Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84results about How to "Adapt to large-scale production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Single-layer glazed transmutation brick and preparation method thereof

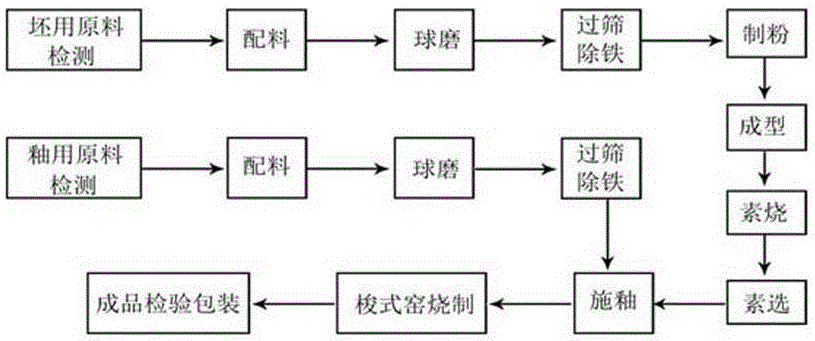

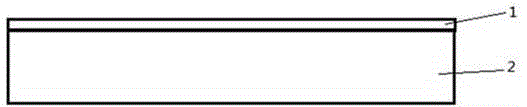

The invention discloses a single-layer glazed transmutation brick and a preparation method thereof and relates to production of architectural ceramic glazed bricks. The method comprises the following steps: (1) preparation of green body slurry; (2) preparation of a glazing material; (3) forming and biscuit firing of a green body; (4) glazing of the green body; (5) firing of the transmutation brick. The glazed green body is fired in a kiln after drying and is subjected to a transmutation reaction through two times of temperature increasing and decreasing, and the single-layer glazed transmutation brick is obtained. The method has the advantages as follows: firstly, the problem about combination of the green body and glaze is solved, the product qualification rate is increased, and the method is suitable for large-scale production; secondly, a ground coat and cover glaze are combined into single glaze layer, a glazing process is simplified, color difference caused by different thickness of the ground coat and the cover glaze is avoided, and the brick can adapt to large-area paving for architectural decoration; thirdly, the firing temperature and firing time for the transmutation glaze are reduced, energy is saved, and consumption is reduced; fourthly, through optimization of a green body formula and a firing process, the brick is magnetized while is not hardened too much, and construction cutting is facilitated.

Owner:JIANGXI GANXIN CRAFT CERAMICS CO LTD

Method for improving dewaterability of activated sludge through addition of microbial flocculant

ActiveCN103435250AWide variety of sourcesFast growth metabolismSludge treatment by de-watering/drying/thickeningWater contentAluminium salts

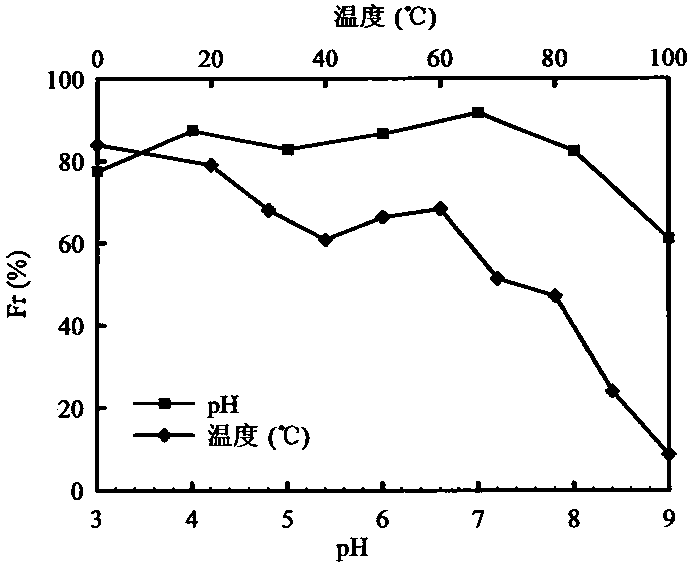

The invention discloses a method for improving dewaterability of activated sludge through addition of a microbial flocculant. According to the method, Klebsiella pneumoniae capable of generating the microbial flocculant is separated, purified and screened from activated sludge in a sewage treatment plant, then shake fermentation cultivation is carried out at a temperature of 25 to 40 DEG C at a rotating speed of 100 to 200 r / min for 2 to 3 d, and a flocculant sample is extracted from fermentation supernatant through frozen ethanol precipitation; and the microbial flocculant is added into an activated sludge sample, specific resistance of filtration (SRF) and water content of the regulated sludge are respectively reduced to 4.66*10<12> m / kg and 83.74%, and compared to chemical flocculants like aluminum sulfate and poly aluminum chloride (PAC), the microbial flocculant enables a better dewatering effect to be obtained. The microbial flocculant has good adaptability to characteristics like sludge salt waste and a pH value, and the regulated activated sludge has substantially improved dewaterability and the advantages of easy biodegradability, high efficiency, no toxicity, etc.

