Filtering-free oil removing machine and method for removing oil through filtering-free oil removing machine

A deoiler and oil drum technology, which is used in the lubrication of engines, centrifuges, mechanical equipment, etc., can solve the problems of difficult cleaning of the deoiler, affecting the efficiency and quality of deoiling, time-consuming and laborious, and achieving a simple and easy structure. Clean, cleverly conceived effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

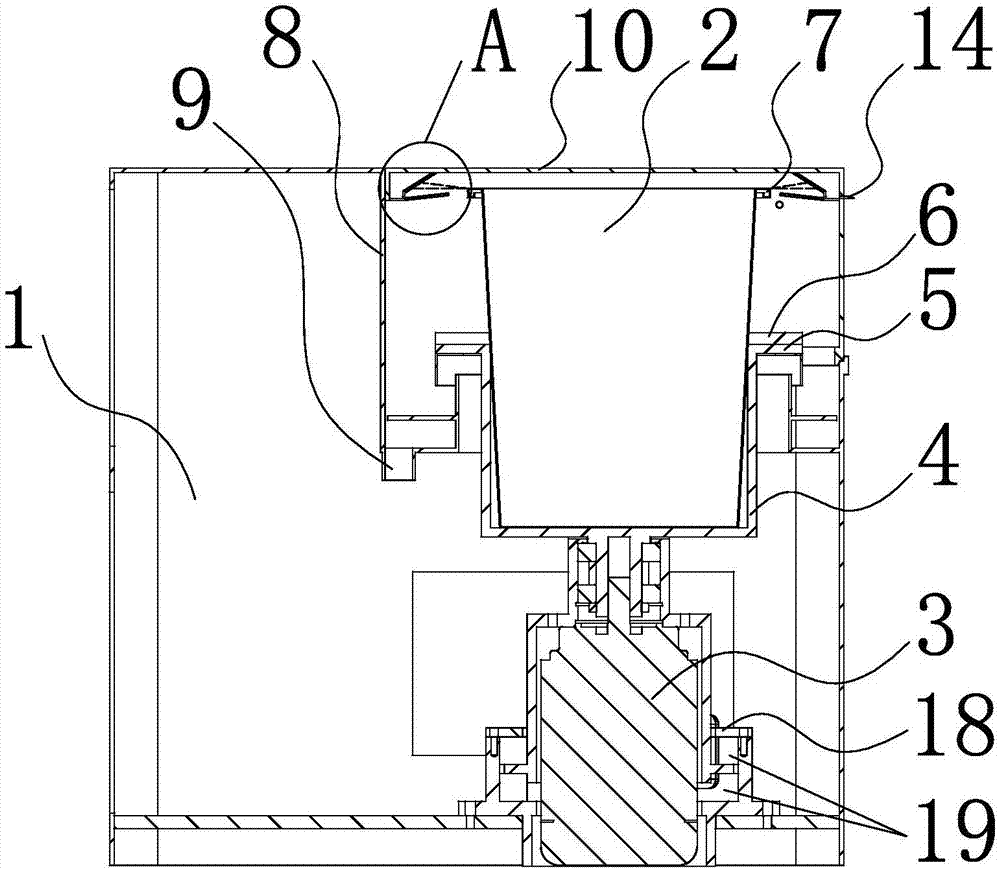

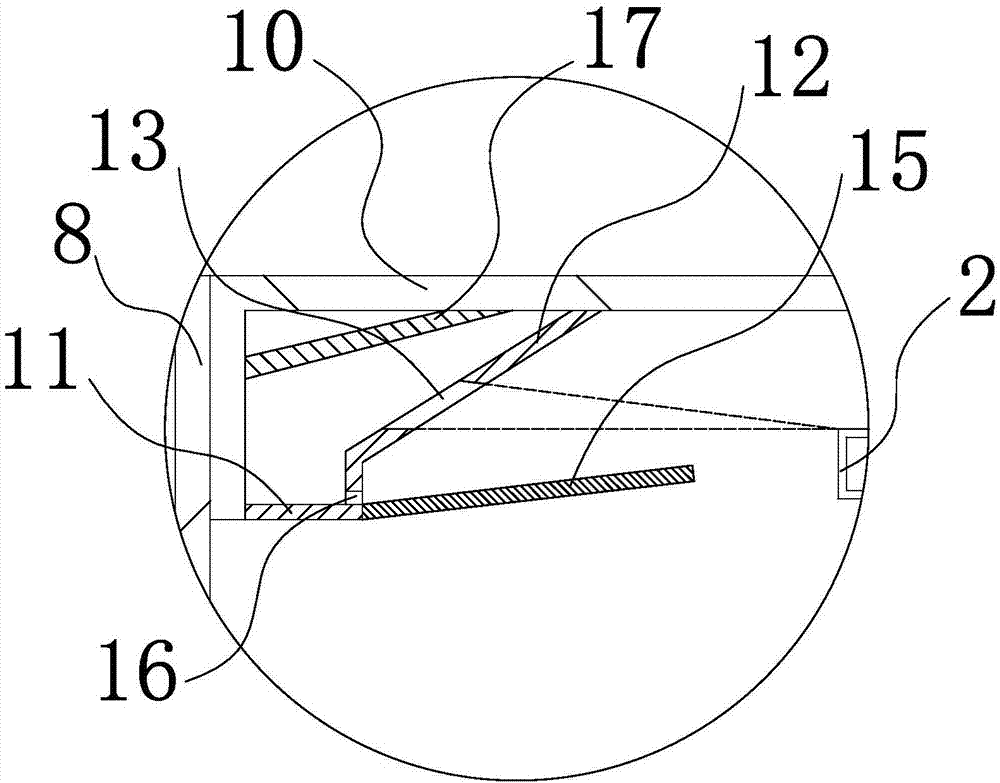

[0027] Such as figure 1 As shown, a filter-free deoiler of the present invention includes a box body 1, and the box body 1 has a motor positioning cover 18 on the bottom surface of the box body 1, and the output shaft 31 of the drive motor 3 is upwardly matched and embedded. It is installed in the motor positioning cover 18, and the corresponding drive motor 3 in the motor positioning cover 18 is covered with two anti-vibration and anti-swing rings 19 made of rubber, and the anti-vibration and anti-swing ring 19 on the top is clamped on the outside of the drive motor 3. Between the upper surface of the horizontal partition and the top surface of the corresponding motor positioning cover 18, the shockproof and anti-swing ring 19 below is clamped between the lower surface of the horizontal partition outside the drive motor 3 and the bottom surface of the corresponding motor positioning cover 18, and the output shaft 31 extends to the outside of the motor positioning cover 18, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com