Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "High deoiling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

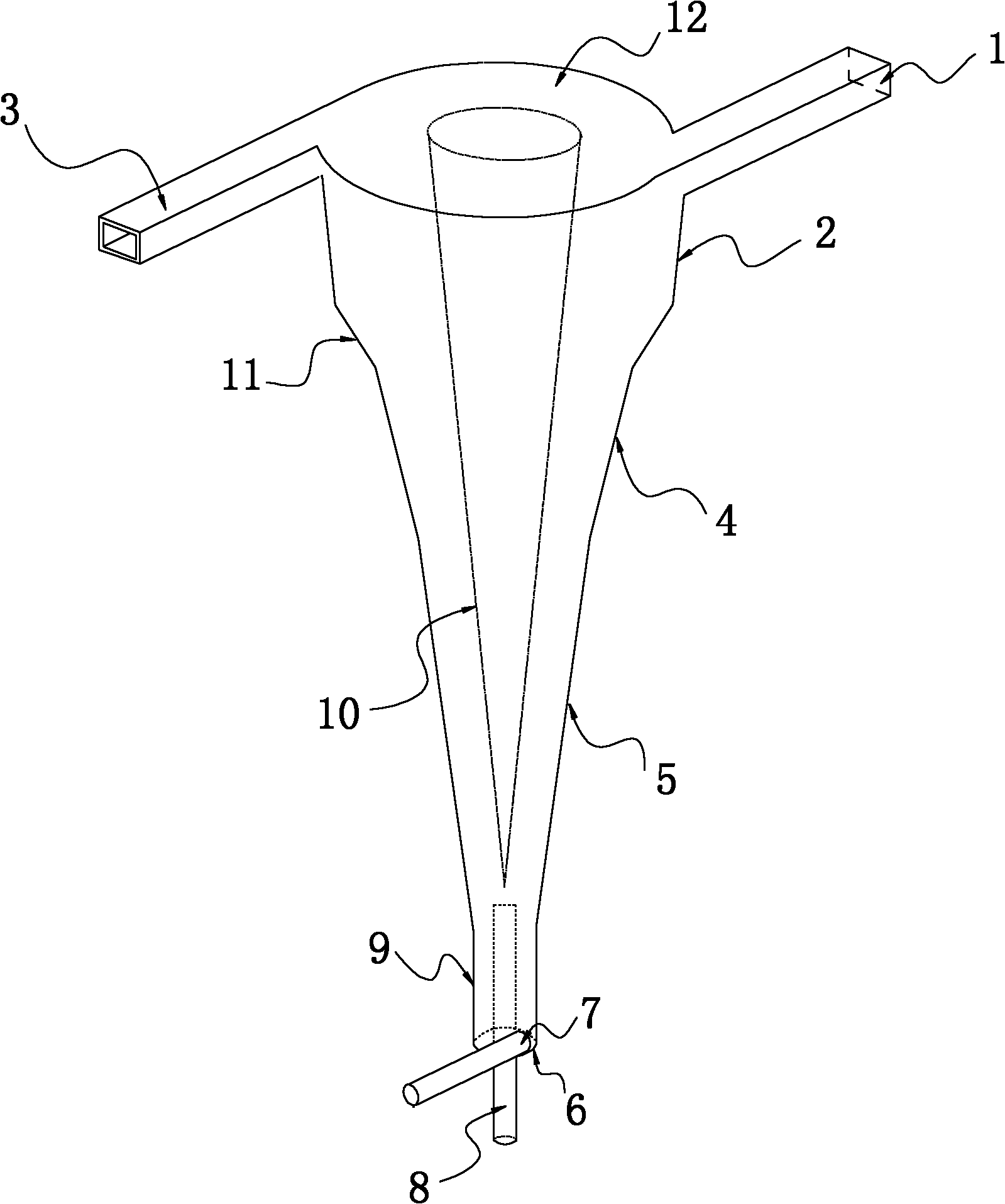

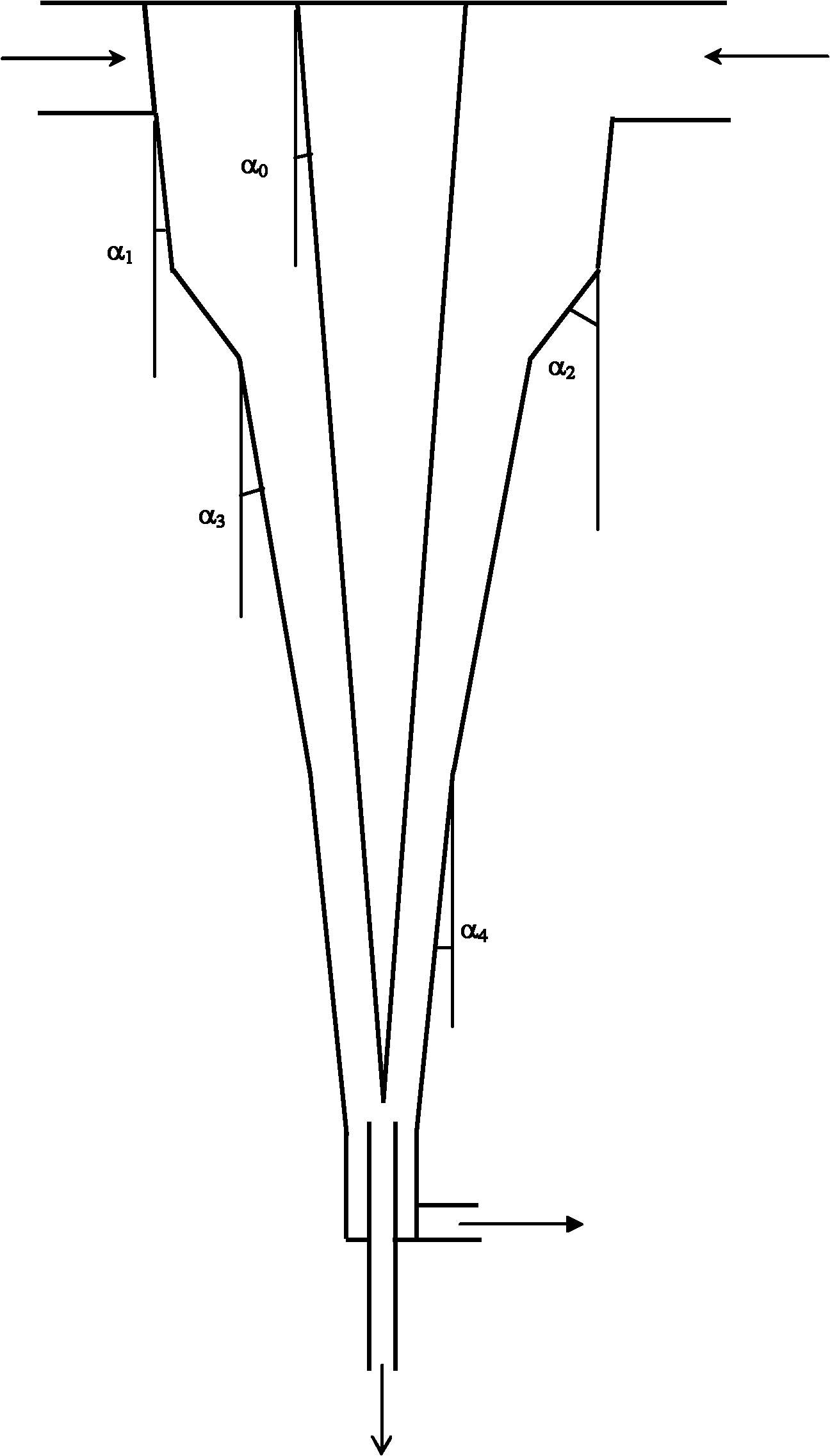

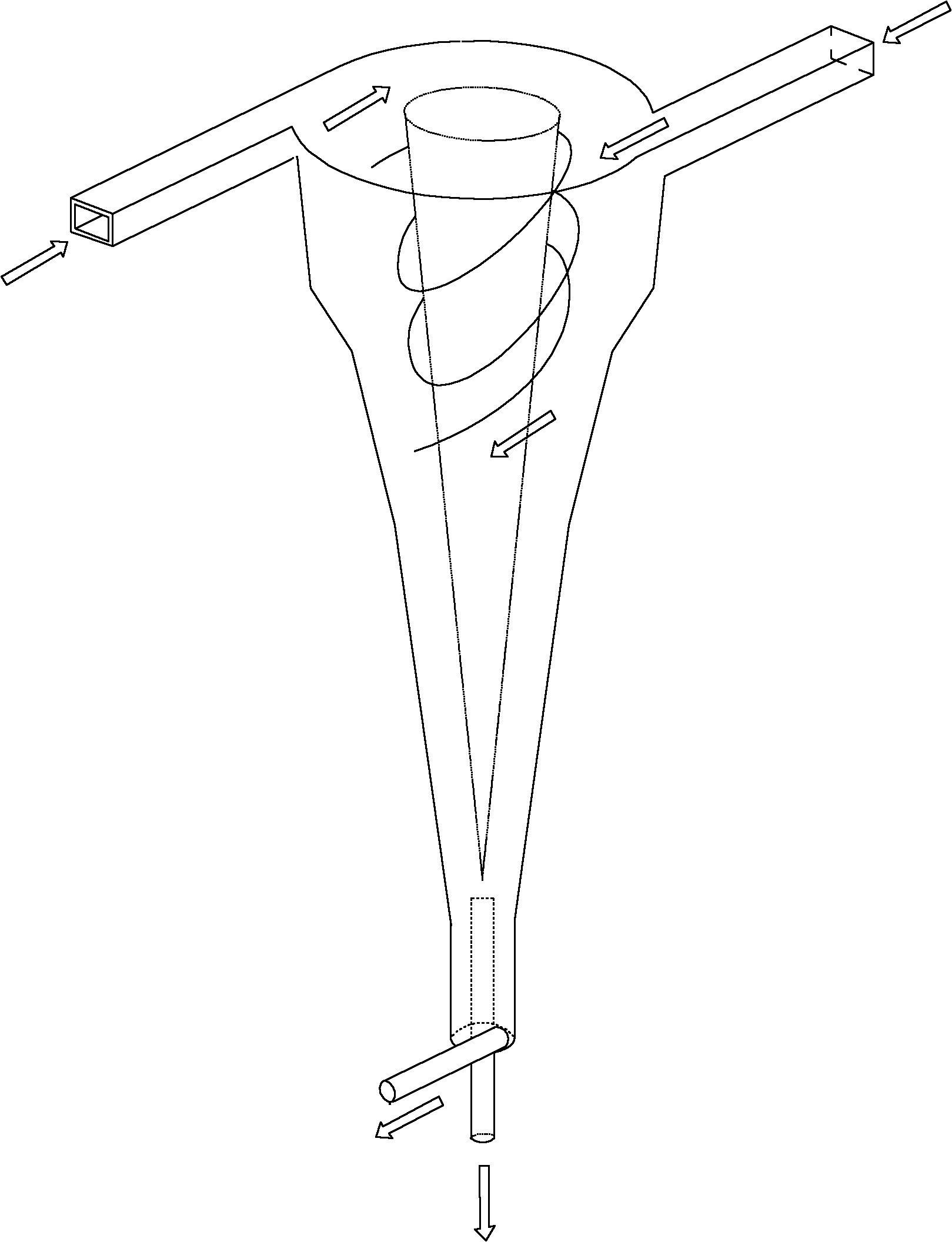

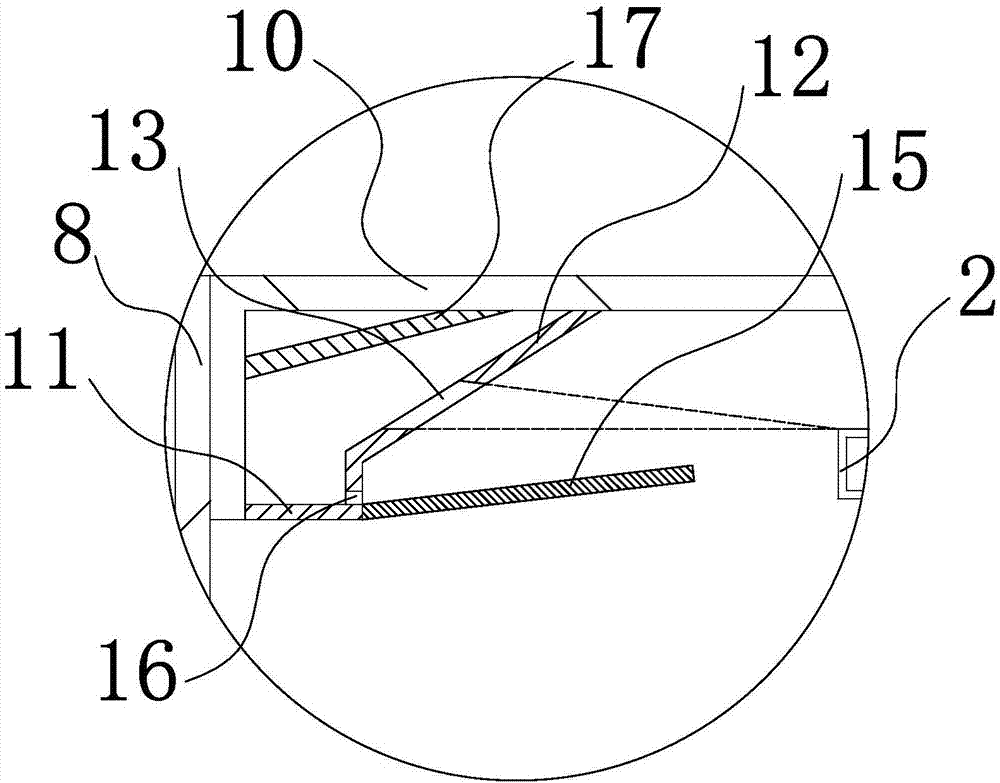

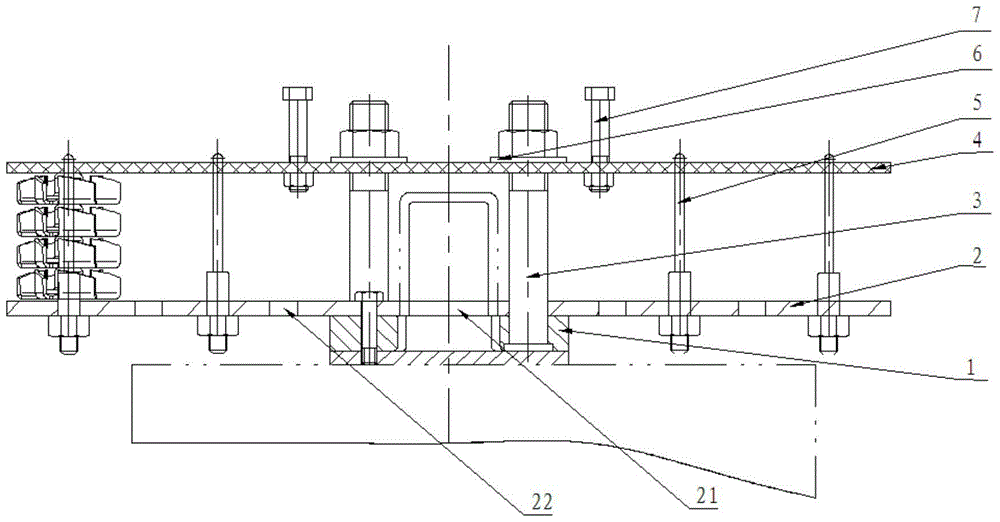

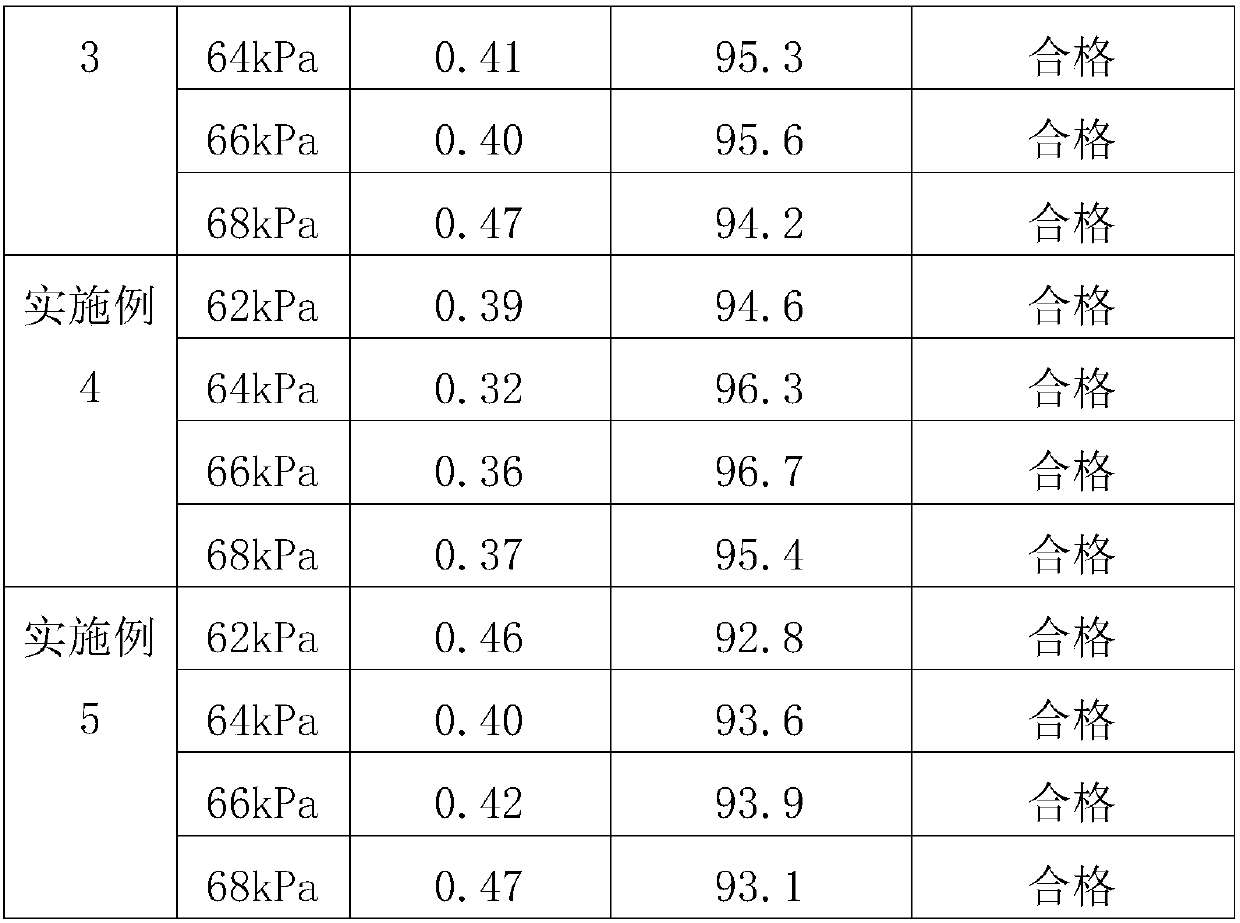

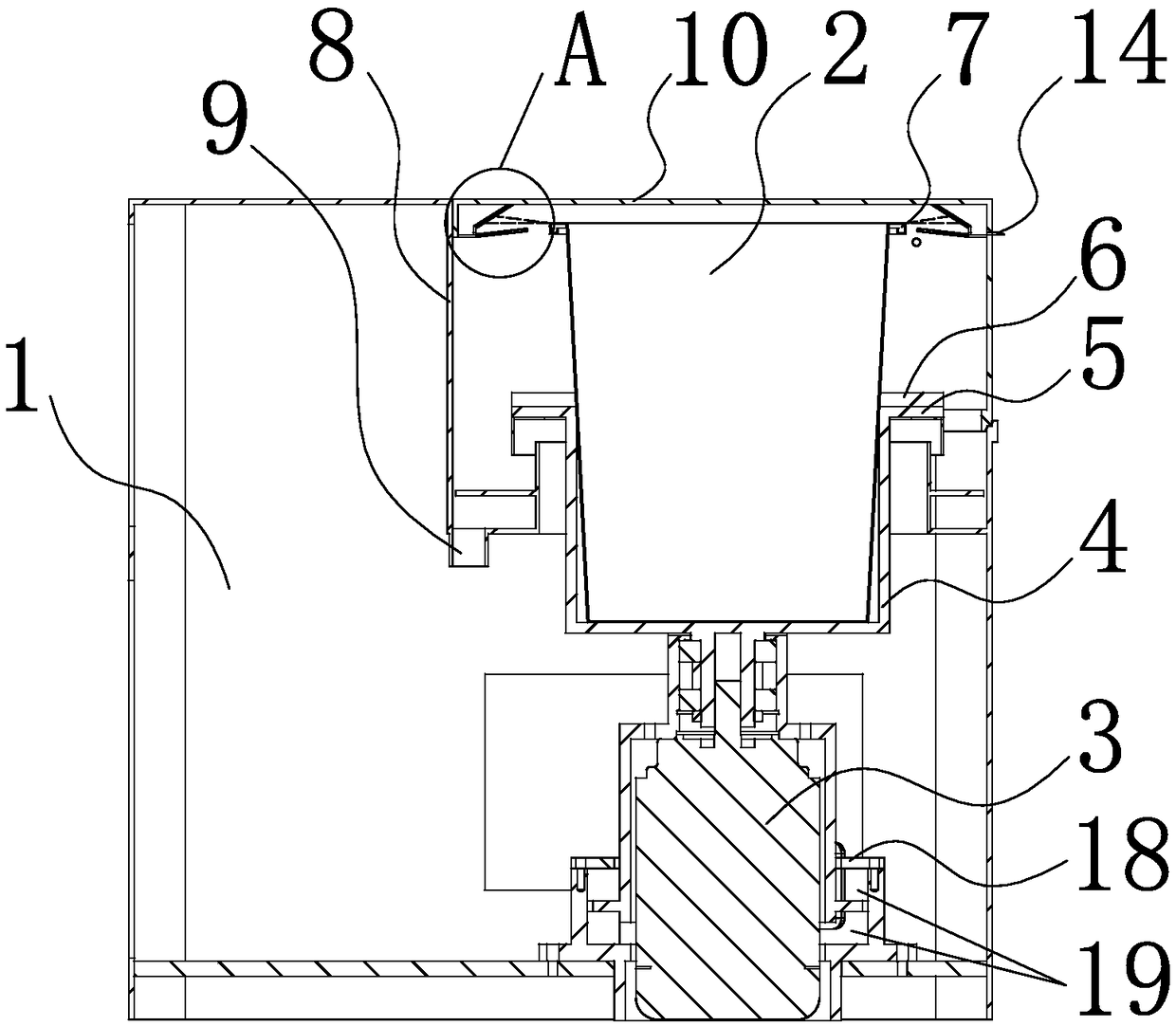

Equidirectional drainage reverse taper type high-efficiency rotational flow separator