Owner:BEIJING NORMAL UNIVERSITY

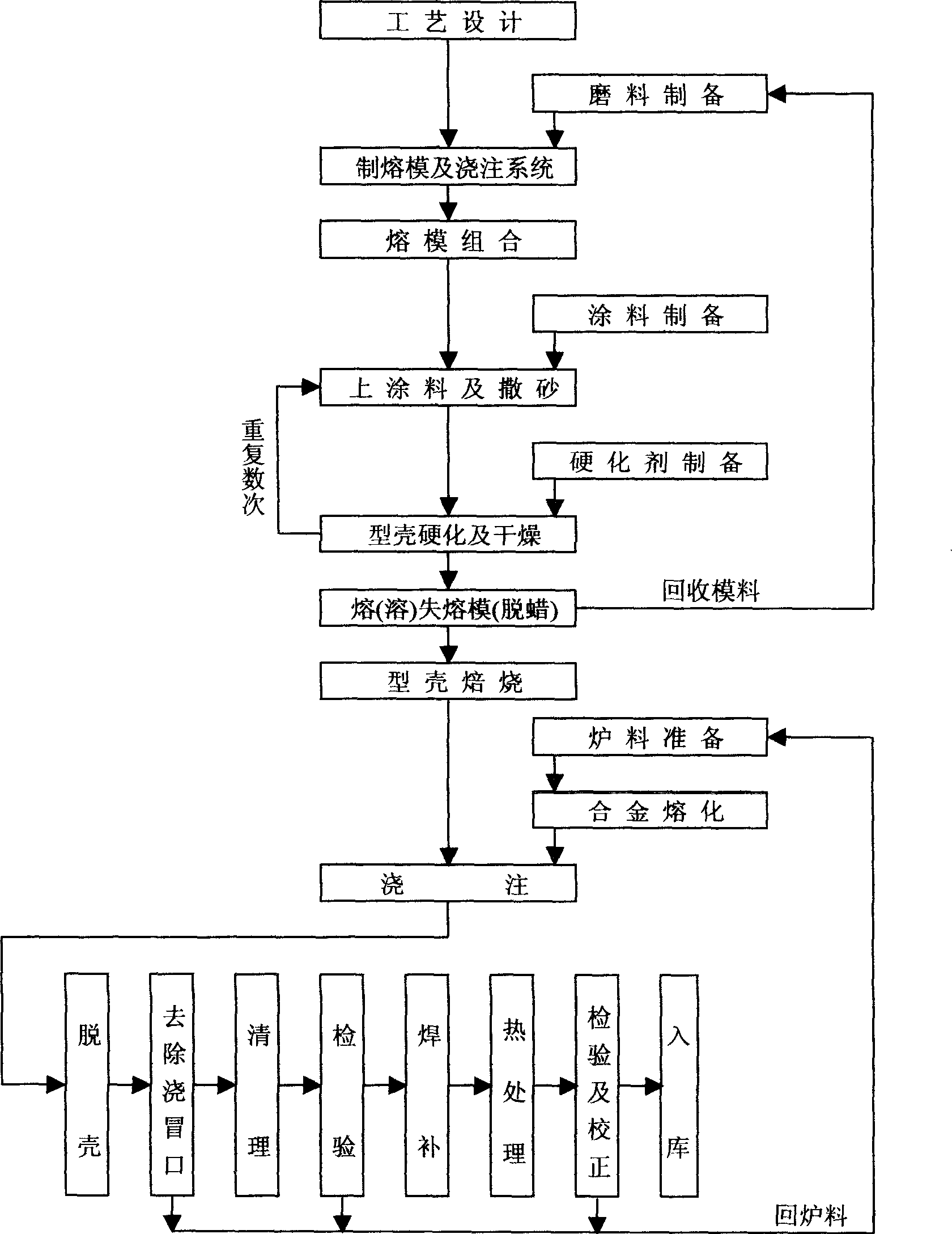

Technology method relating to component in manufacturing artificial limb knee-joint

InactiveCN101120894ASimplify production and processing proceduresImprove adaptabilityArtificial legsSolution treatmentTO-18

The invention discloses a process method for manufacturing related components in prosthetic knee joints. In the method, a silica sol precision casting process is used to replace the forging process. The relevant process steps and process parameters are as follows: a. Prepare high-strength aluminum alloy materials, except for the main components In addition to Al, it also includes: Cu: 4.6-5.3, Mn: 0.3-0.5, Si≤0.06, Fe≤0.30, and the total amount of other impurities≤0.60. b. Melting and pouring: melting temperature 680-720°C, pouring temperature 680-700°C; c. heat treatment process: solid solution treatment at 533-543°C for 10-18 hours, aging treatment at 170-180°C for 4-5 hours Hour. Adopting the process of the present invention obviously simplifies the processing procedure of the relevant parts in the prosthetic knee joint, and the product is formed by one-time casting, which avoids many cutting and forging processes, improves the production efficiency and the utilization rate of metal materials, and not only simplifies the equipment and process, It also reduces the production cost and facilitates the formation of large-scale production capacity.

