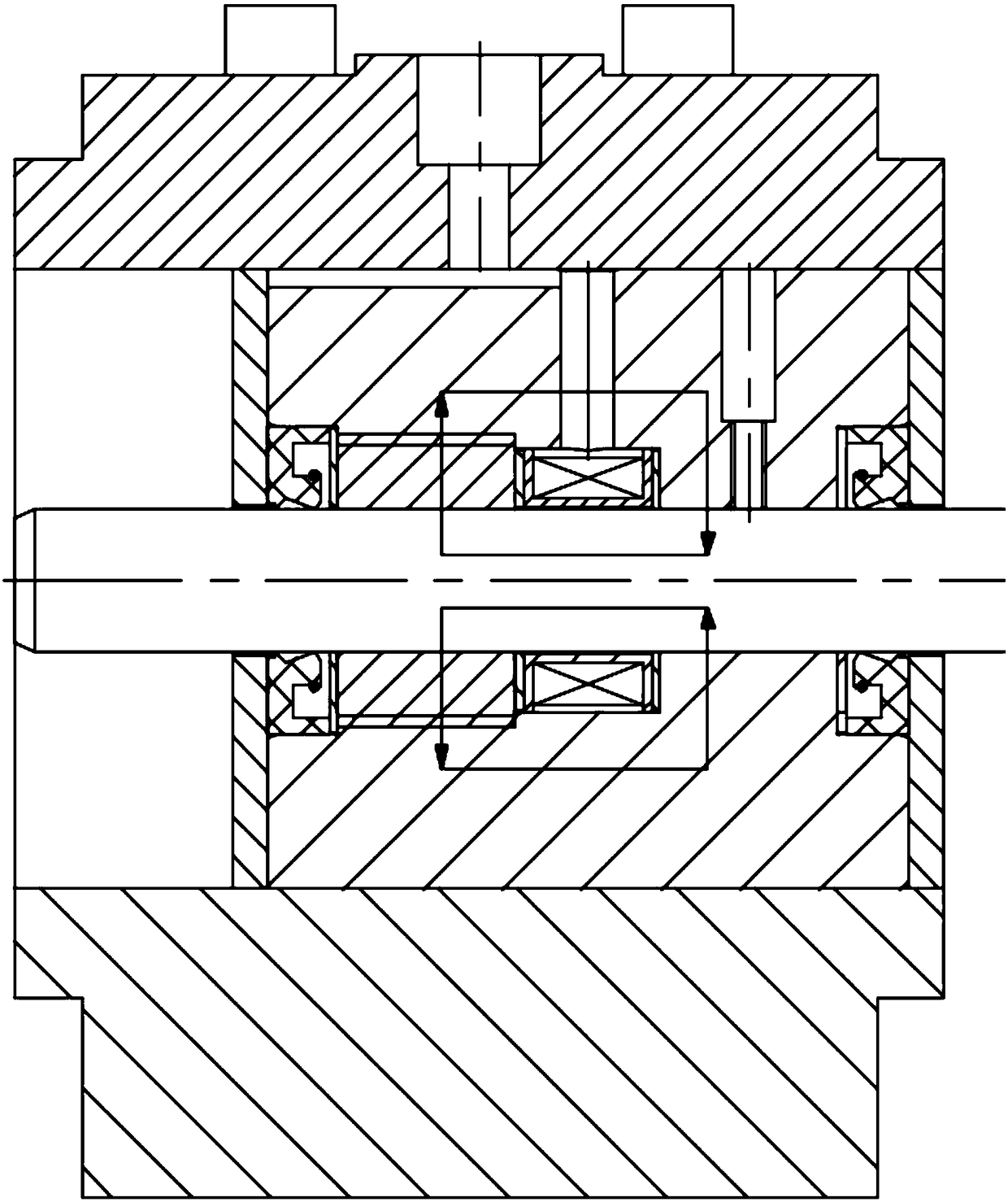

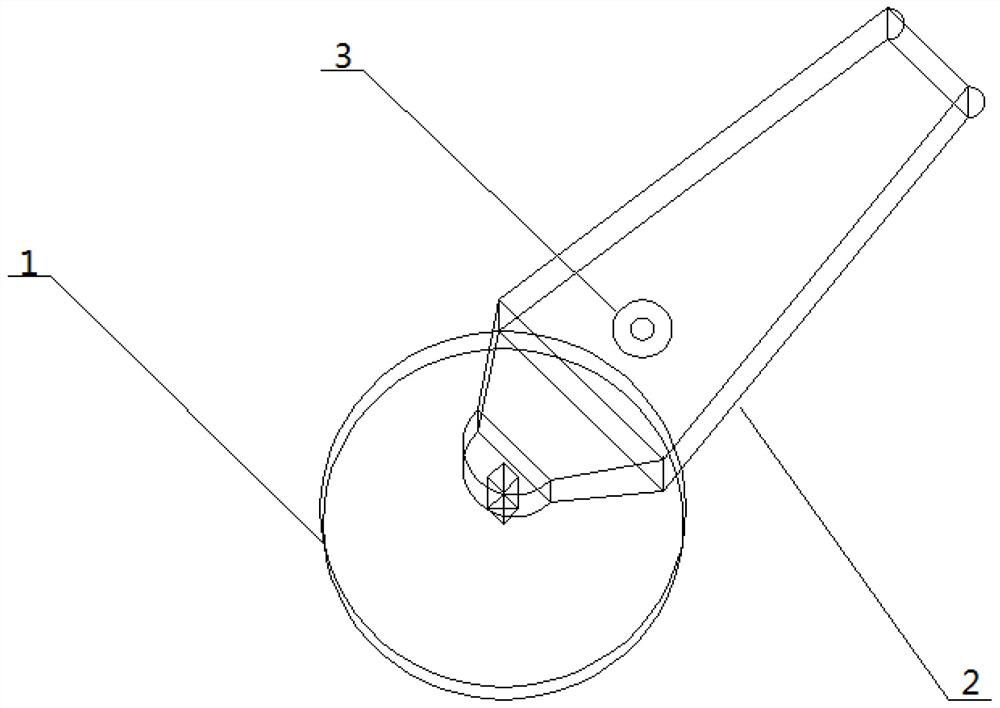

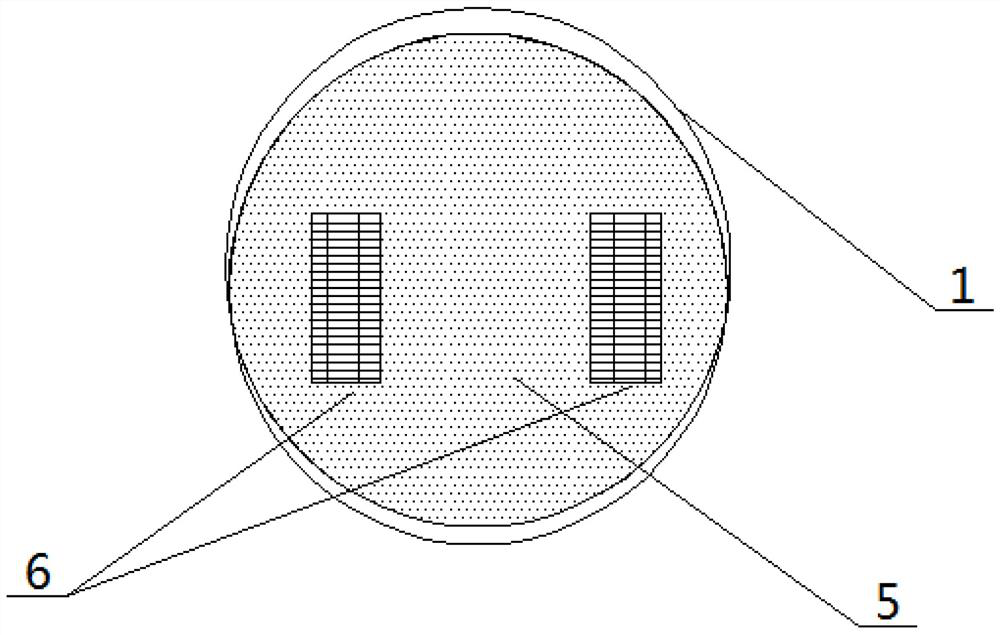

Magnetic fluid sliding bearing

InactiveCN108506344ARealize developmentChange stickinessBearing componentsBearingsSlider bearingMagnetorheological fluid

The invention discloses a magnetic fluid sliding bearing, and belongs to the field of bearings. The magnetic fluid sliding bearing comprises a magnetic conductive shaft and a sealing casing coaxiallysleeving the magnetic conductive shaft, wherein a coil cylinder barrel, a coil framework, a short magnetic conductive sleeve, a long magnetic conductive sleeve and a magnetorheological fluid diversionhole are also arranged and formed in the sealing casing; the coil cylinder barrel is coaxial with and adjacent to the magnetic conductive shaft; the coil framework is coaxial with the magnetic conductive shaft; an outer ring of the coil framework is fixed in the inner side wall of the coil cylinder barrel; a circle of exciting coil winds the coil framework; the magnetorheological fluid diversionhole is used for injecting magnetorheological fluid into the sealing casing; the magnetorheological fluid fills gaps among the coil cylinder barrel, the coil framework and the magnetic conductive shaft; the magnetic conductive shaft rotates relative to the coil cylinder barrel and the coil framework; the exciting coil is powered to generate an axial magnetic field; a magnetic induction line penetrates through the magnetorheological fluid and enters the short magnetic conductive sleeve; the magnetic induction line passes through the short magnetic conductive sleeve, then vertically penetrates through the magnetorheological fluid and enters the magnetic conductive shaft to form a closed loop. A magnetic field of the magnetic fluid sliding bearing disclosed by the invention is a non-uniform magnetic field, so that different positions on the magnetic conductive shaft have different bearing capacities.

Owner:SHANGHAI INST OF TECH +1

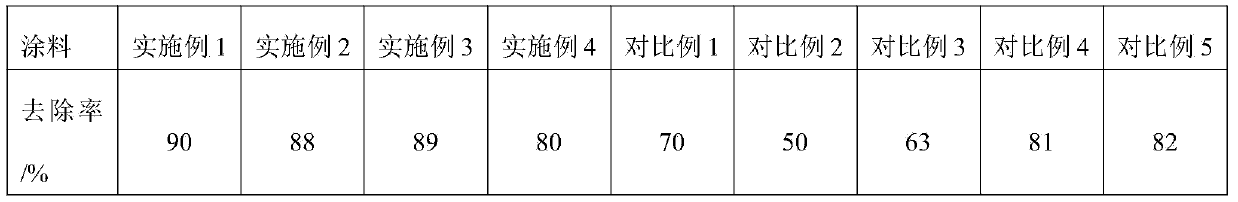

Formaldehyde removal coating and preparation method thereof

PendingCN109880465AGood removal effectRemove completelyAntifouling/underwater paintsPaints with biocidesPolyphenol oxidaseDefoaming Agents

The invention provides a formaldehyde removal coating and a preparation method thereof, and relates to the field of formaldehyde treatment. The formaldehyde removal coating comprises the following components in parts by weight: 5-10 parts of an activated carbon loaded nano TiO2 material, 3-5 parts of chitosan, 3-5 parts of rosin resin, 0.1-1 part of nano graphene, 5-10 parts of lignin, 1-5 parts of a plant extract, 1-5 parts of light calcium, 0.2-2 parts of biological enzyme, 30-50 parts of silicone acrylic emulsion, 0.05-1 part of a coalescing agent, 0.05-1 part of a defoaming agent, 0.05-1 part of a dispersing agent and 20-40 parts of water, the biological enzyme comprises peroxidase, formaldehyde dehydrogenase and polyphenol oxidase, wherein the plant extract is an aloe extract, a Chinese ivy extract, an Agave americana extract and a dayflower extract. Through use of the formaldehyde removal coating, formaldehyde is removed in a manner of combining physical adsorption, chemical catalysis, the biological enzyme and the plant extracts, the removal effect is improved, and the formaldehyde removal coating is safe, non-toxic and harmless.

Owner:浙江健煦环境科技有限公司

Manufacturing method for improving uniwafer output of light emitting diode

InactiveCN107394016AImprove light extraction efficiencyThe range of available light angles is increasedSemiconductor/solid-state device manufacturingSemiconductor devicesLaser cuttingEngineering

The present invention provides a manufacturing method for improving uniwafer output of a light emitting diode, and relates to the production technology field of a quaternary system light emitting diode. A relatively thin blade is used at a right side for half cutting, or the ICP dry method etching and laser cutting is employed to make cutting channels with a certain width and depth, a cutting walk way is subjected to photoetching at a back side, the dry method etching technology is employed to etch a cutting channel with a certain depth, and a relative thick blade is used to cut through a LED chip at the back side. The production efficiency is improved, the positive collapse is reduced, a chip gain structure with a big the right side and a small back side is obtained, the absorption of the substrate for light is reduced, the emergent light from the right side is increased, and the light extraction efficiency is increased.

