Annular space gas lifting type loop reactor

A technology of reactor and internal circulation, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of large initial bubble diameter, poor gas distribution effect, particle deposition clogging distributor, etc., and achieve good gas-liquid separation , Good gas-liquid separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

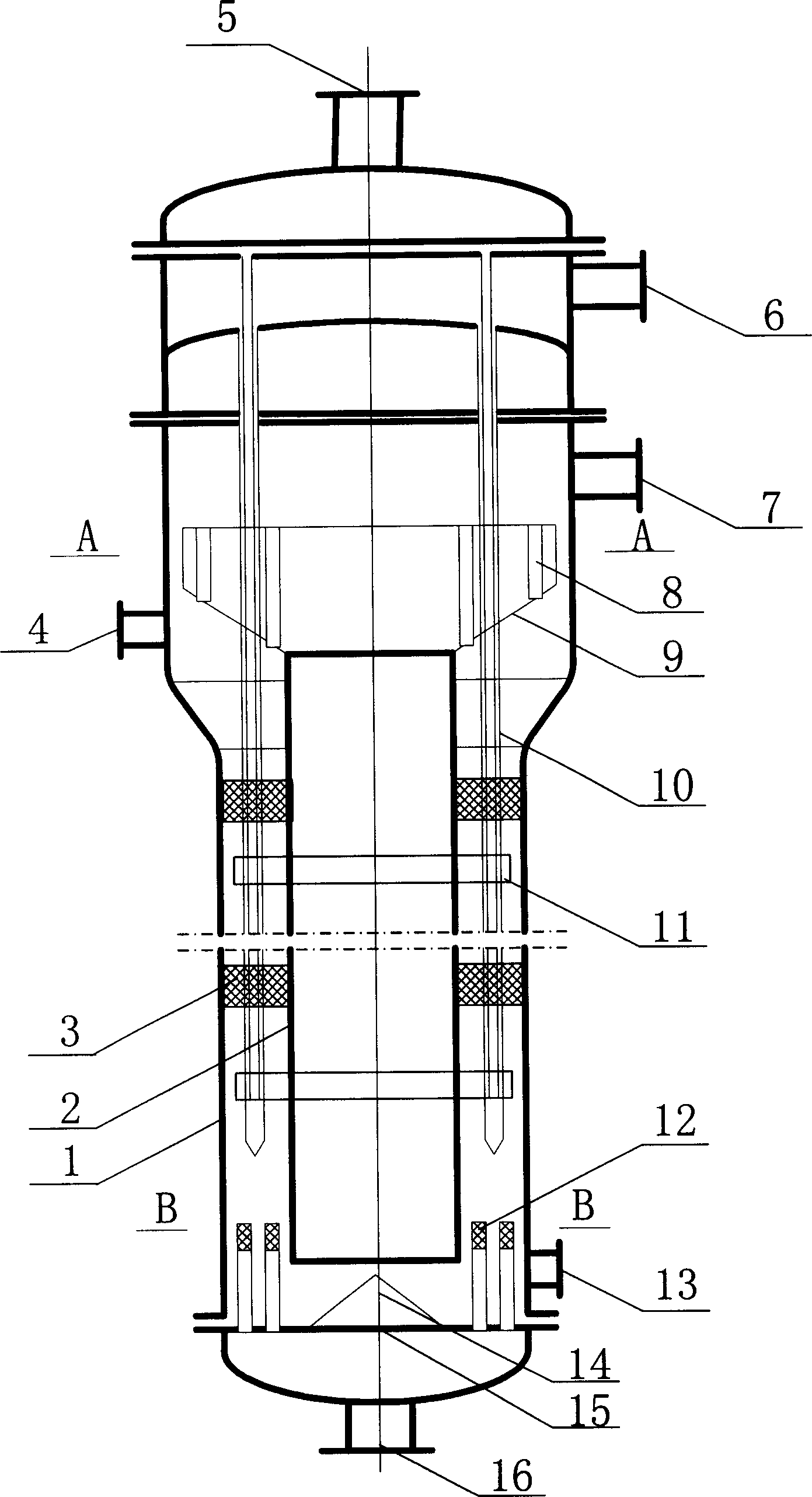

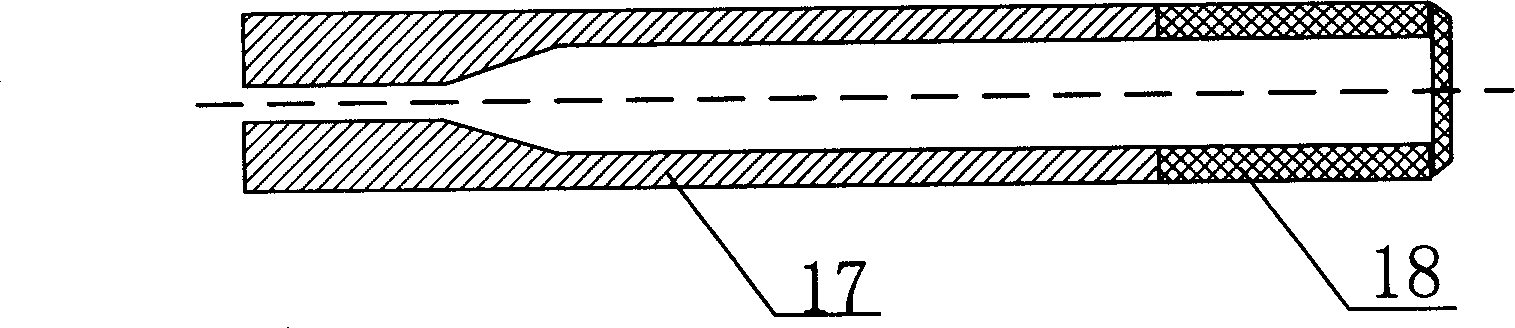

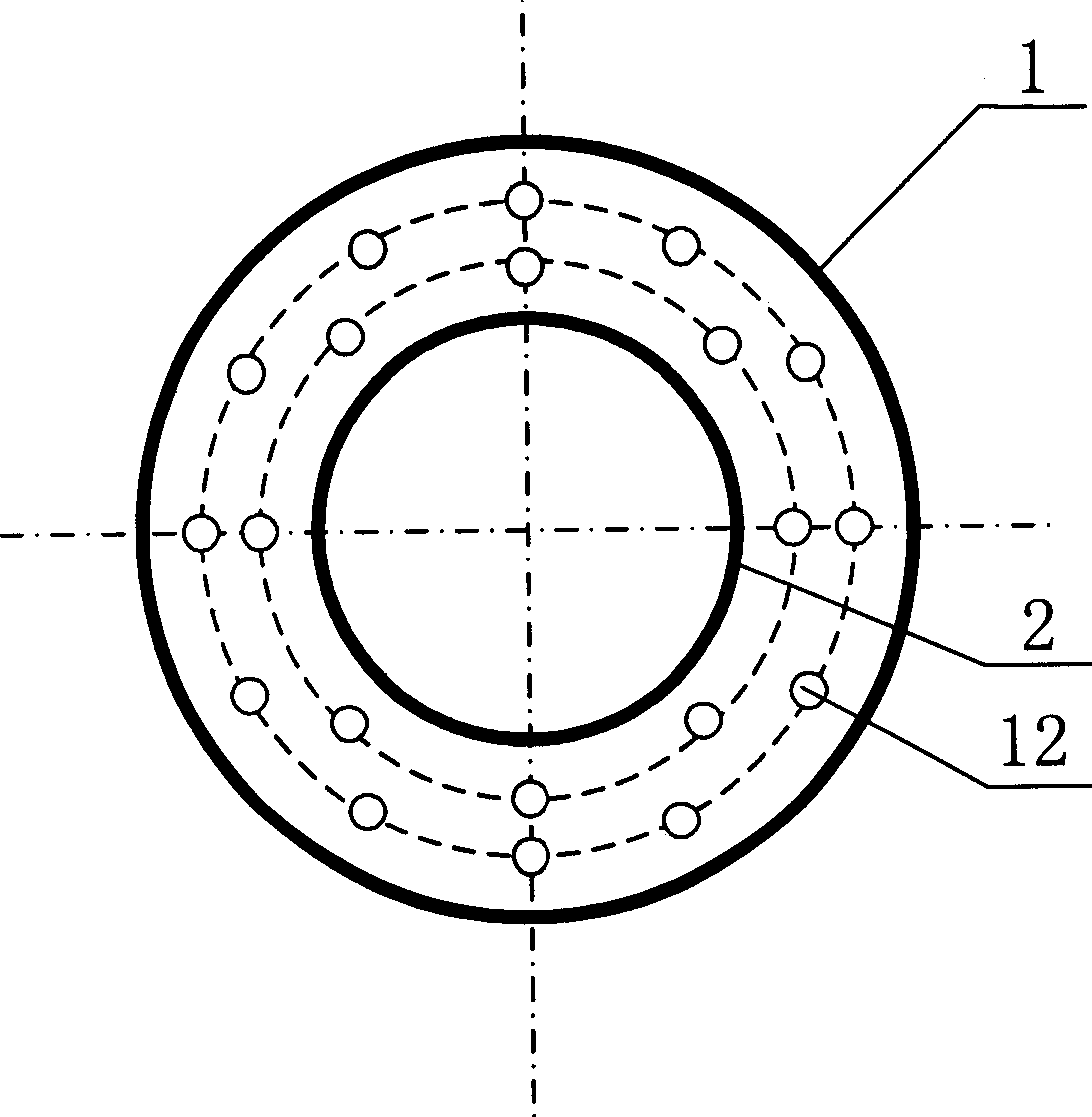

[0021] The annulus air-lift internal circulation reactor provided by the present invention is mainly composed of a reactor outer cylinder 1, a reactor inner cylinder 2 installed concentrically with the reactor outer cylinder, an internal member 3 arranged in the annulus riser, and a heat exchange reactor. Component 10, the gas-liquid separator funnel 9, the vertical thin tube 8 installed on the tapered side wall of the gas-liquid separator funnel (the gas-liquid separator funnel 9 forms together with all the vertical thin tubes 8 installed thereon gas-liquid separator), the distributor substrate 15 arranged at the bottom of the reactor and the gas distribution pipe 12 arranged on the substrate, and the conical guide plate 14 are formed, such as figure 1 shown. The bottom end of the reactor outer cylinder 1 is connected to the distributor base plate 15 in the form of a flange, and there is a certain distance between the reactor inner cylinder 2 and the distributor base plate 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com