Owner:上海市机械制造工艺研究所有限公司

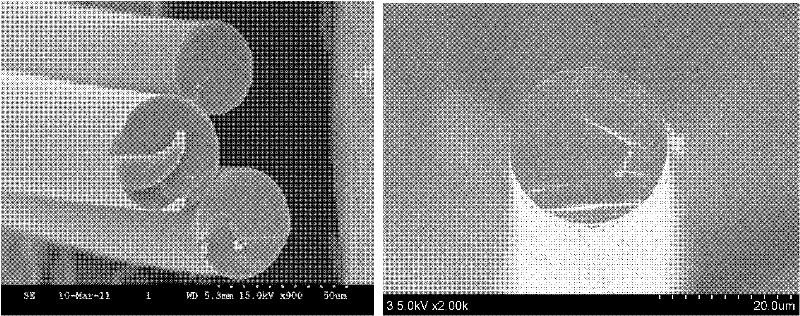

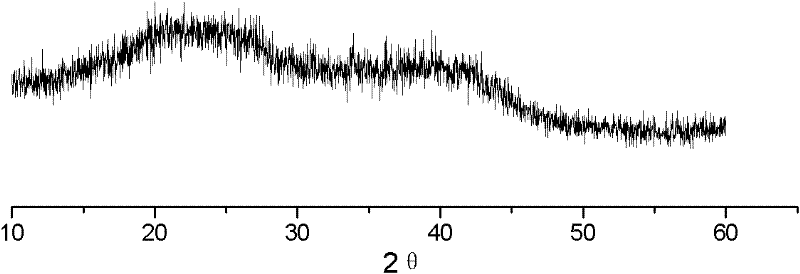

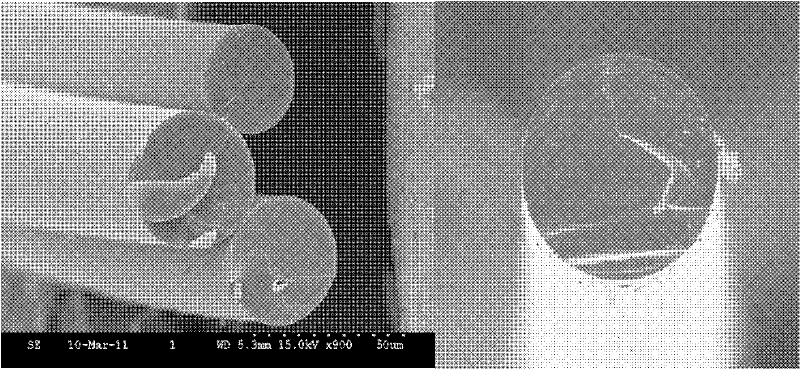

Continuous preparation method of silicon boron nitrogen-based ceramic fiber

The invention relates to a continuous preparation method of a silicon boron nitrogen-based ceramic fiber, which comprises the following steps 1) melt spinning a precursor polymer polyborosilazane by insulating air under the temperature of 120-250 DEG C to obtain the precursor polymer fiber; 2) putting the precursor polymer fiber in a cracking furnace, introducing mixed gas, heating with 0.5-5 DEG Cmin to 200-350 DEG C and insulating for 2-10 hours to obtain the crosslinked fusion-free fiber; 3) under the condition that the above mixed gas is introduced, continuously heating with 0.5-5 DEG Cmin to 400-1000 DEG C and insulating for 2-10 hours, and heating with 0.5-5 DEG Cmin to 1200-1700 DEG C and insulating for 2-10 hours to obtain the product. The precursor polymer nascent fiber can effectively inhibit the introduction of oxygen element and enhance the anti-oxidation performance of inorganic ceramic fiber, the cost of the raw material is low, the process is stable and easy to adjust, and the method of the invention is suitable for large scale production.