Owner:YANGZHOU CHANGELIGHT

A clean melting method for lead-containing waste slag

InactiveCN106167855AGood melting adaptabilityChange stickinessProcess efficiency improvementBrickIron powder

A clean melting method for lead-containing waste slag is disclosed. The method includes 1) curing and converting, 2) curing and hardening and 3) melting. The method includes firstly mixing the lead-containing waste slag with calcium oxide, curing, converting, fully mixing with iron powder, shaping, making a brick, curing and hardening the brick, then sending the brick into a blast furnace, and performing reduction melting to recover lead and iron-sulfur, thus achieving clean melting. The method significantly improves compactness, strength and temperature resistance of the shaped brick, reduces thermo-collapse and pyrolysis powdering of the shaped brick in a melting process, reduces furnace accretion and dust, and increases the direct recovery rate of lead melting in the blast furnace and the hearth melting period. The method is simple in operation, low in adding amounts of sulfur fixing agents, adhesives, and the like, environmental friendly, high in metal recovery rate and heat utilization efficiency, low in impurity content, low in production energy consumption, and suitable for large-scale industrial production.

Owner:云南业胜环境资源科技有限公司

Production method of weather-proof, low-aldehyde and medium-density fiber office table special board

InactiveCN109203172AConducive to alleviating the contradiction between supply and demandLow water resistanceFlat articlesDomestic articlesWeather resistanceSizing

The invention discloses a production method of a weather-proof, low-aldehyde and medium-density fiber office table special board. The method comprises the following steps: (1) pretreating raw materials, (2) screening, (3) cooking and softening, (4) grinding, (5) sizing and drying, (6) pre-pressing, (7) hot pressing, (8) sawing and sanding, (9) veneering hot pressing, and (10) edge cutting. In thisway, a finished product is obtained. According to the invention, eucalyptus barks, branches and waste leftover materials left in the manufacturing process are taken as main raw materials. Meanwhile,other miscellaneous wood is added, so that the full and effective utilization of wood resources can be realized. The modified paraffin and the weather-proof urea-formaldehyde resin adhesive are added,and the production process is strictly controlled. As a result, the waterproof and weather-proof performance is greatly improved and the board is low in formaldehyde content. The prepared medium-density fiber wardrobe special board is environment-friendly, low in formaldehyde content and excellent in weather resistance. Therefore, the board is a safe, environment-friendly and low-formaldehyde-content office table special board.