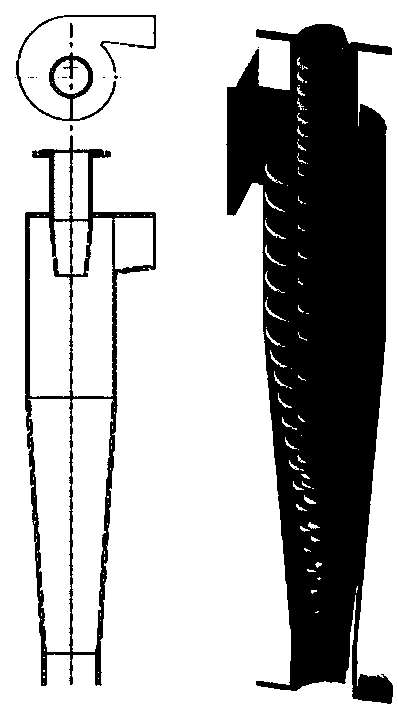

InactiveCN101983779AReduce volumeSmall footprintReversed direction vortexPetroleum engineeringHydrocyclone

The invention relates to an equidirectional drainage reverse taper type high-efficiency rotational flow separator, which mainly solves the problems of poor separation effect of tiny oil drops, large volume and inconvenient installation of the traditional hydraulic cyclone separator. The invention is mainly characterized in that a rotational flow cavity section, a large taper section, a small taper section, a tail pipe section and an outlet section are successively distributed between upper and lower sealing faces; the components form a rotational flow cavity body gradually converged towards the central axis after being successively connected; a tapered thimble in the rotational flow cavity body is fixed on inner side surface of the upper sealing face; the taper top of the tapered thimble points to one side of the lower sealing face; an oil outlet pipe is vertically and fixedly connected to the lower sealing face through the center of the lower sealing face; the pipe orifice of the oil outlet pipe is positioned on the lower part of the taper top of the tapered thimble; and a water outlet pipe is horizontally connected to the bottom end of the outlet section along the tangential direction of a cycle. The rotational flow separator has the characteristics of good elimination effect on the tiny oil drops. Compared with the traditional hydraulic rotational flow separator, the rotational flow separator has the advantages of stable flow field and high separation efficiency, and is convenient for technological installation.

Owner:NORTHEAST GASOLINEEUM UNIV

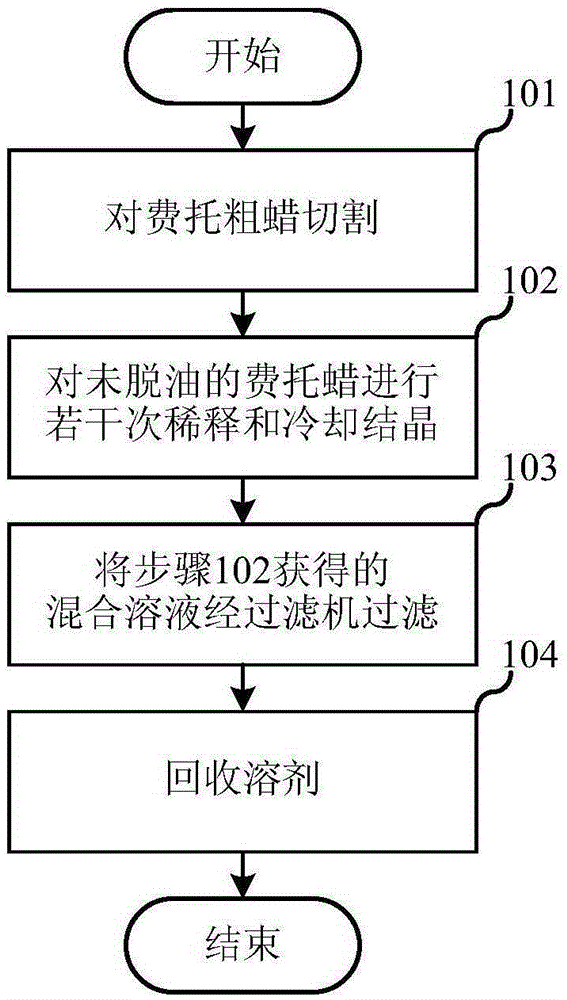

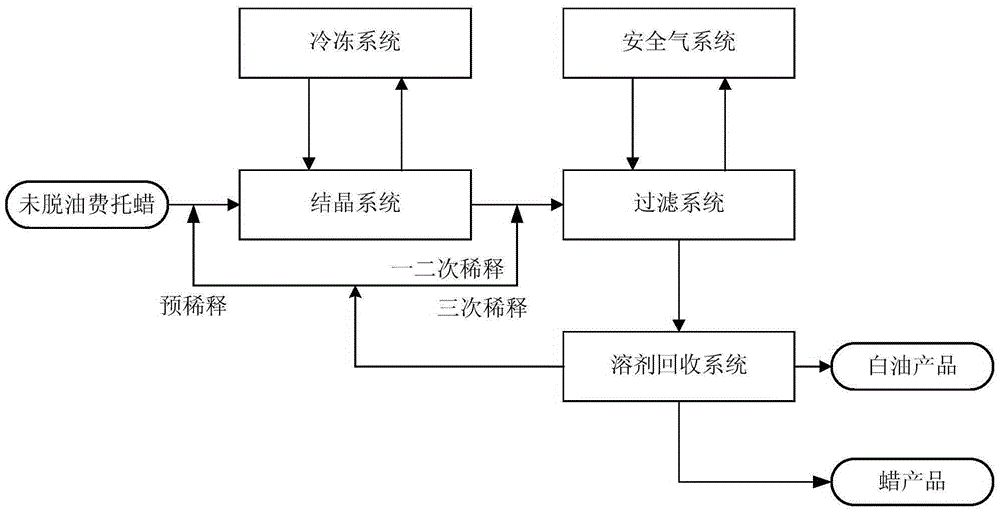

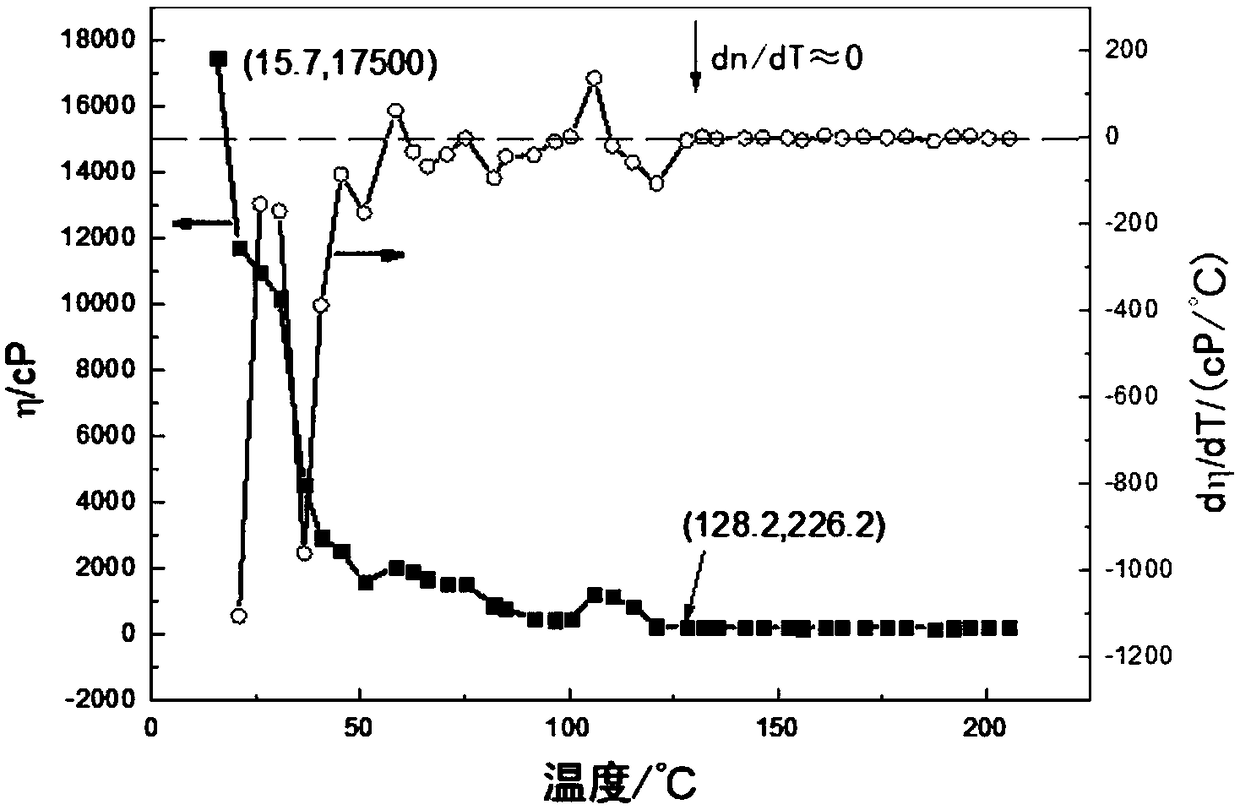

Deoiling method for Fischer-Tropsch synthesis wax

The present invention relates to the field of chemical industry, and discloses a deoiling method for Fischer-Tropsch synthesis wax. The deoiling method comprises the following steps: a methyl isobutyl ketone solvent is used as a single solvent to dilute oil-bearing Fischer-Tropsch synthesis wax; a solvent-containing crystalline liquid is obtained after a plurality of dilutions and cooling crystallizations; and the crystalline liquid is filtered through a filter to obtain a deoiled cerate, and the product wax is obtained after the deoiled cerate is evaporated and the solvent is recovered. In the embodiment of the present invention, when the method is applied to deoiling of the Fischer-Tropsch wax, the deoiling efficiency is high, the wax yield is relatively high and the filtration speed is fast.

Owner:YASHENTECH CORP

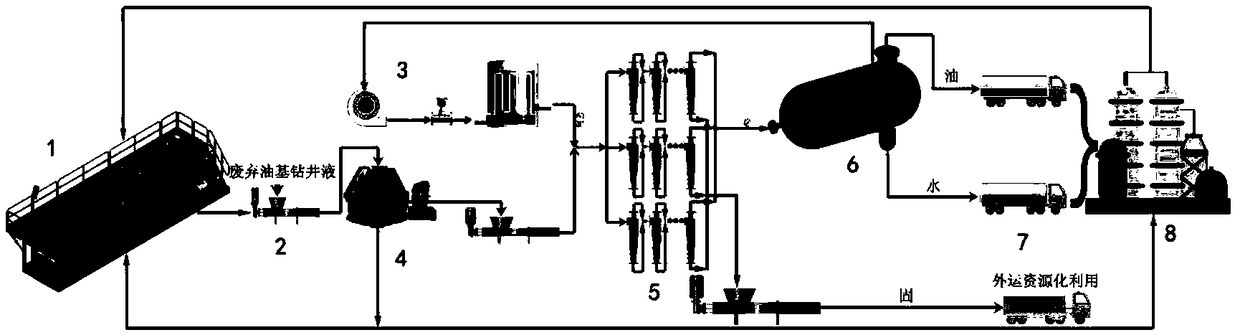

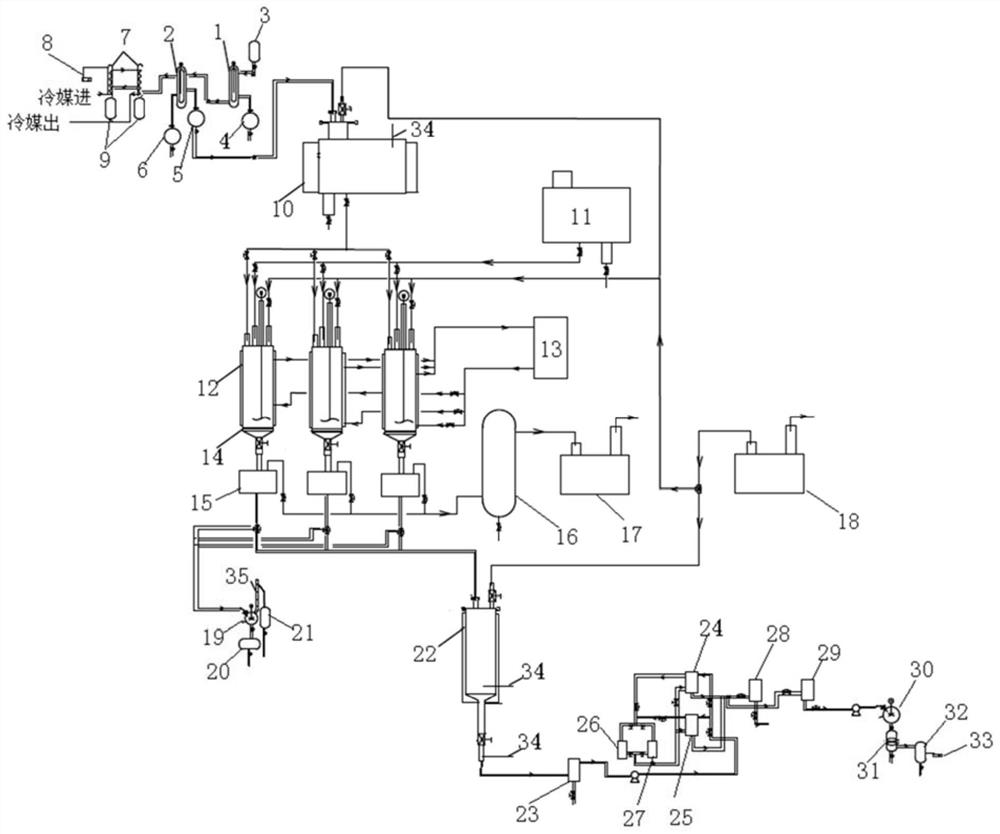

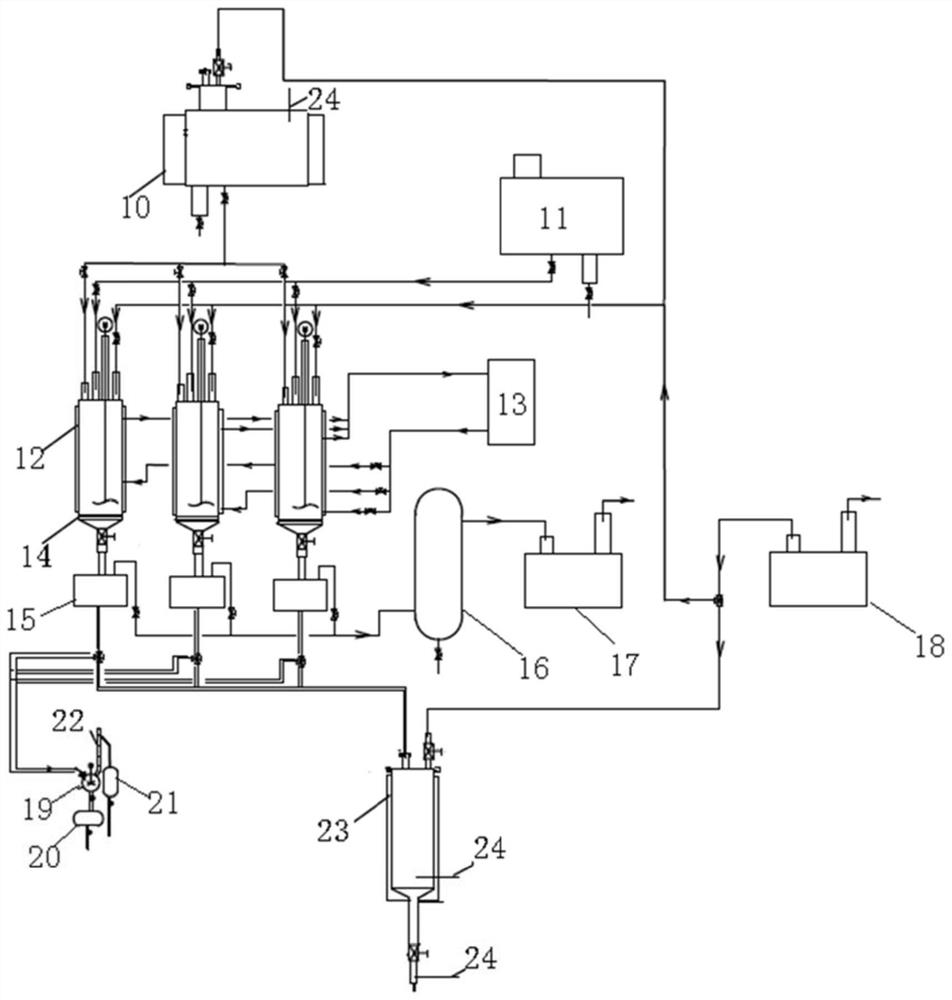

Process and device for mobile type rapid elution of oil contaminated soil

ActiveCN109365512AHigh deoiling efficiencyShort processing timeContaminated soil reclamationDesorptionPetroleum

The invention relates to a process and device for mobile type rapid elution of oil contaminated soil. The process specifically comprises the steps of sieve modulation, oxidative desorption, static separation, jet air flotation, flocculation air flotation, and oil-water separation. The process uses a Fenton-like reagent as an oxidizing agent, and the micro-bubbles generated during the reaction process adhere to the oil hydrocarbon molecules. After the micro-bubbles float to the surface of the water, the loaded oil droplets converge to form an oil film. After static separation, an oil scraping device is used to scrape the surface oil slick; then mud subjected to surface deoiling is fed into an air flotation separation device by a jet device; and the tiny bubbles in the mud sand are quickly collected into large bubbles and are released to the surface of a water layer; and an oil film is formed by oil hydrocarbons with the bubbles on the surface of the water, and removed by the oil scraping device to achieve oil-water separation. The process of the invention is used to treat oil-contaminated soil, and has the characteristics of high deoiling efficiency and short disposal time, and thedevice can realize armorization and form a complete set for mobile rapid elution of oil contaminated soil.