Owner:DONGHUA UNIV

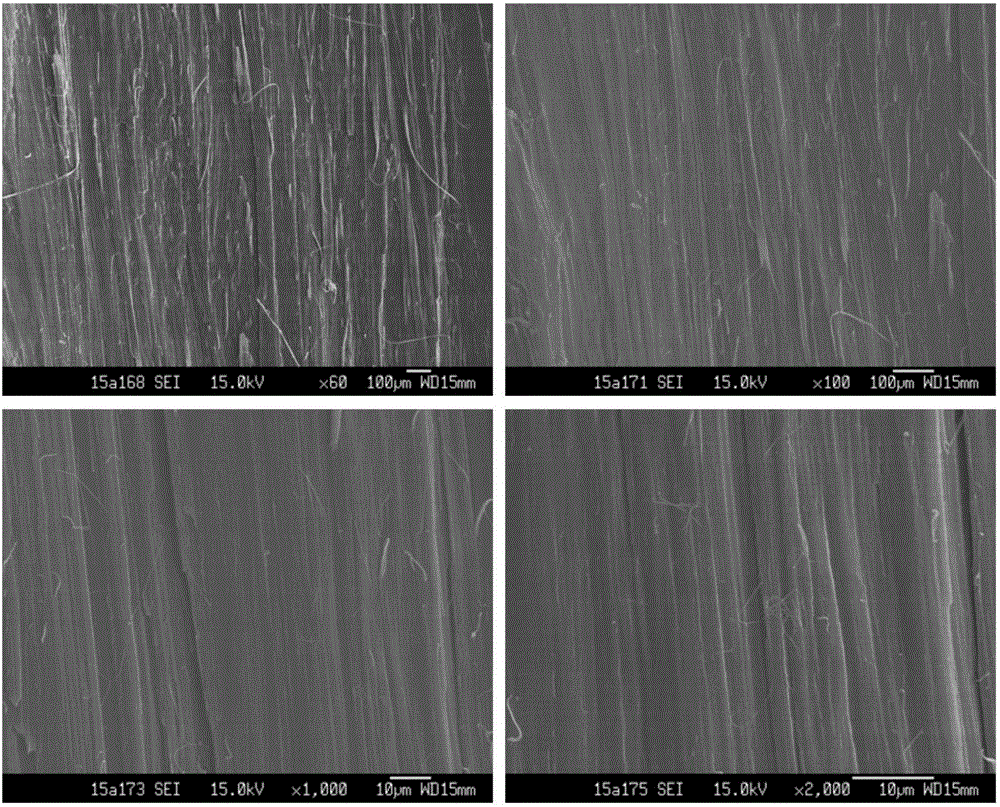

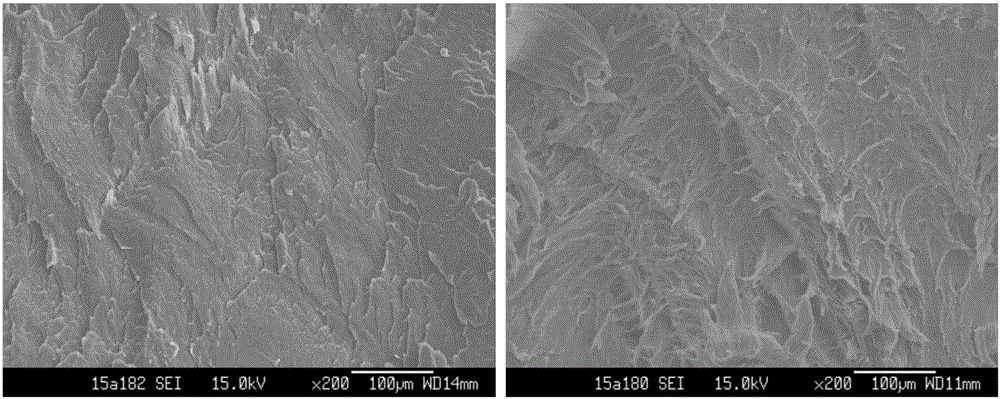

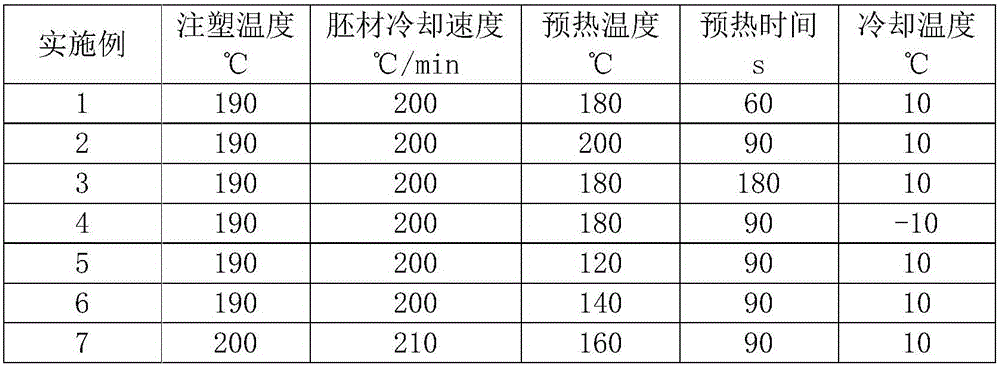

Method for preparing orientated-state polylactic acid profile

ActiveCN106426973AWide range of practical applicationsArranged orderlyCoatingsPolymer scienceBiocompatibility Testing

The invention discloses a method for preparing an orientated-state polylactic acid profile. The method comprises the following steps of 1, conducting injection molding on dried polylactic acid raw materials through an injection molding machine, so that a billet material is obtained, or heating and pressurizing the polylactic acid raw materials, so that the polylactic acid raw materials are made into the billet material through forging; 2, conducting oriented intensification on the billet material obtained in step 1, wherein extrusion or forging is adopted as the oriented intensification method; and 3, conducting cooling and quenching on the billet material obtained in step 2, so that after the billet material is stabilized, the profile is formed. According to the method for preparing the orientated-state polylactic acid profile, technological parameters for preparing the polylactic acid profile are controlled, so that the orientation effect of polylactic acid molecules and a crystalline region is improved to the greatest extent; and the unexpected technical effect is gained, and thus the polylactic acid profile which is excellent in mechanical performance is obtained. The orientated-state polylactic acid profile prepared through the method is stable in performance, healthy, harmless and good in biocompatibility.

Owner:SUZHOU SEEMINE NEBULA BIOTECH CO

Method for extracting theophylline sodium salt or theophylline by styrene type macroporous resin

ActiveCN102344450AQuality improvementImprove extraction efficiencyOrganic chemistryBenzeneDesorption

The invention discloses a method for extracting theophylline sodium salt or theophylline from a theophylline sodium salt or theophylline mother solution by a styrene type macroporous resin adsorption method, which comprises the following steps: (1) regulating the pH value of the theophylline sodium salt or theophylline mother solution; (2) filtering the mother solution and removing suspended impurities in the mother solution; (3) adsorbing the mother solution by adsorption resin; (4) desorbing the adsorption resin after adsorption saturation by a desorbing agent to obtain a desorption solution; (5) regulating the pH value of the desorption solution, standing and crystallizing theophylline sodium salt or theophylline; (6) centrifugally filtering; and (7) drying to obtain solid theophylline sodium salt. The method provided by the invention has the advantages that the theophylline sodium salt or theophylline crude product has better quality, the operation safety is better, the extraction efficiency is higher, the extraction cost is low, and the method is more suitable for mass production and facilitates realizing automatic operation. With the method disclosed by the invention, the extraction cost of the theophylline sodium salt and theophylline can be reduced, the extraction yield of the theophylline sodium salt and theophylline is increased, and the competitiveness of enterprises is enhanced.