Owner:广西横州丽冠环保材料有限公司

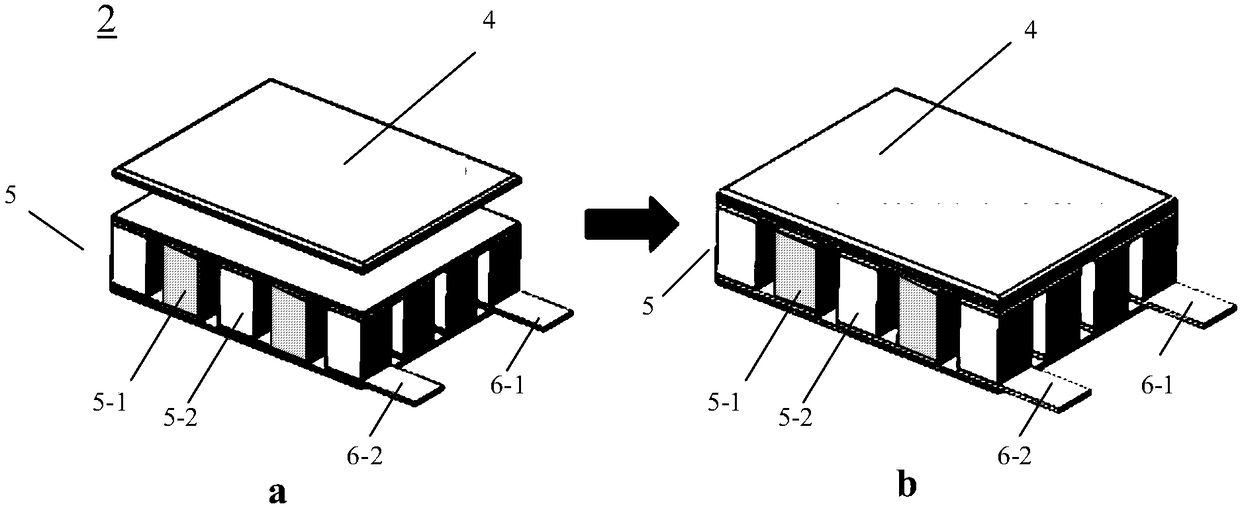

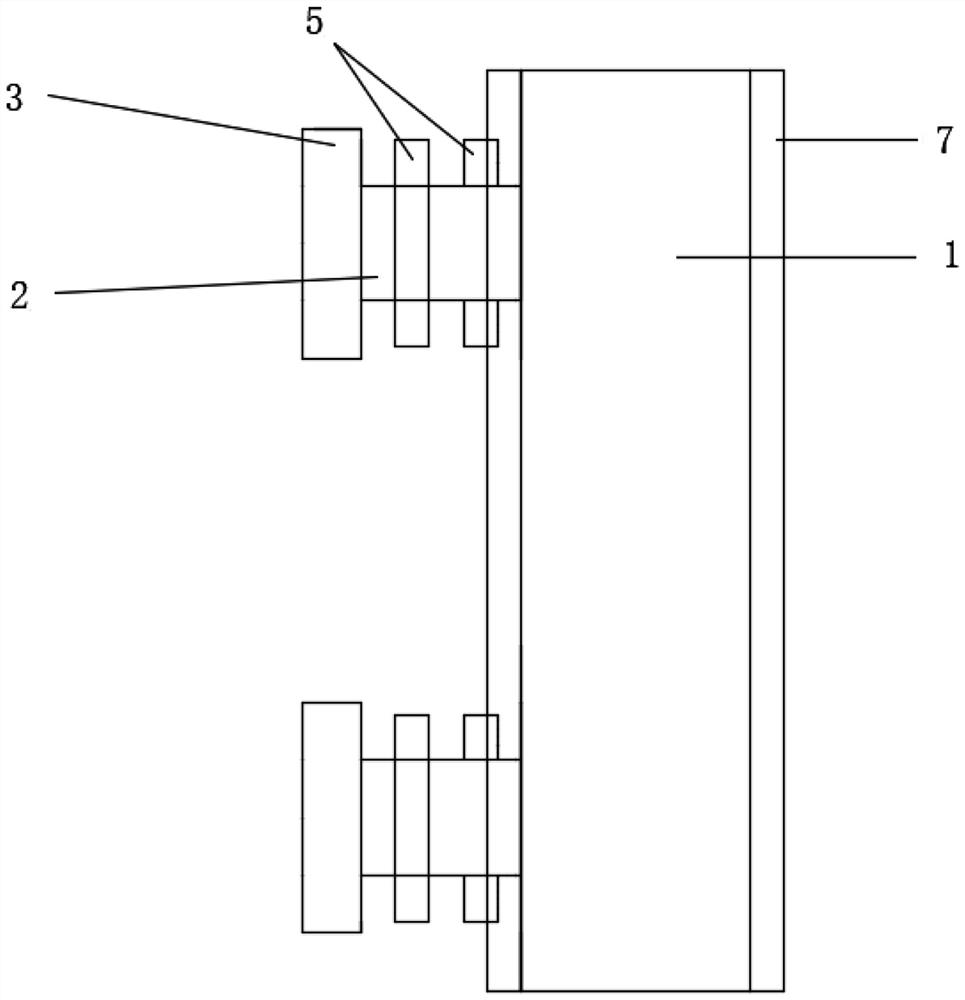

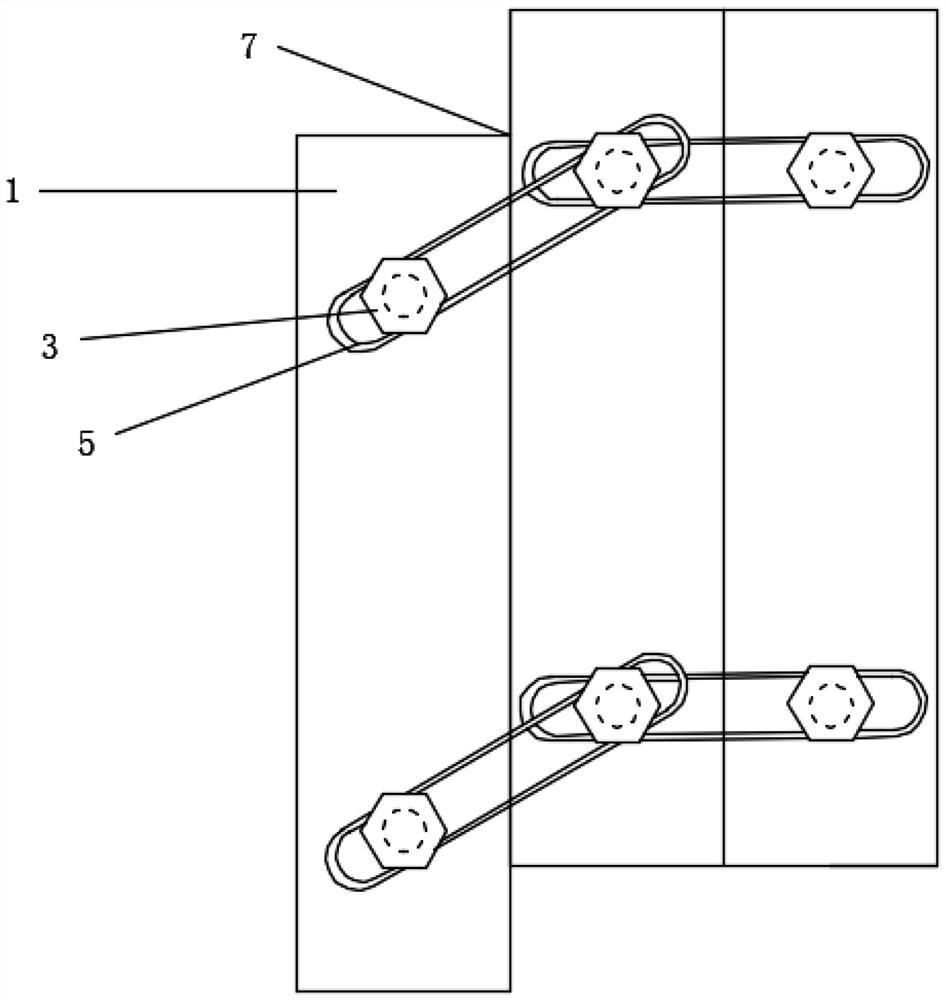

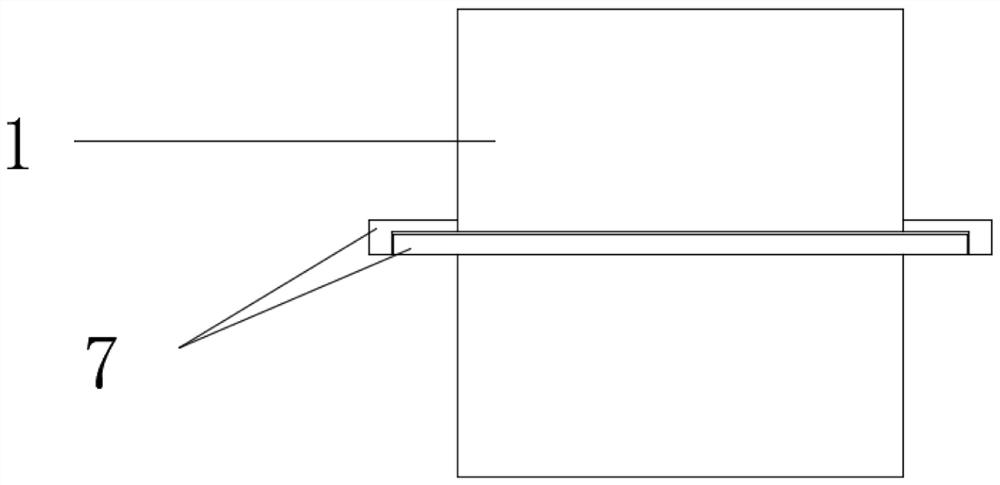

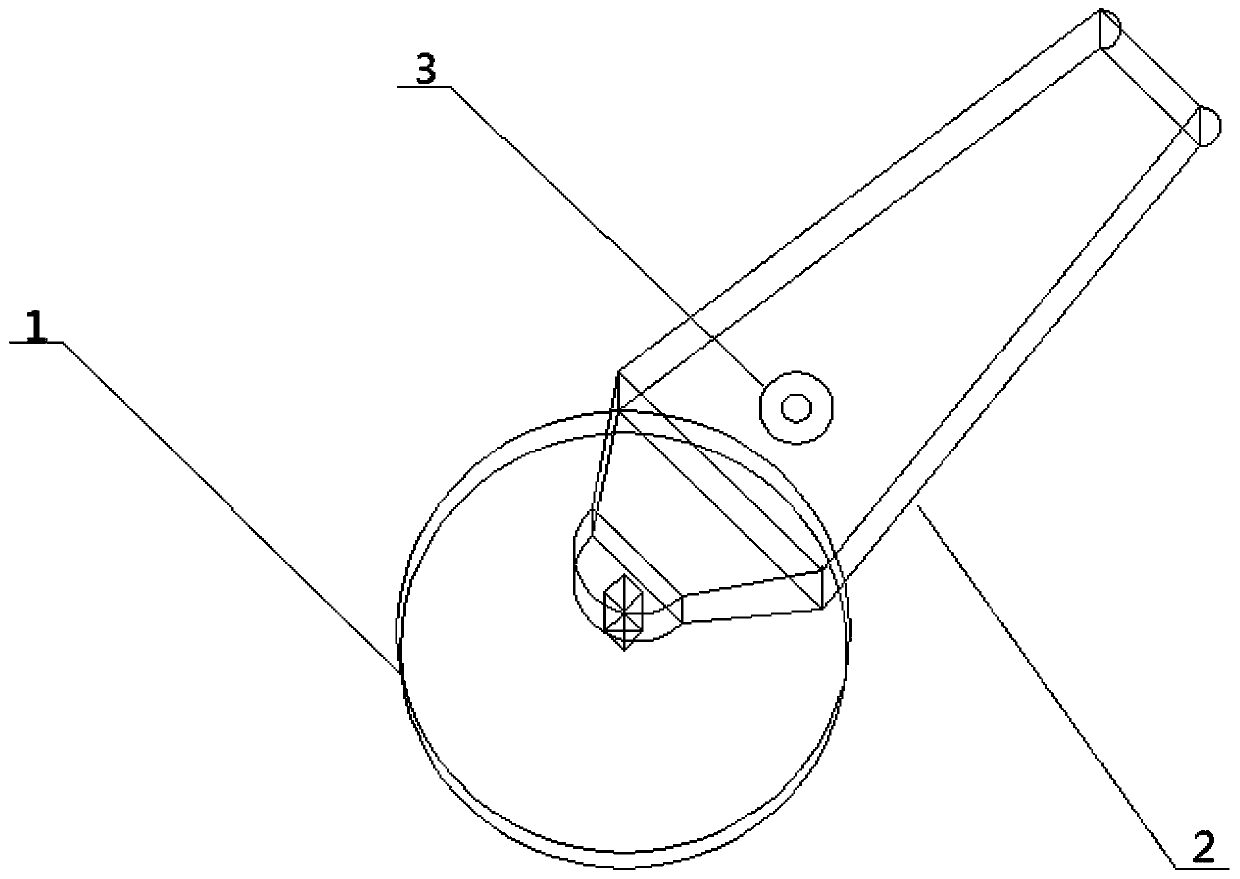

Carrying device

InactiveCN108598038AChange stickinessAvoid fixationVacuum evaporation coatingSolid-state devicesEngineeringMechanical engineering

The disclosure provides a carrying device comprising a carrying part for carrying a to-be-carried object, adhesive members arranged on the carrying part, and support members arranged on the carrying part. The adhesive members have the variable viscosity to realize attachment and separation between the to-be-carried object and the carrying device. The support members are used for supporting the to-be-carried object. According to the carrying device provided by the disclosure, attachment and separation of the substrate or the device are realized quickly in a vacuum environment.

Owner:BOE TECH GRP CO LTD +1

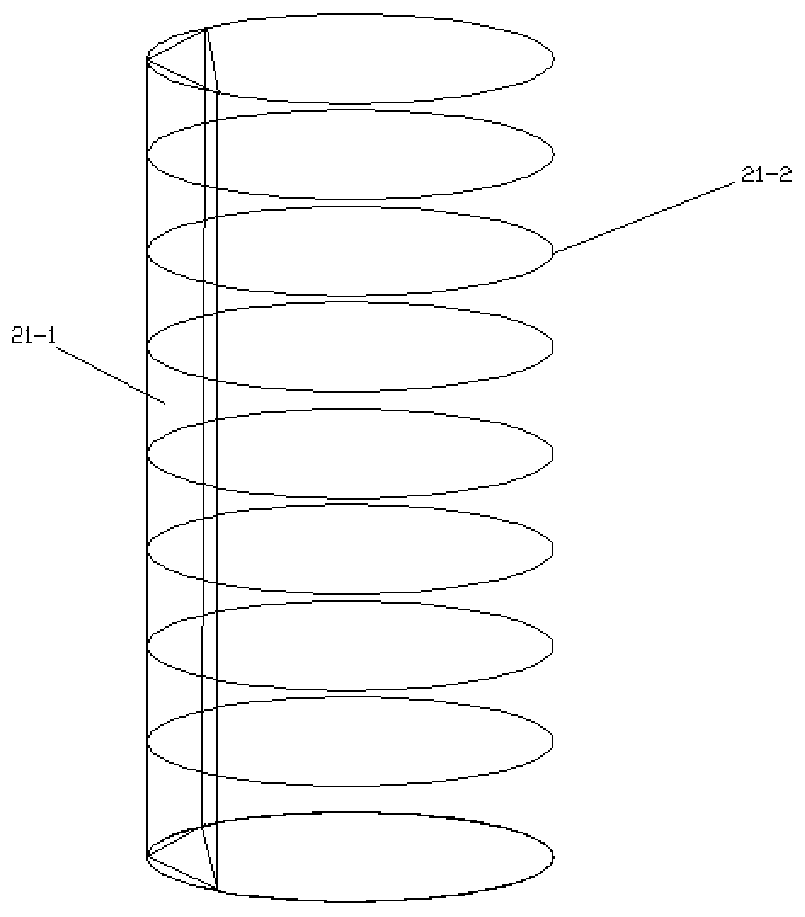

Magnetorheological-fluid based infinite pressure-regulating body builder

InactiveCN104127984AChange the strength of the magnetic fieldChange stickinessMuscle exercising devicesMagnetorheological fluidEngineering

The invention relates to a magnetorheological-fluid based infinite pressure-regulating body builder which is composed of a frame, cushions, handles and a pressure damper. The pressure damper is composed of a piston rod, a shell, retaining rings, travel switches, a reset spring, pistons, electromagnetic coils and magnetorheological fluid. After the electromagnetic coils are powered, the magnetorheological fluid is instantly changed into Bingham fluid high in viscosity and low in mobility