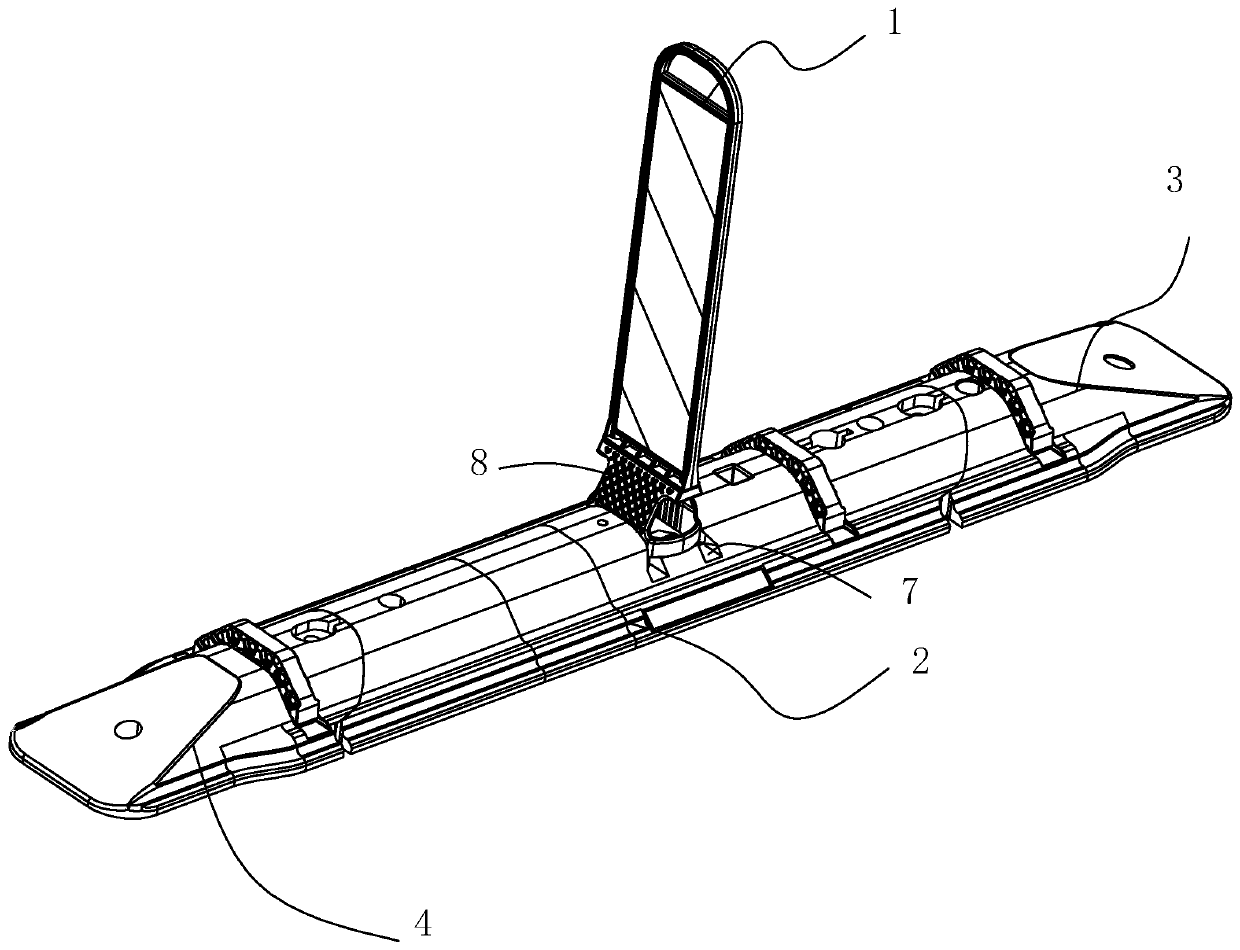

A kind of isolation belt and its processing technology

A technology of isolation strips and substrates, applied in the field of traffic safety appliances, can solve the problems of blind areas of reflective strips and poor warning effects, etc., and achieve the effects of enhanced heat resistance, excellent reflective effects, and enhanced firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The reflective layer 6 includes the following components in parts by weight, 80 parts of PVC resin, 10 parts of glass beads, 10 parts of polyurethane resin, 10 parts of ethylene-propylene rubber, 2 parts of silicon carbide, 5 parts of cellulose, and 20 parts of nano-calcium carbonate whiskers. 40 parts, 40 parts of acetyl tributyl citrate, 5 parts of nanometer reinforcing agent;

[0054] The bottom layer 5 includes the following components in parts by weight, 50 parts of rubber waste, 10 parts of ethylene-propylene rubber, 2 parts of nano-calcium carbonate whiskers, 2 parts of PC, 20 parts of silicone, and 10 parts of PVC;

[0055] The warning post 1 includes the following components in parts by weight: 50 parts of rubber waste, 10 parts of ethylene-propylene rubber, 2 parts of nanocellulose whiskers, 2 parts of PC and / or ABS, and 20 parts of silicone.

Embodiment 2

[0057] The reflective layer 6 includes the following components in parts by weight, 84 parts of PVC resin, 12 parts of glass beads, 12 parts of polyurethane resin, 12 parts of ethylene-propylene rubber, 3 parts of silicon carbide, 6 parts of cellulose, and nano-silica whiskers 28 parts, 42 parts of tributyl citrate, 7 parts of nanometer reinforcing agent, 2 parts of polytetrafluoroethylene;

[0058] The bottom layer 5 includes the following components in parts by weight, 60 parts of rubber waste, 12 parts of ethylene-propylene rubber, 3 parts of nano-calcium carbonate whiskers, 3 parts of ABS, 22 parts of organic silicon, and 12 parts of PVC;

[0059] The warning post 1 includes the following components by weight: 60 parts of rubber waste, 12 parts of ethylene propylene rubber, 3 parts of silicon carbide nano whiskers, 3 parts of ABS, and 22 parts of silicone.

Embodiment 3

[0061] The reflective layer 6 includes the following components in parts by weight, 92 parts of PVC resin, 15 parts of glass beads, 15 parts of polyurethane resin, 15 parts of ethylene-propylene rubber, 4 parts of silicon carbide, 7 parts of cellulose, and 30 parts of nano-calcium carbonate whiskers. 23 parts, 23 parts of tributyl citrate, 23 parts of epoxy soybean oil, 9 parts of nanometer reinforcing agent, 1 part of polytetrafluoroethylene;

[0062] The bottom layer 5 includes the following components in parts by weight, 65 parts of rubber waste, 15 parts of ethylene-propylene rubber, 4 parts of nanocellulose whiskers, 4 parts of PC, 25 parts of silicone, and 15 parts of PVC;

[0063] The warning post 1 includes the following components in parts by weight: 65 parts of rubber waste, 15 parts of ethylene-propylene rubber, 4 parts of nanocellulose whiskers, 4 parts of PC and / or ABS, and 25 parts of silicone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com