Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

391results about How to "Avoid entrainment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

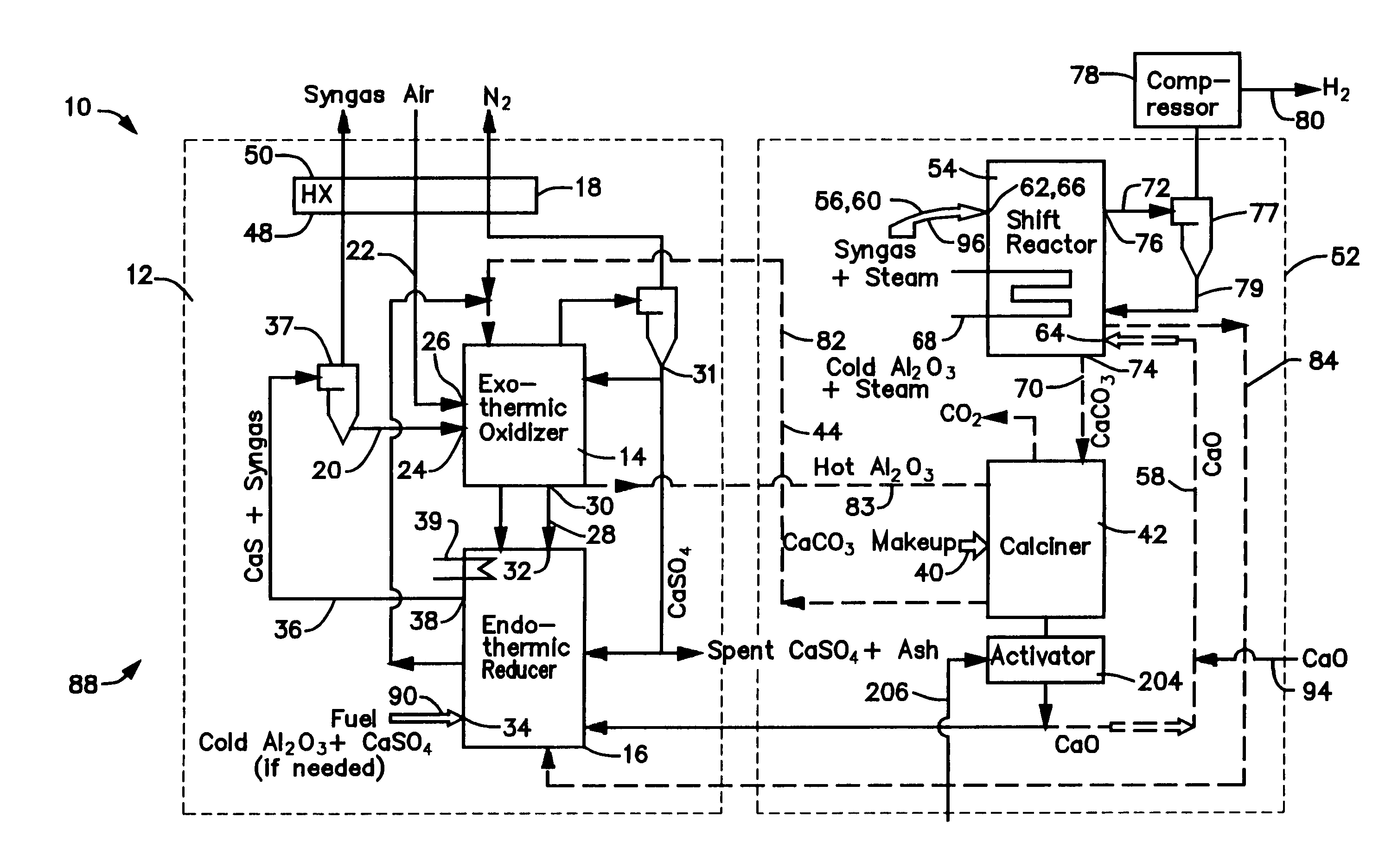

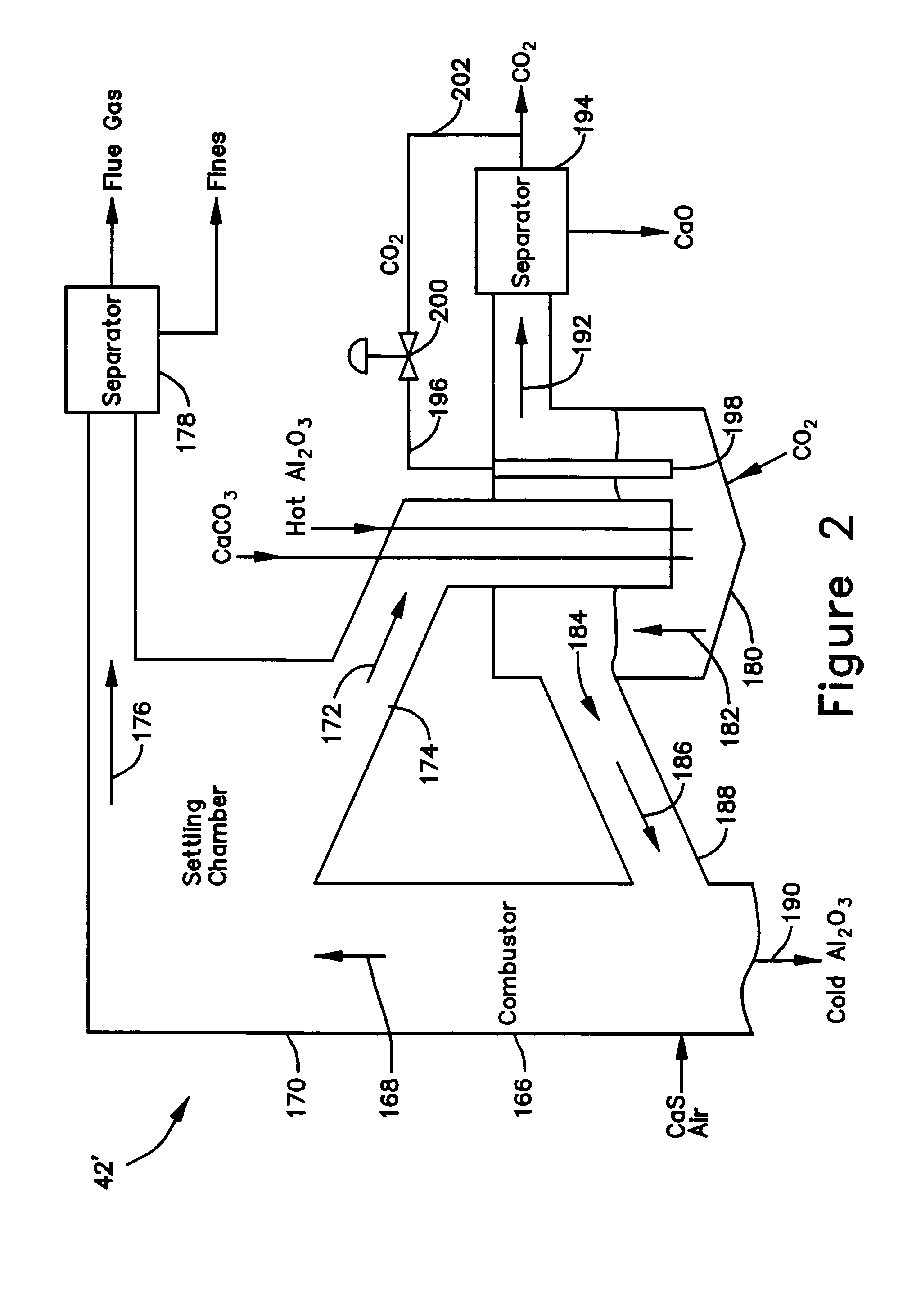

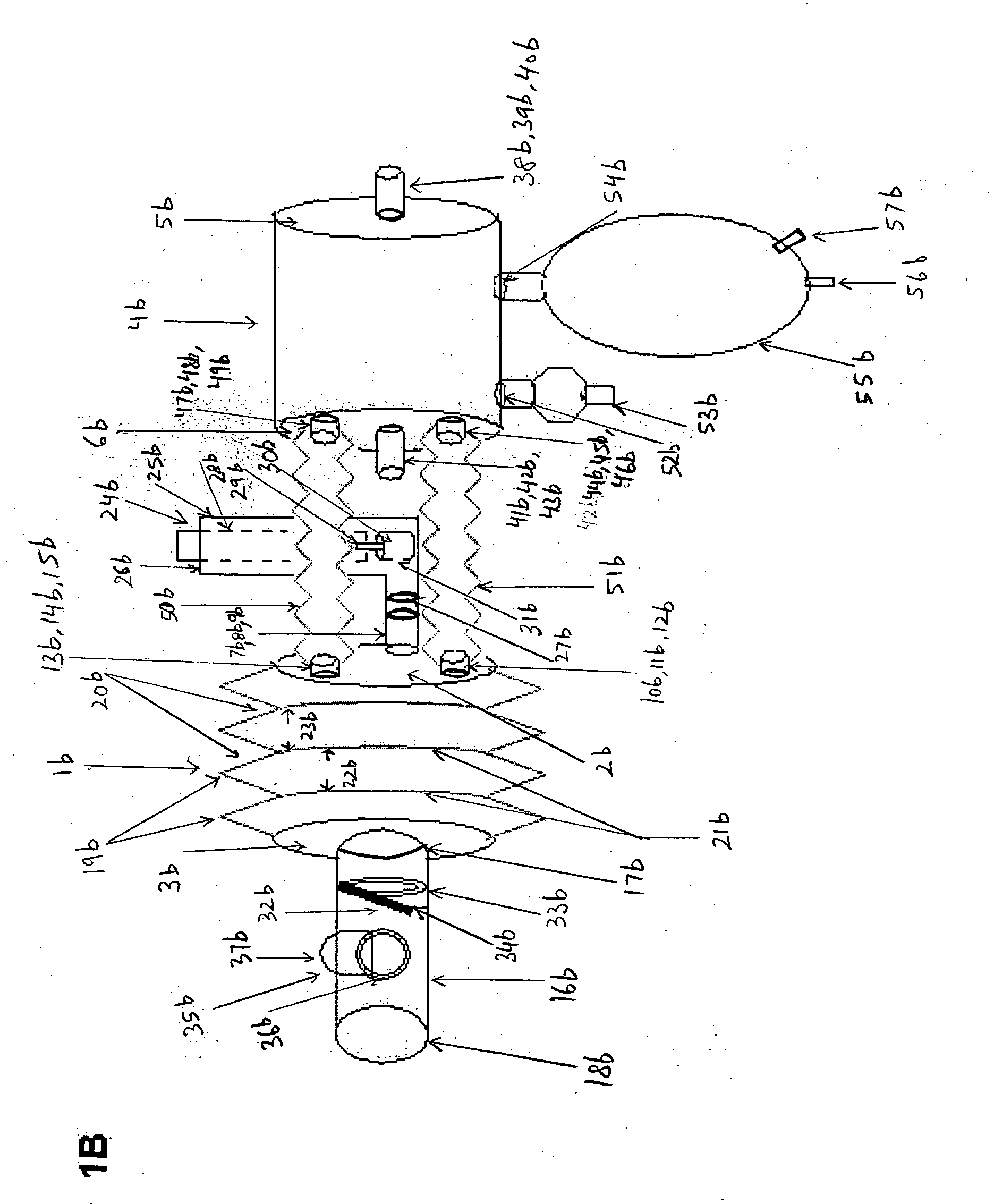

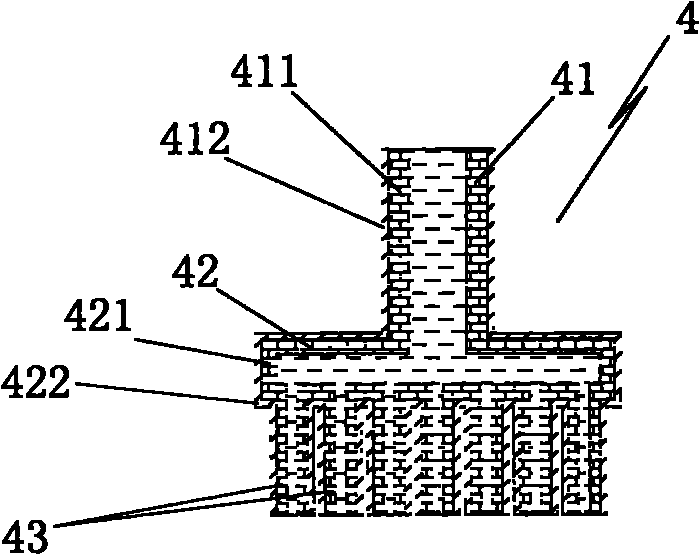

Hot solids gasifier with CO2 removal and hydrogen production

ActiveUS7083658B2Avoid entrainmentEfficient captureMuffle furnacesGas modification by gas mixingCo2 removalWater-gas shift reaction

A gasifier 10 includes a first chemical process loop 12 having an exothermic oxidizer reactor 14 and an endothermic reducer reactor 16. CaS is oxidized in air in the oxidizer reactor 14 to form hot CaSO4 which is discharged to the reducer reactor 16. Hot CaSO4 and carbonaceous fuel received in the reducer reactor 16 undergo an endothermic reaction utilizing the heat content of the CaSO4, the carbonaceous fuel stripping the oxygen from the CaSO4 to form CaS and a CO rich syngas. The CaS is discharged to the oxidizer reactor 14 and the syngas is discharged to a second chemical process loop 52. The second chemical process loop 52 has a water-gas shift reactor 54 and a calciner 42. The CO of the syngas reacts with gaseous H2O in the shift reactor 54 to produce H2 and CO2. The CO2 is captured by CaO to form hot CaCO3 in an exothermic reaction. The hot CaCO3 is discharged to the calciner 42, the heat content of the CaCO3 being used to strip the CO2 from the CaO in an endothermic reaction in the calciner, with the CaO being discharged from the calciner 42 to the shift reactor 54.

Owner:AIR PROD & CHEM INC +1

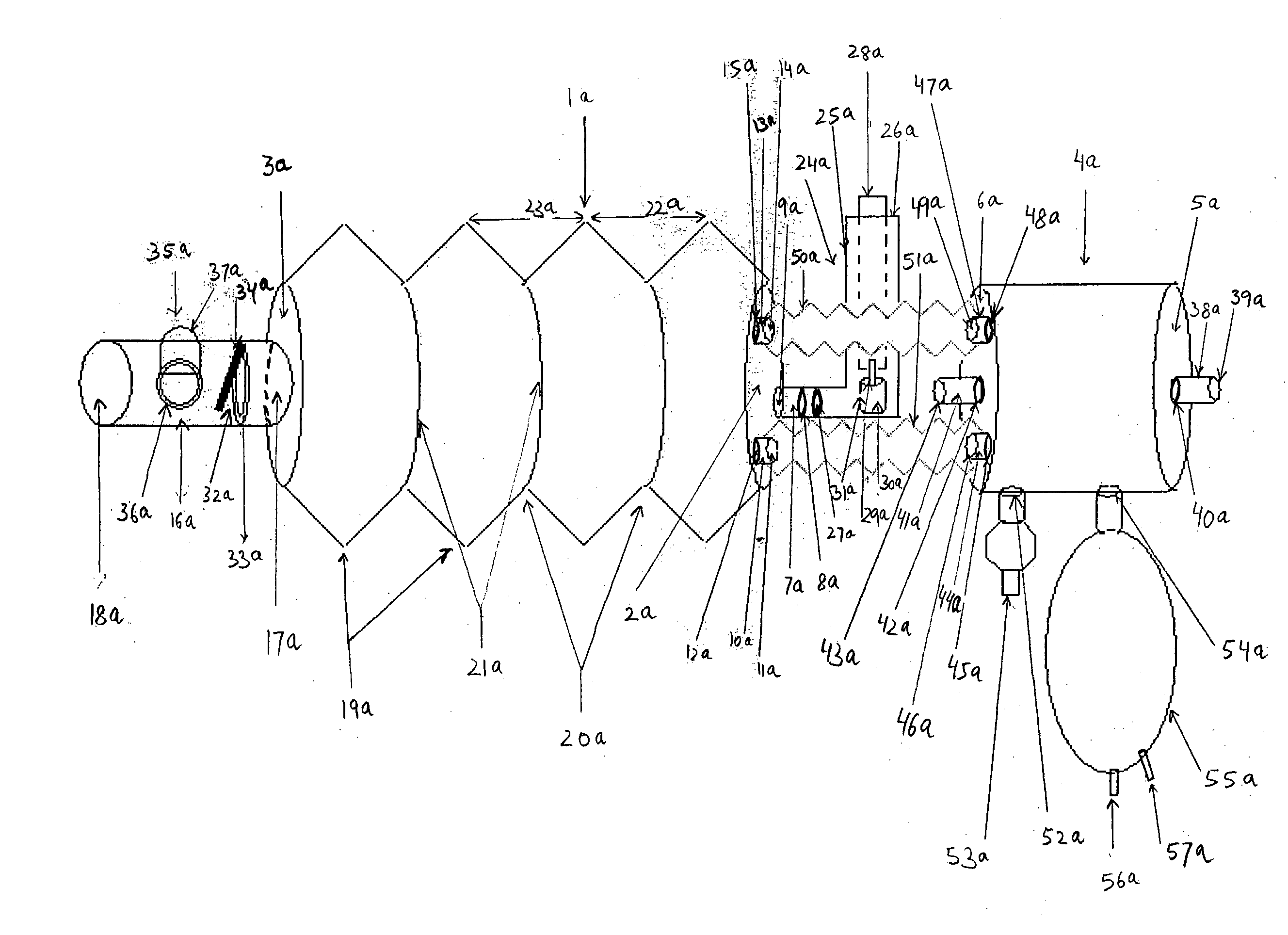

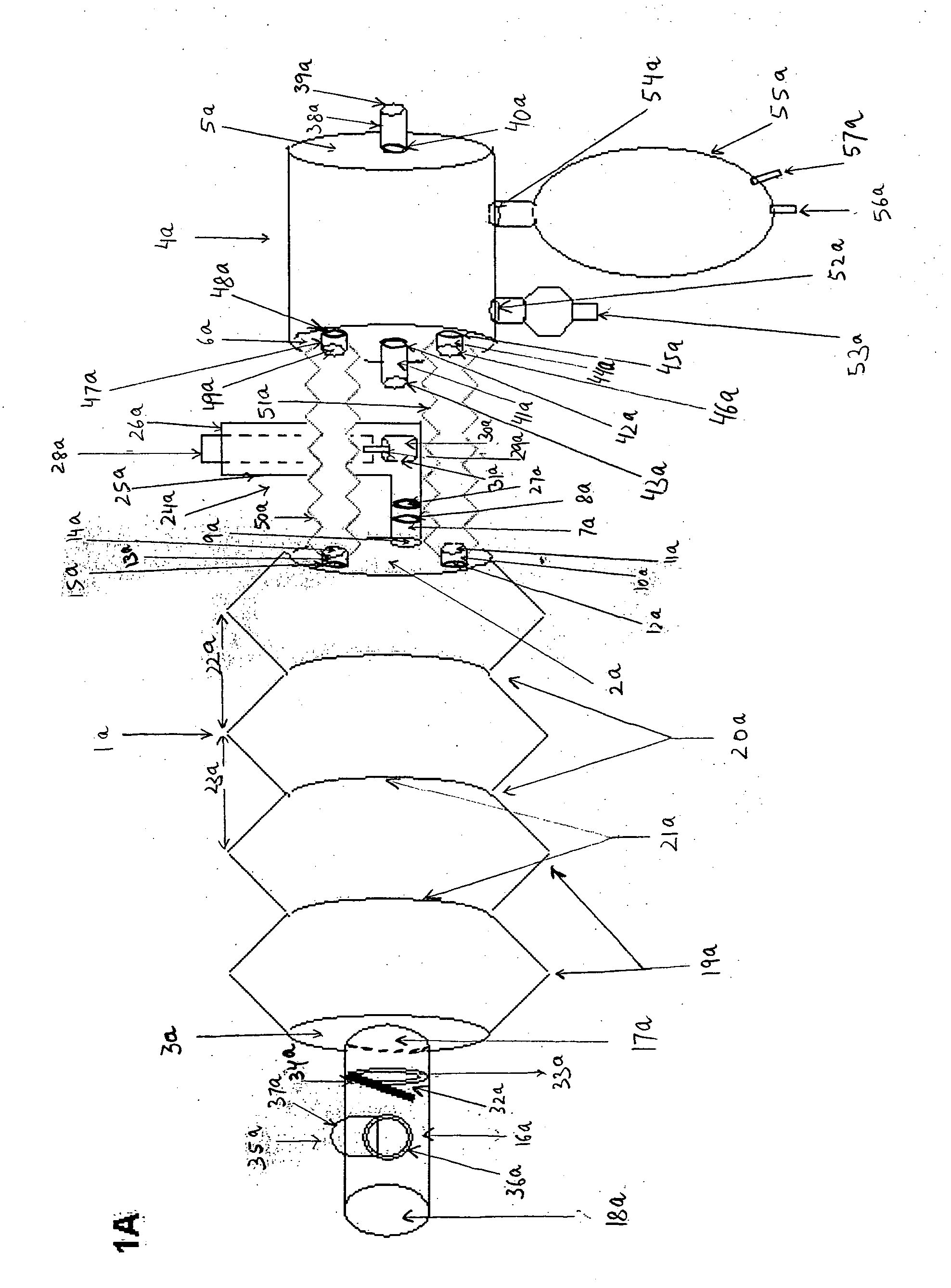

Aerosol deliver apparatus IV

InactiveUS20050217667A1Avoid wastingConvenient to accommodateRespiratorsLiquid surface applicatorsVolumetric Mass DensityNon-rebreather mask

A multipurpose aerosol medication delivery apparatus that includes a collapsible / expandable, or a fixed volume, or a combination of partially fixed volume and partially collapsible / expandable holding chamber for use with a metered dosed inhaler (MDI) and / or any standard small volume nebulizer. The holding chamber is designed to deliver-aerosol medication particles generated by an MDI; aerosol medication particles generated by a nebulizer; a single gas or a mixture of gases; a single gas or a mixture of gases that can yield a gas density that will enhance aerosol delivery of medication with both MDI and nebulizer; a single gas or a mixture of gases that will yield and deliver an oxygen concentration to a patient ranging from room air concentration to 100%. The device includes a reservoir that stores nebulized aerosol generated during exhalation to be inhaled during the next breath. The device also included a one way valve to prevent carbon dioxide generated during exhalation from rebreathing by not allowing the exhaled air from entering the holding chamber. The device includes an exit port with a second one way valve that allows the exhaled air to exit the device but closes during inhalation to prevent any entrainment of room air gas. The exit port may instead have a filter with one-way valve to trap the exhaled aerosol particles while allowing the exhaled gases to escape. The filter valve will similarly close during inhalation to prevent entrainment of room air gas. The holding chamber will allow a uniform mixture of aerosol medication and gases to flow together during inhalation to the patient via a mouthpiece or a facemask. The holding chamber is connected to a nebulizer chamber with a single or multiple connecting tubes that allow gas mixtures with varying density, viscosity, humidity and concentration of oxygen to flow into the holding chamber from the nebulizer chamber. The pattern of flow of the gas(es) does not disturb the flow of the nebulized medication from the nebulizer chamber to the holding chamber or interfere with the plume generated by an MDI. The device also serves as a facemask for delivering precise concentrations of oxygen or as a 100% non-rebreather mask. The device also serves to deliver precise concentrations of different density gases i.e. nitrogen, helium, oxygen, etc. This will allow varying fractions of inspired oxygen to deliver aerosol medication via MDI or a nebulizer. Thus, the device has the ability to deliver aerosol medication with an MDI or a nebulizer while retaining the ability to simultaneously deliver different density gas mixtures and varying fraction of inspired oxygen without interrupting one for the other.