Owner:HEBEI UNIV OF TECH

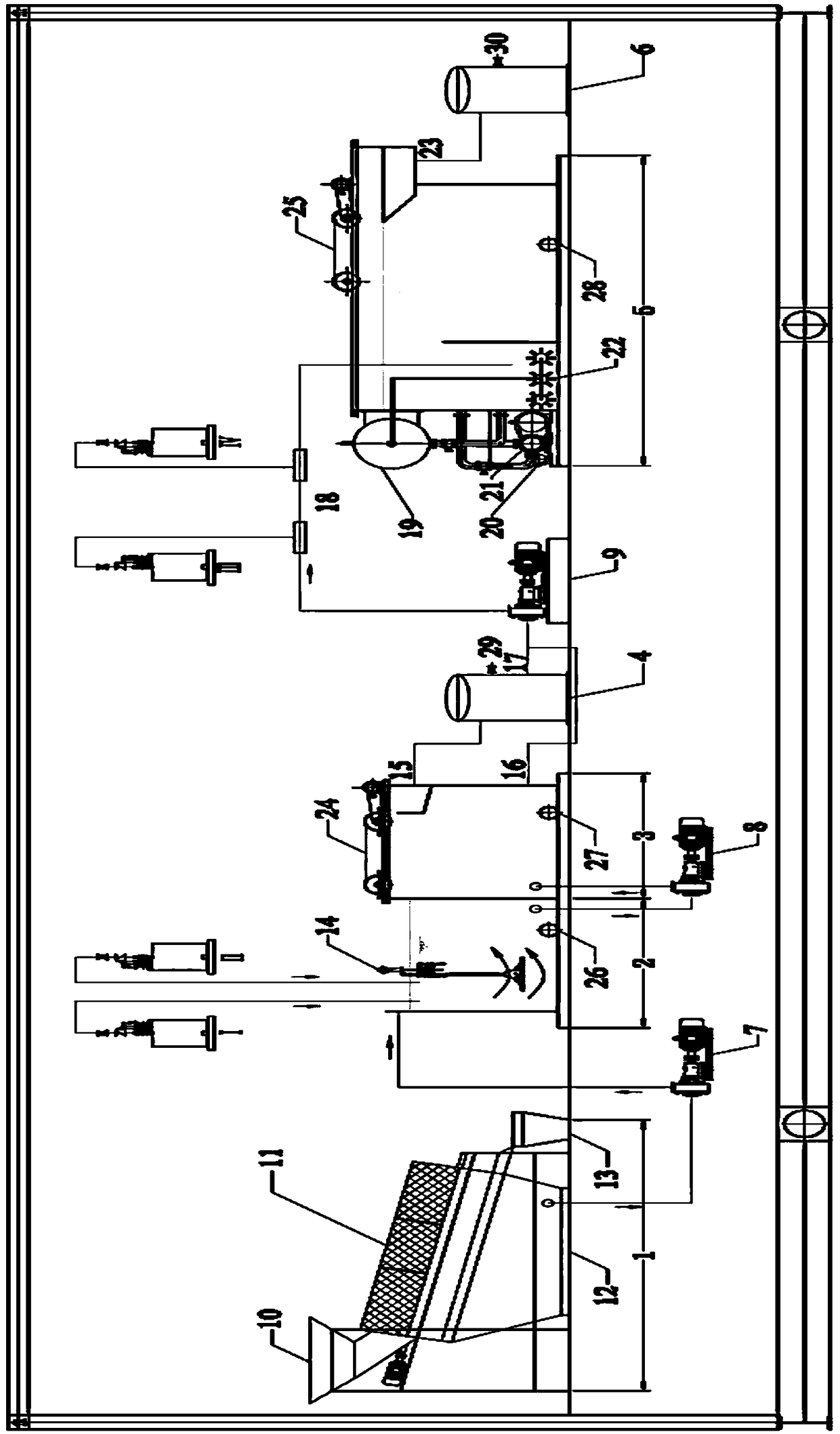

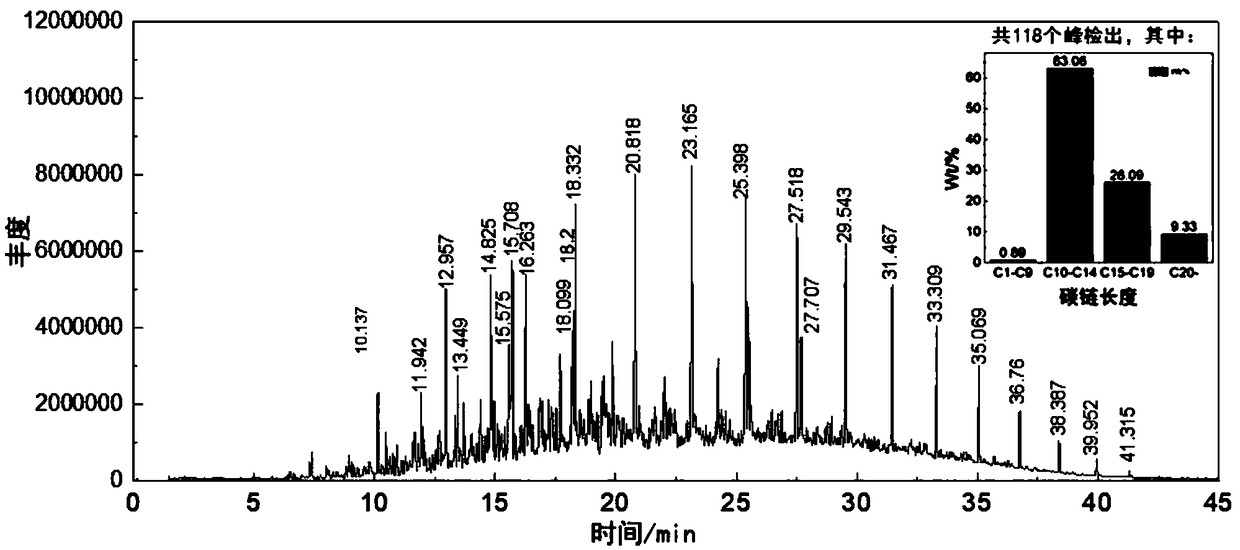

Method and device for recycling mud and base oil in waste oil base drilling fluid through grading

ActiveCN109267953ARealize the function of crushing and dispersingImprove the efficiency of heating viscosity reductionLiquid hydrocarbon mixture productionFlushingBase oilMoisture

The invention relates to a method and device for recycling mud and base oil in waste oil base drilling fluid through grading and provides the method for recycling the mud and base oil in the waste oilbase drilling fluid through grading. The method comprises the following steps of centrifugal deoiling, rotational flow deoiling and heterogeneous separation of oil and moisture. The invention furtherprovides the device for recycling the mud and base oil in the waste oil base drilling fluid through grading.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION +1

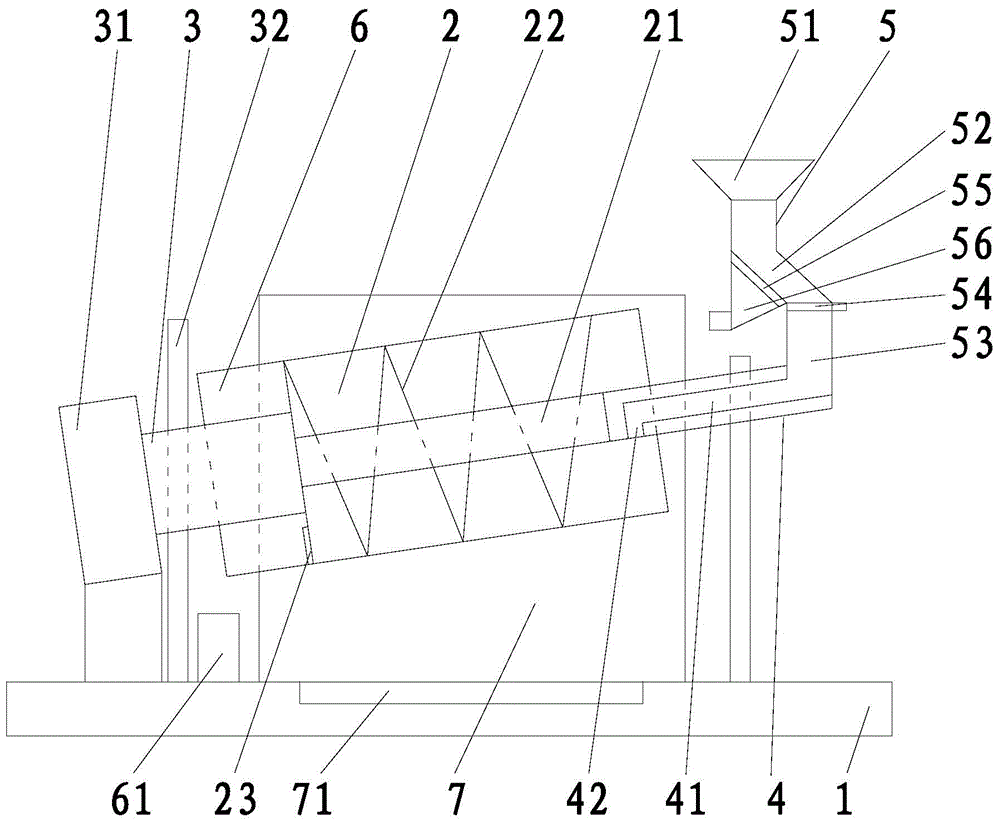

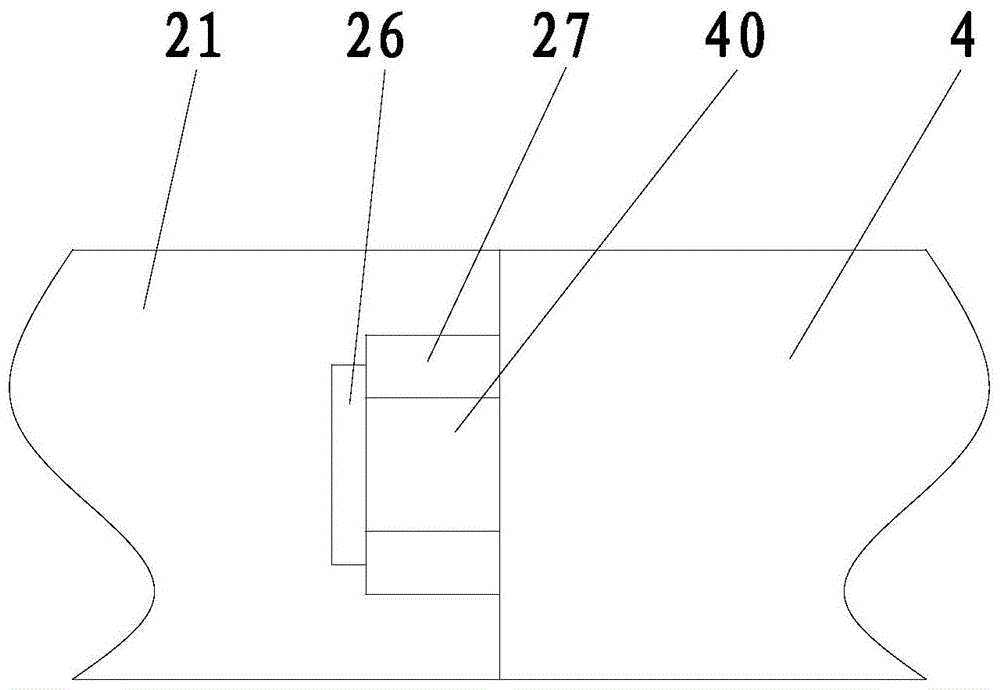

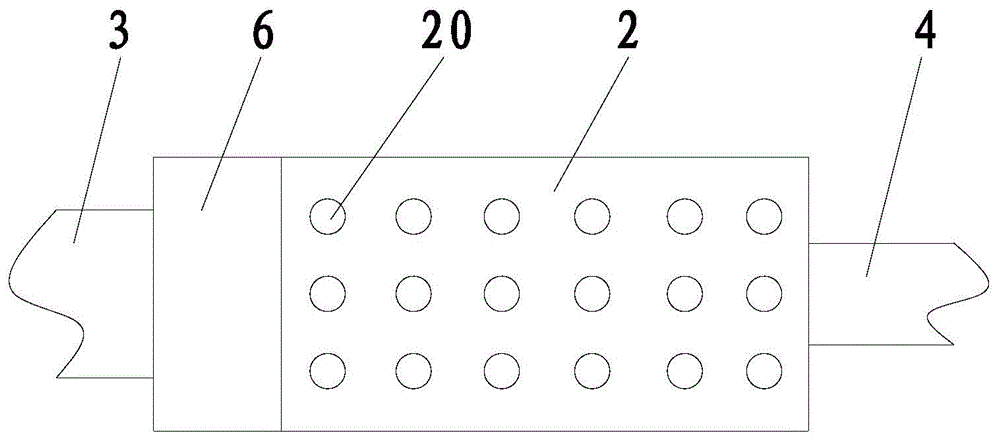

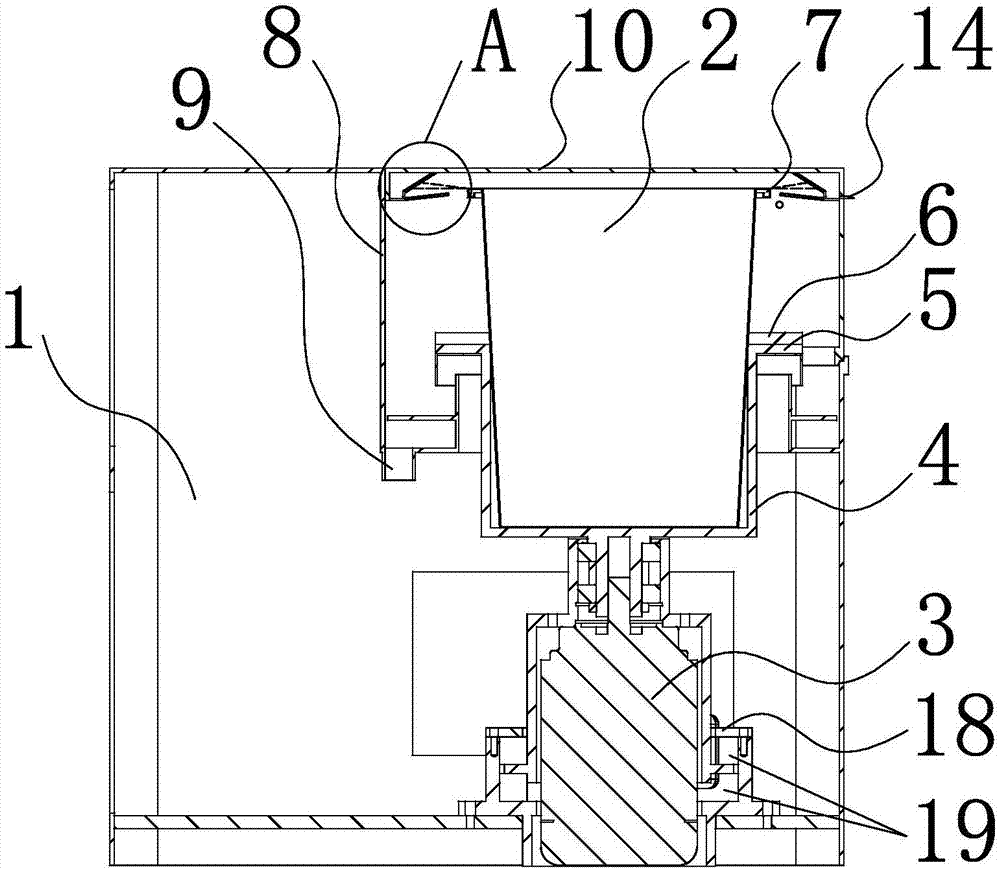

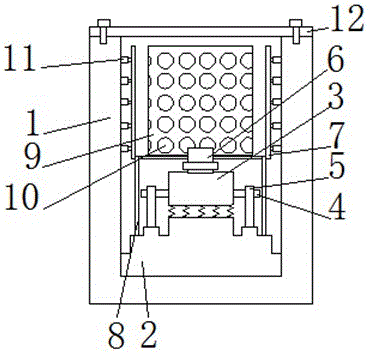

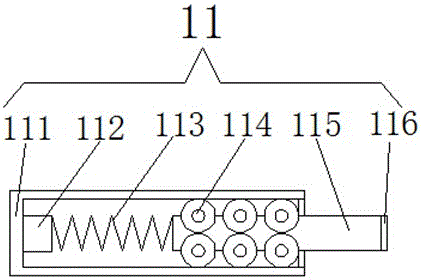

Automatic blanking discharging de-oiling machine

ActiveCN104399599ARealize automatic feeding and dischargingExtension of timeRotary centrifugesEngineeringMechanical engineering

The invention discloses an automatic blanking discharging de-oiling machine which comprises a rotating drum, a rotating shaft, a power device, a supporting shaft, a feeding hopper and a frame, wherein the rotating drum is connected with the rotating shaft; the rotating shaft is connected with the power device; the power device is fixed on the frame; a plurality of oil draining holes are uniformly distributed in a drum wall of the rotating drum; a central pillar is arranged in the rotating drum; a spiral baffle is arranged on the central pillar; a blanking channel is arranged in the supporting shaft; a blanking hole is arranged in a side wall of an end part of the blanking channel in the rotating drum; the interior of the rotating drum and the blanking channel are communicated with each other by the blanking hole; the other end of the blanking channel is connected with the feeding hopper; a discharging door is arranged on the end part of one side, which is connected with the rotating shaft, of the rotating drum; a protecting fence is arranged on the side, connected with the rotating shaft, of the rotating drum; an oil baffle cover is arranged on the outer periphery of the rotating drum; an oil collecting slot is arranged in the frame under the oil baffle cover. According to the automatic blanking discharging de-oiling machine, the blanking channel and the feeding hopper are connected with each other and the discharging door is arranged on the rotating drum, so that the automatic blanking and discharging of the de-oiling machine are realized, the de-oiling process is continuously performed and the de-oiling efficiency is increased.

