Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Avoid deformation stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser scanning method used for fast forming high-temperature alloy structural member

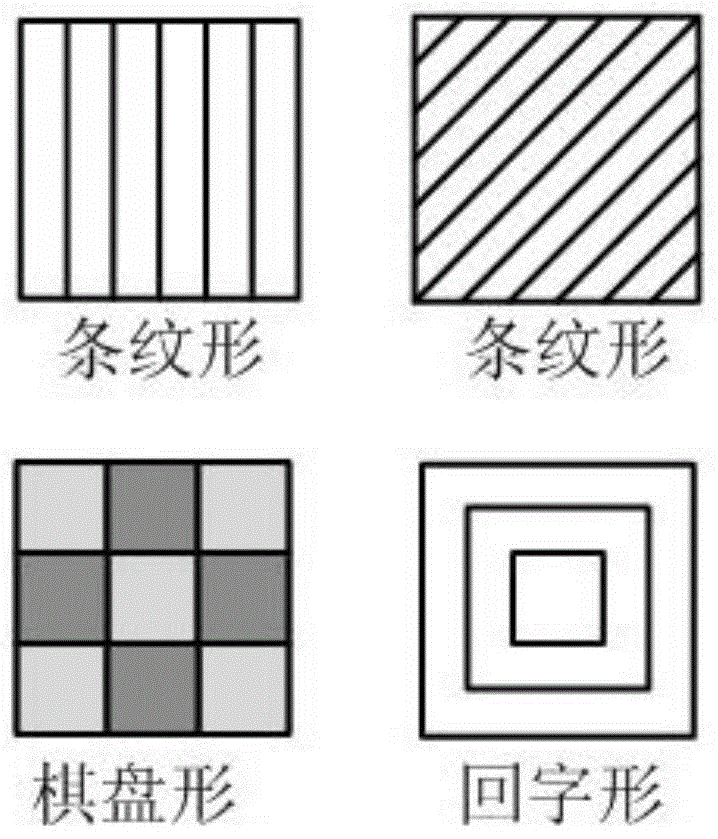

The invention discloses a laser scanning method used for fast forming a high-temperature alloy structural member. The method comprises the following steps that (a), according to the geometric feature comprising the area S, the wall thickness H and the shape P and the precision requirement of the structural member, a geometric model of each layer is divided into a plurality of areas, scanning methods for the different areas are determined, and the rectangular-ambulatory-plane shape, the stripe shape and the chess board shape are involved in the scanning methods; (b), forming scanning is carried out, the different areas in each layer are sequentially scanned, and the structural member is formed; (c), the outer surface is scanned, the outer surface of the formed structural member is scanned for the second time, and fast repair and heat treatment on the outer surface of the structural member are realized. According to the method, all the slice layers are divided into areas, the different scanning methods are selected, and therefore the problems of stress deforming and cracking caused by heat concentration are effectively avoided; the mechanical property and the surface precision of the high-temperature alloy structural part fast formed are improved.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

