Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36 results about "Internal circulation reactor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The internal circulation reactor (IC reactor) is a form of anaerobic digester. It is primarily designed to treat wastewater. The IC reactor is an evolution of the UASB and EGSB digestion systems. The digester typically produces biogas with a high concentration methane (c80%). In essence the IC to improve digestion rates and gas yields. The foot print for the IC reactor is therefore typically smaller. However, it is taller due to the increased complexity of the reactor.

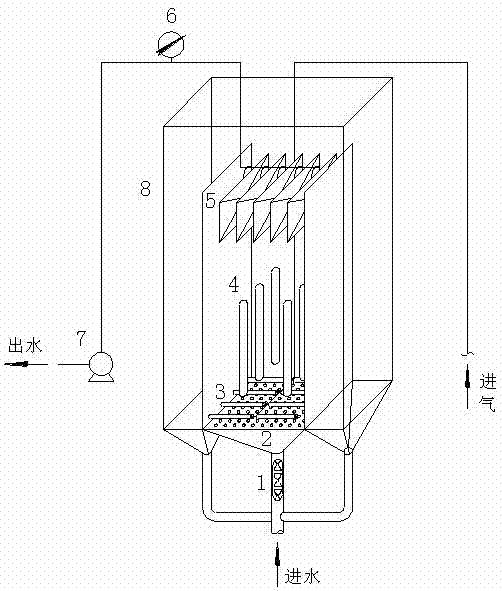

Adsorption regeneration-photocatalysis advanced oxidation water treatment equipment

InactiveCN102180556AImprove adsorption capacityAvoid it happening againMultistage water/sewage treatmentUltraviolet lightsWater quality

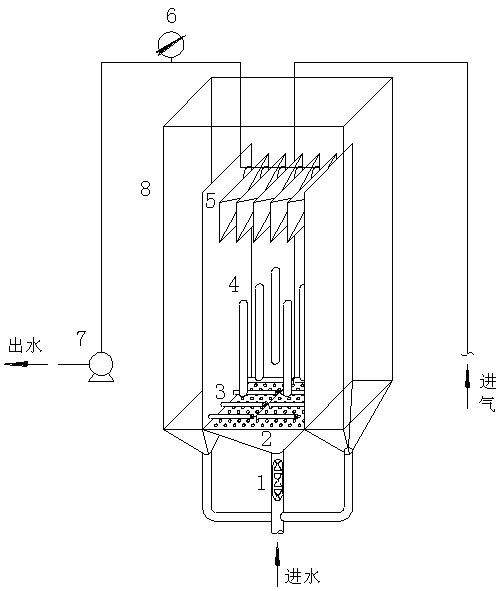

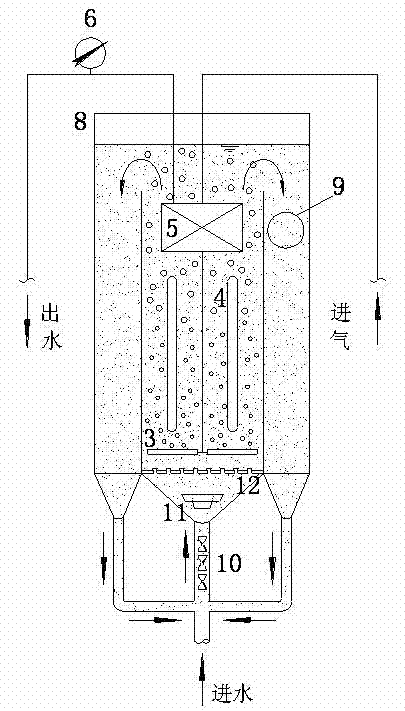

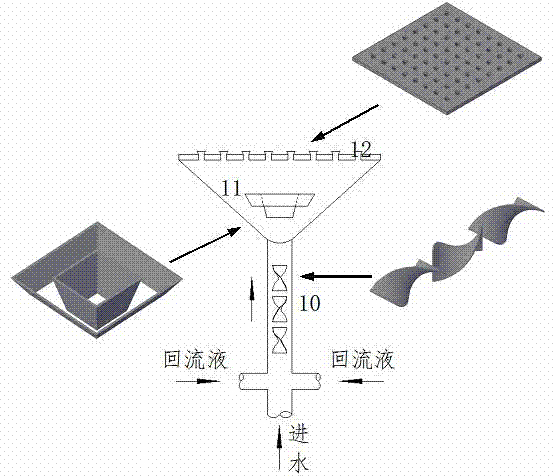

The invention relates to adsorption regeneration-photocatalysis advanced oxidation water treatment equipment, which consists of a pipeline static mixer, a water distributor, an aeration pipe, an ultraviolet light source, a membrane component, a vacuum meter, a water outlet pump, an air lift internal circulation reactor and a powder photocatalyst, wherein the aeration pipe, the ultraviolet light source and the membrane component are positioned in the air lift internal circulation reactor; the middle of the air lift internal circulation reactor is provided with an upward circulating flow channel; both sides of the air lift internal circulation reactor are provided with downward circulating pipelines; the bottom of the upward circulating flow channel is connected with the water distributor; the water distributor is connected with the pipeline static mixer; the membrane component is connected with the water outlet pipe through a hose to form a water outlet pipeline; the water outlet pipe is connected with the water outlet pump; water is sucked by the water outlet pump; the vacuum meter is connected in series to the water outlet pipeline; the bottom of each downward circulating pipeline is connected with a return pipe; the return pipe is connected to the front part of the pipeline static mixer; and the powder photocatalyst is suspended in the air lift internal circulation reactor. The water treatment equipment has the advantages of compact structure, mild reaction condition, high reaction efficiency, easiness of maintenance, high drained water quality and strong economic competition, and is suitable for treating various kinds of non-degradable organic matter waste water and hospital sewage and removing non-degradable organic matters remaining in water drained from sewage plants.

Owner:TONGJI UNIV

Treatment method of antibiotic production wastewater

ActiveCN104843934APromote degradationReduce water concentrationMultistage water/sewage treatmentElectrolysisWater quality

The invention discloses a treatment method of antibiotic production wastewater. The innovation point is as follows: through an adjusting tank, antibiotic successively enters an iron-carbon micro-electrolysis tank, an FT oxidation tank, a coagulative precipitation tank, an air floatation tank, a treating tank equipped with an anaerobic internal circulation reactor, an upflow sludge blanket filtering basin, a hydrolysis acidification pool, a contact aeration basin and a secondary sedimentation tank so as to undergo recovery processing. According to the treatment method of antibiotic production wastewater, improved iron-carbon micro-electrolysis and improved coal / natural gas indirect liquefaction FT oxidation technologies are adopted for pretreatment, so as to destroy and degrade hardly-degraded and toxic organic pollutants in wastewater. Thus, toxicity is destroyed and water concentration is reduced while biodegradable performance of pollutants in wastewater is improved. Favorable conditions are created for follow-up biochemical treatments, and treatment efficiency and effluent quality standard are raised.

Owner:NANTONG DAHENG ENVIRONMENTAL ENG CO LTD

Internal circulation reactor and method for continuously preparing phosphorus pentafluoride

InactiveCN102976298AStable concentrationIncrease production capacityPhosphorus halides/oxyhalidesAutomatic controlInternal circulation reactor

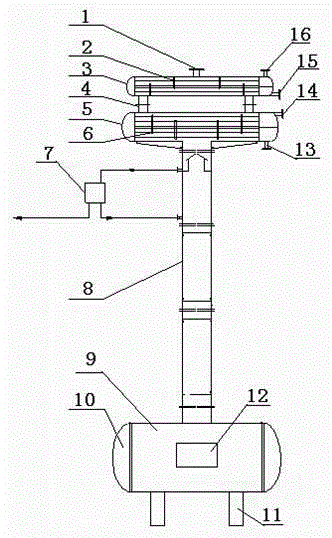

The invention discloses an internal circulation reactor and method for continuously preparing phosphorus pentafluoride. The internal circulation reactor comprises a cylinder body with a heat exchange jacket, wherein planar end closures are arranged at the upper and lower ends of the cylinder body, and a concentric inner cylinder body is arranged in the cylinder body; the upper end closure is provided with a mixed gas leading-out pipe; the lower end closure is provided with a three-way gas intake pipe; and a reaction solution eduction pipe and a feed liquid ingress pipe are arranged on the cylinder body. The process of preparing phosphorus pentafluoride comprises the following steps: blowing the reactor with an inert gas; creating a low temperature environment of the reactor with a refrigerant; adding a phosphorous pentachloride solution, anhydrous hydrogen fluoride and the inert gas to the reactor for reaction; and continuously leading out mixed gas containing phosphorus pentafluoride and part of a low-concentration phosphorous pentachloride solution, and at the same time continuously adding a phosphorous pentachloride concentrated solution, anhydrous hydrogen fluoride and the inert gas to realize continuous operation. The internal circulation reactor and method for continuously preparing phosphorus pentafluoride have the advantages that the concentration stability of reactants in the reactor can be maintained, and continuous production and automatic control of phosphorus pentafluoride are realized.

Owner:TIANJIN LONGER NEW MATERIAL SCI & TECH

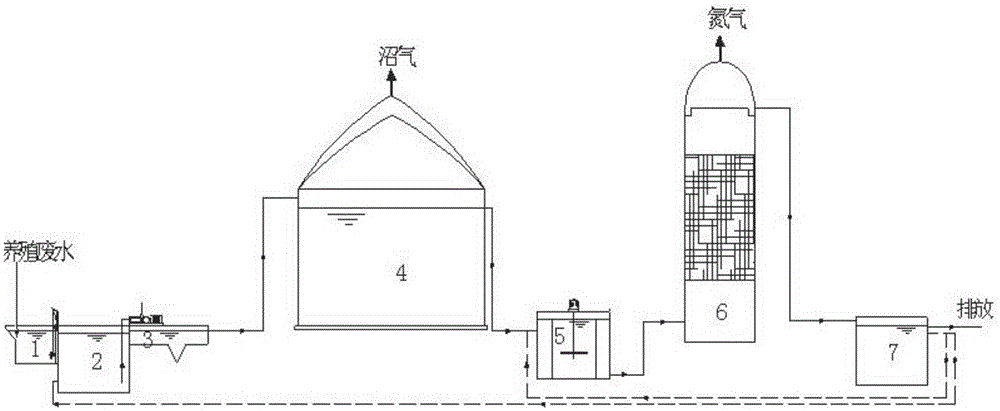

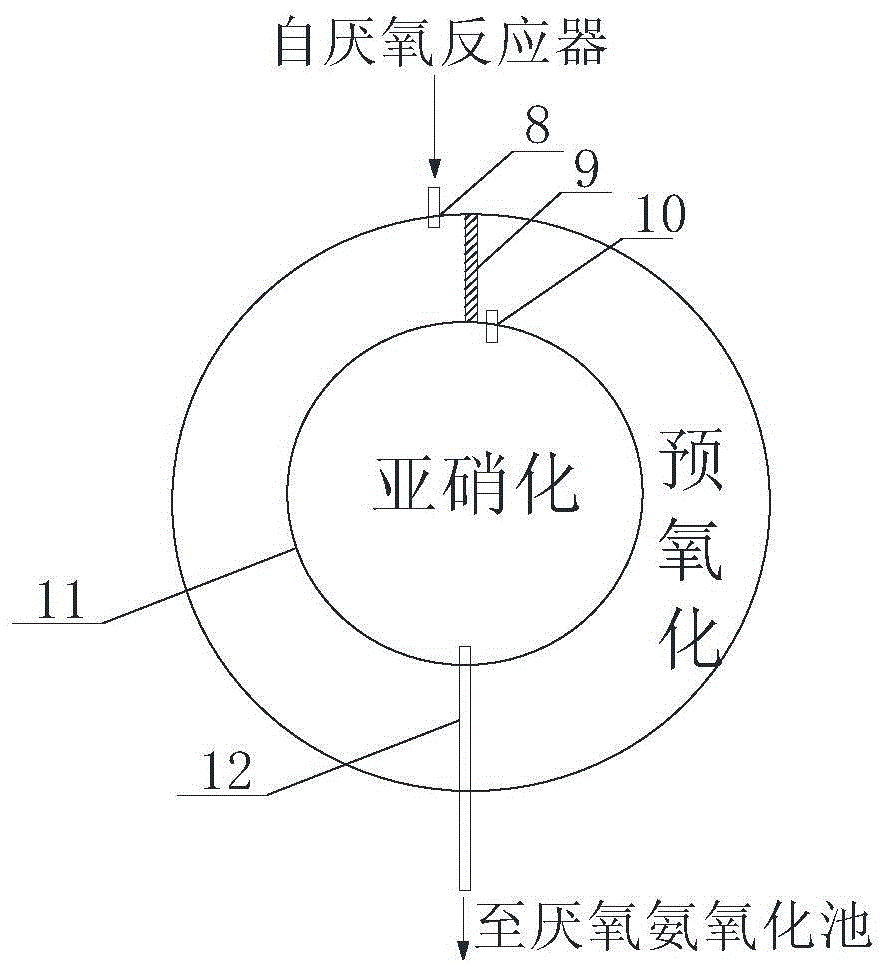

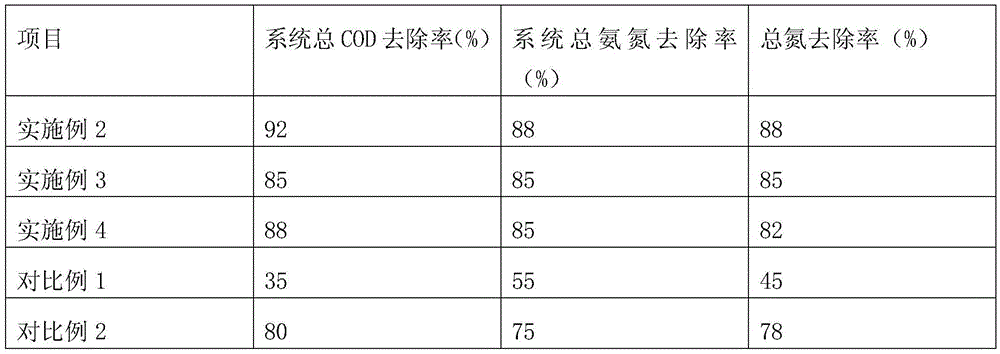

Culture wastewater efficient degrading and denitrifying treatment system and treatment method thereof

ActiveCN105601025AGood effectImprove degradation efficiencyMultistage water/sewage treatmentHigh concentrationAnaerobic reactor

The invention relates to a culture wastewater efficient degrading and denitrifying treatment system and a treatment method thereof. The system comprises, sequentially connected, an equalizing basin, a sand precipitation basin, a feeding basin, an anaerobic reactor, a preoxidation-nitrosation integration basin, an anaerobic ammoxidation reactor and an outlet water return basin, the anaerobic reactor is an anaerobic internal circulation reactor, wastewater flows through an external circular basin cavity and then enters an internal circular basin cavity, the anaerobic ammoxidation reactor is an upflow anaerobic packed tower, culture wastewater goes through above structures to sequentially undergo purifying reactions comprising hydrolysis, sand removal, anaerobic treatment, nitrosation and anaerobic ammoxidation, and harmful pollutants can be efficiently removed through multi-grade degrading treatment. The method combines an anaerobic process with an anaerobic ammoxidation process, and allows COD to be removed through the anaerobic process and nitrogen to be removed through the anaerobic ammoxidation process, so efficient removal of high-concentration pollution components in the culture wastewater is realized, and the method is simple to operate and stably runs.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

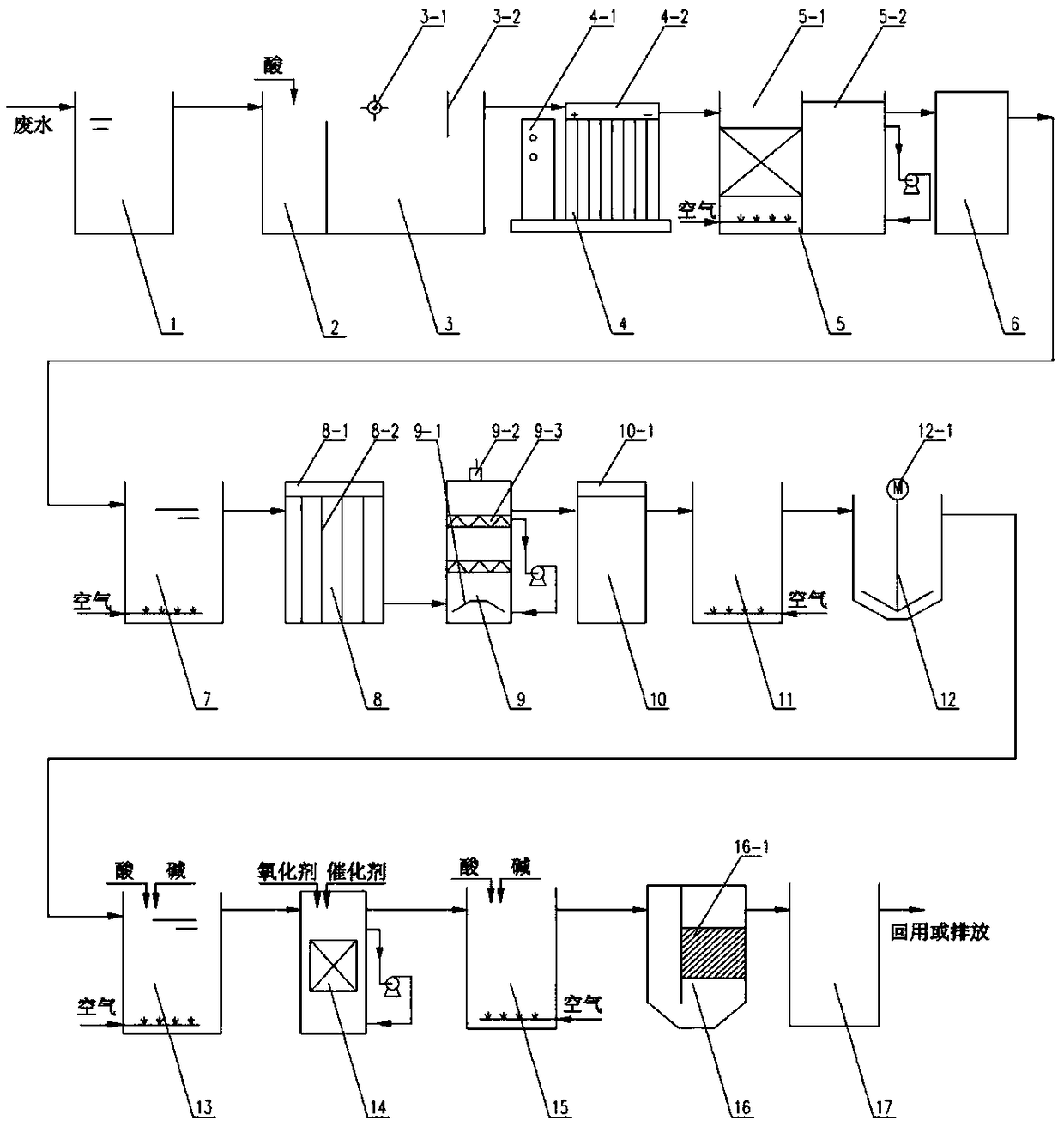

Device and method for treating high concentration refractory organic wastewater

InactiveCN109020090AImprove biodegradabilityFatty/oily/floating substances removal devicesTreatment with aerobic and anaerobic processesHigh concentrationHydrolysis

