Reinforced multi-cavity steel pipe and concrete shear wall and system and construction method

A technology of steel pipe concrete and shear walls, which is applied to walls, building components, buildings, etc., can solve the problems of difficult construction quality control, poor seismic performance, and slow construction speed, so as to improve construction quality, improve collapse resistance, Effect of Seismic Performance Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

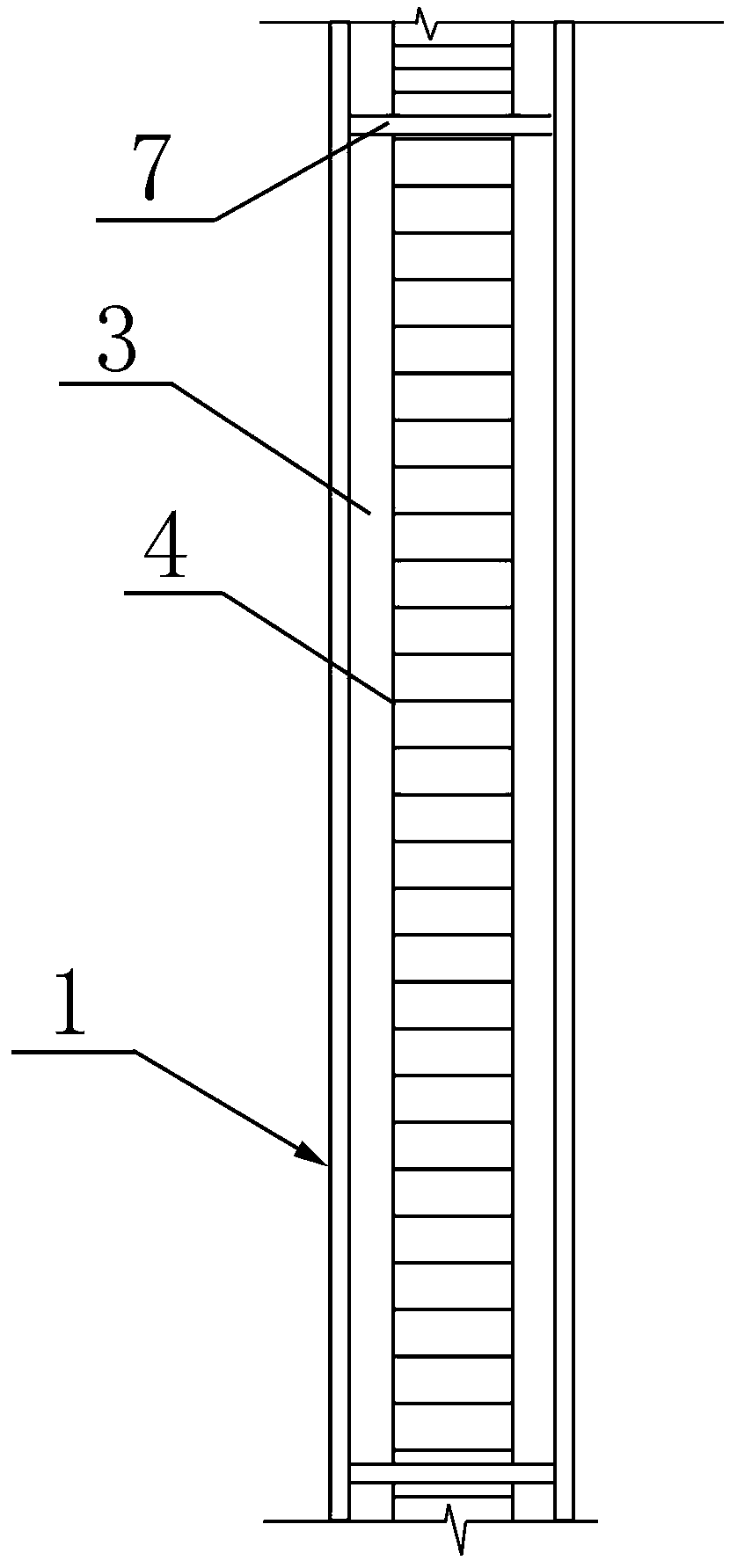

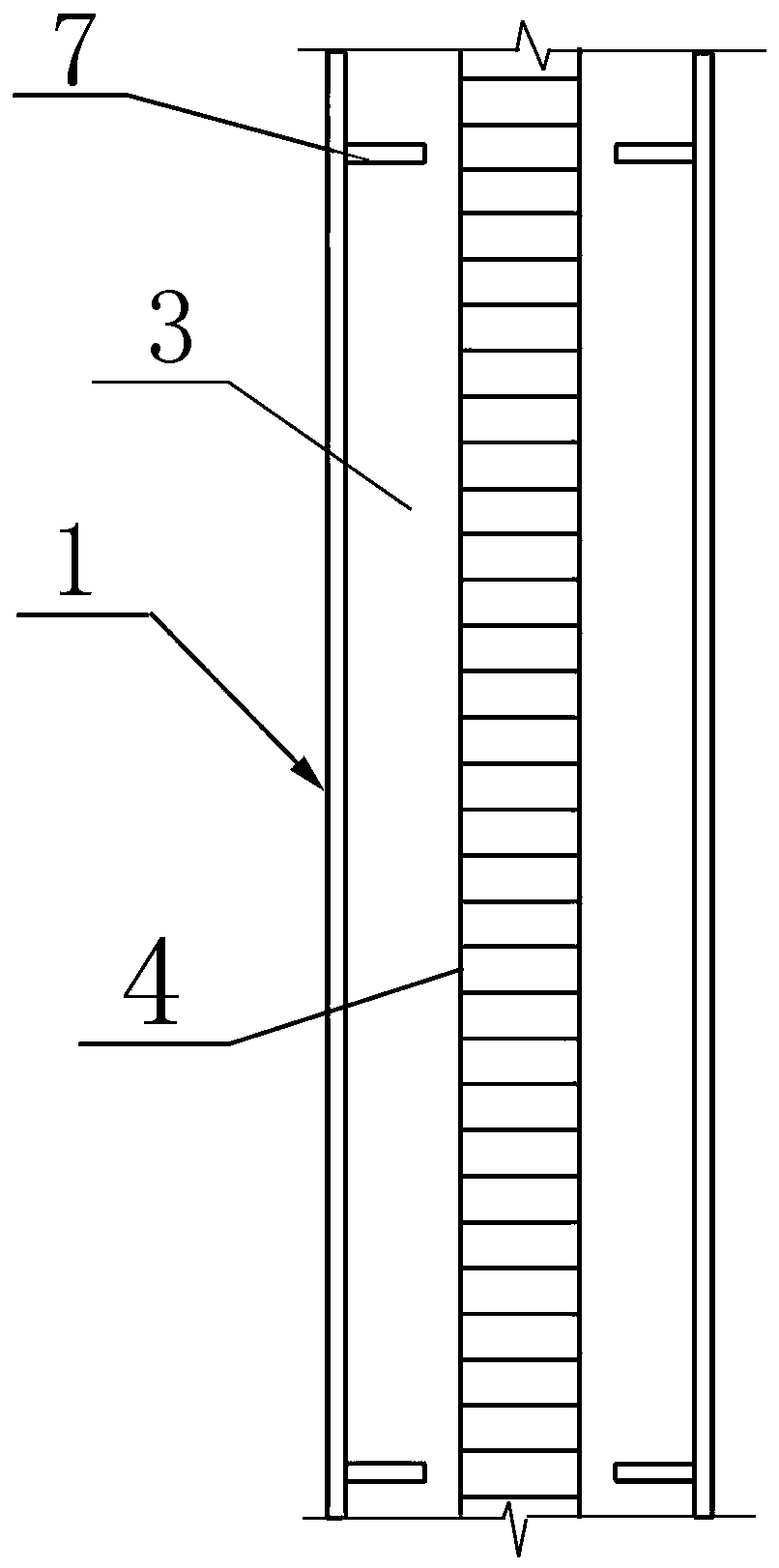

[0037] Such as Figure 1-10 As shown, this reinforced multi-cavity steel tube concrete shear wall includes a multi-cavity steel tube 1 and wall concrete 2 poured in the multi-cavity steel tube 1; the multi-cavity steel tube 1 is composed of a multi-cavity steel tube monomer 1.1 and Enclosed by plates 1.3; the multi-cavity steel pipe monomer 1.1 has a group, arranged along the horizontal direction, and adjacent multi-cavity steel pipe monomers 1.1 are butt welded; the horizontal section of the multi-cavity steel pipe monomer 1.1 is I-shaped , including two multi-cavity steel pipe monomer units 1.1.1; the horizontal section of the multi-cavity steel pipe monomer unit 1.1.1 is T-shaped, and is cut from I-shaped steel, H-shaped steel or I-shaped steel; the The web end of the multi-cavity steel pipe unit 1.1.1 is vertically spaced with grooves 6.1; the webs of the two multi-chamber steel unit units 1.1.1 are butt welded to form a vertical partition 5; The grooves 6.1 on the single...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com