Rail wagon corner post assembly welding deformation control device

A welding deformation and control device technology, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of inability to straighten at the same time, consume more labor hours, and unstable product quality, so as to facilitate processing and operation , the overall structure is simple, good replicable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0031] In conjunction with the accompanying drawings.

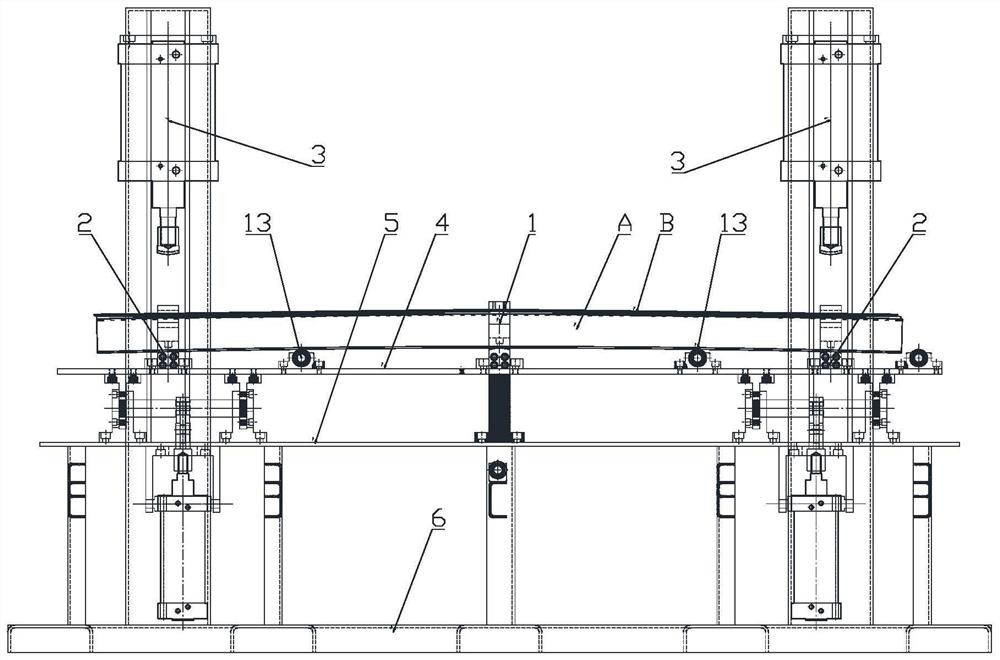

[0032] Such as figure 1 As shown, the welding deformation control device composed of corner columns of railway freight cars includes a steel structure and a workbench 6 arranged along the length direction of the corner columns. The end overturning positioning mechanism 2 and a group of oil cylinder pressing mechanisms 3; the middle overturning positioning mechanism 1 and the two groups of end overturning positioning mechanisms 2 have the same overturning positioning composition. Flip horizontal substrate 4 follow-up connection;

[0033] The end turni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com