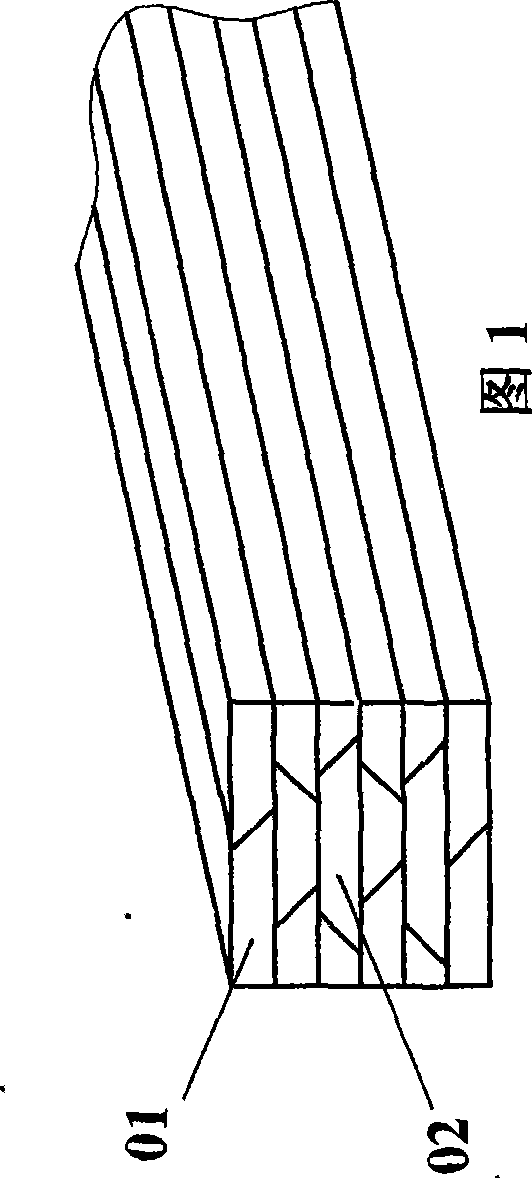

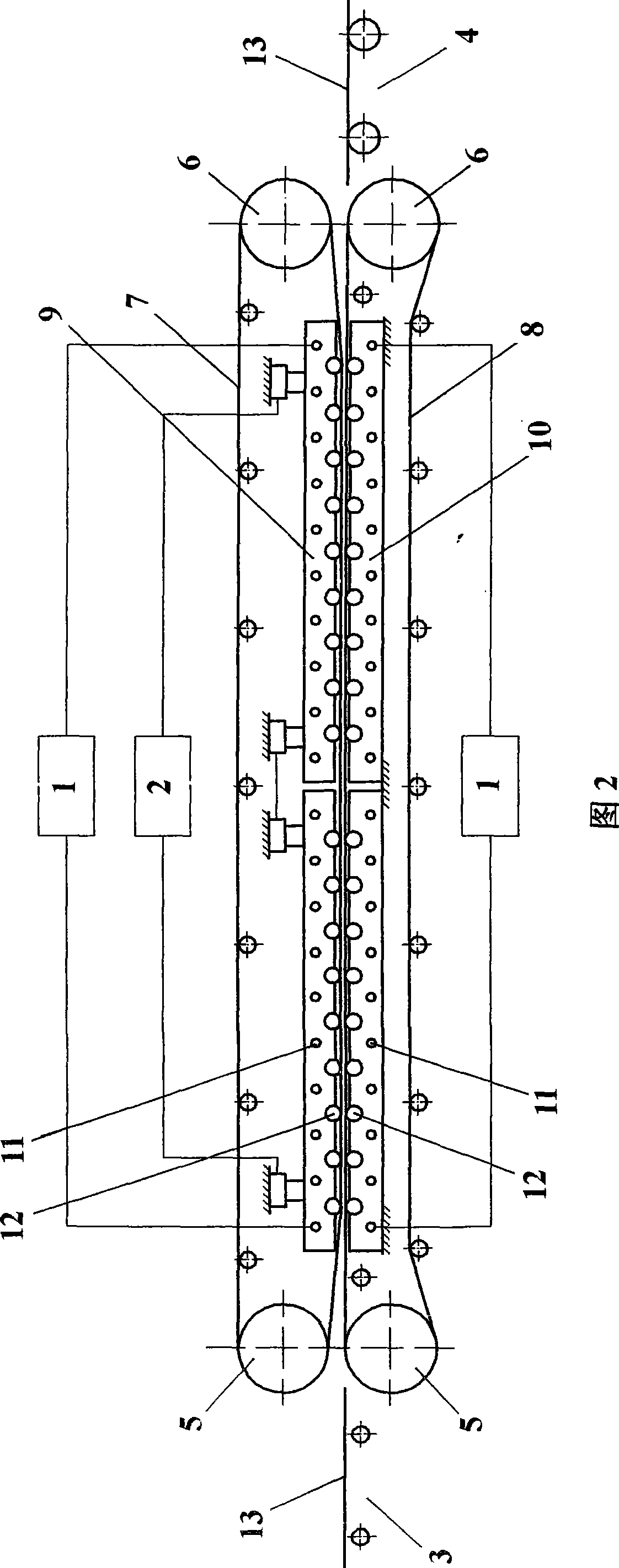

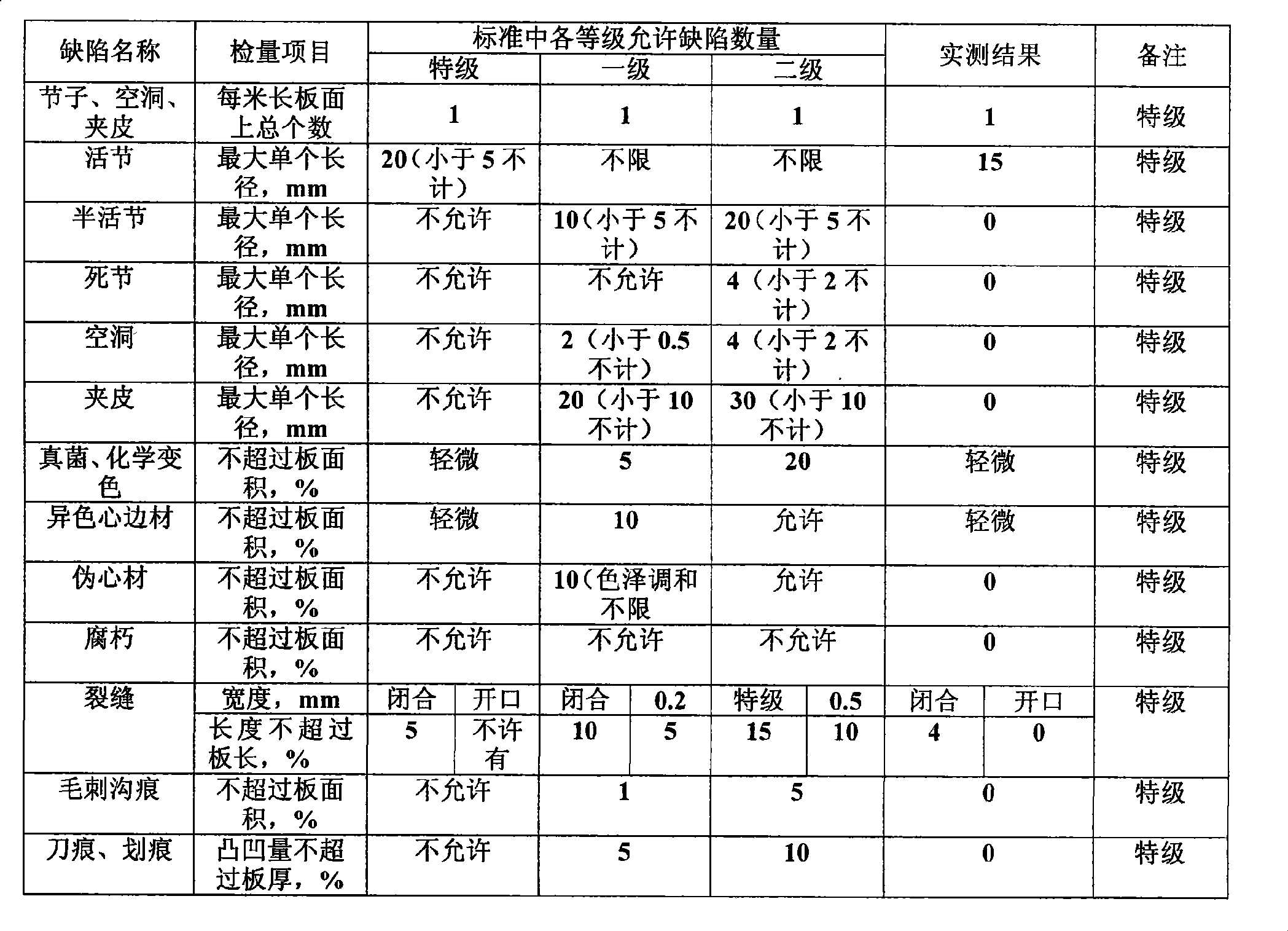

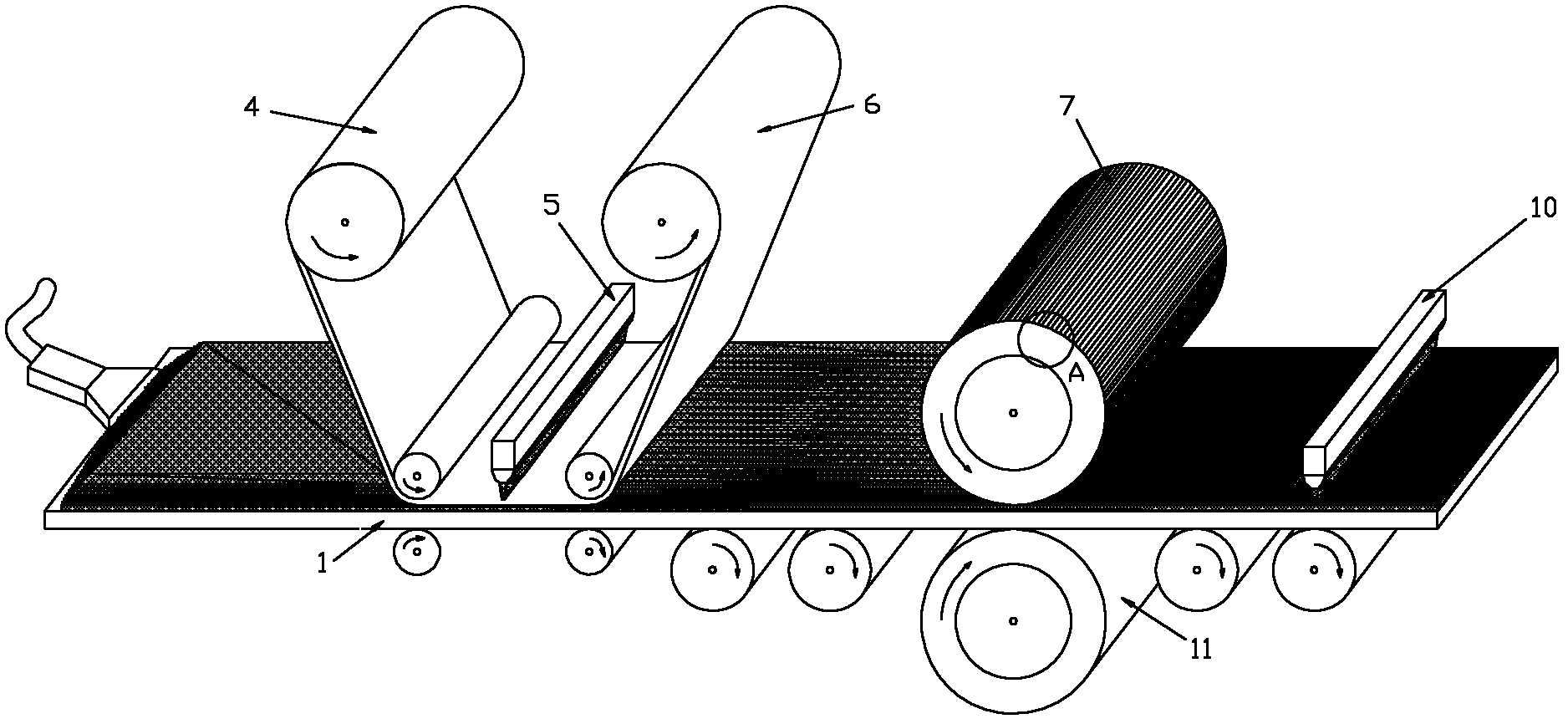

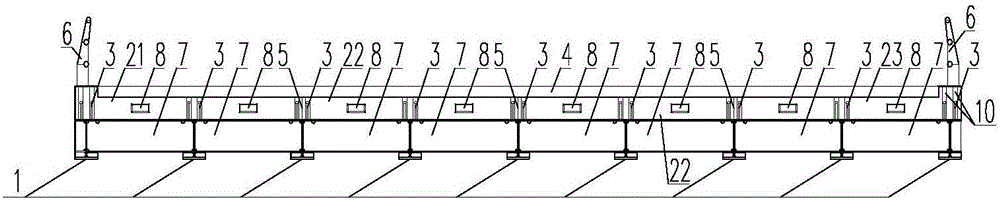

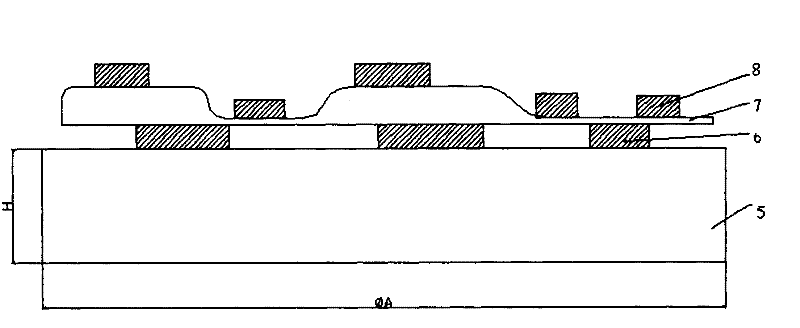

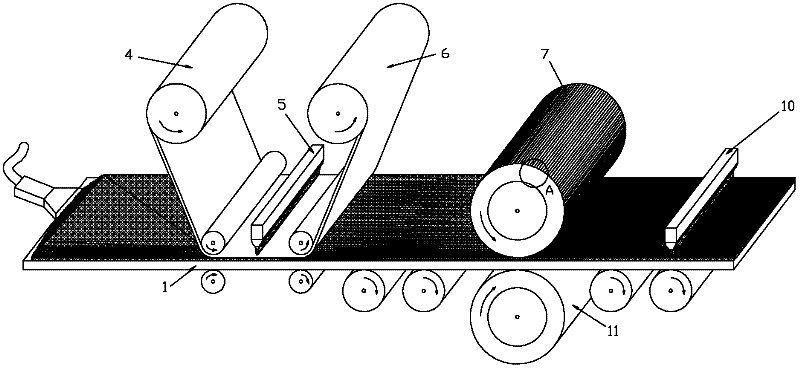

Small wood integrated shaving thin-wood manufacture method and leveling drying device thereof

InactiveCN101417451AHighlight substantiveSignificant technological progressVeneer manufacturePressure impregnationAdhesive cementEconomic benefits

The invention relates to a manufacturing method of small-diameter wood glulam slicing veneers and a leveling drying device. Small-diameter wood, tended wood, inferior wood or cordwood produced in the cutting and manufacturing process, and the like which are not easily efficiently used are softened by a composite agent by being infused with pressure, and then after flitches are integrated by finger joining and obliquely slotting the wood with a moisture-curable type adhesive, the flitches are sliced into wet veneers, and the wet veneers are then sent to a special continuous high-temperature ironing leveling dryer to be leveled and dried into sliced veneers in the clamping of upper and lower steel belts. The invention integrates a series of special technologies and transforms small-diameter wood which is not easily used into sliced veneers which meet requirements of various technical specifications with very wide application ranges. Low-grade wood is fully used, which improves the added value of products and comprehensive utilization efficiency of forest resources. The invention has the advantages of simple and reasonable technique method, low equipment cost, good product quality, broad development prospects and the like. Significant social and economic benefits can be produced after the implementation.

Owner:BEIHUA UNIV

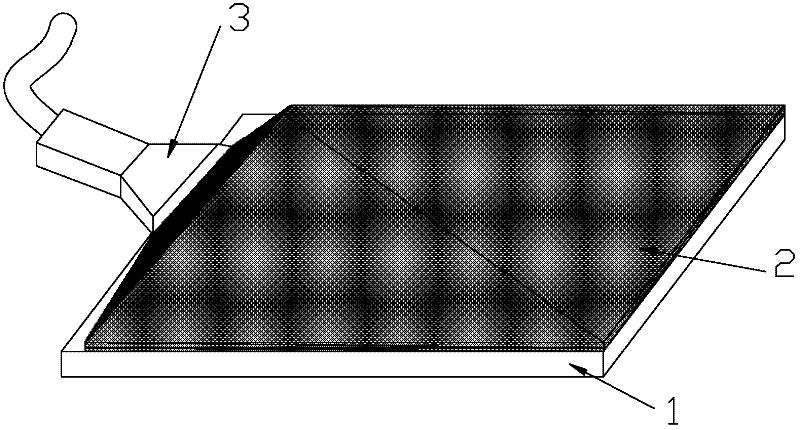

Method for forming grating for machine tool measurement in two-step solidifying rolling pressing forming manner

ActiveCN102193310ALow costIncrease productivityDiffraction gratingsPhotomechanical exposure apparatusStress concentrationGrating

The invention relates to a method for forming a grating for machine tool measurement in a two-step solidifying rolling pressing forming manner, which comprises the following steps: 1) coating an ultraviolet light solidifying adhesive layer on a grating blank substrate; 2) manufacturing a rolling mould having a prototype grating structure on the surface of a cylindrical mould, making an alignment mark, and polishing and performing low surface energy treatment on the surface of the rolling mould; 3) coating a flexible film on the adhesive layer on the grating blank substrate, carrying out primary exposure and peeling the film; 4) comparing the alignment mark on the grating blank substrate with an acquired alignment mark image on the surface of the rolling mould, adjusting and calibrating; 5) gluing the rolling mould with the grating, applying a pressing force, and compounding the prototype grating structure on the surface of rolling mould on the adhesive layer on the surface of the substrate; 6) carrying out exposure on the compounded ultraviolet light solidifying adhesive layer; and 7) collecting and packaging the grating. According to the method, the required pressing force is small, and thus, the substrate deformation and stress concentration are avoided. The method has high production efficiency and can be used for realizing the mass production of the grating for large-area and altitude machine tool measurement.

Owner:XI AN JIAOTONG UNIV

Novel prefabricated type steel-concrete composite beam bridge upper structure and manufacturing technology thereof

InactiveCN106120532AReduce quality problemsReduce fatigueBridge structural detailsBridge materialsManufacturing technologyConcrete beams

The invention provides a novel prefabricated type steel-concrete composite beam bridge upper structure comprising main steel beams, transverse connecting steel beams, metal connecting pieces and prefabricated reinforced concrete bridge deck slabs. The main steel beams are arranged according the shape of a bridge. The webs of the adjacent main steel beams are connected through the transverse connecting steel beams. The upper flanges of the main steel beams are provided with the metal connecting pieces. The prefabricated reinforced concrete bridge deck slabs are laid on the upper flanges of the main steel beams and provided with preformed holes used for grouting of grouting materials after the bridge deck slabs are well installed. The metal connecting pieces are located in the preformed holes. The invention further provides a manufacturing technology of the novel prefabricated type steel-concrete composite beam bridge upper structure. By the adoption of the novel prefabricated type steel-concrete composite beam bridge upper structure and the manufacturing technology of the novel prefabricated type steel-concrete composite beam bridge upper structure, damaged medium and small span concrete beam bridges can be rapidly replaced, the structure safety is good, the construction period is short, the cost is low, and the durability is good.

Owner:宁波金蛟龙重工钢构有限公司

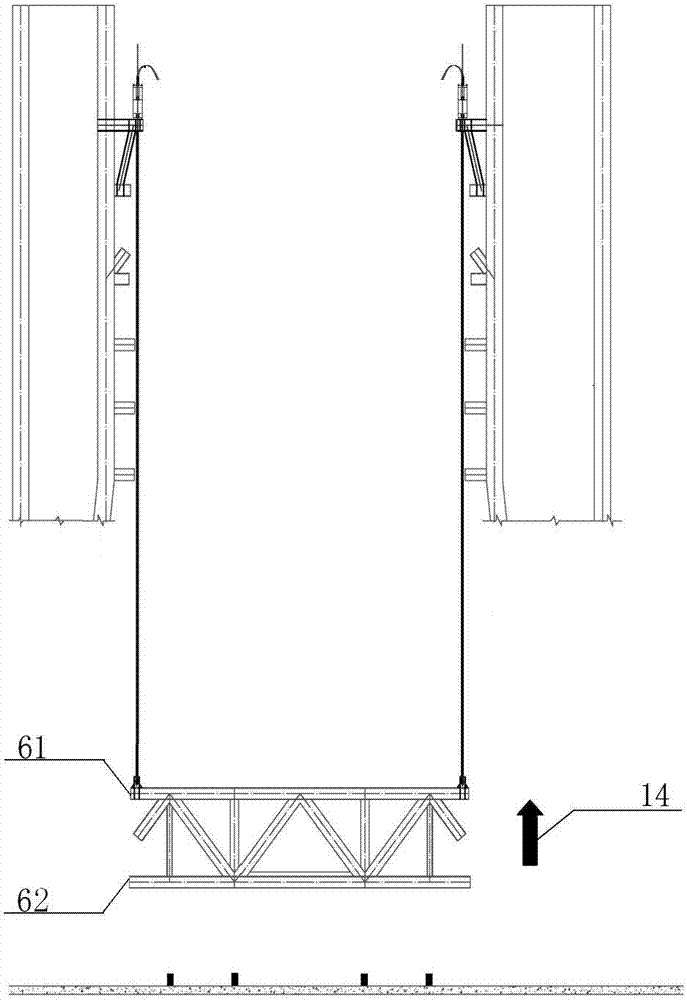

Construction method of suspended steel gallery

ActiveCN106930541AReduce workloadGuarantee the construction qualityBuilding material handlingBasementTime segment

The invention discloses a construction method of a suspended steel gallery. The suspended steel gallery is connected between main body structures; a preassembled bar is firstly arranged at designed elevation of the suspended steel gallery, a lifting platform is arranged, and meanwhile, a hydraulic lifter is arranged; an upper truss structure of the suspended steel gallery is spliced on the ground, the hydraulic lifter is debugged to lift in a segmented manner, wherein the lifting height of each time is the height of one layer of suspended structure; and the suspended steel gallery is lifted to the elevation for welding after assembly is completed. According to the method, one-time overall lifting method of the multi-layer suspended steel gallery is changed into a hydraulic multi-time segmented lifting method, so that large-range reinforcement of a basement roof is avoided, the construction period is shortened, the cost is reduced, the designed mechanical principle is matched and stress deformation and internal stress generation of a suspended structure are avoided. The appearance quality of the steel gallery and the quality of a welding line and a member meet the national current acceptance standard requirements; and the design idea is achieved.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD +1