Owner:DHUPER SUNIL +1

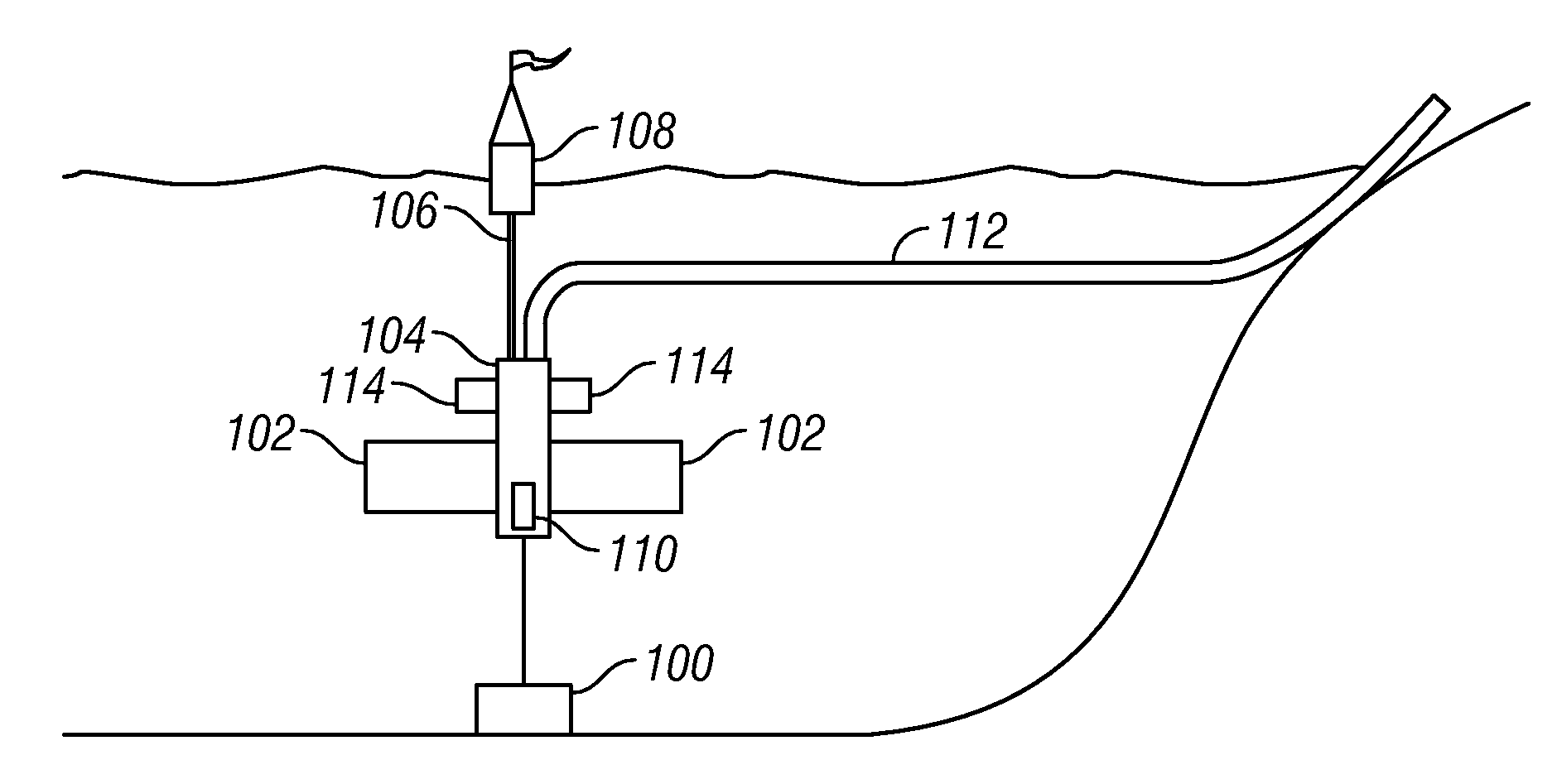

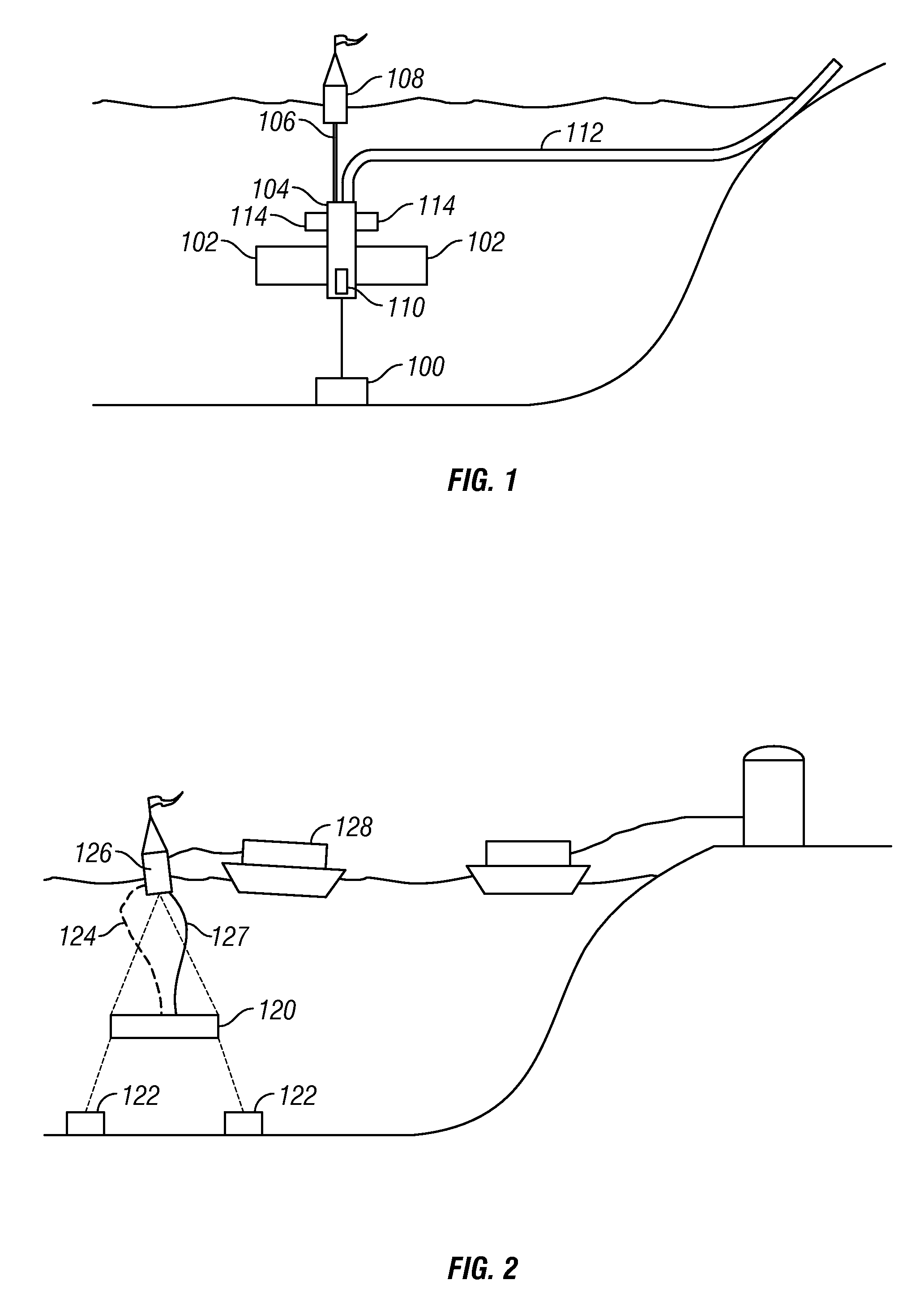

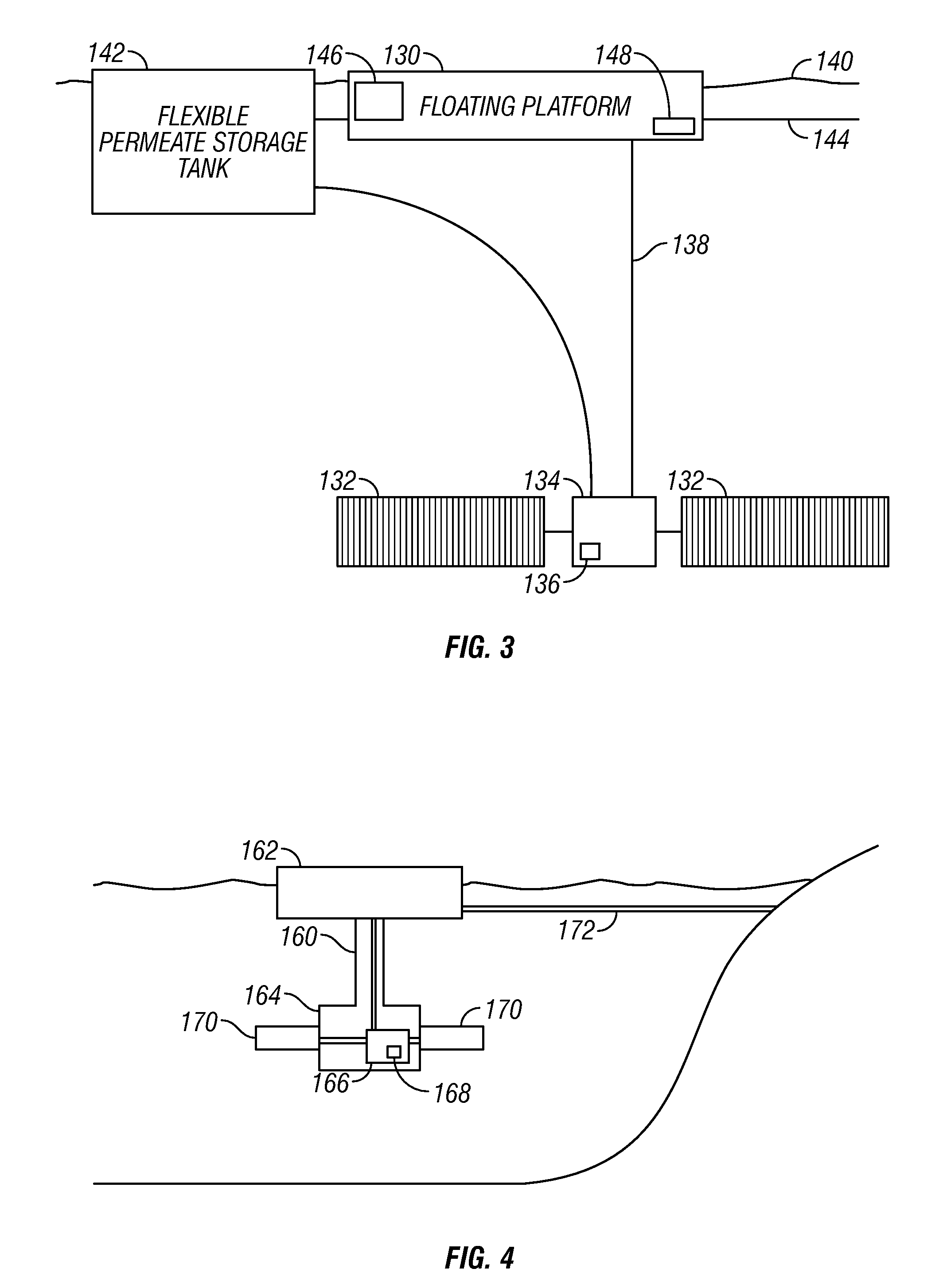

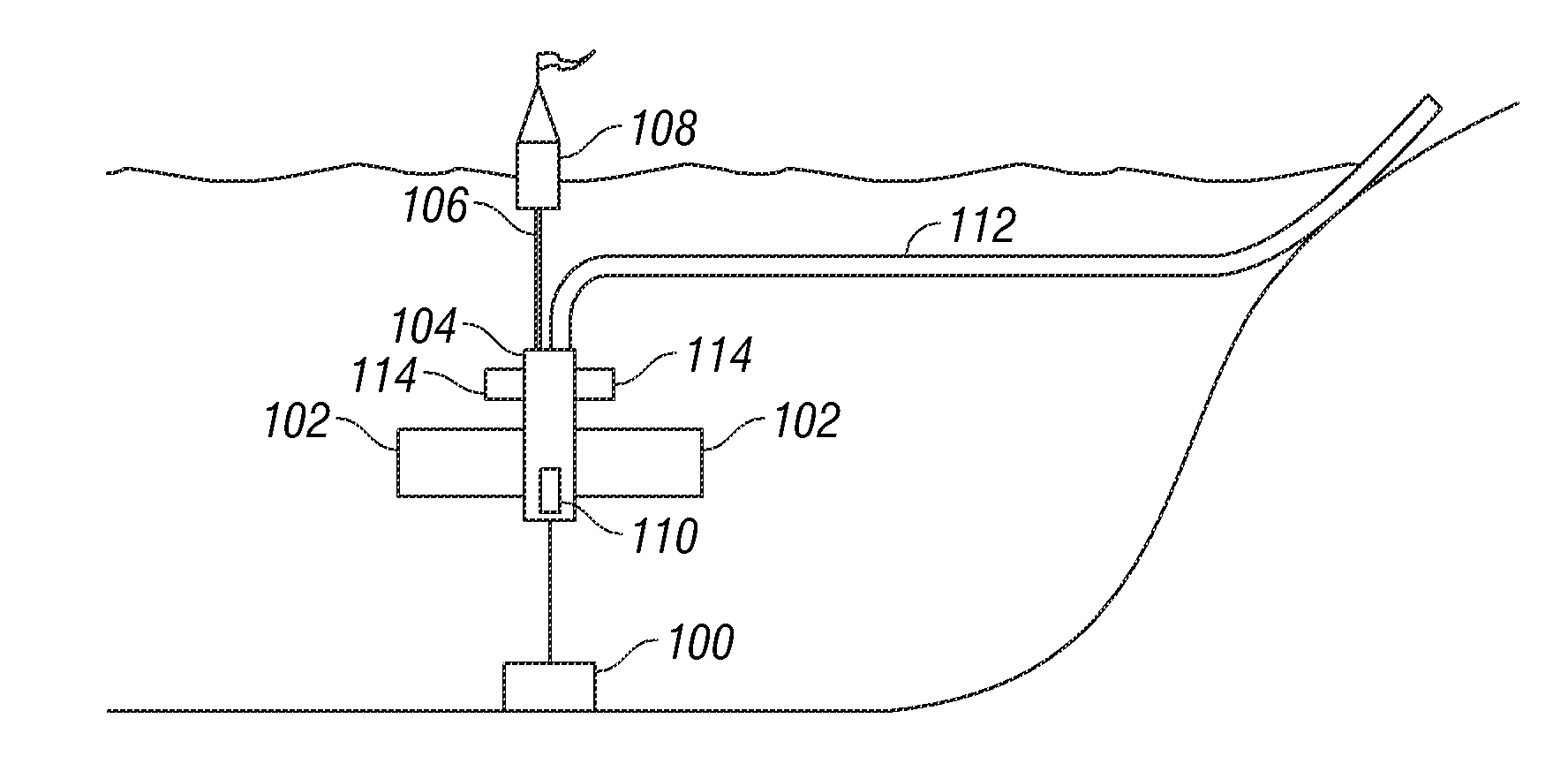

Depth exposed membrane for water extraction

InactiveUS20080190849A1Improve efficiencyHighly innovativeMembranesWater cleaningOcean bottomWater treatment system

A DEMWAX™ water treatment system includes membrane modules and a collection channel. The membrane modules are submerged at depth and tethered to one or more anchors on the ocean floor. A breathing tube extends between the collection channel and a buoy floating on the surface of the ocean to expose the collection channel to atmospheric pressure. A pump pumps the permeate from the collection channel to shore through a permeate pipe. One or more permeate storage tanks can optionally be disposed within the system, for example, as part of or extending from the collection channel, to provide extra storage.