Owner:SUNRESIN NEW METERIALS CO LTD XIAN

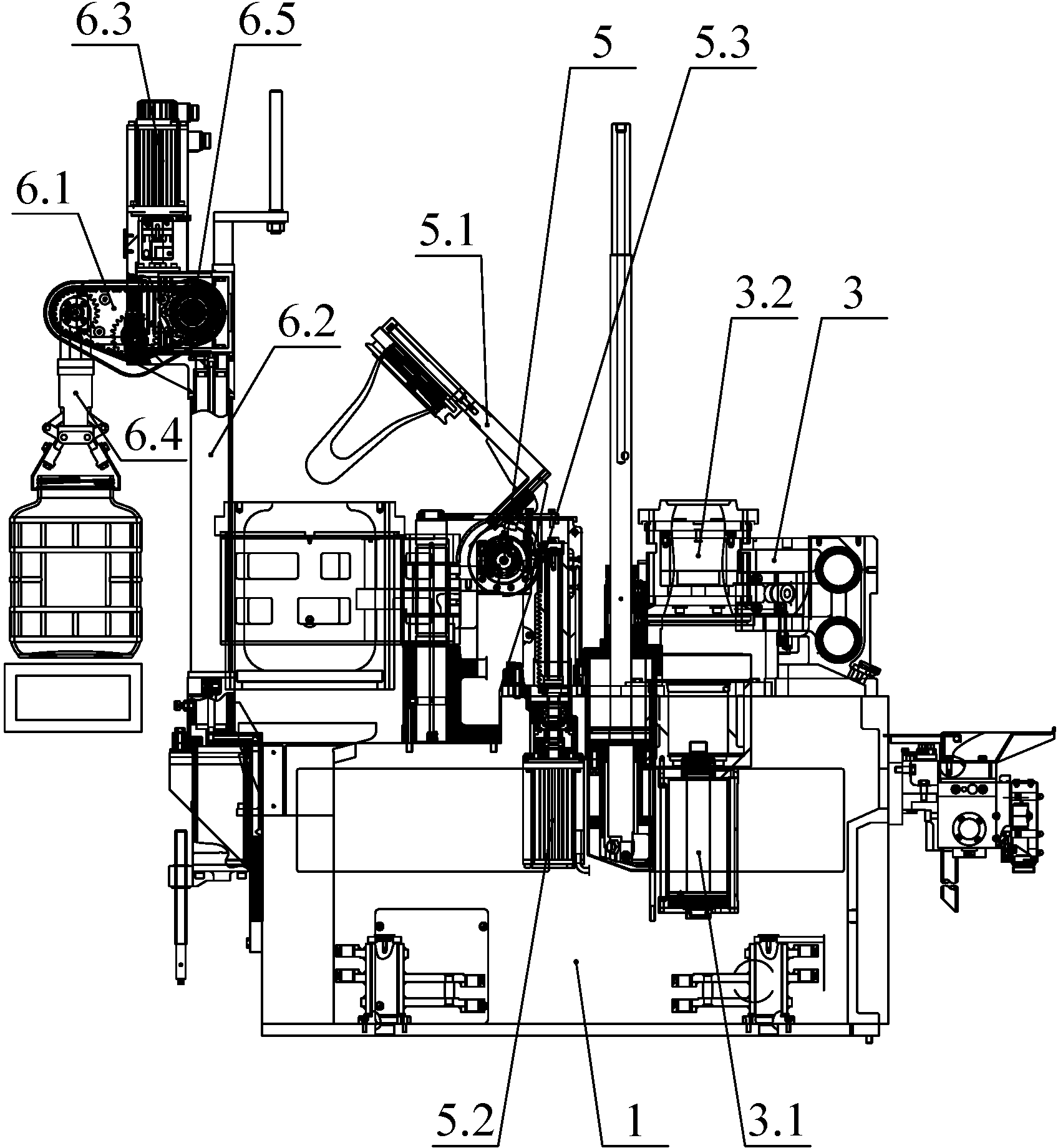

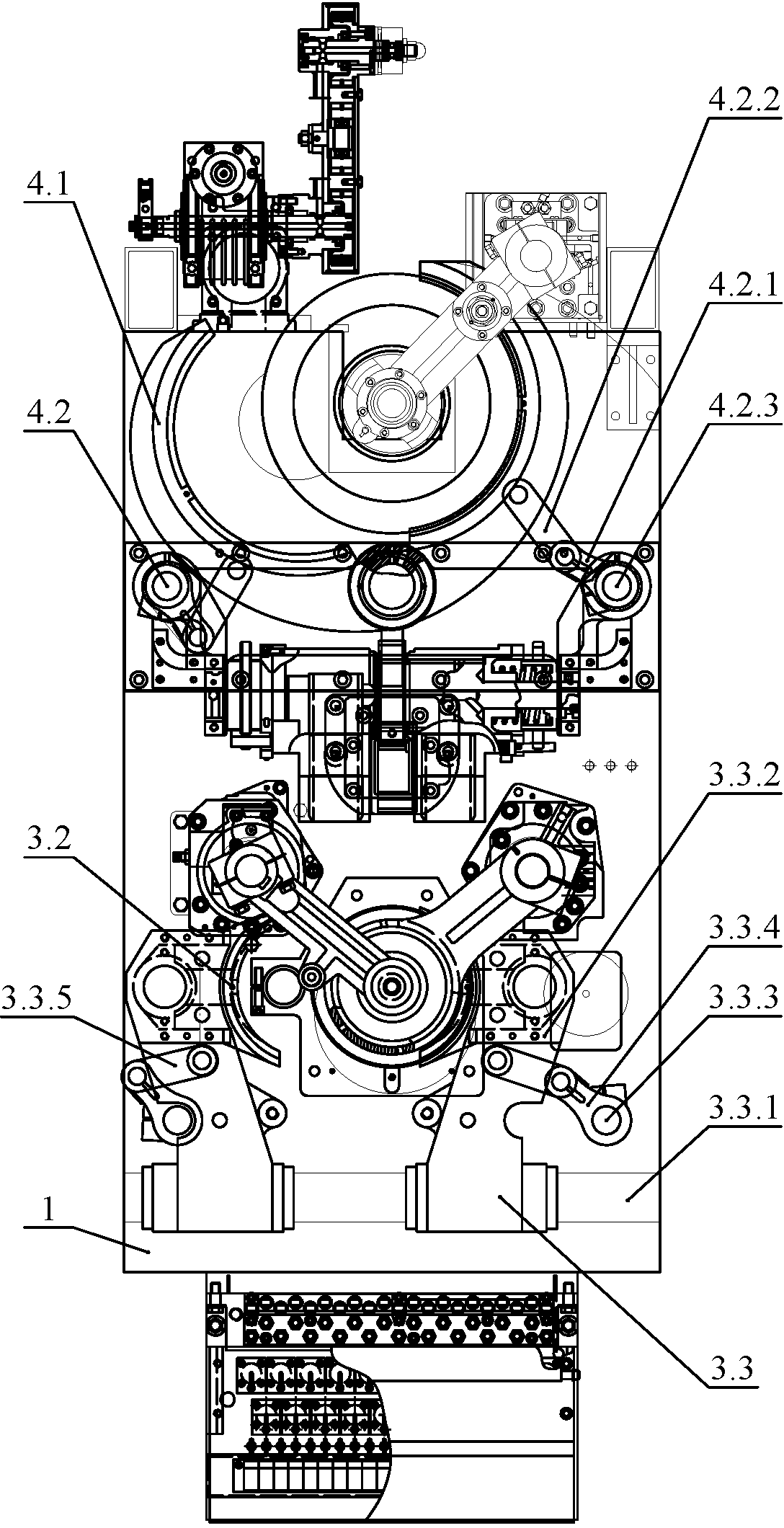

Bottle-making machine and production process for manufacturing extra-large glass bottles

ActiveCN104108856ARealize mechanical automation productionIncrease productionBlowing machine gearingsPress and blow machinesEngineeringBottle

The invention relates to a bottle-making machine and a production process for manufacturing extra-large glass bottles, and belongs to the field of bottle-making machine equipment. The bottle-making machine comprises a rack, and a primary mold forming mechanism, a formed mold forming mechanism and a turnover mechanism which are arranged on the rack, wherein the primary mold forming mechanism comprises a stamping device, a primary mold and a parallel switching mechanism; the stamping device is mounted on the rack; the parallel switching mechanism comprises a horizontal guide shaft mounted on the rack, a clamp arm which sleeves on the horizontal guide shaft, and