from original New ton fluid, and force hindering movement of arms is formed; the travel switches are mounted at two ends of the shell, and when the pistons on two sides move to positions near enough to touch two ends of the shell, a system is automatically powered off, and damping pressure disappears instantly; due to action of the reset spring in the middle, automatic reset of the pistons can be realized; magnetic field intensity around the magnetorheological fluid can be changed by changing the size of current, infinite change of the damping pressure can be realized, arm strength requirements of different crowds can be met, and personal characteristics of the body builder can be fully embodied.

Owner:ZHEJIANG NORMAL UNIVERSITY

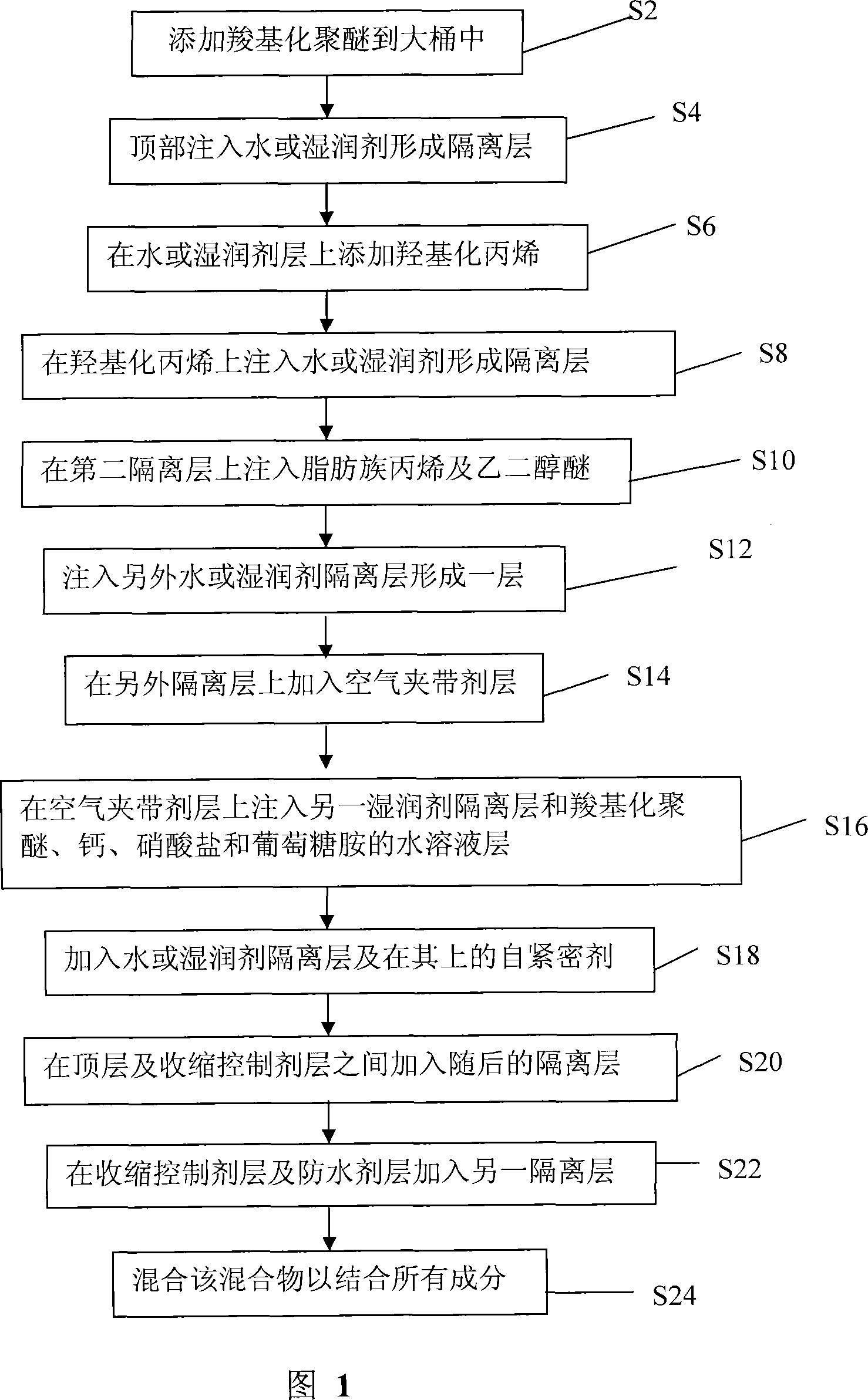

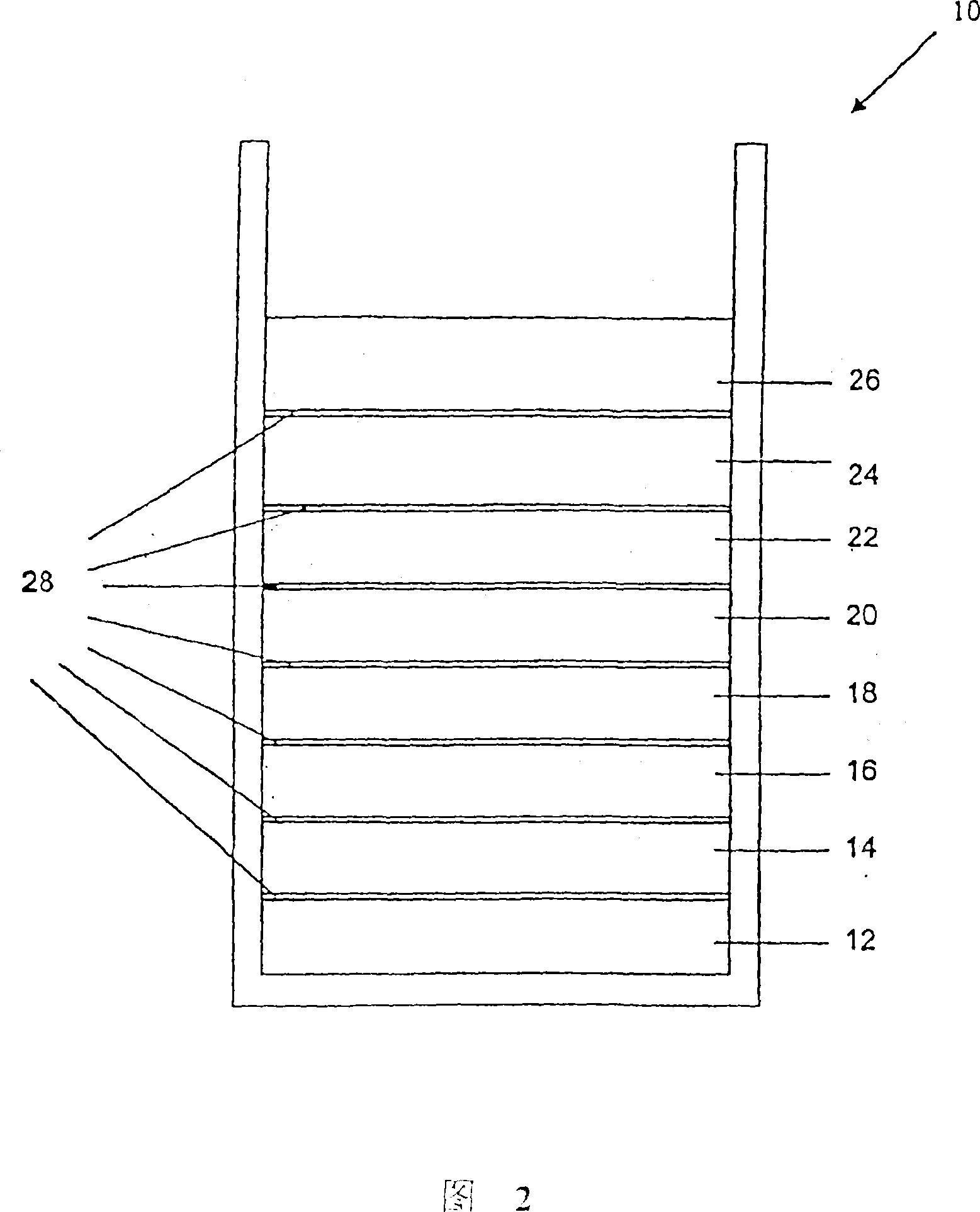

Viscous materials and method for producing

InactiveCN101014553AReduce weightAvoid crackingTransportation and packagingMixing operation control apparatusIsolation layerVolumetric Mass Density

A method for minimizing reactions between a plurality of reactionary chemicals comprising the activities of adding a first chemical and adding a first barrier layer, the first barrier layer resting atop the first chemical. Thereafter, adding a second chemical, the second chemical resting atop first barrier layer. A second barrier layer is added whereby, the second barrier layer rests atop the second chemical. A further chemical is added wherein the further chemical resting atop the second barrier layer. The chemicals and barrier layers are mixed uniformly, thereby evenly distributing each of the first, second and further chemical to form a mixture wherein the chemicals are added in order of decreasing density.

