Carrying device

A technology of carrying device and carrying parts, applied in vacuum evaporation plating, coating, thermoelectric device parts and other directions, can solve problems such as substrate cracking, and achieve the effect of rapid adsorption and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment provides a carrying device, figure 1 is a schematic structural diagram of the carrying device according to this embodiment.

[0026] like figure 1 As shown, the carrying device includes: a carrying part 1, which is used to carry the object to be supported. The object to be supported here is generally the substrate of the display device, and it can also be other devices. In the following description, the object to be supported is OLED The substrate is taken as an example, but the embodiment is not limited thereto; the adhesion element 2 is arranged on the carrying part, and the viscosity of the adhesion element is variable to realize the adhesion and separation of the object to be supported and the carrying device; The supporting member 3 is arranged on the carrying part and is used for supporting the object to be carried.

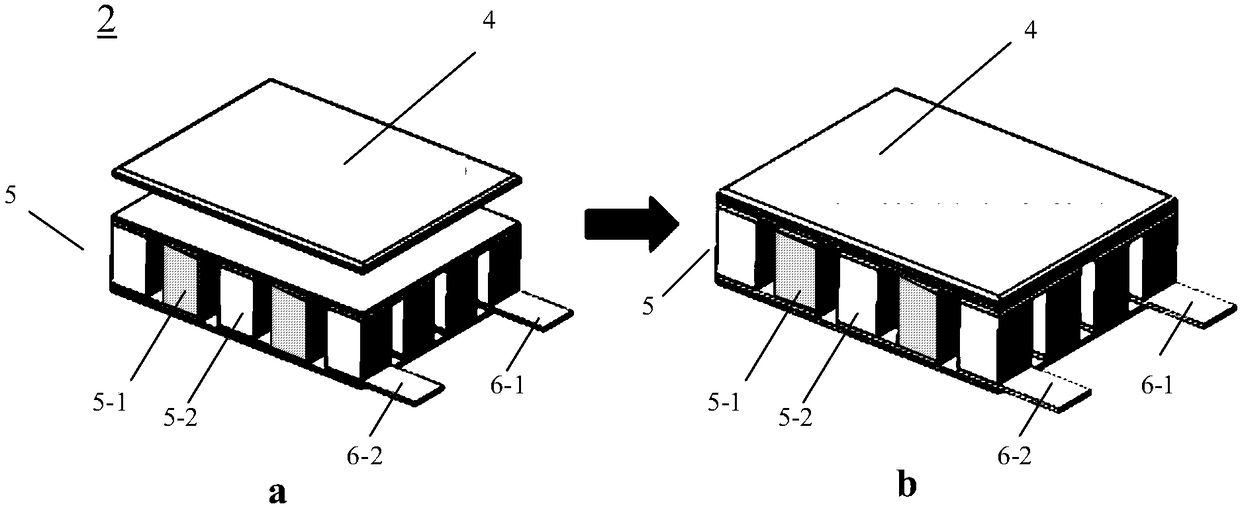

[0027] figure 2 is a schematic structural diagram of an adhesive element according to an embodiment of the present disclosure. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com