Visual measurement device for crack repair and using method

A measuring device and crack technology, applied in the field of rock crack repair, can solve problems such as difficult cracks, simulation, and many rocks and soils, and achieve the effect of increasing the degree of lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

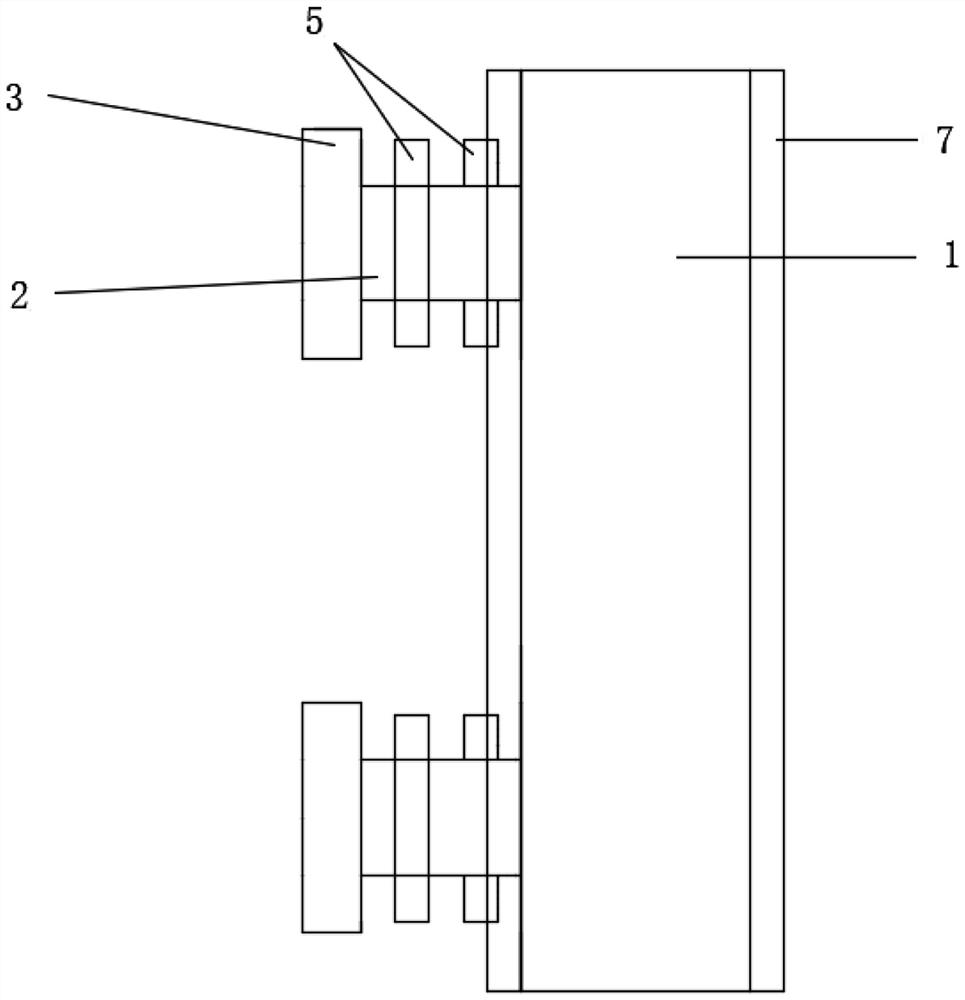

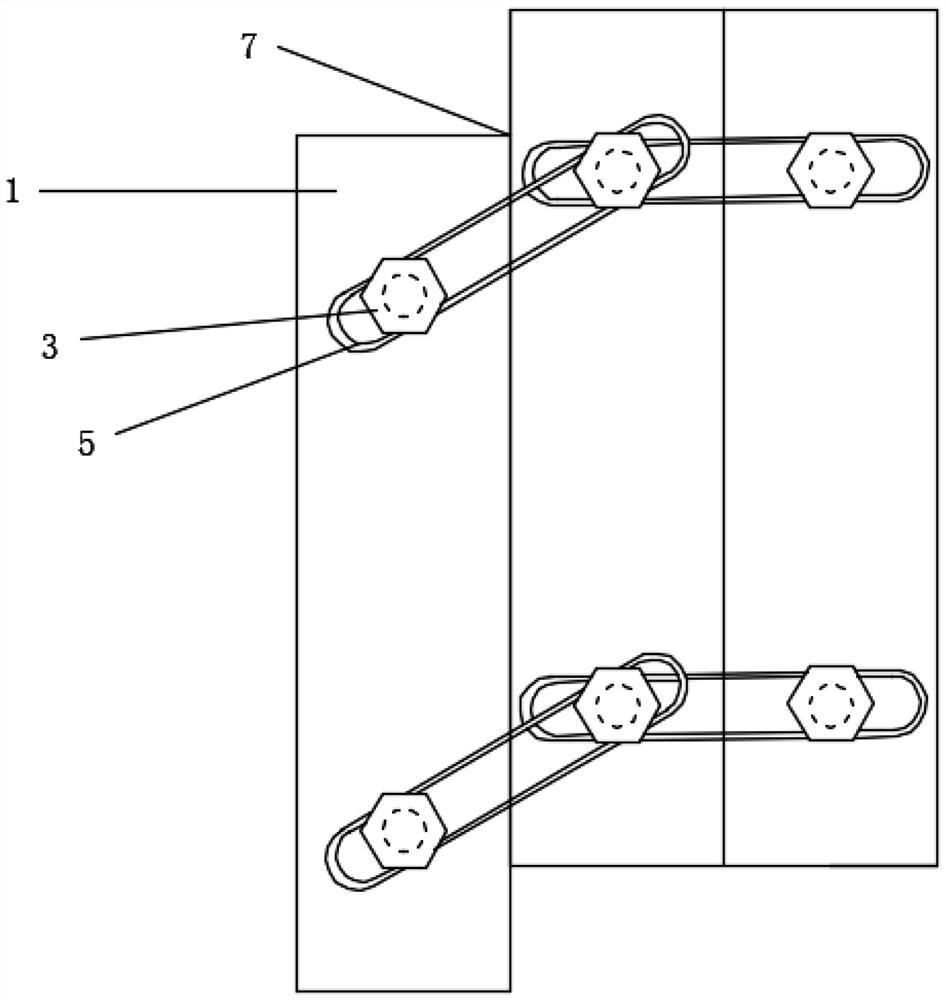

[0039] Such as Figure 1-6 As shown, a visual measurement device for crack repair, which includes a turn frame structure assembled around a plurality of steel plates 1, each bottom corner of the turn frame structure is welded and fixed for the entire turn frame structure The threaded plate 4 for support; the contact end surfaces of two adjacent steel plates 1 are connected by a mortise and tenon sliding structure; the outer walls of two adjacent steel plates 1 are connected by a sliding lever structure, and make the adjacent two The plates 1 can slide up and down within a certain range. By adopting the measuring device with the above structure, the crack is surrounded by the flip template structure, and the shape of the crack and the geological environment are rubbed through the rubbing effect of silica gel. However, considering that the surface crack is too small, the silica gel cannot flow into the crack, so the silica gel Add nano-scale magnetic powder into the mixture, us...