Owner:ZHEJIANG RONNIE PRECISION MACHINE

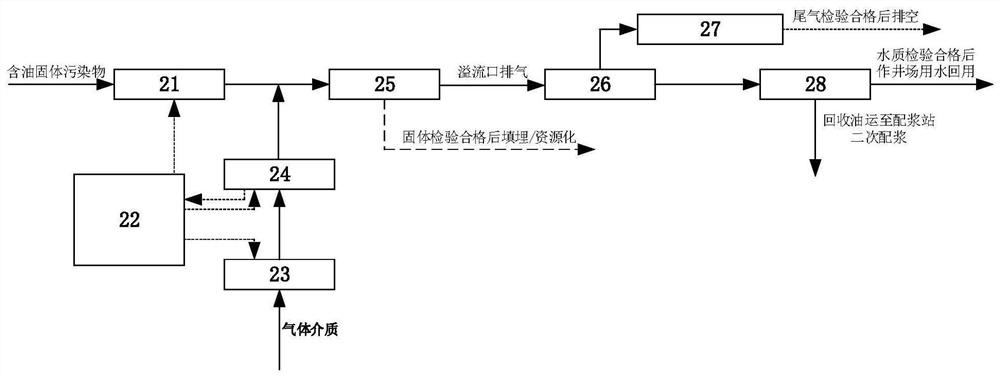

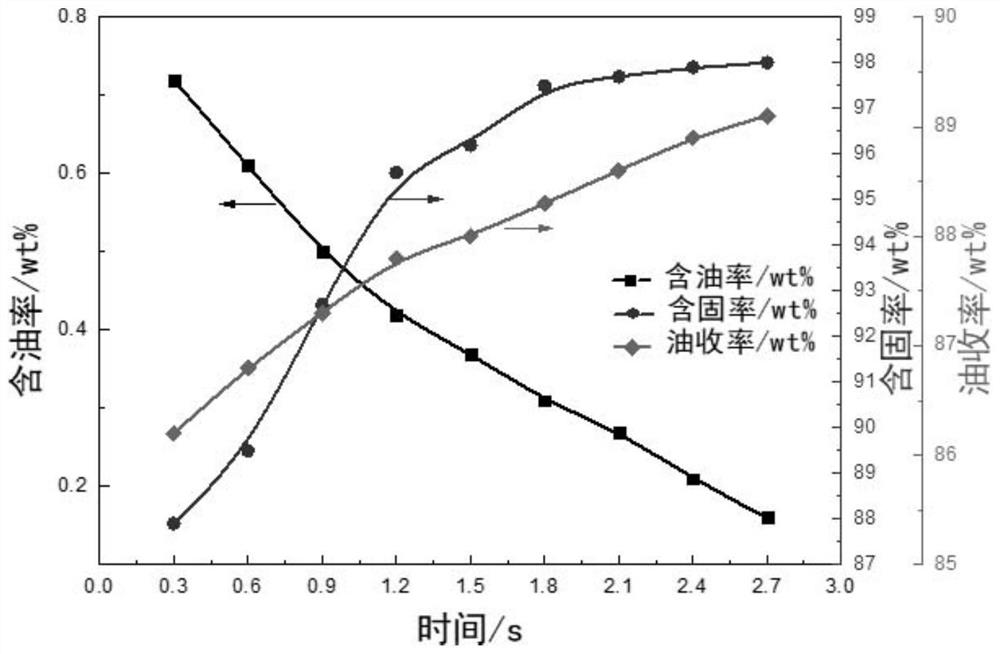

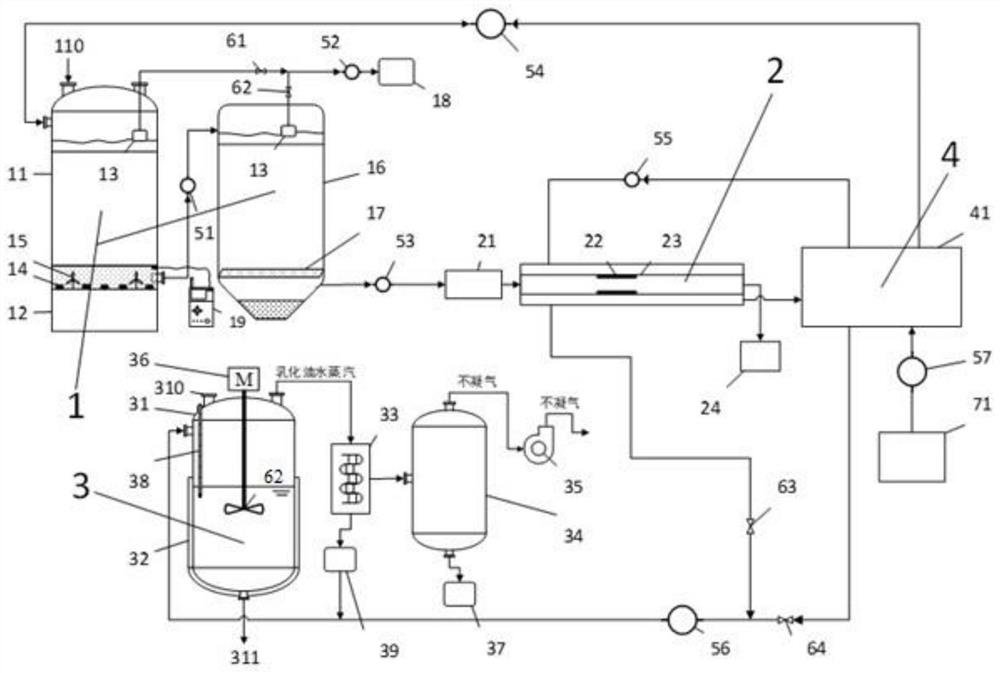

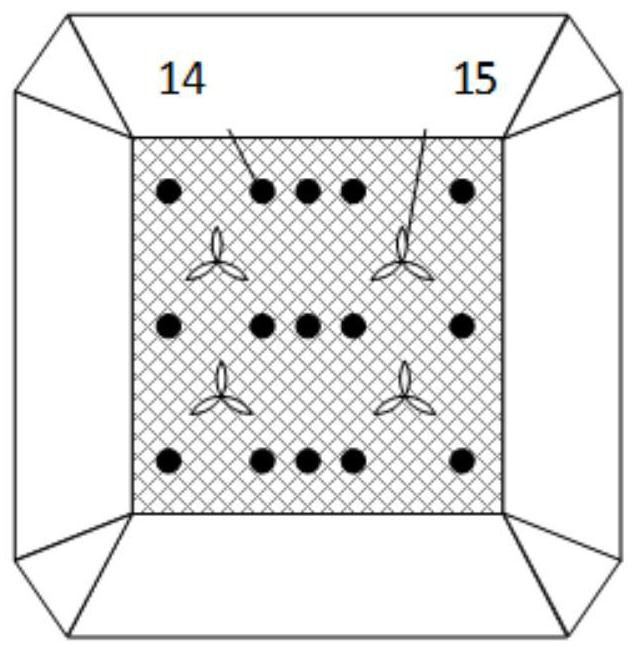

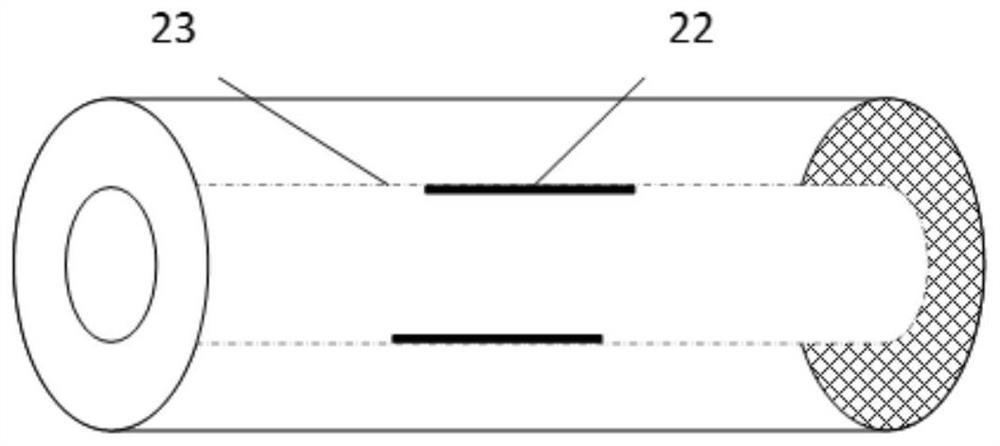

Oil-based mud rock debris treatment method and drill-accompanying device for ocean drilling platform

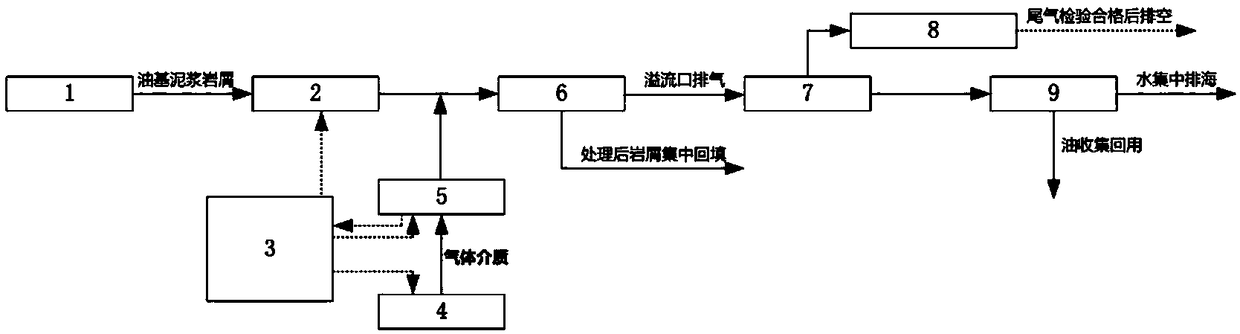

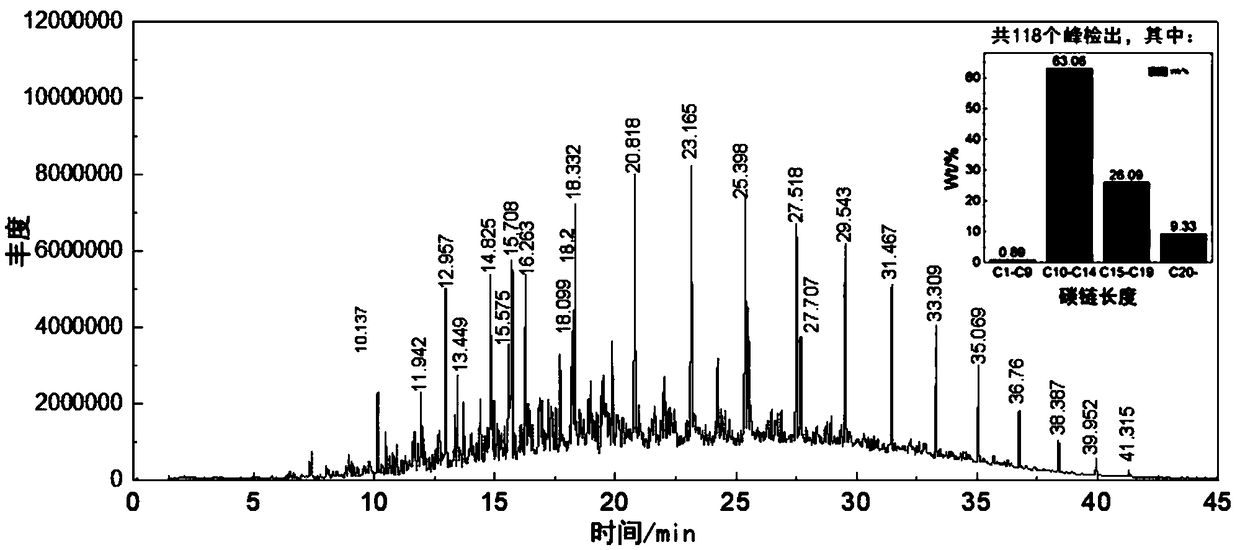

PendingCN109045770ARealize the function of crushing and dispersingImprove the efficiency of heating viscosity reductionCentrifugal force sediment separationVapor condensationCycloneWell drilling

The invention relates to an oil-based mud rock debris treatment method and a drill-accompanying device for an ocean drilling platform. The invention provides the oil-based mud rock debris treatment method for an ocean drilling platform, and the method comprises the following steps: (A) de-oiling by a rotary flow: feeding heated gas media carrying oil-based mud rock debris particles into a cyclone,in order to strengthen the removal of contaminants on the particle surfaces and in the pores, so as to realize the separation of the rock debris particles from the contaminants; (B) overflow gas condensation: condensing the oil in the gas media to reduce the oil content in the exhaust, thus achieving gas-liquid separation and obtaining an oil-water mixture and a mixed gas of gas media and non-condensable gas; (C) gas purification: performing gas purification of the mixed gas obtained in step (B); and (D) oil-water separation: performing oil-water separation of the oil-water mixture obtained in step (B). The invention also provides the drill-accompanying device for treating oil-based mud rock debris for an ocean drilling platform.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION +1

Filtering-free oil removing machine and method for removing oil through filtering-free oil removing machine

ActiveCN107401669ANo need for secondary separation and filtrationEasy to cleanRotary centrifugesLubrication elementsDrive motorLubrication

The invention relates to an oil removing machine and provides a filtering-free oil removing machine and a method for removing oil through the filtering-free oil removing machine. The filtering-free oil removing machine is simple in structure and can automatically separate out oil adhering to steel cuttings and is high in oil removing efficiency and good in quality, and separated oil is free of secondary separation and filtering. The technical problems that in the prior art, separated cooling lubrication oil needs secondary separation and filtering, time and labor are wasted, and as small holes of the wall of an oil removing barrel are blocked by metal cuttings in the process, the oil removing barrel is extremely difficult to clean, and the oil removing efficiency and quality are affected are solved. The filtering-free oil removing machine comprises a tank and an oil throwing barrel suspended in the tank, a drive motor is arranged at the position, corresponding to the oil throwing barrel, of the bottom face of the tank, an output shaft of the drive motor faces upwards and drives the oil throwing barrel to rotate, an opening of the oil throwing barrel faces upwards, and a containing cavity of the oil throwing barrel is in a circular truncated cone shape with a large opening and a small bottom.

Owner:宁波市北仑区丛峰机械有限公司

Device and method for preparing high-quality wax

ActiveCN112625746ALow recovery rateHigh recovery rateFatty substance recoveryPetroleum wax recoveryWaxOil separation

The invention discloses a device and a method for preparing high-quality wax. The device comprises a solvent deoiling unit, a solvent recovery unit, a fractional crystallization unit and a clay refining unit; the solvent deoiling unit comprises a deoiling raw material tank, a solvent tank, a deoiling tower and a solvent and under-wax oil collecting tank; the solvent recovery unit is used for separating the solvent from the under-wax oil collected in the solvent and under-wax oil collecting tank and recovering the solvent; the fractional crystallization unit comprises a plurality of crystallizers connected in series and is used for removing light components in the rectified fraction to obtain a target crystallized component; the clay refining unit comprises a filter, and a filter screen is arranged in the filter. The method is simple to operate, low in cost, wide in adaptability and high in solvent recovery rate and deoiling efficiency.

Owner:INNER MONGOLIA YITAI COAL BASED NEW MATERIALS RES INST CO LTD

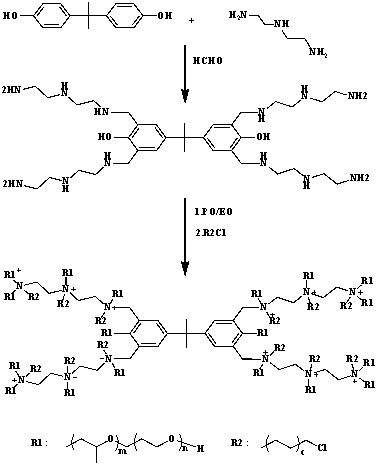

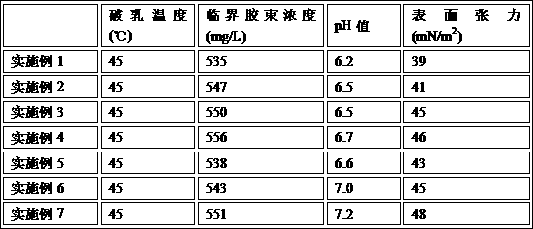

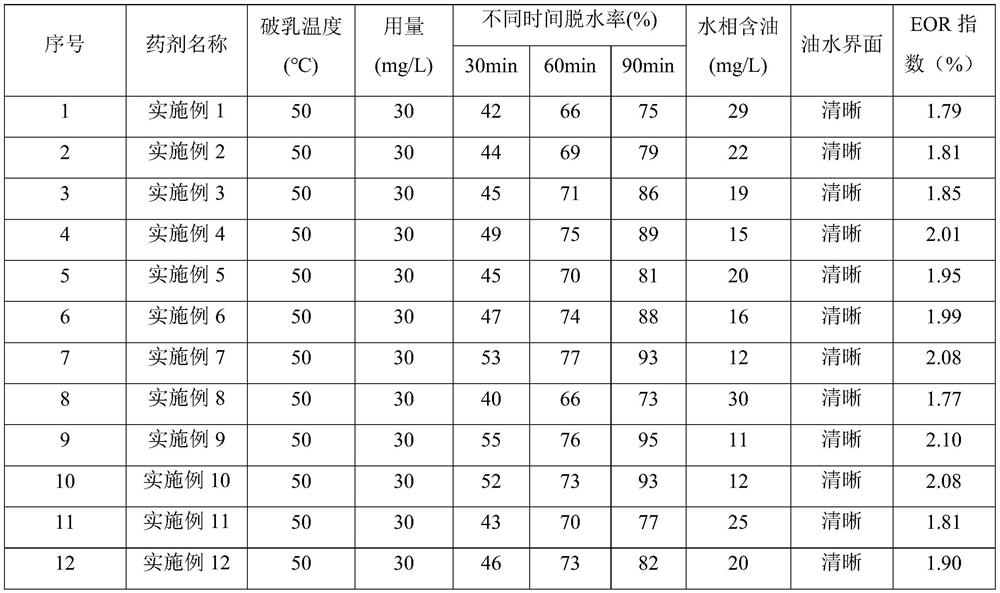

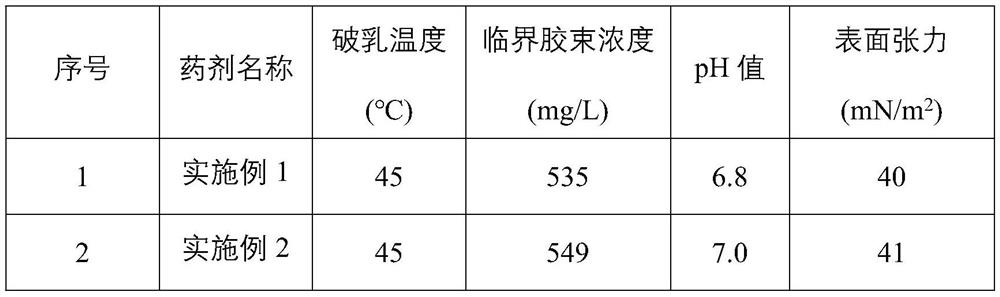

Preparation method of novel multi-branched cationic polyether reverse demulsifier and multi-branched cationic polyether reverse demulsifier

InactiveCN111423903AGood demulsification effectComplex structureDewatering/demulsification with chemical meansPolyamine CompoundPolymer science

The invention discloses a preparation method of a multi-branched cationic polyether reverse demulsifier. Bisphenol A is used as a block polyether initiator, phenolic hydroxyl ortho-hydrogen, formaldehyde and vinylamine undergo an amine methylation reaction to generate a polyamine compound with bisphenol A serving as a core, vinylamine serving as a branch and a phenolic hydroxyl group as a leaf, the polyamine compound and epoxy compounds such as epoxypropane and ethylene oxide undergo a ring opening polymerization reaction to produce a multi-branched polyether, and further the tail end of the multi-branched polyether is subjected to modification with different cationization degrees to obtain the multi-branched cationic polyether reverse demulsifier. The prepared multi-branched cationic polyether reverse demulsifier is higher in deoiling rate and demulsifying efficiency and better in demulsifying capacity, and can well make up for the functional defects of a traditional demulsifier, theoil exploitation cost can be effectively reduced, energy is saved, emission is reduced, and development of an oil exploitation process is facilitated.

Owner:JINHU JINLING NEW MATERIAL SCI & TECH

Vibrating de-oiling method of fried food

InactiveCN101347191AHigh deoiling efficiencyReduce processing costsFood preparationProcessing costFood processing

A vibrating oil removing method for fried food relates to the technical field of food processing method and technique thereof, in particular to the oil removing method and technique for the fried food in the processing procedure. The vibrating oil removing method and technique for the fried food are characterized in that the fried food is put on a vibratile bracket or a vibratile container and the fried food is correspondingly vibrated by controlling vibration of the bracket or the container, then the oil in the fried food is quickly removed from the food. The oil removing method and technique for the fried food in the processing procedure have the beneficial effects of high oil removing efficiency for the fried food, low oil content of the food, and can lower the processing cost and can be beneficial to the health of people.

Owner:天津庞氏商贸集团有限公司

Centrifugation de-oiling method of fried food

InactiveCN101396081AHigh deoiling efficiencyReduce processing costsFood preparationCentrifugationResidual oil

The invention provides a centrifugal deoiling method used for fried food, relating to a food processing method and technology, in particular to the deoiling method and technology during the process of the fried food. The fried food is put in a centrifuging machine; the fried food is driven to rotate by the centrifuging machine so as to lead the residual oil of the fried food to be thrown out of the fried food under the action of the centrifugal force; the method has the beneficial effects that the deoiling efficiency of the fried food is high, the oil content of the food is low, the processing cost is reduced and the fried food is beneficial for the health of people.