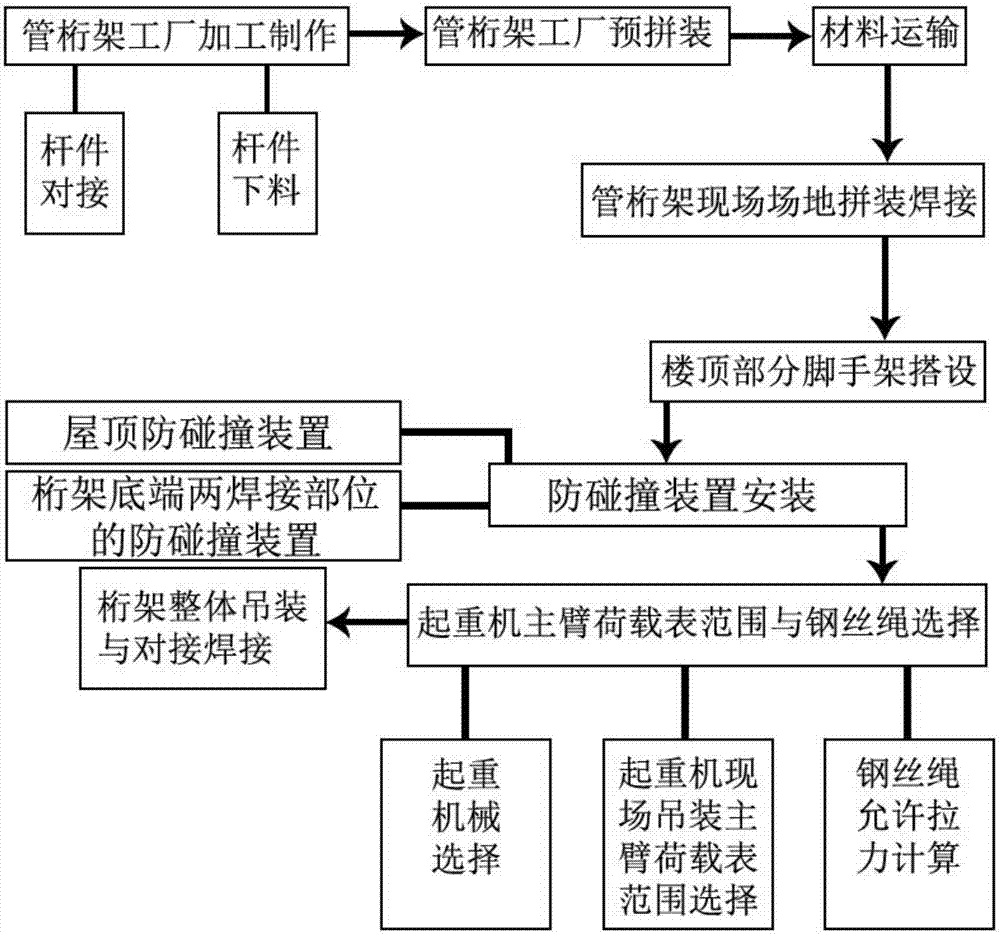

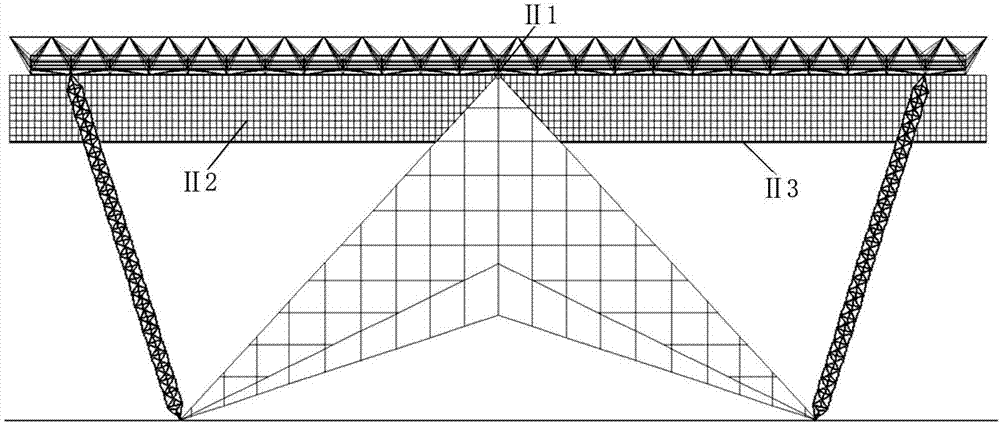

Construction method for integrally hoisting large-size multi-edge-and-corner overhanging truss

ActiveCN107100309AImprove assembly efficiencyEasy constructionBuilding roofsBuilding material handlingTerrainButt welding

A construction method for integrally hoisting a large-size multi-edge-and-corner overhanging truss is disclosed. Integral assembling of a steel pipe truss is conducted on site, and integral hoisting is conducted after assembling is completed; the truss is connected with three welding positions in a butt-joint mode and then is welded firmly; two 500 t all-terrain cranes and a 350 t all-terrain crane are adopted to hoist the whole truss simultaneously, and step-by-step hoisting is conducted from south to north; the truss is totally provided with three main stress support joints which are all fixed by adopting butt welding, a third calibration point support is located at the top of the truss, a welded ball joint at the position of the third calibration point is a support point of a steel rainshed grid frame actually, a first calibration point support and a second calibration point support are located on both the left and right sides of the bottom of the truss correspondingly, and the first calibration point support and the second calibration point support are global stress supporting points of the truss. The construction method for integrally hoisting the large-size multi-edge-and-corner overhanging truss has the characteristics that the construction safety is high, the construction period is short, the engineering quality is easy to guarantee, the ground integral assembling efficiency is high, and the construction cost is reduced greatly.

Owner:FUJIAN MINNAN CONSTR ENG

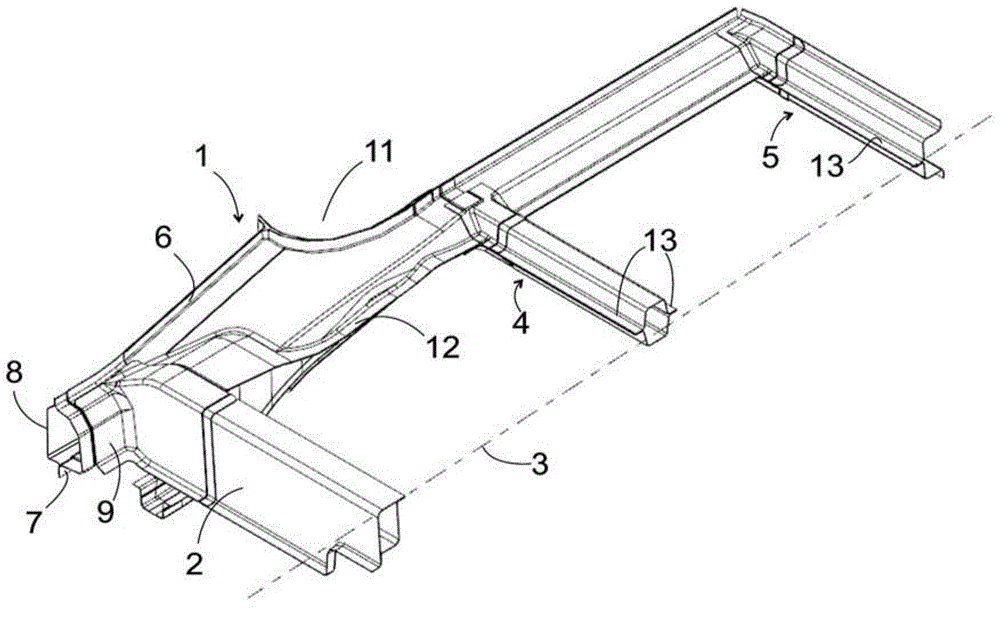

Structure formed by multiple parts

InactiveCN105313990AAvoid deformation stressSuperstructure subunitsSuperstructure connectionsEngineeringMechanical engineering

The invention relates to a structure, especially a vehicle body. The structure includes at least two components (21, 22) made from materials with different heat expansion coefficients and fastened to one another on an elongated overlap zone. The overlap zone on at least one first component (21) is subdivided by weak points (16) oriented in its transverse direction into portions (17) following one another in longitudinal direction.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method for preventing hot working warpage and deformation of large titanium alloy isothermal precise thin web plate forge pieces

The invention relates to a method for preventing hot working warpage and deformation of large titanium alloy isothermal precise thin web plate forge pieces. The method is characterized by comprising the following steps of: taking isothermal precise forge pieces out of a high-temperature forging mould, and then hanging the forge pieces on a bracket for air cooling; and before heat treatment in a furnace, flatly placing forge pieces with warpage on base plates, and putting cushion blocks between the forge pieces and base plates and firmly padding, wherein if the bottom surfaces of the forge pieces are parallel and have equal height, the heights of the cushion blocks are consistent, and if the bottom surface of the forge pieces have height falls, the heights of the cushion blocks have identical falls. By adopting the method, heat in the processes of cooling after isothermal forging and cooling after heat treatment of large complicated titanium alloy plane structures with unequal cross section areas is uniformly dispersed, and the forge piece warpage parts are pressed flatly in the heat treatment process. The process provided by the invention has the advantages of simplicity, easiness in application and low cost.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

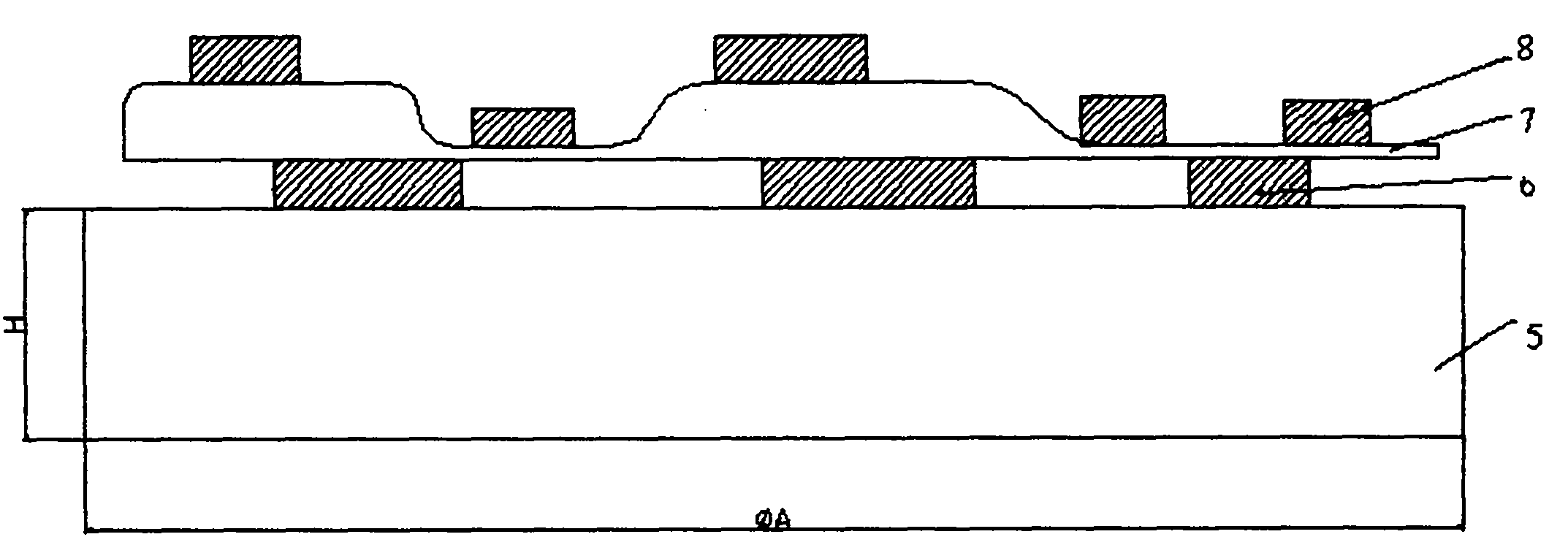

Defect repairing tool for submarine pipeline

ActiveCN106979383ASimple structureReduce radial loadPipe laying and repairOcean bottomMarine engineering

The invention provides a defect repairing tool for a submarine pipeline. The defect repairing tool for the submarine pipeline comprises a clamping module structure, a coating module structure and a coiling module structure, wherein the coating module structure capable of forming a coating layer on a defect area of the submarine pipeline to be repaired is connected to one side of the clamping module structure which is controlled through a remote operated vehicle (ROV) and capable of clamping the submarine pipeline to be repaired; the coating module structure sleeves the outer wall of the submarine pipeline to be repaired in a circumferential opening-closing manner and can axially move along the submarine pipeline to be repaired; the coiling module structure capable of forming a coiling layer on the coating layer is connected to one side, far away from the clamping module structure, of the coating module structure; the coiling module structure can axially move along the submarine pipeline to be repaired and can be rotated around the submarine pipeline to be repaired. The repairing tool is operated through the ROV, so that the maximum diving depth of workers can be overcome; the repairing process is continuous, complete and high in efficiency; and the problem of defect repairing of the submarine pipeline in a deep water environment can be solved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