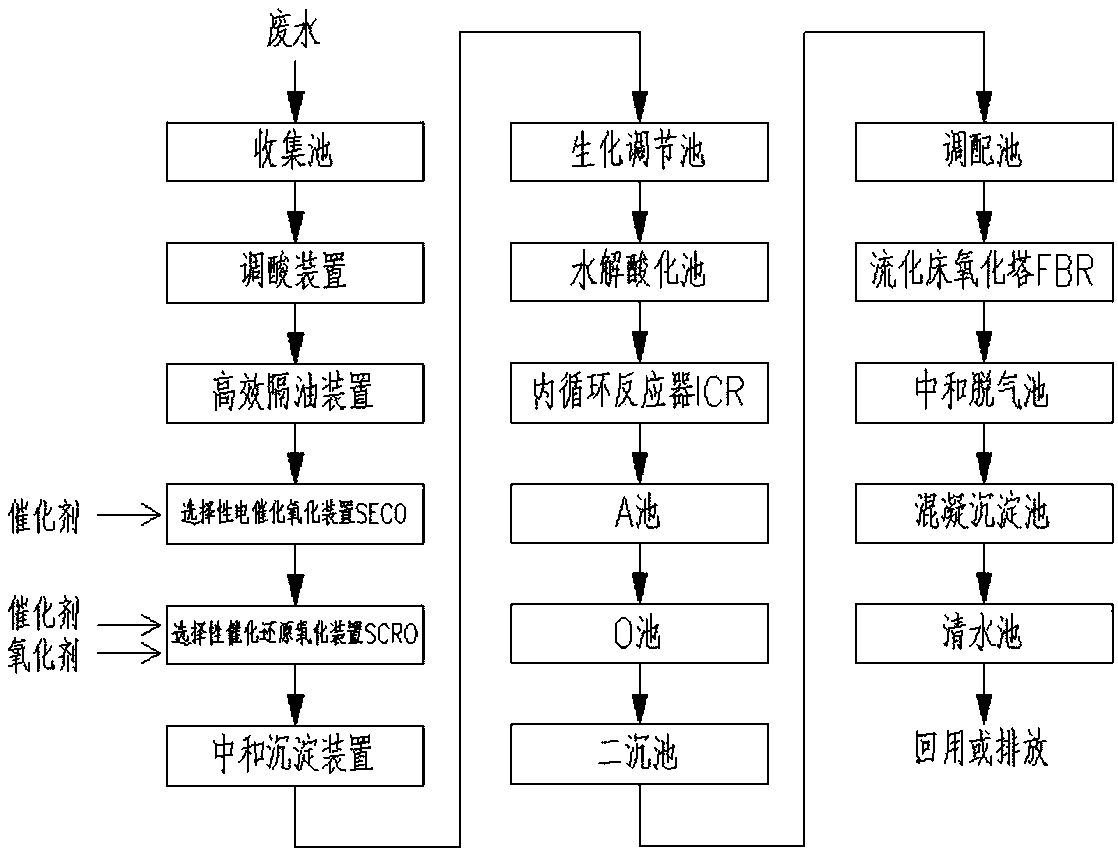

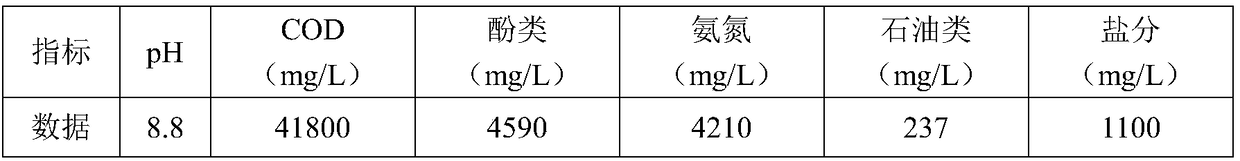

The invention relates to a device and a method for treating high concentration refractory organic wastewater. The device comprises a pretreatment system, a biochemical treatment system and a deep treatment system which are sequentially communicated with each other by means of pipelines; the pretreatment system comprises a collection tank, an acid adjustment device, a high-efficiency oil separationdevice, a selective electrocatalytic oxidation device (SECO), a selective catalytic reduction oxidation reactor (SCRO) and a neutralization and sedimentation tank which are sequentially communicatedwith each other, wherein the selective catalytic reduction oxidation reactor (SCRO) comprises a selective catalytic reduction device (SCR) and a selective catalytic oxidation device (SCO), and the selective catalytic reduction device (SCR) and the selective catalytic oxidation device (SCO) are sequentially independent of each other and are communicated with each other; the biochemical treatment system comprises a biochemical regulation tank, a hydrolysis and acidification pool, an internal circulation reactor (ICR), an anoxic tank, an aerobic tank and a secondary settling tank which are sequentially communicated with each other; the deep treatment system comprises a blending pool, a fluidized bed oxidation tower, a neutralization degassing tank, a coagulative precipitation tank and a clearwater tank which are sequentially communicated with each other.

Owner:南京科莱恩环境工程有限公司

Energy-saving tower-type internal circulation reactor

PendingCN110372097ASmall footprintAvoid wastingTreatment with aerobic and anaerobic processesSustainable biological treatmentBiochemical engineeringWater quality

The invention discloses an energy-saving tower-type internal circulation reactor. The energy-saving tower-type internal circulation reactor comprise an inner tower, an outer tower, an entering water distribution pipe and a water producing pipe, the inner tower is arranged in the outer tower, an inner overflow weir is arranged at the top end of the side wall of the inner tower, a cofferdam ring isfixedly connected to the outside of the inner overflow weir, an outer overflow weir is arranged on the side wall, away from the inner tower, of the cofferdam ring, the height of the outer overflow weir is smaller than the height of the inner outer overflow weir, a membrane bio-reactor (MBR) membrane reaction unit is arranged at the upper end in the inner tower, a channel is formed in the lower endin the inner tower, an aerator is arranged in the channel, the aerator is located under the MBR membrane reaction unit, an aerobiotic biological membrane reaction area, an anoxic and anaerobic biological membrane reaction area and a mud sump area are arranged between the outer tower and the inner tower, the aerobiotic biological membrane reaction area is filled with aerobiotic biological fillers,and the anoxic and anaerobic biological membrane reaction area is filled with an anoxic and anaerobic biological filler. According to the energy-saving tower-type internal circulation reactor, underthe premise of ensuring that the water quality of produced water reaches the standard and is stable, operation energy consumption can be significantly reduced, and the construction land is saved.

Owner:桂润环境科技股份有限公司

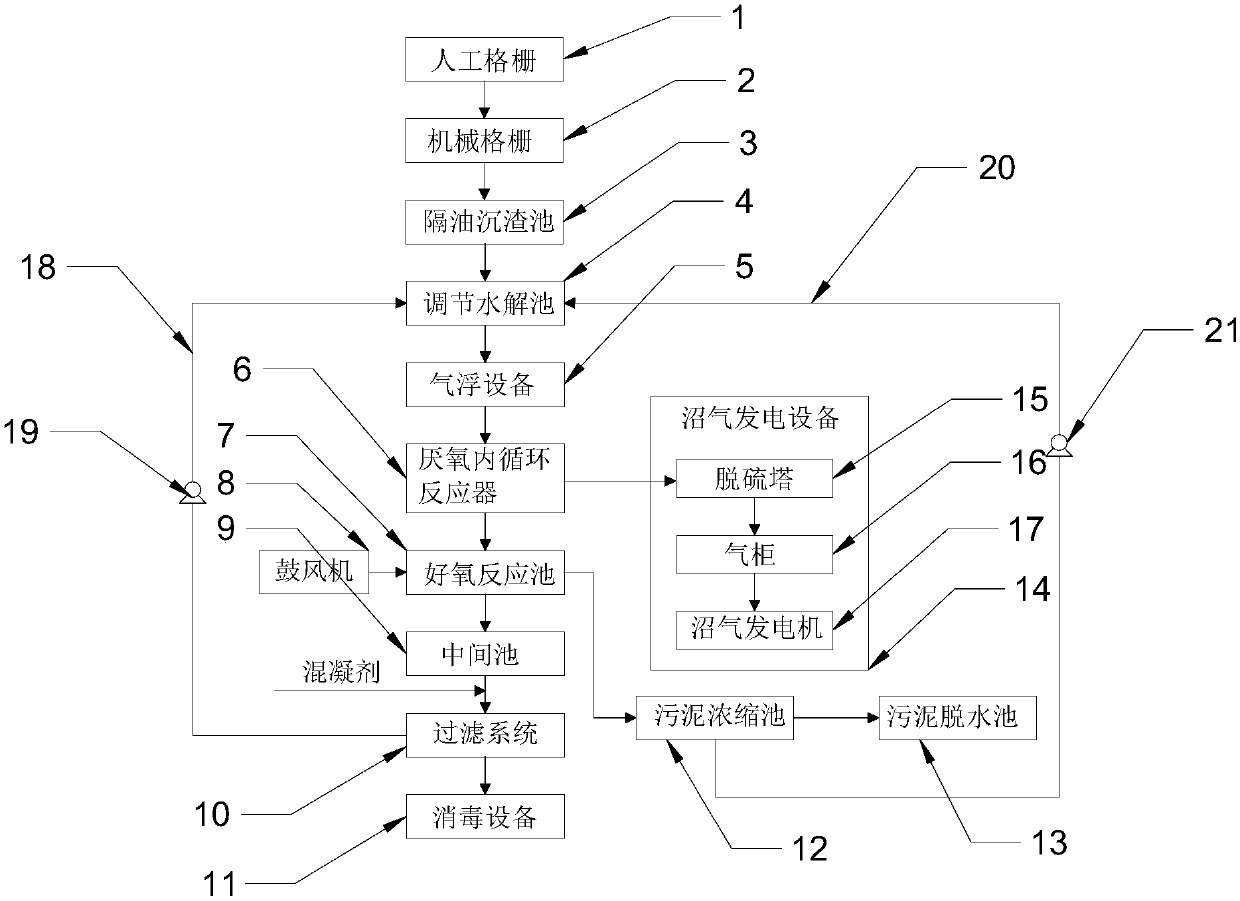

Domestic sewage treatment system

InactiveCN107777824AEasy to cleanSimple structureTreatment using aerobic processesInternal combustion piston enginesFiltrationElectric control

The invention discloses a domestic sewage treatment system. The system comprises an artificial grill a mechanical grill, an oil-separation and sedimentation tank, a regulation and hydrolysis tank, anair floatation device, an anaerobic internal circulation reactor, an aerobic reaction tank, an intermediate tank, a filtration system, a disinfection device, a sludge thickening tank and a biogas power generation device, the input end of the aerobic reaction tank is connected with a blower, the output end of the aerobic reaction tank is connected with a sludge dewatering tank through the sludge thickening tank, the biogas power generation device includes a desulfurization tower, a gas cabinet and a biogas power generator, and the output end of the anaerobic internal circulation reactor is sequentially connected with the biogas power generator through the desulfurization tower and the gas cabinet. The domestic sewage treatment system has the advantages of simple structure, easiness in use,and realization of good purification of slaughter wastewater; and biogas produced by the anaerobic internal circulation reactor generates power after passing through the desulfurization tower, the gascabinet and the biogas power generator in order to generate a large amount of electric energy, and an electric control system powers the electric devices of the domestic sewage treatment system in order to produce significant economic benefits while treating the wastewater.

Owner:云南云创数字生态科技有限公司

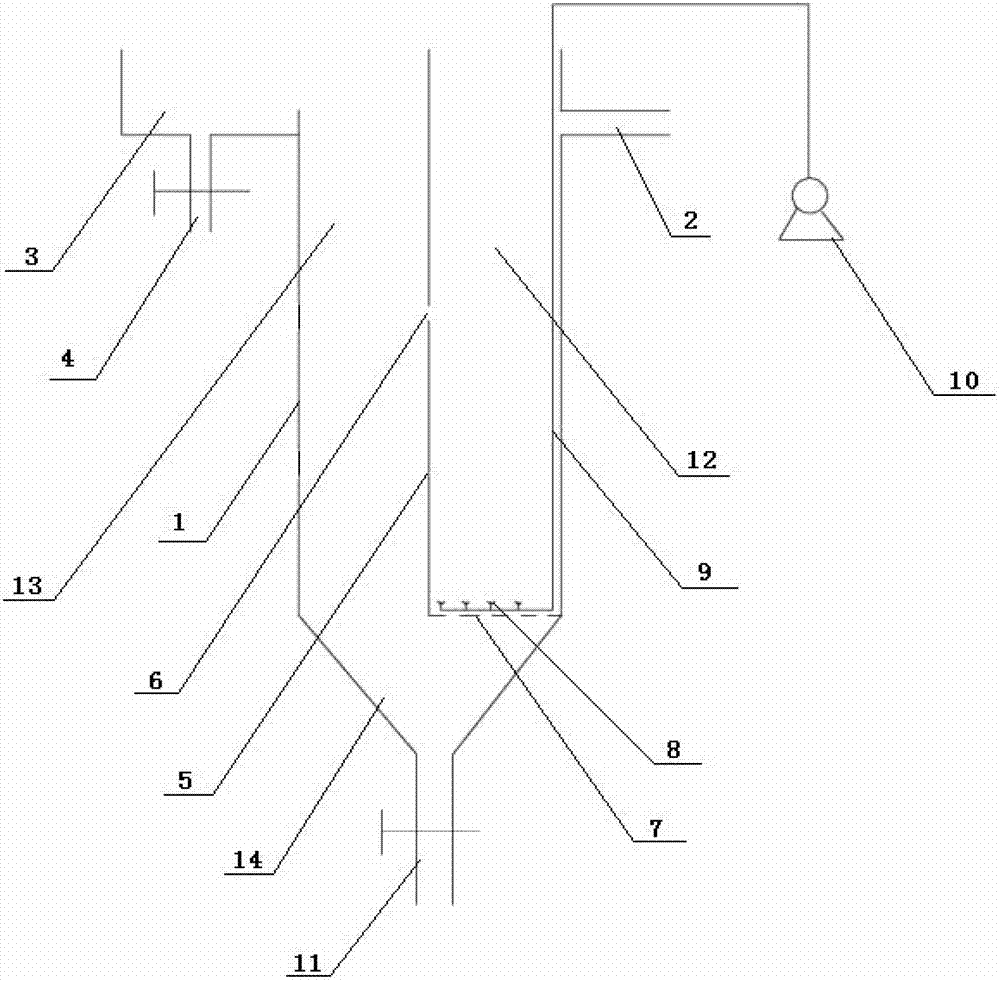

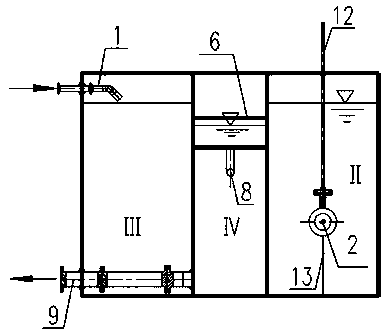

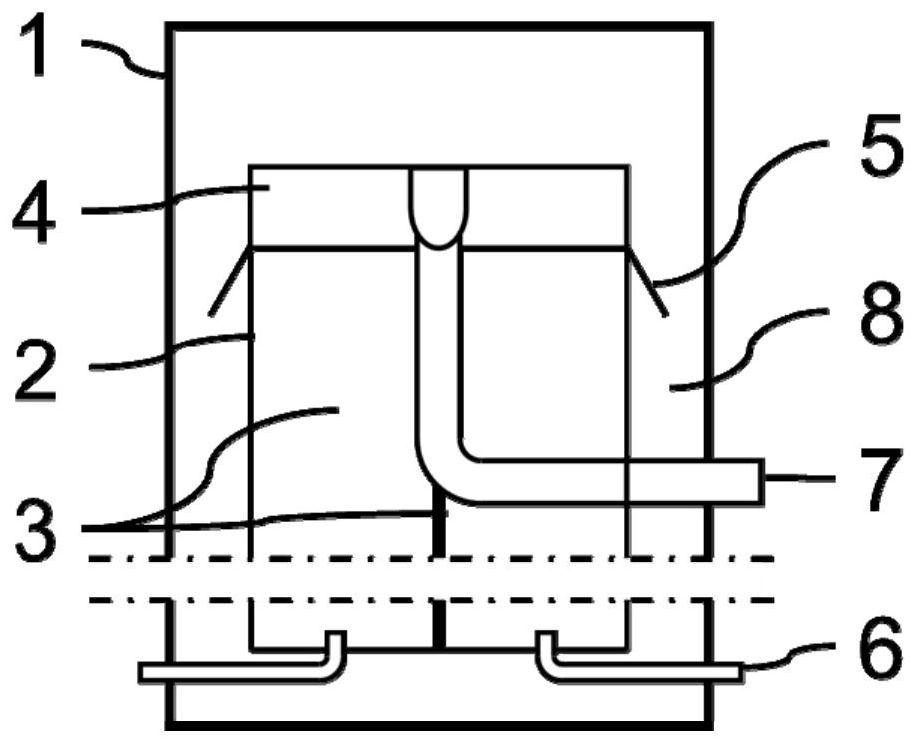

Negative-pressure internal circulation reactor and method for treating sewage by utilizing reactor

InactiveCN102923858AStable in natureEasy to adjustTreatment with aerobic and anaerobic processesInternal circulation reactorAir pump

The invention relates to a negative-pressure internal circulation reactor and a method for treating sewage by utilizing the reactor, which solves the problems of poor low-temperature operation effect, complex operation management and high cost when the sewage of a small town in a cold region is treated in the prior art. The negative-pressure internal circulation reactor comprises a tank body, a water feeding pipe, a water discharge weir, a water discharging pipe, a vertical partition plate, a communication hole, a transverse partition plate, an aerating device, pipes, an air pump and a mud discharging opening. The method for treating the sewage by utilizing the reactor comprises the following steps: 1, the sewage firstly enters a hydrolysis acidification reaction device, and discharged water enters an aerating region of a low-temperature sewage treatment device through a water discharging pipe to form muddy water mixture; and 2, the muddy water mixture enters a sediment region so that mud and water are separated, the mud is precipitated in a mud concentration region and is refluxed into the aerating region through a hole of the transverse partition plate under negative pressure generated in an aeration process, the residue mud is discharged from the mud discharging opening, and supernatant is discharged from the water discharging pipe so that above process is circulated, and continuous operation is carried out. The negative-pressure internal circulation reactor and the method for treating the sewage by utilizing the reactor, disclosed by the invention, are applied to the sewage treatment field.