Owner:马修皮扎

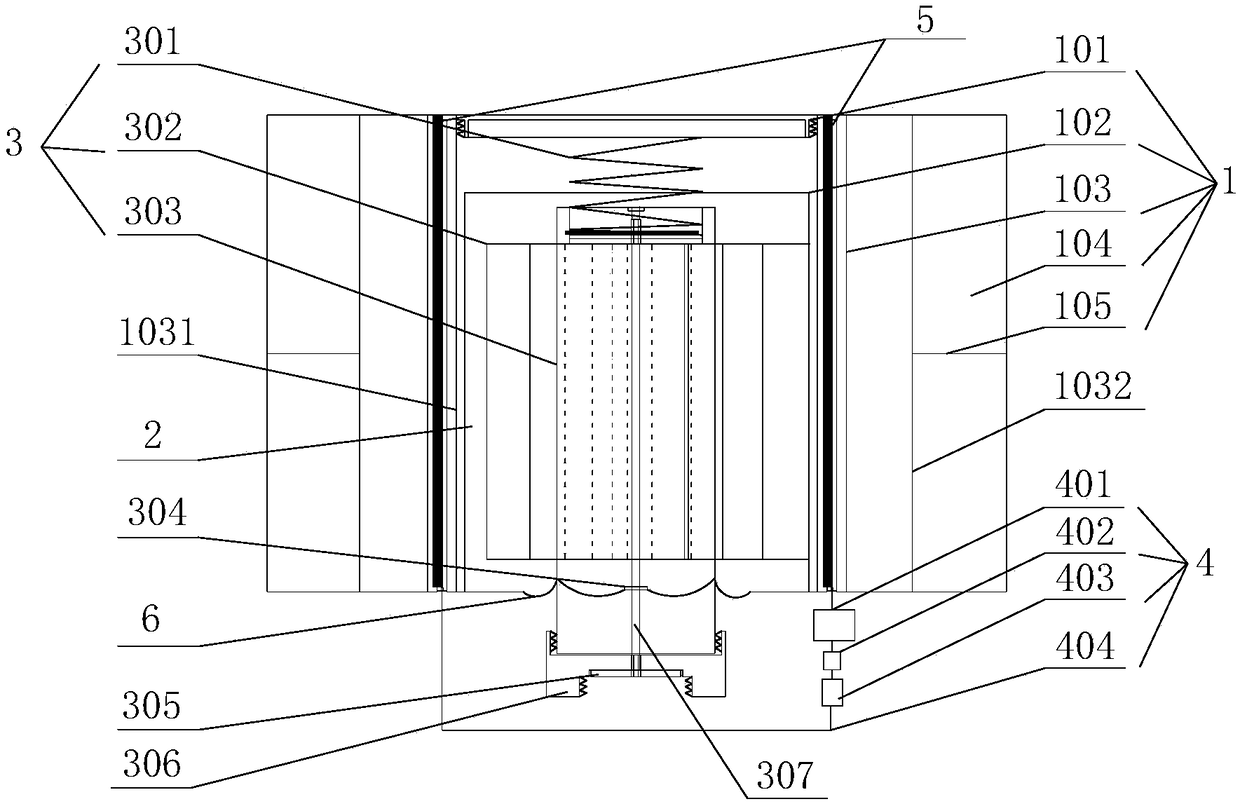

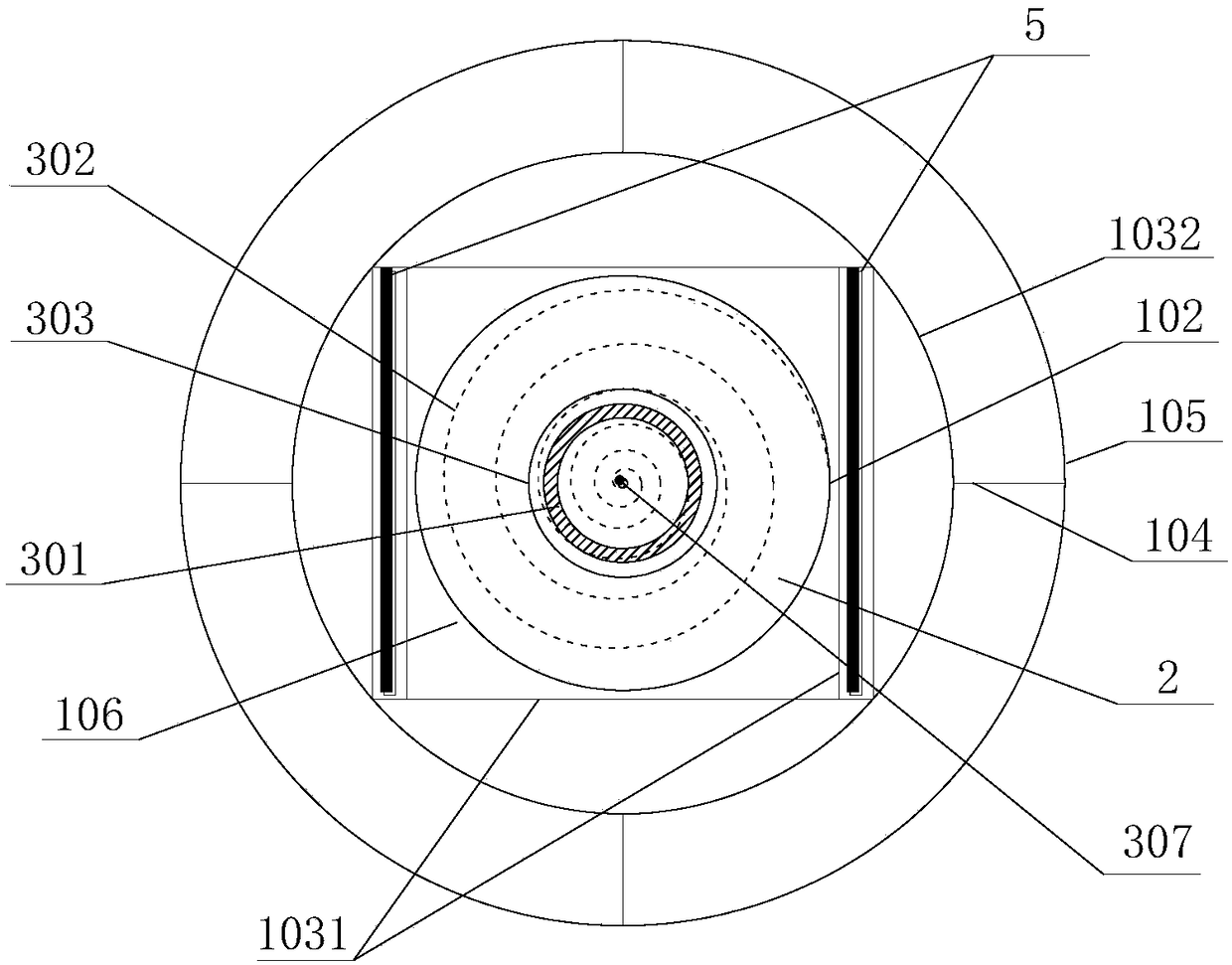

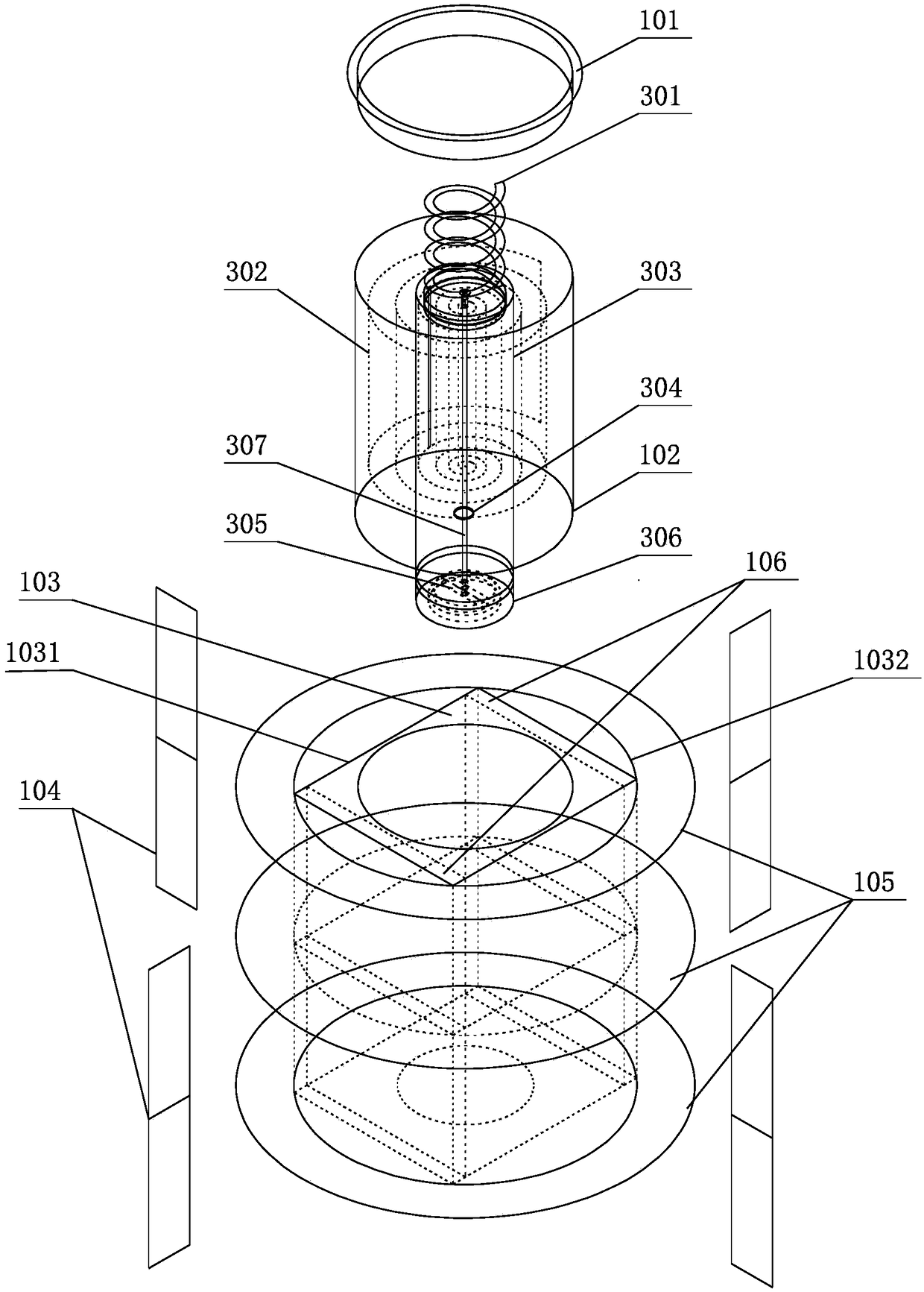

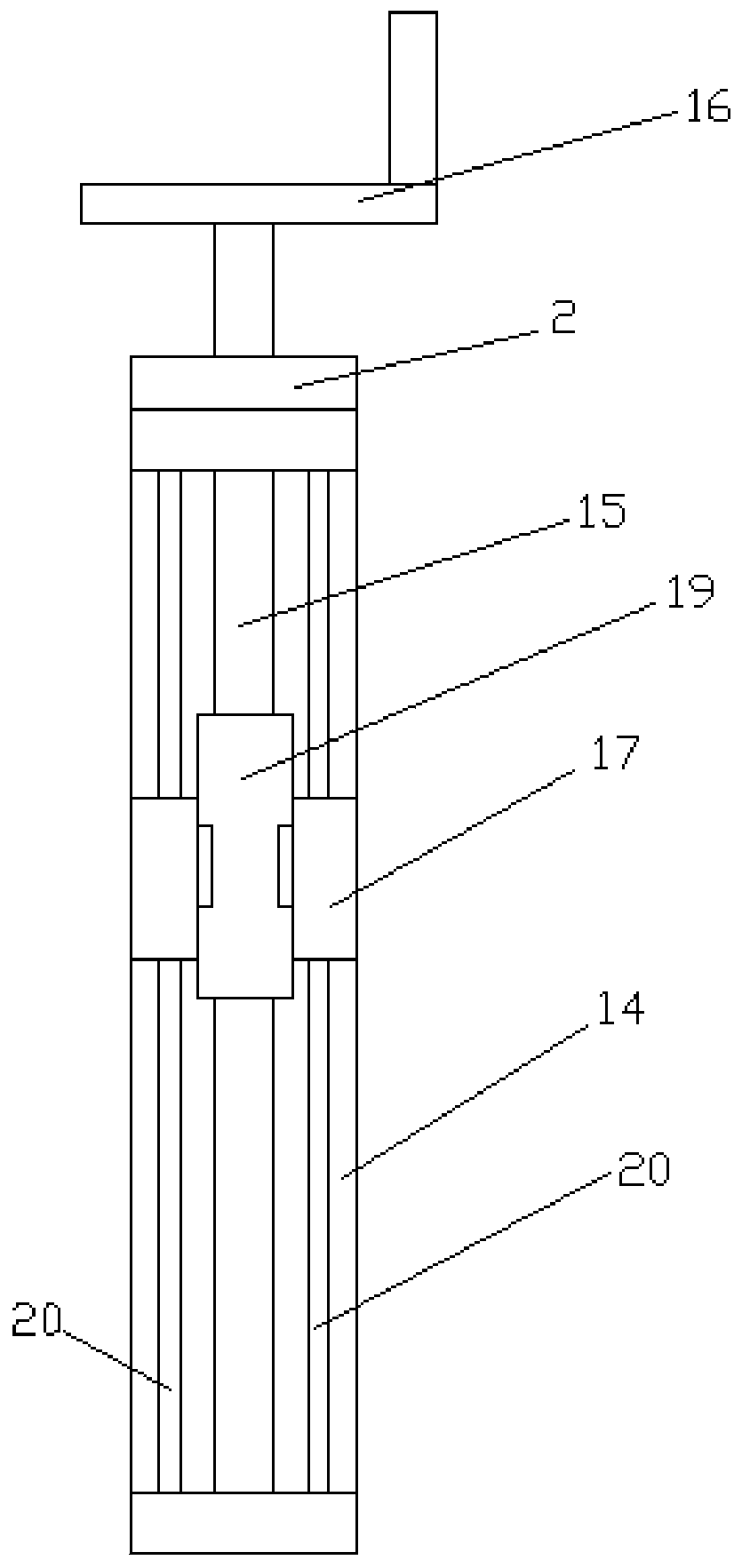

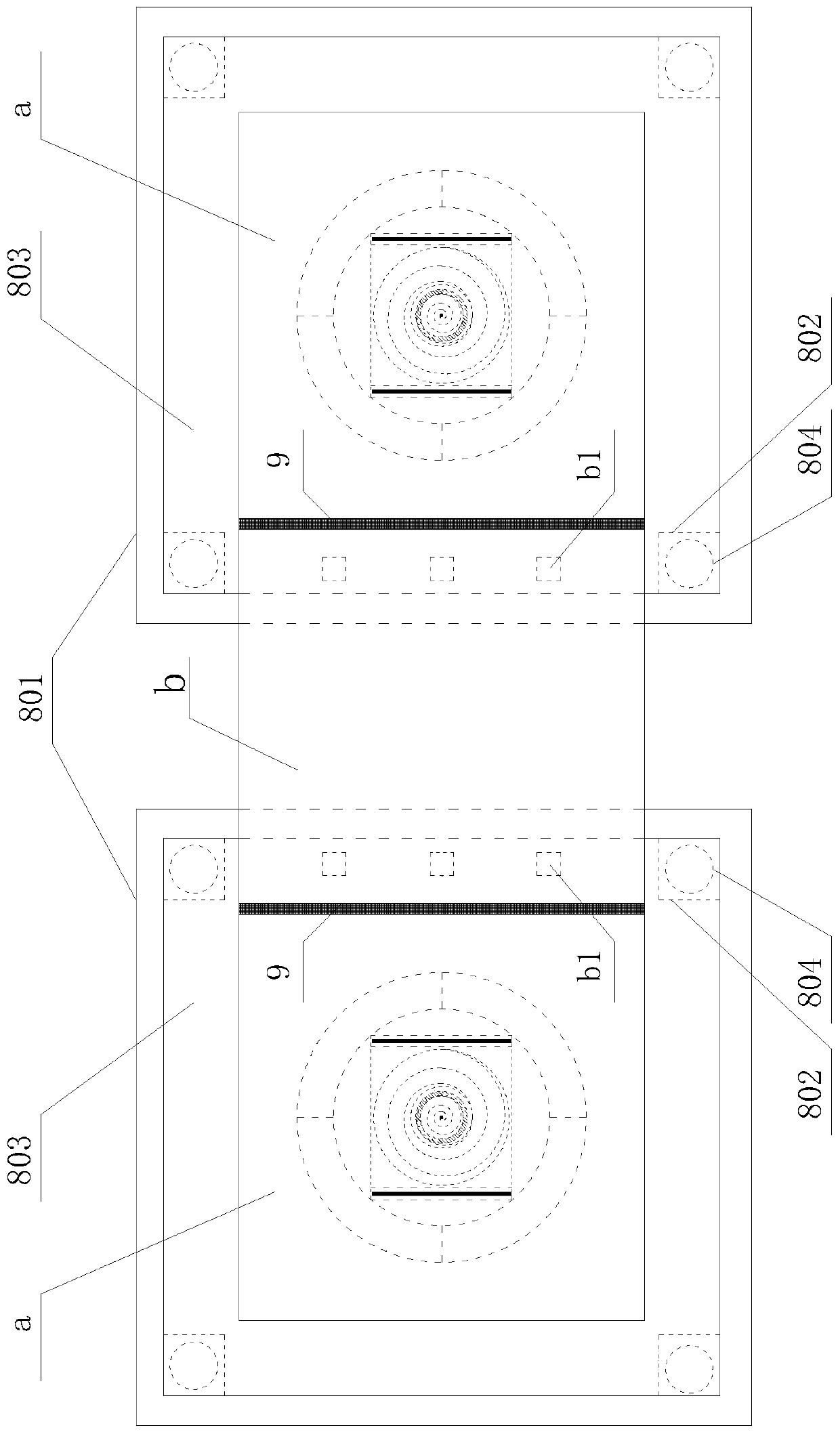

Multi-point earthquake motion test rigidity and damping adjustable boundary system suitable for vibrating table

PendingCN108425983AChange stickinessChange the electric field strengthSpringsNon-rotating vibration suppressionHorizontal forceEngineering

The invention provides a multi-point earthquake motion test rigidity and damping adjustable boundary system suitable for a vibrating table. The multi-point earthquake motion test rigidity and dampingadjustable boundary system suitable for the vibrating table comprises a force guiding device, electrorheological fluid, a rigidity control device, a damping control device, positive and negative plates and seepage-proof tarpaulin. The force guiding device is a cylindrical structure with an opening in the lower portion and comprises a force guider, a contact cylinder, a horizontal force guiding plate and a vertical force guiding plate; the force guider comprises a force guider cover, a force guider outer wall and a force guider inner wall fixed in the opening of the lower surface in the force guider outer wall; the horizontal force guiding plate and the vertical force guiding plate are fixedly connected to the force guider outer wall; the contact cylinder is placed in the force guider innerwall; the rigidity control device has a cylindrical structure, is placed in the contact cylinder and comprises a rigidity controller, a platy annular spring and a disc spring; the seepage-proof tarpaulin is fixedly connected to the lower portion of the force guiding device and the inside of the rigidity controller in a closed manner; and the seepage-proof tarpaulin is in sealed connection with the outer periphery of a seepage-proof bearing, and is in sealed connection with the inner periphery of the force guider inner wall. Rigidities of the spring in multiple directions can be adjusted simultaneously, and the multi-point earthquake motion test rigidity and damping adjustable boundary system suitable for the vibrating table can be applied to simulating an artificial boundary in a multi-point earthquake motion test.

Owner:TIANJIN UNIV

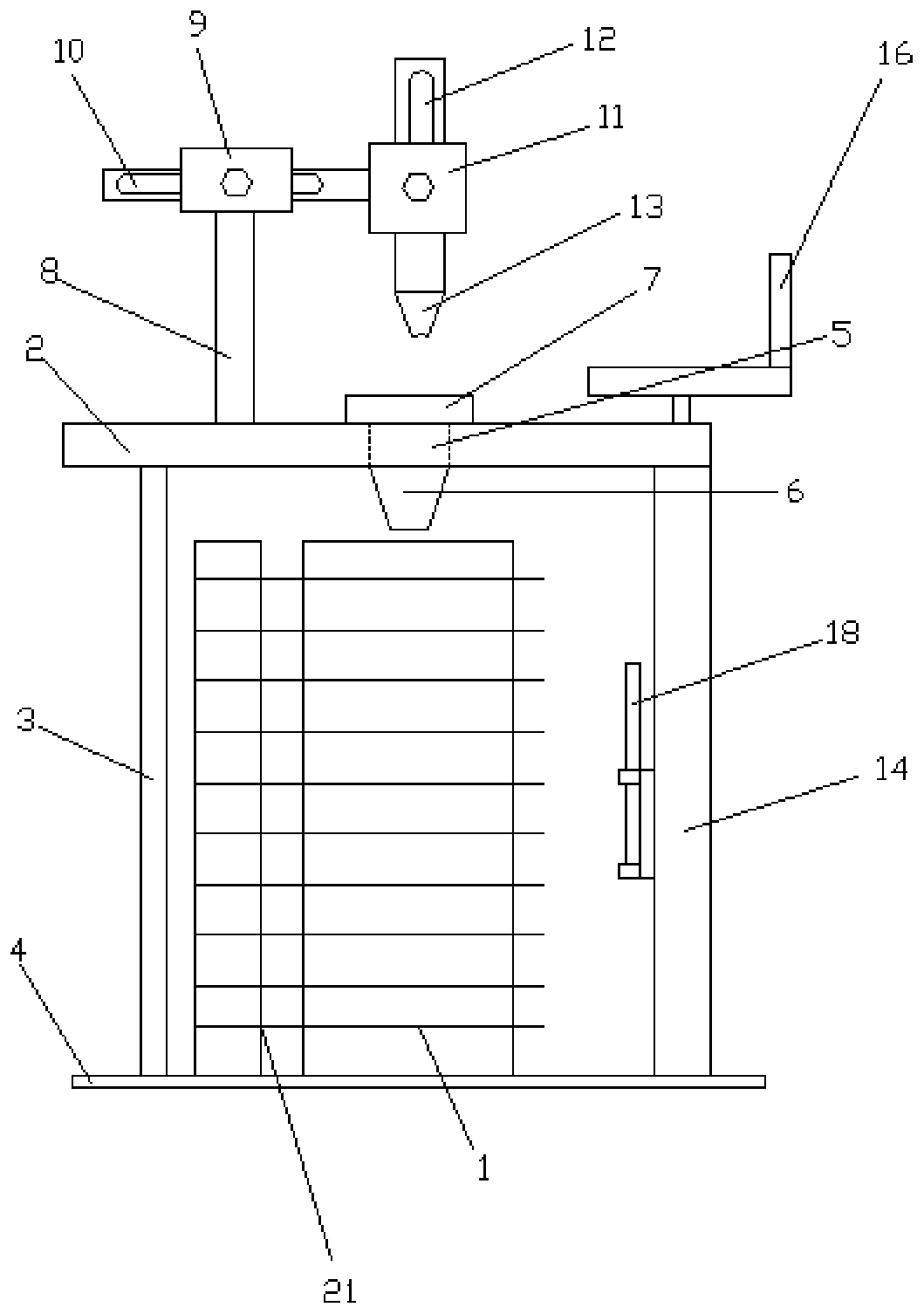

Liquid viscosity coefficient measuring device and working method

PendingCN110286061ANo initial horizontal velocityAvoid pollutionFlow propertiesMeasurement deviceLiquid viscosity

The invention relates to a liquid viscosity coefficient measuring device and a working method. The liquid viscosity coefficient measuring device comprises a liquid accommodating device, wherein a cross beam is arranged above the liquid accommodating device; an aligning mechanism is fixedly arranged on the cross beam; the aligning mechanism is positioned over the liquid accommodating device, and is used for adjusting a small ball used for experiments to fall off along the vertical direction; a support is arranged on one side of the aligning mechanism; the support is connected with an electromagnet through an adjusting mechanism; the adjusting mechanism can adjust the positions of the electromagnet in the vertical direction and the vertical direction; the electromagnet is used for adsorbing the small ball used for experiments; a picture recording device support is arranged on one side of the liquid accommodating device; a lifting mechanism is arranged on the picture recording device support; the lifting mechanism is connected with a picture recording device; the picture recording device is used for recording pictures in the falling process of the small ball. The measuring device is convenient to use, high in measuring efficiency and accurate in measuring results.