a first spline shaft, a first rocker arm, a first connecting rod and a first switching cylinder which vertically sleeve at two sides of the rack; one end of the first connecting rod is hinged with the clamp arm while the other end of the first connecting rod is hinged with the first rocker arm; the first rocker arm is connected with the first switching cylinder through the first spline shaft; the primary mold is mounted on the clamp arm. The bottle-making machine has the beneficial effects that the extra-large glass bottles are produced in a manner of automatic mechanized production for replacing manual production, so that the yield of the extra-large glass bottles is increased and the quality of the extra-large glass bottles is improved.

Owner:SHANDONG JIAFENG GLASS MACHINERY

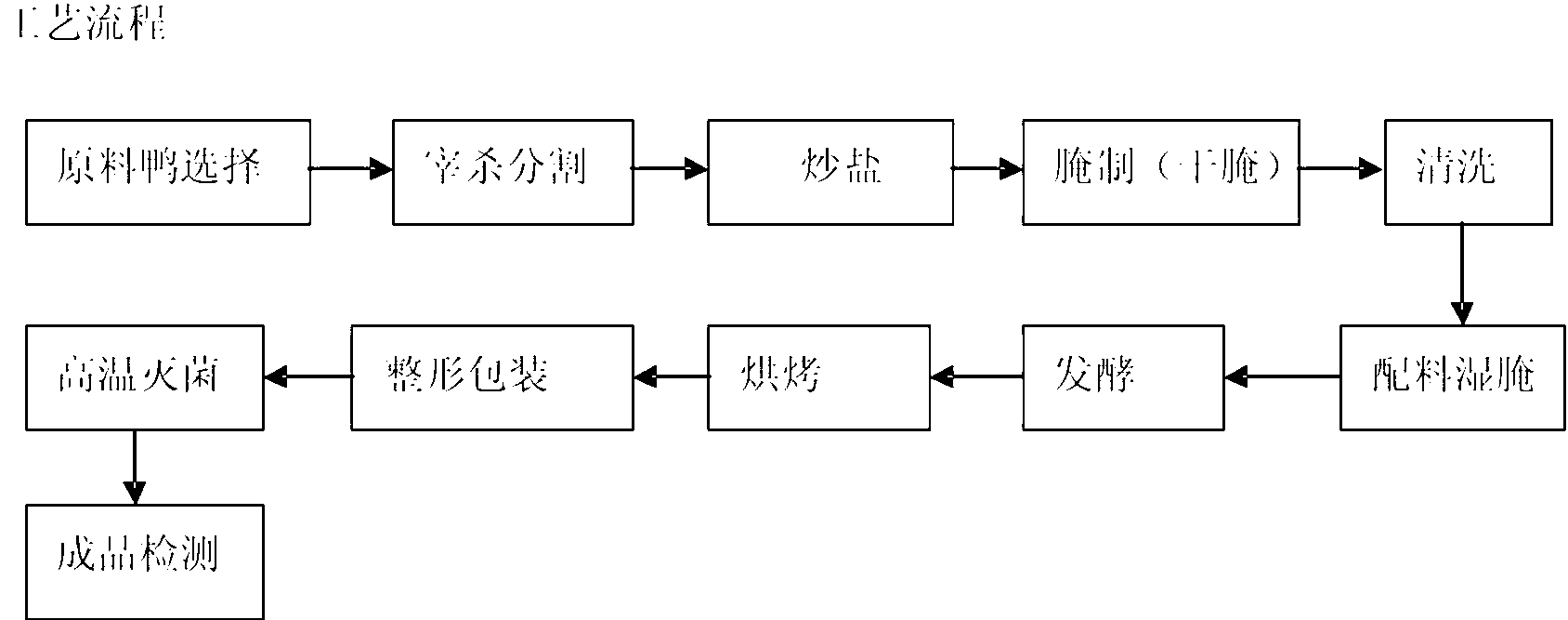

Processing process of special-flavor sauced and pressed wild duck

InactiveCN103181577ATight textureSimple processClimate change adaptationFood preparationBiotechnologyMonosodium glutamate