Owner:HARBIN INST OF TECH

Novel high-efficiency internal circulation reactor

InactiveCN103480316AShort reaction timeRapid responseChemical/physical/physico-chemical nozzle-type rreactorsThermodynamicsInternal circulation reactor

Owner:洛阳昶威机械制造安装有限公司

Process for treating sulfamide-containing pharmaceutical wastewater

InactiveCN102976560AProcessing speedEasy to handleMultistage water/sewage treatmentSocial benefitsTreatment effect

The invention discloses a process for treating sulfamide-containing pharmaceutical wastewater. Through pretreatment, microelectrolysis, a regulating reservoir, an IC anaerobic internal circulation reactor, anoxic and aerobic treatment and a biological aerated filter, the speed and the effect of treating the sulfamide-containing pharmaceutical wastewater are improved. The process has the advantages of little investment for treating various kinds of wastewater, small occupation area, good treatment effect and low operation cost, and has remarkable economic benefit and social benefit. The process is suitable for treatment of municipal and domestic wastewater and various kinds of industrial wastewater, is also suitable for treatment of wastewater in rivers and lakes, and has a special treatment effect especially on high-difficulty organic wastewater and high-ammonia nitrogen wastewater which can not be treated by adopting the traditional method.

Owner:CHANGZHOU UNIV

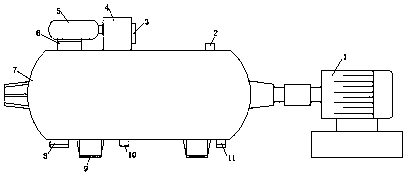

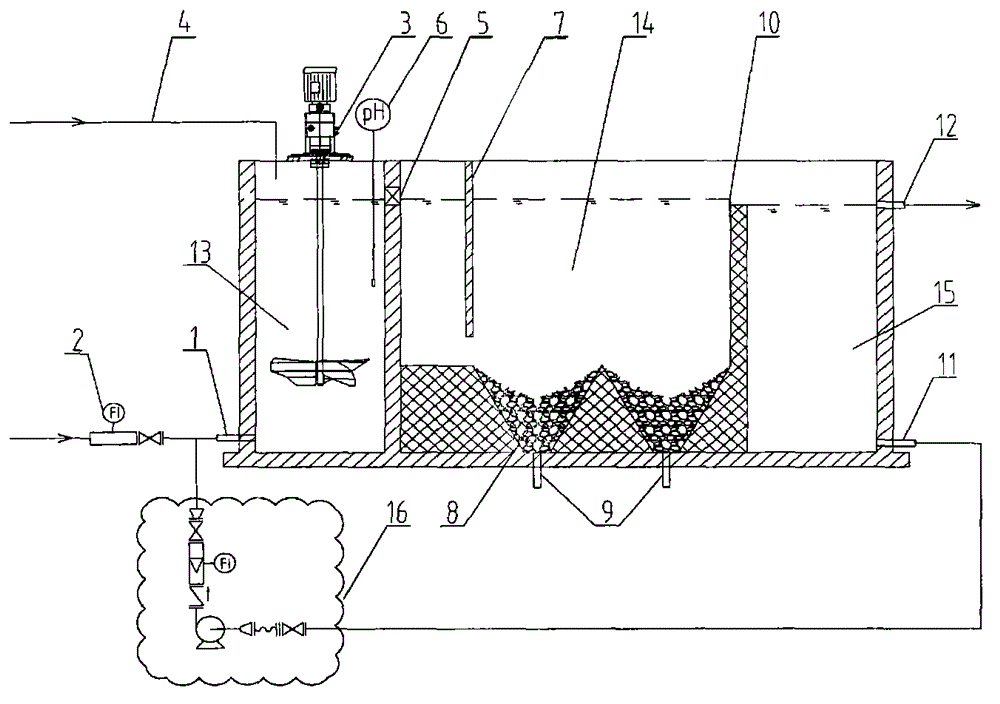

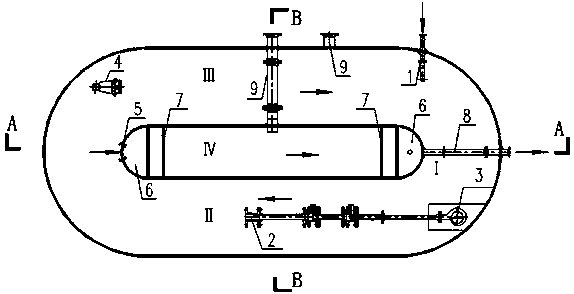

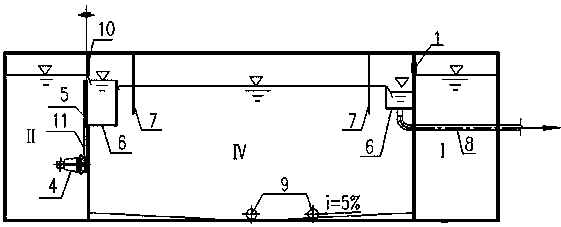

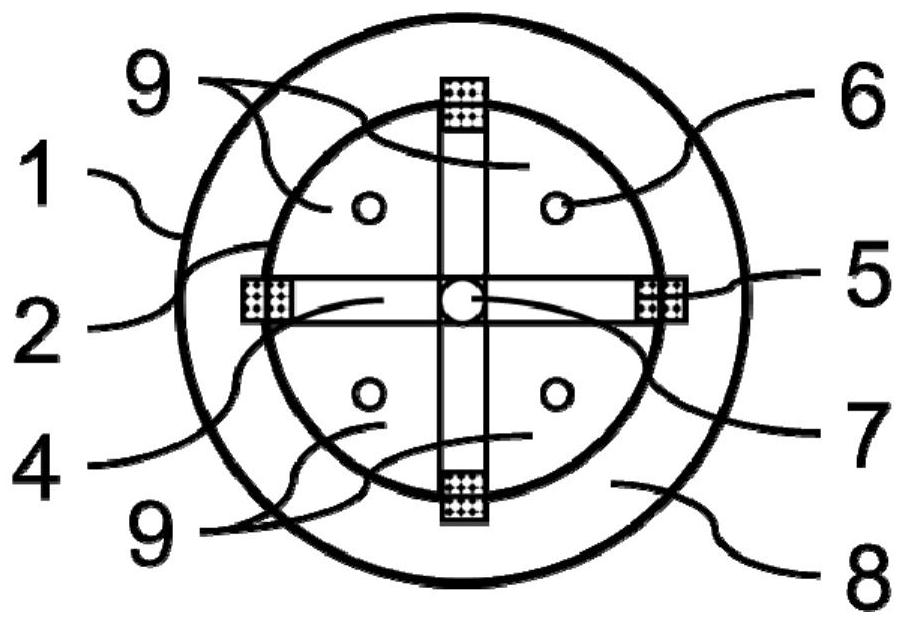

Environment-friendly horizontal internal circulation stirring reactor

PendingCN111495285AAvoid direct dischargeImprove cycle performanceDispersed particle separationChemical/physical processesThermodynamicsVapor–liquid separator

The invention discloses an environment-friendly horizontal internal circulation stirring reactor. The invention relates to the technical field of internal circulation reactors. The reactor comprises acirculating stirring reactor body, a feeding hole, two supporting seats, a heat conduction oil inlet and a discharging hole are arranged at the bottom of the circulating stirring reactor body; the two supporting seats and the heat conduction oil inlet are arranged between the feeding port and the discharging port. A stirring motor is arranged on one side of the circulating stirring reactor body;and the heat conduction oil outlet and an exhaust port are formed in the top of the circulating stirring reactor body. According to the invention, a gas-liquid separator and a peculiar smell adsorption box are arranged at the exhaust port; liquid in the gas is filtered through the gas-liquid separator, only the gas is exhausted, and a peculiar smell adsorption box adsorbs chemical peculiar smell in the gas, so that the exhausted gas is more environment-friendly, and problems that no device for treating the exhausted gas is arranged, the peculiar smell of the chemical liquid and chemicals contained in the gas is exhausted into the atmosphere, and environmental pollution is caused are solved.

Owner:POLYTEX CHEM ENG CO LTD

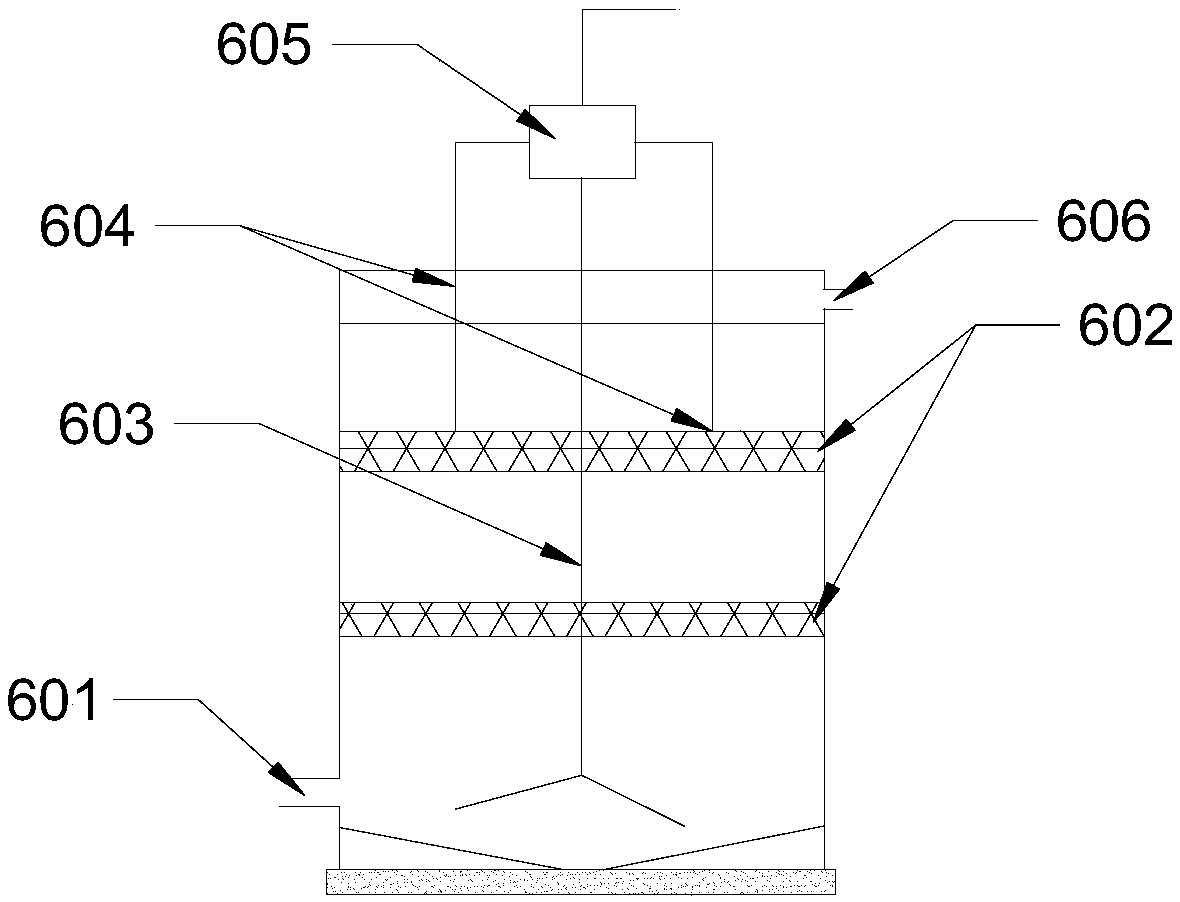

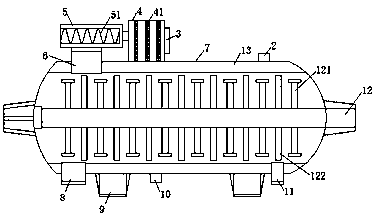

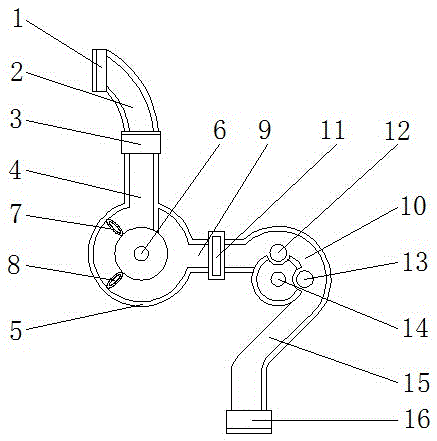

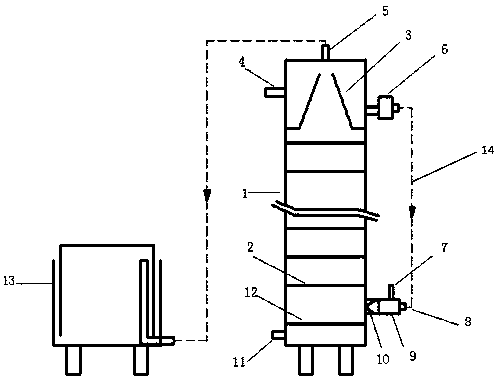

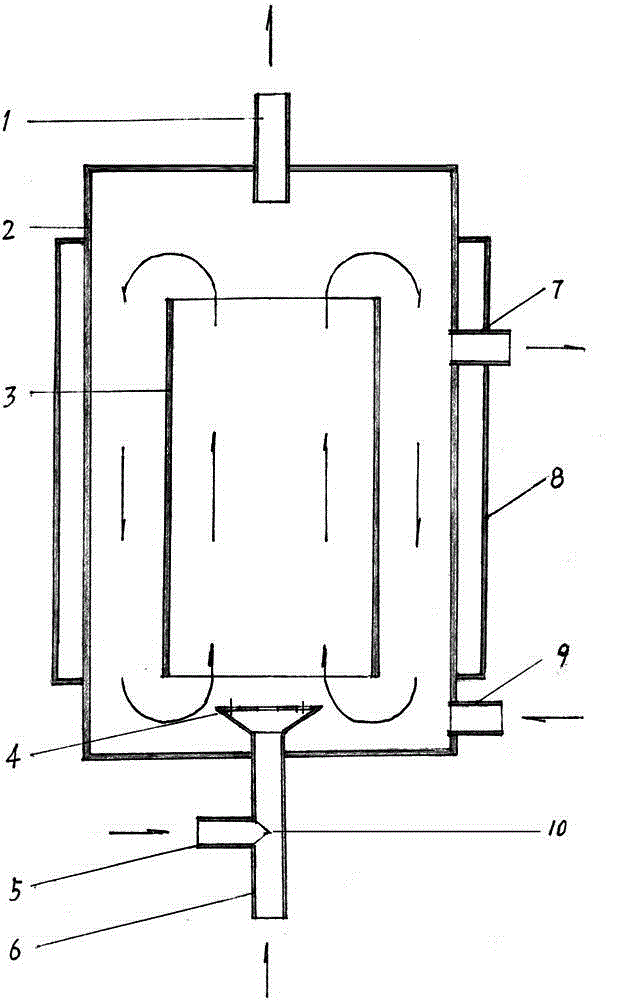

High-efficiency bioreactor capable of realizing gas-liquid atomization

ActiveCN108251286AImprove efficiencyIncrease dissolved oxygenBioreactor/fermenter combinationsBiological substance pretreatmentsHydrogenFiltration