Owner:DXV WATER TECH

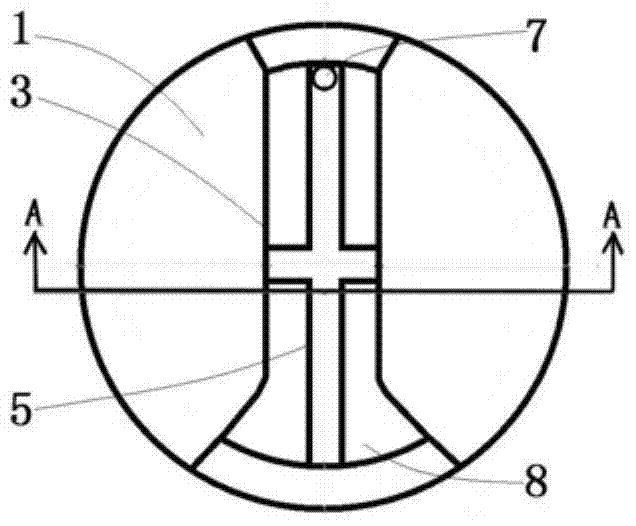

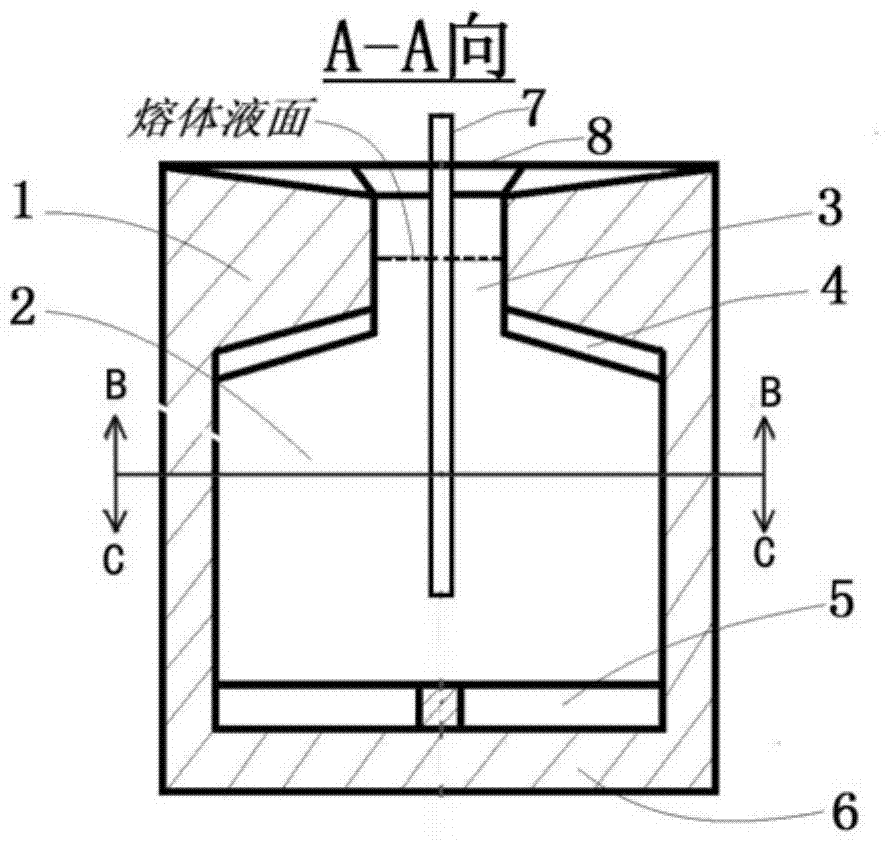

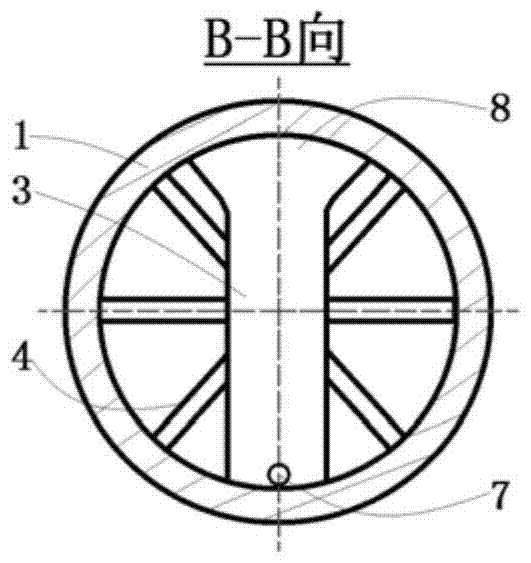

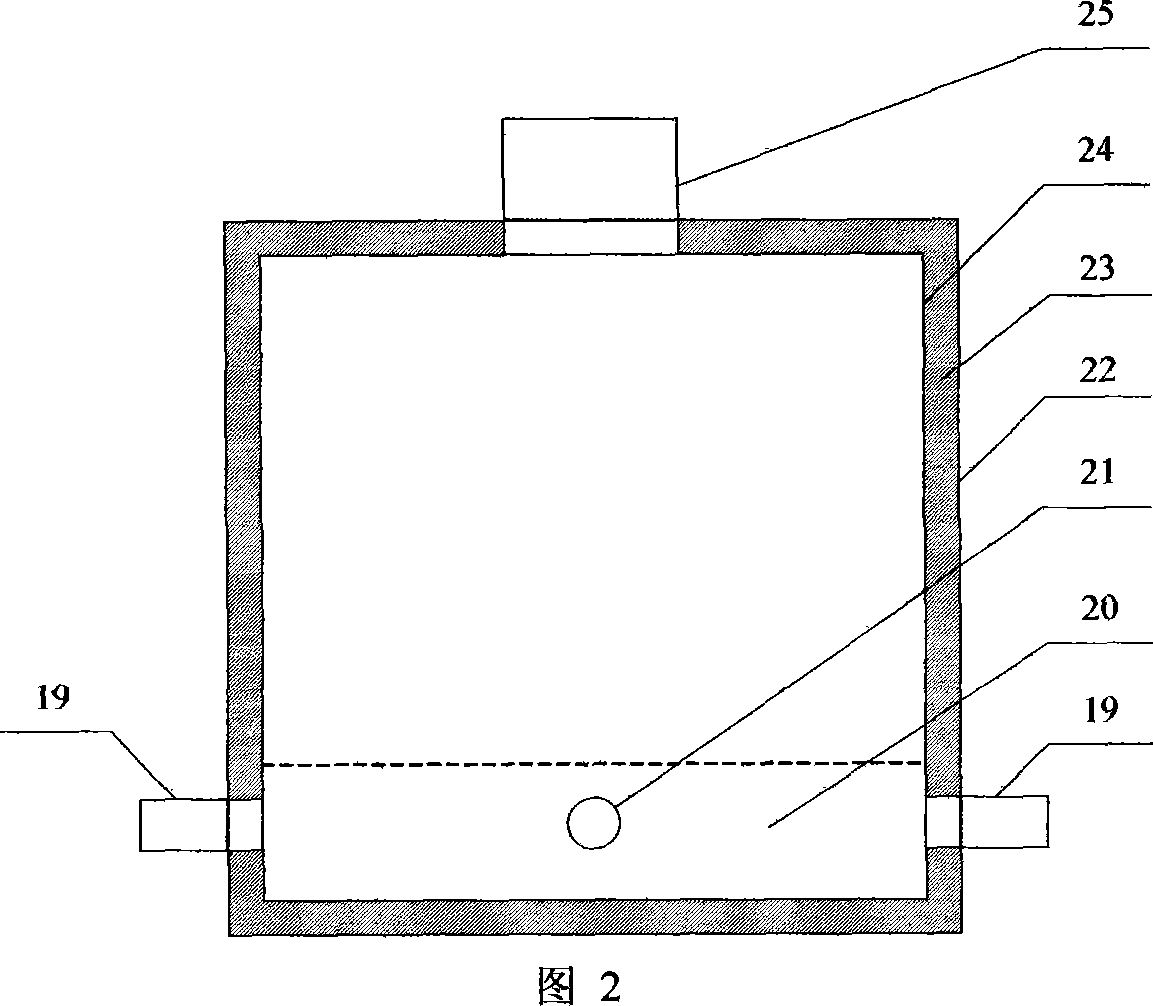

Stirring chamber for stirring molten metal and using method thereof

The invention discloses a stirring cavity used for stirring metal melt and a use method thereof, which belong to the field of material processing apparatuses for metallurgy, casting, chemical engineering and the like. The stirring cavity structurally consists of a melt container, a stirring cavity body, an upper stop opening, an upper blocking flange, a lower blocking flange, a lower bottom, a temperature sensor and a liquid taking / pouring port. According to the stirring cavity, the melt liquid level inside the stirring cavity is narrowed, so the stirring effect is effectively stopped from transferring to the liquid level, and the problems of melt oxidation and entrapped air risk are solved. The stirring cavity can be applied to various metal melt stirring and casting occasions; when the stirring cavity is used for batch-type casting such as pressure casting, the stirring cavity is adopted as the internal cavity structure of a pouring ladle; when the stirring cavity is used for continuous casting, the stirring cavity is adopted as the internal cavity structure of a melt hot top and can be directly connected with a continuous casting crystallizer; and full automation is realized in the whole process of melt stirring, chemical refining and casting in a pressure casting site.

