Special oil removing tank for extruding ultrahigh molecular weight polyethylene gel

A polyethylene gel, ultra-high molecular weight technology, applied in textiles and papermaking, sustainable manufacturing/processing, rayon recycling, etc., can solve the problems of extraction agent leakage, container deformation, environmental pollution, etc., to improve production efficiency , high degree of automation and high deoiling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. back.

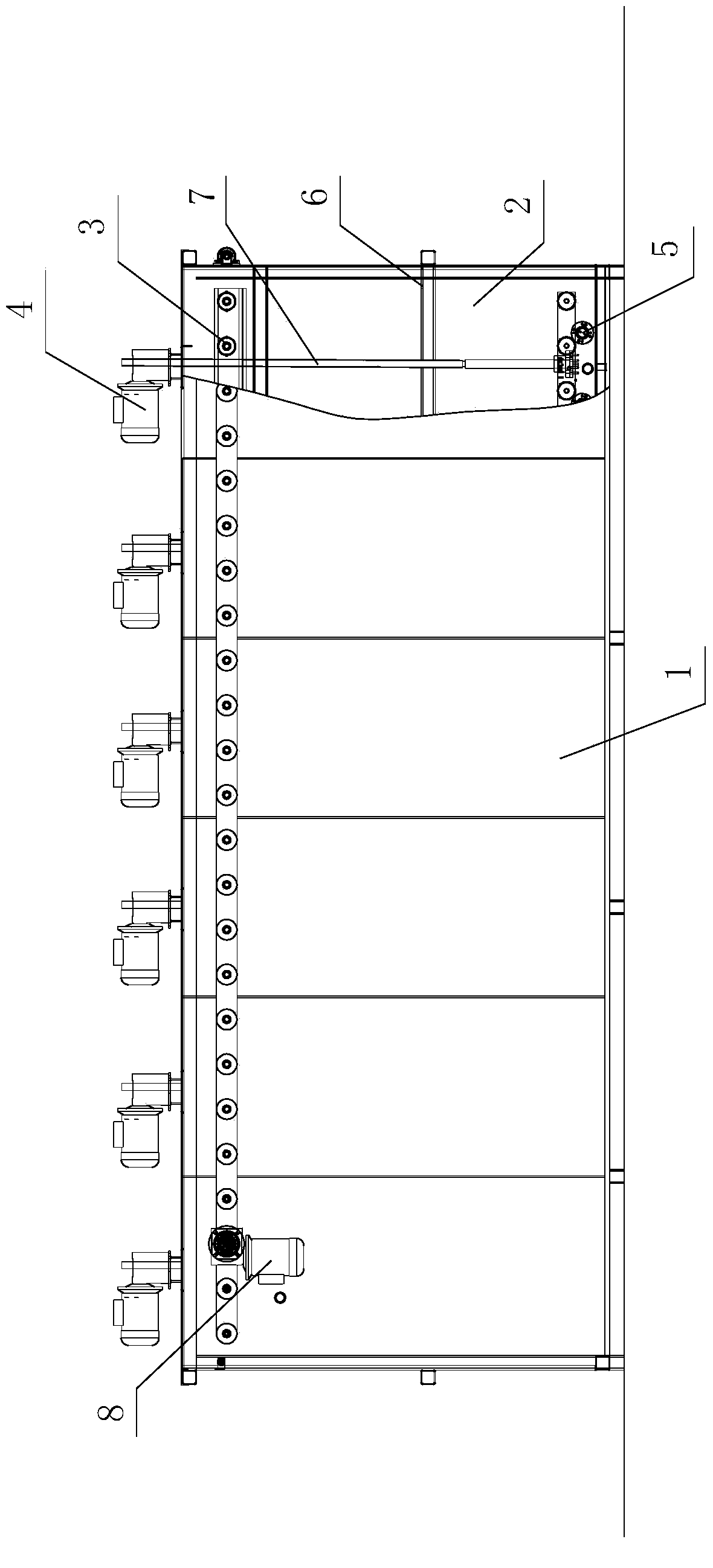

[0016] like figure 1 As shown, a special deoiling box for ultra-high molecular weight polyethylene gel extrusion. The deoiling box includes a box body 1 and an outer frame-type reinforcement frame 6 fixed in the box body 1. A plurality of partitions 7 are formed in the box body 1. Inner box 2, the height of the partitions between adjacent inner boxes 2 decreases stepwise from the back to the front, so that the liquid level for storing the extraction liquid also decreases stepwise, so as to dilute the process oil step by step, and at the same time ensure the removal of the PE separator Oiling time and deoiling amount.

[0017] As a preferr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com