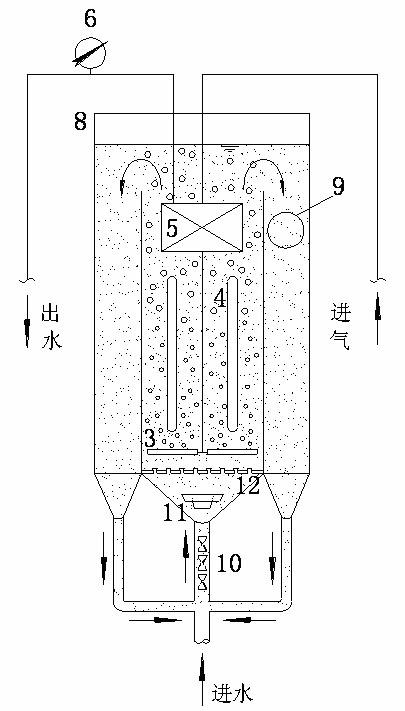

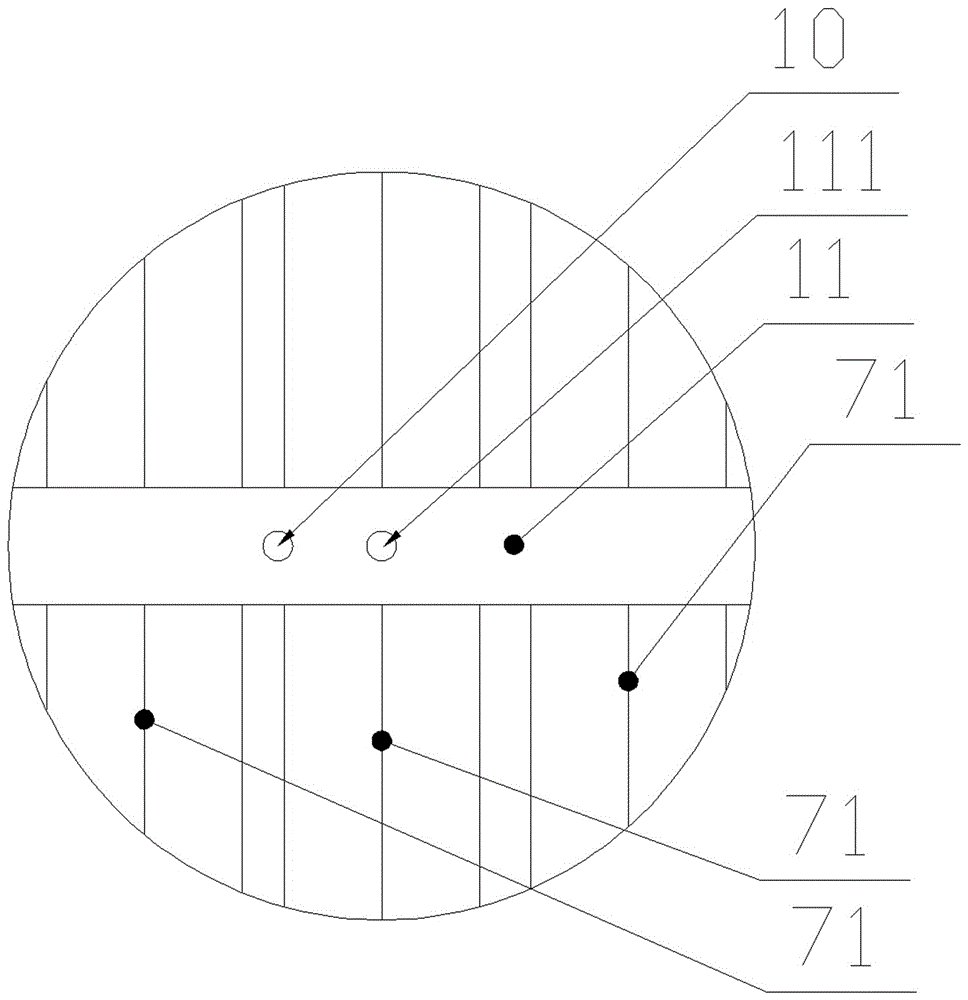

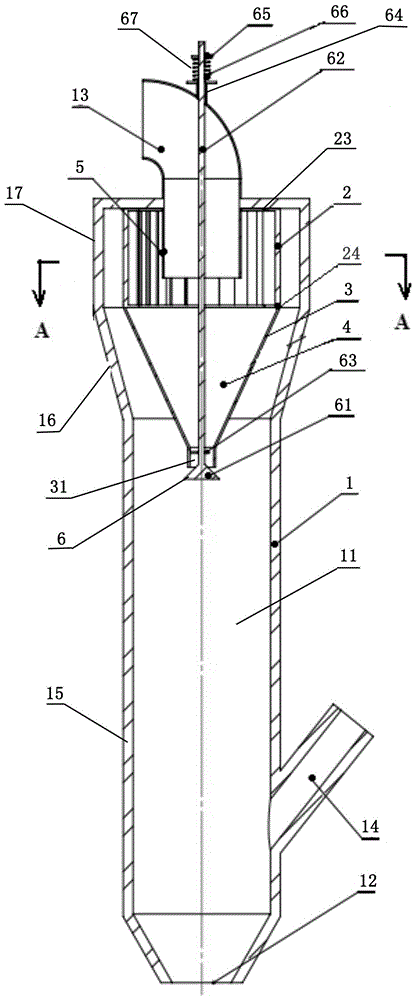

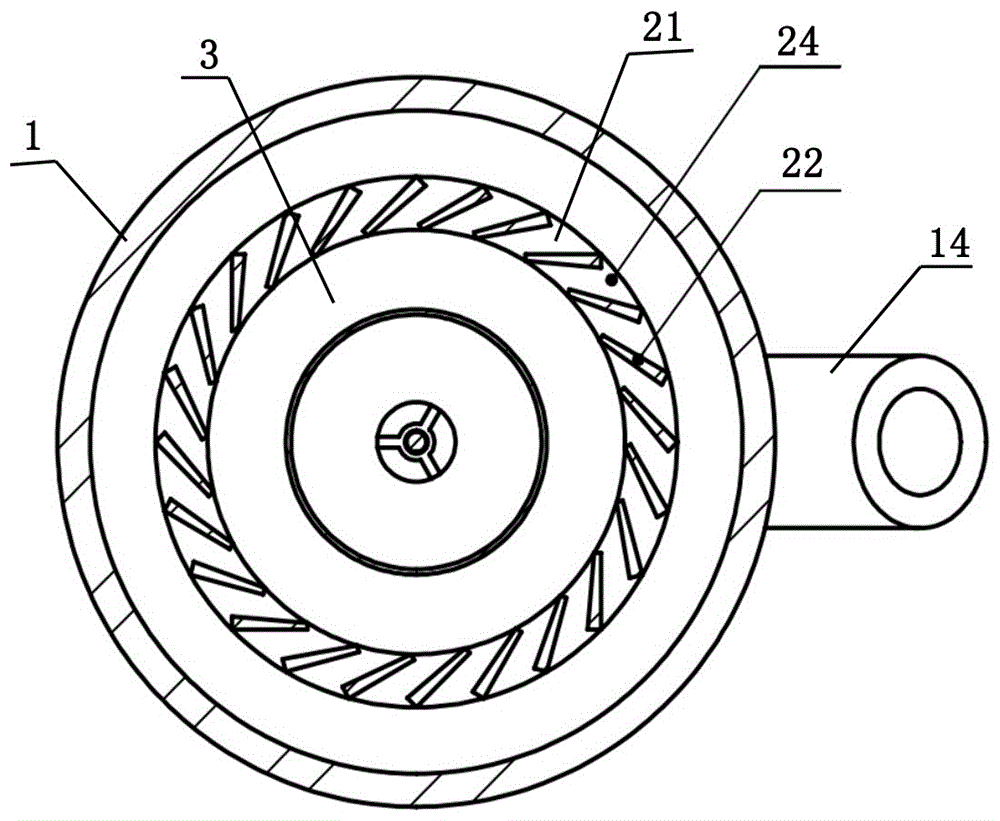

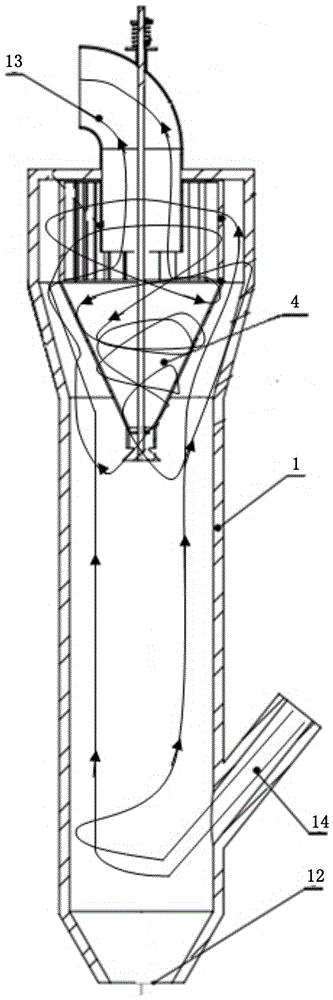

The invention discloses a high-efficiency bioreactor capable of realizing gas-liquid atomization. The high-efficiency bioreactor comprises a main bioreactor body (1), gas deflectors (2), a three-phaseseparator (3), a discharge outlet (4), a gas outlet (5), a filtration system (6), a gas inlet (7), a liquid inlet (8), a gas-liquid mixer (9), an atomization system (10), a feed inlet (11), a liquiddistributor (12), a gas cabinet (13) and an external circulation system (14). The high-efficiency bioreactor capable of realizing gas-liquid atomization mainly adopts the principles of gas-liquid mixing and atomization to realize mixing and atomization of liquid and gas; after mixing and atomization, the gas and the liquid are jetted into the bioreactor, so the liquid and the gas can more fully contact with microorganisms in the bioreactor; and thus, mass transfer effect is enhanced, and the efficiency of the bioreactor is improved. The high-efficiency bioreactor is applicable as an aerobic aeration device, a device for reducing carbon dioxide with hydrogen, an airlift bioreactor, an expanded granular sludge bed reactor, an internal circulation reactor, a gas-stirring fully-mixing reactor,and the like.

Owner:YUNNAN NORMAL UNIV

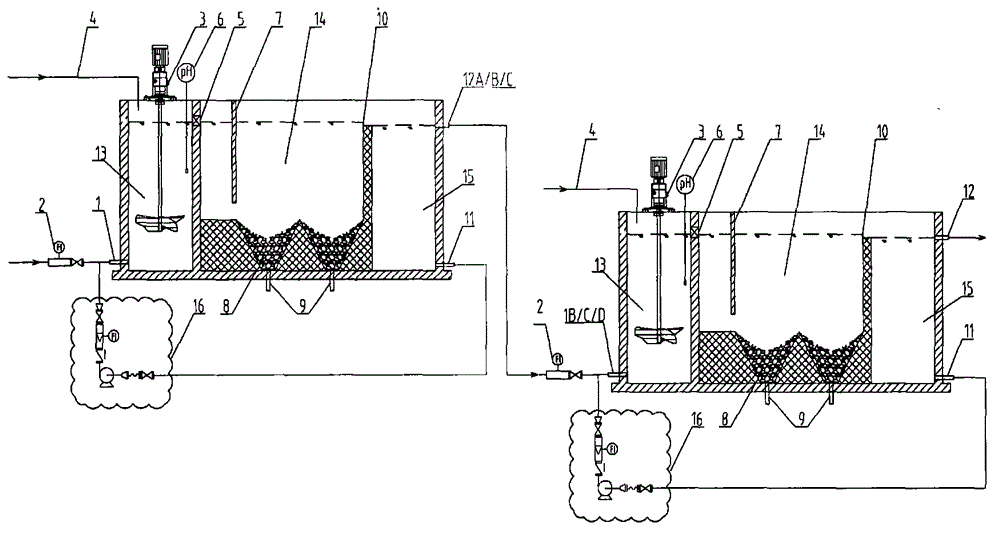

Pretreatment method for step-by-step demulsification and flocculation of DMTO catalyst centrifugal mother liquid through integrated internal-circulation reactor

InactiveCN104529010ANecessary condition for eliminating reaction reversionAdequate responseMultistage water/sewage treatmentNature of treatment waterFlocculationPretreatment method

The invention discloses a pretreatment method for step-by-step demulsification and flocculation of DMTO catalyst centrifugal mother liquid through an integrated internal-circulation reactor and relates to industrial sewage pretreatment methods. The pretreatment method aims to solve the technical problems that when an existing demulsification method is used for treating the DMTO catalyst centrifugal mother liquid, existing aluminium phosphate gel, sarciniform silicon aluminium phosphate gel (Al2O3-P2O5-SiO2-H2O) and other colloids are not dissolved out thoroughly, and in the flocculation treatment process, reaction re-dissolution happens, phosphate and aluminium gel is regenerated again, and the subsequent treatment process is disturbed. An integrated internal-circulation reactor system is composed of a reaction tank, a variable speed blender, a settling pond, an outflow water relay pond and an internal circulation backflow system. After the centrifugal mother liquid is treated step by step according to the order of pre-demulsification, demulsification, primary flocculation and secondary flocculation, COD is lowered by 70-90 percent, the sludge density index SDI15 of hydrocolloids is lower than four, and advanced treatment of recycling units is benefited. The method can be applied to pretreatment of other industrial sewage.

Owner:马同奎 +2

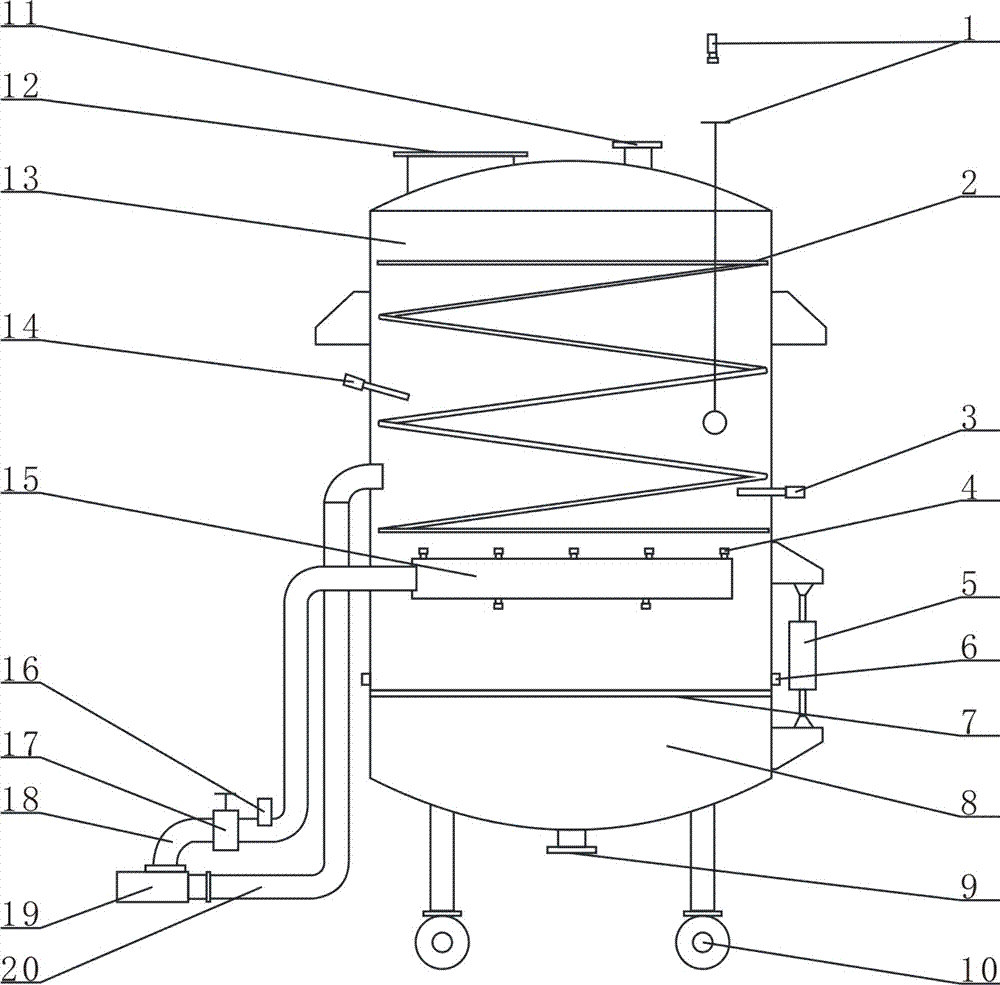

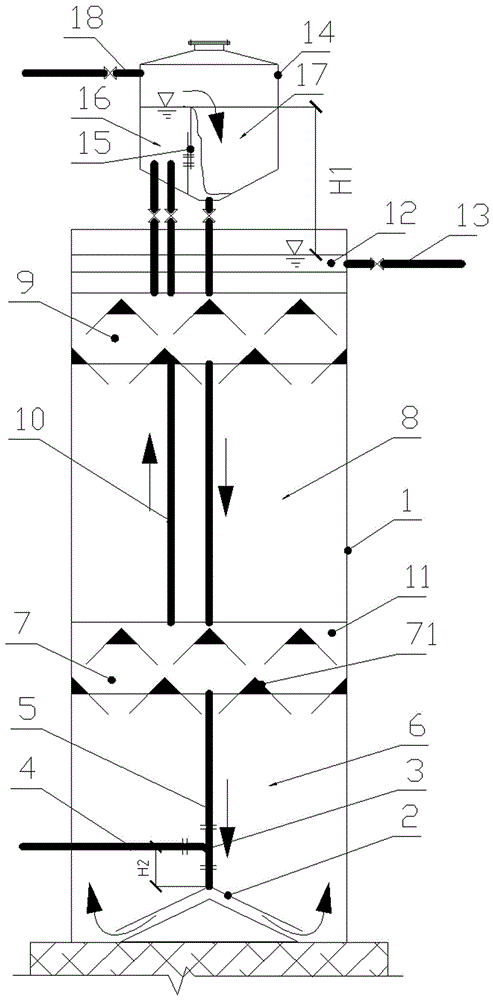

Anaerobic internal circulation reactor

InactiveCN106396095APowerfulNot paralyzedBiological treatment apparatusWaste based fuelInternal circulation reactorEngineering

The invention relates to an anaerobic internal circulation reactor. The anaerobic internal circulation reactor comprises a reactor barrel and a gas-water separating box positioned at the top end of the barrel. A first reaction region and a second reaction region are arranged in the reactor barrel from bottom to top. A flow guide device is arranged at the bottom of the first reaction region, an upstream end of the flow guide device communicates with a water feeding tube and a downcomer, and a downstream end of the flow guide device communicates with the first reaction region in the reactor barrel. The gas-water separating box at the top end of the reactor barrel is divided into a mixed liquid ascending region and a mixed liquid descending region by a height-adjustable overflow weir plate; the bottom of the mixed liquid descending region communicates with the upstream end of the flow guide device through the downcomer; and the mixed liquid ascending region of the gas-water separating box is respectively connected with a gas collecting groove ascending tube of a first three-phase separator on the upper part of the first reaction region and a gas collecting groove ascending tube of a second three-phase separator on the upper part of the second reaction region. An internal circulation system is good in adjustability, and the reactor is high in running stability.