Embodiment 2

[0043] The method for using the visual measurement device for crack repair comprises the following steps:

[0044] The first step: Prepare materials: steel plate 1, screw rod 2, nut 3, bolt plate 4, sliding lever 5, super glue, stainless steel sliding bar 7, silica gel, silicone oil, nano-scale magnetic powder, transparent resin, iron frame, lighting, magnets and jacks;

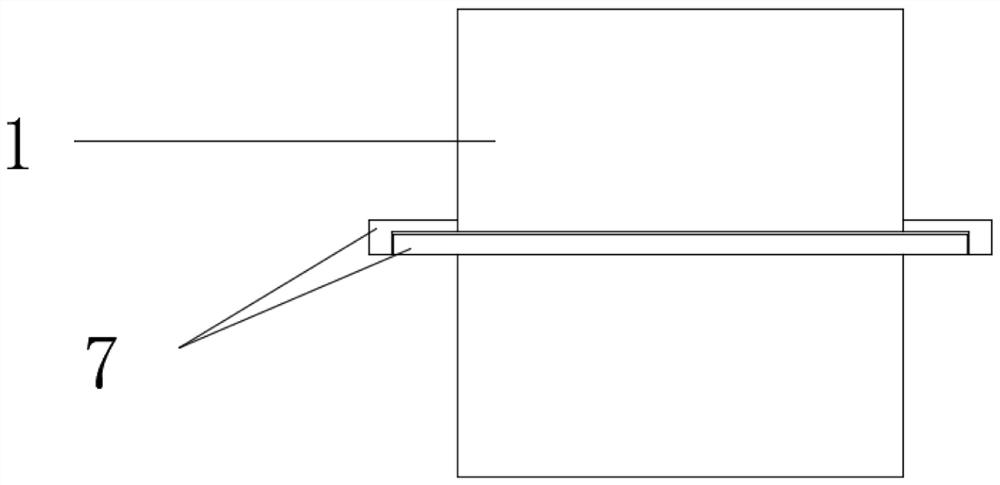

[0045]Step 2: Install the formwork frame structure: Weld the screw rod 2 at the same position up and down on one side of each steel plate 1, weld the stainless steel sliding strip 7 on both sides of the steel plate 1, the left side is the tenon wrapping structure, and the right side is the tenon Eyelet structure, two adjacent steel plates 1 form a sliding fit through tenons and mortises, and the corners of the rectangular frame structure are fixed together by welding, and the bottom of the steel plate at the bottom edge of the four corners of the formwork structure is welded for The whole device is supported...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com