An impeller degreasing fixture

A degreasing and fixture technology, which is used in the parts of pumping devices for elastic fluids, non-variable volume pumps, centrifuges, etc., can solve problems such as customer unacceptance, affecting product appearance, and increasing the amount of anti-rust oil. , to achieve the effect of simple and novel structure, improving the quality and efficiency of deoiling, and high deoiling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

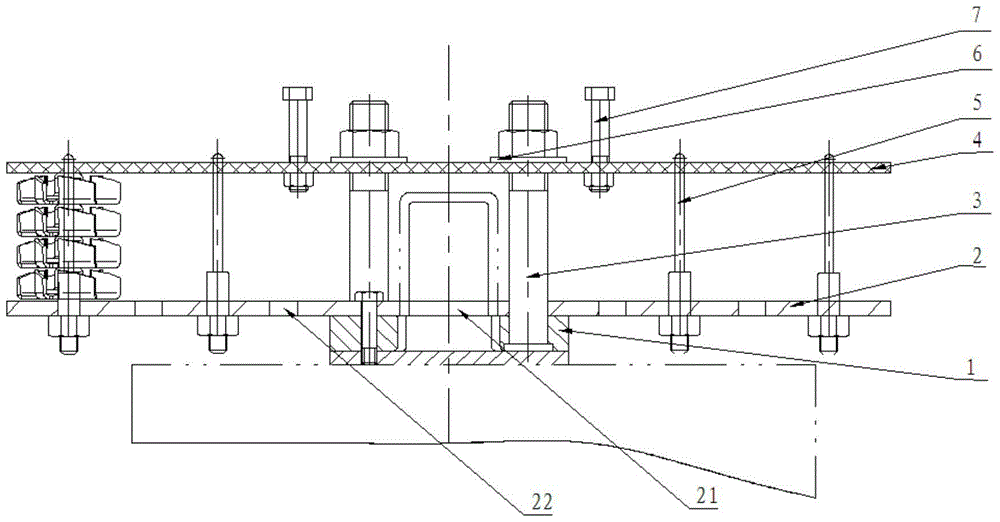

[0014] like figure 1 The illustrated impeller deoiling fixture includes a base plate 2 and a cover plate 4 located above the base plate 2, a positioning plate 1 is connected below the base plate 2, and a guide hole 21 is provided in the center of the base plate 2, and a guide hole 21 is provided in the guide hole. The base plate 2 around 21 is densely covered with oil leakage and weight-reducing holes 22, the base plate 2 and the cover plate 4 are connected by positioning columns 3, and the positioning columns 3 are two, respectively located on both sides of the guide hole 21 , the upper end of the positioning column 3 protrudes from the cover plate 4, and the extended end is connected with a nut through a washer 6, and several screw rods 5 are connected between the base plate 2 and the cover plate 4, that is, on the base plate 2 Two turns of the screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com