Owner:天津庞氏商贸集团有限公司

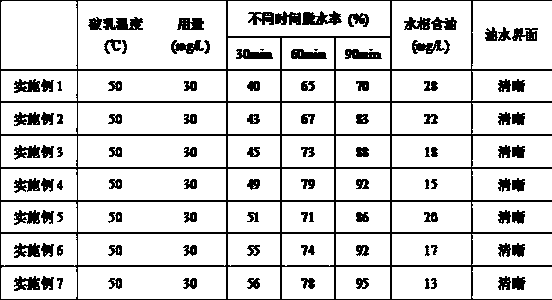

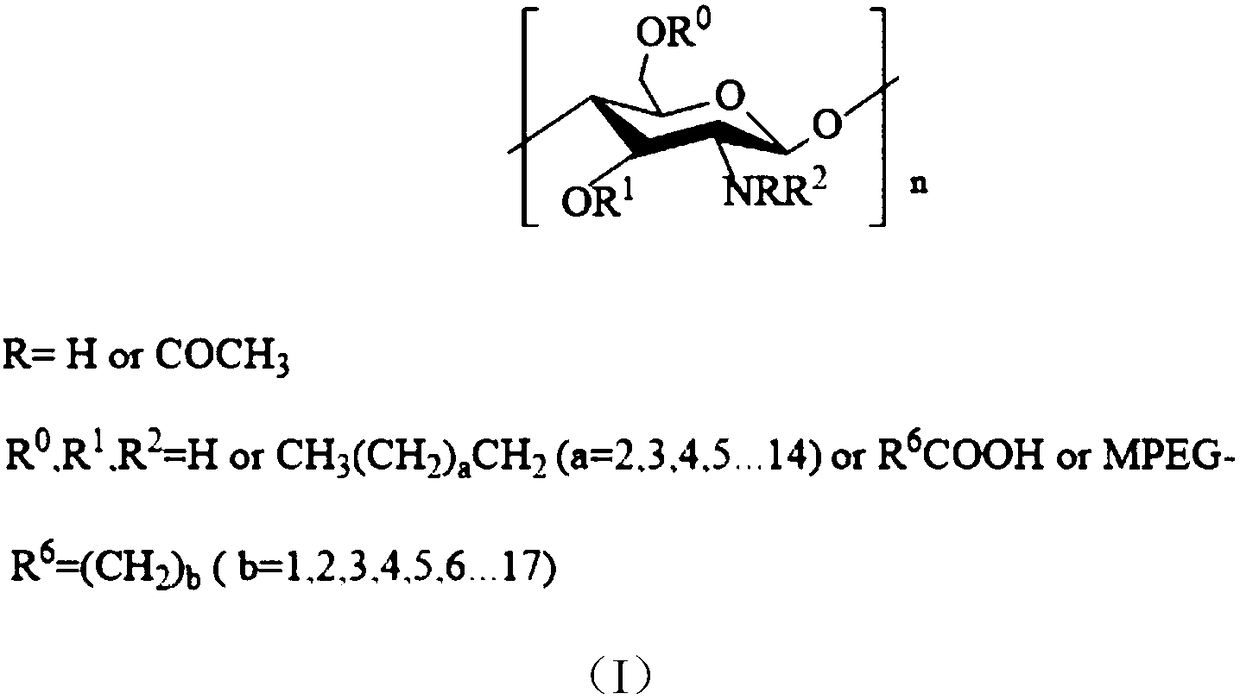

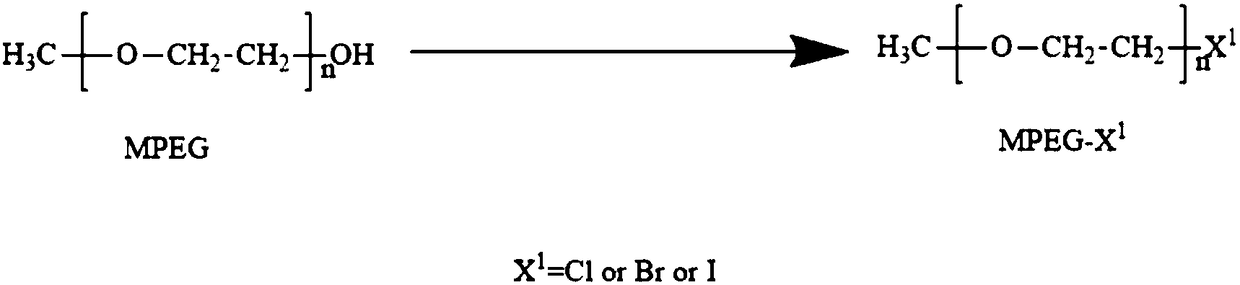

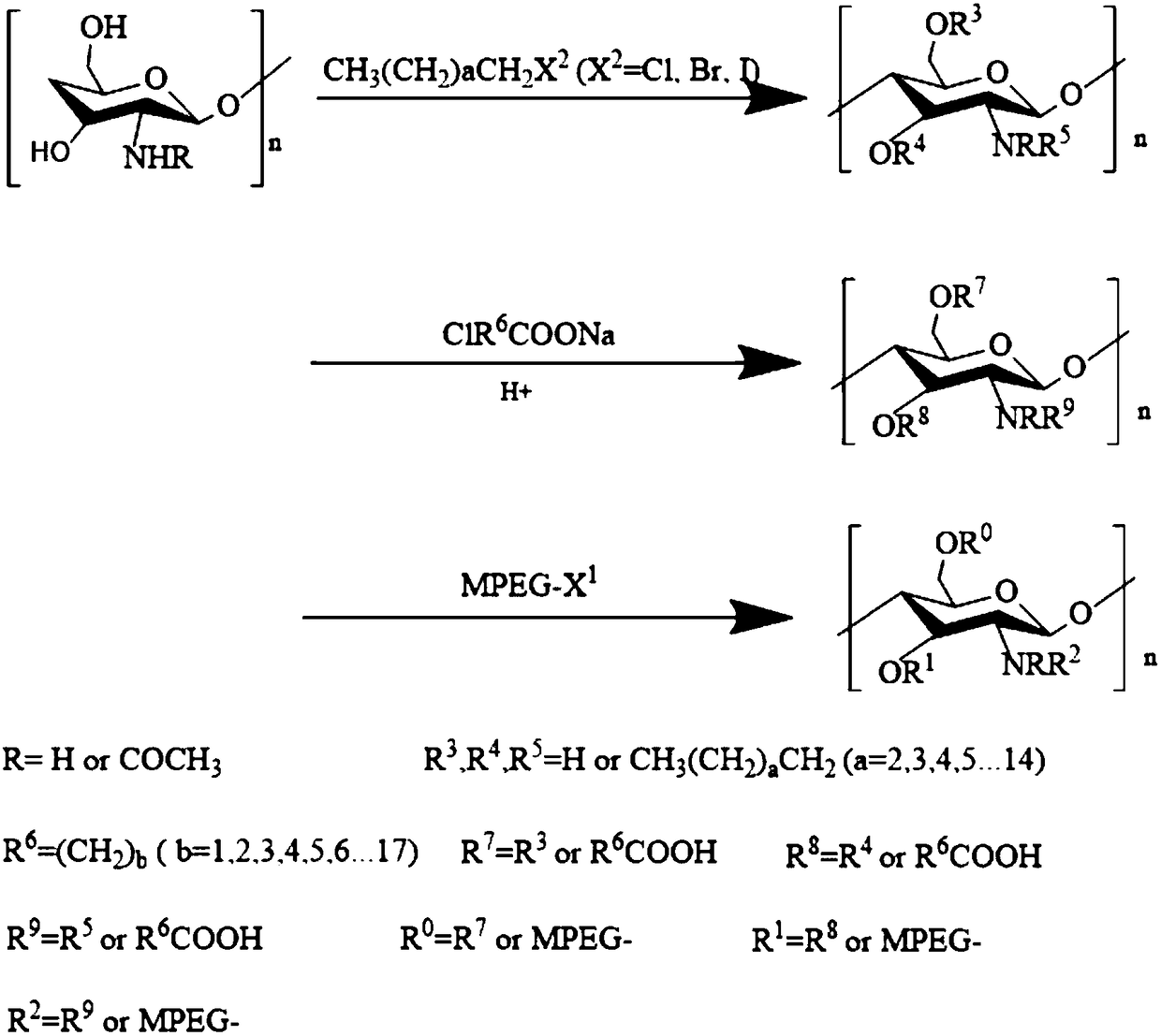

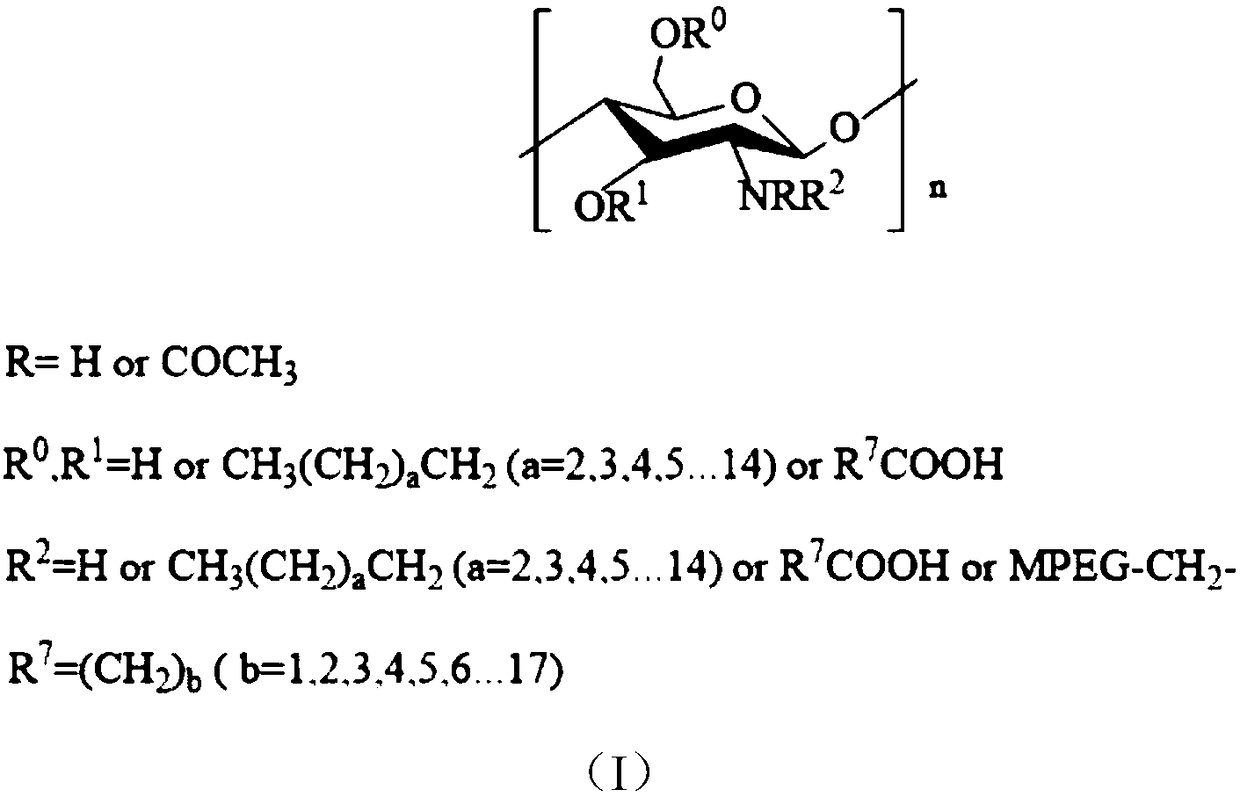

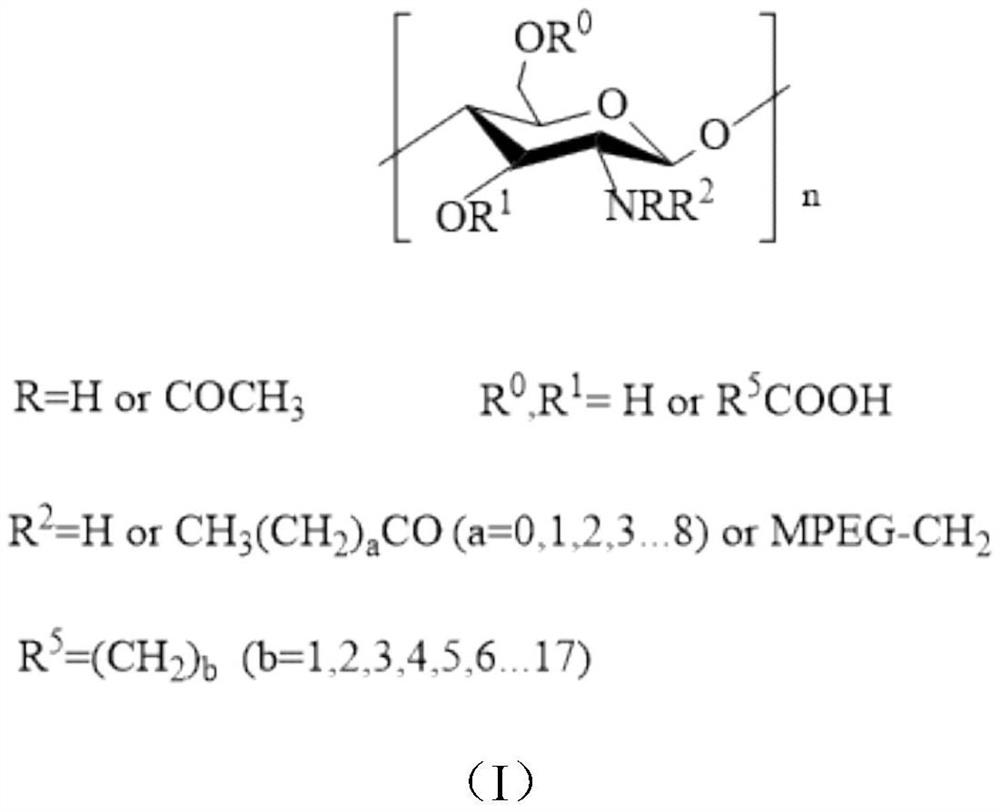

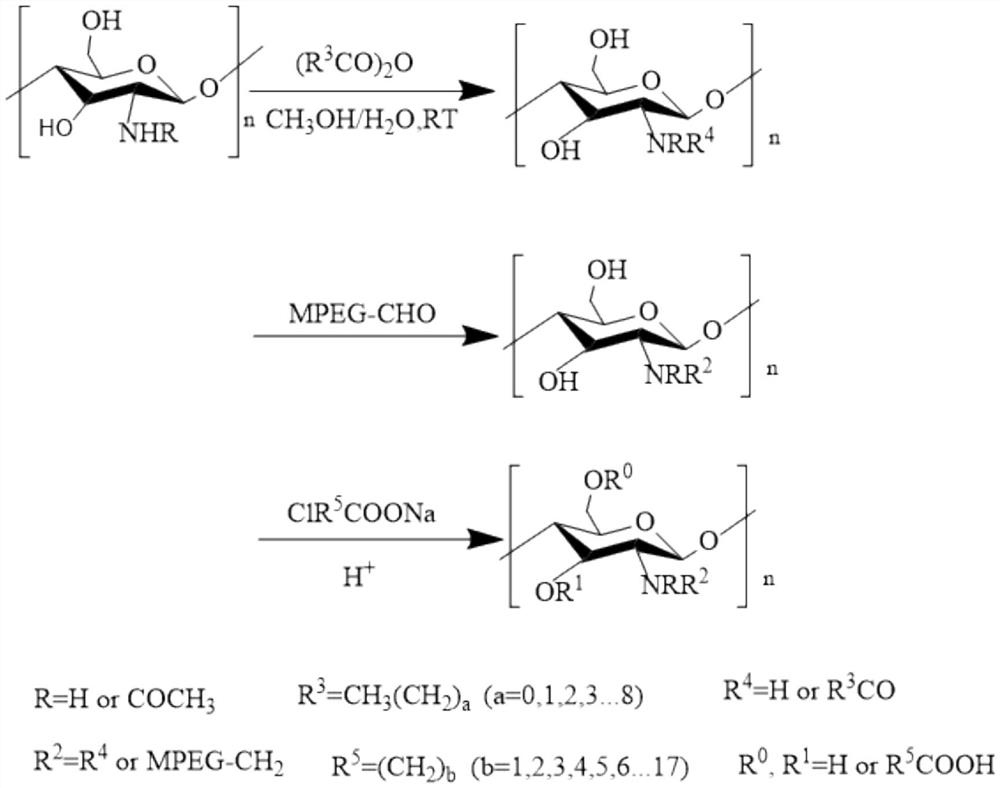

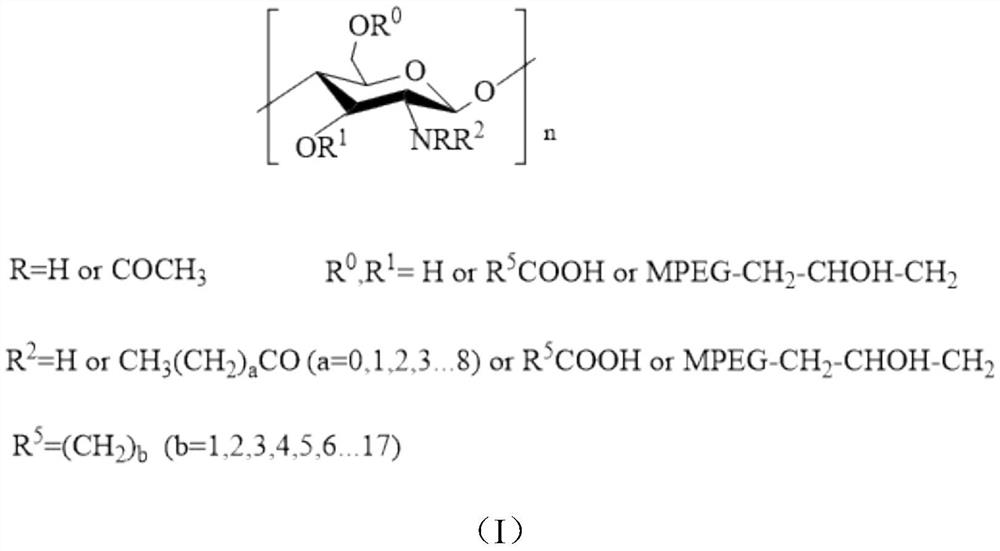

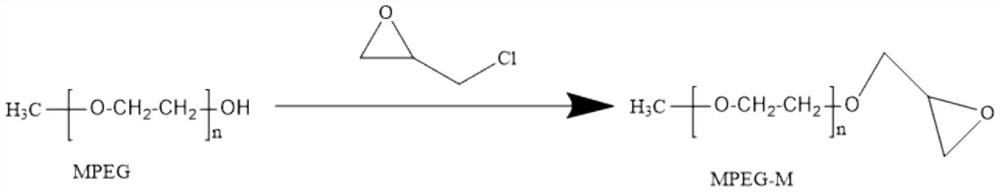

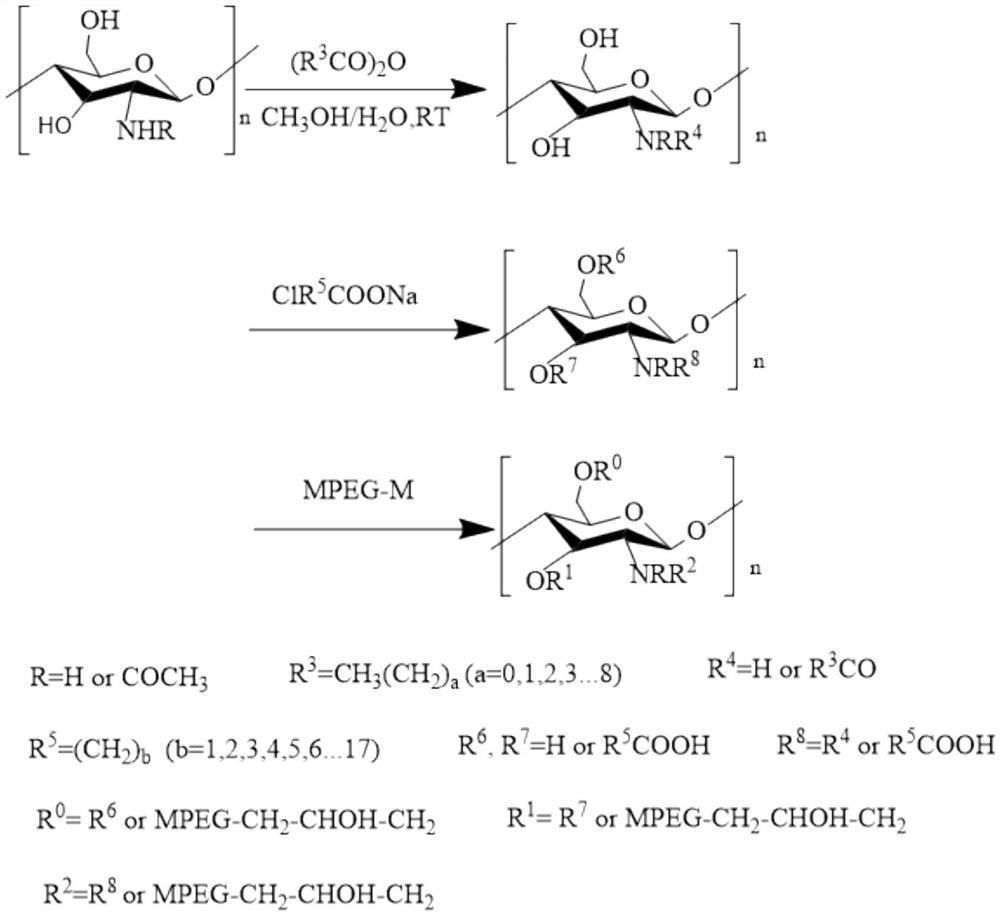

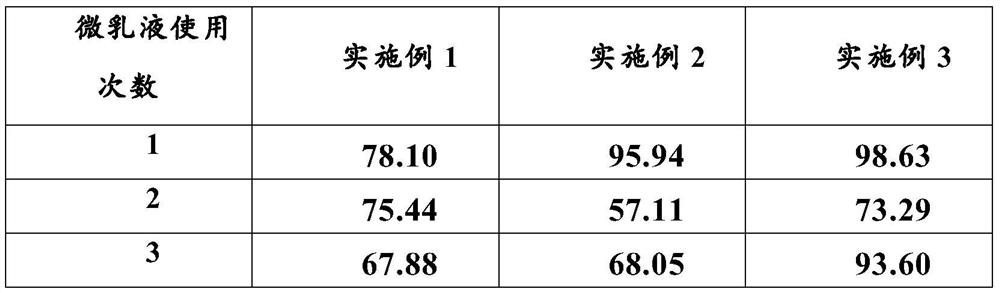

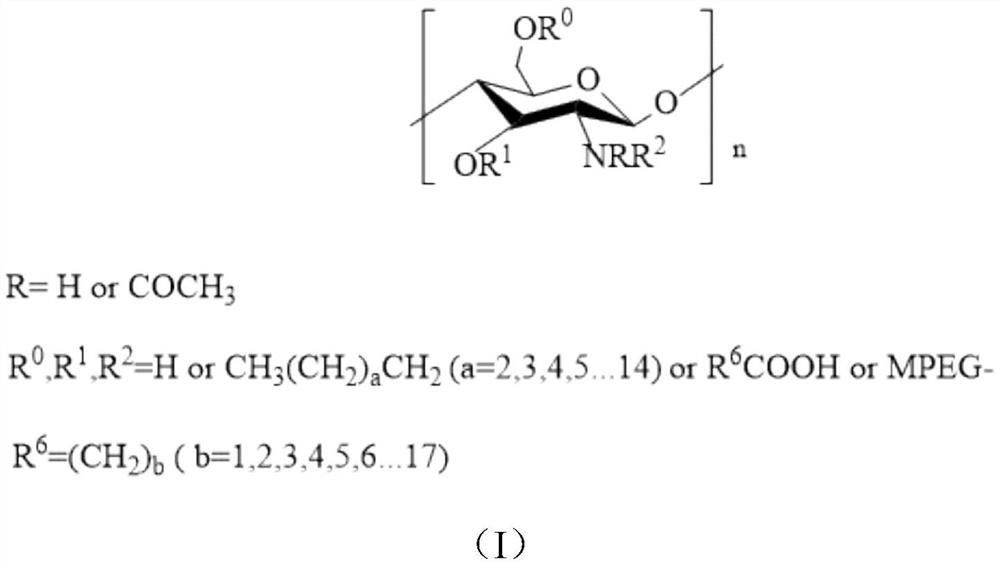

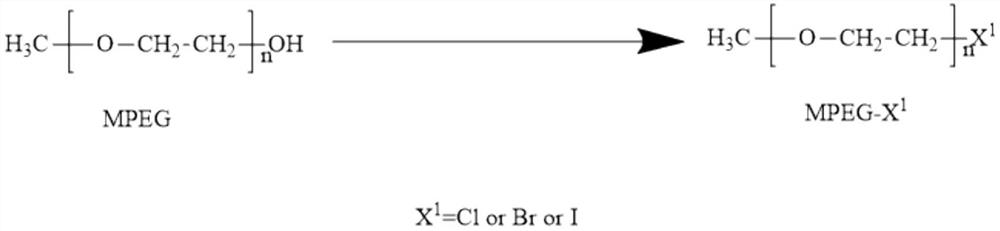

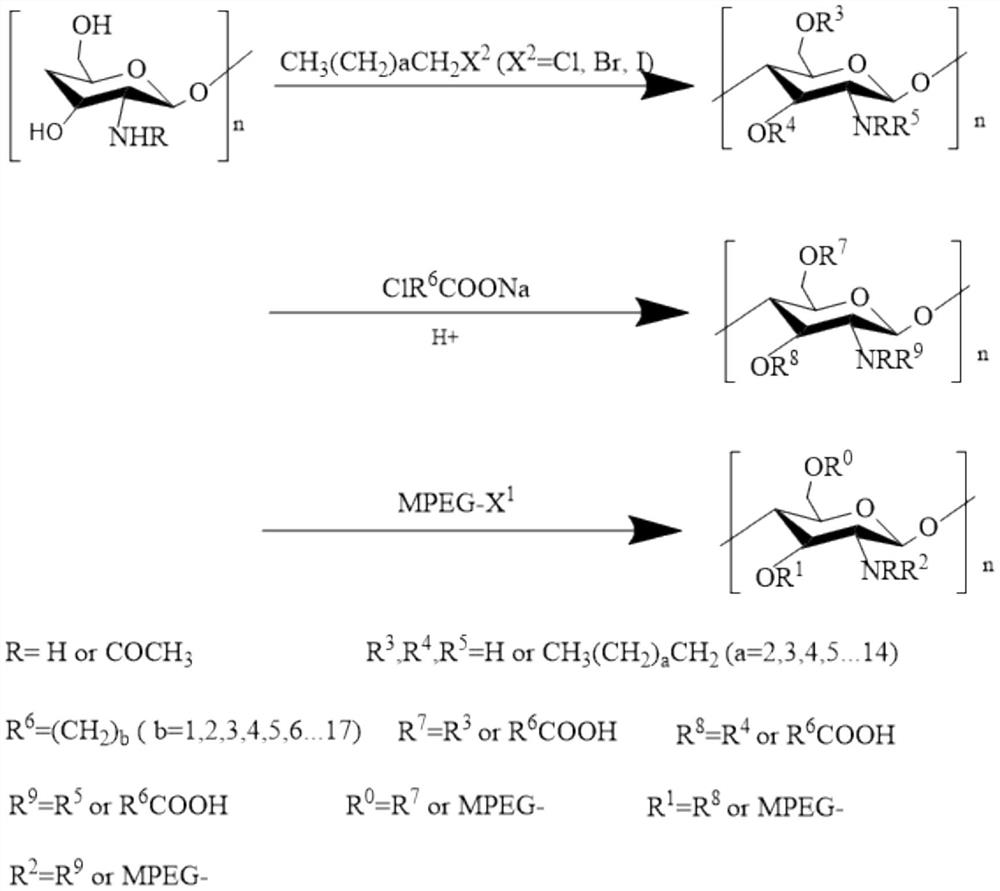

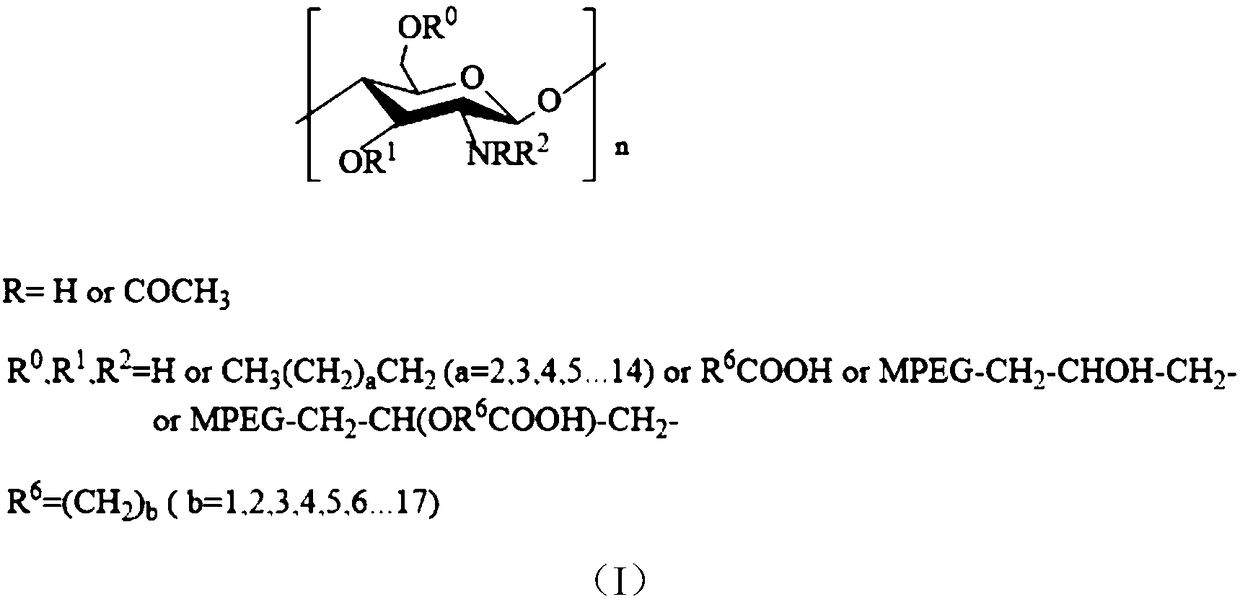

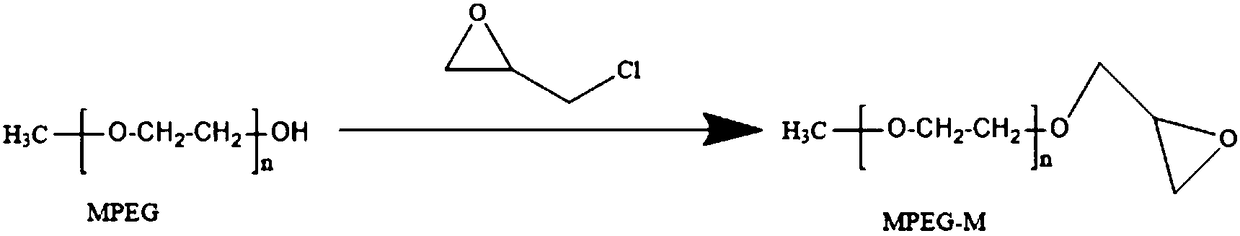

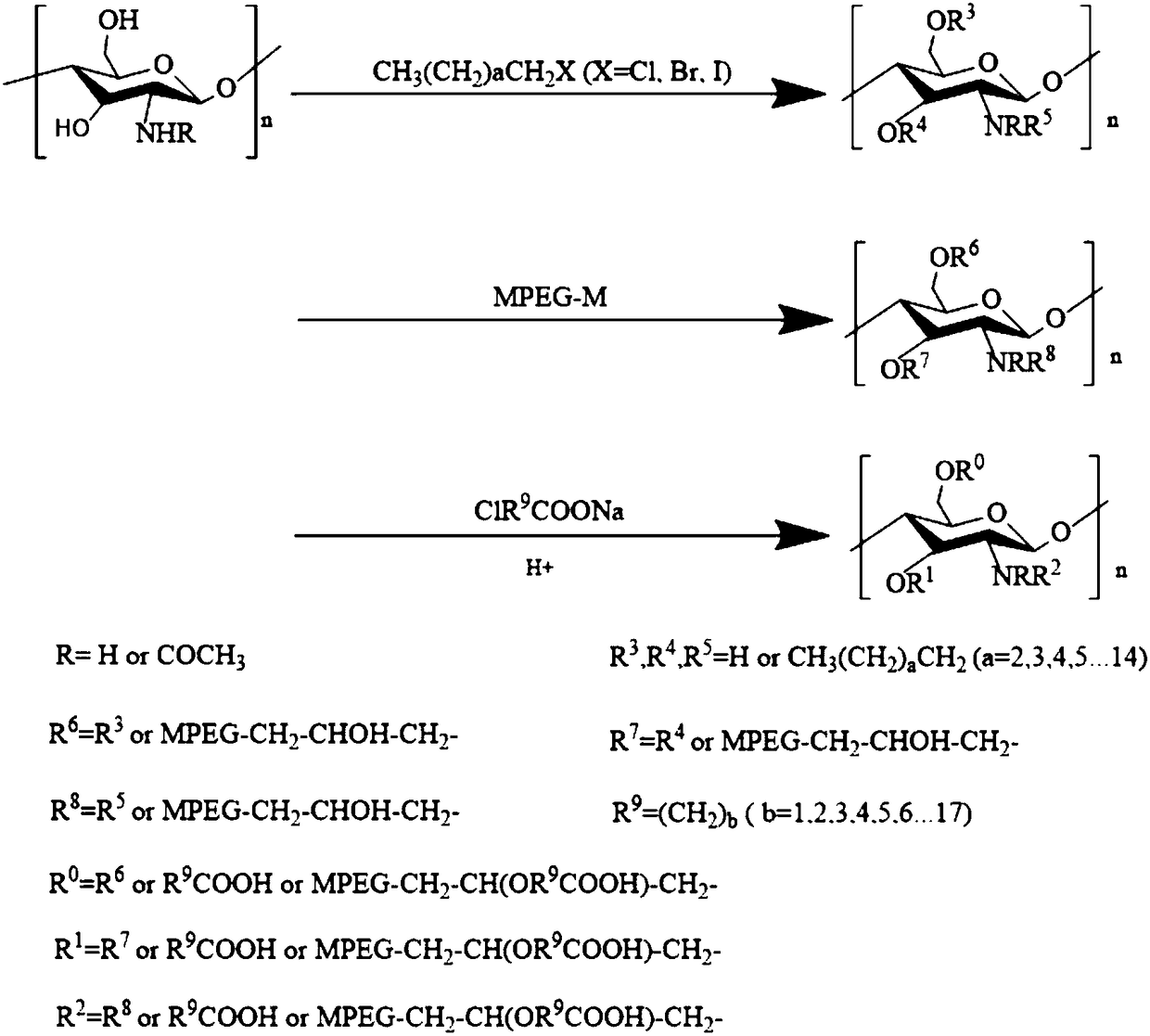

Chitosan oil-in-water type crude oil demulsifier and preparation method thereof

ActiveCN108865220AWide variety of sourcesDegradableDewatering/demulsification with chemical meansHydrocarbon oils treatmentSide chainPolythylene glycol

The invention relates to a chitosan oil-in-water type crude oil demulsifier and a preparation method thereof. A structure general formula of the demulsifier is as shown in formula I, and the preparation method thereof comprises the following steps: 1) performing alkylation modification on chitosan, to obtain alkylation chitosan; (2) performing carboxyalkylation modification on the alkylation chitosan, to obtain alkylation carboxy alkyl chitosan; (3) performing halogenation modification on a terminal hydroxyl of methoxypolyethylene glycol, to obtain halogenation modified methoxypolyethylene glycol; and 4) enabling the modified methoxypolyethylene glycol to react with the alkylation carboxy alkyl chitosan, to obtain methoxypolyethylene glycol grafted alkylation carboxy alkyl chitosan. The demulsifier is capable of using chitosan natural macromolecular compounds as raw materials, and has the advantages of wide source, nature, non-toxicity, good biocompatibility, degradation and the like.A carboxy group, an group and a polyether side chain are introduced into a chitosan molecular chain, and through controlling a position and a substitution degree of each substituent group, a series ofthe efficient demulsifiers suitable for oil-in-water (O / W) emulsion is obtained.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

De-oiling device

