Solvent deoiling device and method

A deoiling device and solvent technology, applied in petroleum wax recovery, fatty substance recovery, recycling technology, etc., can solve the problems of low output per unit volume, large size, space occupation, etc., achieve low cost and reduce floor space , a wide range of adaptable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

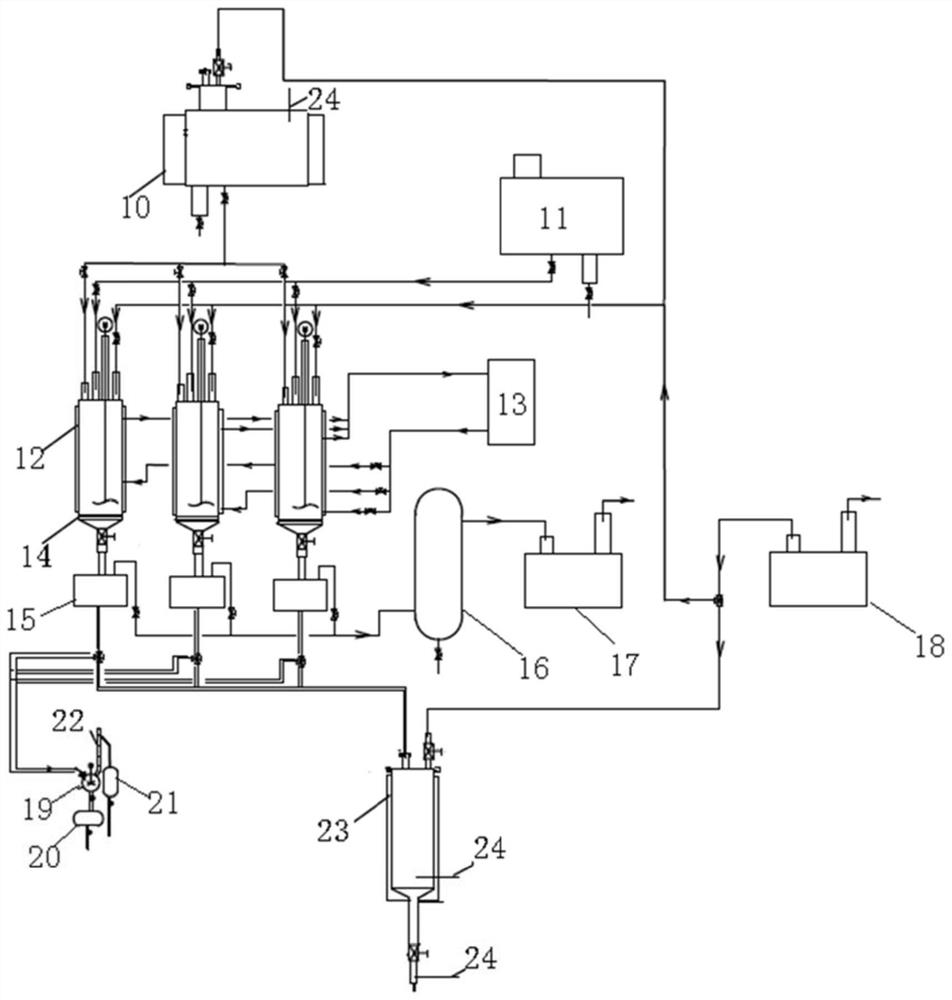

[0028] Such as figure 1 As shown, the embodiment of the present invention provides a solvent deoiling device, which changes the traditional sweating room or oven room into a tubular deoiling tower, reducing the footprint of a unit deoiling device.

[0029] The solvent deoiling device in the embodiment of the present invention includes a deoiling raw material tank 10, a solvent tank 11, a deoiling tower 12, a solvent and wax oil collection tank 15, a second buffer tank 16, a second vacuum pump 17, and a safety gas unit 18 .

[0030] The deoiling raw material tank 10 is used to accommodate the raw material to be deoiled, and it can be provided with a heating unit, such as an electric heating unit or a heat transfer oil hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com