Negative-pressure internal circulation reactor and method for treating sewage by utilizing reactor

A reactor and internal circulation technology, which is applied in the field of negative pressure internal circulation reactors, can solve the problems of poor low-temperature operation, complicated operation management, and high cost, and achieve the effects of short cycle period, simple operation management, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

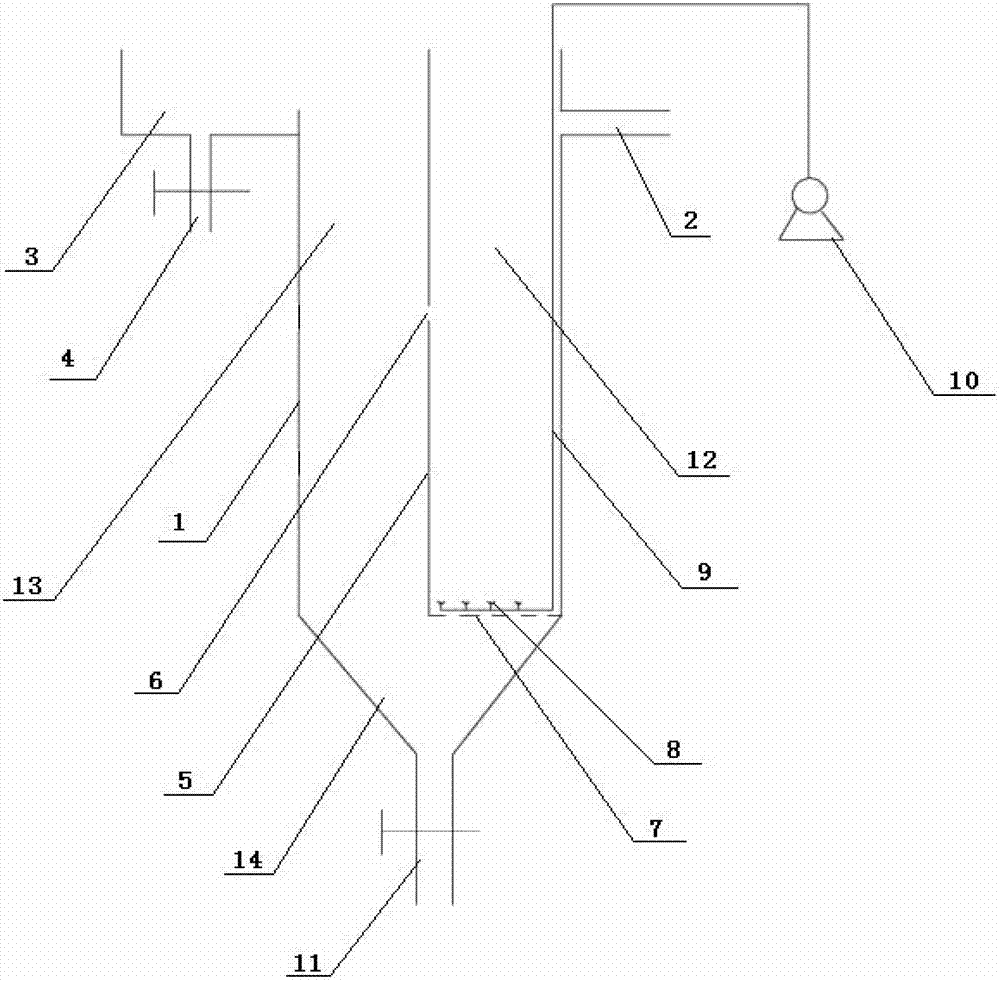

[0016] Specific implementation mode one: combine figure 1 Describe this embodiment, the negative pressure internal circulation reactor of this embodiment comprises a tank body 1, a water inlet pipe 2, an outlet weir 3, an outlet pipe 4, a vertical partition 5, a communication hole 6, a transverse partition 7, an aeration device 8, Pipeline 9, air pump 10 and mud outlet 11, the upper part of tank body 1 is cylindrical, the lower part of tank body 1 is conical, and the inside of the upper cylindrical area of tank body 1 is provided with vertical partition 5, vertical partition 5 is provided with a communication hole 6 in the center, and the vertical partition 5 divides the upper cylindrical area of the tank body (1) into an aeration area 12 and a sedimentation area 13, and the lower conical area of the tank body 1 is a sludge concentration area 14. The horizontal partition 7 is semicircular, and is horizontally arranged at the junction of the aeration zone 12 and the sludg...

specific Embodiment approach 2

[0017] Specific implementation mode two: combination figure 1 This embodiment is described. The difference between this embodiment and the first embodiment is that the diameter of the hole on the diaphragm 7 is greater than 50 mm, and the opening ratio of the diaphragm 7 is 40% to 60%. Others are the same as in the first embodiment.

[0018] In this embodiment, the porosity is the percentage of the area of holes in the total area of the diaphragm.

specific Embodiment approach 3

[0019] Specific implementation mode three: combination figure 1 Illustrate this embodiment, adopt specific embodiment one to be applicable to the method for the low-temperature sewage treatment device treatment sewage of small town, carry out according to the following steps:

[0020] The sewage first enters the hydrolysis and acidification reaction device, stays for 7-9 hours, and then exits the water, enters the aeration zone 12 of the low-temperature sewage treatment device suitable for small towns through the water inlet pipe 2, and opens the aeration device 8 at the same time, after the hydraulic retention time is 5-7 hours , the remaining sludge is discharged from the mud outlet 11, and the supernatant is discharged from the outlet pipe 4 through the outlet weir 3, and the sewage treatment is completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com