Owner:胡明成

An internal circulation reactor

ActiveCN104654785BControl circulation volumeAdjust the air leakage rateFluidised-bed furnacesAcute angleGranularity

The invention discloses an internal circulation type reacting furnace. The internal circulation type reacting furnace comprises a furnace body with a furnace chamber, wherein a reacting furnace outlet pipe is arranged at the top of the furnace body; an internal circulation component is arranged on the upper part in the furnace chamber and comprises a guide inner cylinder, an air guide cylinder, an inverted conical cylinder connected to the bottom of the air guide cylinder, and a valve component; an internal circulation chamber is formed between the air guide cylinder and the inverted conical cylinder; a plurality of air guide passages used for guiding materials in the furnace chamber into the internal circulation chamber are arranged on the side wall of the air guide cylinder; the plurality of air guide passages are uniformly arranged around the axial line of the air guide cylinder at intervals; the included angle between the direction in which each air guide passage guides materials into the internal circulation chamber and the tangential line, at the corresponding air guide passage, of the air guide cylinder is an acute angle; a communicating opening communicating the furnace chamber to the internal circulation chamber is formed in the bottom of the inverted conical cylinder; the valve component is used for controlling the size of the communicating opening. The internal circulation type reacting furnace has the advantages that reaction temperature can be reduced, the energy-saving effect is better, the time required by complete reaction of materials with different granularity can be satisfied, the reaction degree is relatively controllable, and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

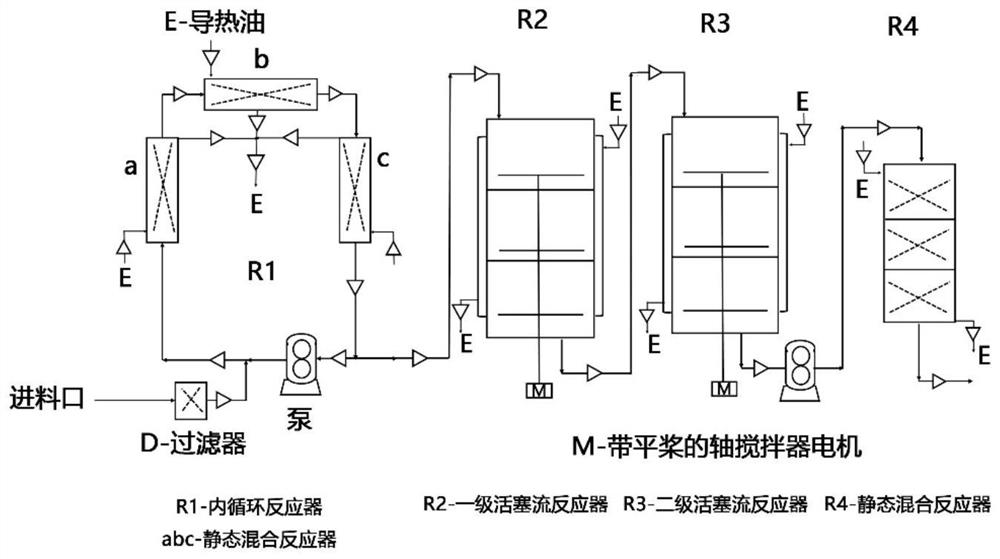

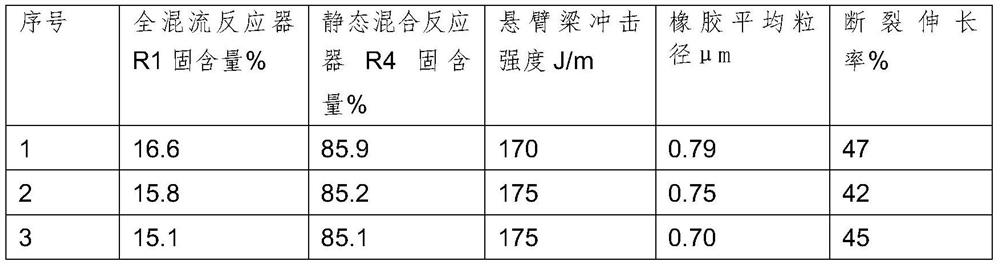

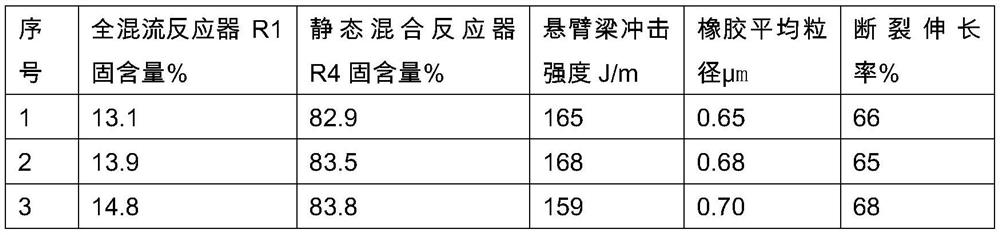

HIPS (High Impact Polystyrene) resin production process system containing internal circulation device and high-performance HIPS resin preparation method

ActiveCN114870750AImprove stabilityReduce energy consumptionChemical industryPressure vessels for chemical processPolymer scienceInternal circulation reactor

The invention belongs to the technical field of high polymer materials, and particularly relates to an HIPS (High Impact Polystyrene) resin production process system containing an internal circulation device and a body preparation method. The system comprises an internal circulation reactor, a piston flow reactor and a static mixing reactor which are sequentially connected in series through pipelines, the internal circulation reactor consists of three static mixers which are sequentially connected in series; the number of the piston flow reactors is two. The problems of poor operation stability, high energy consumption, wide molecular weight distribution of rubber particles, poor dispersibility and the like in the prior art are effectively solved, the rubber particles with small sizes and unreacted monomers are pumped back into the system by the internal circulation reactor to continue to react, the rubber grafting rate and the monomer conversion rate are improved, the product quality is stabilized, and the production cost is reduced. The improved device is stable in operation and low in energy consumption, the prepared HIPS resin product has the characteristics of narrow molecular weight distribution of rubber particles, uniform dispersion and high impact strength, the industrial production prospect is good, and the economic benefit is remarkable.

Owner:DALIAN UNIV OF TECH

A chemical sewage treatment device with ozone sterilization and harmful gas treatment

InactiveCN106809981AQuick filterThe filtering effect is thoroughMultistage water/sewage treatmentInternal circulation reactorSewage

The invention discloses a chemical sewage treatment device with ozone sterilizing and harmful gas treatment, which comprises a chemical sewage inlet, a sewage connecting pipe, a water volume control valve, a water inlet pipe, a sewage filtering device, a first rotator, a first filter, a second Second filter, sewage transition pipe, ozone sterilizing device, sewage detector, internal circulation reactor, ozone generator, second rotator, water outlet pipe and water outlet pipe interface, the water inlet pipe is connected with the sewage filter device, the The right side of the sewage filtering device is connected to the ozone sterilizing device through the sewage transition pipe, and the inner circulation reactor and the ozone generator are installed in the ozone sterilizing device. The chemical sewage treatment device with ozone sterilization and harmful gas treatment has more thorough filtration and sterilization, which greatly improves the working efficiency of the device, and the filtration efficiency is higher, and the device is not only more stable in structure, not easy to damage, and can be used for a long time. And it works more smoothly.

Owner:XIAN TIANREN SOFTWARE SCI & TECH

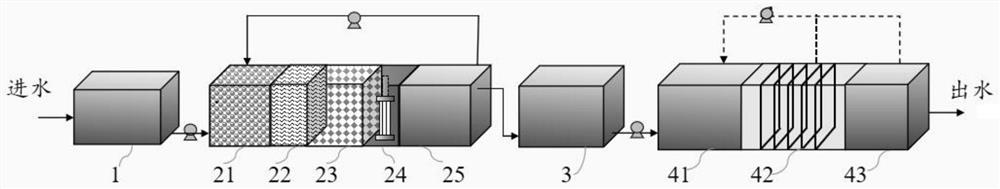

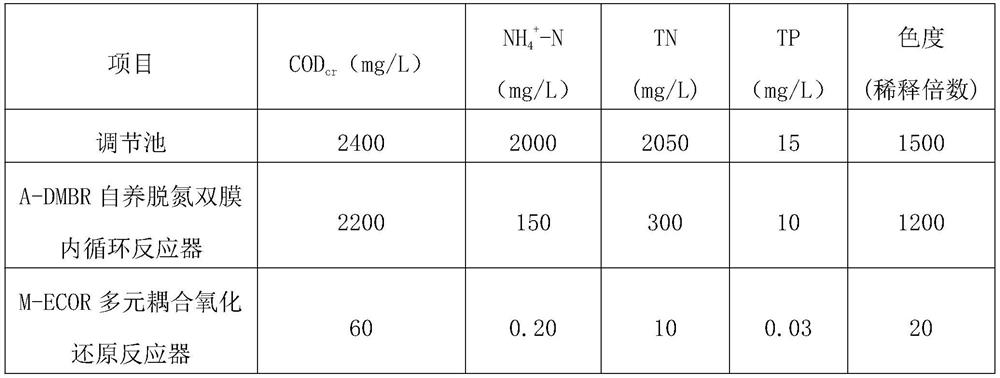

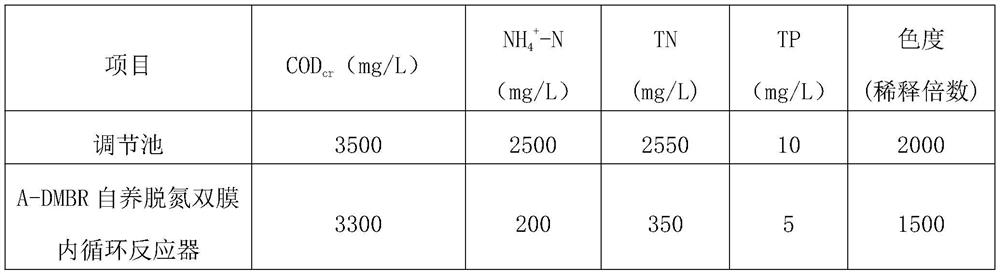

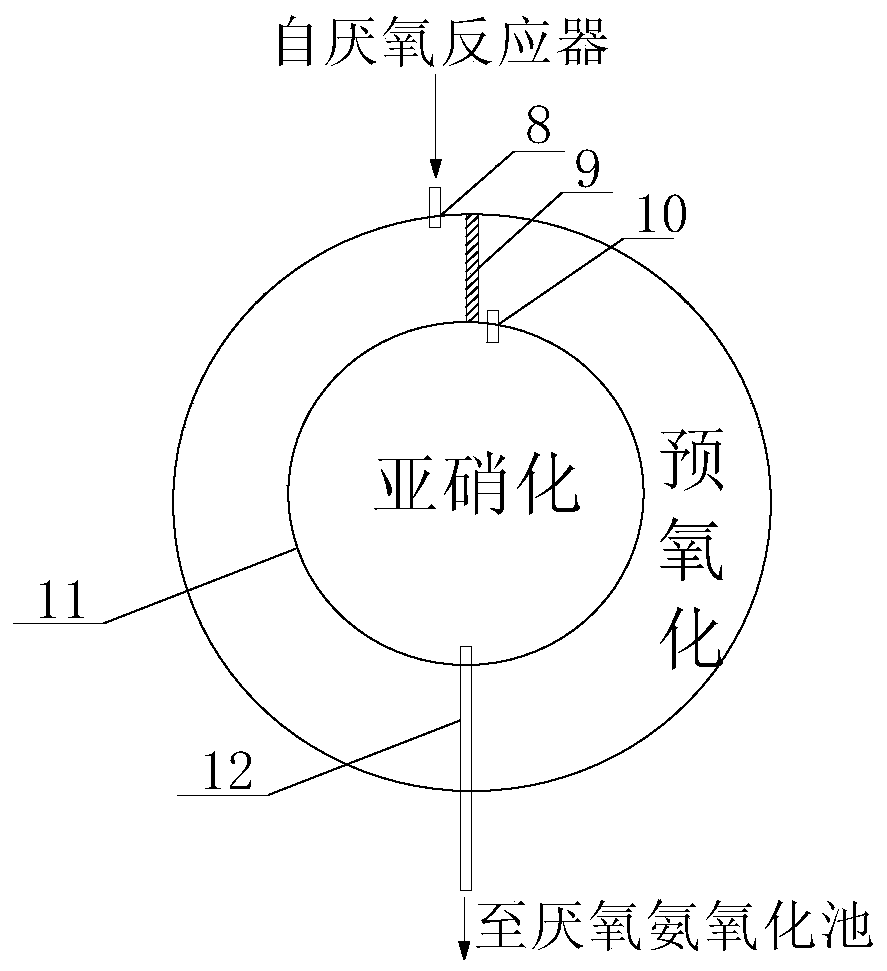

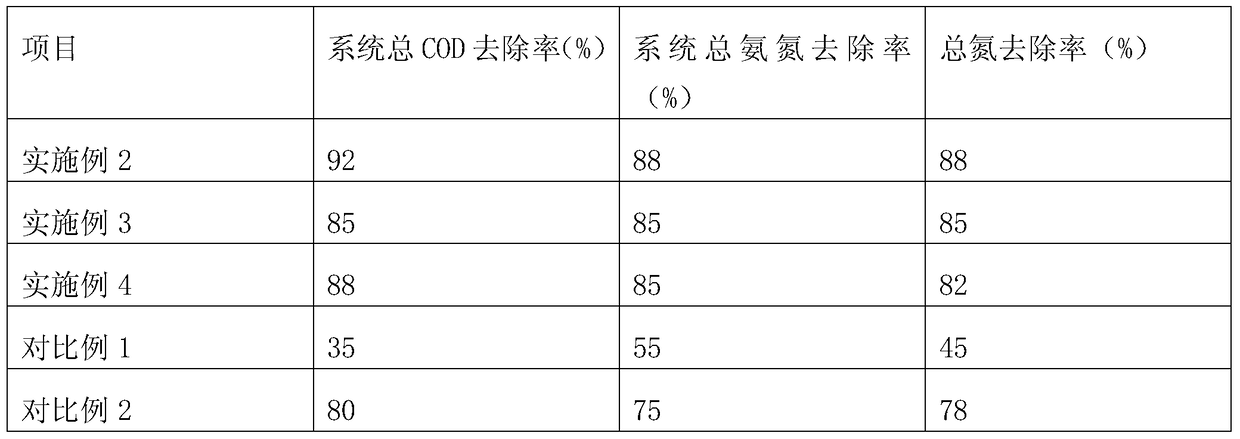

Autotrophic nitrogen removal and full quantification treatment device and method for high-salt and high-ammonia-nitrogen wastewater

ActiveCN114873851ARealize full autotrophic denitrificationAchieving processing powerWater treatment parameter controlTreatment by combined electrochemical biological processesAmmoniacal nitrogenNitrogen removal

Owner:桂润环境科技股份有限公司

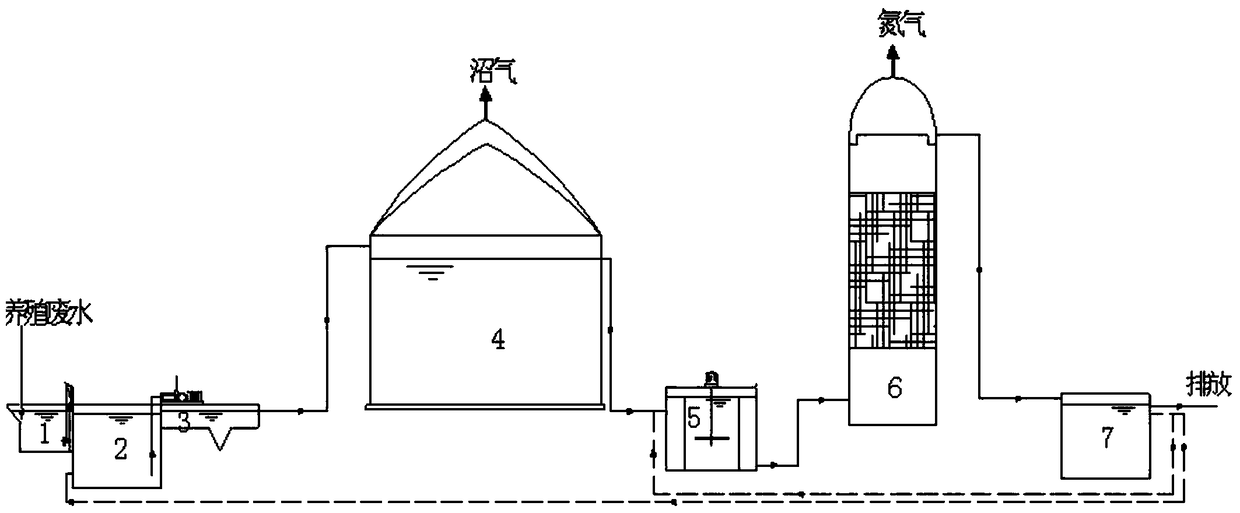

A kind of high-efficiency degradation and denitrification treatment system and treatment method of aquaculture wastewater

