Device and method for improving internal mixing in internal circulation reactor and reactor

A reactor and internal circulation technology, applied in fluid mixers, chemical instruments and methods, mixers, etc., can solve problems such as unsatisfactory uniformity, achieve the goal of promoting balanced concentration distribution, improving effects, and reducing overall energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The preferred embodiments of the present invention will be further described in detail below.

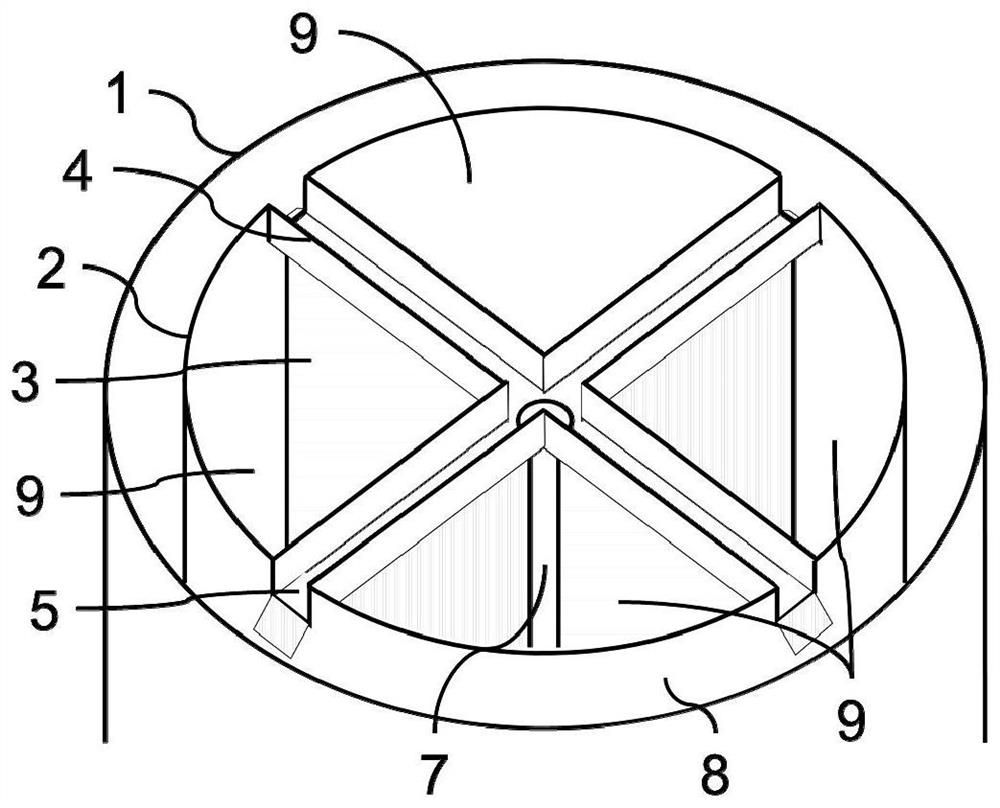

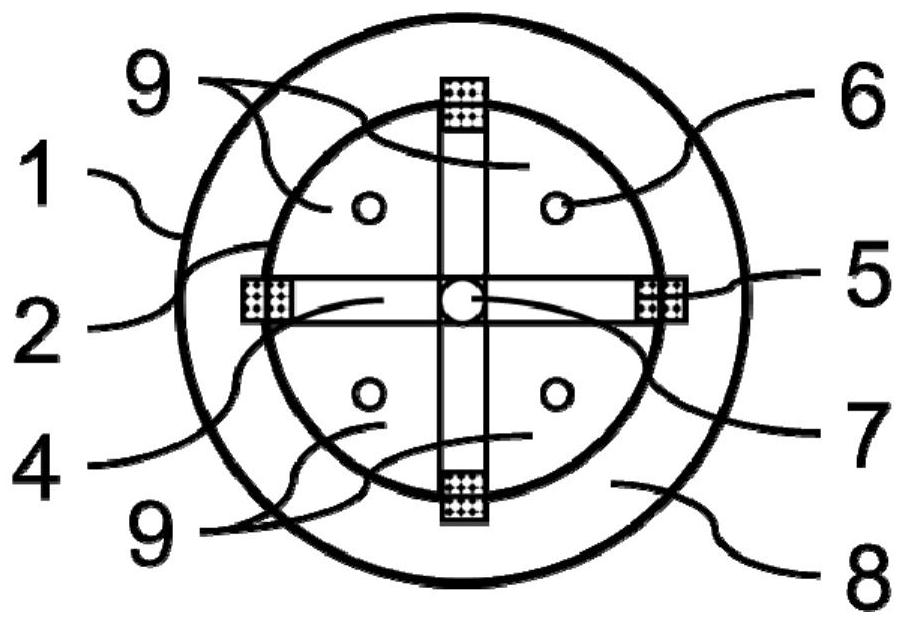

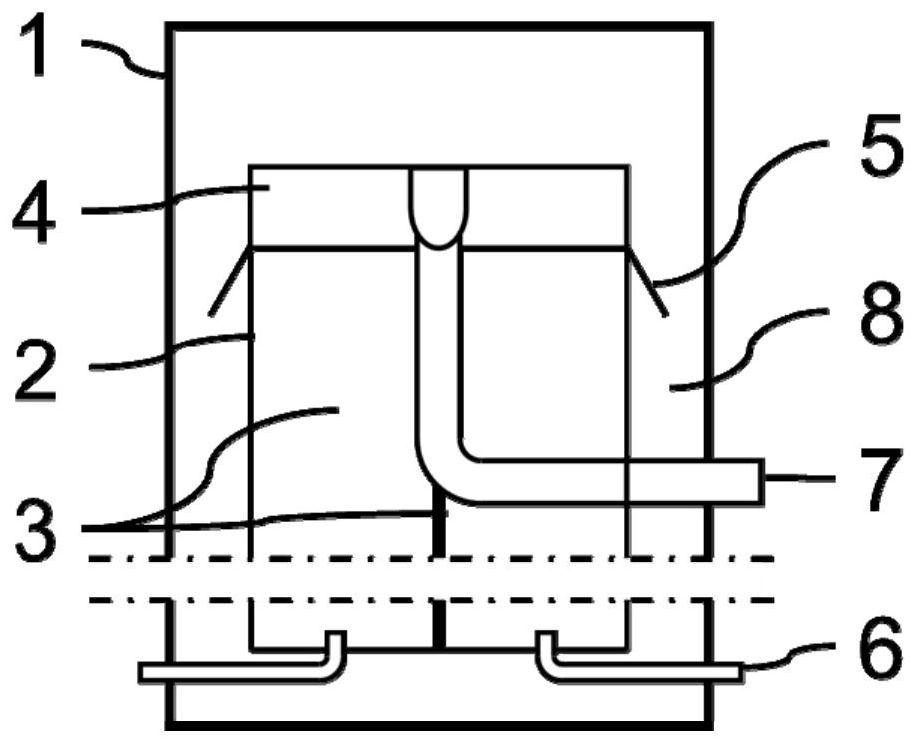

[0041] Such as Figure 1~Figure 5 As shown, a device for improving internal mixing in an internal circulation reactor, the internal circulation reactor includes a plurality of vertically arranged diversion channels 9, the diversion channels 9 are separated by a partition wall 3, and the divided The upper part of the partition wall 3 is provided with a collection tank 4; a gap for fluid flow is left between the outer wall 2 of the diversion channel and the inner wall 1 of the reactor, forming an annular area 8; the bottom of the diversion channel 9 is provided with a gas injection port 6. There is a gap between the partition wall 3 , the bottom end of the diversion channel 9 and the bottom of the reactor, so as to realize the mixing and exchange of the liquid in the annular area 8 and the diversion channel 9 . In this embodiment, each partition wall 3 is connected in the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com