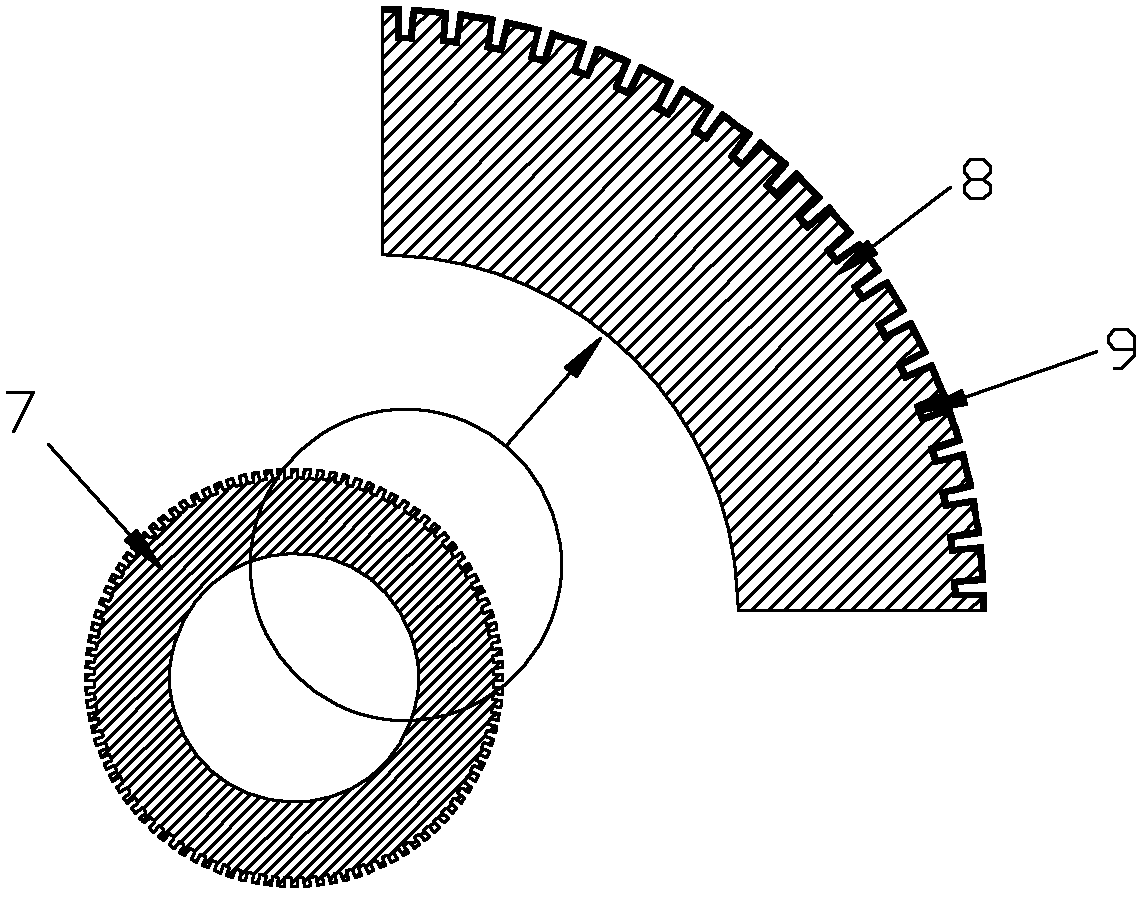

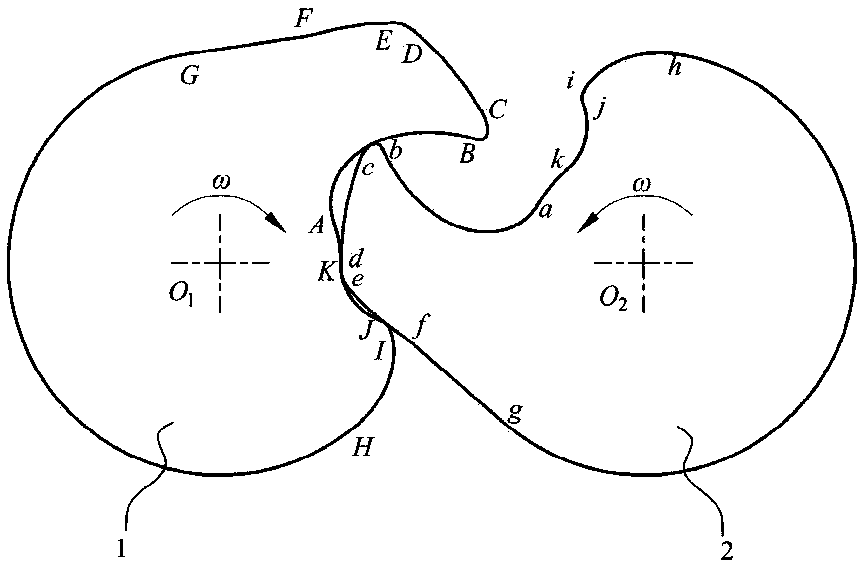

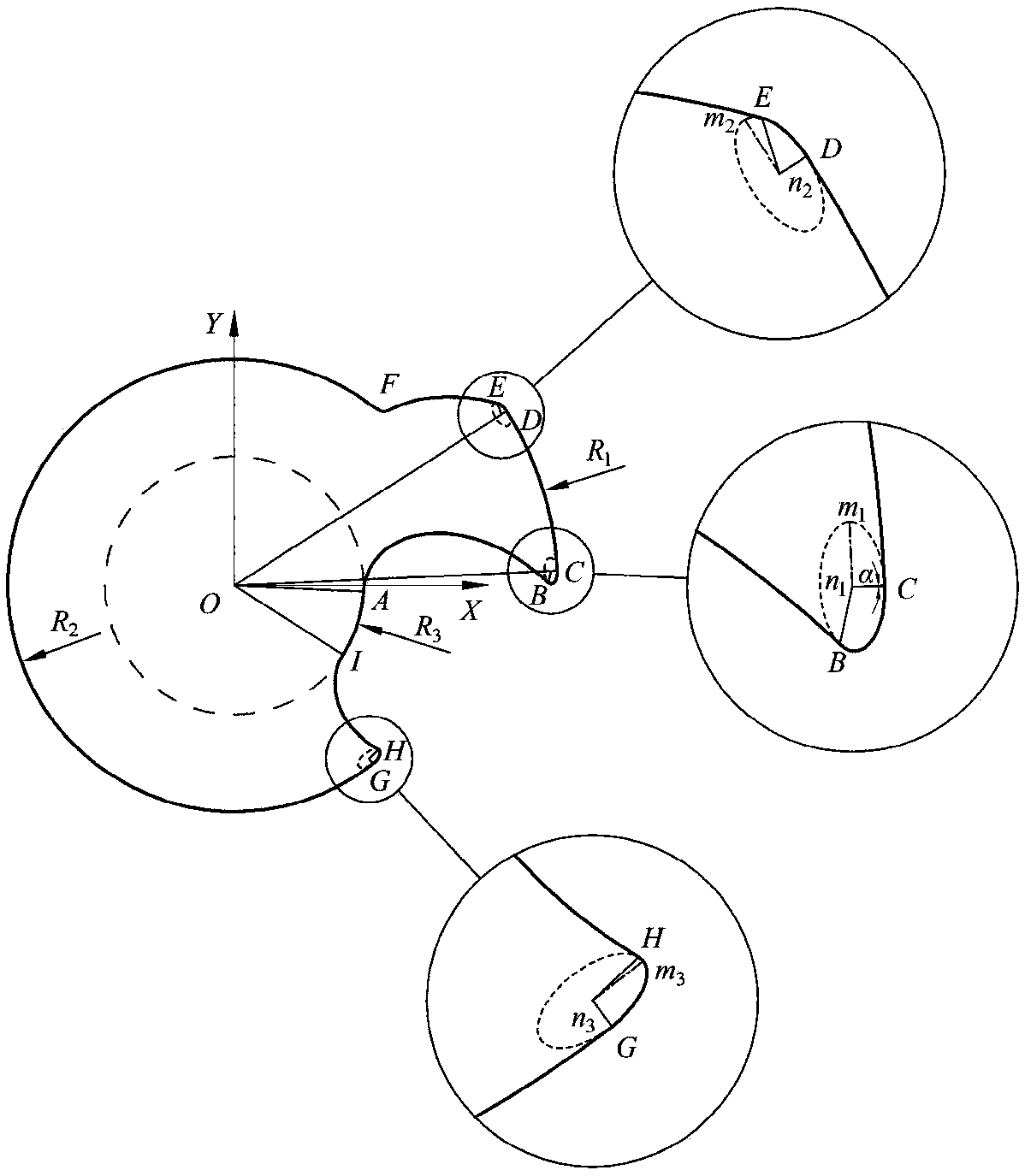

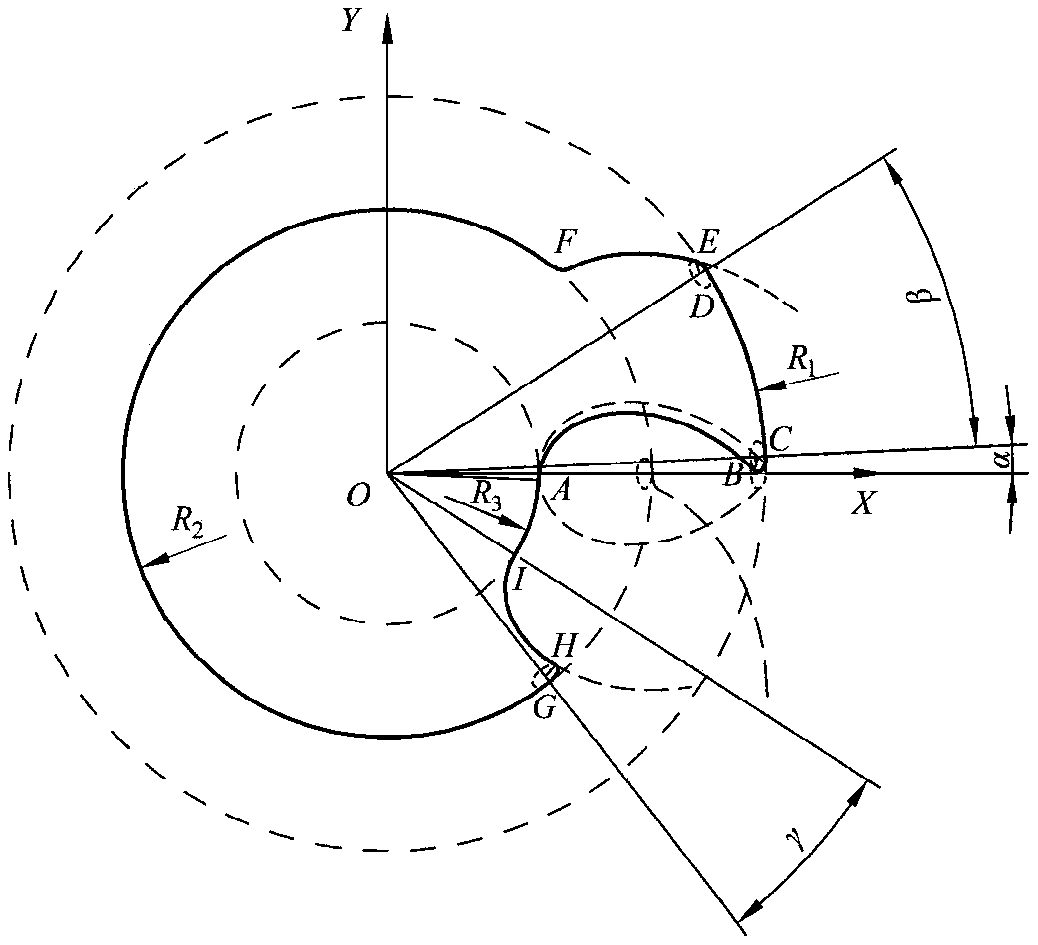

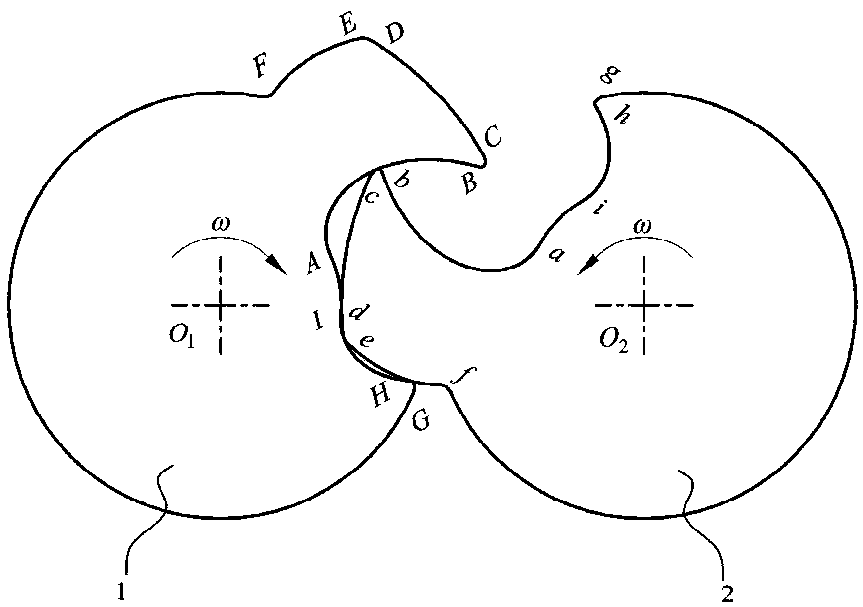

Straight jaw rotor of claw type vacuum pump and profile design method of straight jaw rotor

ActiveCN108757464AIncreased engagement rangeEngagement wire lengthGeometric CADRotary piston pumpsEllipseCycloid

The invention discloses a straight claw rotor of a claw type vacuum pump and a profile design method of the straight claw rotor. The straight claw rotor is composed of eleven segments of curves comprising four segments of arcs, two segments of elliptical arcs, two segments of elliptical arc envelope lines, one segment of equidistant curve of a cycloid, one segment of line segment and one segment of envelope line. The rotor uses the elliptical arcs and the envelope lines of the elliptical arcs to construct the profile at the top of a claw and the tip of the claw, and uses the arcs and the equidistant curve of the cycloid to construct the profile at the bottom of the claw, adjacent curves are all connected smoothly, no non-smooth connection point exists, and the mechanical properties, the meshing performance and the sealing performance of the straight jaw rotor are improved. Two rotors meshing with each other are identical and the correct meshing of the profile can be achieved. The rotorhas a smaller clearance volume and improves the compression ratio of the claw vacuum pump. The top of the claw is more flat, the meshing range is large, a mesh line is long, and abrasion is further reduced. The rotor enriches profile types of claw type rotors and promotes the development of claw type vacuum pumps.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Curved claw rotor of claw type vacuum pump and molded line design method thereof

PendingCN108678954AIncreased engagement rangeEngagement wire lengthGeometric CADRotary piston pumpsEllipseEngineering