ActiveCN105601025BGood effectImprove degradation efficiencyMultistage water/sewage treatmentHigh concentrationAnaerobic reactor

The invention relates to a treatment system and treatment method for high-efficiency degradation and denitrification of aquaculture wastewater, including a regulating tank, a grit chamber, a feeding tank, an anaerobic reactor, a pre-oxidation-nitrosation integrated tank, and anaerobic ammonium oxidation Reactor and effluent reflux pool, the anaerobic reactor is an anaerobic internal circulation reactor, the waste water flows through the outer ring pool cavity and then enters the inner ring pool cavity, and the anaerobic ammonium oxidation reactor is an upflow anaerobic reactor Oxygen packing tower, aquaculture wastewater undergoes purification reactions through the above structures in sequence, and undergoes hydrolysis, sand removal, anaerobic, nitrosation, anaerobic ammonia oxidation and other reactions respectively. After multi-stage degradation treatment, harmful pollutants in wastewater can be efficiently removed. The present invention combines the anaerobic process and the anaerobic ammonium oxidation process, firstly removes COD through anaerobic process, and then denitrifies through the anaerobic ammonium oxidation process, so as to realize efficient removal of high-concentration pollution components in aquaculture wastewater, and the process is easy to operate and stable in operation.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

Jet membrane method internal circulation reactor and sewage treatment method thereof

PendingCN109970197ATo achieve the purpose of biological phosphorus removalShort processTreatment with aerobic and anaerobic processesSustainable biological treatmentMembrane methodTreatment effect

The invention discloses a jet membrane method internal circulation reactor. The reactor comprises an embedded inner shell and an embedded outer shell, wherein the upper end and the lower end of the inner shell are fixed on the upper end surface and the lower end surface of the outer shell respectively; the inner shell is a precipitation zone; the outer cavity of the inner shell is provided with abiological reaction zone; the outer biological reaction zone is provided with an anaerobic zone, an aerobic zone and an anoxic zone in sequence; a jet device and an ancillary submersible pump are arranged in the aerobic zone; a plug flow device is arranged at the starting end of the anoxic zone; a water outlet of the reactor is arranged at the tail end of the aerobic zone; a water inlet pipe is arranged at the starting end of the anaerobic zone; a shutter is arranged on the inner shell corresponding to the tail end of the aerobic zone, the inner shell is internally provided with a first overflow groove corresponding to the shutter; a first baffle is arranged outside the first overflow groove, the middle part of the bottom of the inner shell is provided with a mud pipe extending to the outer part of the outer shell; a second baffle and a second overflow groove are arranged on the tail end, in the water flow, of the inner shell in sequence, the second overflow groove is communicated witha water outlet pipe extending to the outer part of the outer shell. The invention also discloses a sewage treatment method by using the reactor. The reactorhas the advantages of simple structure, lowcost, convenient operation management and stable treatment effect.

Owner:HAINAN TIANHONG MUNICIPAL DESIGN CO LTD

Environmentally-friendly chemical sewage treatment system

InactiveCN104108808AIncrease update rateIncrease contact timeMultistage water/sewage treatmentWater/sewage treatment by oxidationInternal circulation reactorSewage

The invention discloses an environmentally-friendly chemical sewage treatment system. Sewage is fed into an internal circulation reactor by a sewage treatment pipe, an ozone catalytic ozonation agent is added into the internal circulation reactor and is used for ozone catalytic ozonation, the reactor is divided into a lifting zone and a dropping zone, the liquid in the reactor can be recycled in the two zones by being pushed by gas, the mixed gas fully contacts with the reaction liquid and is dissolved in the reaction liquid in the lifting zone in a micropore aeration way, the gas and liquid drive a solid light catalyst to circulate between the two zones, after a circulation mixing reaction for 12h, the treated water is subjected to concussion treatment, and purified water is output. The environmentally-friendly chemical sewage treatment system greatly improves a replacement rate of gas and liquid on the catalyst surface. The reactor effectively improves an ozone utilization rate, improves time of contact between organic matters and ozone and improves deep treatment efficiency.

Owner:ANHUI DONGZHI GUANGXIN AGROCHEMICAL CO LTD

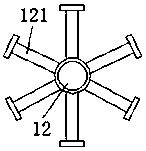

A high-efficiency bioreactor for gas-liquid atomization

ActiveCN108251286BImprove efficiencyIncrease dissolved oxygenBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismFiltration

The invention discloses a high-efficiency bioreactor capable of realizing gas-liquid atomization. The high-efficiency bioreactor comprises a main bioreactor body (1), gas deflectors (2), a three-phaseseparator (3), a discharge outlet (4), a gas outlet (5), a filtration system (6), a gas inlet (7), a liquid inlet (8), a gas-liquid mixer (9), an atomization system (10), a feed inlet (11), a liquiddistributor (12), a gas cabinet (13) and an external circulation system (14). The high-efficiency bioreactor capable of realizing gas-liquid atomization mainly adopts the principles of gas-liquid mixing and atomization to realize mixing and atomization of liquid and gas; after mixing and atomization, the gas and the liquid are jetted into the bioreactor, so the liquid and the gas can more fully contact with microorganisms in the bioreactor; and thus, mass transfer effect is enhanced, and the efficiency of the bioreactor is improved. The high-efficiency bioreactor is applicable as an aerobic aeration device, a device for reducing carbon dioxide with hydrogen, an airlift bioreactor, an expanded granular sludge bed reactor, an internal circulation reactor, a gas-stirring fully-mixing reactor,and the like.

Owner:YUNNAN NORMAL UNIV

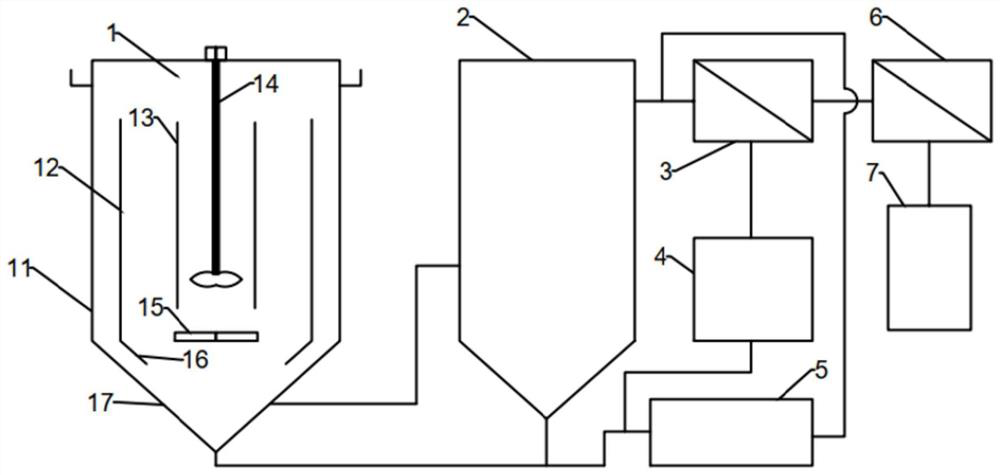

Drilling wastewater treatment system

PendingCN113415940AReduce oil contentHigh deoiling efficiencyWaste water treatment from quariesFatty/oily/floating substances removal devicesThermodynamicsWater treatment system

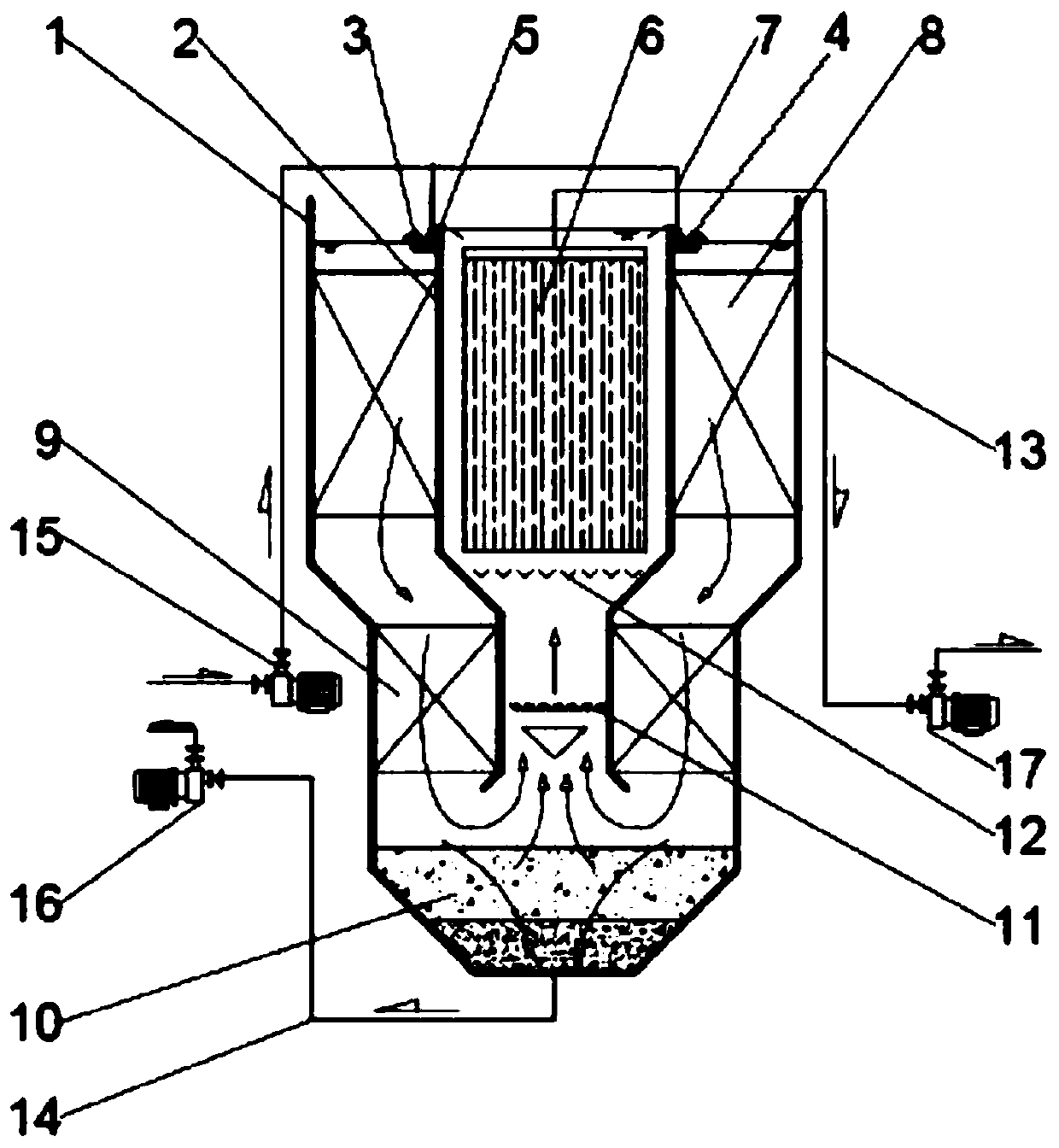

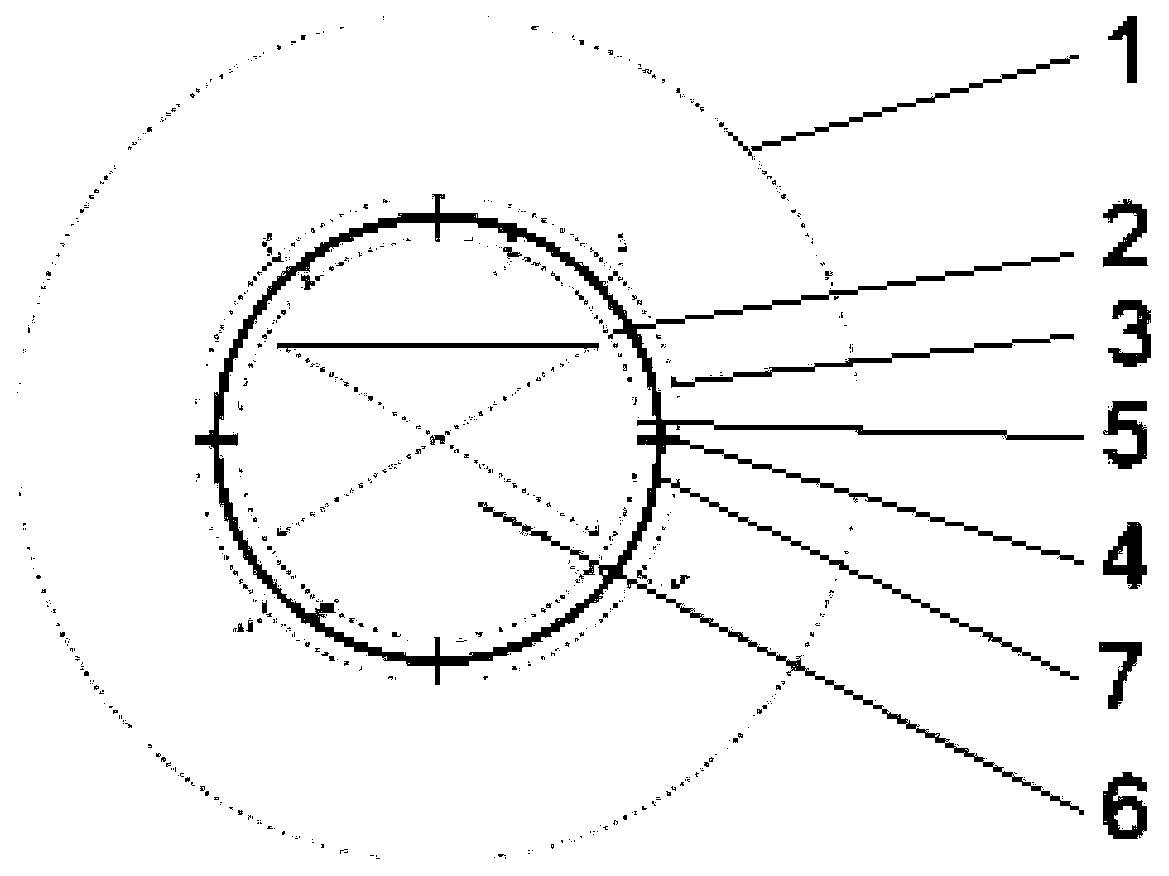

The invention relates to a drilling wastewater treatment system which comprises an internal circulation reactor (1), a sedimentation tank (2), an ultrafiltration device (3), an oxidation tank (4) and a plate-and-frame filter (5). The circulating reactor (1) comprises a shell (11), an outer cylinder (12), an inner cylinder (13), a stirring device (14), an aeration head (15), a folded plate (16) and a conical bottom (17). The shell (11) is of a barrel-shaped structure, and the bottom of the barrel-shaped structure is connected with a cone bottom (17). A drain pipe is arranged at the middle upper part of the cone bottom (17) and / or the shell (11) and is communicated with the sedimentation tank (2), and a drain pipe is arranged at the middle upper part of the sedimentation tank (2) and is communicated with the ultrafiltration device (3). A concentrated drain pipe of the ultrafiltration device (3) is communicated with the oxidation pond (4), and the oxidation pond (4) is communicated with the plate-and-frame filter (5). And a stirring device (14) is arranged on a central shaft of the cylindrical structure. The drilling wastewater treatment system can improve the deoiling efficiency.

