Membrane module of using compact polymer membrane in application for separating gas mixture

A technology of polymer membranes and membrane modules, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of small effective area, low absorption efficiency, high cost, etc., and achieve liquid phase mass transfer with small resistance, The effect of large absorption driving force and high penetration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

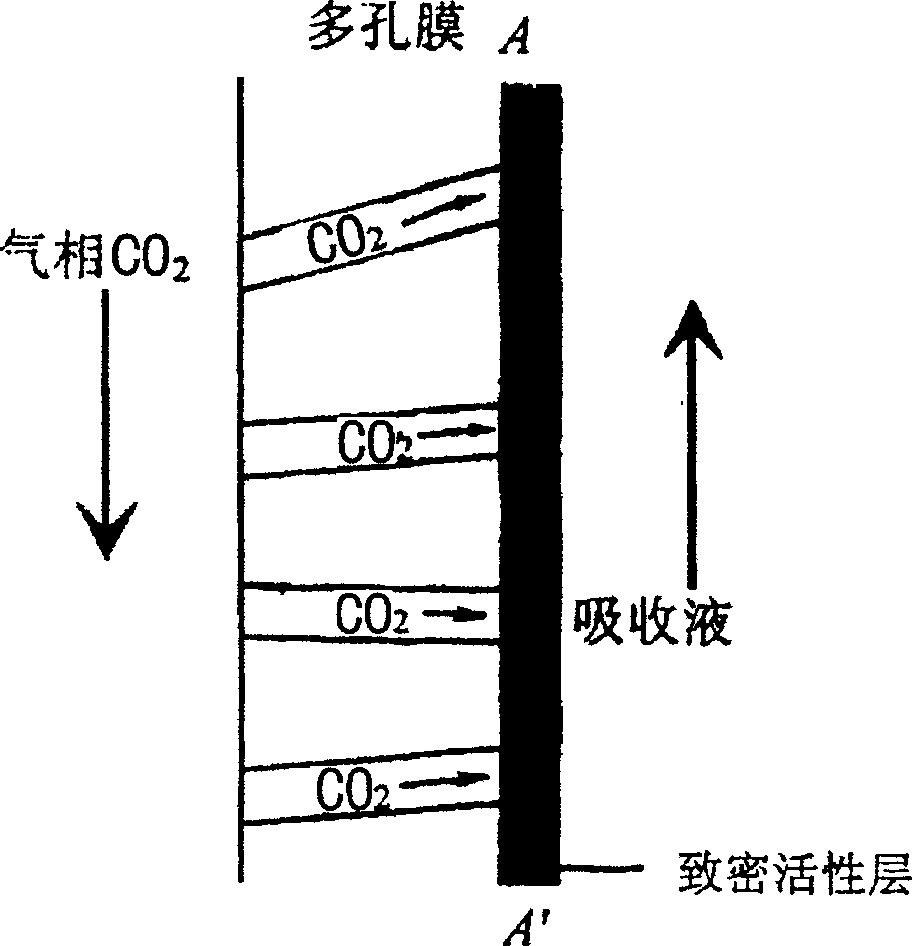

Method used

Image

Examples

Embodiment 1

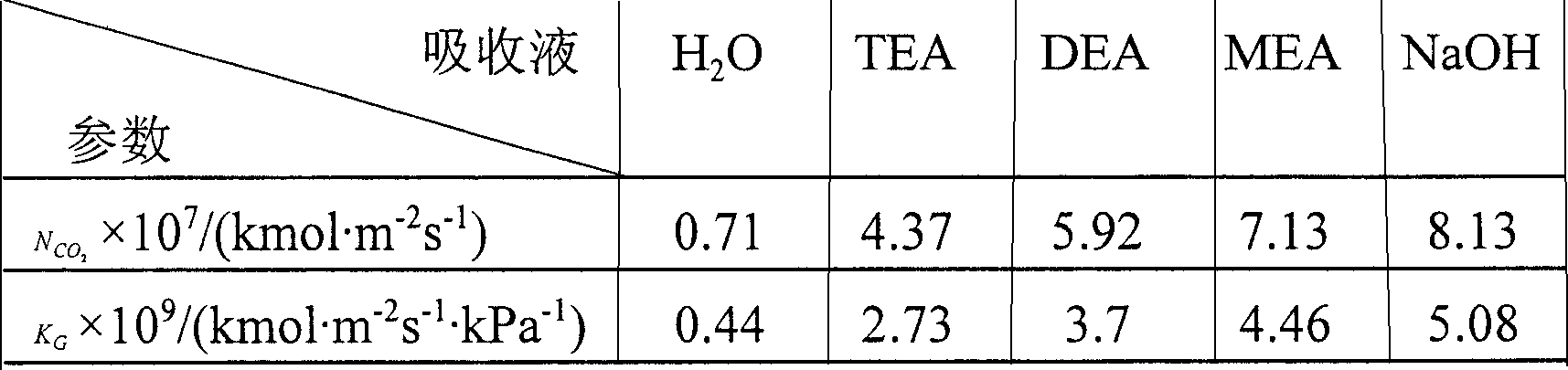

[0030] Use water, alcohol amine aqueous solution (monoethanolamine / MEA, diethanolamine / DEA, triethanolamine / TEA), NaOH aqueous solution, etc. as the absorption liquid to absorb and remove CO 2 , the absorption liquid concentration is 2M, the absorption liquid flow rate: 6.94×10 -6 m 3 ·s -1 ; Liquid phase pressure 0.2MPa (absolute pressure); gas phase pressure 0.16MPa (absolute pressure); CO 2 Mass transfer flux N CO2 , total mass transfer coefficient K G The relationship with the type of absorption liquid is shown in Table 2 below:

[0031] Table 2 CO in different absorption liquids 2 Mass transfer flux N CO2 , total mass transfer coefficient K G

[0032]

[0033] Water is used as the absorption liquid, the absorption is physical absorption, CO 2 Throughput NCO2 Overall mass transfer coefficient K G Both are low, but using alkaline aqueous solution as the absorption liquid, the absorption process is accompanied by chemical reactions, and the solute and CO in diff...

Embodiment 2