The invention discloses a curved claw rotor of a claw type vacuum pump and a molded line design method thereof. The rotor is composed of nine curved lines: three circular arcs, three elliptic arcs andthree elliptic arc envelope lines. Molded lines are constructed at the top, tip and bottom of the claw of the rotor by adopting the elliptic arcs and the elliptic arc envelope lines. Two rotors engaged to each other are totally same and the molded lines can be correctly engaged; adjacent curved lines are smoothly connected without unsmooth connecting points, so that the mechanical property, the engaging property and the sealing property of the curved claw rotor are improved. The rotor has a smaller clearance volume, the compression power consumption is reduced effectively, and the compressionratio of the claw type vacuum pump is improved. The tip of the claw of the rotor is more flat, large in engaging range and long in engaging line, so that wear is further reduced; the rotor is small in area, and the pumping speed and the volume utilization ratio of the vacuum pump are improved; the types of the molded lines of the claw type rotor are enriched according to the rotor, and the rotoris of important significance to development of the claw type vacuum pump.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

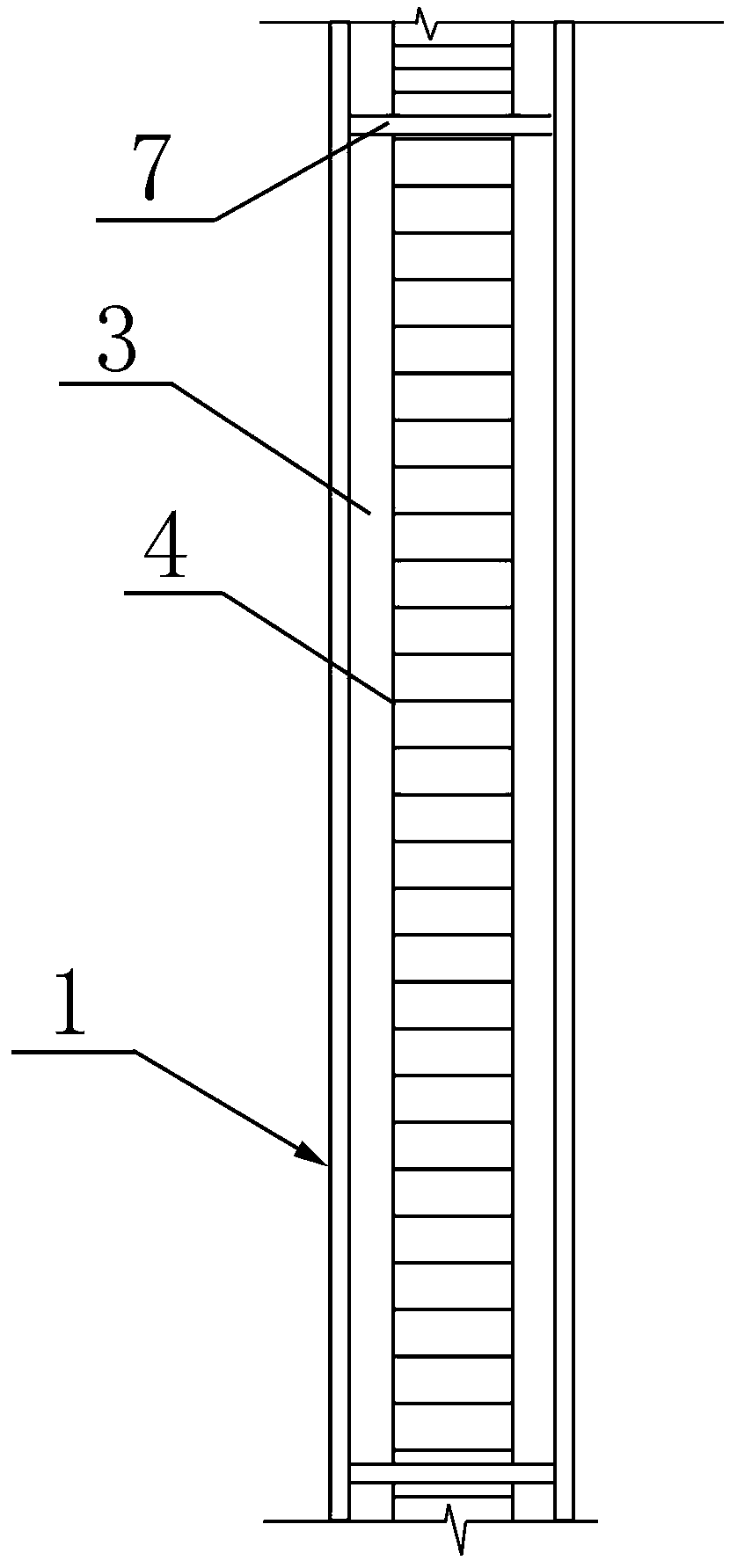

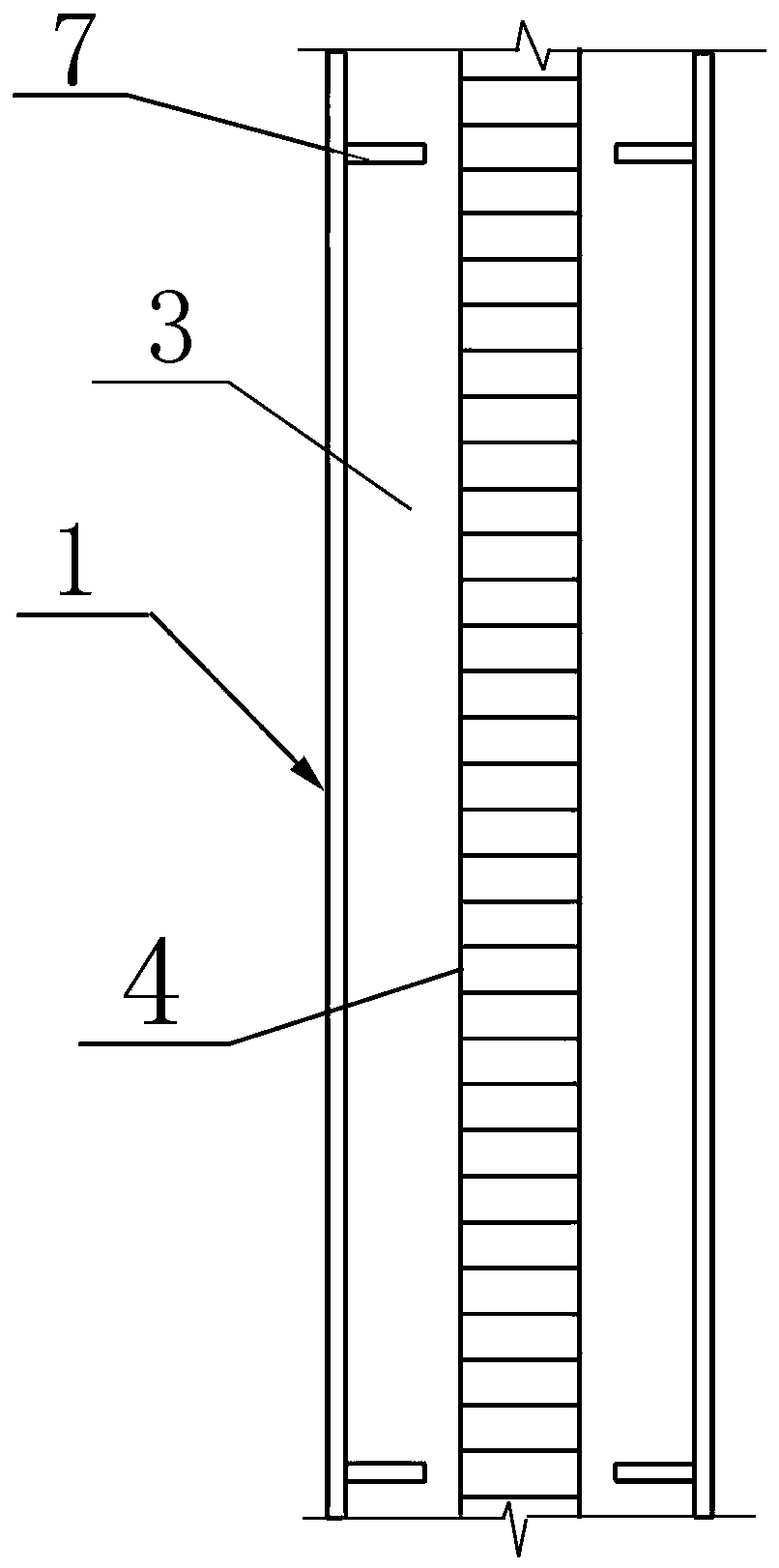

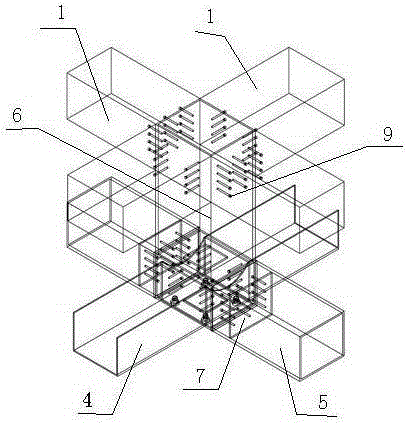

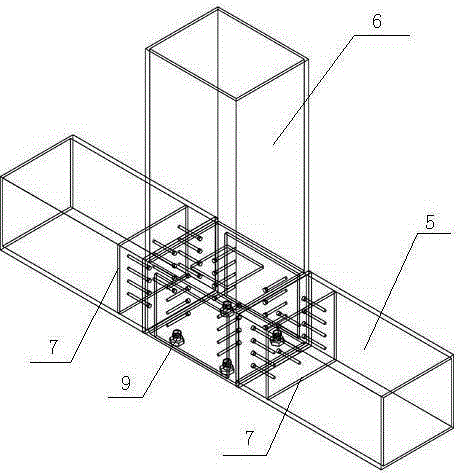

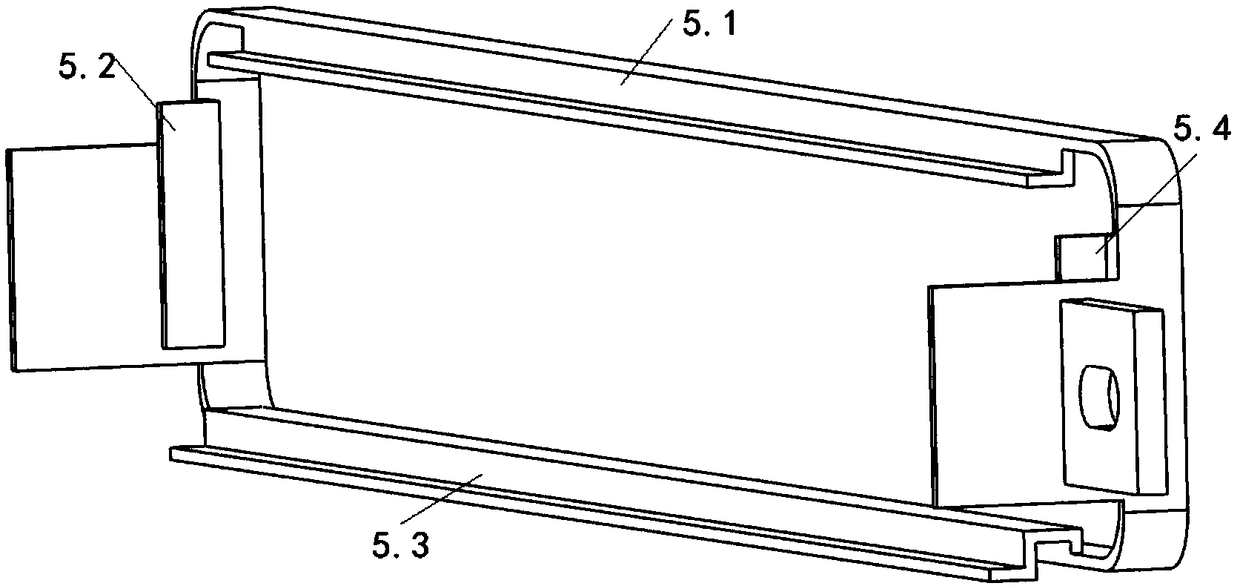

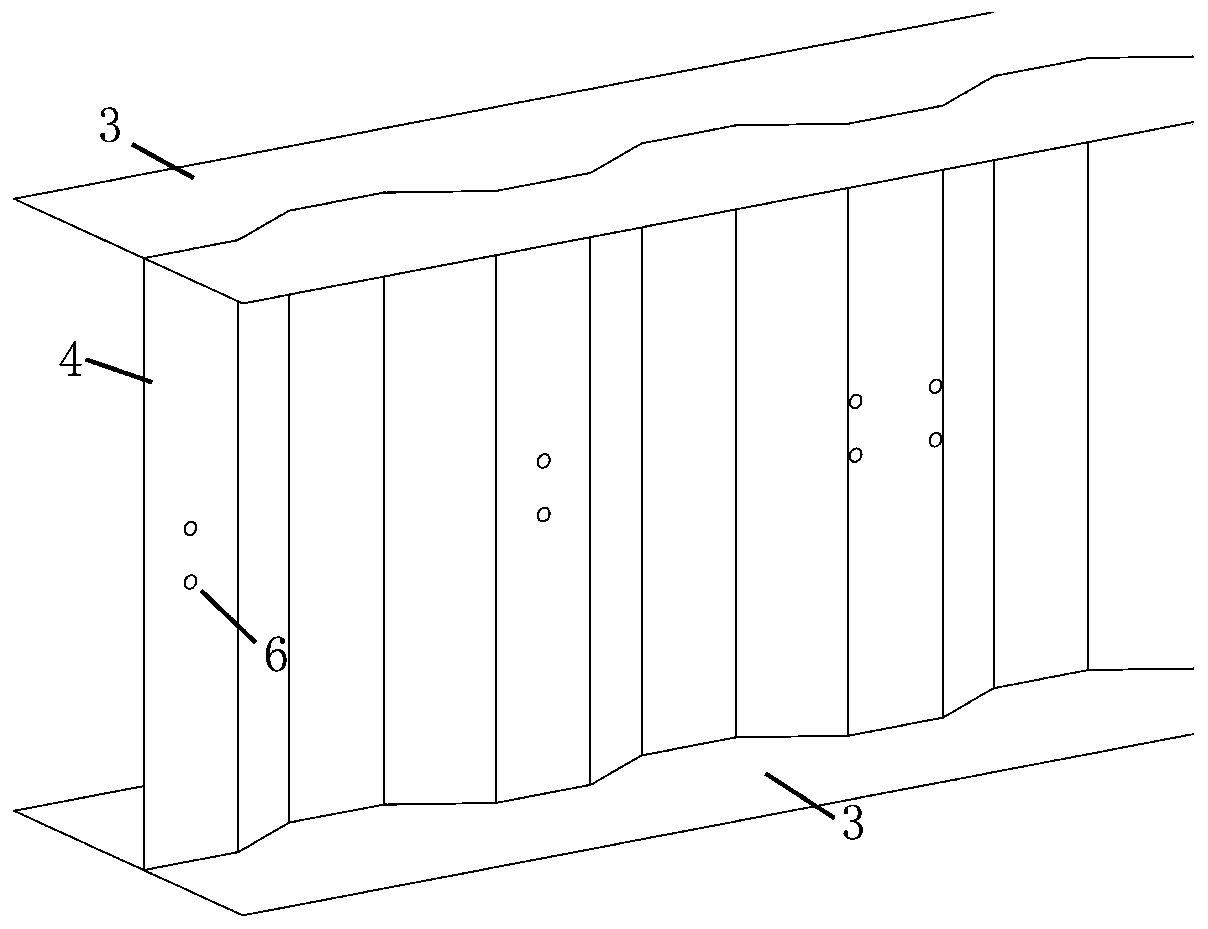

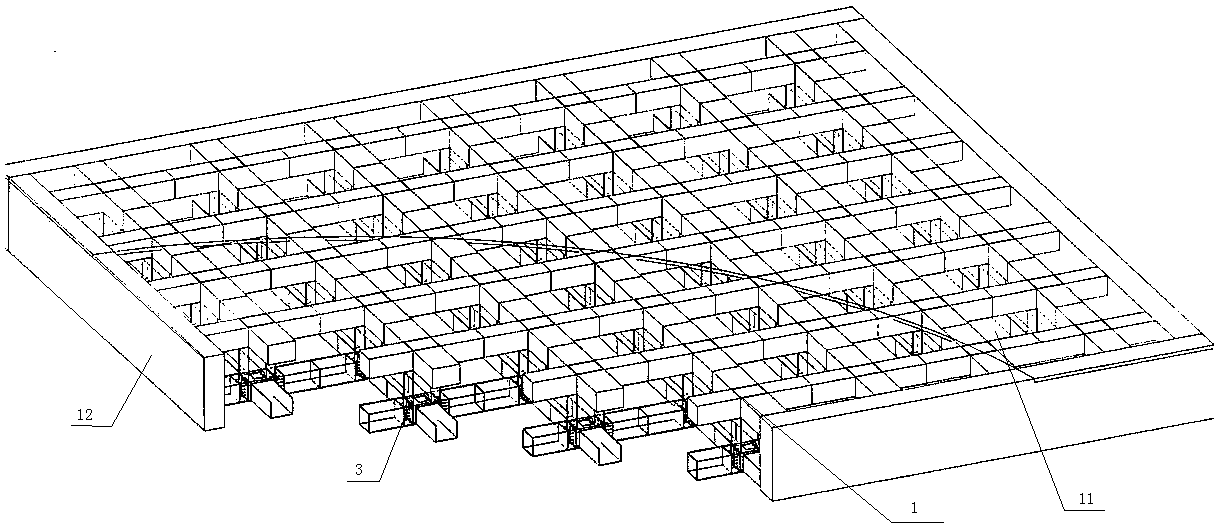

Reinforced multi-cavity steel pipe and concrete shear wall and system and construction method

PendingCN111119376AImproved collapse capacityNot easy to collapseWallsEarthquake resistanceButt welding

The invention relates to a reinforced multi-cavity steel pipe and concrete shear wall and a system and a construction method. The reinforced multi-cavity steel pipe and concrete shear wall comprises amulti-cavity steel pipe and wall concrete, wherein the multi-cavity steel pipe is enclosed by a group of multi-cavity steel pipe monomers and end plates, and the adjacent multi-cavity steel pipe monomers are in butt welding; the horizontal section of each multi-cavity steel pipe monomer is in an I shape, and the multi-cavity steel pipe monomer comprises two multi-cavity steel pipe monomer units;the horizontal section of each multi-cavity steel pipe monomer unit is in a T shape, and the multi-cavity steel pipe monomer unit is cut by I-shaped beams or H-shaped steel or I-shaped steel; groovesare formed in the ends of webs of the multi-cavity steel pipe monomer units; the webs of the two multi-cavity steel pipe monomer units are in butt welding so as to form a vertical partition; and the grooves in the two multi-cavity steel pipe monomer units are correspondingly spliced so as to form a concrete flowing hole. According to the reinforced multi-cavity steel pipe and concrete shear wall,the technical problems of large difficulty in control over the construction quality, long construction cycle, poor fireproof performance, low construction speed, low tensile strength and poor seismicperformance of a traditional shear wall structure and poor ductility and easiness in brittle failure under the action of an earthquake are solved.

Owner:北京峰筑工程技术研究院有限公司

Winding pipe capable of sealing gap by expanding and mounting method thereof