Owner:SHANDONG FIRST MEDICAL UNIV & SHANDONG ACADEMY OF MEDICAL SCI

Clean production method of copper smelting smoke and lead-containing secondary material

ActiveCN111676374AEfficient separation and recoveryEfficient separationProcess efficiency improvementLead smeltingSmelting process

The invention discloses a clean production method of copper smelting smoke and a lead-containing secondary material, and aims to provide a method for smelting smoke using copper and smelting lead using the lead-containing secondary material. The clean production method comprises the steps that silicon, calcium-containing oxide materials, iron-containing oxides and binders are added to copper smelting smoke and / or the lead-containing secondary material and are batched in batches; water is added and the materials are mixed to form a material with a certain shape; and after the material is stacked to solidify and harden, the material is mixed with coke to complete preheating, reduction, smelting and separation in a blast smelting furnace, and metals are recovered in layers. The clean production method uses the principle of preferential formation of copper matte between sulfur and copper without using sintering desulfurization and molten pool smelting conditions, and reaction characteristics of SiO2 with slag, copper matte, and iron oxide during the smelting process. Slag type is adjusted to overcome harmful effects of copper, sulfur, and arsenic on the production process in traditional lead smelting, and the goal of effectively separating and recovering copper, lead, arsenic, sulfur and other metals is achieved. Not only can the problem of environmental protection in the lead smelting process be solved, but also the overall economic benefits of production can be improved.

Owner:方喜

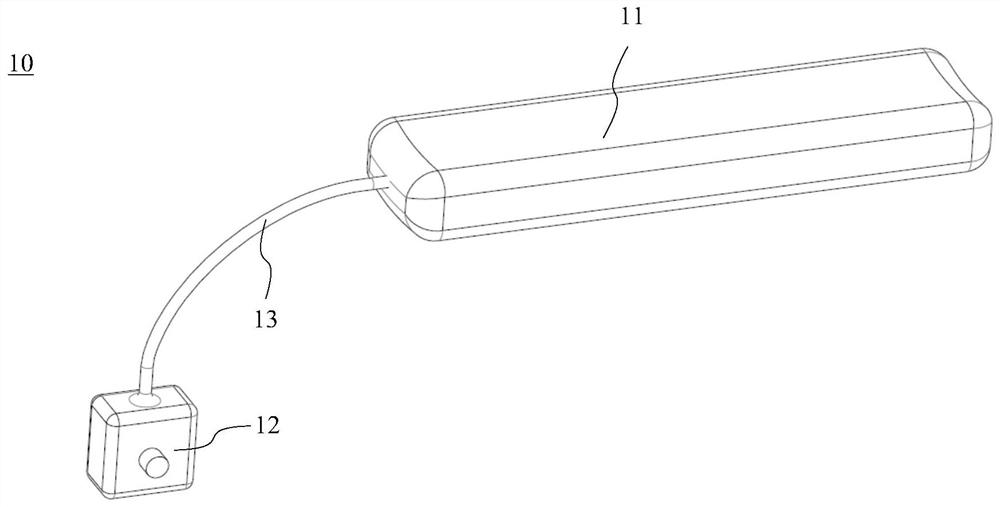

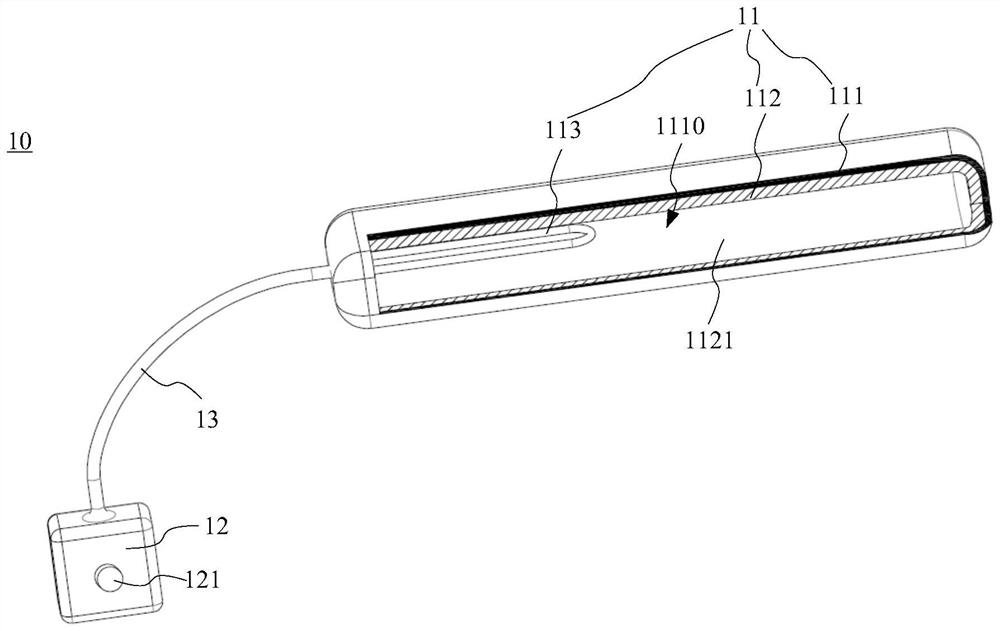

Erection assisting instrument

The invention provides an erection assisting instrument. The erection assisting instrument mainly comprises an erection assisting assembly and a control assembly, wherein the erection assisting assembly can be implanted into a penis and can be filled with a hardness-adjustable material, so that the hardness of the hardness-adjustable material is adjusted by changing the temperature of the erectionassisting assembly; or the erection assisting assembly can be filled with an electrorheological fluid material, so that the viscosity of the electrorheological fluid material is adjusted by changingthe intensity of an external electric field applied to the erection assisting assembly; and besides, the erection assisting assembly can be filled with a magnetorheological fluid material, so that therheological property of the magnetorheological fluid material is adjusted by changing the external electric field applied to the erection assisting assembly. By means of the various modes, the purpose of adjusting the hardness of the erection assisting assembly can be achieved, and the technical effect of assisting in erection of the penis is achieved.

Owner:SHANGHAI CLINICAL ENGINE TECH DEV CO LTD

Low temperature ash-eliminating agent

The low temperature ash-eliminating agent features its composition including MnO2 1-15 wt%, CuCl2 0-6 wt%, NaNO3 30-42 wt%, NH4Cl 33-45 wt%, MgO 1-18 wt%, and ZnO 1-10 wt%. The present invention introduces MnO2 as main catalyst to reduce the burning point of soot to 200-220 deg.c. The low temperature ash-eliminating agent is used in various boilers, and through the common effect of the said components on soot, the carbon in soot is burnt out at 200-250 deg.c to reduce exhausted SO2 and NOx while protecting heat conducting area.

Owner:门振镒

Making method of ormosia oat instant medical rice gruel

InactiveCN105707670AChange shapeChange stickinessNatural extract food ingredientsFood ingredient functionsSolid particleSweet Almonds

Disclosed is a making method of ormosia oat instant medical rice gruel.The method is made from ormosia, oat, rice, corns, medlar fruits, astragalus membranaceus, sweet almonds, honey and chitosan.The ormosia, oat, rice, corns, medlar fruits, astragalus membranaceus and sweet almonds are separately cooked, filtered and separated, solids are dried to obtain solid particles, liquid is concentrated and dried, and the solid particles and powder are mixed to be uniform and packaged separately to obtain the medical rice gruel.The method has the advantages that nutrients are rich, carrying is easy, the rice gruel can be conveniently and rapidly eaten, the health care function is achieved, the taste is good and full, the requirement of consumers for the gruel is met, and the rice gruel is suitable for being eaten during living and traveling.

Owner:BOHAI UNIV

Visual measurement device for crack repair and using method

ActiveCN112627153AEasy to useChange mobilitySoil preservationMortise and tenonStructural engineering

The invention discloses a visual measuring device for crack repair and a using method. The visual measurement device comprises a mold-making rack structure formed by by assembling a plurality of steel plates in a surrounding mode, and a threaded plate used for supporting the whole mold-making rack structure is welded and fixed to each bottom corner of the mold-making rack structure; the contact end faces of every two adjacent steel plates are connected through a mortise and tenon sliding structure; and the outer side walls of every two adjacent steel plates are connected through a sliding lever structure, and every two adjacent steel plates can slide up and down within a certain range. According to the device, when cracks difficult to observe are repaired, a transparent sample is molded twice by utilizing the rubbing function of the silica gel and the transparent resin; and different repairing mortar is selected to repair rubbed cracks, the critical crack filling depth and the critical crack filling width of the mortar are observed, and the device can be used for observing and repairing.

Owner:合肥九州龙腾科技成果转化有限公司

Stiffness-adjustable grinding device and using method

ActiveCN111168503AReduce the effect of grinding hardnessAdjust stiffnessBelt grinding machinesLeather surface mechanical treatmentRubber materialConvex structure

The invention provides a stiffness-adjustable grinding device and a using method. The stiffness-adjustable grinding device comprises a motor for providing power; a switch used for controlling the motor to start is mounted on the motor; a grinding wheel or a grinding belt used for grinding is mounted on an output shaft of the motor; a grinding area on the grinding wheel or the grinding belt is divided into a plurality of layers by adopting a rubber material; the intermediate layer adopts a hydraulic layer or a pulse layer which can produce instantaneous acting force; the remaining layers are the stiffness layers that can provide different grinding stiffness; the hydraulic layer or the pulse layer are respectively connected with a hydraulic device or a pulse device correspondingly; a convexstructure used for enhancing a grinding effect is arranged on the surface of the grinding wheel and the grinding belt; the outer surface of the convex structure is wrapped with a flexile material layer; and by changing the grinding material of the stiffness layer in real time, the object can be polished by fine adjustment of appropriate stiffness. Compared with a common grinding device, the stiffness-adjustable grinding device has wider practicality and economic benefits, and better meets the grinding requirements required by production and living.

Owner:CHINA THREE GORGES UNIV

Two-component compound synergistic inorganic fireproof glue and preparation method thereof

ActiveCN110240867AGood dispersionTransparent appearanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesCombustionPolyphosphate

The invention relates to two-component compound synergistic inorganic fireproof glue and a preparation method thereof, the two-component compound synergistic inorganic fireproof glue comprises a material A and a material B, the material A comprises the following components in parts by weight: 50 parts of water, 12-18 parts of polyacrylamide and 1-5 parts of a dispersing aid, and the material B comprises 50 parts of water, 15-25 parts of urea, 20-30 parts of borax, 3-10 parts of a silica gel binder and 35-45 parts of polyphosphate. The fireproof glue is divided into two parts, wherein the material A is a master batch and the material B is a curing agent, and the material B is added into the material A to perform curing reaction to form the fireproof glue, and most of the components of the fireproof glue are inorganic substances, so that the fireproof glue can resist long-term flame combustion.

Owner:滁州圣好材料科技有限公司

Production method of convenient coarse cereal and vegetable health-maintaining porridge

InactiveCN105614660AChange shapeChange stickinessFood ingredient as flavour affecting agentFood ingredient as mouthfeel improving agentBrassicaLiquid state

The invention provides a production method of convenient coarse cereal and vegetable health-maintaining porridge. The production method comprises the following steps: after soaking lens culinaris in baking soda liquid, thoroughly cooking the lens culinaris with clean water; at the moment of 1-2 minutes before the lens culinaris is thoroughly cooked, adding honey and a chitosan solution; after soaking sorghum rice in water, thoroughly cooking the sorghum rice with clean water; then adding the thoroughly cooked lens culinaris, uniformly stirring and filtering; drying particle parts to obtain solid particles; drying liquid-state parts and crushing to obtain powder; thoroughly cooking rice with clean water and filtering; drying particle parts to obtain solid particles, drying liquid-state parts and crushing to obtain powder; steaming chopped Chinese yams and drying to obtain solid particles; steaming brassica chinensis, pumpkins and carrots respectively, drying and mixing to obtain solid particles; and packaging the powder and the solid particles to obtain the convenient health-maintaining porridge. The health-maintaining porridge has abundant nutrients, is easy to carry and convenient to eat, has obvious features, has a health-maintaining effect, a good mouth feel and a rich taste, meets the requirements on porridge of consumers, and is suitable for people to enjoy at home and in travels.