Owner:GRIMAT ENG INST CO LTD

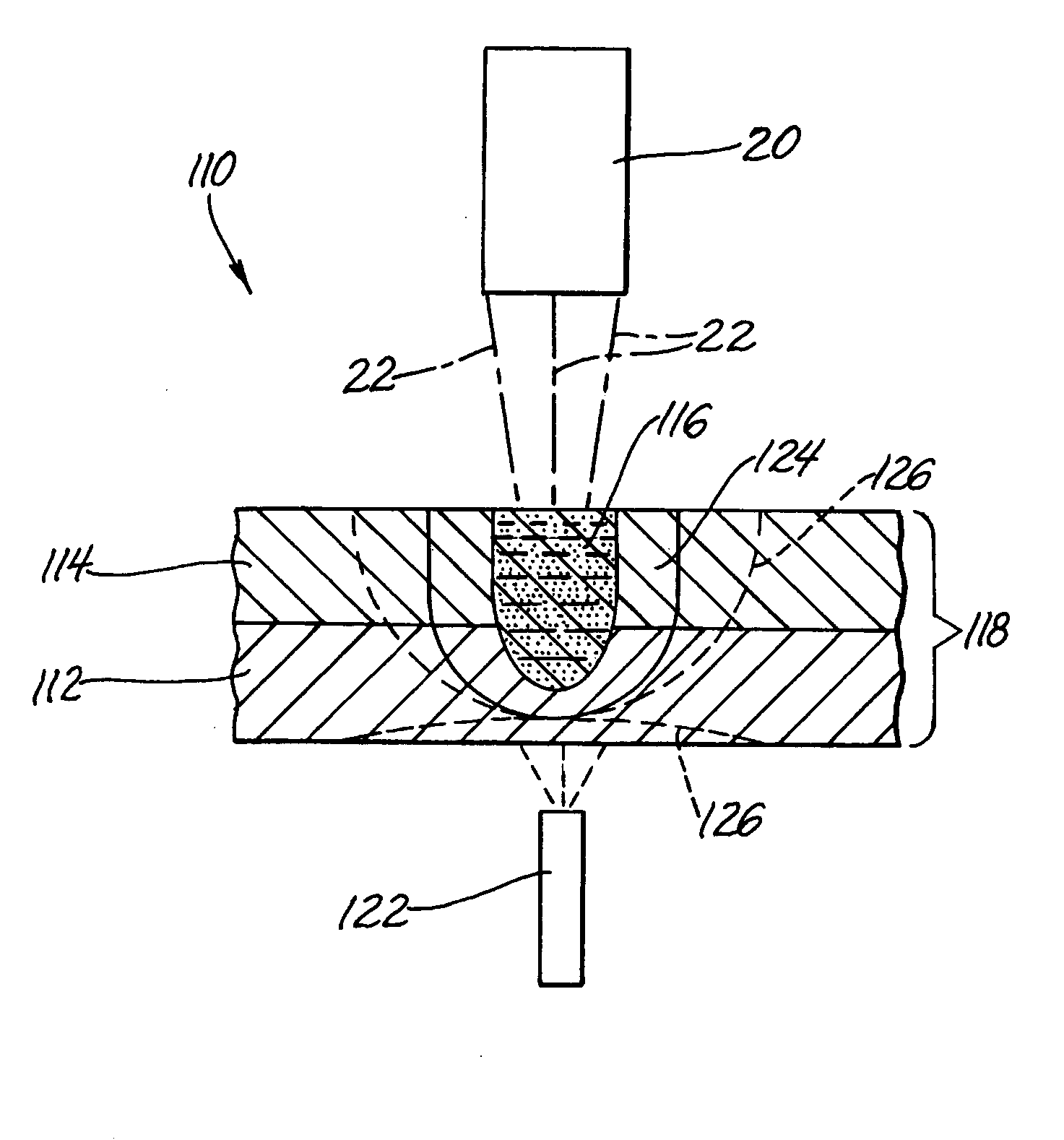

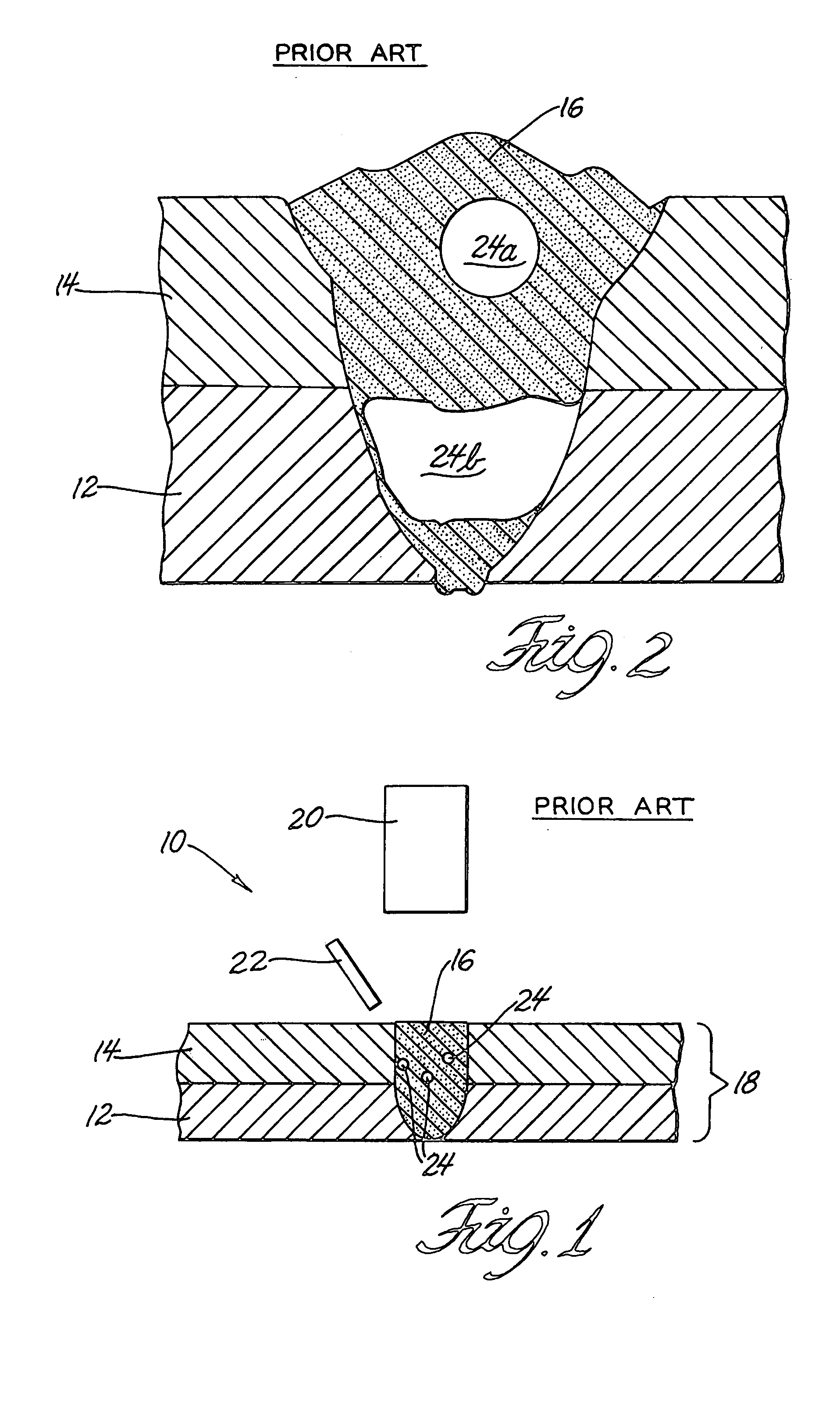

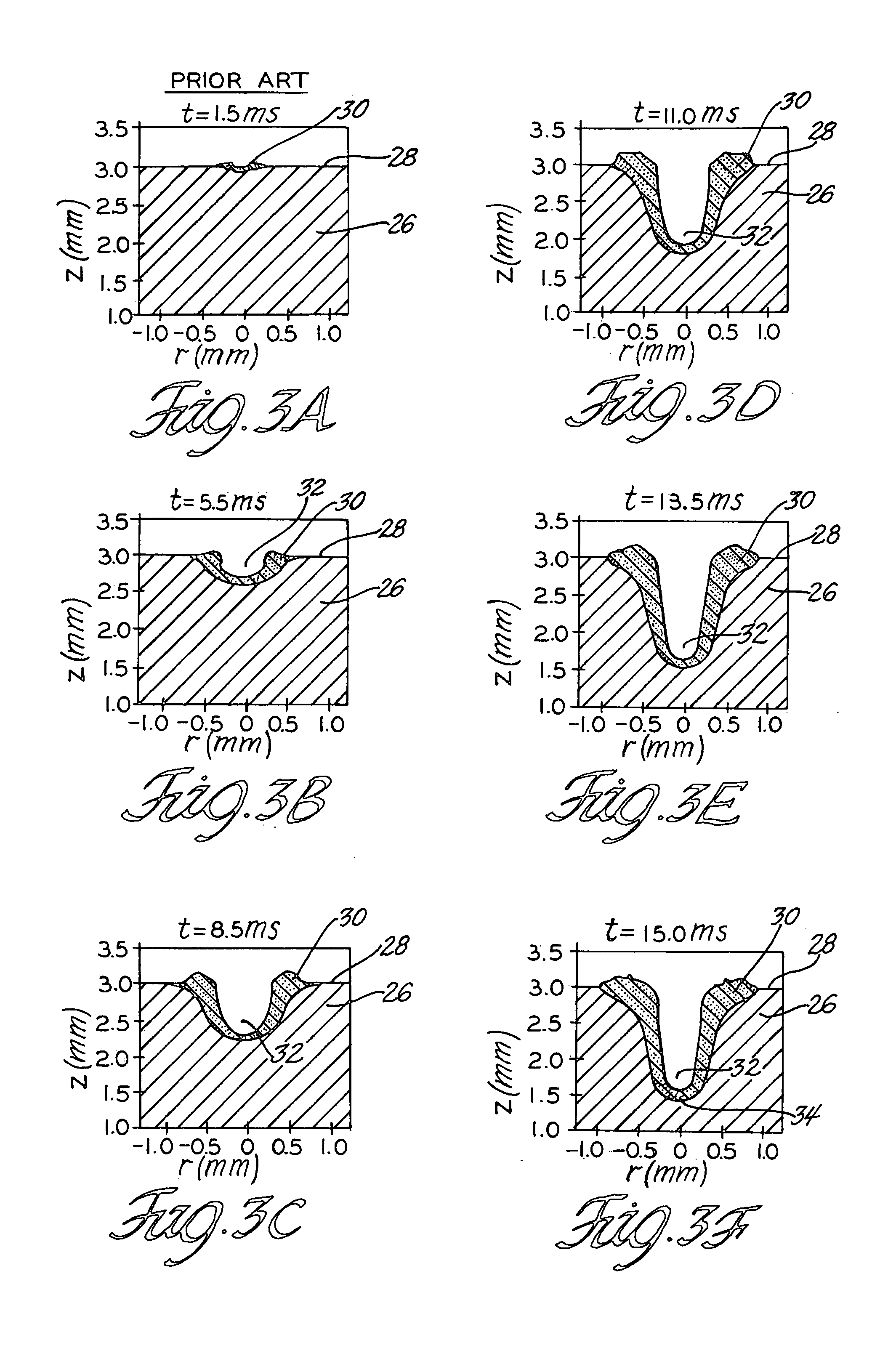

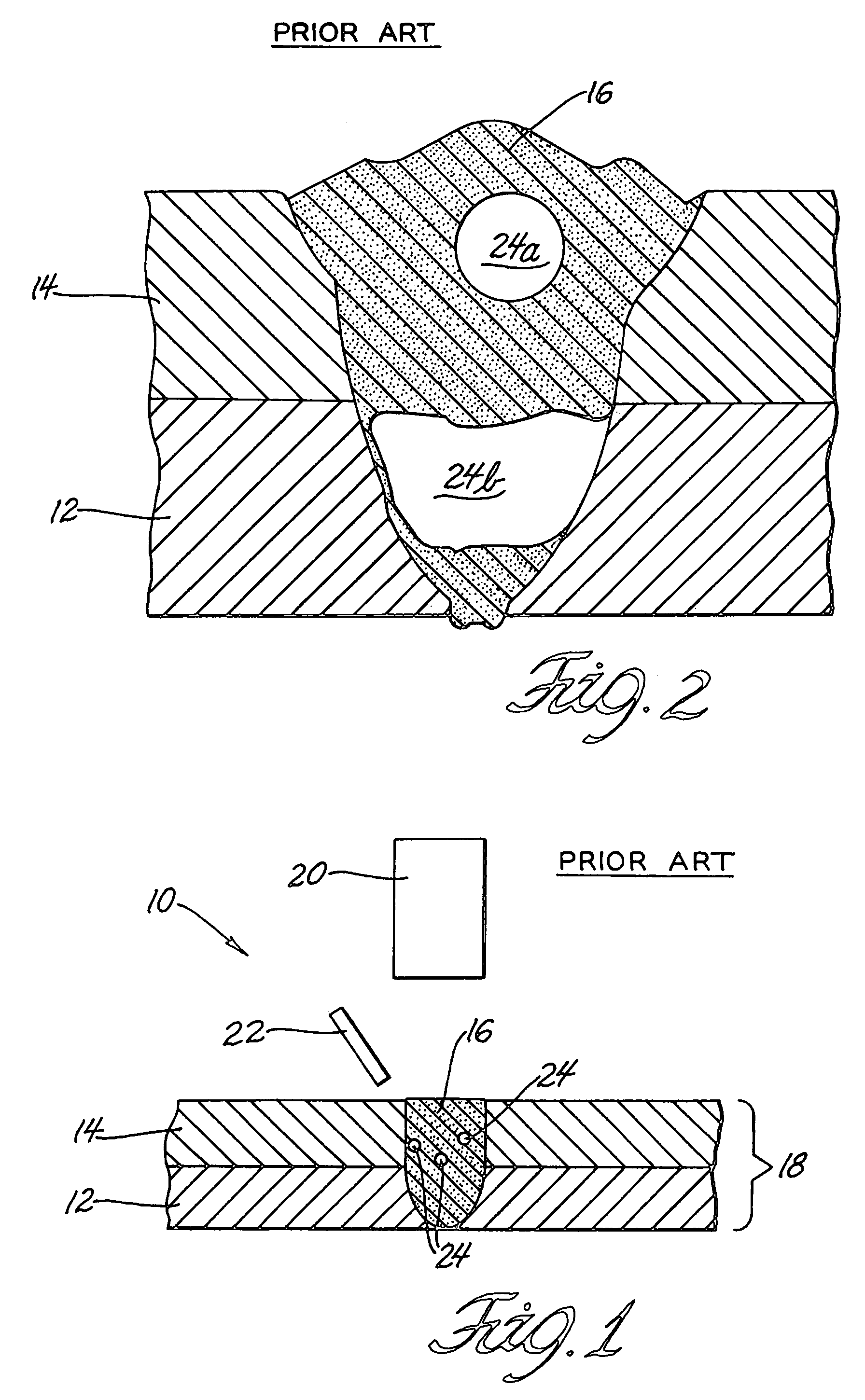

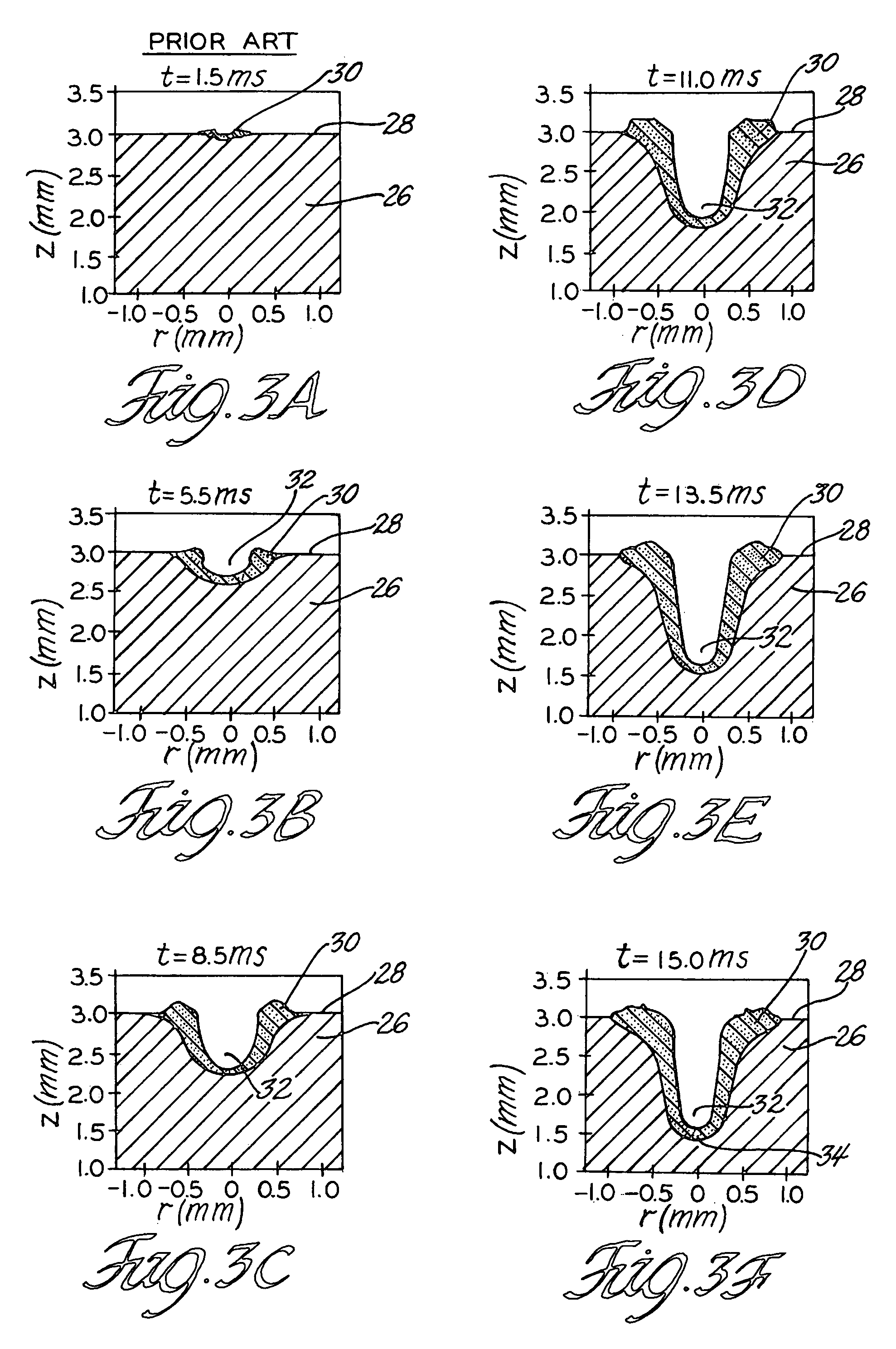

Method of improving weld quality

InactiveUS20050121426A1Improve temperature distributionReduce solidificationWelding/soldering/cutting articlesLaser beam welding apparatusIrradiationLaser beams

A method of improving weld quality between aluminum members by slowing the rate of solidification of a molten weld trough into solidified material. Upper and lower aluminum members are positioned together in contact between facing surfaces thereof to expose a first outer surface of the upper aluminum member to laser irradiation. A welding laser beam is moved in a path over the first outer surface, wherein the welding laser beam has an energy and width to progressively melt a trough of molten metal to a depth through the upper aluminum member and into the lower aluminum member. The molten metal in the trough has a void filled with gas, and the molten metal re-solidifies into re-solidified metal after the passage of the welding laser beam. An area in and around the trough is heated to slow the rate of solidification of the molten metal into the re-solidified metal, thereby preventing entrainment of the gas within the re-solidified metal.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

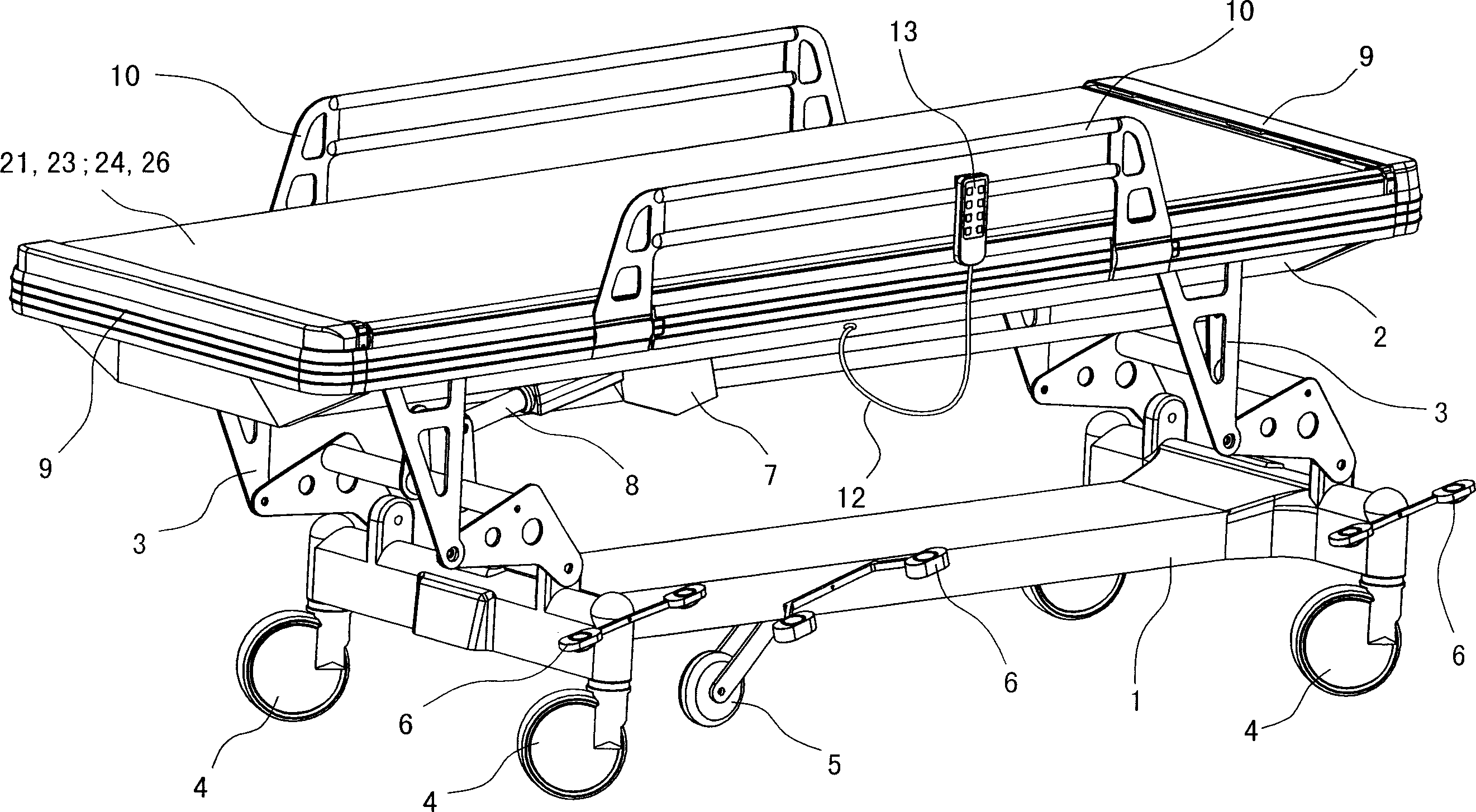

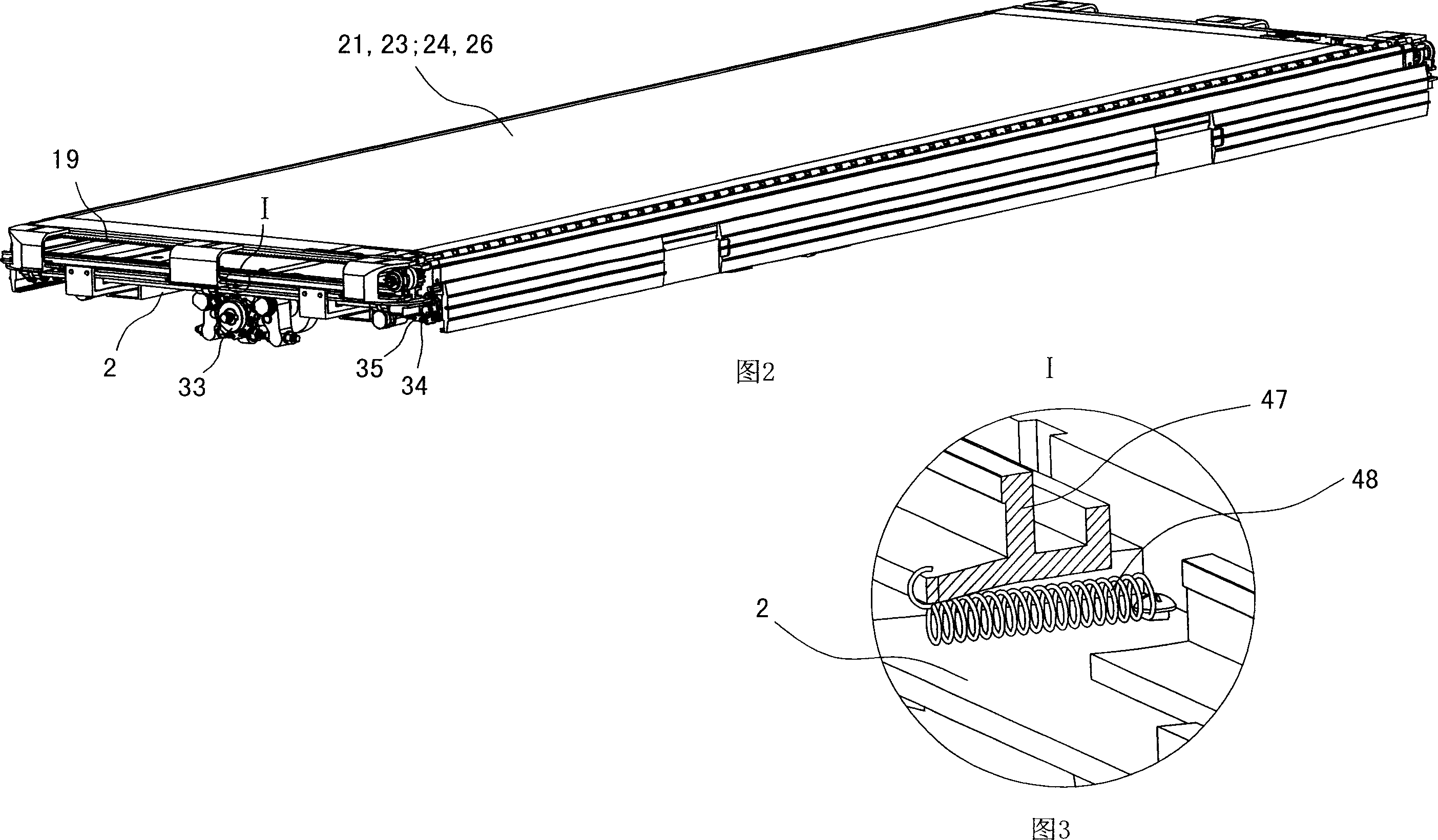

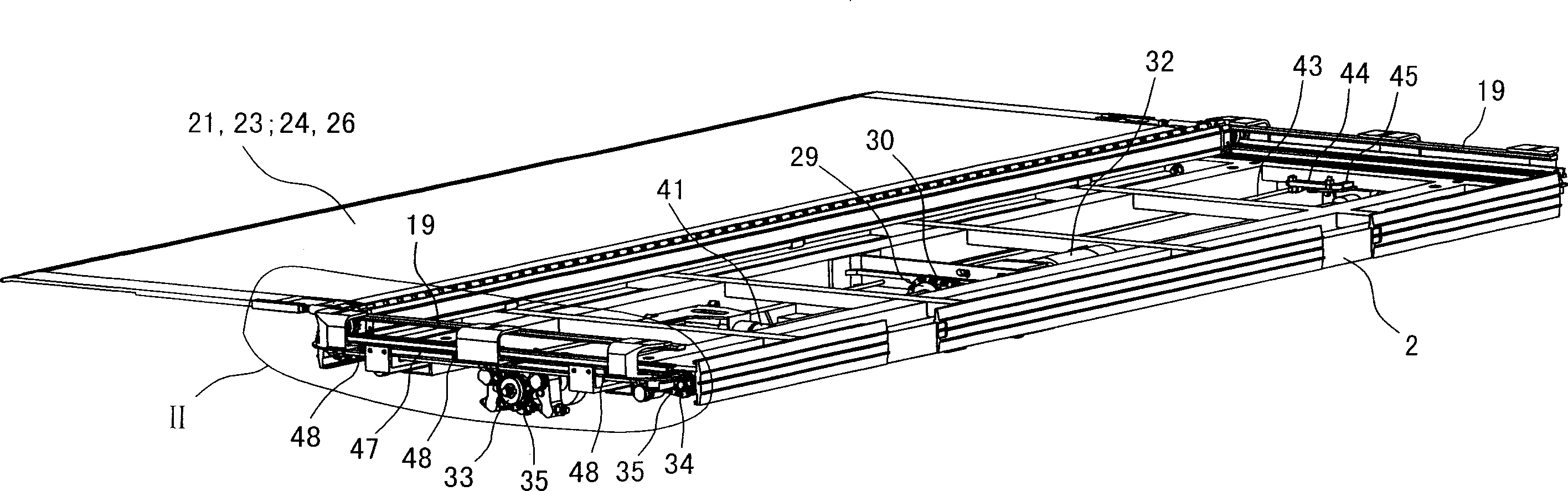

Medical use carrier for transferring patient

A medical patient transfer handcart is composed of a main body with lift mechanism and universal castors, and a transversely movable plate mechanism with dual-layer structure consisting of cloth reel and its frame end jointer holder, clutch gear, and upper and lower movable clothes (or plates).

Owner:宁波启发医疗科技有限公司

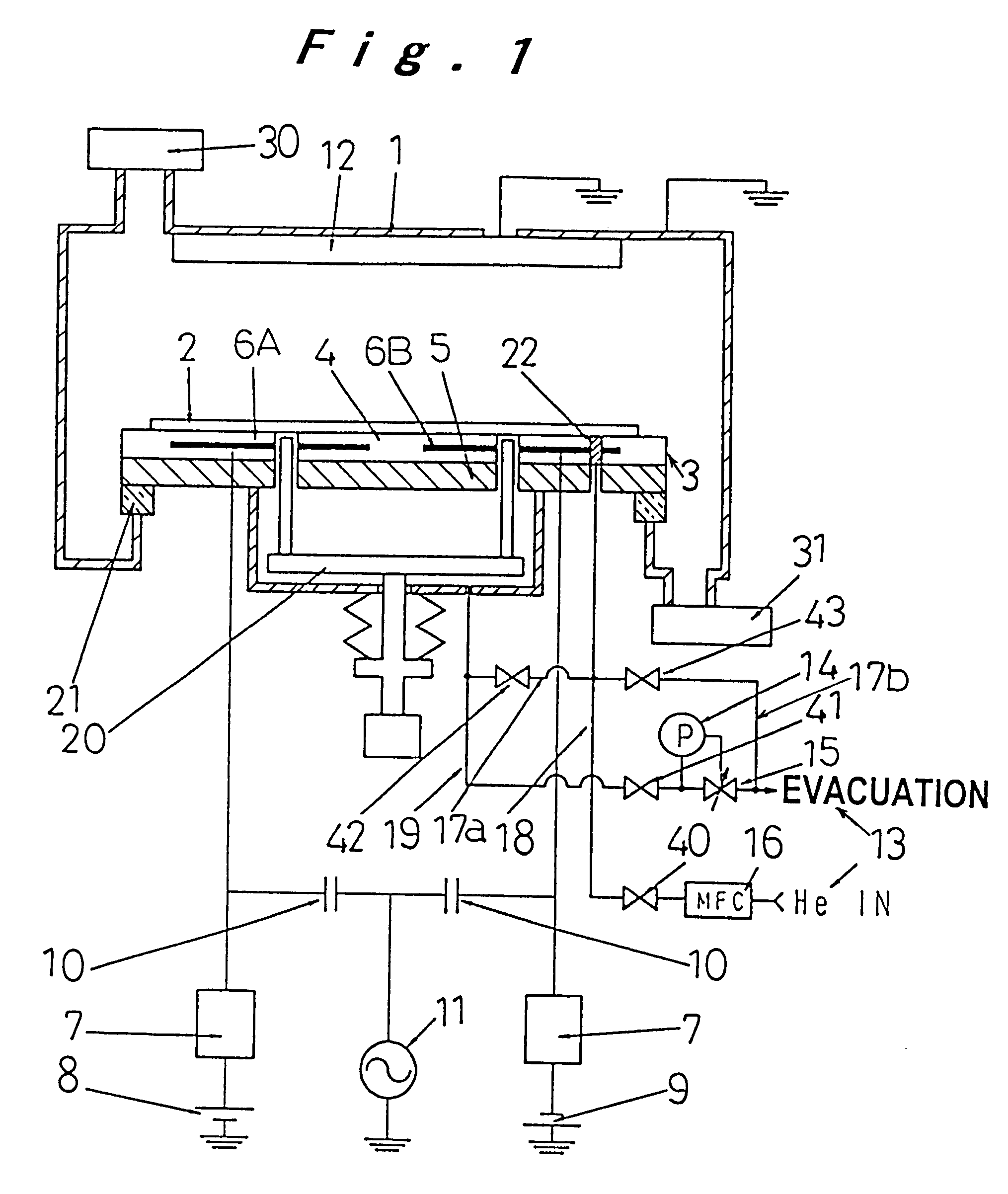

Substrate temperature control method and device

InactiveUS6254683B1Increase flow rateReduce flow rateLiquid surface applicatorsElectric discharge tubesElectrical and Electronics engineeringTemperature control

In processing the surface of a substrate 2 that is held with its under-surface in contact with a substrate holder 3 in a vacuum chamber 1, the temperature of substrate 2 is controlled by supplying a heat-conductive gas between the substrate 2 and substrate holder 3. Supply and evacuation of the heat-conductive gas are effected rapidly at high flow rate from both supply line 18 and evacuation line 19 using bypass lines 17a, 17b, while pressure regulation is effected with a low flow rate.