The invention relates to the field of pipelines, and particularly to a winding pipe capable of sealing a gap by expanding and a mounting method thereof. The winding pipe capable of sealing the gap by expanding comprises a pipe body and a plurality of rubber strips, wherein the plurality of rubber strips are arranged on the outer side of the pipe body; the rubber strips are made from a water-expandable material; the pipe body comprises a first connecting pipe, a second connecting pipe and a telescopic pipe; and the first connecting pipe is connected with the second connecting pipe through the telescopic pipe. According to the winding pipe capable of sealing the gap by expanding and the mounting method thereof, the plurality of rubber strips are arranged, the raw materials of the rubber strips comprise the water-expandable material, the rubber strips can expand in the presence of water to be increased in the volume, so that the rubber strips with the volume being increased can seal the gap between the winding pipe capable of sealing the gap by expanding and a surrounding filling structure thereof, and water or a fluid is prevented from leakage; and besides, the telescopic pipe can overcome the deformation stress of the pipe body in the axial direction, and the fracture risk of the pipe body due to shrinkage is reduced.

Owner:四川都得利管业有限公司

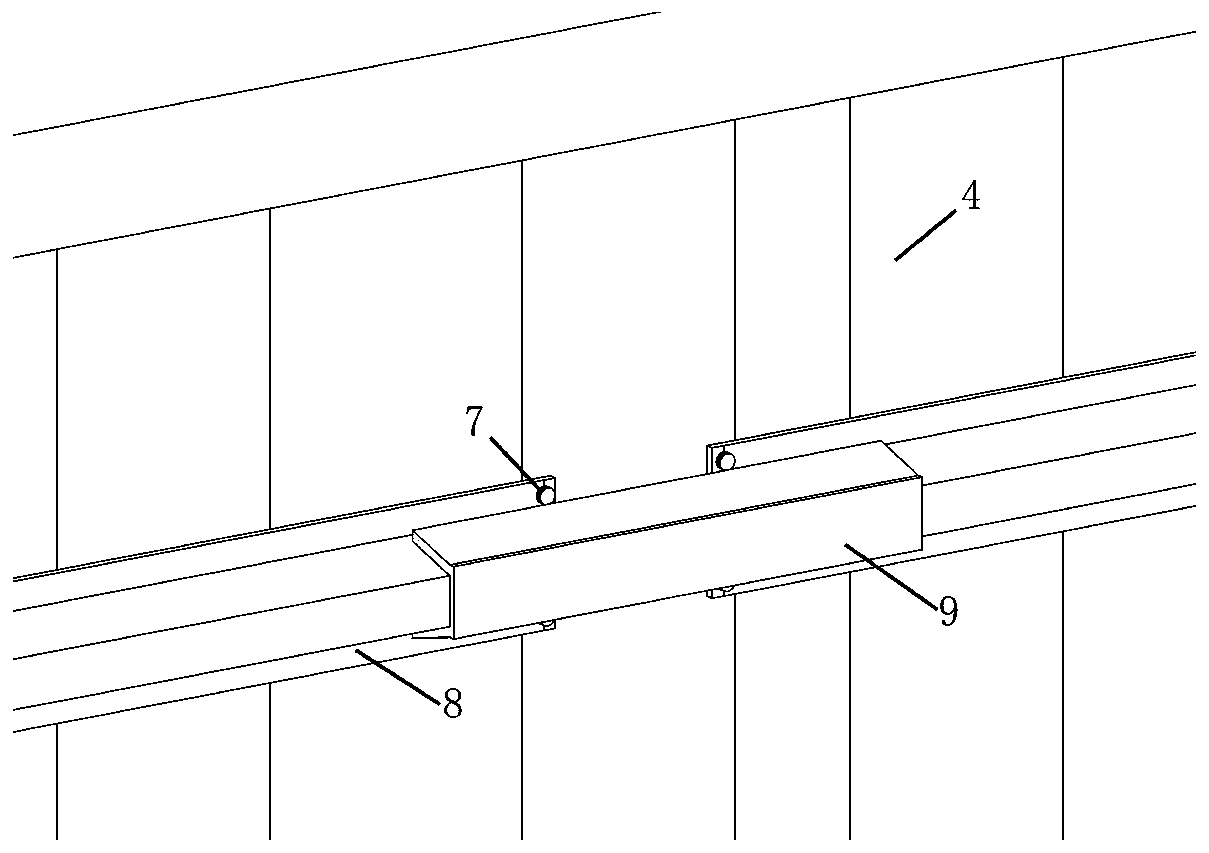

Steel-concrete partially-prefabricated composite beam structure using layered perforated plate connecting piece and manufacturing process thereof

ActiveCN105887648AShorten the construction periodEase traffic pressureBridge erection/assemblyBridge materialsComposite beamsSuperstructure

The invention relates to a steel-concrete partially-prefabricated composite beam structure using layered perforated plate connecting pieces. The steel-concrete partially-prefabricated composite beam structure using the layered perforated plate connecting pieces comprises steel main beams, transverse connecting steel plates, perforated plate connecting pieces, prefabricated portion slabs and cast-in-situ portion slabs, wherein the perforated plate connecting pieces are arranged on upper flanges of the steel main beams, an upper row of openings and a lower row of openings are formed in the perforated plate connecting pieces, the transverse connecting steel plates are connected between webs of adjacent steel main beams, the prefabricated portion slabs are located on the upper flanges of the steel main beams, the perforated plate connecting pieces are exposed out of the prefabricated portion slabs, the lower row of openings are located in the prefabricated portion slab, the upper row of openings are located above the prefabricated portion slabs, the cast-in-situ portion slabs are located on the prefabricated portion slabs, and the upper row of openings are located in the cast-in-situ portion slabs. The invention further provides a manufacturing process of a steel-concrete partially-prefabricated composite beam structure using layered perforated plate connecting pieces. The steel-concrete partially-prefabricated composite beam structure using the layered perforated plate connecting pieces and the manufacturing process have the advantages that the replacement time of a bridge superstructure can be greatly reduced, the construction period is shortened and the urban traffic pressure is greatly relieved; and the mass of the bridge superstructure is reduced.