Owner:南通固润环保科技有限公司

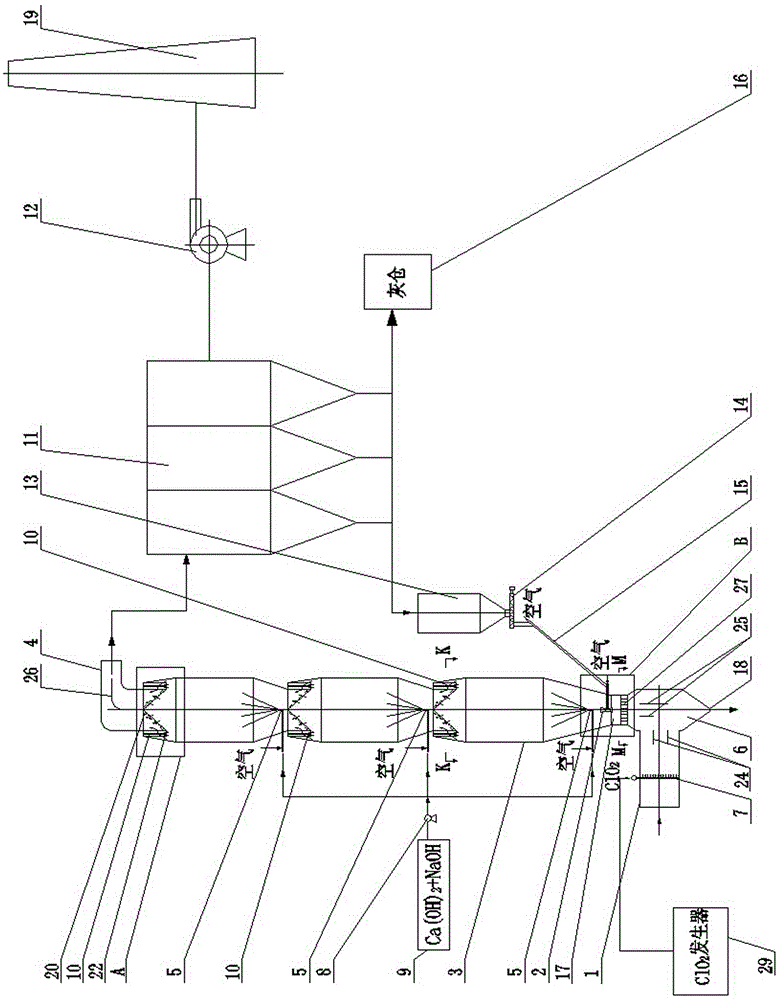

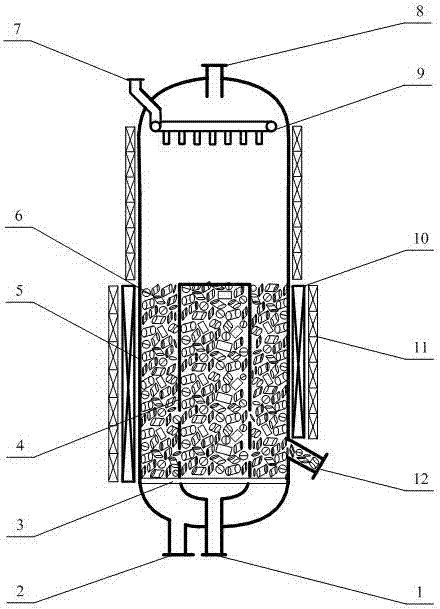

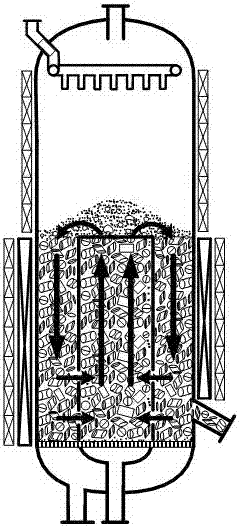

Multi-stage internal circulation semi-dry desulfurization, denitrification and mercury removal integrated device

ActiveCN104984656BSimple structureImprove reaction efficiencyDispersed particle filtrationNitrateSulfur

The invention provides a multistage internal circulation semi-dry method desulfurization, denitrification and demercuration integrated device and belongs to the field of smoke purification. The integrated device can remove sulfur, nitrate and mercury in smoke in a combined mode. A large Venturi tube is arranged at the lower portion of a first-stage internal circulation reactor, a small Venturi tube is arranged in the large Venturi tube, the large Venturi tube is communicated with an ash bucket, the ash bucket is communicated with a smoke inlet, and a ClO2 distributor is installed in the smoke inlet. A dual-alkali liquid atomizing nozzle is arranged in each stage of internal circulation reactor, each dual-alkali liquid atomizing nozzle is communicated with a container containing dual-alkali liquid through a slurry pump, a U-shaped groove separator is fixed to the top of each stage of internal circulation reactor, the Nth-stage internal circulation reactor is communicated with a smoke outlet, the smoke outlet is communicated with a bag-type dust remover, the bag-type dust remover is communicated with an induced draft fan, the bag-type dust remover is communicated with an ash storage tank and an ash bin through an ash discharge pipeline, a spiral feeder is arranged in the lower port of the ash storage tank, and an ash discharge port of the spiral feeder is communicated with the small Venturi tube through a discharge pipe. The integrated device is used for removing sulfur, nitrate and mercury in smoke.

Owner:HARBIN INST OF TECH

Internal circulation reactor and method for continuously preparing phosphorus pentafluoride

InactiveCN102976298BStable concentrationIncrease production capacityPhosphorus halides/oxyhalidesAutomatic controlInternal circulation reactor

The invention discloses an internal circulation reactor and method for continuously preparing phosphorus pentafluoride. The internal circulation reactor comprises a cylinder body with a heat exchange jacket, wherein planar end closures are arranged at the upper and lower ends of the cylinder body, and a concentric inner cylinder body is arranged in the cylinder body; the upper end closure is provided with a mixed gas leading-out pipe; the lower end closure is provided with a three-way gas intake pipe; and a reaction solution eduction pipe and a feed liquid ingress pipe are arranged on the cylinder body. The process of preparing phosphorus pentafluoride comprises the following steps: blowing the reactor with an inert gas; creating a low temperature environment of the reactor with a refrigerant; adding a phosphorous pentachloride solution, anhydrous hydrogen fluoride and the inert gas to the reactor for reaction; and continuously leading out mixed gas containing phosphorus pentafluoride and part of a low-concentration phosphorous pentachloride solution, and at the same time continuously adding a phosphorous pentachloride concentrated solution, anhydrous hydrogen fluoride and the inert gas to realize continuous operation. The internal circulation reactor and method for continuously preparing phosphorus pentafluoride have the advantages that the concentration stability of reactants in the reactor can be maintained, and continuous production and automatic control of phosphorus pentafluoride are realized.

Owner:TIANJIN LONGER NEW MATERIAL SCI & TECH

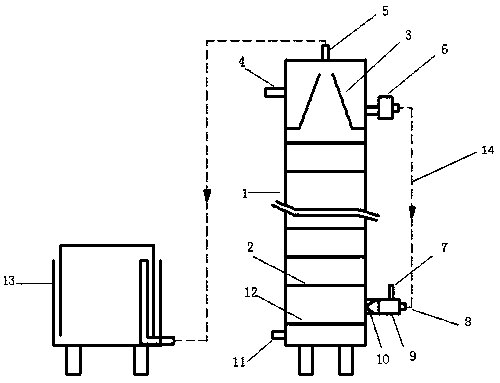

Adsorption regeneration-photocatalysis advanced oxidation water treatment equipment

InactiveCN102180556BEfficient degradationMild reaction conditionsMultistage water/sewage treatmentWater qualityUltraviolet lights

The invention relates to adsorption regeneration-photocatalysis advanced oxidation water treatment equipment, which consists of a pipeline static mixer, a water distributor, an aeration pipe, an ultraviolet light source, a membrane component, a vacuum meter, a water outlet pump, an air lift internal circulation reactor and a powder photocatalyst, wherein the aeration pipe, the ultraviolet light source and the membrane component are positioned in the air lift internal circulation reactor; the middle of the air lift internal circulation reactor is provided with an upward circulating flow channel; both sides of the air lift internal circulation reactor are provided with downward circulating pipelines; the bottom of the upward circulating flow channel is connected with the water distributor; the water distributor is connected with the pipeline static mixer; the membrane component is connected with the water outlet pipe through a hose to form a water outlet pipeline; the water outlet pipe is connected with the water outlet pump; water is sucked by the water outlet pump; the vacuum meter is connected in series to the water outlet pipeline; the bottom of each downward circulating pipeline is connected with a return pipe; the return pipe is connected to the front part of the pipeline static mixer; and the powder photocatalyst is suspended in the air lift internal circulation reactor. The water treatment equipment has the advantages of compact structure, mild reaction condition, high reaction efficiency, easiness of maintenance, high drained water quality and strong economic competition, and is suitable for treating various kinds of non-degradable organic matter waste water and hospital sewage and removing non-degradable organic matters remaining in water drained from sewage plants.

Owner:TONGJI UNIV

Multistage internal circulation reactor for chemical industry

InactiveCN105152235AReduce resistanceReduce lossesWater/sewage treatmentChemical/physical/physico-chemical processesChemical industryReflux

The invention relates to a multistage internal circulation reactor for the chemical industry and belongs to the technical field of chemical industrial equipment. The multistage internal circulation reactor for the chemical industry comprises a multistage reactor, a reaction chamber and a collector, wherein the multistage reactor is connected with a recoverer which comprises a casing and a sealing head, supporting legs are mounted at the lower end of the casing, a reflux control system is arranged on the multistage reactor, the reaction chamber is mounted at the top of the multistage reactor and directly connected with the multistage reactor, a discharge port is formed in the position, close to two side plates, of the bottom of the reaction chamber, and the collector is communicated with the reaction chamber through a connection pipe. The multistage internal circulation reactor has the benefits as follows: the pipeline is simple, pipe resistance is little, the vacuum degree of the system is high, the loss of pipes is little, operation is simple and convenient, the reaction rate is high, the effective volume of the reactor is large, a reaction can be performed more completely, and accordingly discharge of sewage is reduced.

Owner:温州联益线束胶粘带有限公司

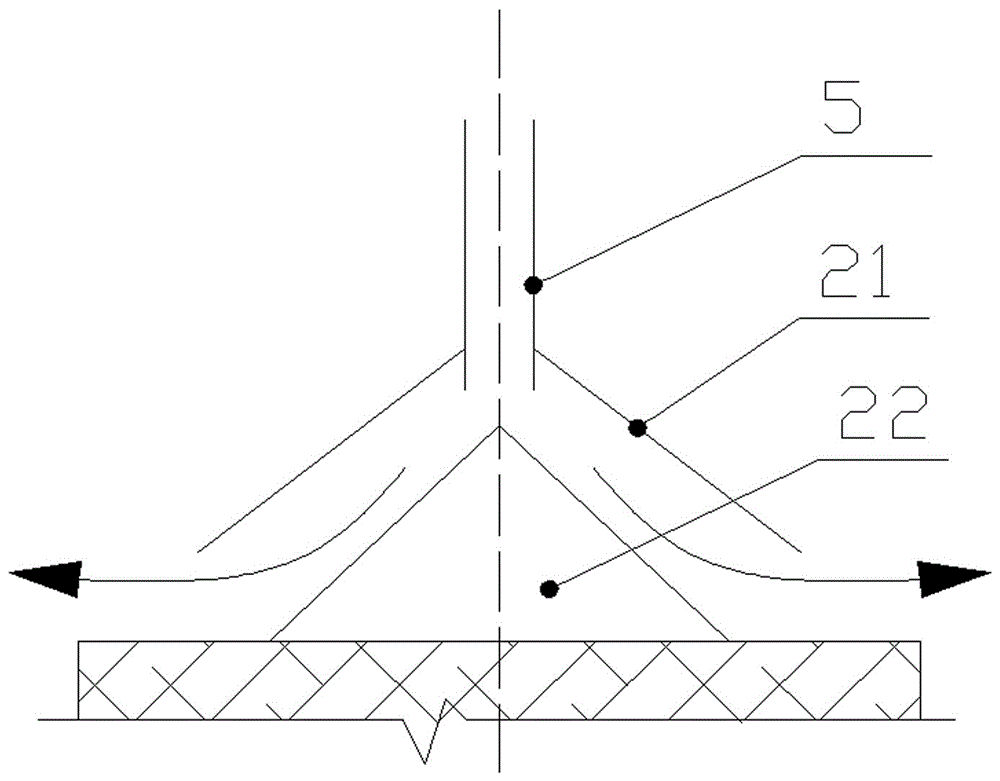

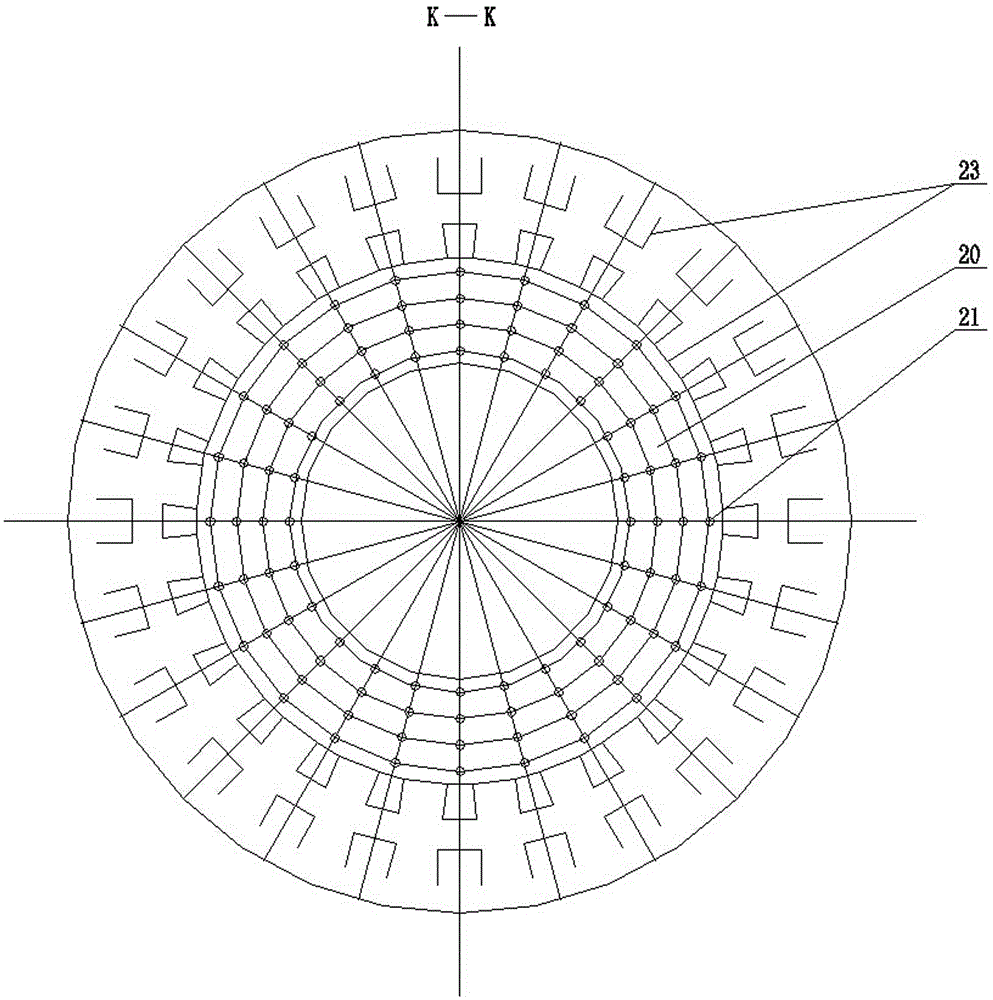

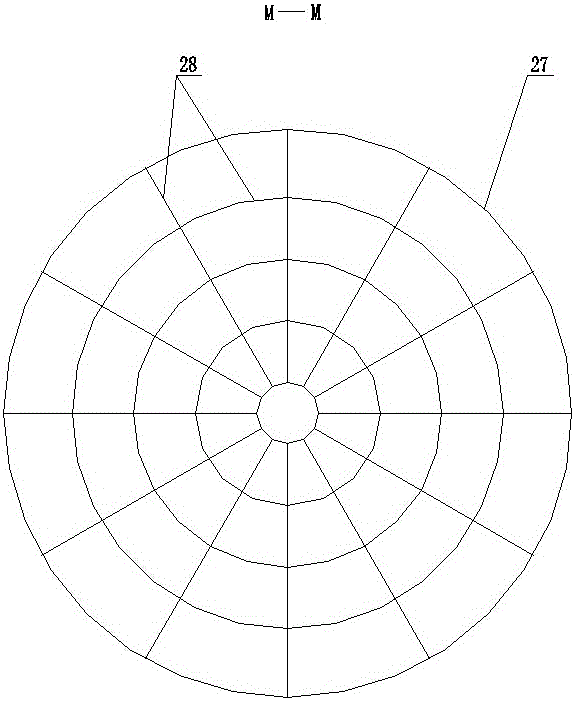

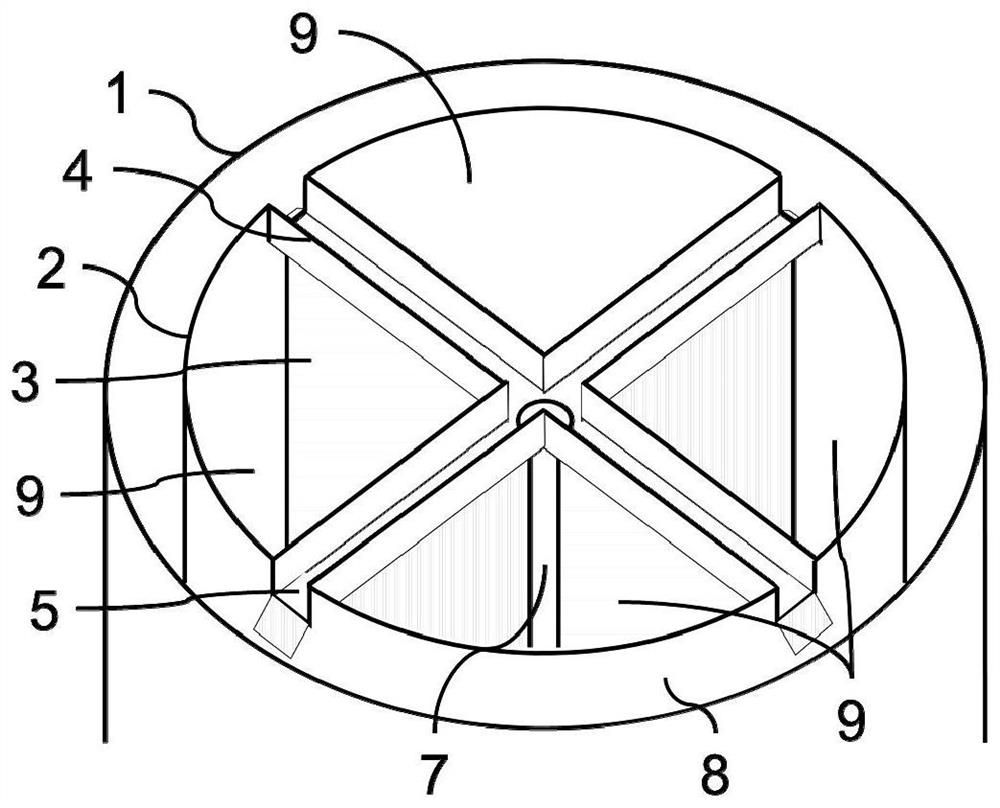

Device and method for improving internal mixing in internal circulation reactor and reactor

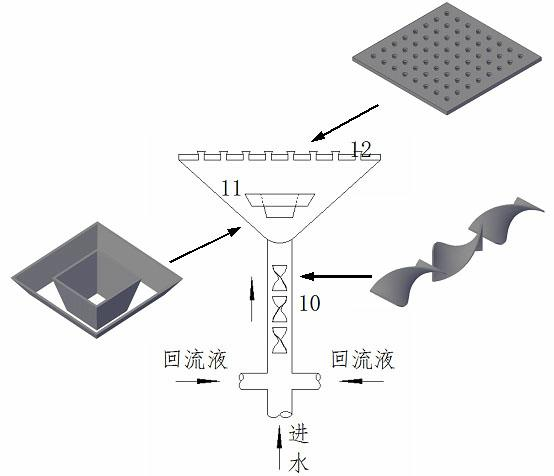

ActiveCN113262657AReduce consumptionReduce gas requirementsFlow mixersTransportation and packagingThermodynamicsInjection equipment

The invention provides a device and a method for improving internal mixing in an internal circulation reactor and a reactor. The internal circulation reactor comprises a plurality of vertically arranged flow guide channels, the flow guide channels are separated by partition walls, and the upper part of each partition wall is provided with a collecting tank; a gap for fluid to flow is reserved between the outer wall of each flow guide channel and the inner wall of the reactor, and an annular area is formed by the gaps between the outer walls of the flow guide channels and the inner wall of the reactor; and a gas injection port is formed in the bottom of each flow guide channel and is connected with gas injection equipment through a pipeline. By adopting the technical scheme of the invention, the liquid between the regions in the internal circulation reactor can be exchanged, the overall gas demand is reduced, the internal mixing effect between the plurality of regions is improved, the concentration balanced distribution in the large internal circulation reactor is promoted, and the overall energy consumption for mixing is reduced.