The invention discloses a deoiling device, which comprises an outer barrel, an oil storage tank is arranged at the bottom of the inner cavity of the outer barrel, and a rotating motor is connected to the top of the oil storage tank through a damping spring, and the left and right sides of the rotating motor Fixed rods are respectively provided, and the fixed rods are fixedly connected with the oil storage tank through a fixed shaft. The output shaft of the rotating motor is connected with the main shaft through a coupling. The top of the main shaft is provided with an inner barrel, and the outer wall of the inner barrel The outer barrel is connected with a shock absorber provided on the top, and the shock absorber includes a shock absorber shell, a fixing plate, a shock absorber spring, a shock absorber wheel, a shock absorber rod and a rubber shock absorber head. The deoiling device adopts the comprehensive use of fixed rods, shock absorbers and shock absorbing springs, which reduces the vibration of the device during operation, reduces the damage to the deoiling barrel during operation, and thus prolongs the service life of the device , which reduces the cost of production and improves the efficiency of deoiling at the same time.

Owner:WUXI GANGSHENG HEAVY EQUIP CO LTD

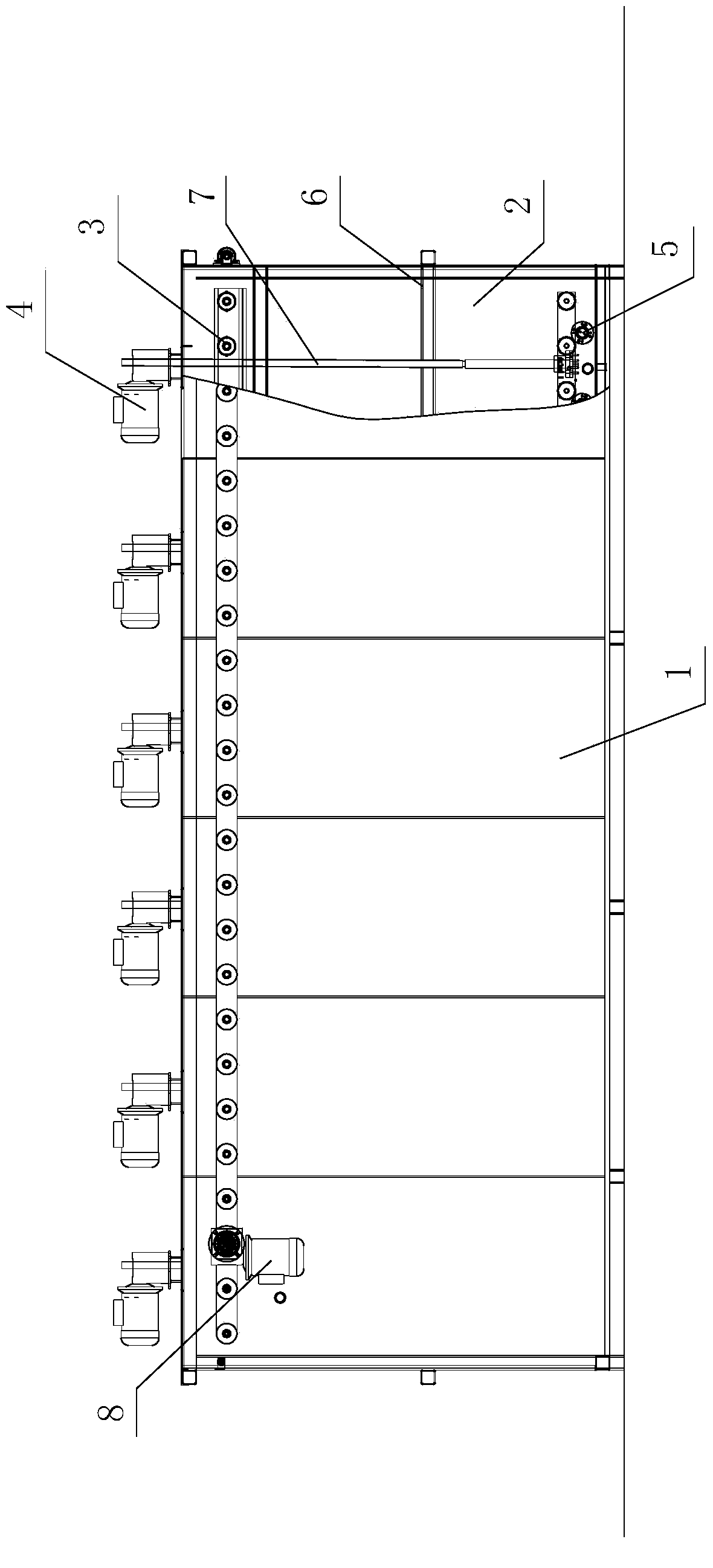

Special oil removing tank for extruding ultrahigh molecular weight polyethylene gel

InactiveCN103710793AEasy to useQuick collectionArtificial filament recoveryTextile/flexible product manufactureOrganic solventFuel tank

The invention relates to a special oil removing tank for extruding ultrahigh molecular weight polyethylene gel. The special oil removing tank comprises a tank body and an outer frame type reinforcing frame fixed in the tank body, wherein a plurality of inner tanks are formed in the tank body through partitioning plates, heights of the partitioning plates between adjacent inner tanks are reduced in a step manner from rear to front so that the liquid level of a stored extracting solution is reduced in a step manner so as to dilute process oil grade by grade; and meanwhile, the oil removing time and the oil removing amount of the PE (polyethlene) partitioning plates are ensured. The special oil removing tank is beneficial to online recovery and circulation of the extracting agent and the process oil. The special oil removing tank has the advantages of high oil removing efficiency, simple operation, high automation degree and good sealing effect; the extracting agent and the process oil can be rapidly collected and recycled after being conveniently separated, the production benefit is increased, and the waste of an organic solvent and the pollution to the environment are effectively reduced.

