Onshore Oil and Gas Field Oil-Containing Solid Pollutants Circulating Method and Device Without Landing

A technology for pollutants and oil and gas fields, which is applied in chemical instruments and methods, sludge treatment, and hydrocarbon oil treatment. It can solve the problems of low oil phase recovery efficiency, waste of resources, and efficient separation and utilization of difficult oils. It achieves high centrifugal force, Effect of improving efficiency and high deoiling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

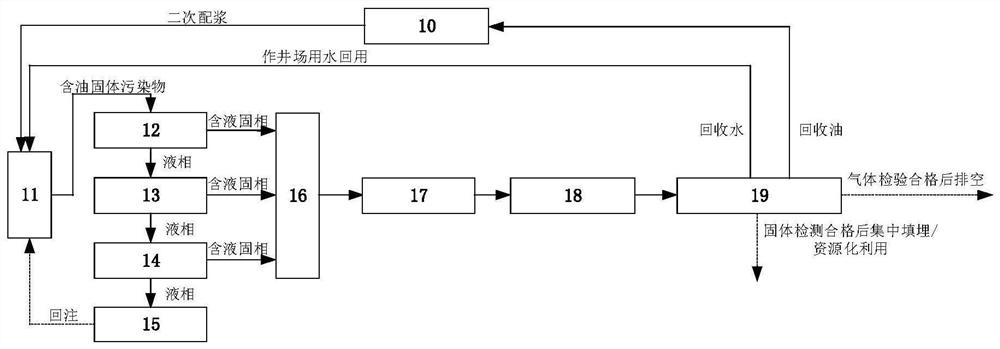

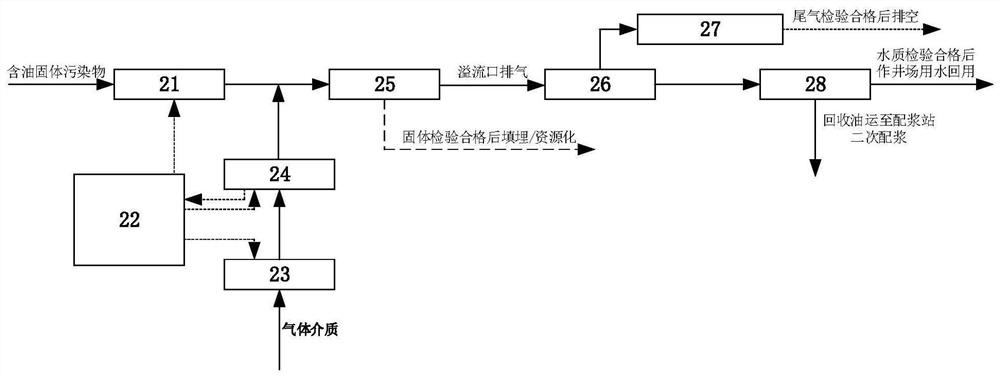

Method used

Image

Examples

Embodiment 1

[0085] The oil-containing solid pollutants produced by the oil-based mud drilling project in a shale gas block in Chongqing are mainly waste oil-based drilling fluids. The waste oil-based drilling fluids are treated according to the method and device of the present invention. The specific operation process and effects are described as follows:

[0086] 1. Implementation process

[0087] Implement with reference to the method of the present invention, specifically as follows:

[0088] In this embodiment, the heating gas medium is air, so the gas heating method is an air duct electric heater; the material transportation is a screw conveyor.

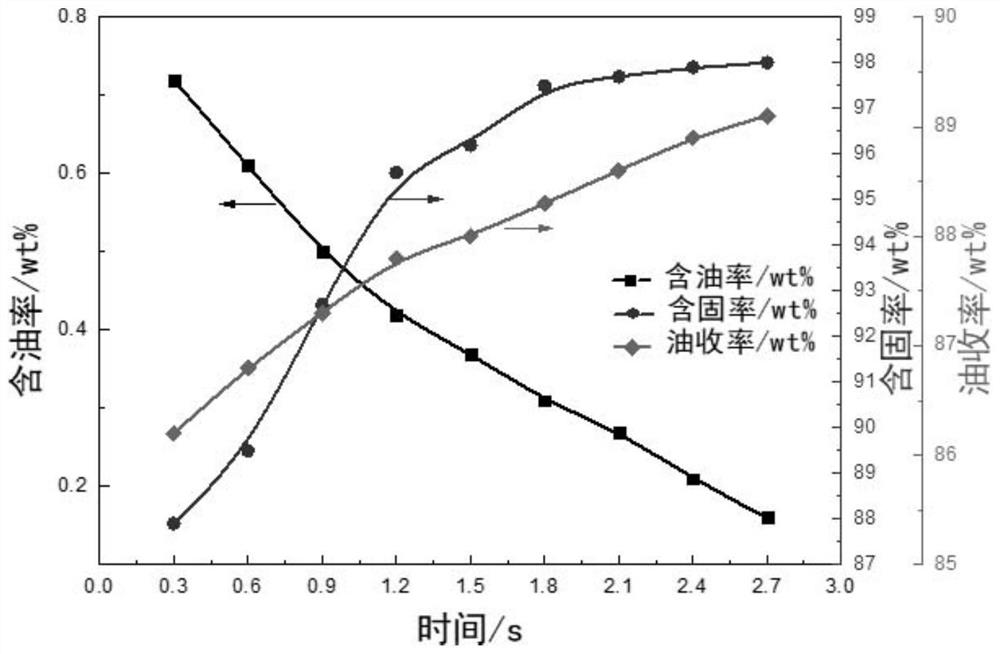

[0089] 1) Air is pumped in by the blast system and heating system (200m 3 / h) and heated to 160°C, mixed with oil-based cuttings (feed rate 50kg / h, oil content ≤ 5% after centrifugal drying) conveyed by the conveying device, and then enter the cyclone group for deep drilling Degreasing treatment. A sampling port is provided at the underf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com