Owner:宁波万泰建设工程有限公司

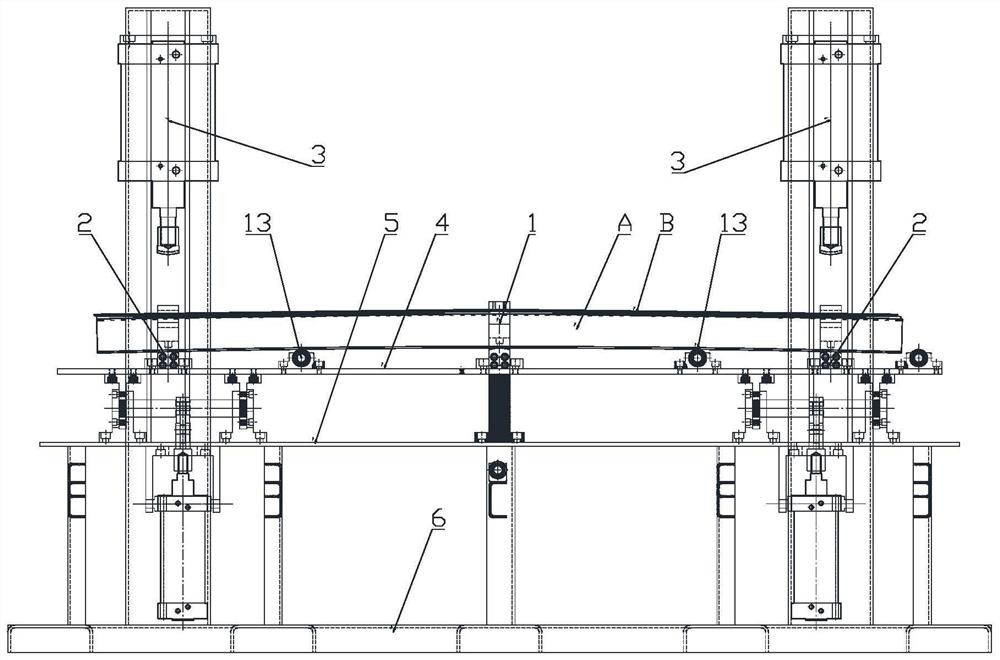

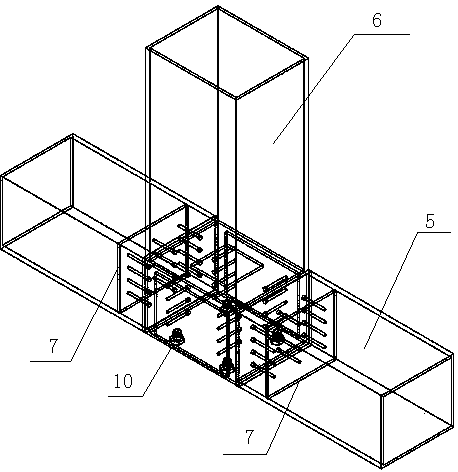

Rail wagon corner post assembly welding deformation control device

PendingCN112756888AAvoid deformation stressReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringWelding deformation

The invention discloses a rail wagon corner post assembly welding deformation control device. The rail wagon corner post assembly welding deformation control device comprises a workbench, a middle turning over and positioning mechanism is arranged in the middle of the workbench, the two ends of the workbench are each provided with an end part turning over and positioning mechanism and an oil cylinder pressing mechanism, the middle turning over and positioning mechanism and the two end part turning over and positioning mechanisms are provided with the same turning over and positioning assemblies, and the turning over and positioning assemblies are in follow-up connection through an turning over horizontal base plate arranged in the length direction of the workbench, the turning over and positioning assemblies are arranged on the turning over horizontal base plate through deflection inserts, and a plurality of spring type conveying rollers are arranged on the turning over horizontal base plate at intervals. According to the rail wagon corner post assembly welding deformation control device, deflection reversible deformation can be prefabricated on a welding part in advance, the deformation stress of the part in the welding process is counteracted, by arranging a turning over device, the deflection inserts and the spring type conveying rollers, the labor intensity in the conveying process can be relieved, deflection reversible deformation can be automatically prefabricated, all the systems are fused and assembled on the workbench to form a combined integrated structure, and the working efficiency is improved.

Owner:CRRC MEISHAN

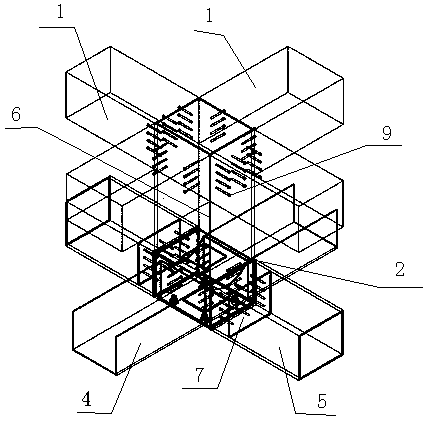

Novel steel-concrete combined open web girder system

Concrete upper ribs and floors of a novel steel-concrete combined open web girder system are made of cast-in-place concrete and form an orthogonal cross shape; holes are formed in reverse T-shaped joints of combined components so that concrete can be conveniently cast into the holes and shear connectors can be formed; reverse T-shaped steel pipes and U-shaped steel plates are all prefabricated in a factory, in the use process, the U-shaped steel plates penetrate through reserved holes in the bottoms of the reverse T-shaped steel pipes, and the T-shaped steel pipes and the U-shaped steel plates are positioned through high-strength bolts of bottom plates, and concrete is cast into the shear connectors into a whole. The system has the advantages that the structural deadweight is reduced, and rigidity is less reduced; the size of the shear connectors is reduced, and the rigidity of the shear connectors is improved; tensile force is borne by the square steel pipes, the steel pipes participate in shear resistance at the joint shear connectors, and the mechanical performance of materials is brought into full play; no welding or formworks are needed, welding stress and deformation are avoided, construction procedures are reduced, and construction efficiency is greatly improved.

Owner:CHINA AEROSPACE CONSTR GROUP

Glass fiber reinforced plastic air duct for rail vehicle

The invention provides a glass fiber reinforced plastic air duct for a rail vehicle. The glass fiber reinforced plastic air duct for the rail vehicle comprises multiple sub air ducts; the sub air ducts comprise an air inlet duct, a horizontal air duct, a bend air duct and an air outlet duct; the air inlet duct is connected with the air outlet duct through the bend air duct and the horizontal air duct; each sub air duct is connected by using a flange so that the air duct is connected to form a whole body; the connecting part of each sub air duct is in sealed connection; rigid connecting pieceshaving effects of air duct main frameworks are arranged at the connecting parts of the air inlet duct, the air outlet duct and a vehicle body; the rigid connecting pieces are bonded and embedded in the pasting process of the air inlet duct and the air outlet duct; structural adhesive layers are arranged on one surfaces of the rigid connecting pieces; and embedded layers are arranged on the other surfaces of the rigid connecting pieces. According to the glass fiber reinforced plastic air duct for the rail vehicle, the integral intensity of the air duct can be enhanced, outside forces borne on the rigid connecting pieces can be completely transmitted to an air duct body, the connecting strength is guaranteed, the appearance is beautiful, the integral strength and airtightness of the structure can be guaranteed, and good sound insulation and heat insulation performance can also be guaranteed.

Owner:ZHUZHOU LINCE GRP +1

Waveform steel web composite beam structure with multi-section stiffening rib and construction method thereof

ActiveCN110607737AImprove integrityImprove overall shear buckling capacityBridge erection/assemblyBridge materialsWavelength rangeEngineering

The invention discloses a waveform steel web composite beam structure with a multi-section stiffening rib and a construction method thereof, and the waveform steel web composite beam structure comprises a concrete slab, a steel beam and a multi-section FRP stiffening rib; the multi-section FRP stiffening rib is composed of a FRP rib plate and a FRP splicing plate, each section of FRP rib plate isintegrally connected through the FRP splicing plate, a plurality of sections of FRP stiffening ribs are arranged along the beam in a straight line, and are connected to the peaks or troughs of the waveform steel web only in a wavelength range. The waveform steel web composite beam structure with the multi-section stiffening rib has a higher overall shear buckling bearing capacity. The multi-section stiffening rib can flexibly adapt to the waveform steel web with any shape to avoid the complicated construction of the whole corrugated plate stiffening, the residual deformation and residual stress caused by welding the stiffening rib are eliminated, the construction speed is improved significantly, and the construction difficulty is reduced.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST

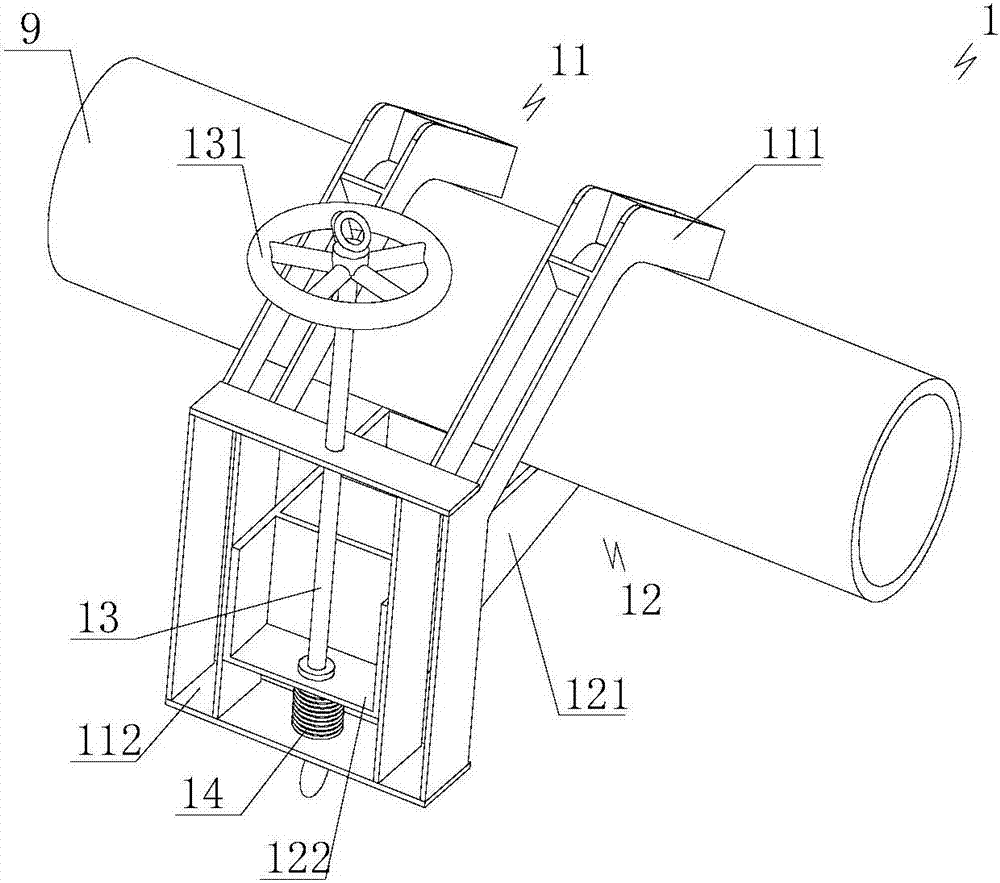

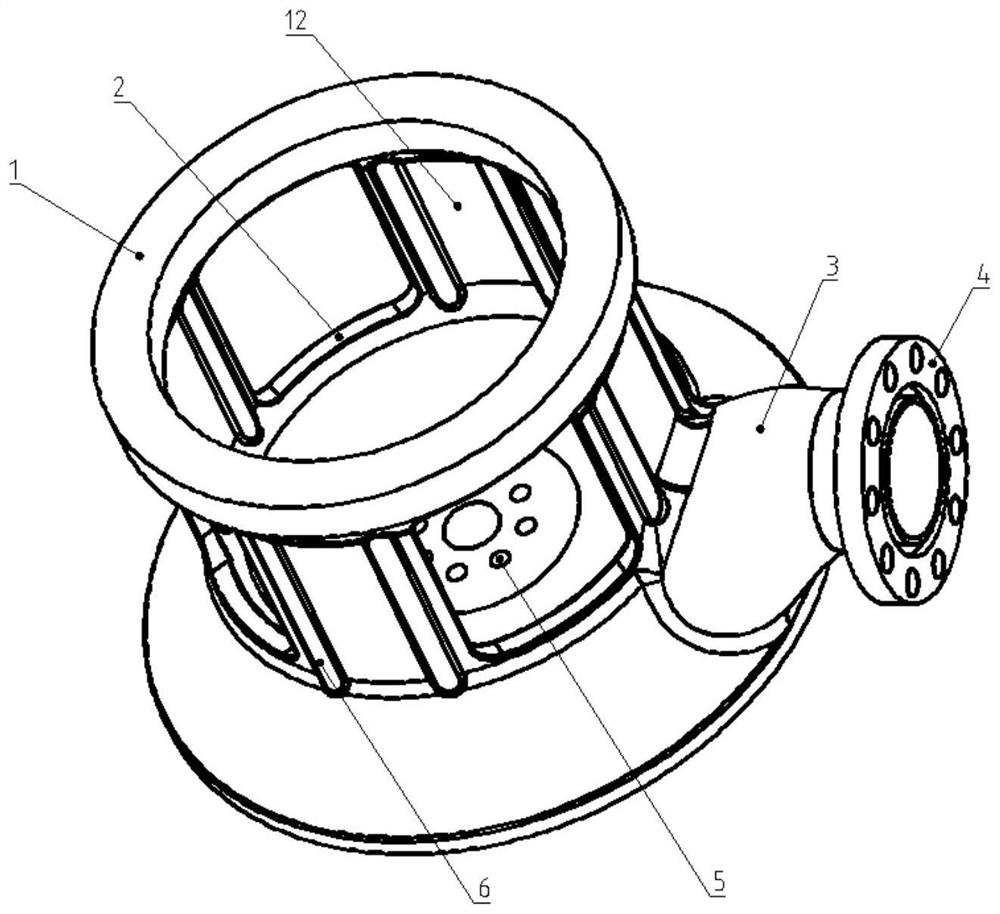

New-type hinge expansion joint for high-temperature flue of flue gas turbine

PendingCN110953429AWork lessReduce thermal stressPipe supportsPipeline expansion-compensationFlue gasExpansion joint

The invention discloses a new-type hinge expansion joint for a high-temperature flue of a flue gas turbine. The new-type hinge expansion joint comprises a pipe nipple I, a pipe nipple II, a corrugatedpipe, a load-bearing frame I, a load-bearing frame II, two sets of hinge mechanisms and eight sets of support assemblies, wherein the pipe nipple I, the corrugated pipe and the pipe nipple II are connected in sequence; the load-bearing frame I is located on the side where the pipe nipple I is located and supports the pipe nipple I through four of the sets of support assemblies; the load-bearing frame II is located on the side where the pipe nipple II is located and supports the pipe nipple II through the other four sets of support assemblies; and the two sets of hinge mechanisms are mounted between the load-bearing frame I and the load-bearing frame II. The invention ensures the persistent working of the expansion joint under high temperature, thereby prolonging the service life of the product.