Owner:PANASONIC CORP

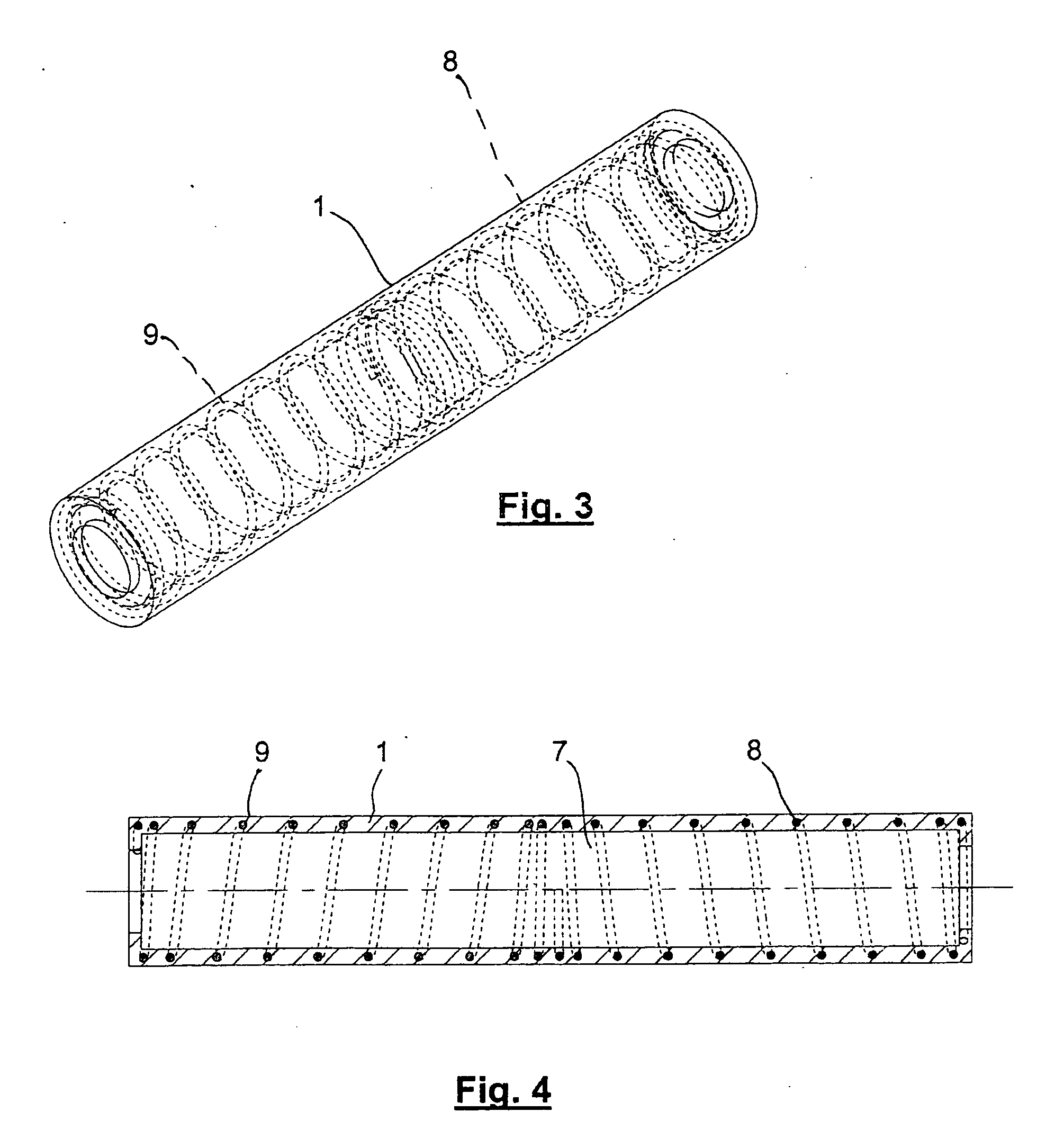

Self-propelled endoscopic device

ActiveUS20070179339A1Same degree of flexibilityHindering efficiency of locomotionSurgeryEndoscopesCoil springEngineering

An endoscopic device for autonomous locomotion through a body cavity with a predetermined direction, the device comprising a tubular body constructed of a relatively elastic material that extends between two, preferably, the front and rear, end portions, respectively. The tubular body includes an anchor for temporarily and alternately attaching the end portions to a wall portion of the body cavity in synch with corresponding axial extensions and contractions of the tubular body. The tubular body incorporates a reinforcement structure distributed along its length that is substantially rigid in a radial direction and yields in an axial direction, the structure specifically comprising either a plurality of relatively rigid rings or at least one helical spring.

Owner:ERA ENDOSCOPY

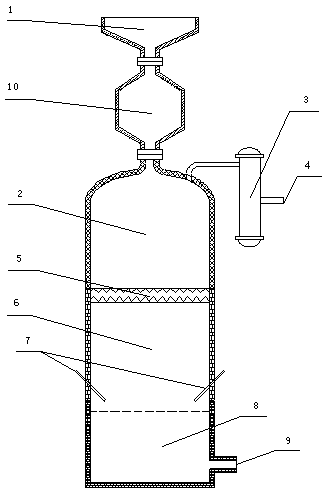

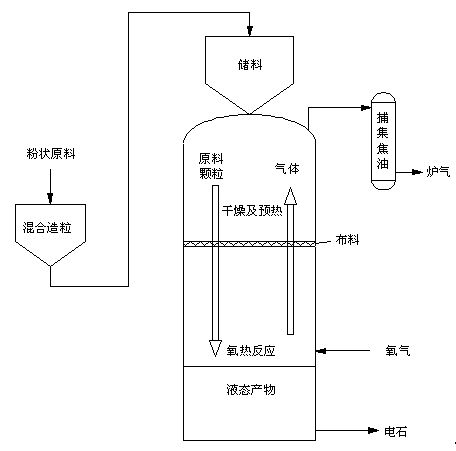

Composite bed reactor and method for combined production of calcium carbide, gas and tar

ActiveCN103272536ATake advantage ofReduce heat lossCalcium carbideSpecial form destructive distillationReaction rateMolten bath

The invention relates to a composite bed reactor and a method for combined production of calcium carbide, gas and tar, and belongs to the field of calcium carbide production. The reactor comprises a hopper, a brake bunker, a moving bed preheating chamber, a tar collector, a gas outlet, a distributing device, an oxygen heat reaction chamber, oxygen spraying burners, a product molten pool and a product outlet, and the hopper is connected with the moving bed preheating chamber by the brake bunker, and the top side surface of the moving bed preheating chamber is provided with the tar collector, and the tar collector is provided with a gas outlet, and the moving bed preheating chamber bottom is provided with a distributing device, and the moving bed preheating chamber is communicated with an oxygen heat reaction chamber by a distributing device, and the oxygen heat reaction chamber bottom is connected with a product molten pool, and the upper portion of the connection between the oxygen heat reaction chamber and the product molten pool is provided with the oxygen spraying burner, and the middle bottom of the product molten pool is provided with a product outlet. The reactor of the invention has the advantages of simple structure and high efficiency, and large scale production is easy to realize, and the raw material is pelleted by powder form carbonaceous raw material and powder form calcium containing raw material, and the contact surface between raw materials is large, the reaction rate is fast, and reactor is convenient for reusing calcium carbide slags.

Owner:BEIJING UNIV OF CHEM TECH

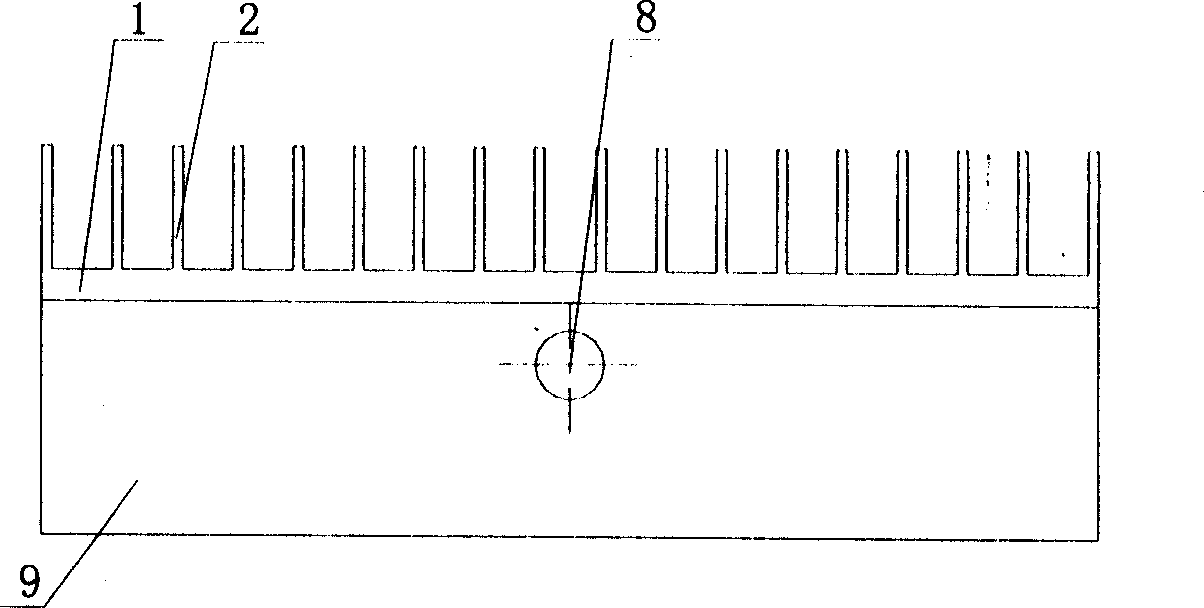

Plane capillary core evaporimeter with fin for CPL

InactiveCN1725947AIncrease contactReduce thermal contact resistanceInstrumental cooling apparatusCooling/ventilation/heating modificationsHeat transfer efficiencyEngineering

A planar capillary core evaporator with fin for CPL consists of base , top cover being fixed and sealed with base , isolation plate for isolation top cover to be liquid collection cavity and steam collection cavity , liquid collection cavity formed by horizontal and longitudinal grooves cross arranged and opened with liquid return inlet on it , steam collection cavity opened with vapor outlet on it , fin set on outer surface of top cover ,longitudinal steam channel connected to steam cavity on base and capillary core set between liquid collection cavity and steam channel .

Owner:HUAZHONG UNIV OF SCI & TECH

Hot solids gasifier with co2 removal and hydrogen production

InactiveUS20060207177A1Avoid entrainmentEfficient captureMuffle furnacesGas modification by gas mixingCo2 removalWater-gas shift reaction

A gasifier 10 includes a first chemical process loop 12 having an exothermic oxidizer reactor 14 and an endothermic reducer reactor 16. CaS is oxidized in air in the oxidizer reactor 14 to form hot CaSO4 which is discharged to the reducer reactor 16. Hot CaSO4 and carbonaceous fuel received in the reducer reactor 16 undergo an endothermic reaction utilizing the heat content of the CaSO4, the carbonaceous fuel stripping the oxygen from the CaSO4 to form CaS and a CO rich syngas. The CaS is discharged to the oxidizer reactor 14 and the syngas is discharged to a second chemical process loop 52. The second chemical process loop 52 has a water-gas shift reactor 54 and a calciner 42. The CO of the syngas reacts with gaseous H2O in the shift reactor 54 to produce H2 and CO2. The CO2 is captured by CaO to form hot CaCO3 in an exothermic reaction. The hot CaCO3 is discharged to the calciner 42, the heat content of the CaCO3 being used to strip the CO2 from the CaO in an endothermic reaction in the calciner, with the CaO being discharged from the calciner 42 to the shift reactor 54.

Owner:GENERAL ELECTRIC TECH GMBH

Fume desulfurizing process employing multiple circulation and stable double alkali method and apparatus

ActiveCN1864811APrevent oxidationExtend regeneration reaction timeDispersed particle separationSlagProcess engineering

The invention relates to field of atmosphere pollution control and treatment, especially relates to a process of multiple circulate and stable flue gas desulfurization by means of double aluminium subsulfate. It is characterized in that it comprises: desulfurizing absorption liquid internal cycle, external cycle, internal cycle of desulfurizing slag, internal cycle of desulfurizing agent, and external cycle of desulfurizing salg. The invention also relates to the device for said process. THe invention is characateized by stable process, low investment, high desulfurizing rate and low operating cost.

Owner:广州市天赐三和环保工程有限公司

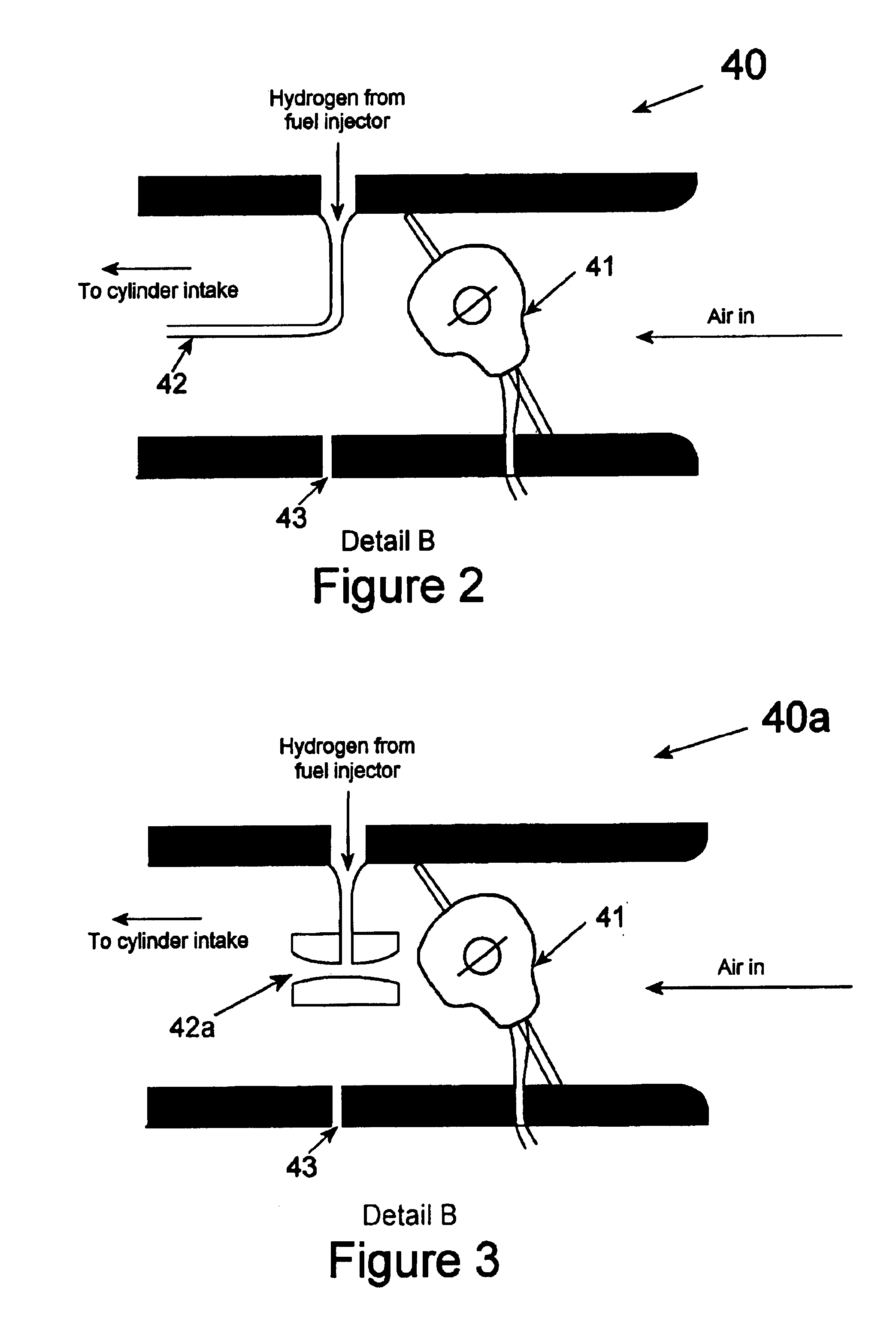

Hydrogen powered scooter

InactiveUS6918382B2Avoid entrainmentInternal combustion piston enginesGaseous engine fuelsMicrocontrollerControl system

A scooter powered by a hydrogen powered internal combustion engine fueled by a throttled stream of air into which a controlled amount of hydrogen is injected. A hydrogen fuel control system is used to control the amount of hydrogen injected into the throttled air stream using multiple parameters. The amount of hydrogen present in the hydrogen storage unit is monitored using an on-board hydrogen fuel measurement system utilizing a microcontroller and multiple sensors.

Owner:ENERGY CONVERSION DEVICES INC

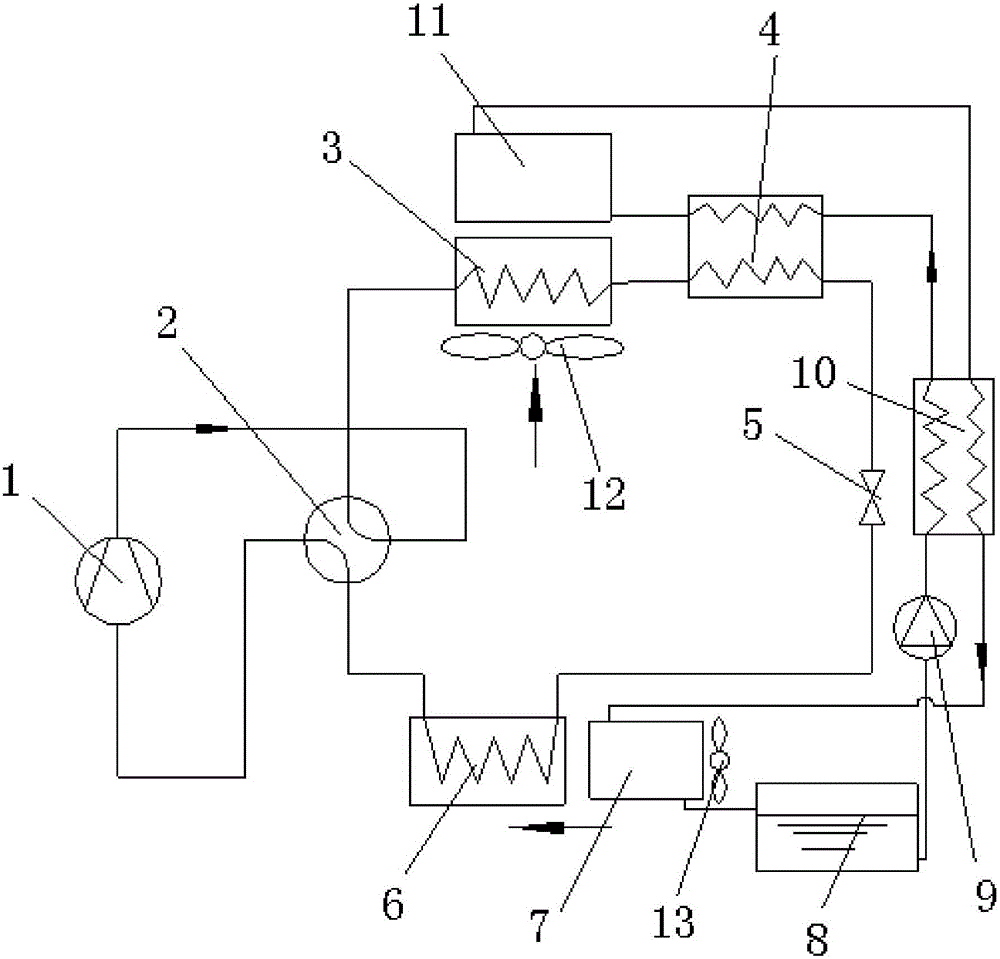

Frostless air source heat pump device and method based on membrane method dehumidification and indoor regeneration humidification

ActiveCN106051975APrevent heat pump from frostingAvoid pollutionAir treatment detailsHeat recovery systemsMembrane methodEngineering

The invention discloses a frostless air source heat pump device and method based on membrane method dehumidification and indoor regeneration humidification. The frostless air source heat pump device comprises a refrigerant circulation loop and a solution dehumidification / humidification circulation loop. The refrigerant circulation loop comprises a compressor (1), a four-way reversing valve (2), an indoor heat exchanger (3), a regeneration condenser (4), a throttling valve (5) and an outdoor heat exchanger (6) which are sequentially connected together in series through a first communication pipeline. The solution dehumidification / humidification circulation loop comprises a heat recovery heat exchanger (10), a regeneration condenser (4), an indoor humidification membrane assembly (11), a heat recovery heat exchanger (10), an outdoor dehumidification membrane assembly (7) and a dehumidification solution storage tank (8). According to the frostless air source heat pump device and method based on membrane method dehumidification and indoor regeneration humidification, outdoor air latent heat is converted into sensible heat through the dehumidification membrane assembly, frosting is avoided, and moisture introduced through a dehumidification solution is regenerated and used for indoor humidification.