The invention relates to a processing process of a special-flavor sauced and pressed wild duck. A main material comprises wild duck, and auxiliary materials comprise a flavoring A and a spice B. The flavoring A comprises edible salt, soy sauce, bean paste, matured vinegar, white sugar, monosodium glutamate, and prickly ash oil. The spice B comprises anise seed, prickly ash seed, cinnamon, tsao-ko amomum fruit, kaempferia galangal, villous amonmum fruit, ginger, chili, and fennel. A process flow comprises the steps of: raw material duck selecting, slaughtering and separating, salt stir-frying, salting, washing, material wet preserving, fermenting, bake-drying, trimming and packaging, high-temperature sterilizing, and finished product examining. The method has the advantages of simple process and easy operation. The product has the advantages of good and full appearance, compact surface skin, compact muscle texture, bright and maroon color, chewy meat texture, rich and fragrant aftertaste, and a unique flavor. The process is suitable for large-scale productions.

Owner:XUZHOU HUINONG DUCK IND CO LTD

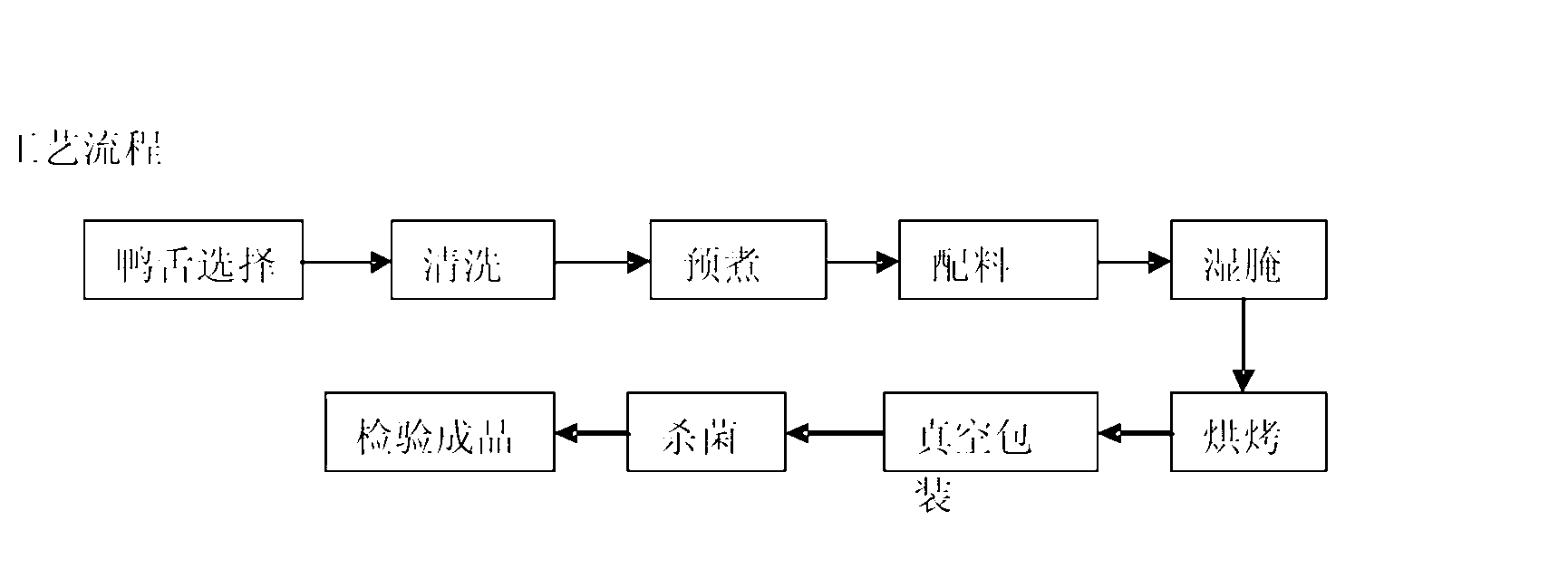

Sauce-flavor duck tongue processing technology

The invention relates to a sauce-flavor duck tongue processing technology, and discloses a special flavored duck tongue processing technology. A main material comprises examined and qualified frozen duck tongue, and auxiliary materials comprise a flavoring A and a spice B. The flavoring A comprises edible salt, soy sauce, bean paste, aromatic vinegar, white sugar, and monosodium glutamate. The spice B comprises aniseed, cinnamon, bay leaves, ginger, cumin, paniculate jasminorange twig and leaf, and Taiwan angelica root. A process flow comprises the steps of: duck tongue selecting, washing, precooking, (material preparing), wet preserving, bake-drying, vacuum packaging, sterilizing, and finished product examining. The method has the advantages of simple process and easy operation. The product has the advantages of good and full appearance, bright and maroon color, chewy meat texture, rich and fragrant aftertaste, and a unique flavor. The process is suitable for large-scale productions.

