Method for preventing hot working warpage and deformation of large titanium alloy isothermal precise thin web plate forge pieces

A titanium alloy and thin web technology is used in the field of preventing warpage deformation of large-scale isothermal precision thin web forgings of large titanium alloys during thermal processing, and can solve the problems of inappropriate small area correction and large elastic modulus of titanium alloys.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

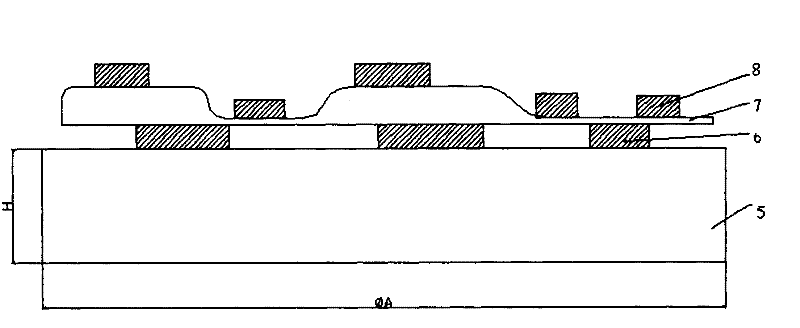

[0021] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0022] The outer contour size obtained in this embodiment is about 1180mm×1090mm, the inner contour size is about φ900mm, the average rib height is 70mm, the average web thickness is 10mm, and the XX aircraft TA15 titanium alloy overall frame forging with a local solid height of 180mm.

[0023] Step 1: Take the titanium alloy isothermal precision thin-web forging out of the high-temperature forging die, hang it on the hanging column, place the part with large mass above the hanging column, and heat it at 960°C with 10 -2 -10 -5 the s -1 The strain rate is isothermal forging out of the mold and suspended in air to room temperature; if it is directly placed on the ground to cool, the amount of warping deformation of the forging and the distortion deformation when the forging is ejected from the mold will be superimposed as high as 15mm-25mm / 1000mm;

[0024] on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com