Owner:SOUTHEAST UNIV

Method for removing zinc slag from hot galvanizing liquid

InactiveCN1730712AImprove surface qualityEfficient removalHot-dipping/immersion processesLorentz force separationSlagZinc

The invention relates to a method for removing zinc slag from hot galvanizing liquid by utilizing the difference of electrical conductivity between zinc slag and zinc liquid, the method comprises exerting electric-magnetic force field through direct or induction modes, building up a pressure gradient in zinc liquid within the ceramic tube, thus bringing directional emigration to the zinc slag with poor conductivity under the action of electromagnetic extrusion pressure exerted by the ambient zinc liquid, as a result, the zinc slag is trapped onto the walls of the ceramic tube.

Owner:SHANGHAI JIAO TONG UNIV +1

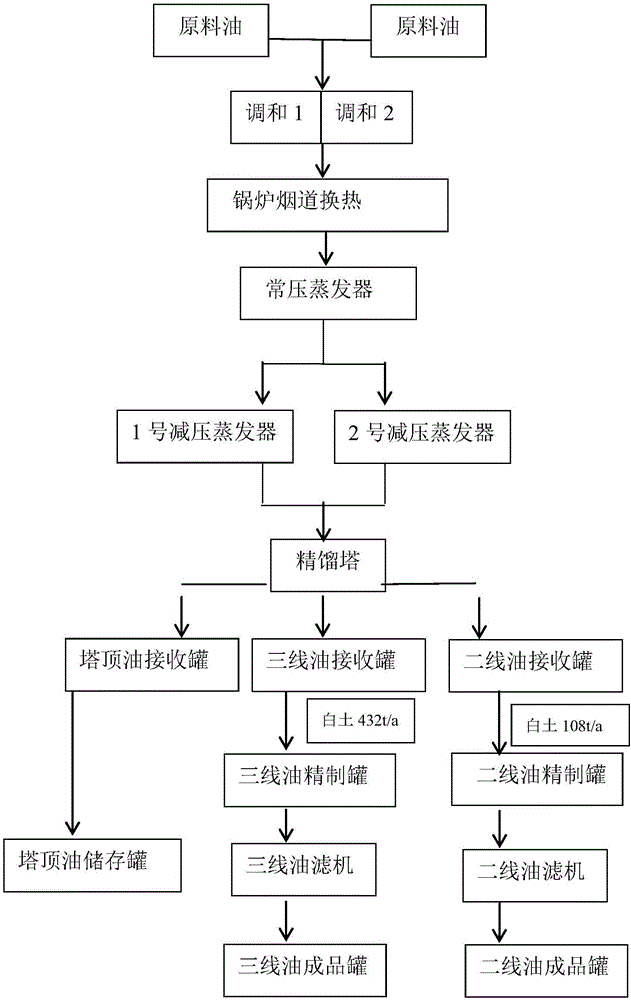

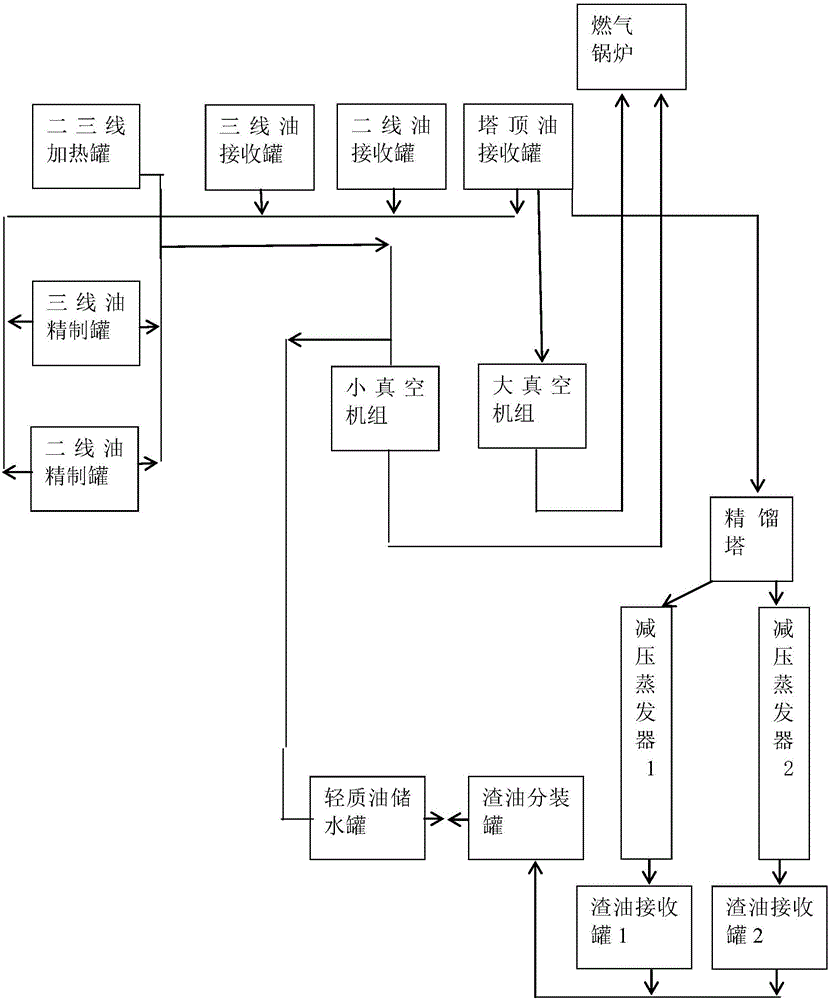

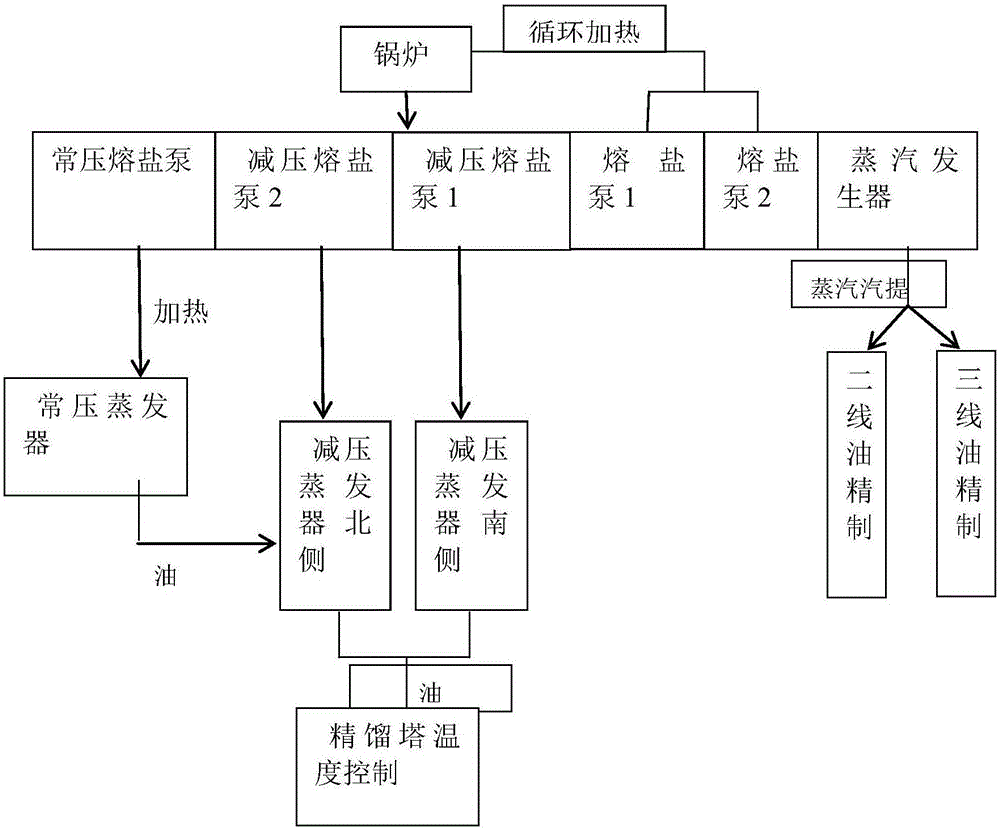

Refining technique of base oil regenerated from used lubrication oil

Disclosed is a refining technique of base oil regenerated from used lubrication oil, and the refining technique comprises the following steps of 1, removing solid waste, which includes removing solid waste from used lubrication oil by centrifugation; 2, solvent pretreatment, which includes extracting mixed impurities and moisture through a solvent and obtaining raw oil after removing upper oil; 3, flocculation treatment, which includes turning mixtures obtained from step 2 into a mixture of flocculation; 4, atomospheric distillation; 5, carrying out reduced pressure distillation; 6, carrying out rectification; 7, solvent refining: putting oil produced from a rectifying column into a treatment tank and when the height of the oil level in the treatment tank reaches 65%-75% of the height of the treatment tank, adding by mass 10%-40% of 1-Methyl-2-pyrrolidinone, and carrying out solvent refining. The refining technique of base oil regenerated from used lubrication oil has the advantages of low investment and high yield efficiency, meanwhile, the refining technique accords with the requirement of environmental protection, reduces vacuum residuum by 15%, improves product yield, facilitates the overhauling of equipment, prolongs the production period, largely improves production efficiency and appearance quality of minus line oil, and helps to obtain high quality regenerated base oil.

Owner:济南亿诺再生资源有限公司

Depth exposed membrane for water extraction

InactiveUS20100237016A1Easy to useImprove efficiencyMembranesGeneral water supply conservationOcean bottomWater treatment system

Owner:DXV WATER TECH

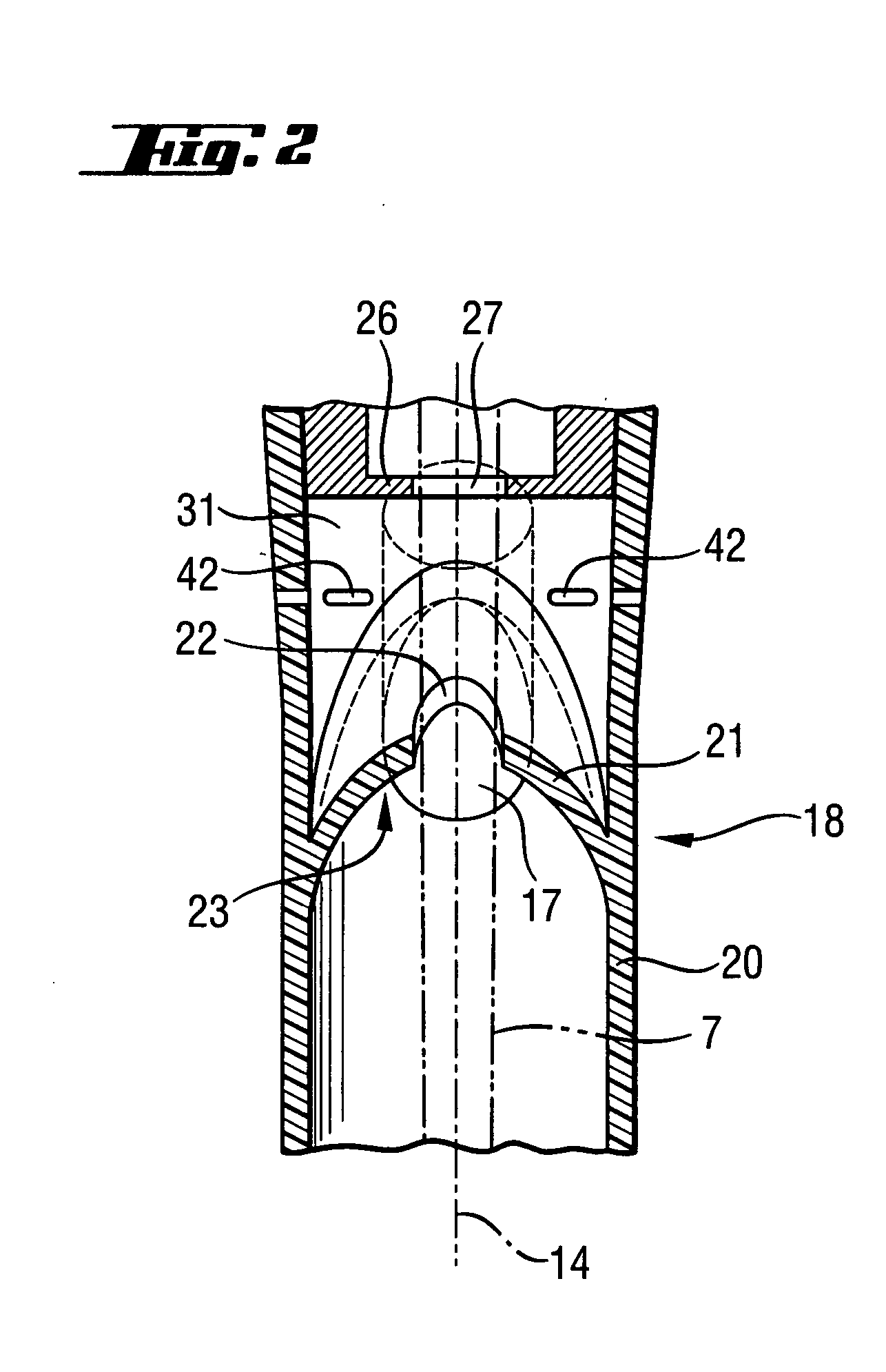

Suction device for pick power tool

A suction device for a pick power tool includes a securing device provided at the first axial end of the suction device for securing the suction device (11) on the pick power tool (6), a connection element(17) for a vacuum source inclined to the longitudinal axis (14) of the suction device (11), and a first baffle wall (21) and at least one further baffle wall (26) spaced from the first baffle wall (21), with the first baffle wall being located between the connection element (17) and the first end (12) of the suction device (11) and the at least one further baffle wall (21) being located between the first baffle wall and the first end (12), and the first baffle wall (21) and the second baffle wall (26) each having, respectively, a through-opening (22, 27) for the working tool (7) of the pick power tool (6).