Owner:BOHAI UNIV

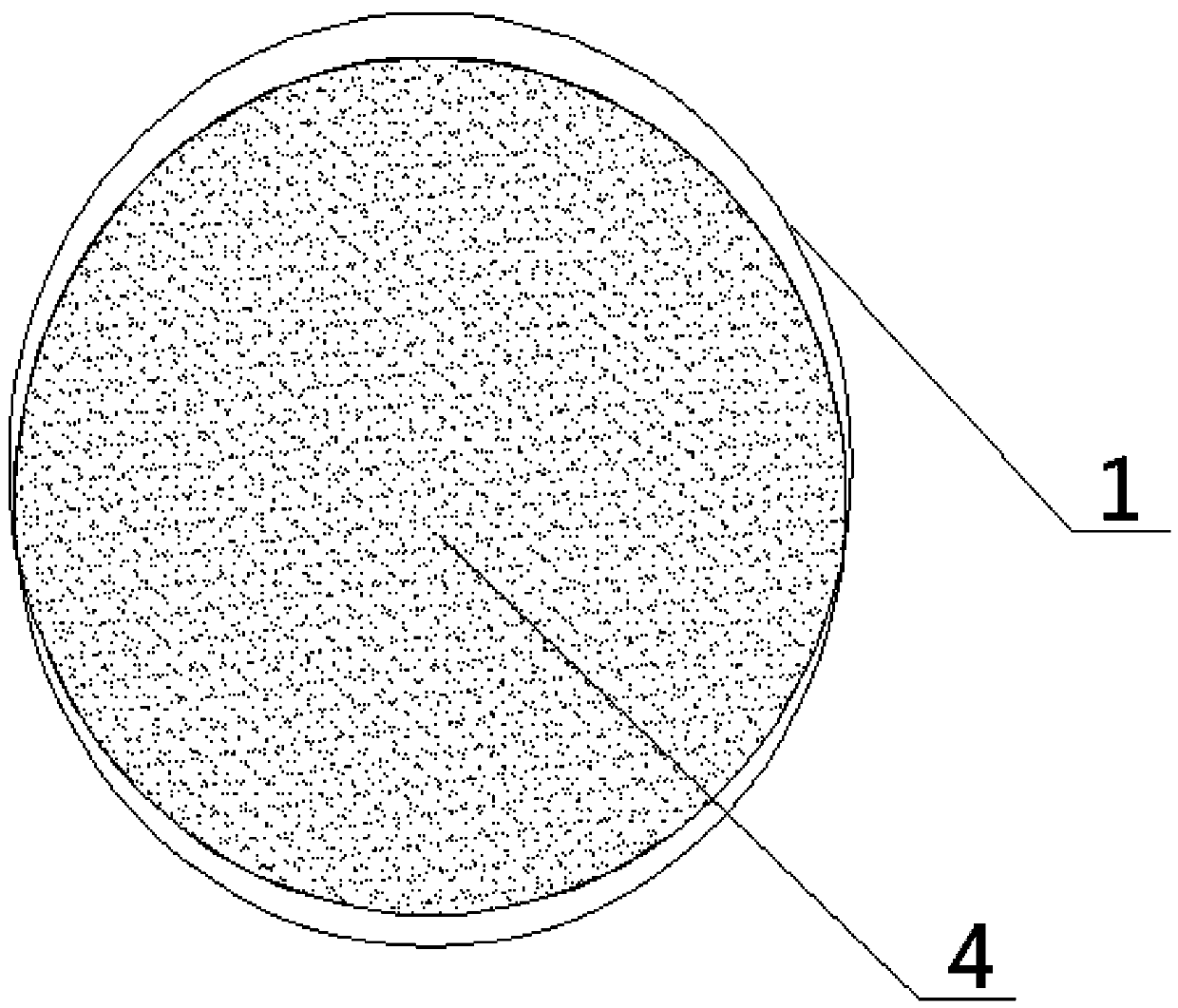

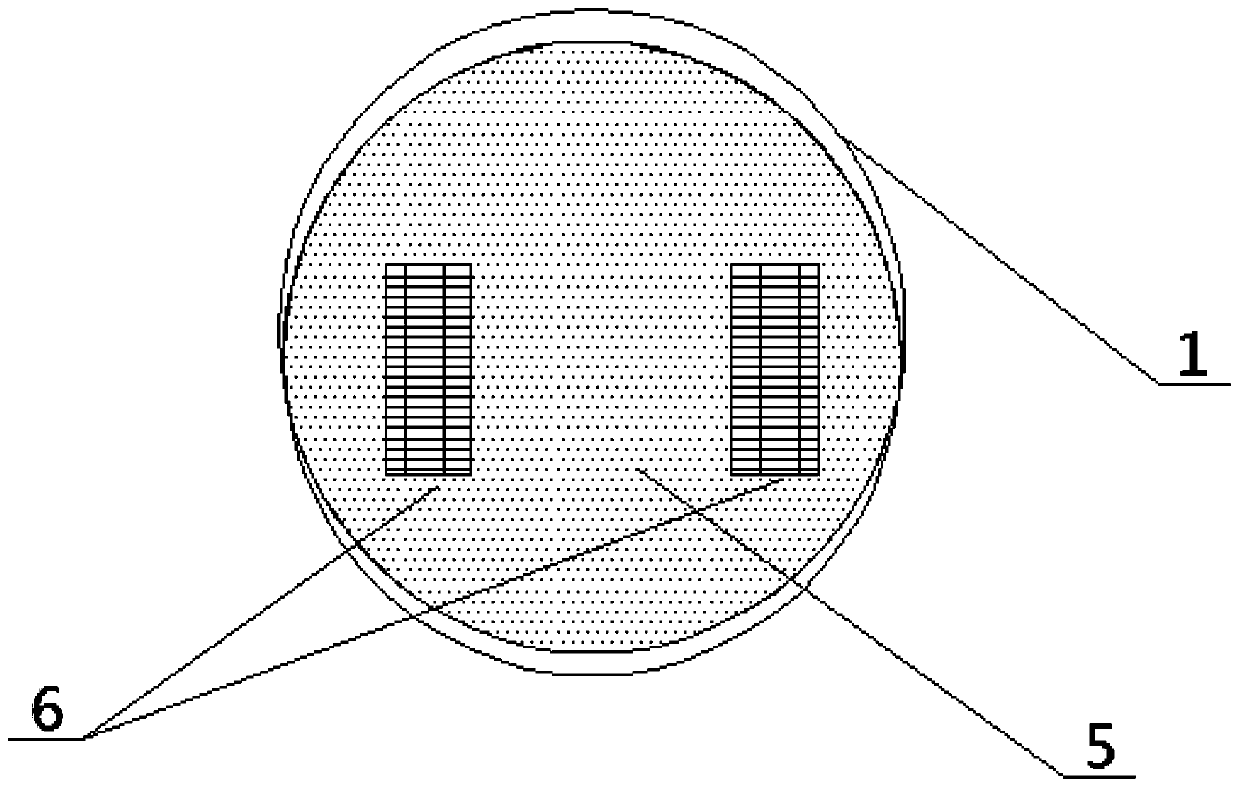

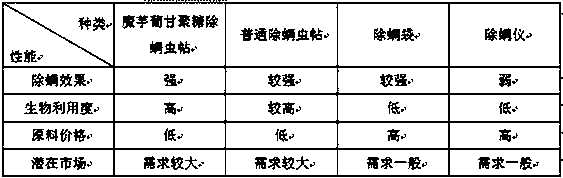

Konjac glucomannan mite killing patch and preparation method thereof

InactiveCN110839631AChange stickinessIncrease stickinessBiocideAnimal repellantsBiotechnologyAdhesive

The invention relates to a konjac glucomannan mite killing patch and a preparation method thereof. The preparation method comprises following steps: preparing a konjac glucomannan adhesive solution; filtering; preparing a konjac glucomannan / chitosan nano fibrous membrane; and preparing the mite killing patch. The konjac glucomannan / chitosan nano fibrous membrane is taken as the carrier of the konjac glucomannan mite killing patch; a mite attractant and other auxiliary agents are added; and mites in bedclothes and sofas can be effectively eliminated. The mite killing patch has an excellent adhesive performance, kills mites in a physical mode, and is harmless for human body. Konjac glucomannan is used as the main material of the mite killing patch; compared with a plastic plate, konjac glucomannan has a better drug carrying performance and stronger mite killing performance, and the mite killing patch can keep the cleanness and hygiene of bedclothes for a long term. The konjac glucomannanmite killing patch can be completely and biologically decomposed, is environmentally friendly and low-carbon, moreover, the raw materials are easily available, the price is cheap, and the productiontechnology is simple.