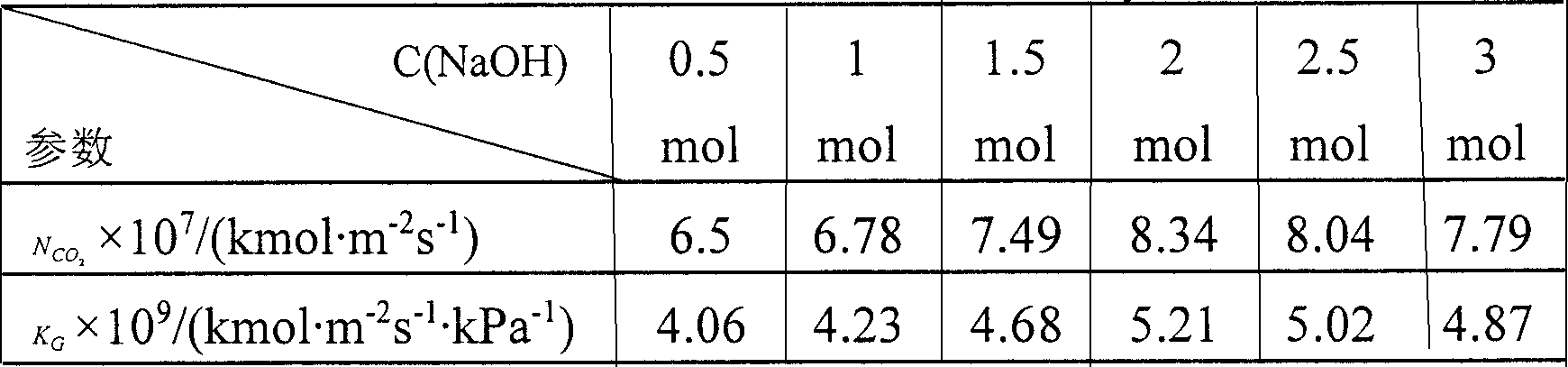

[0035] Using different concentrations of NaOH aqueous solution as the absorption liquid to absorb and remove CO 2 , absorption liquid flow rate: 6.94×10 -6 m 3 ·s -1 ; Liquid phase pressure 0.2MPa (absolute pressure); gas phase pressure 0.16MPa (absolute pressure); CO 2 Mass transfer flux N CO2 , total mass transfer coefficient K G The relationship with the concentration of NaOH solution is shown in Table 3.

[0036] Table 3 CO at different NaOH solution concentrations 2 Mass transfer flux N CO2 , total mass transfer coefficient K G

[0037]

[0038] When the concentration of NaOH in the absorption solution increases, due to the CO 2 Increased reaction rate with NaOH solution and OH in the boundary layer - The increase in the concentration of CO 2 Throughput N CO2 , total mass transfer coefficient K G The maximum absorption rate is obtained at 2M; when the concentration of NaOH continues to increase, the viscosity of the solution increases due to the increase o...

Embodiment 3

[0040] Water (absorbing liquid 1) and 2MNaOH (absorbing liquid 2) are used as the absorbing liquid, the liquid phase pressure is 0.2MPa (absolute pressure), and the gas phase pressure is 0.16MPa (absolute pressure); CO 2 Mass transfer flux N CO2 , total mass transfer coefficient K G The relationship with the absorption liquid flow rate is shown in Table 4.

[0041] Table 4 CO at different absorption liquid flow rates 2 Mass transfer flux N CO2 , total mass transfer coefficient K G

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com