Owner:HILTI AG

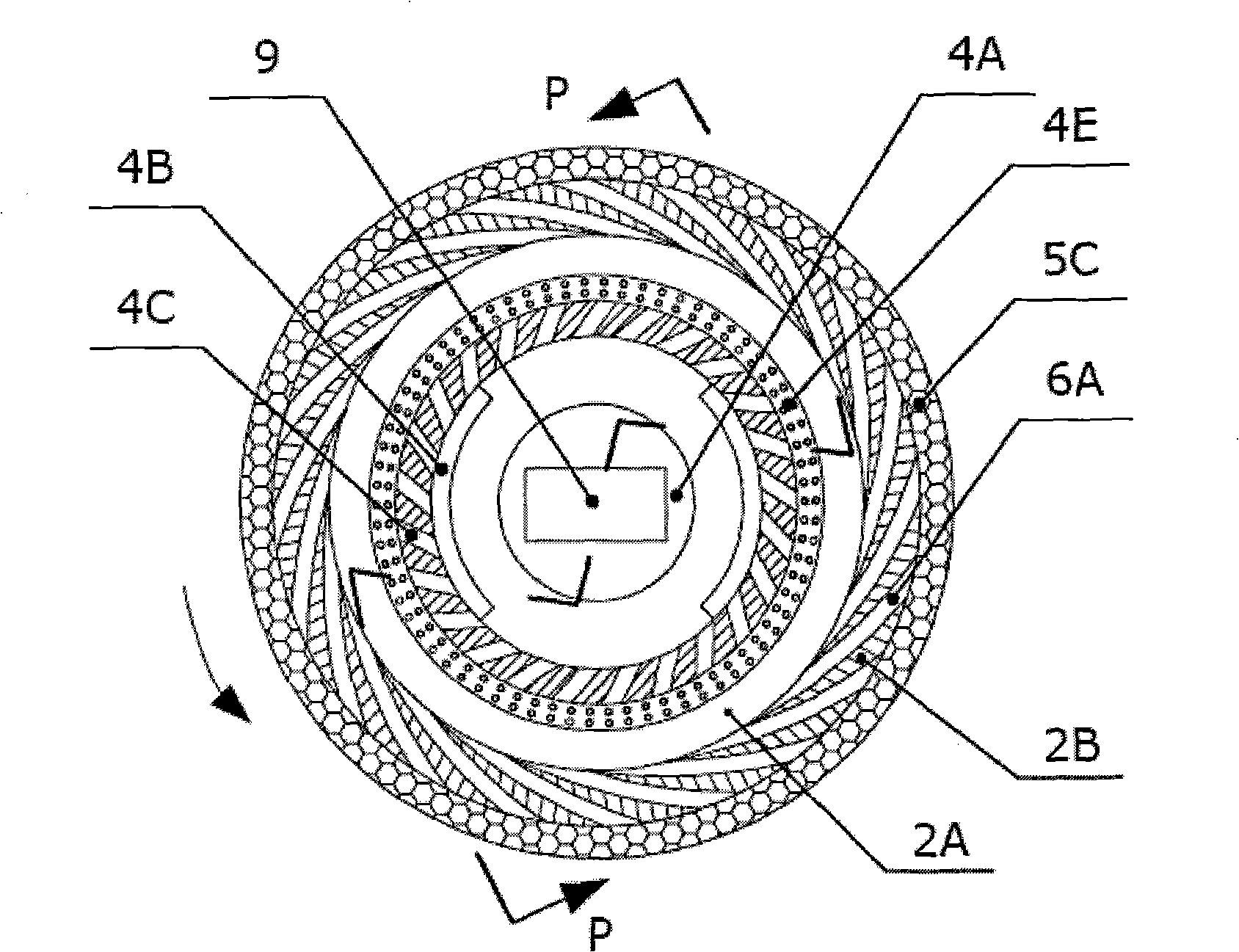

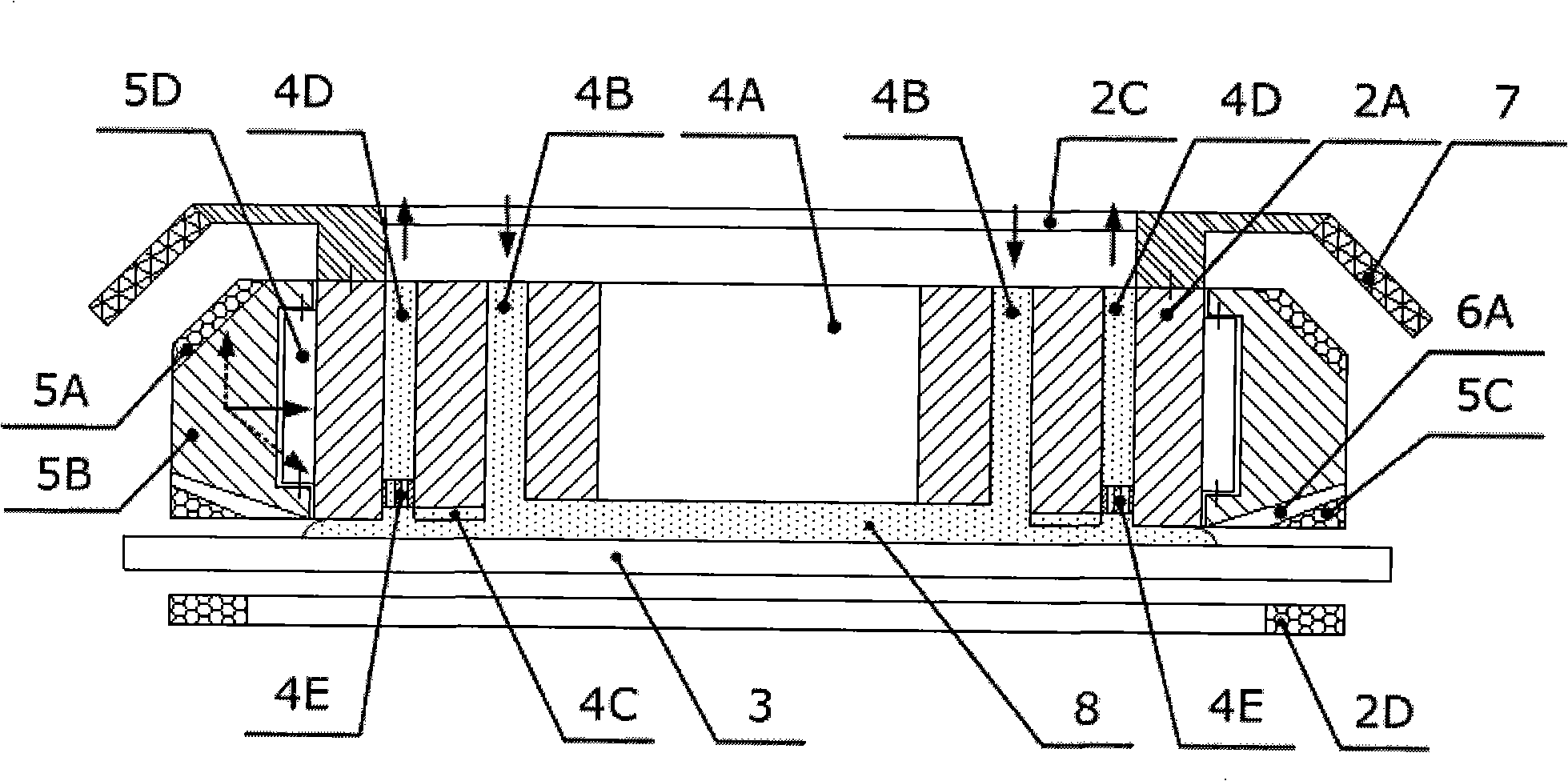

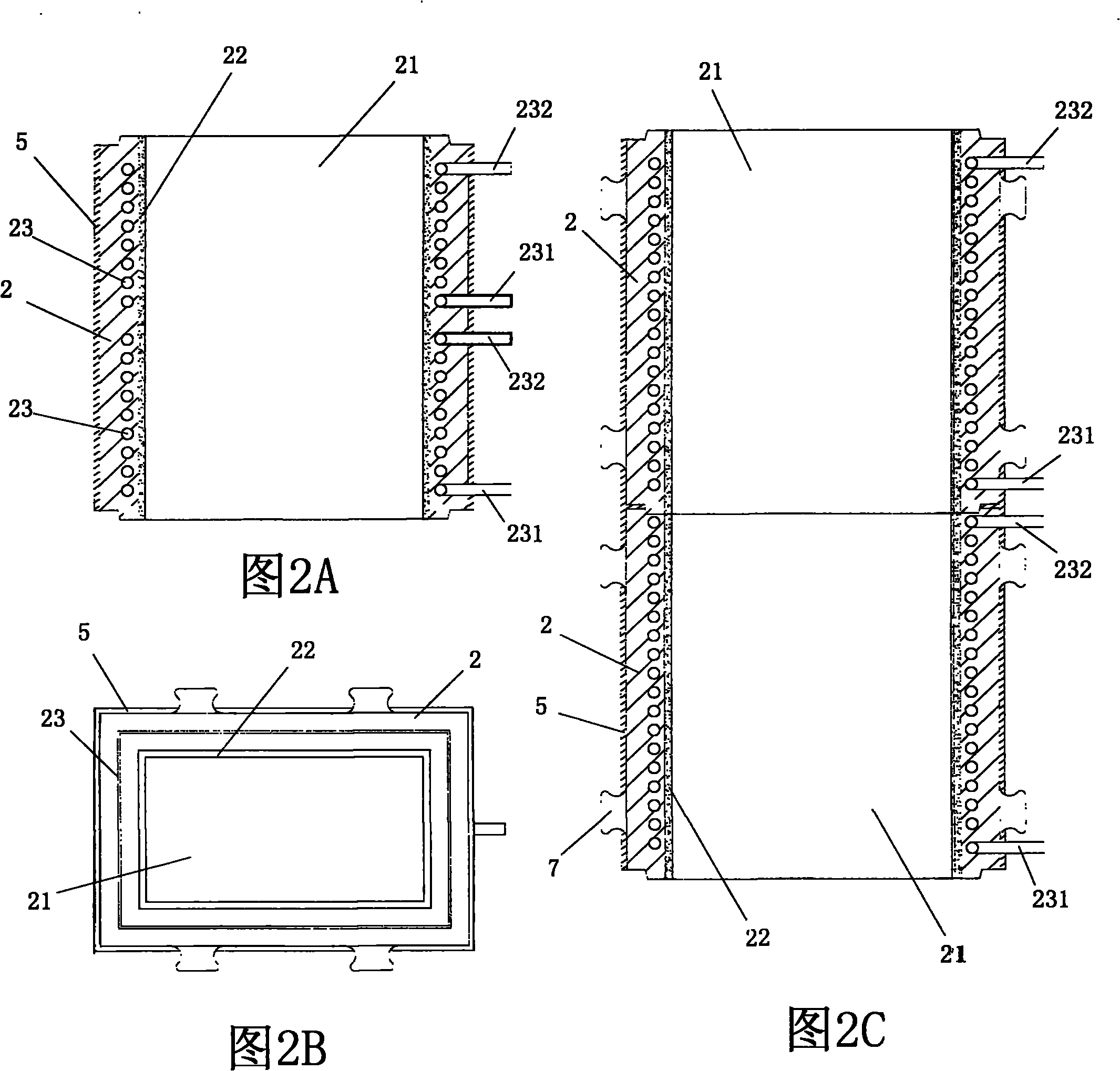

Immersion self-adaptation rotary sealing device for photo-etching machine

InactiveCN101515118AContainment leakStop the leakPhotomechanical exposure apparatusMicrolithography exposure apparatusContact positionProjection lens

The invention discloses an immersion self-adaptation rotary sealing device for photo-etching machine, which is arranged between a projection lens group and a substrate and comprises an inner chamber, a rotary member, a rotary excitation structure and a permanent magnet plate. A plurality of groups of spiral air inlet slots arranged on the rotary member, the outside air is sucked from the air inlet slots by the rotary motion of the rotary member, a cylindrical air curtain is formed at the boundary of flow field to prevent the liquid from leaking outsides. The rotary air curtain is benefical to rapidly guide the redundant liquid at the backward contact angle to the forward contact position under the high-speed movement of the substrate, the relatively steady boundary flow field is obtained by the compensation. When the liquid enters into the air inlet slots because of the big pulling of the substrate, the inward backflow impact for the boundary flow field is formed by liquid in the air inlet slots under the movement of the rotary member, thus counteracting the outward leaking power of liquid, and the counteracting power increases with the increase of the outward impact force of liquid.

Owner:ZHEJIANG UNIV

Bidirectional ventilation and pneumatic pile-turning composting process

ActiveCN101062872AControl layered non-uniform stateReduces the problem of entrainment out of the reactorBio-organic fraction processingClimate change adaptationAir volumeSludge

The invention discloses a bidirectional flow ventilation and air pressure composting method, which comprises the following steps: dwelling pile body with height at 2-2. 5m and upper margin at 0. 5-1. 0m in box compost reactor; inserting three heat indicators and three pile body gap gas sampling pipe into different height; adopting 0. 1-0. 2m3 / min fixing air quantity per m3 initial compost raw material and batch process; venting; changing the direction of ventilation when the biggest differential temperature more than 5 deg. c of the three heat indicators; turning over the pile at the second day for one time one day; compressing the air with impulse; discharging momentary; making the pile body float and drop; testing oxygen concentration of the gas in the pile body per 15 min; finishing the compost when the biggest differential value less than 1. 0% of adjacent twice. This invention possesses low operating cost without twice pollution, which can be used to the compost of life garbage, agricultural waste and sludge of the waste water treatment plant.

Owner:TONGJI UNIV

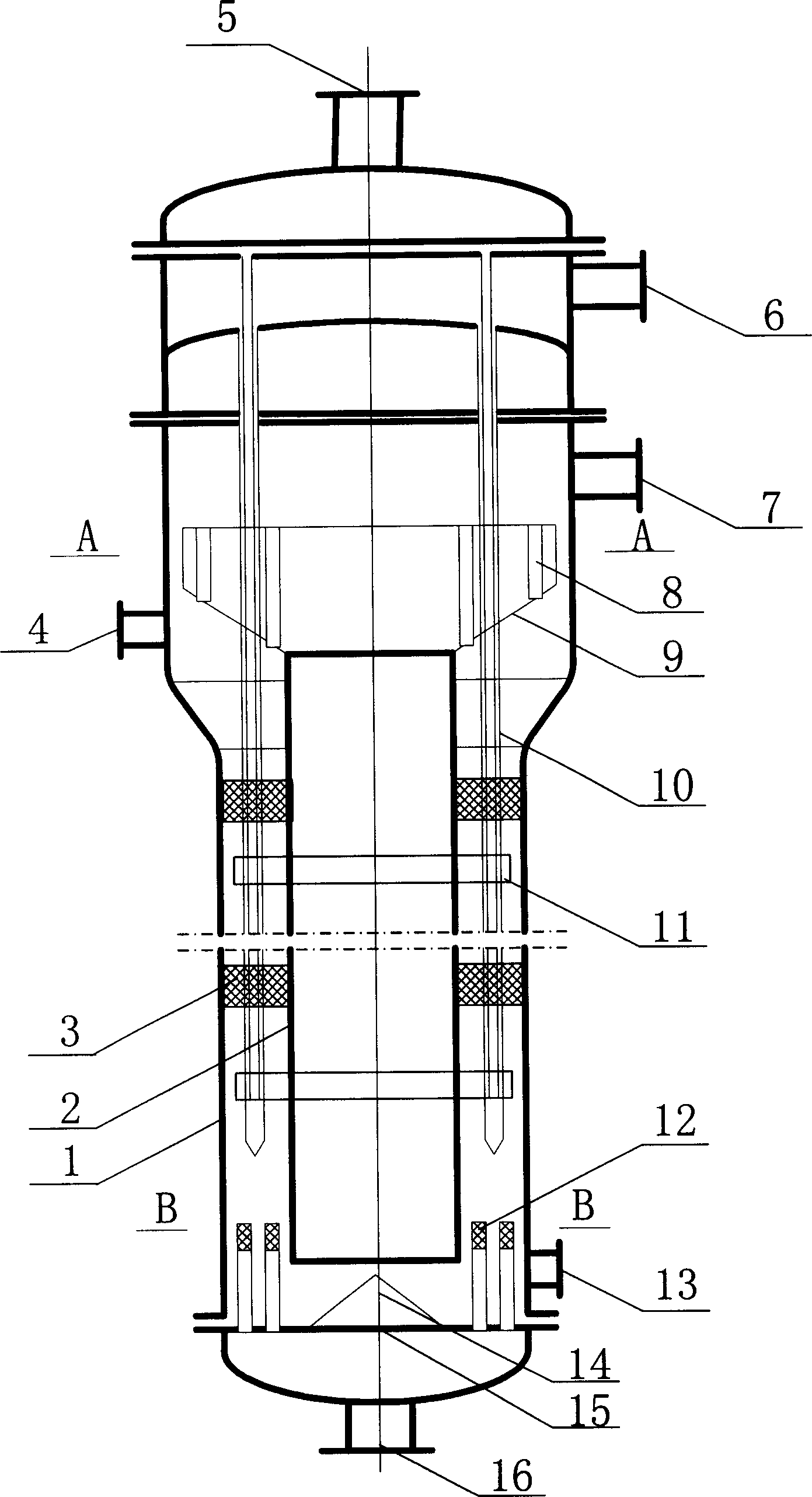

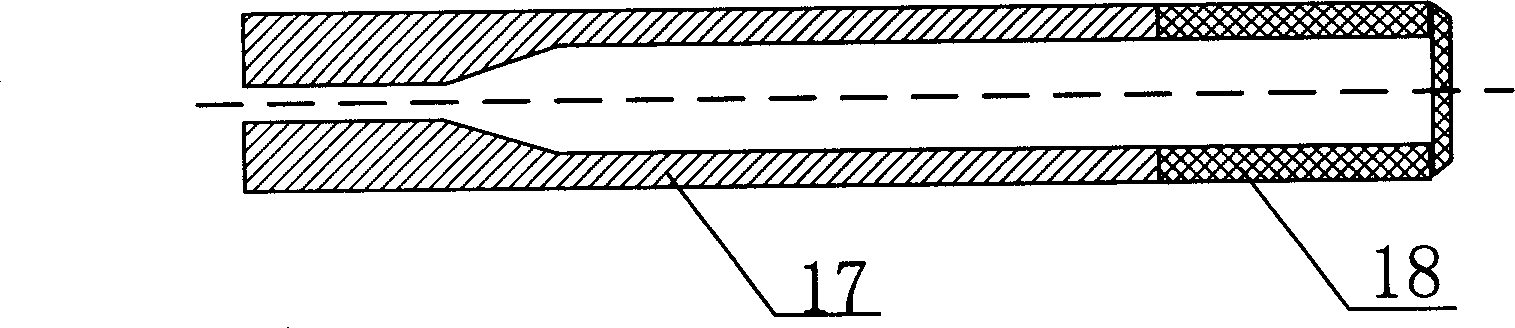

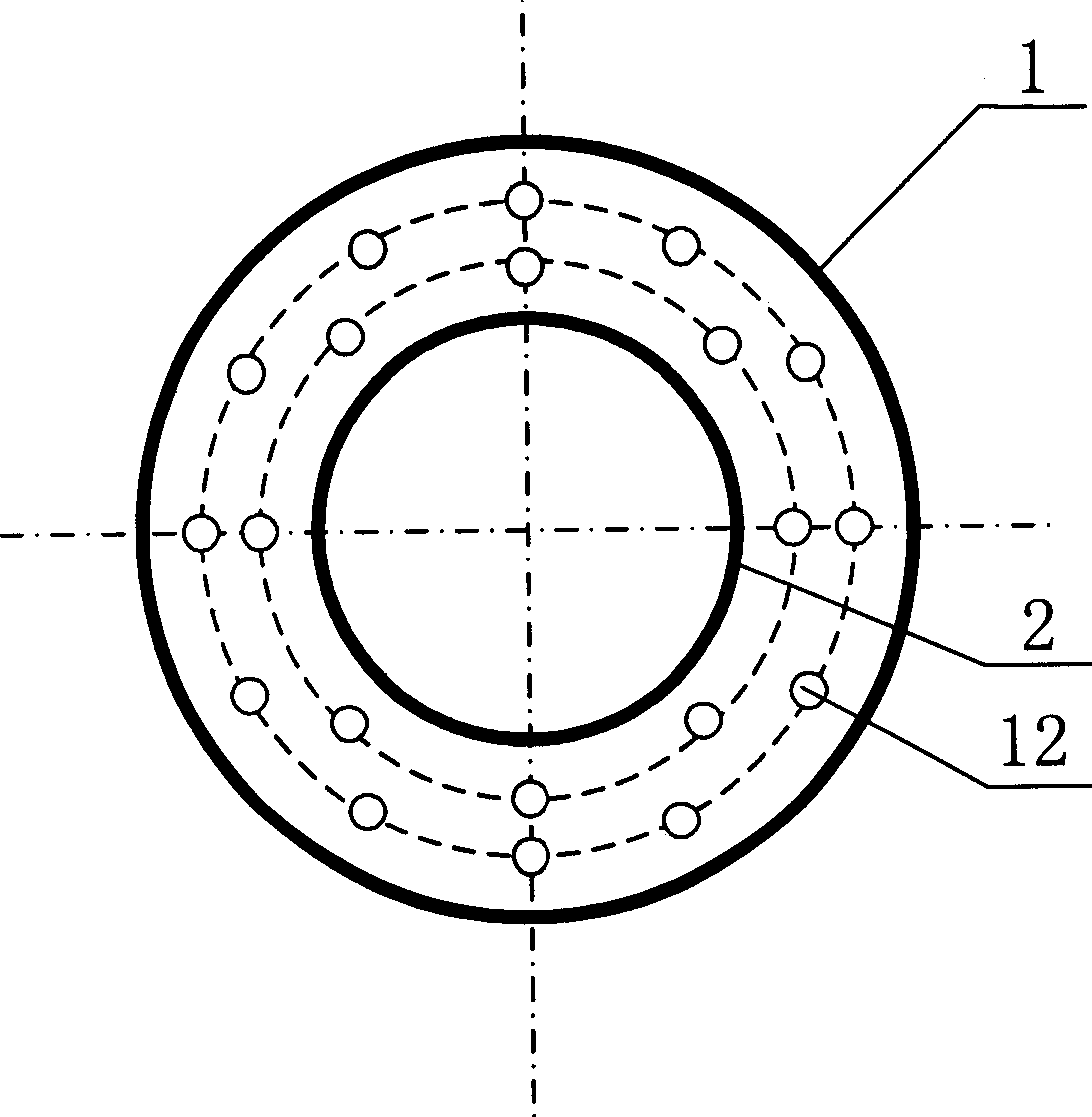

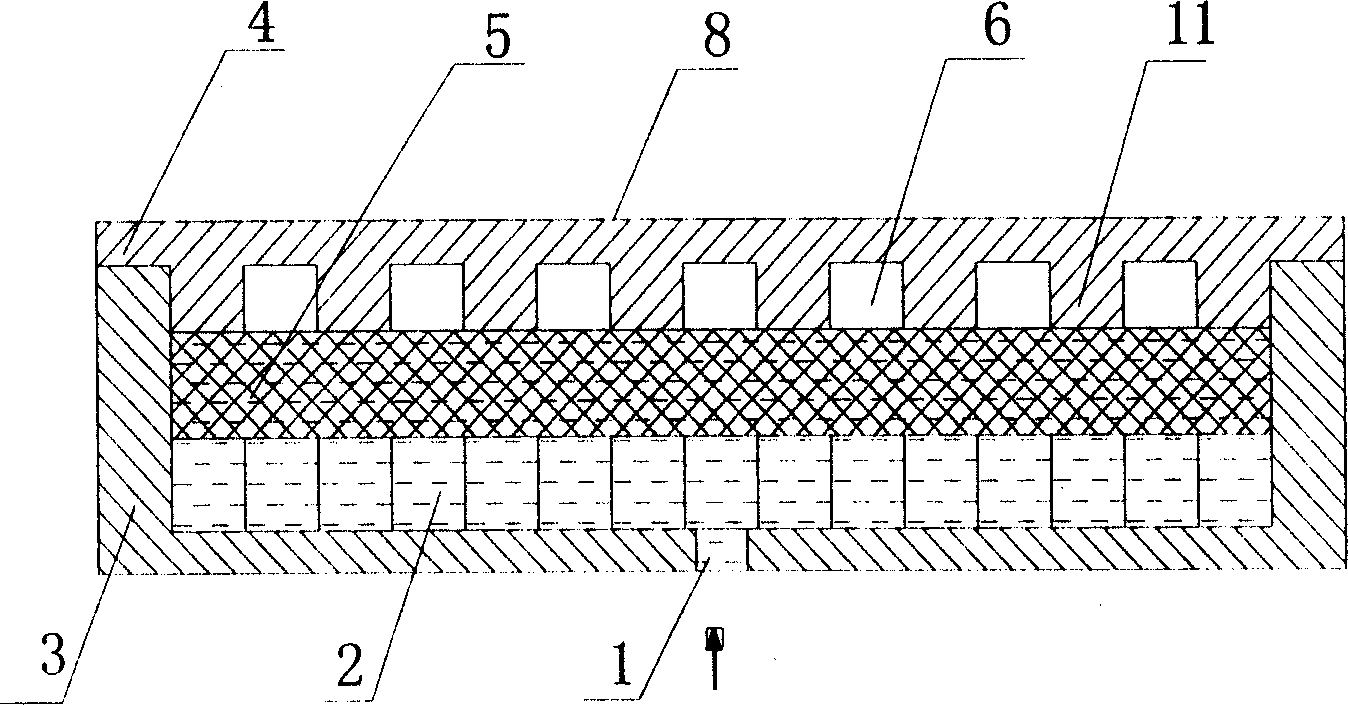

Annular space gas lifting type loop reactor

InactiveCN1605385AReduce production efficiencyAvoid entrainmentChemical/physical processesVapor–liquid separatorEngineering

The annular air-lift inner circulating reactor is one inner circulating reactor with high gas-liquid separating efficiency and excellent gas distributing effect. Technologically, the present invention features that the gas-liquid separator in funnel-fine pipe separating structure has complete gas-liquid separation; and that the sintered pipe gas distributor has relatively small initial bubble size resulting in excellent gas distributing effect. In order to improve flow and reinforce mass transfer, the annular air-lift pipe is provided with inner member; and in order to introduce out or in heat for reaction, the annular air-lift pipe is provided with heat exchange member of fingered or coiled pipe. The reactor has the features of high gas-liquid separating efficiency, high gas distributing effect, homogeneous radial gas distribution, homogeneous radial liquid speed distribution and no reverse fluid circulation.

Owner:TSINGHUA UNIV

Plane capillary core evaporimeter for CPL

InactiveCN1725946AReduce thermal contact resistanceImprove heat transfer efficiencyInstrumental cooling apparatusCooling/ventilation/heating modificationsWire gauzeEngineering

A planar capillary core evaporator for CPL consists of base, top cover being fixed and sealed with base, an isolation plate for isolating top cover to liquid and steam collection cavity, the liquid collection cavity formed by horizontal and longitudinal channels and cross arranged and opened with return liquid inlet on it, steam collection cavity opened with vapor outlet, top cover longitudinal steam channel being connected to steam cavity and capillary core set between two cavities.