Owner:江苏诚盟装备股份有限公司

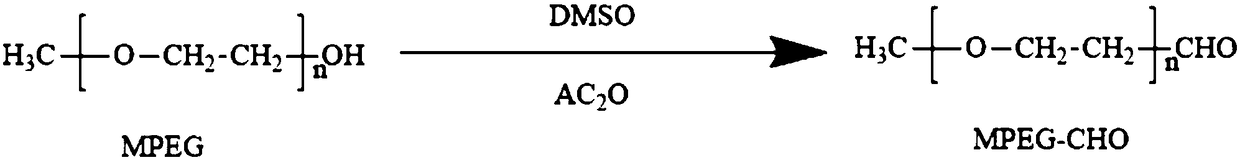

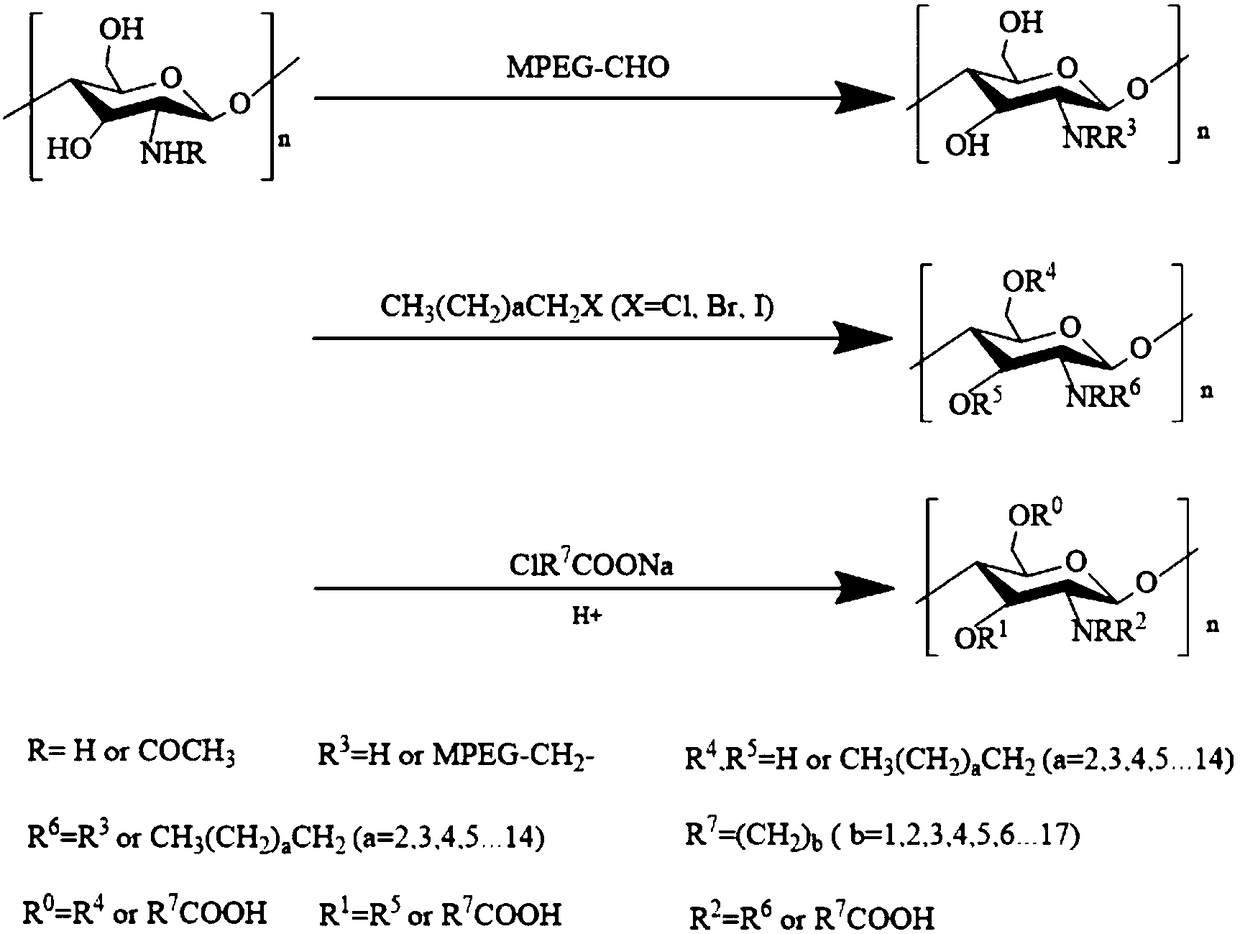

Polyether grafted oil-in-water type crude oil demulsifier and preparation method thereof

ActiveCN108865224AWide variety of sourcesSustainableDewatering/demulsification with chemical meansHydrocarbon oils treatmentNon toxicitySide chain

The invention relates to a polyether grafted oil-in-water type crude oil demulsifier and a preparation method thereof. A structure general formula of the demulsifier is as shown in formula I, and thepreparation method thereof comprises the following steps: 1) performing aldehydes modification on a terminal hydroxyl of methoxypolyethylene glycol; 2) enabling the modified methoxypolyethylene glycolto react with chitosan, to obtain methoxypolyethylene glycol grafted chitosan; 3) performing alkylation modification on the methoxypolyethylene glycol grafted chitosan; and 4) performing carboxy alkylation modification on methoxypolyethylene glycol grafted alkylation chitosan, to obtain methoxypolyethylene glycol grafted alkylation carboxy alkyl chitosan. The demulsifier is capable of using chitosan natural macromolecular compounds as a raw material, and has the advantages of wide source, nature, non-toxicity, good biocompatibility, degradation and the like. A carboxy alkyl, an alkyl and a polyether side chain are introduced into a chitosan molecular chain, and through controlling a position and a substitution degree of each substituent group, a series of the efficient demulsifiers suitable for oil-in-water (O / W) emulsion is obtained.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Oil remover and its production

InactiveCN100453164CRich sourcesRich varietyOther chemical processesDispersed particle separationPhysical chemistryOxidizing agent

Owner:河南宇新活性炭厂

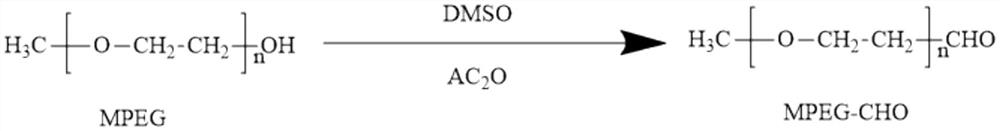

A kind of polyether grafted polysaccharide crude oil demulsifier and preparation method thereof

ActiveCN108865234BWide variety of sourcesSustainableDewatering/demulsification with chemical meansHydrocarbon oils treatmentPolymer scienceSide chain

The invention relates to a polyether grafted polysaccharides crude oil demulsifier and a preparation method thereof. A structure general formula of the demulsifier is as shown in formula I, and the preparation method thereof comprises the following steps: 1) performing acylation modification on chitosan, to obtain N-acylated chitosan; 2) performing aldehydes modification on a terminal hydroxyl ofmethoxypolyethylene glycol, to obtain aldehyde methoxypolyethylene glycol; 3) enabling the modified methoxypolyethylene glycol to react with N-acylated chitosan, to obtain methoxypolyethylene glycol grafted N-acylated chitosan; 4) performing carboxy alkylation modification on the methoxypolyethylene glycol grafted N-acylated chitosan, to obtain methoxypolyethylene glycol grafted N-acylated carboxyalkyl chitosan. The demulsifier is capable of using chitosan natural macromolecular compounds as a raw material, wide in source, natural, non-toxic, good in biocompatibility, and degradable. A carboxy alkyl, an acyl and a polyether side chain are introduced into a chitosan molecular chain, and through controlling a position and a substitution degree of each substituent group, a series of the efficient demulsifiers suitable for oil-in-water (O / W) emulsion is obtained.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

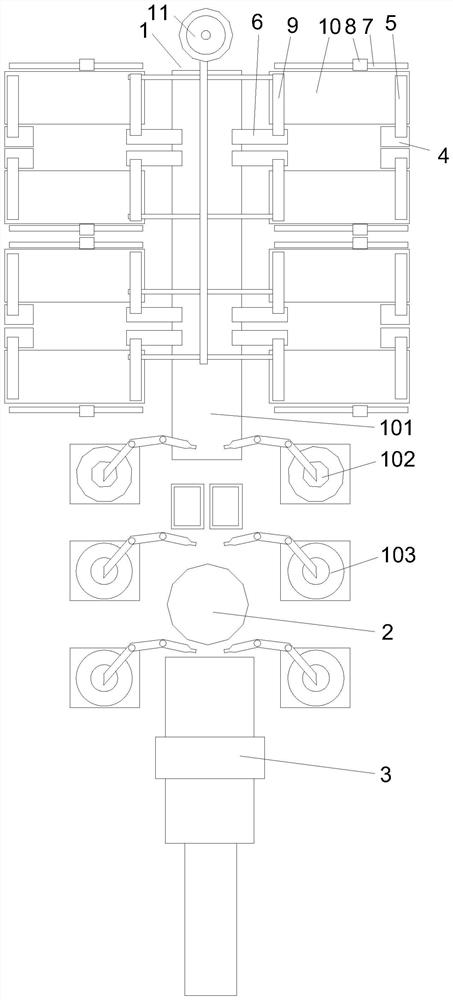

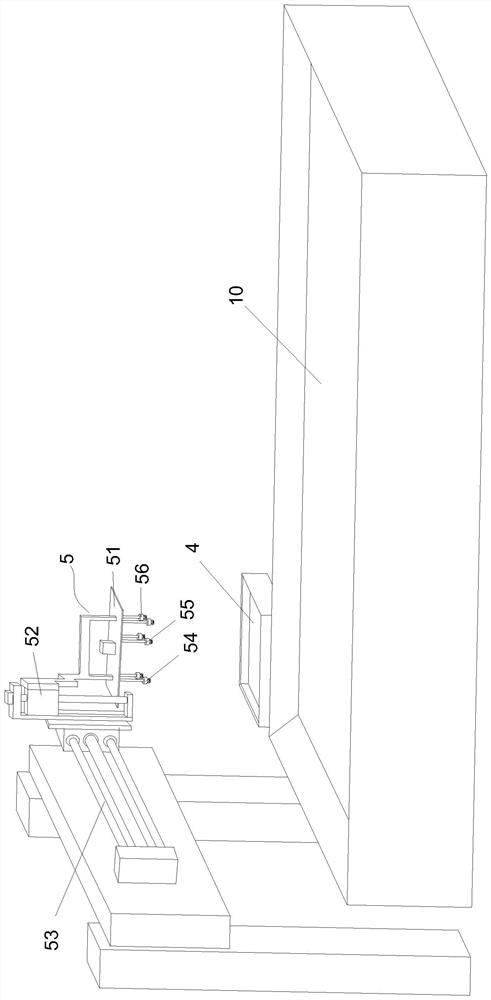

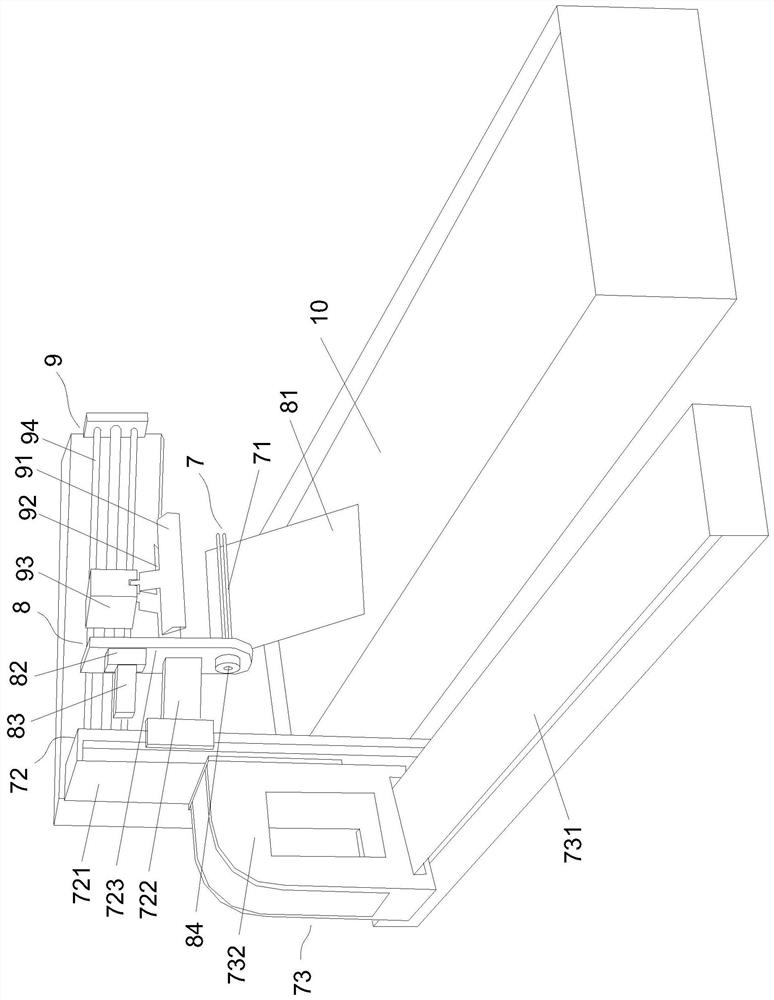

Fried beancurd skin roll production line

ActiveCN114766524AGuaranteed fixed effectRealize automated productionRotary centrifugesOil/fat bakingMechanical engineeringBiomedical engineering

The invention provides a fried beancurd skin roll production line which comprises a plurality of roll frying mechanisms used for frying beancurd skin rolls, an output mechanism used for outputting and boxing the fried beancurd skin rolls, a deoiling mechanism used for spin-drying and deoiling the beancurd skin rolls and a slitting mechanism used for trimming and slitting the beancurd skin rolls. The deoiling mechanism comprises a deoiling box used for placing beancurd skin rolls and a deoiling cylinder used for accommodating the deoiling box and driving the deoiling box to rotate; the output mechanism comprises a main conveying belt used for outputting the beancurd skin rolls, a first mechanical arm used for sorting the beancurd skin rolls on the main conveying belt and putting the beancurd skin rolls into the deoiling tank, and a second mechanical arm used for putting the deoiling tank into the deoiling barrel. According to the automatic feeding and frying device, automatic feeding and frying of the bean curd skin can be achieved, automatic production is achieved, manual production is omitted, the production efficiency is effectively improved, and the frying quality is guaranteed.

Owner:泉州鼎成食品有限公司

An impeller degreasing fixture

ActiveCN104500431BNovel structureEasy to implementPump componentsCentrifugesImpellerPulp and paper industry

Owner:CHONGQING FEILONG JANSANT AUTO PARTS

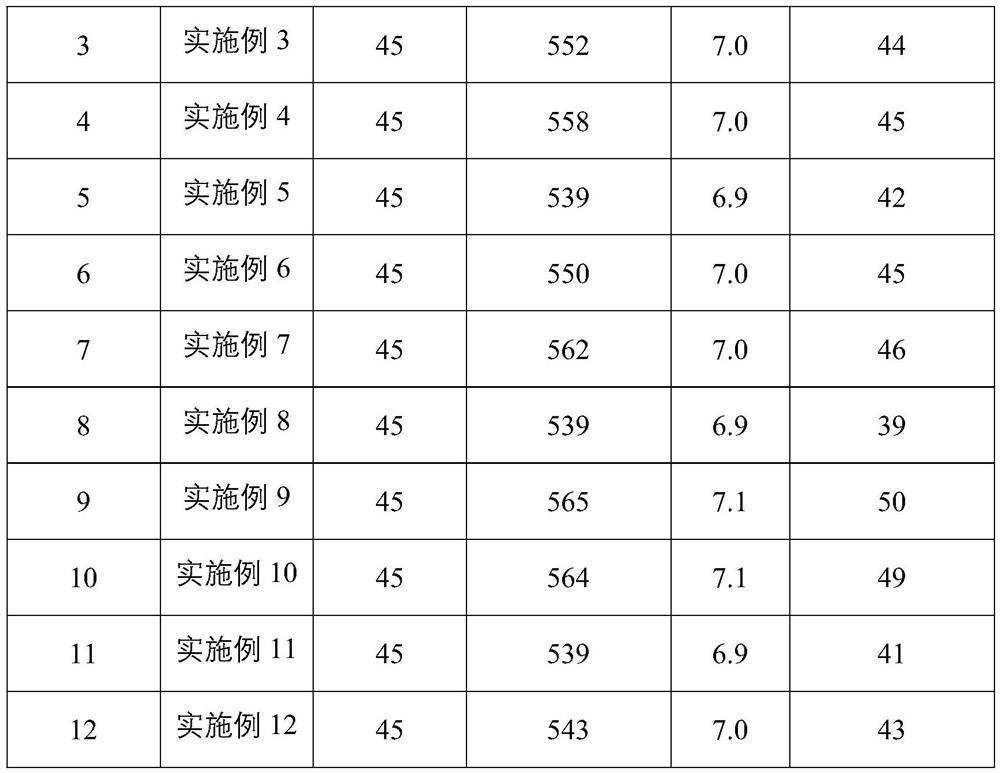

Preparation method of multi-branched cationic polyether microbial demulsifier

PendingCN113637497AEasy to separateImprove EOR indexDewatering/demulsification with chemical meansMicroorganism based processesBiotechnologyCyanide compound

The invention discloses an environment-friendly multi-branched cationic polyether microbial demulsifier synthesized based on a double metal cyanide complex catalyst, bisphenol A is used as a block polyether initiator and reacts with formaldehyde and vinylamine to generate a polyamine compound which takes bisphenol A as a core, vinylamine as a branch and phenolic hydroxyl as a leaf, then ring-opening polymerization is performed on the modified cationic polyether and epoxy compounds including epoxypropane and ethylene oxide to obtain multi-branched polyether, and further the multi-branched polyether reacts with a microbial metabolite and a surfactant to obtain the multi-branched cationic polyether microbial demulsifier. The multi-branched cationic polyether microbial demulsifier prepared by using the double-metal cyanide complex catalyst has no acid-base property problem, has good chemical and biological characteristics and oil and water amphipathy, can effectively reduce the surface tension of water, can be used under the conditions of extreme temperature, pH value and salinity, is non-toxic, environment-friendly and energy-saving, the demulsifier is biodegradable, has higher deoiling rate and demulsification efficiency and better demulsification capability, does not need post-treatment, and overcomes the defects of the traditional demulsifier in function and preparation process; the oil exploitation cost is reduced, and the development of an oil exploitation process is promoted.

Owner:JINHU JINLING NEW MATERIAL SCI & TECH

A kind of novel crude oil demulsifier and preparation method thereof

ActiveCN108865233BWide variety of sourcesSustainableDewatering/demulsification with chemical meansHydrocarbon oils treatmentPolymer scienceSide chain

The invention relates to a novel crude oil demulsifying agent and a preparation method thereof. A structural general formula of the novel crude oil demulsifying agent is shown as a formula I. The preparation method of the demulsifying agent comprises the following steps: 1) performing acylation modification on chitosan to obtain N-acylation chitosan; 2) performing carboxyl alkylation modificationon the N-acylation chitosan to obtain N-acylated carboxyl alkyl chitosan; 3) performing epoxidation modification on methoxypolyethylene glycol terminal hydroxyl to obtain epoxidation methoxypolyethylene glycol; 4) reacting modified methoxypolyethylene glycol with N-acylated carboxyalkyl chitosan to obtain a target product of methoxypolyethylene glycol grafted N-acylated carboxyalkyl chitosan. According to the novel crude oil demulsifying agent disclosed by the invention, chitosan natural polymer compound is utilized as a raw material; the raw material has the advantages of wide sources, natural performance, no toxin, good biocompatibility, degradation and the like; carboxyalkyl, alkyl and a polyether side chain are guided into a molecular chain of the chitosan; by means of controlling positions and substitution degrees of all substituent groups, a series of high-efficiency demulsifying agents suitable for oil-in-water (O / W) type emulsion can be prepared.

