Fried beancurd skin roll production line

A bean curd roll and production line technology, which is applied in oil/fat roasting, centrifuges, metal processing, etc., can solve the problems of large appearance differences, inconsistent frying time, and burns during production, so as to realize automatic production and ensure frying quality , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

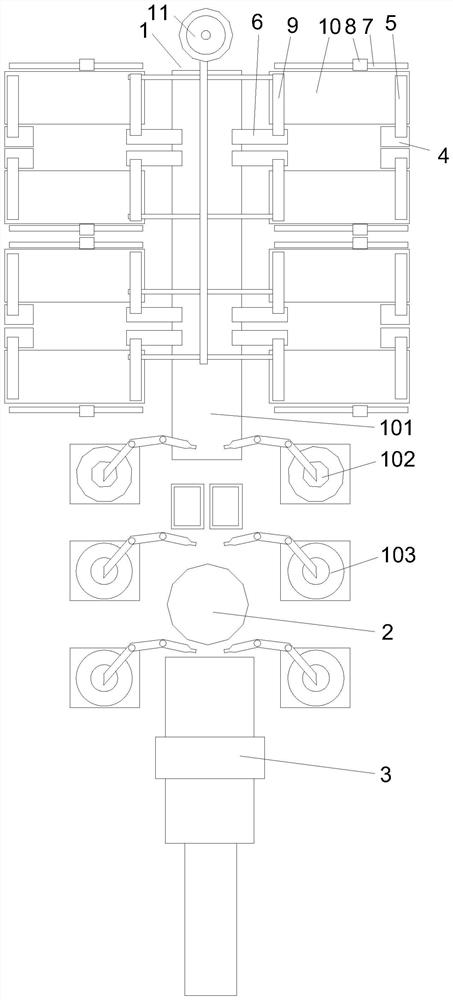

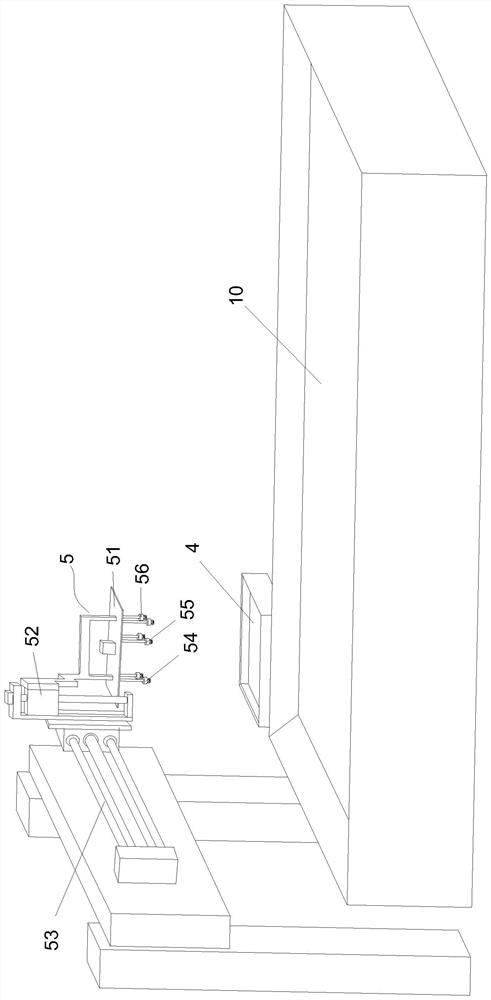

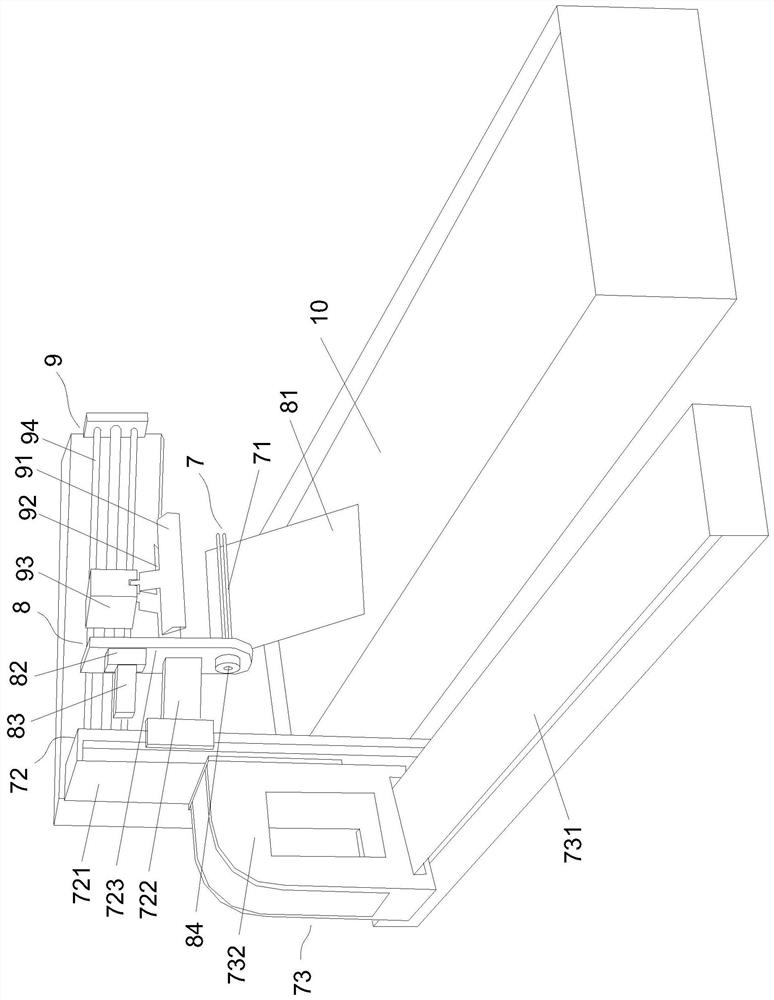

[0037] Specific example: as Figure 1-9 As shown, this embodiment provides a production line for deep-fried tofu rolls, including a number of fried roll mechanisms for frying tofu rolls 12, and an output mechanism 1 for outputting the fried tofu rolls 12 into boxes. , a deoiling mechanism 2 for drying and deoiling the bean skin roll 12 and a slitting mechanism 3 for trimming and cutting the bean skin roll 12, the deoiling mechanism 2 includes a deoiling tank for placing the bean skin roll 12 21 and a de-oiling cylinder 22 for accommodating the de-oiling box 21 to drive the de-oiling box 21 to rotate, and the output mechanism 1 includes a main conveyor belt 101 for outputting the bean husk roll 12, The skin roll 12 is sorted and put into the first manipulator 102 in the degreasing tank 21 and the second manipulator 103 is used for putting the degreasing tank 21 into the degreasing cylinder 22;

[0038] Several fried roll mechanisms are arranged on both sides of the main convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com