Owner:HUAZHONG UNIV OF SCI & TECH

Weight sorter

InactiveUS6877611B2Easy to processReduce manufacturing costWeighing apparatus testing/calibrationCapsule deliveryEngineeringMechanical engineering

A weight selecting apparatus capable of automatically performing calibration, and providing a weight selecting apparatus capable of certainly carrying objects to be inspected with a relatively simple mechanism and performing weight measurement of the objects. The objects, after being subjected to weight measurement by a first weighing unit 2, are sampled by a sampler 5, and those of the objects thus sampled are subjected to weight measurement by a second weighing unit 6. A calibration unit compares, for the same object, the measured result with that obtained by the first weighing unit 2 and discriminates whether or not a difference therebetween is within a specific error range, to perform calibration of the first weighing unit 2. Further, as a carrier 3 for carrying the objects to the weighing unit 2 one by one uses an intermittently rotatable carrying roller 32 having in its outer peripheral surface portion a plurality of carrying pockets 321.

Owner:SHIONOGI QUALICAPS

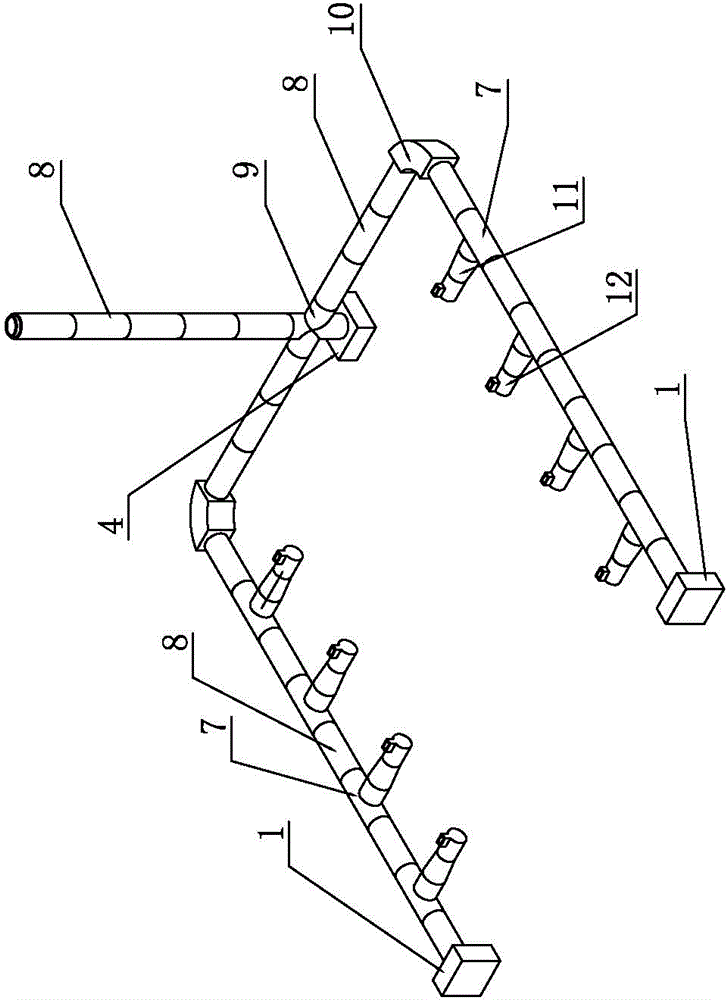

Ceramic casting system

ActiveCN103978158APurified hot metalEasy to manufactureFoundry mouldsFoundry coresMaterials scienceCasting

The invention discloses a ceramic casting system in the technical field of casting. A sprue, a cross gate and an ingate of the ceramic casting system are obtained by connection of several equal-diameter straight pipes, a fourway pipe, elbow pipes, variable-diameter straight pipes, t-branch pipes and flat mouth pipes made of a ceramic material. The sprue and the inlet section of the cross gate are obtained by connection of the equal-diameter straight pipes. The upward opening of the fourway pipe is connected to a lower end of the sprue. Two side openings of the fourway pipe are connected to one end of the inlet section of the cross gate. The elbow pipes are connected between the inlet section and an outlet section of the cross gate. The outlet section of the cross gate is obtained by connection of the equal-diameter straight pipes and the t-branch pipes. The equal-diameter straight pipes are connected to straight-through openings of the t-branch pipes. The ingate is obtained by connection of the variable-diameter straight pipes and the flat mouth pipes. Large-diameter ends of the variable-diameter straight pipes are connected to side openings of the t-branch pipes and each one of small-diameter ends of the variable-diameter straight pipes is connected to an end of the corresponding flat mouth pipe. Sides of the flat mouth pipes are provided with rectangular outlets communicated with a casting cavity. The ceramic casting system solves the problem of sand washing of the existing casting system in large-scale part casting, improves casting quality and is suitable for large-scale part casting.

Owner:KOCEL EQUIP

Manufacturing device of ultra-large type special thick plate rectangular ingotblank

ActiveCN101791682AEliminate taperHigher requirements for lower openingsManufacturing technologyThick plate

The invention discloses a manufacturing device of an ultra-large type special thick plate rectangular ingotblank. The manufacturing device of the ingotblank comprises a water-cooling metal mould chassis on which a water-cooling metal mould is arranged; the top of the water-cooling metal mould is provided with a heat insulation and heat preservation dead head; the interior of the water-cooling metal mould is a taperless rectangular hollow cavity which is through up and down; and the hollow cavity of the water-cooling metal mould is internally through and is provided with a width delivery device. By adopting a taperless water-cooling metal mould structure based on a traditional roller manufacturing technology, the invention can eliminate the taper of a casting, lower the higher requirement for the opening degree of a rolling mill, reduce the impact of the taper to the rolling of the rolling mill at the initial stage and ensure that the produced ingotblank more approaches to a finished plate in shape. The manufacturing device is provided with the width delivery device by combining the characteristics of the ultra-large type rectangular ingotblank, thereby ensuring that the filling of liquid steel and the formed temperature field are more uniform, avoiding the occurrence of cracks and trapped gas conditions, being beneficial to the upward flotation of impurities, and improving the quality of the ingotblank. The width delivery device has simple structure and convenient use.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

Method of improving weld quality

InactiveUS7154064B2Reduce solidificationReduce porosityWelding/soldering/cutting articlesLaser beam welding apparatusIrradiationLaser beams

A method of improving weld quality between aluminum members by slowing the rate of solidification of a molten weld trough into solidified material. Upper and lower aluminum members are positioned together in contact between facing surfaces thereof to expose a first outer surface of the upper aluminum member to laser irradiation. A welding laser beam is moved in a path over the first outer surface, wherein the welding laser beam has an energy and width to progressively melt a trough of molten metal to a depth through the upper aluminum member and into the lower aluminum member. The molten metal in the trough has a void filled with gas, and the molten metal re-solidifies into re-solidified metal after the passage of the welding laser beam. An area in and around the trough is heated to slow the rate of solidification of the molten metal into the re-solidified metal, thereby preventing entrainment of the gas within the re-solidified metal.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

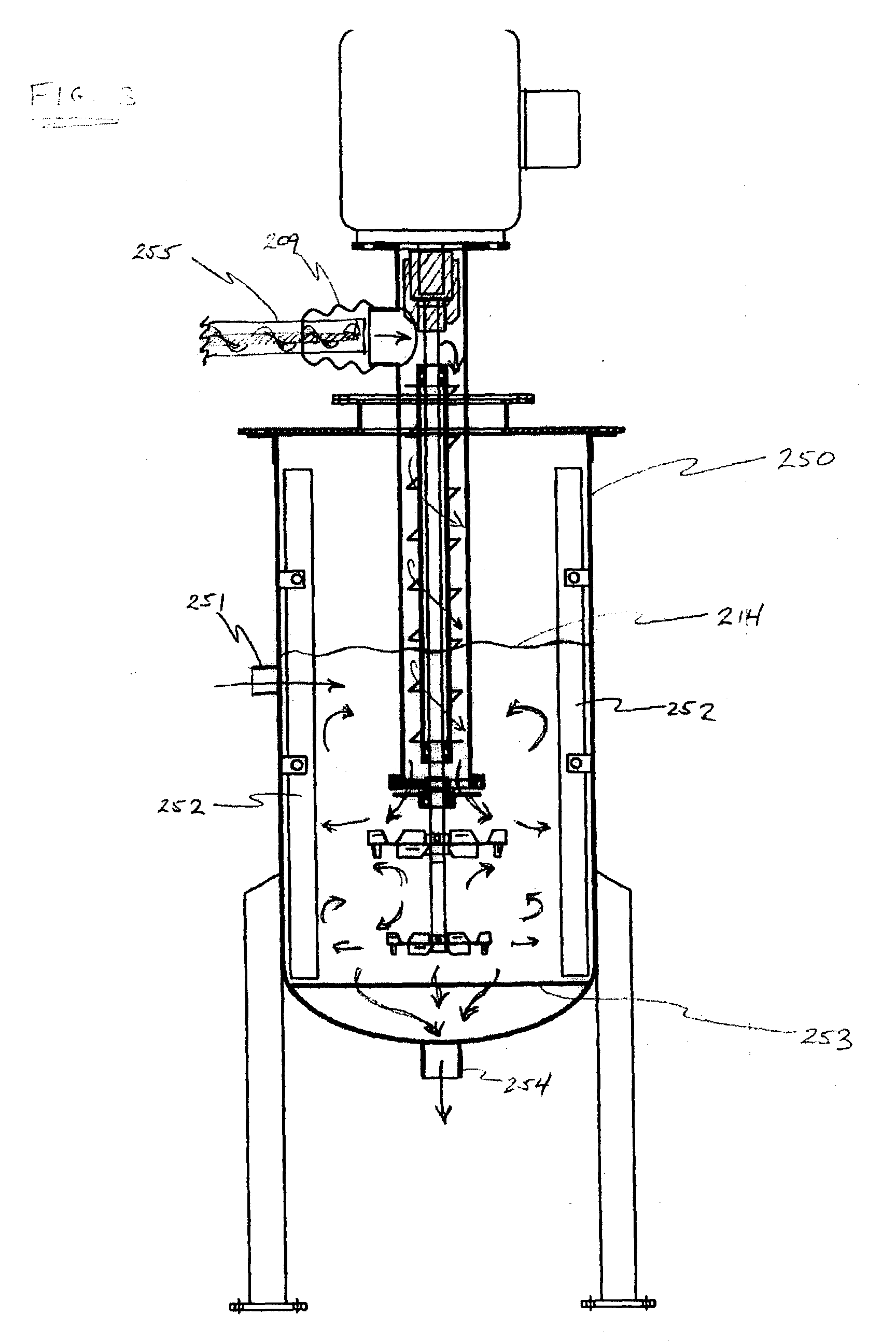

Apparatus and method for continuously removing air from a mixture of ground polyurethane particles and a polyol liquid

InactiveUS20030233937A1Facilitate cleanup and shutdownAvoid entrainmentRotary stirring mixersMixing methodsPolyolDeaerator

The disclosed system comprises an apparatus and a method continuously removing air from a mixture of ground polyurethane particles and a polyol liquid. The apparatus for continuously removing air from a mixture of ground polyurethane particles and a polyol liquid comprises a deaerator having an inlet to receive a mixture of liquid and fine particles and an outlet to disperse the mixture. The deaerator further comprises a rotating bowl, wherein the bowl is attached to a shaft such that the bowl and the shaft rotate. The bowl has an inside and an outside surface that is coupled to the inlet of the deaerator to receive the mixture such that when the bowl is rotated, the mixture is spread on the inside surface of the bowl. A pickup tube is located in the bowl that catches the mixture and directs it through a conduit to the outlet. The rotation of the bowl imparts sufficient energy to the mixture to pump it through the conduit. A vacuum chamber that has a front plate and a back plate encompasses the bowl and the back plate contains an assembly by which the shaft rotates and the low absolute pressure within the vacuum chamber prevents bubbles from being re-entrained in the mixture as it is directed toward the outlet via the conduit.

Owner:MOBIUS TECH

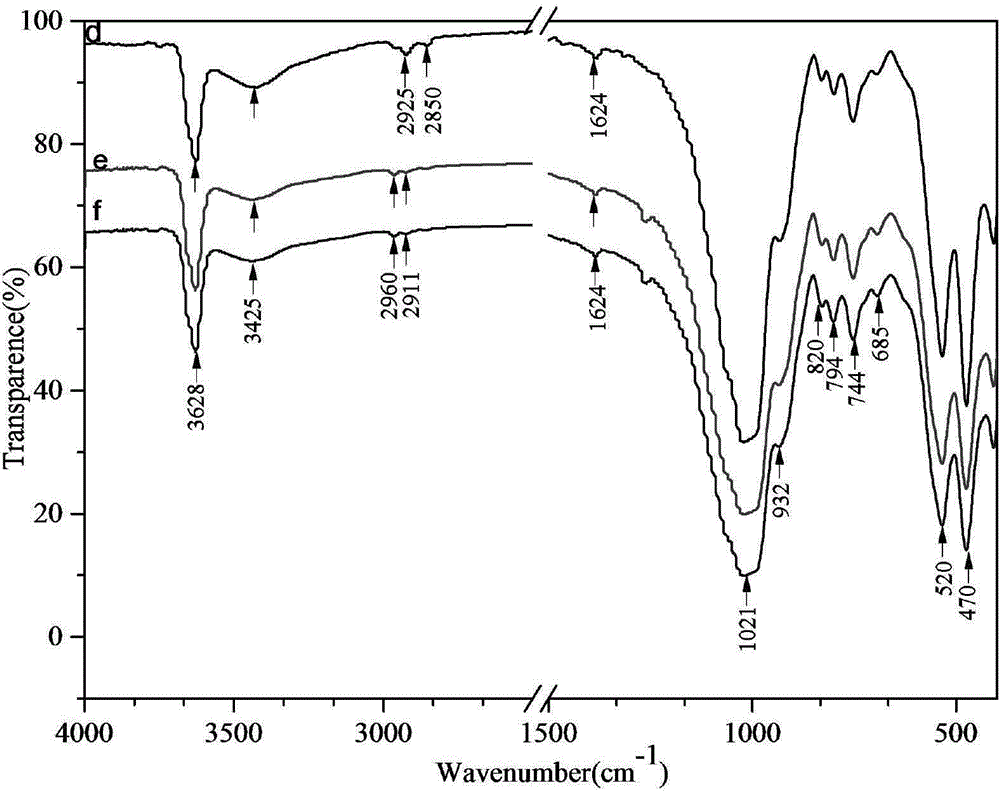

Method used for preparing sericite powder used for cosmetics

InactiveCN104909380AUniversally applicableHigh selectivityCosmetic preparationsToilet preparationsDispersityFlocculation

The invention discloses a method used for preparing sericite powder used for cosmetics. The method comprises following steps: shear flocculation, wherein a sericite quartz powder ore pulp with a mass concentration of 10 to 60% is delivered into a stirring sanding dispersing multifunction machine for shearing and stirring, and an inhibitor, a pH value regulating agent, a surface conditioning agent, and a cation collector are added successively so as to complete preliminary modification of sericite and formation of hydrophobic flocculation; flotation and purification, wherein after shear flocculation, the sericite quartz powder ore pulp is delivered into a flotation machine so as to obtain ore concentrate via floatation, wherein floatation concentration is controlled to be 3 to 20%, ore pulp pH value is controlled to be 2 to 3; and aging and modification, wherein obtained ore concentration I and II are subjected to dewatering and drying, and aging at high temperature so as to obtain the modified sericite powder used for cosmetics. The technological process of the method is coherent; operation is simple; the prepared cosmetic pigment is high in purity, excellent in dispersity, glossiness, malleability, and skin paste performance; skin feeling is fresh; the performance of the sericite powder is capable of satisfying quality requirements of extender pigments used for cosmetics; and the method can be used for matured industrialized large-scaled production.

Owner:WUHAN UNIV OF TECH +1

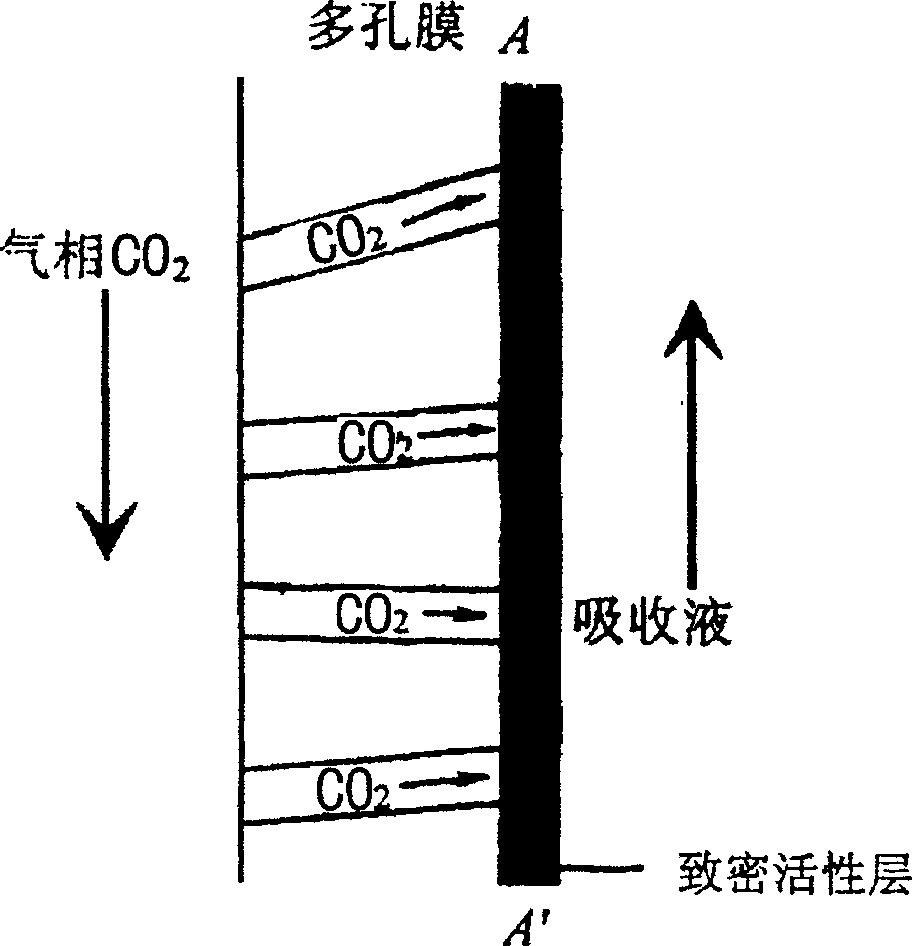

Membrane module of using compact polymer membrane in application for separating gas mixture

InactiveCN1759922AAvoid entrainmentAvoid bubblingDispersed particle separationChemical physicsDifferential pressure

An application of the membrane module with compact polymer membrane in gas-liquid separation is disclosed. Its working process includes such steps as diffusing the gas via micropores of membrane to the compact active layer, dissolving-diffusing to make it reach the interface of polymer membrane and absorbing liquid, reacting on absorbing liquid to generate transfer mass, and carrying gas away by the absorbing liquid.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Forming method of cylinder cover

ActiveCN107900284AIncrease stiffnessSmall amount of feedFoundry mouldsFoundry coresInlet channelAlloy

The invention relates to a forming method of a cylinder cover, which is simple and convenient in process and good in effect. Manufacturing of an upper outer mold shell and a lower outer mold shell isas follows: a template is preheated to 180 to 220 DEG C, a coating film naturally falls into a forming cavity formed by the template and a sand blocking frame, the template is continuously heated to 250 to 260 DEG C and heat is preserved for 680 to 760 seconds; manufacturing of gas inlet channel shell cores and gas exhausting channel shell cores is as follows: a mold cavity is preheated to 180 to250 DEG C, film coating sand naturally falls into a core box mold cavity, the mold cavity is continuously heated to 275 to 285 DEG C and heat is preserved for 50 to 70 seconds; manufacturing of cooling water cavity solid cores, a pouring cup, a straight pouring gate, a transverse-inner pouring gate, an exhausting channel side upper core base solid core and an exhausting channel side lower core base solid core is as follows: the mold cavity is preheated to 180 to 260 DEG C, the film coating sand is blown into the mold cavity, the mold cavity is continuously heated to 280 to 290 DEG C and heat is preserved for 90 to 110 seconds; a film coating sand casting type structural component is subjected to coating, drying and assembling; a casting mold is modeled; alloy is smelted and inoculation isconducted; and gravity casting, solidification and separation are conducted. The forming method of the cylinder cover is suitable for manufacturing the cylinder cover.

Owner:贵州英吉尔机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com