Owner:滨州市立德石油科技有限公司

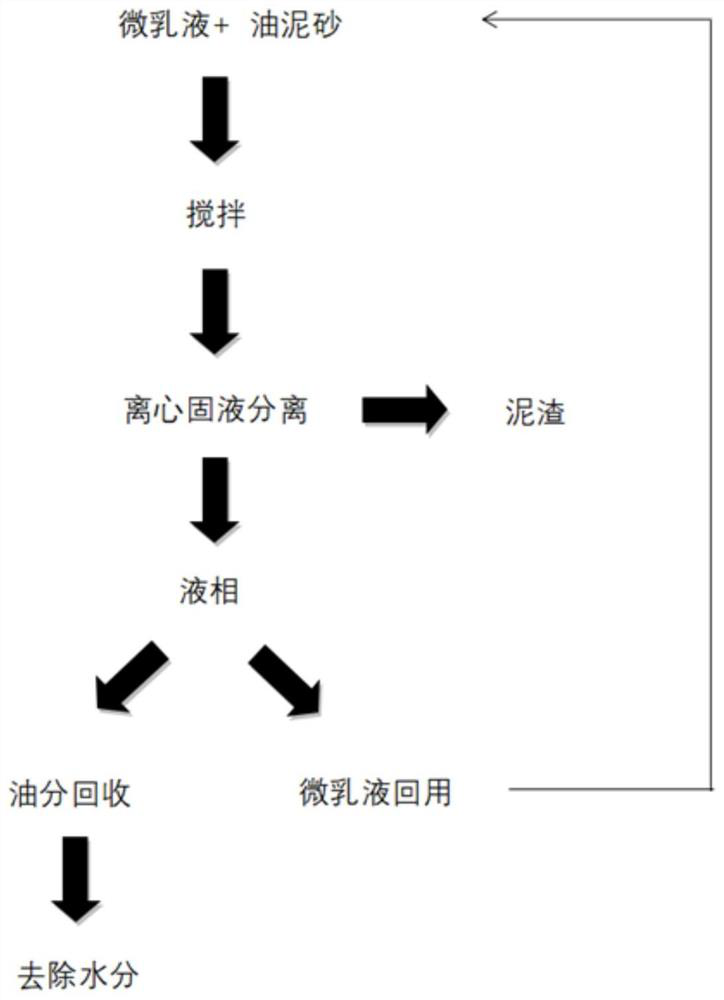

Method for recovering crude oil by cleaning oil sludge sand

ActiveCN110760328BReduce adhesionEfficient removalWaste water treatment from quariesLiquid hydrocarbon mixture productionInorganic saltsFluid phase

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of chitosan oil-in-water type crude oil demulsifier and preparation method thereof

ActiveCN108865220BWide variety of sourcesSustainableDewatering/demulsification with chemical meansHydrocarbon oils treatmentSide chainPolythylene glycol

The invention relates to a chitosan oil-in-water type crude oil demulsifier and a preparation method thereof. A structure general formula of the demulsifier is as shown in formula I, and the preparation method thereof comprises the following steps: 1) performing alkylation modification on chitosan, to obtain alkylation chitosan; (2) performing carboxyalkylation modification on the alkylation chitosan, to obtain alkylation carboxy alkyl chitosan; (3) performing halogenation modification on a terminal hydroxyl of methoxypolyethylene glycol, to obtain halogenation modified methoxypolyethylene glycol; and 4) enabling the modified methoxypolyethylene glycol to react with the alkylation carboxy alkyl chitosan, to obtain methoxypolyethylene glycol grafted alkylation carboxy alkyl chitosan. The demulsifier is capable of using chitosan natural macromolecular compounds as raw materials, and has the advantages of wide source, nature, non-toxicity, good biocompatibility, degradation and the like.A carboxy group, an group and a polyether side chain are introduced into a chitosan molecular chain, and through controlling a position and a substitution degree of each substituent group, a series ofthe efficient demulsifiers suitable for oil-in-water (O / W) emulsion is obtained.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

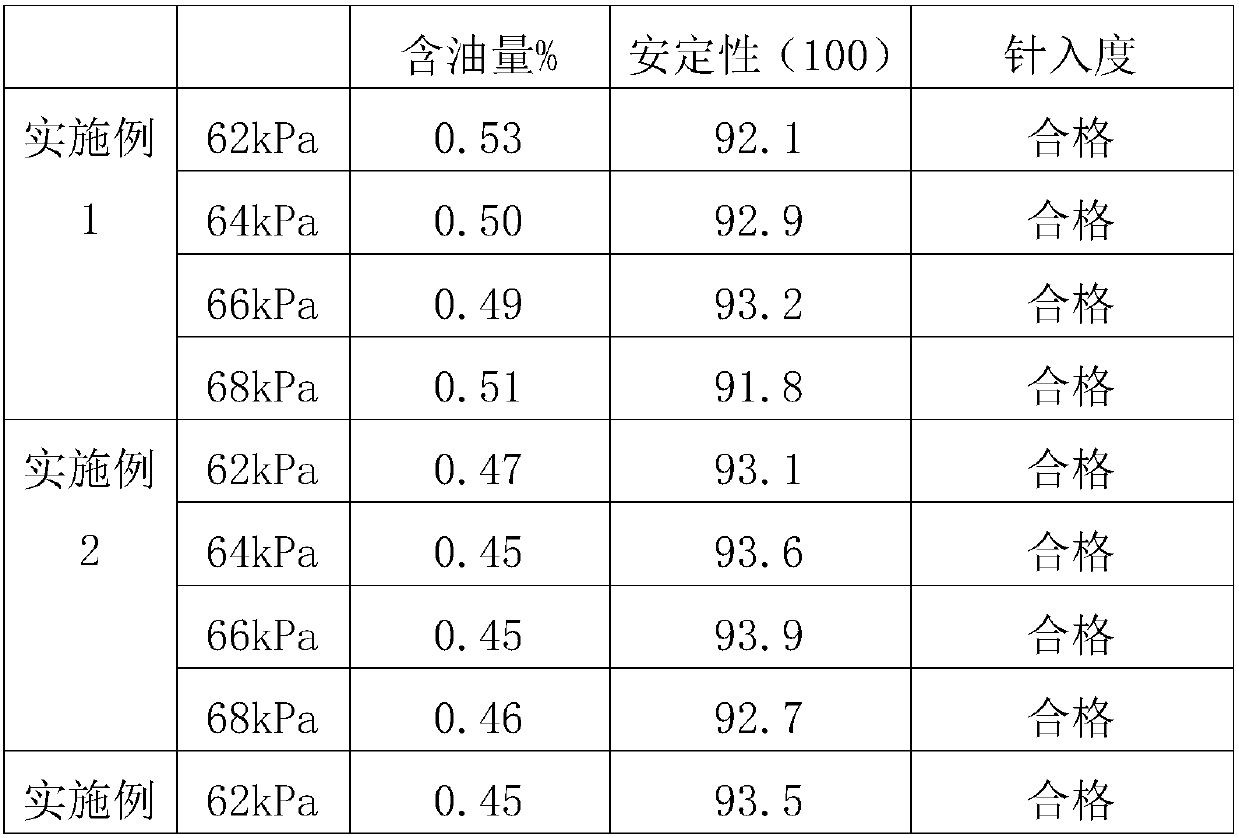

Lubricating oil production residue recovery method

PendingCN109652125AImprove oil support effectHigh deoiling efficiencyPetroleum wax recoverySolventParaffin wax

The invention relates to the technical field of residue recovery, and especially relates to a lubricating oil production residue recovery method. The method can improve the purity of separated cerate,improve the storage stability, facilitate storage, transportation and use and improve the deoiling effect. The method includes the following steps: (1) heating, and dilution; (2) cooling crystallization: cooling of a uniformly mixed material to 30 DEG C to precipitate wax, and filtration for separating precipitated paraffin crystals; (3) solvent recovery; (4) atomization treatment: heating of theseparated paraffin crystals to 60 DEG C for remelting, spraying of the melted crystals into a spray tower through a high pressure nozzle at a high temperature, and adjustment of the pressure in the spray tower to 62-68 kPa to solidify paraffin drops into fine particles; (5) reverse absorption: spraying of a lubricating oil solvent in a direction opposite to the spraying direction of the paraffinparticles to make the lubricating oil solvent in full contact with the paraffin particles, and output of oil carrying the paraffin particles; (6) solvent recovery; and (7) melting, and molding.

Owner:SHANDONG YUANGEN PETROLEUM CHEM

A filter-free deoiler and method for deoiling by using the filter-free deoiler

ActiveCN107401669BNo need for secondary separation and filtrationEasy to cleanRotary centrifugesLubrication elementsOil and greaseDrive motor

The invention relates to an oil removing machine and provides a filtering-free oil removing machine and a method for removing oil through the filtering-free oil removing machine. The filtering-free oil removing machine is simple in structure and can automatically separate out oil adhering to steel cuttings and is high in oil removing efficiency and good in quality, and separated oil is free of secondary separation and filtering. The technical problems that in the prior art, separated cooling lubrication oil needs secondary separation and filtering, time and labor are wasted, and as small holes of the wall of an oil removing barrel are blocked by metal cuttings in the process, the oil removing barrel is extremely difficult to clean, and the oil removing efficiency and quality are affected are solved. The filtering-free oil removing machine comprises a tank and an oil throwing barrel suspended in the tank, a drive motor is arranged at the position, corresponding to the oil throwing barrel, of the bottom face of the tank, an output shaft of the drive motor faces upwards and drives the oil throwing barrel to rotate, an opening of the oil throwing barrel faces upwards, and a containing cavity of the oil throwing barrel is in a circular truncated cone shape with a large opening and a small bottom.

Owner:宁波市北仑区丛峰机械有限公司

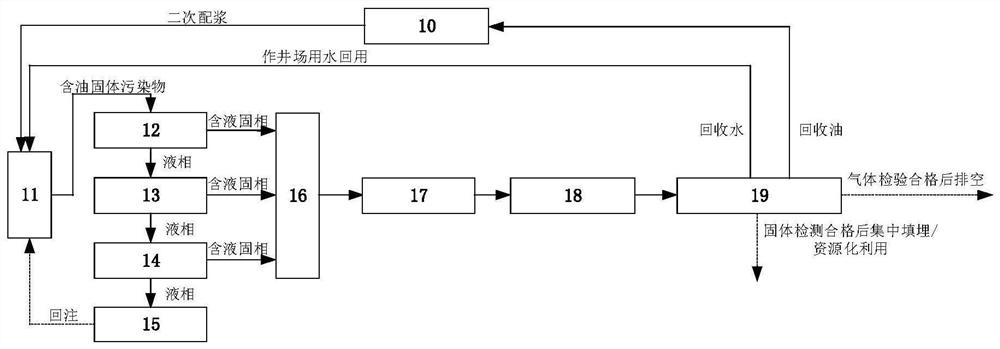

Onshore Oil and Gas Field Oil-Containing Solid Pollutants Circulating Method and Device Without Landing

ActiveCN109020123BRealize the function of crushing and dispersingImprove the efficiency of heating viscosity reductionSludge treatmentLiquid hydrocarbon mixture productionThermodynamicsPetroleum engineering

The disclosure relates to a method and device for non-falling circulation of oily solid pollutants in onshore oil and gas fields, and provides a non-falling circulation method for oily solid pollutants in onshore oil and gas fields. The method includes the following steps: (A) three-stage solid control; (B) Centrifugal drying; (C) cyclone autorotation deoiling; (D) heterogeneous separation of oil, water and gas; and (E) gas purification. Also provided is an onshore oil and gas field oily solid pollutant non-falling circulation device.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION +1

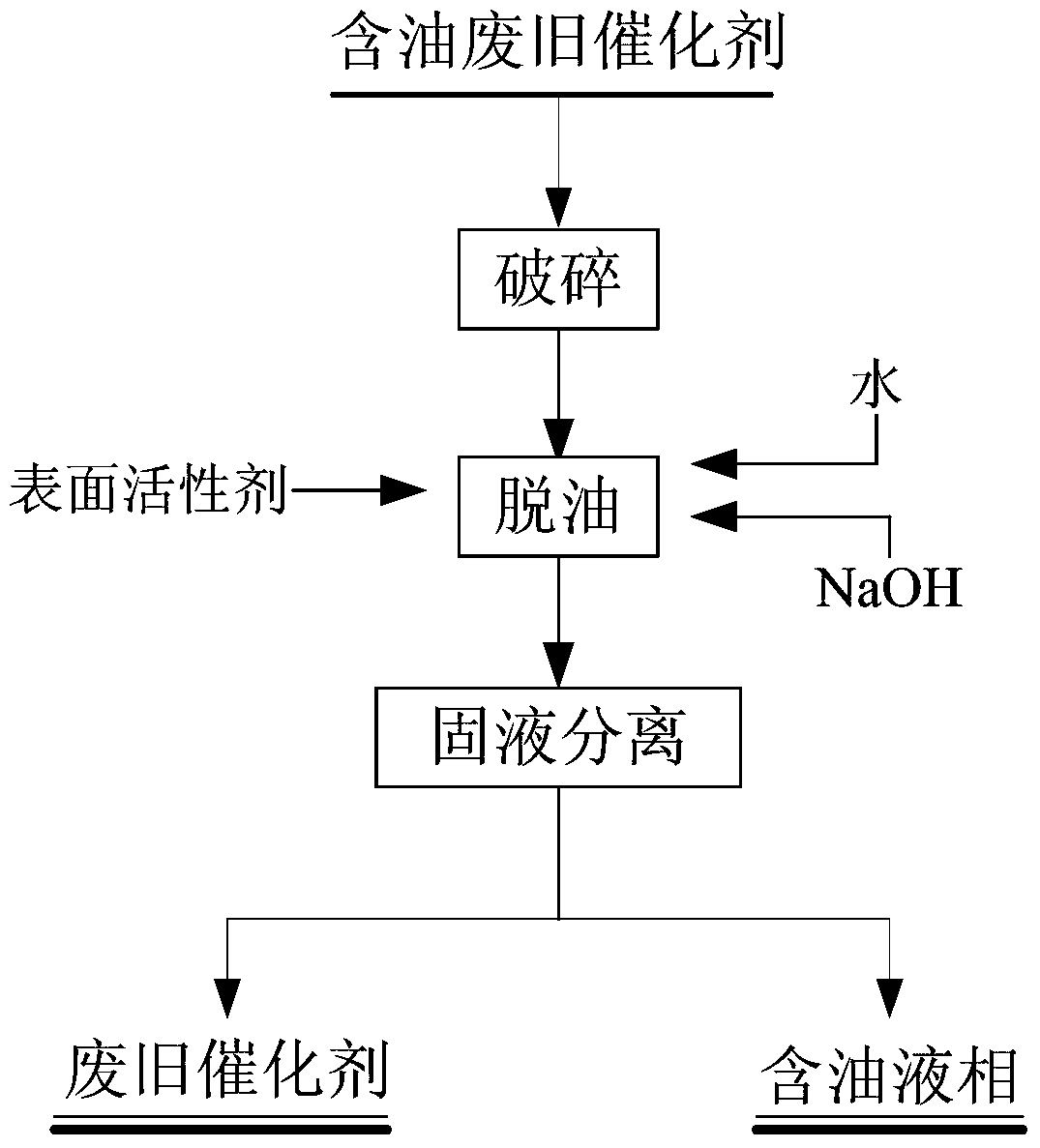

A method for deoiling oily spent catalyst

ActiveCN105498860BAvoid generatingAvoid emissionsHeterogenous catalyst chemical elementsCatalyst regeneration/reactivationHydrodesulfurizationMass ratio

The invention discloses a method for deoiling an oil-bearing waste catalyst. The key points of the technical scheme are that the waste catalyst is crushed until the particle diameter is less than 1,000 [mu]m, and the deoiling conditions are that the mass ratio of water to the waste catalyst is (12-6):1, the mass concentrations of NaOH and a surfactant are respectively controlled to be 0.05-3 wt% and 0.01-0.3 wt%, and the deoiling temperature is 40-100 DEG C. When the color of the deoiling cleaning solution does not change obviously, a conventional solid-liquid separation means is adopted to separate the oil-bearing liquid and solid. According to the technical scheme, the deoiling treatment of the oil-bearing waste catalyst is successfully realized, and the method is applicable to deoiling of one or a mixture of more of a hydrodesulfurization catalyst, a hydrodenitrification catalyst and other oil-bearing waste catalysts. The method is low in energy consumption, high in deoiling efficiency, strong in adaptability, low-carbon and environment-friendly, and can effectively avoid generation of difficultly decomposed composite oxide, so as to create favorable conditions for valuable metal extraction and cyclic utilization of the waste catalyst.

Owner:TSINGHUA UNIV

Modified chitosan type crude oil demulsifier and preparation method thereof

ActiveCN108865229AWide variety of sourcesDegradableDewatering/demulsification with chemical meansHydrocarbon oils treatmentSide chainBiocompatibility Testing

The invention relates to a modified chitosan type crude oil demulsifier and a preparation method thereof. The structural general formula of the demulsifier is shown as formula I; the preparation method comprises the following steps: 1) performing alkylation modification on chitosan to obtain alkylated chitosan; 2) performing epoxidation modification on the terminal hydroxyl of polyethylene glycolmonomethyl ether to obtain epoxidized polyethylene glycol monomethyl ether; 3) enabling the modified polyethylene glycol monomethyl ether to react with the alkylated chitosan to obtain polyethylene glycol monomethyl ether grafted alkylated chitosan; 4) performing carboxyl alkylation modification on the polyethylene glycol monomethyl ether grafted alkylated chitosan to obtain polyethylene glycol monomethyl ether grafted alkylated carboxyl alkyl chitosan. With chitosan type natural high-molecular compounds as raw materials, the modified chitosan type crude oil demulsifier provided by the invention has the advantages of wide source, natural property, no toxicity, high biocompatibility, degradability and the like. A series of efficient demulsifiers suitable for oil-in-water (O / W) type emulsionare obtained by introducing carboxyl alkyl, alkyl and polyether side chain to a chitosan molecular chain and controlling the position and substitution degree of each substituent.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Solvent deoiling device and method

ActiveCN112625747ALow recovery rateHigh recovery rateFatty substance recoveryPetroleum wax recoveryPhysical chemistryEngineering

The invention relates to a solvent deoiling device, which comprises a deoiling raw material tank, a solvent tank, a deoiling tower and a solvent and under-wax oil collecting tank, the deoiling raw material tank and the solvent tank are connected with an inlet of the deoiling tower, a filter screen is arranged at the bottom of the deoiling tower, and an outlet of the deoiling tower is connected to the solvent and under-wax oil collecting tank, and a heating and cooling jacket is arranged on the outer wall of the deoiling tower. The device is simple to operate, low in cost, wide in adaptability and high in solvent recovery rate and deoiling efficiency.

Owner:INNER MONGOLIA YITAI COAL BASED NEW MATERIALS RES INST CO LTD

Oil removal system

ActiveCN114436485AGood degreasing effectHigh deoiling efficiencySludge treatment by thermal conditioningSpecific water treatment objectivesWater reservoirTreatment system

The invention provides an oil removal system which comprises a primary ultrasonic treatment system, an ultrafiltration membrane device, a secondary thermal distillation treatment system and a water circulation system, the primary ultrasonic treatment system comprises an ultrasonic reaction chamber and a standing tank, the secondary thermal distillation treatment system comprises a reaction kettle, a condenser and an oil storage tank, and the water circulation system comprises a reservoir; a second inlet of the ultrasonic reaction chamber is connected with the reservoir, an outlet of the ultrasonic reaction chamber is connected to an inlet of the standing tank, floating oil collectors are arranged in the ultrasonic reaction chamber and the standing tank respectively, and an outlet of the standing tank is connected to the ultrafiltration membrane device; a first outlet of the ultrafiltration membrane device is connected to the reservoir, and a second outlet of the ultrafiltration membrane device is connected to an inlet of the reaction kettle; a first outlet of the reaction kettle is connected to an inlet of the condenser, and a first outlet of the condenser is connected to an inlet of the oil storage tank. The oil removal effect of the oil-containing silt is improved, the working efficiency is improved, and resources are saved.

Owner:SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com