Process and device for mobile type rapid elution of oil contaminated soil

A kind of oil pollution, mobile technology, applied in the recovery of polluted soil and other directions, can solve the problems of low cleaning efficiency, small hydrophobic core, unfavorable development of mobile elution equipment, etc., to achieve high deoiling efficiency and short disposal time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

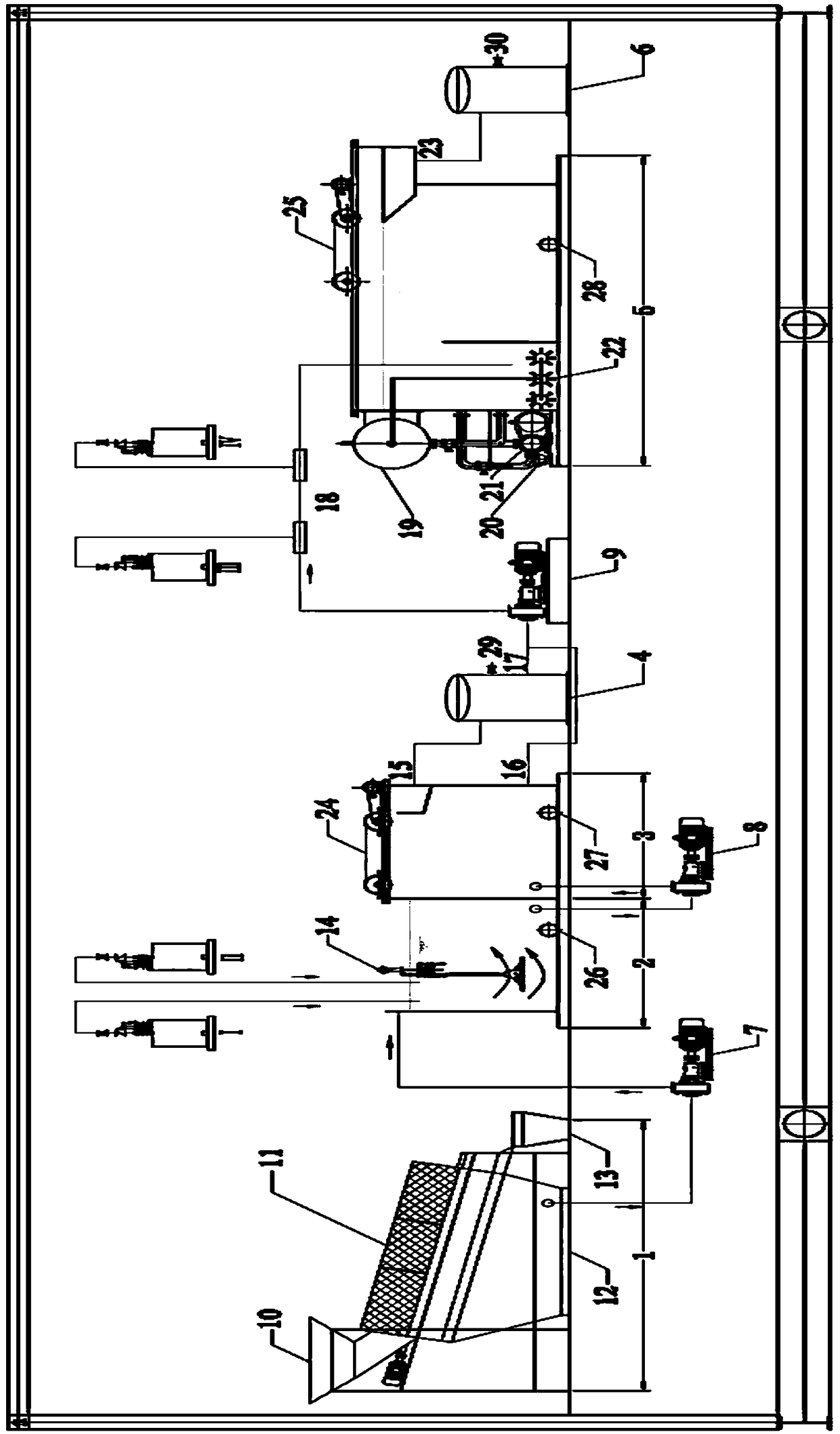

Image

Examples

Embodiment 1

[0049] This embodiment will be 0.6m 3 Petroleum-contaminated soil (60% soil moisture content, 16% oil content) is added to the upper hopper, and the impurities are removed through a drum screen and then enters the homogenization tank. At the same time, 3.4m is added to the homogenization tank 3 Water, keep stirring to make it evenly. Use the first mud pump 7 to pump the sieved slurry into the oxidation desorption device, and add 9L of 0.6mol / L citric acid solution, 9L of 0.6mol / L sodium hydroxide solution, and 1.2mol / L of hydrochloric acid. 90L and 18L of 0.3mol / L ferrous sulfate solution, turn on the mixer to mix and stir evenly, and finally slowly add 54L of hydrogen peroxide with a mass concentration of 28% to the slurry, and continue to stir to make it fully react. The time for in-situ oxidation and air flotation is 2h, after the reaction is over, use the second mud pump to pump the mud into the sedimentation separation device. After standing for 30 minutes, use the oil scra...

Embodiment 2

[0052] Will be 0.6m 3 Petroleum-contaminated soil (60% soil moisture content, 16% oil content) is added to the upper hopper, and the impurities are removed through a drum screen and then enters the homogenization tank. At the same time, 3.4m is added to the homogenization tank 3 Water, keep stirring to make it evenly. Use a mud pump to drive the sieved slurry into the oxidation desorption device, add 6L of 0.6mol / L citric acid solution, 6L of 0.6mol / L sodium hydroxide solution, 60L of 1.2mol / L hydrochloric acid and 0.6 mol / L ferrous sulfate solution 12L, turn on the mixer to mix and stir evenly, and finally add 54L of hydrogen peroxide with a mass concentration of 28% into the mud slowly, continue to stir to make it fully react, and the time for in-situ oxidation and air floatation is 2h. After the end, use the mud pump to drive the mud into the sedimentation separation device, and after standing for 30 minutes, use the oil scraper to scrape the surface oil into the mud collecti...

Embodiment 3

[0055] Will be 0.6m 3 Petroleum contaminated soil (soil water content of 50%, oil content of 15%) is added to the upper hopper, after passing through a roller screen to remove impurities, it enters the homogenization tank, while adding 3.4m to the homogenization tank 3 Water, keep stirring to make it evenly. Use a mud pump to drive the sieved slurry into the oxidation desorption device, add 9L of 0.6mol / L citric acid solution, 9L of 0.6mol / L sodium hydroxide solution, 90L of 1.2mol / L hydrochloric acid and 0.6 mol / L ferrous sulfate solution 18L, turn on the mixer to mix and stir evenly, finally slowly add 90L of hydrogen peroxide with a mass concentration of 14% to the mud, continue to stir to make it fully react, where the in-situ oxidation and air floatation time is 2h, the reaction After the end, use the mud pump to drive the mud into the sedimentation separation device, and after standing for 30 minutes, use the oil scraper to scrape the surface oil into the mud collection bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com