Owner:柏中环境科技(上海)股份有限公司 +1

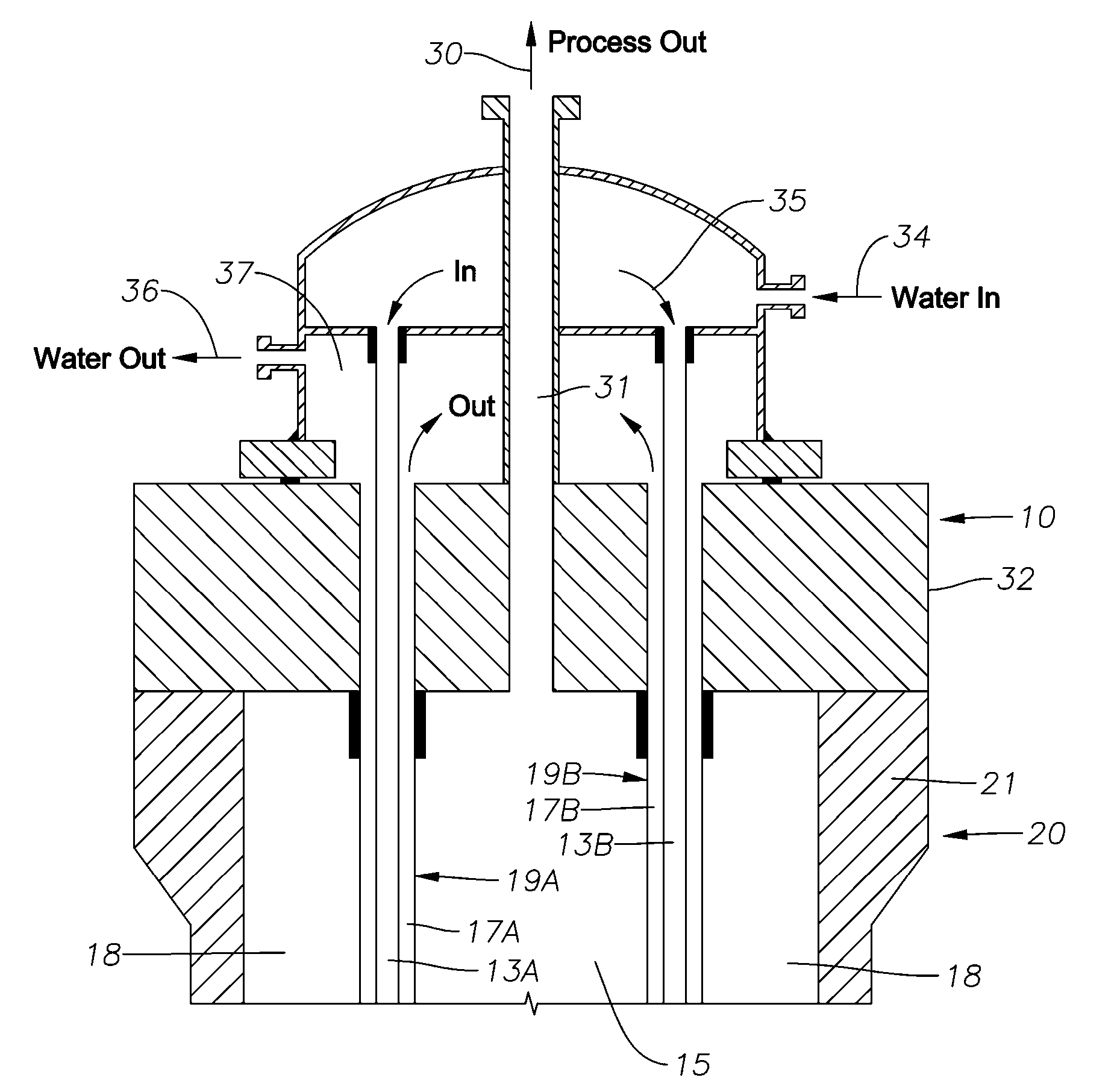

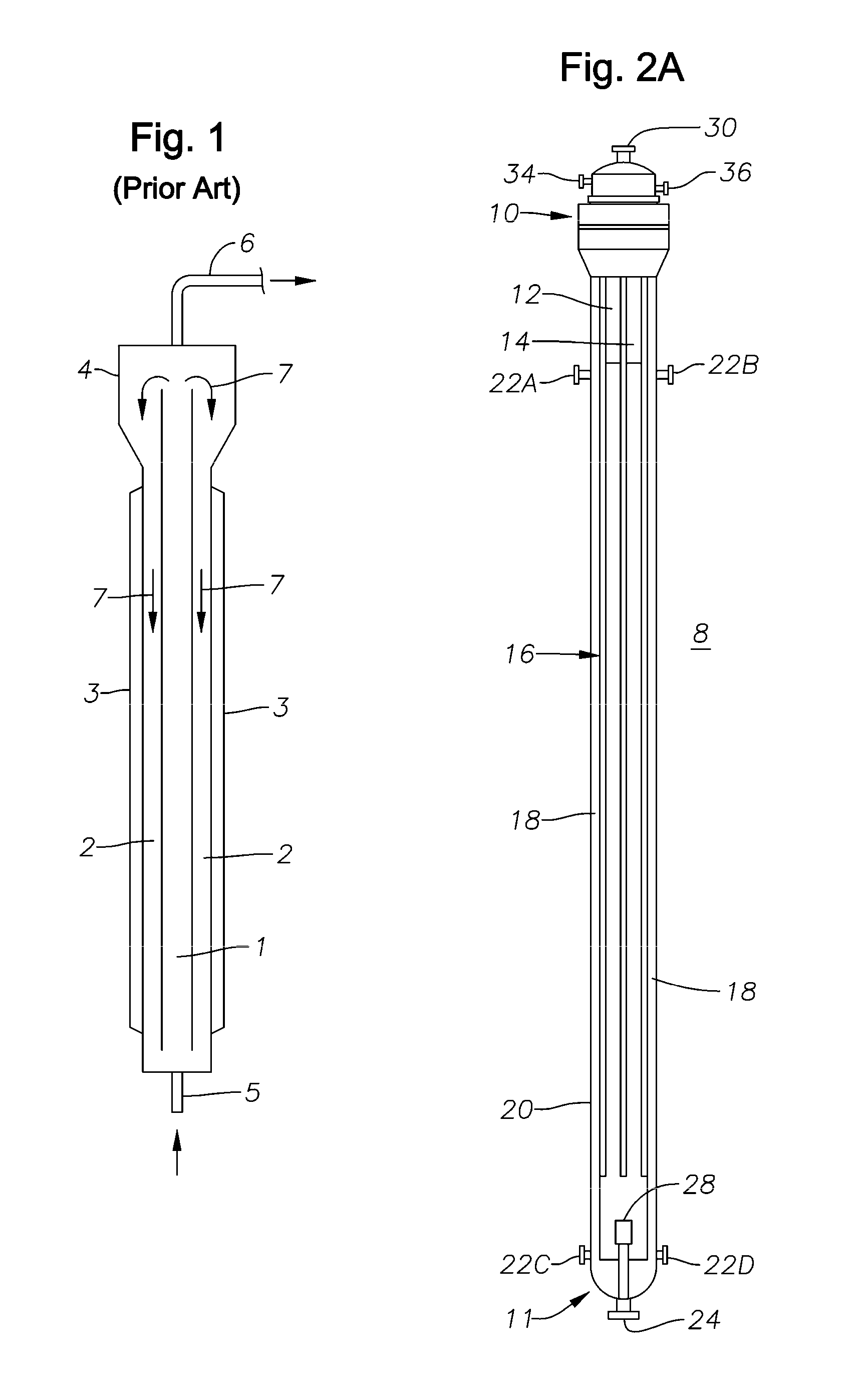

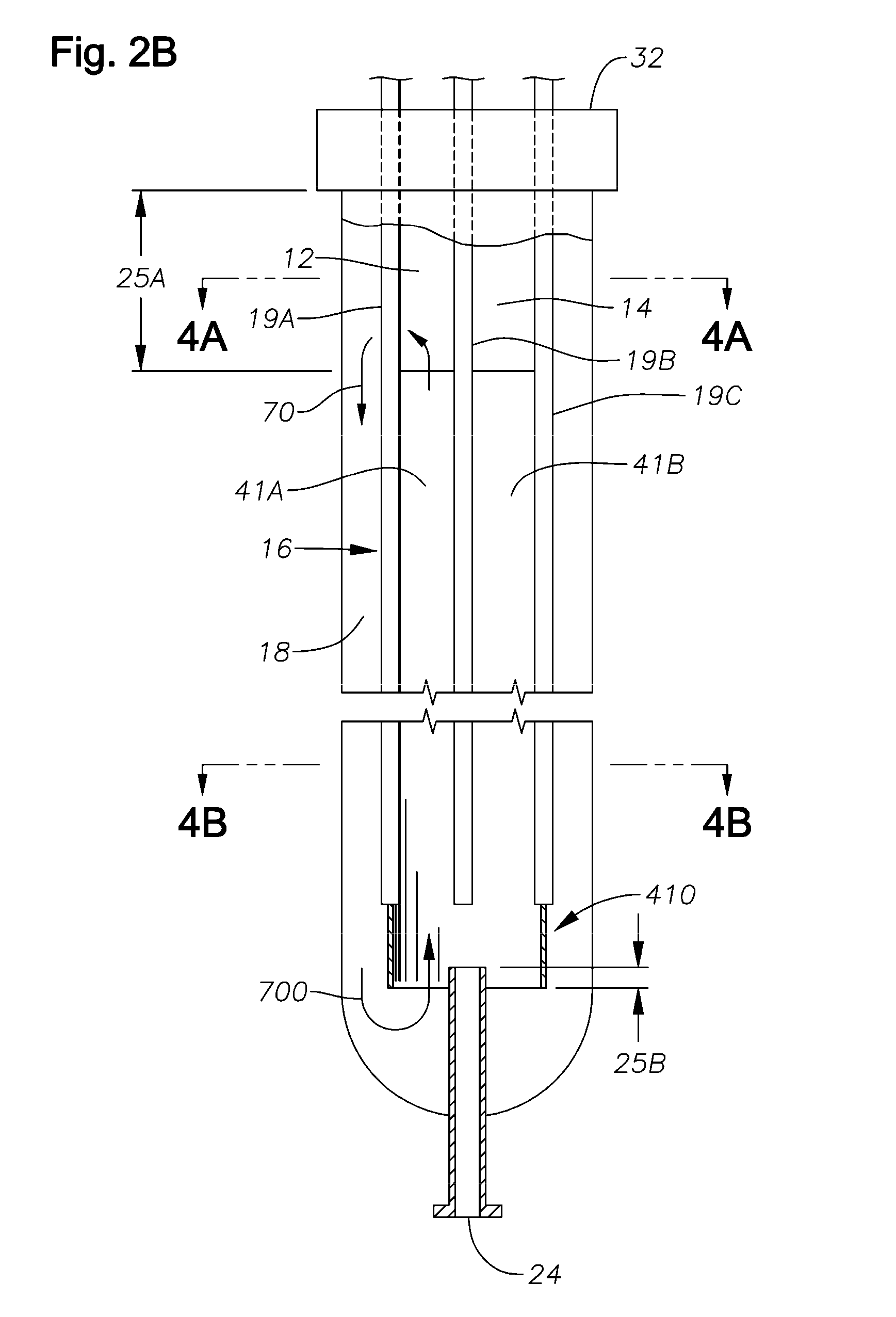

Internal Loop Reactor And OXO Process Using Same

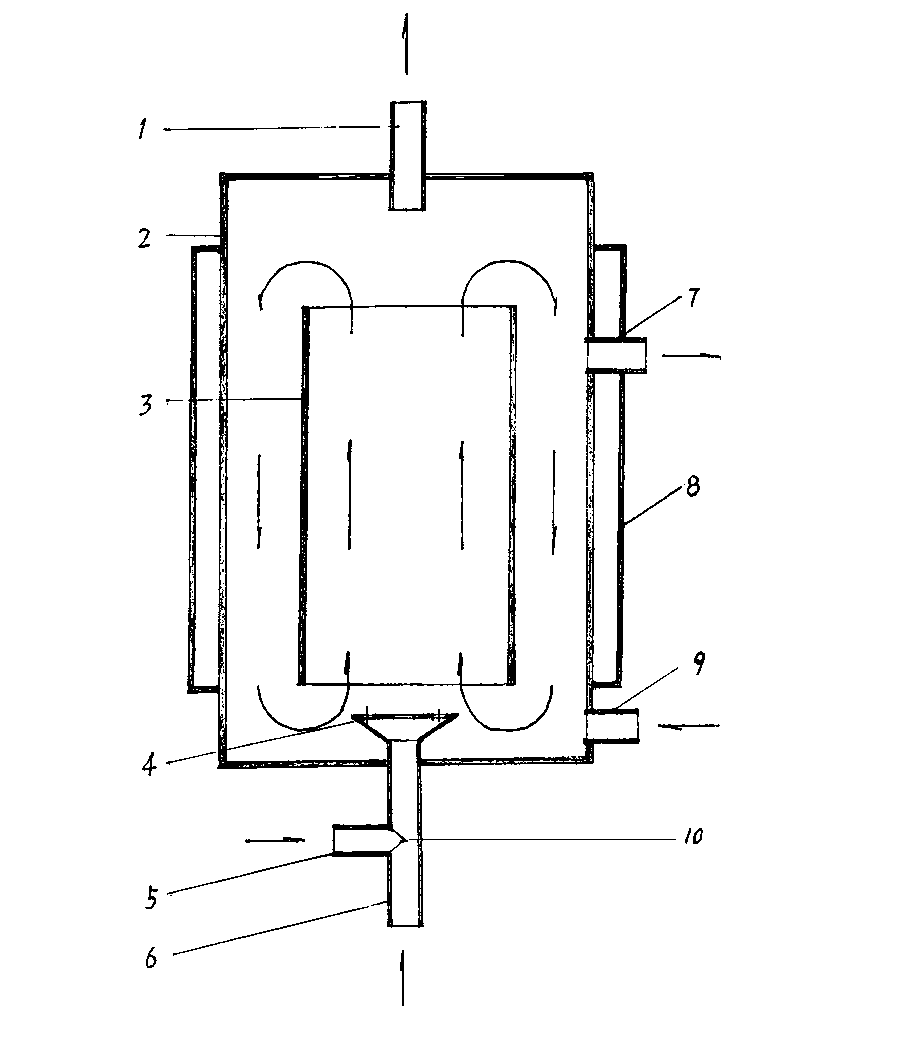

ActiveUS20100105956A1Allow flexibilityFacilitate easeOrganic compound preparationPreparation by carbon monoxide reactionThermodynamicsInternal circulation reactor

The invention relates to improvements in internal loop reactors. The reactor of the invention is characterized by a plurality of cooling tubes which form the annulus between the riser and the downcomer path of said internal loop reactor. The reactor also provides improvements in hydroformylation reactions using the improved reactor.

Owner:EXXONMOBIL CHEM PAT INC

An inner loop reactor for water detritiation and its realization method

ActiveCN105654998BExtended stayIncrease gas holdupRadioactive decontaminationGas phaseInternal circulation reactor

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com