Owner:FUJIAN AGRI & FORESTRY UNIV

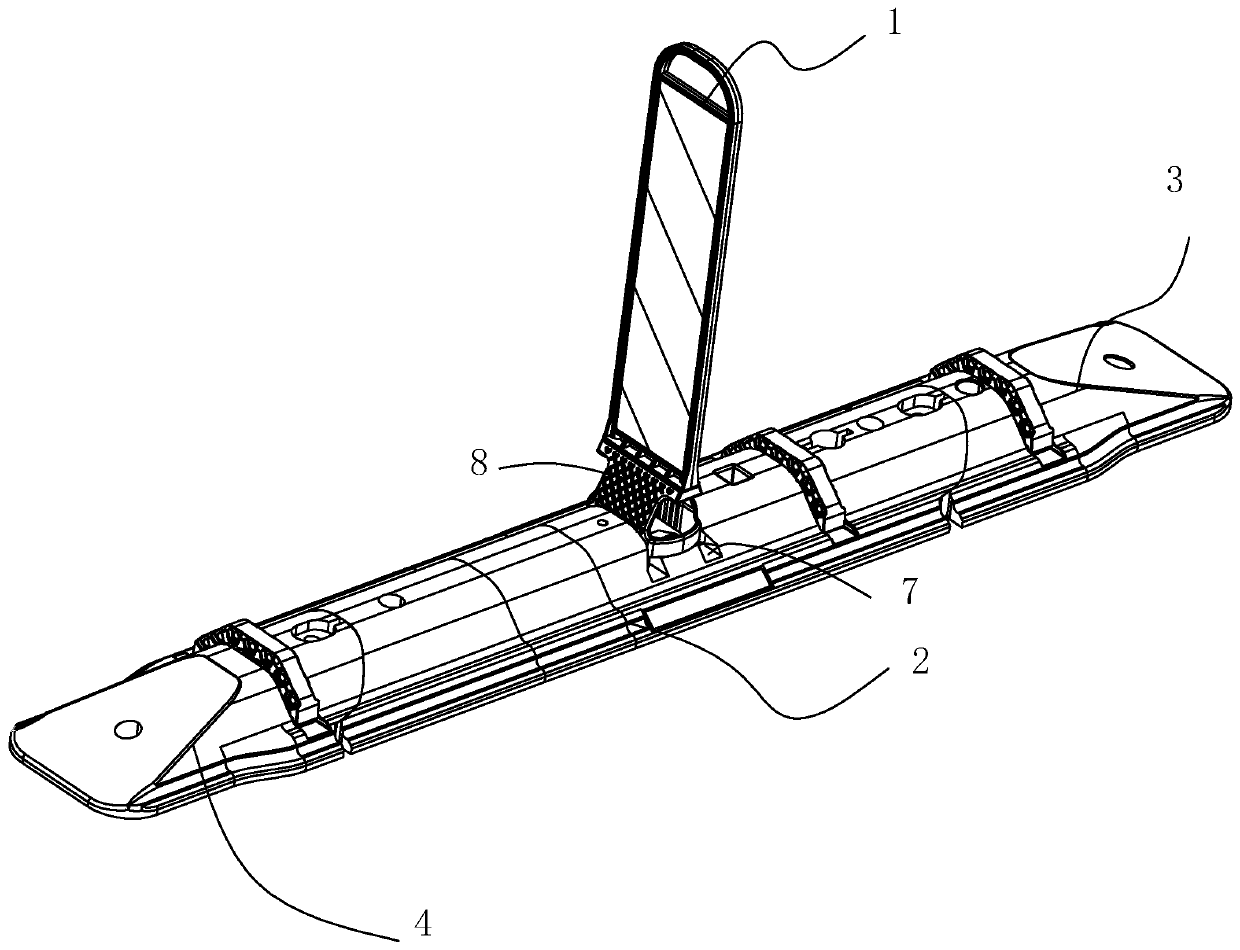

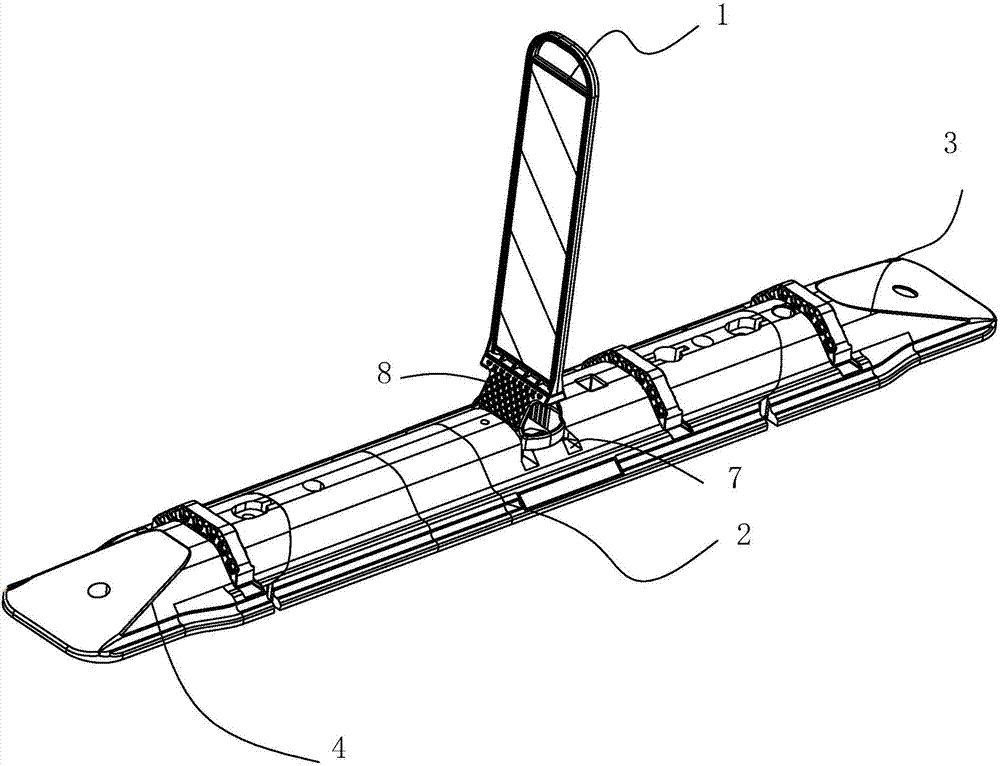

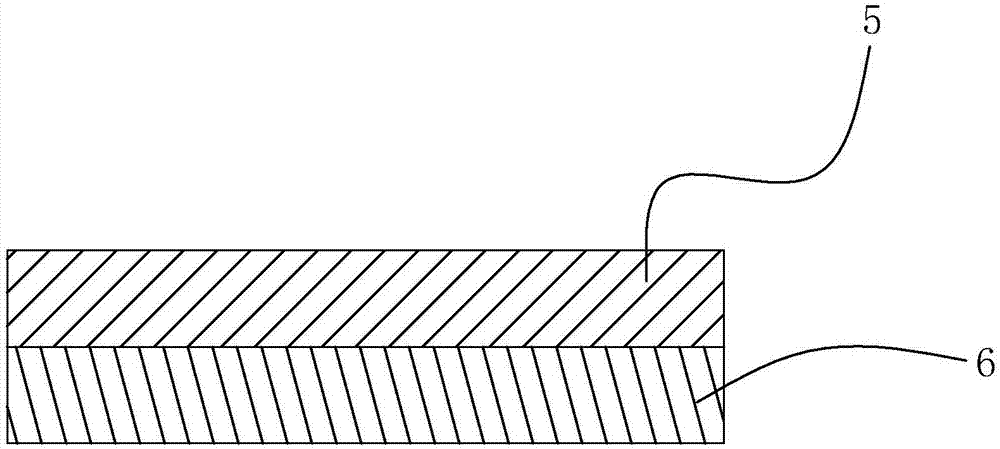

A kind of isolation belt and its processing technology

ActiveCN107447702BFacilitate cross-linkingIncrease reflectionCellulose coatingsPolyurea/polyurethane coatingsCarbide siliconCellulose

The invention discloses an isolation belt and a processing technology thereof. According to the technical key points, the isolation belt comprises a base plate and a warning pile fixed to the base plate. The two ends of the base plate are connected with a first side plate and a second side plate correspondingly, and an inset groove is formed in the base plate; the side, close to the base plate, of the warning pile is provided with an insert block inserted into the insert groove to fix the warning pile, and the base plate comprises a bottom layer and a light reflecting layer; the light reflecting layer comprises the following components of, by weight, 80-100 parts of PVC resin, 10-20 parts of glass beads, 10-20 parts of polyurethane resin, 10-20 parts of ethylene propylene rubber, 2-5 parts of silicon carbide, 5-10 parts of cellulose, 20-40 parts of filling agent, 40-50 parts of non-phthalate plasticizer and 5-12 parts of manometer reinforcing agent. The cross-linking property of the light reflecting layer and the bottom layer can be reinforced through adding of the polyurethane resin in the light reflecting layer, when the cellulose encounters water, the glass beads are driven to dialyse towards the surface of the light reflecting layer, so that the light reflecting effect is excellent, and meanwhile the overall abrasion resistance of the isolation belt is also excellent.

Owner:浙江鼎海科技股份有限公司

Compound type sludge dewatering conditioner and application method thereof

ActiveCN103113013BChange surface chargeEfficient dehydrationSludge treatment by de-watering/drying/thickeningChemical industryActive agent

Owner:SHENZHEN WATER GRP CO LTD

Outer coating powder composition for fried chicken products and preparation process of outer coating powder composition

PendingCN110604256AEasy generationPlay a role in health careFood coatingSodium bicarbonateRetention time

The invention provides an outer coating powder composition for fried chicken products, a preparation method of the outer coating powder composition, and a process for forming the fried chicken products. The composition is prepared by uniformly mixing flour, corn starch, modified starch, sodium bicarbonate or ammonium bicarbonate, cysteine, D xylose and VB1 by stirring. When chicken meat products are fried, the composition is uniformly adhered to the surface of chicken through a certain process to form a layer of powder coating layer adhered to the surface of the chicken. The outer coating powder composition has the characteristics of water retention, beauty, crispness and thick meat flavor, and overcomes the technical problems that a powder coating layer formed by the prior art does not have thick meat flavor, is not beautiful, has short retention time and the like.

Owner:郑州谦益食品有限公司

A grinding device with adjustable stiffness and its use method

ActiveCN111168503BReduce the effect of grinding hardnessAdjust stiffnessBelt grinding machinesLeather surface mechanical treatmentRubber materialAdjustable stiffness

The invention provides a grinding device with adjustable rigidity and a using method, which includes a motor for providing power, a switch for controlling its opening is installed on the motor, and a grinding device for grinding is installed on the output shaft of the motor. wheel or grinding belt; the grinding area on the grinding wheel and grinding belt is divided into multiple layers with rubber material, the middle layer adopts a hydraulic layer or pulse layer that can generate instantaneous force, and the remaining layers are rigidities that can provide different grinding stiffnesses layer; the hydraulic layer or the pulse layer are respectively connected to the hydraulic device or the pulse device; the surface of the grinding wheel and the grinding belt is provided with a raised structure for enhancing the grinding effect, and a layer of flexible material is wrapped on its outer surface ; By changing the grinding material of the stiffness layer in real time, finely adjust the appropriate stiffness to polish the object. Compared with ordinary grinding devices, it has wider practicality and economic benefits, and better meets the grinding requirements required for production and life.

Owner:CHINA THREE GORGES UNIV

Isolation belt and processing technology thereof

ActiveCN107447702AFacilitate cross-linkingIncrease reflectionCellulose coatingsPolyurea/polyurethane coatingsCross-linkCellulose

The invention discloses an isolation belt and a processing technology thereof. According to the technical key points, the isolation belt comprises a base plate and a warning pile fixed to the base plate. The two ends of the base plate are connected with a first side plate and a second side plate correspondingly, and an inset groove is formed in the base plate; the side, close to the base plate, of the warning pile is provided with an insert block inserted into the insert groove to fix the warning pile, and the base plate comprises a bottom layer and a light reflecting layer; the light reflecting layer comprises the following components of, by weight, 80-100 parts of PVC resin, 10-20 parts of glass beads, 10-20 parts of polyurethane resin, 10-20 parts of ethylene propylene rubber, 2-5 parts of silicon carbide, 5-10 parts of cellulose, 20-40 parts of filling agent, 40-50 parts of non-phthalate plasticizer and 5-12 parts of manometer reinforcing agent. The cross-linking property of the light reflecting layer and the bottom layer can be reinforced through adding of the polyurethane resin in the light reflecting layer, when the cellulose encounters water, the glass beads are driven to dialyse towards the surface of the light reflecting layer, so that the light reflecting effect is excellent, and meanwhile the overall abrasion resistance of the isolation belt is also excellent.

Owner:浙江鼎海科技股份有限公司

Method for preparing pharmaceutic adjuvant film coating material

ActiveCN101927003BChange stickinessChange elasticityPharmaceutical non-active ingredientsPolyethylene glycolSolvent

Owner:ANHUI SUNHERE PHARMA EXCIPIENTS

Adhesive for adhering artificial lashes to eye region and method of making same

PendingCN112574701AAvoid allergiesAvoid reactionCosmetic preparationsHair accessoriesArtificial lashesOphthalmology

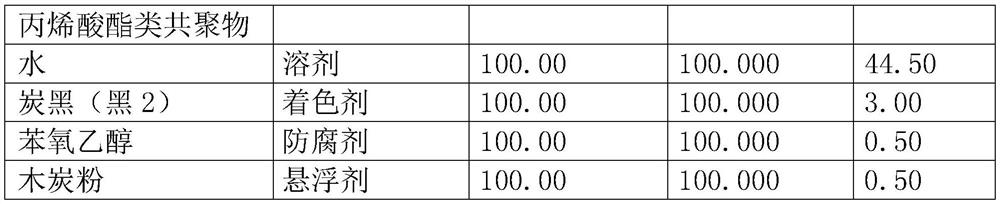

The invention discloses an adhesive composition for adhering artificial lashes to an eye region, the adhesive composition comprising charcoal powder, and the invention discloses a method of manufacturing the adhesive composition. According to the lash adhesive, the sensitivity of human eyes in the process of using the lash adhesive is fully considered, and the possibility of anaphylaxis, such as inflammation, irritation, itching, soreness, redness and / or infection inside and outside the eyes can be reduced, thereby avoiding an allergic or allergy-like reaction of the user to the lash adhesivewhen the adhesive is applied to the eyes.

Owner:莱施菲公司

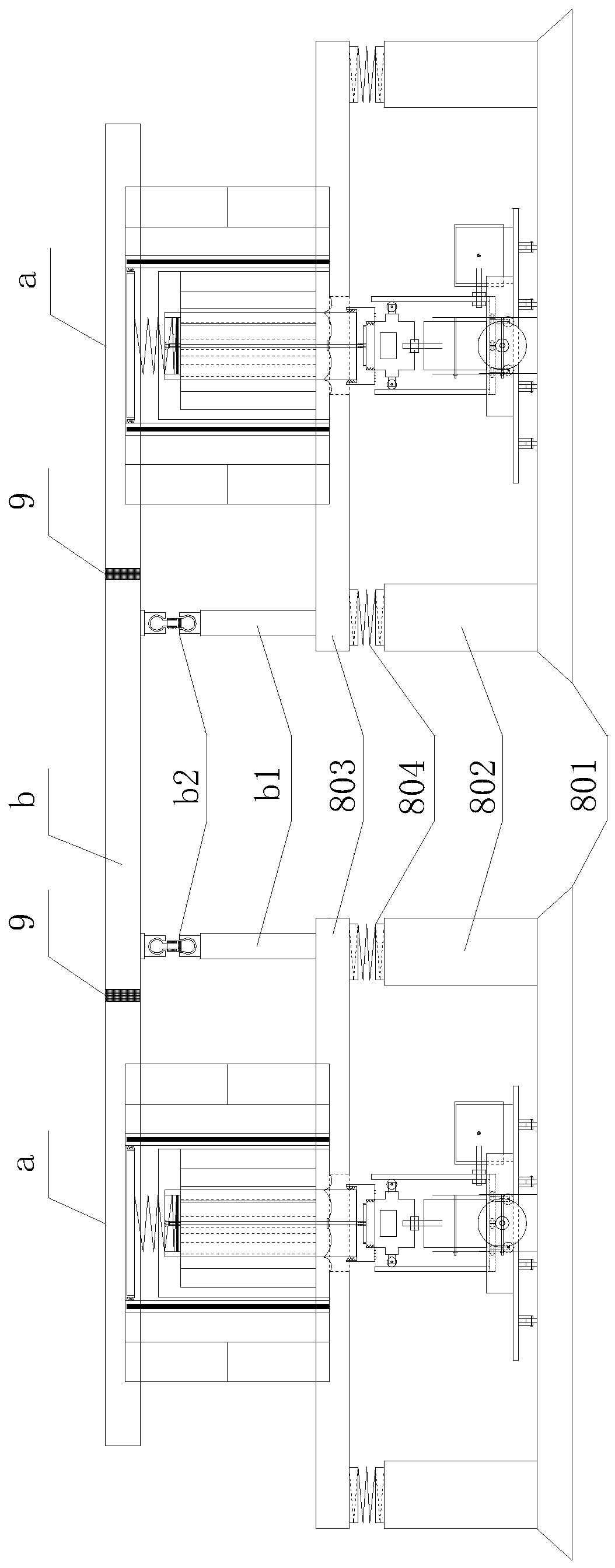

A continuous test device suitable for simulating multi-point seismic input boundaries

ActiveCN109029893BChange lengthRealize the function of adjustable stiffnessVibration testingEngineeringElectrorheological fluid

Owner:TIANJIN UNIV

Environment-friendly type insulated dope for cold rolling non-oriented silicon steel and preparation method for coat thereof

The invention relates to environmental protection type insulating coating used for cold rolling non-orientation silicon steel and the preparation method of a coating layer thereof. The components of the insulating coating comprise phosphate, molybdenate, water, organic resin, silane coupler and glycerine; the weight ratio of each component is as follows: 100 parts of phosphate, 3 to 20 parts of molybdenate, 800 to 1500 parts of water, 20 to 50 parts of organic resin, 0.5 to 5 parts of silane coupler and 8 to 15 parts of glycerine. The preparation method of the coating has the following steps:firstly, the insulating coating is coated on the surface of the cold rolling non-orientation silicon steel; secondly, baking and drying: the baking temperature is 150 to 300 DEG C; thirdly, sintering: the sintering temperature is 400 to 600 DEG C, and the sintering time is 30 to 90 seconds; fourthly, finished product. The insulating coating of the invention contains no damaging element, the coating layer of the invention has good insulating property simultaneously, the adhesivity and the corrosion resistance are good, and the insulating coating of the invention has good punching shear workability and good weldability, and can bear the heat resistance of eliminating stress annealing. The operation of the method in the invention is simple, the coating layer prepared by the method has the good punching shear workability and the good weldability, and can bear the heat resistance of eliminating the stress annealing.

Owner:武钢集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com