Preparation method of multi-branched cationic polyether microbial demulsifier

A cationic polymerization and multi-branching technology, applied in the field of demulsification and dehydration of crude oil, can solve the problems of unsatisfactory demulsification effect, difficult oil-water separation, slow demulsification speed, etc., to speed up the oil-water separation process, complex and diverse structures, and reduce the surface tension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

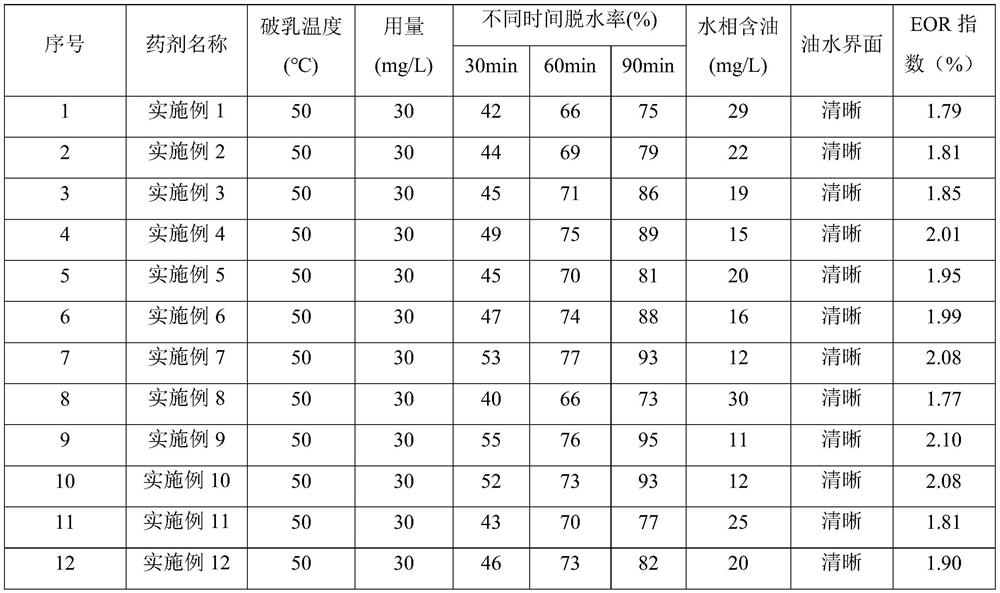

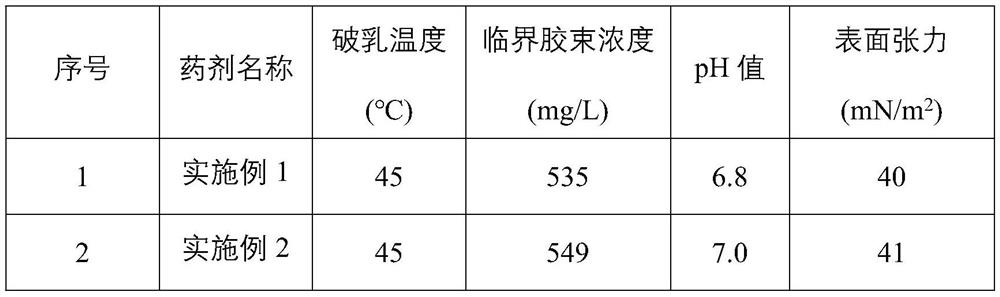

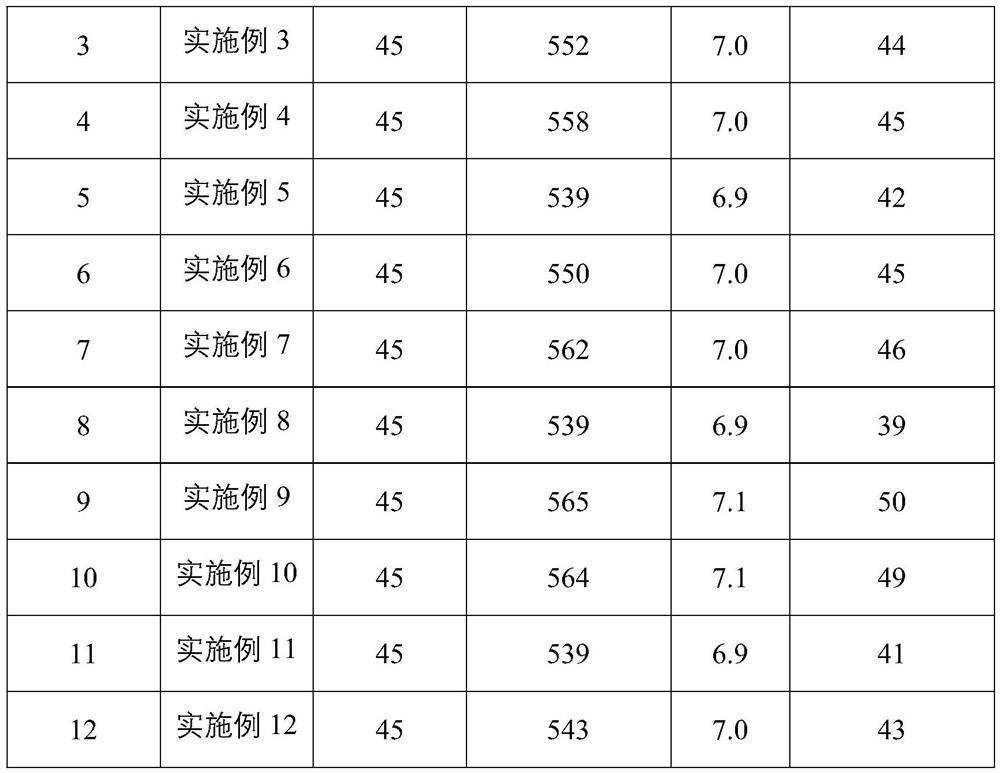

Examples

Embodiment 1

[0034] The preparation method of double metal cyanide complex catalyst is as follows:

[0035] (1) Potassium ferricyanide is dissolved in deionized water, an aqueous solution of copper chloride is added, fully mixed and reacted, filtered and separated to obtain a paste;

[0036] (2) Prepare ethanol and water with a volume fraction of 1:1 to prepare a washing liquid, carry out preliminary washing 2 times to the paste obtained in step (1), add ethanol to the product after preliminary washing, fully mix to form a slurry, filter Separating and taking the filter residue, repeating deep washing of the filter residue several times until the potassium ion content in the filtrate is lower than 10ppm;

[0037] (3) Add ethanol to the filter residue obtained in step (2) and stir evenly, then add polytetrahydrofuran polyether, thioether and glycerin, after stirring and mixing for 30min, filter and separate, and the obtained solid component is vacuum-dried at 60°C, Pulverize to obtain doub...

Embodiment 2

[0044] The molar fraction ratio of PO and EO is 1:2, all the other are the same as embodiment 1.

Embodiment 3

[0046] The mole fraction ratio of branched polyamine compound and double metal cyanide complex catalyst is 2:3, all the other are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com