Owner:QINHUANGDAO TAIDY FLEX TECH

Method for manufacturing small-diameter wood integrated material planed thin sheet

InactiveCN100593461CHighlight substantiveSignificant technological progressVeneer manufacturePressure impregnationAdhesiveIron levels

The invention relates to a manufacturing method of small-diameter wood glulam slicing veneers and a leveling drying device. Small-diameter wood, tended wood, inferior wood or cordwood produced in thecutting and manufacturing process, and the like which are not easily efficiently used are softened by a composite agent by being infused with pressure, and then after flitches are integrated by fingerjoining and obliquely slotting the wood with a moisture-curable type adhesive, the flitches are sliced into wet veneers, and the wet veneers are then sent to a special continuous high-temperature ironing leveling dryer to be leveled and dried into sliced veneers in the clamping of upper and lower steel belts. The invention integrates a series of special technologies and transforms small-diameterwood which is not easily used into sliced veneers which meet requirements of various technical specifications with very wide application ranges. Low-grade wood is fully used, which improves the addedvalue of products and comprehensive utilization efficiency of forest resources. The invention has the advantages of simple and reasonable technique method, low equipment cost, good product quality, broad development prospects and the like. Significant social and economic benefits can be produced after the implementation.

Owner:BEIHUA UNIV

Laser molding method of extra/ultra high-voltage circuit tool

InactiveCN107486522AEasy to operateLow costMetal-working apparatusCleaning using liquidsQuenchingMetallic materials

The invention relates to a laser molding method of an extra / ultra high-voltage circuit tool. The molding method comprises the steps of: cleaning of the surface of a material; preheating of a worktable; placement of a titanium alloy; laser irradiation; rolling of a forging wheel; molding of a test piece; and cooling of the test piece. The laser molding method adopts the laser to melt a filament with a special metal material, melts a microlayer, is superior to a quenching process in performance, easy to operate and lower in cost, and improves the mechanical performance and refines crystallized particles through a layer-by-layer quenching process; protective gas is introduced, so that a protection structure is not oxidized, and microelements can be molten in molding; the laser molding method solves the defect that the technical performance of a general laser cladding technology cannot superior to that of a forged piece; the metal is leveled and forged in the melting and cooling process; different scanning methods are selected for different areas, so that the strain deformation and cracking problems caused by the heat concentration are effectively prevented; and the laser molding method is high in controllability and suitable for popularization and application.

Owner:STATE GRID HUBEI ELECTRIC POWER CO LTD MAINTENANCE CO

Method for preventing hot working warpage and deformation of large titanium alloy isothermal precise thin web plate forge pieces

The invention relates to a method for preventing hot working warpage and deformation of large titanium alloy isothermal precise thin web plate forge pieces. The method is characterized by comprising the following steps of: taking isothermal precise forge pieces out of a high-temperature forging mould, and then hanging the forge pieces on a bracket for air cooling; and before heat treatment in a furnace, flatly placing forge pieces with warpage on base plates, and putting cushion blocks between the forge pieces and base plates and firmly padding, wherein if the bottom surfaces of the forge pieces are parallel and have equal height, the heights of the cushion blocks are consistent, and if the bottom surface of the forge pieces have height falls, the heights of the cushion blocks have identical falls. By adopting the method, heat in the processes of cooling after isothermal forging and cooling after heat treatment of large complicated titanium alloy plane structures with unequal cross section areas is uniformly dispersed, and the forge piece warpage parts are pressed flatly in the heat treatment process. The process provided by the invention has the advantages of simplicity, easinessin application and low cost.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Lens eccentricity fine adjustment mechanism in projection lithography objective

InactiveCN101710204ARestraint torsionGuaranteed radial displacementPhotomechanical exposure apparatusMicrolithography exposure apparatusLithographic artistImaging quality

The invention discloses a lens eccentricity fine adjustment mechanism in a projection lithography objective. The lens eccentricity fine adjustment mechanism is arranged on a lens frame and a lens barrel. The lens frame is positioned in the lens barrel and a certain gap is reserved between the lens frame and the lens barrel to guarantee a displacement adjustment quantity of a lens. The lens eccentricity fine adjustment mechanism comprises a fine adjustment head, a sliding block, a guide post, a guide post pedestal and an elastic cushion, wherein the fine adjustment head is arranged in the lens barrel and is vertical to an optical axis of the objective; an elastic guide mechanism is arranged on a lateral surface of the lens frame, and a contact surface of the guide post pedestal and the lens frame is the elastic guide mechanism; and the sliding block is embedded in the guide post on the guide post pedestal. The lens eccentricity fine adjustment mechanism can perform accurate eccentricity adjustment on each lens in the projection lithography objective to meet the requirement of an offset tolerance of the center of the lens, the alignment accuracy of each lens for the axle centre is improved, adverse effects on the image quality caused by lens eccentricity are overcome, the stability of the image quality and the focal plane is guaranteed, and the lithography quality is guaranteed.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

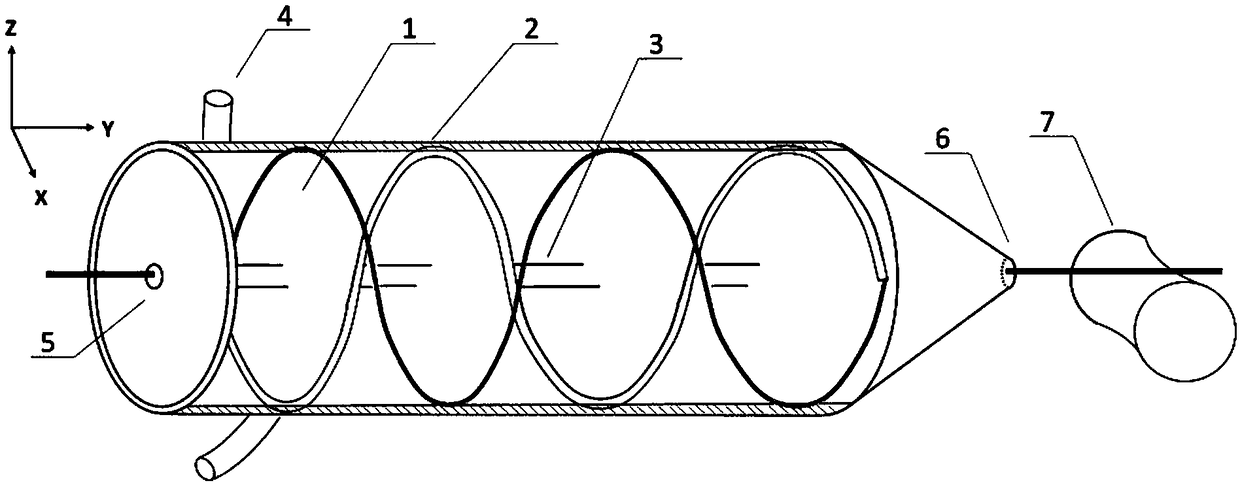

A variable-pitch double-helix air-cooling device suitable for water-soluble silk

The invention belongs to the field of advanced manufacturing related technology and discloses a varying pitch double-spiral air cooling device suitable for water-soluble wires. The varying pitch double-spiral air cooling device comprises at least one air cooling mechanism arranged sequentially oppositely at intervals, so that multi-section type continuous cooling of the water-soluble wires is achieved. Each air cooling mechanism comprises an air cover and a varying pitch double-spiral spoiler arranged in the air cover. Each varying pitch double-spiral spoiler is provided with a through hole, and the water-soluble wires penetrate through the through holes. Wire inlets and wire outlets which communicate with the two ends of the through holes correspondingly are formed in the two opposite ends of the air covers correspondingly. Through the varying pitch double-spiral spoilers of the varying pitch double-spiral air cooling device, cooing airflow forms spiral airflow, the spiral airflow surrounds the wires to cool the wires evenly, the sizes of the semisolid wires shrink evenly in the radial direction, meanwhile, the spiral airflow achieves a supporting function on the wires, and the downward collapse phenomenon of the wires due to gravity is prevented.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD

Method for forming grating for machine tool measurement in two-step solidifying roll-pressing forming method

ActiveCN102193310BLow costIncrease productivityDiffraction gratingsPhotomechanical exposure apparatusStress concentrationGrating

Owner:XI AN JIAOTONG UNIV

A multi-purpose plate steam generator

ActiveCN106642039BStable arrangementOptimize layoutNuclear energy generationCooling arrangementEngineeringSecondary side

The invention discloses a multi-purpose plate steam generator. A plate steam generating assembly includes a heat exchange plate I and a heat exchange plate II, and the surfaces of the heat exchange plates are connected to each other. The heat exchange channel for the reactor coolant is provided on the heat exchange plate I, and the heat exchange channel for the secondary side medium is provided on the heat exchange plate II. The plate surface or the etching grooves on the plate surface are formed in cooperation, and the depth of the etching groove is smaller than the thickness of the heat exchange plate where it is located. The plate steam generator is arranged in the reactor pressure vessel cylinder, and the reactor pressure vessel cylinder is provided with a guide tube, the axial direction of the guide tube is parallel to the axial direction of the reactor pressure vessel cylinder, and at least one of the plate steam generators Distributed in the annular space between the draft tube and the reactor pressure vessel shell. The device has the advantages of compact structure, high heat exchange efficiency, high power volume ratio, low manufacturing cost, stable operation and the like.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Double-steel-plate concrete composite shear wall with U-shaped pull rods arranged in staggered mode

The invention discloses a double-steel-plate concrete composite shear wall with U-shaped pull rods arranged in a staggered mode, and belongs to the technical field of civil engineering composite structures. The double-steel-plate concrete composite shear wall is mainly used for solving the problems of large welding deformation of external steel plates, difficulty in controlling welding residual stress, complexity in bolt perforation and the like in the prior art. The double-steel-plate concrete composite shear wall with the U-shaped pull rods arranged in the staggered mode is mainly composed of steel plates with holes in the two sides, the U-shaped pull rods, internal positioning nuts, external fixing nuts and filling concrete, wherein the U-shaped pull rods are metal products with good ductility such as a rebar, a screw rod, a steel bar and is in a U shape through cold machining, the end parts of the U-shaped pull rods are provided with threads capable of installing a bolt, and the U-shaped pull rods at adjacent positions of the steel plates on the two sides are staggered. Bolt connection is adopted, a large amount of welding work is avoided, welding deformation and welding residual stress do not exist, the outer steel plate can keep higher flatness, the staggered pull rods are large in contact area with concrete and small in shearing slippage, certain constraint can be provided for filling of the concrete, and the cooperative work capacity of the steel plates and the concrete is improved.

Owner:BEIJING UNIV OF TECH

Integrated liquid rocket engine thrust chamber top cover structure

ActiveCN114412663AReduce total pressure distortionImprove reliabilityRocket engine plantsThrust chamberClassical mechanics

The invention discloses an integrated liquid rocket engine thrust chamber top cover structure, and belongs to the technical field of machinery. The top cover comprises a force bearing end face, a propellant inlet bent pipe, a propellant inlet flange, a top cover inner cavity, an inner conical surface, an outer conical surface, a top cover bottom surface and a force bearing wall. Thrust generated by a thrust chamber of the liquid rocket engine is transmitted to the top cover from the bottom face of the top cover, transmitted to the force bearing wall through a triangular force bearing structure formed by the inner conical face and the outer conical face and finally transmitted to an engine rack through the force bearing end face. Propellant enters the top cover from a propellant inlet in the propellant inlet flange, flows through the propellant inlet bent pipe, enters the inner cavity of the top cover and then enters the downstream nozzle.

Owner:BEIJING AEROSPACE PROPULSION INST

A water-cooled heat dissipation power box with resonance weakening

ActiveCN110401120BTimely adsorptionAvoid saturationSubstation/switching arrangement cooling/ventilationAnti-seismic devicesWater vaporEngineering

The invention discloses a water-cooled and heat-dissipating power box with weakened resonance. The structure includes a box body, heat-radiating leaves, heat-dissipating pipes, a safety door and an anti-resonance device. Beneficial effects: the present invention uses the anti-rust structure provided to timely absorb the water droplets splashed by the water-cooled radiator during operation and heat dissipation, and conduct evaporation treatment under the action of the heat generated by the heating ring, so as to avoid the water droplets from making the absorbent cotton It is saturated or overflowing, thus generating water vapor and causing other parts inside the chassis to malfunction due to moisture. This invention utilizes the shock absorbing mechanism provided to deal with the resonance generated during water cooling and heat dissipation, and the interaction between the concave bag and the convex air bag Effectively reduce noise, so as to avoid a large degree of deformation and dynamic stress on the structure of the chassis caused by the resonance.

Owner:滨州市博兴智创数字技术有限责任公司

A steel-concrete composite vierendeel beam system

Concrete upper ribs and floors of a novel steel-concrete combined open web girder system are made of cast-in-place concrete and form an orthogonal cross shape; holes are formed in reverse T-shaped joints of combined components so that concrete can be conveniently cast into the holes and shear connectors can be formed; reverse T-shaped steel pipes and U-shaped steel plates are all prefabricated in a factory, in the use process, the U-shaped steel plates penetrate through reserved holes in the bottoms of the reverse T-shaped steel pipes, and the T-shaped steel pipes and the U-shaped steel plates are positioned through high-strength bolts of bottom plates, and concrete is cast into the shear connectors into a whole. The system has the advantages that the structural deadweight is reduced, and rigidity is less reduced; the size of the shear connectors is reduced, and the rigidity of the shear connectors is improved; tensile force is borne by the square steel pipes, the steel pipes participate in shear resistance at the joint shear connectors, and the mechanical performance of materials is brought into full play; no welding or formworks are needed, welding stress and deformation are avoided, construction procedures are reduced, and construction efficiency is greatly improved.

Owner:CHINA AEROSPACE CONSTR GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com