Viscous materials and method for producing

A technology of composition and mixture, which is applied in the field of composition for preparing building materials, and can solve problems such as stress fracture and increasing the weight of building materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] Example: 5 gallons of mix

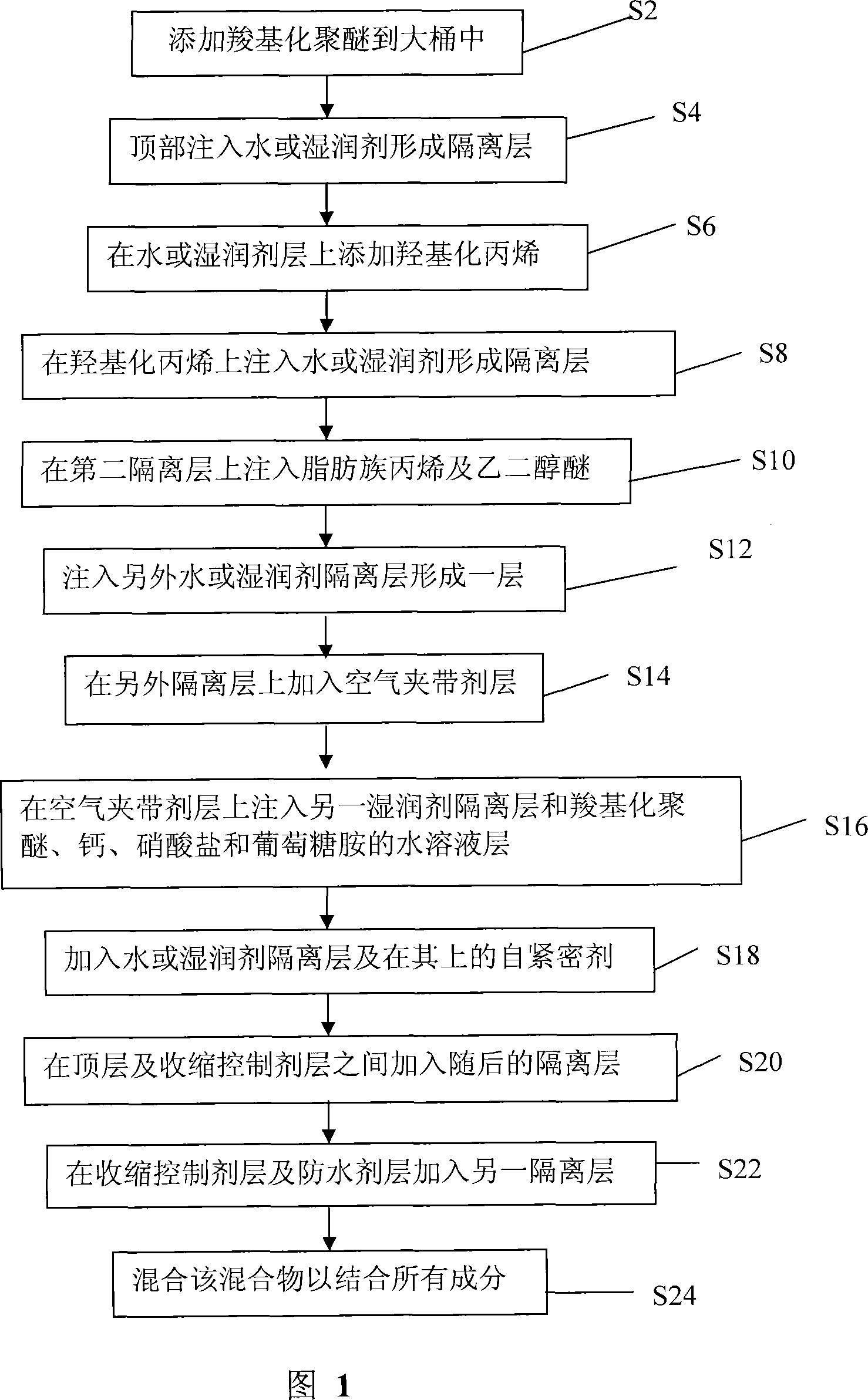

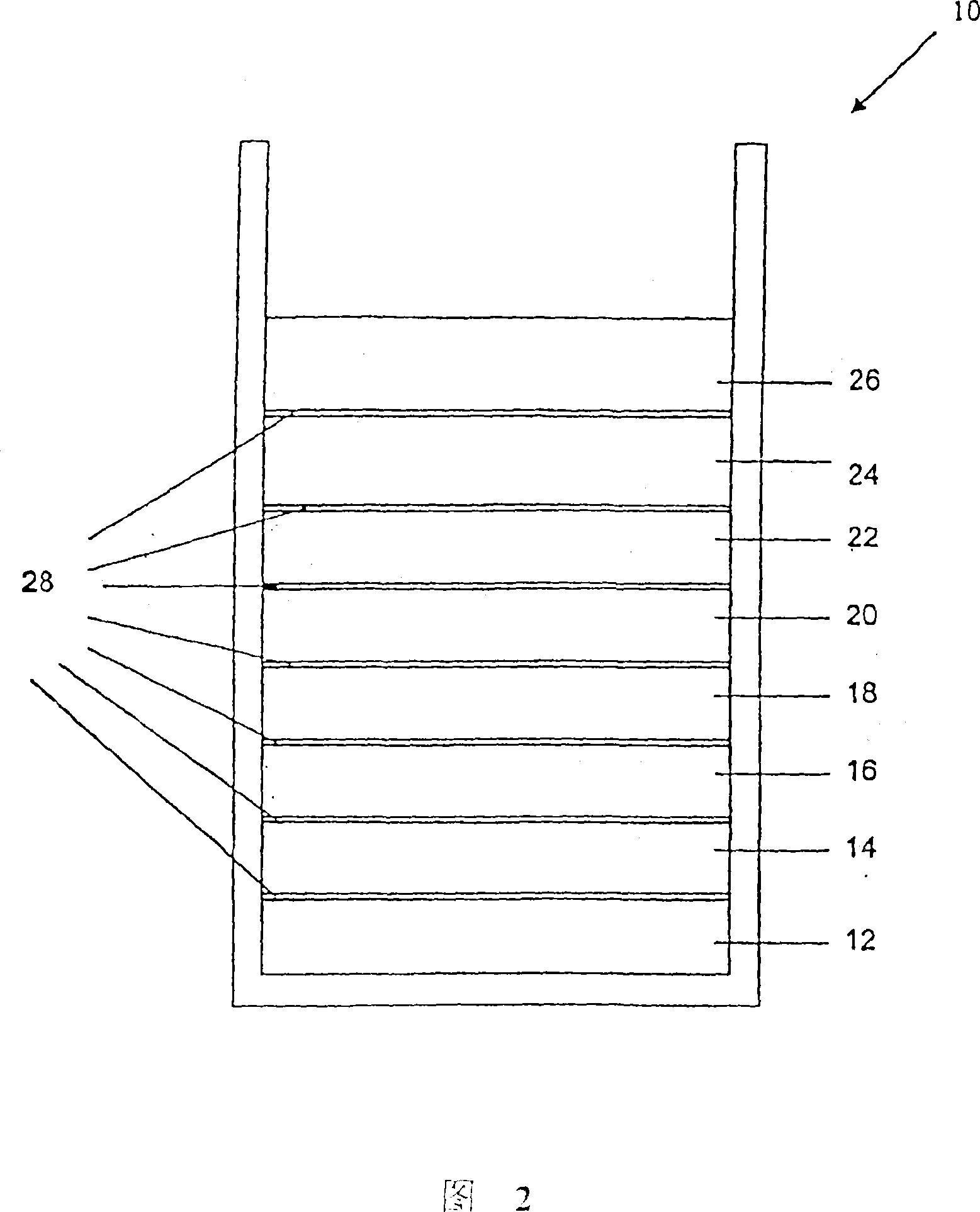

[0061] Using regular tap water, introduce the superplasticizer mixture in the 5 gallon range and add enough water to place about an eighth of an inch of water / surfactant barrier on top of the superplasticizer. The water / surfactant layer acts as a barrier layer and stays on top of the superplastic because the water / surfactant is lighter than the superplastic. There is no flash or chemical reaction when pouring the next ingredient, such as a self-setting agent (or self-compacting agent), on top of the water / surfactant. The process is repeated by placing substantially the same amount of a layer of water / surfactant on top of the second layer and adding a third ingredient, such as a shrinkage reducer. The process is then repeated for each additional ingredient added to the mixture.

[0062] In the above exemplary mixture, having essentially 1 1 / 4 gallons of superplasticizer, essentially 2.5 gallons of self-setting agent, and essentially 3 / 4 gal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com