Multistage internal circulation reactor for chemical industry

A reactor and internal circulation technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical-chemical processes, etc. The effect of small pipeline loss, high reaction rate and simple pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

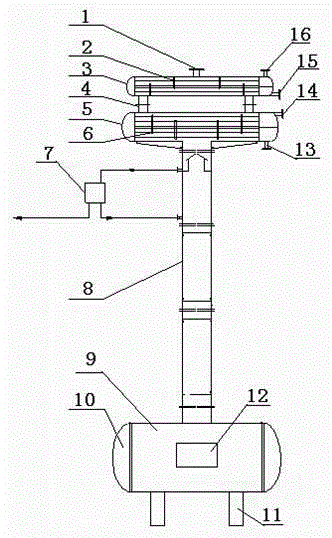

[0014] A kind of multistage internal circulation reactor for chemical industry of the present embodiment comprises multistage reactor 8, reaction chamber 5, collector 3, and multistage reactor 8 is connected with recoverer, and recoverer consists of shell 9 and end cap 10 The lower end of the housing 9 is equipped with a leg 11, the multi-stage reactor 8 is provided with a reflux control system 7, the reaction chamber 5 is installed on the top of the multi-stage reactor 8, and the reaction chamber 5 is directly connected with the multi-stage reactor 8, and the reaction The bottom of the chamber 5 is provided with an outlet 13 near the two side plates, and the collector 3 communicates with the reaction chamber 5 through the connecting pipe 4;

[0015] The housing 9 is provided with a hand hole 12;

[0016] The collector 3 is provided with a first baffle 2;

[0017] The reaction chamber 5 is provided with a second baffle 6;

[0018] The collector 3 is respectively provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com