Owner:XUZHOU HUINONG DUCK IND CO LTD

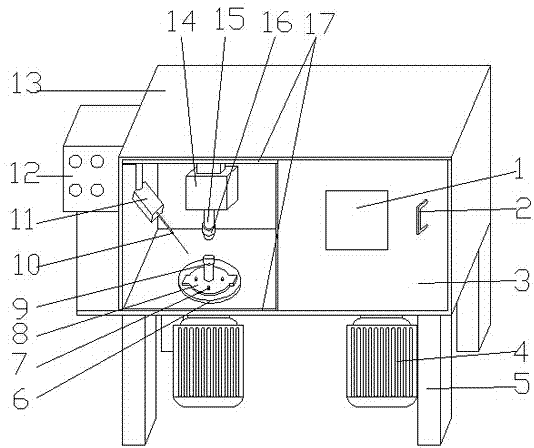

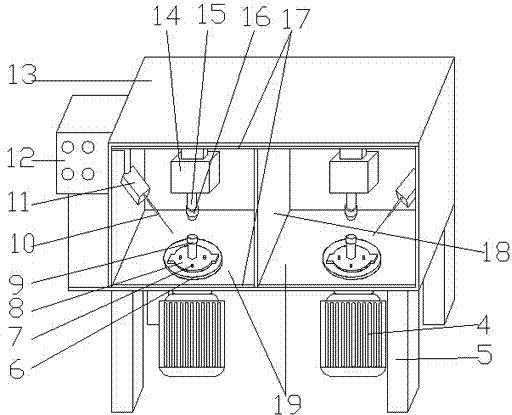

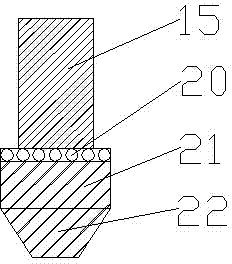

Vertical type double-station steel pipe fitting rotation automatic welding machine tool

ActiveCN104259701AGuaranteed verticalityLow technical proficiency requiredWelding/cutting auxillary devicesAuxillary welding devicesCircular discPipe fitting

The invention discloses a vertical type double-station steel pipe fitting rotation automatic welding machine tool and belongs to the field of automatic welding machine tools. The vertical type double-station steel pipe fitting rotation automatic welding machine tool comprises a body, automatic welding devices and an electric control device; the body comprises two identical welding chambers; identical automatic welding devices are arranged inside the welding chambers; the automatic welding devices comprise welding devices, vertical correction clamping devices and rotation devices; the welding devices comprise welding wire feeding devices and welding guns; the vertical correction clamping devices comprise air cylinder fixing bases, air cylinders and rotary compression heads; the rotary compression heads comprise cylinders, bearings and bosses; the rotation devices comprise motors, rotary discs, bearing discs and positioning core columns; the electric control device respectively controls the welding devices, the vertical correction clamping devices and the rotation devices. The vertical type double-station steel pipe fitting rotation automatic welding machine tool has the advantages of guaranteeing the perpendicularity of a steel pipe and a pipe base, enabling peripheral weld to be uniform and smooth, improving the welding quality and the product yield, enhancing the welded junction soundness and improving the production efficiency due to a double-station welding mode.

Owner:上海铂宝集团股份有限公司

Method for manufacturing lock shaft parts for container

InactiveCN1710227ASimplify production and processing proceduresIncrease productivityBuilding locksEngineeringHigh intensity

The invention discloses a center shaft component for locks of cargo container production technique with investment moulding. The invention provides with a set of rational technique from material selecting, shell making, melting, and heat processing, resolving the many technique problems in center shaft component for locks of cargo container production with investment moulding, simplifying the production procedure and lowering the cost, enhancing productivity so to be more adaptive to mass production.

Owner:上海市机械制造工艺研究所有限公司

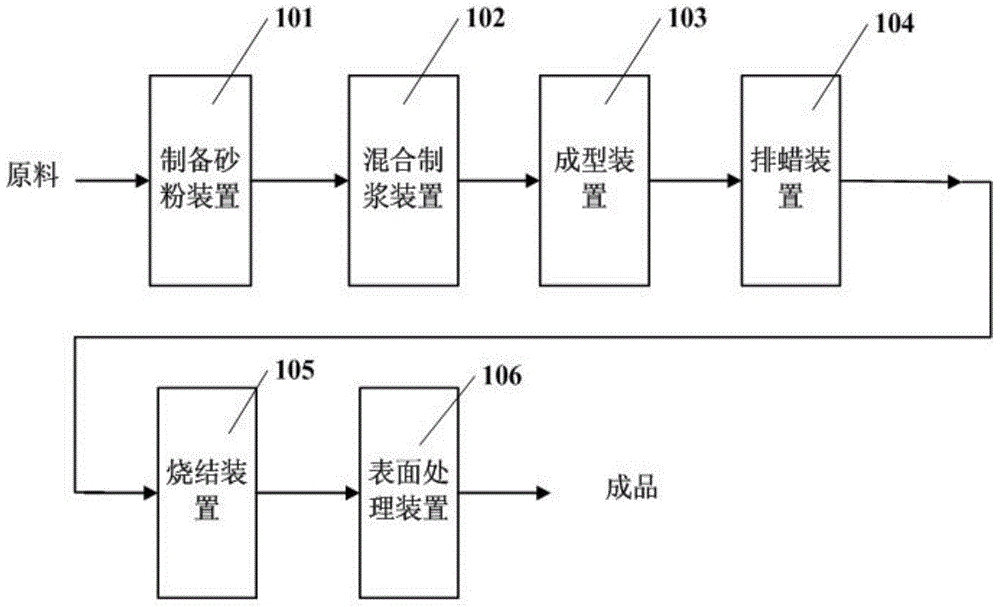

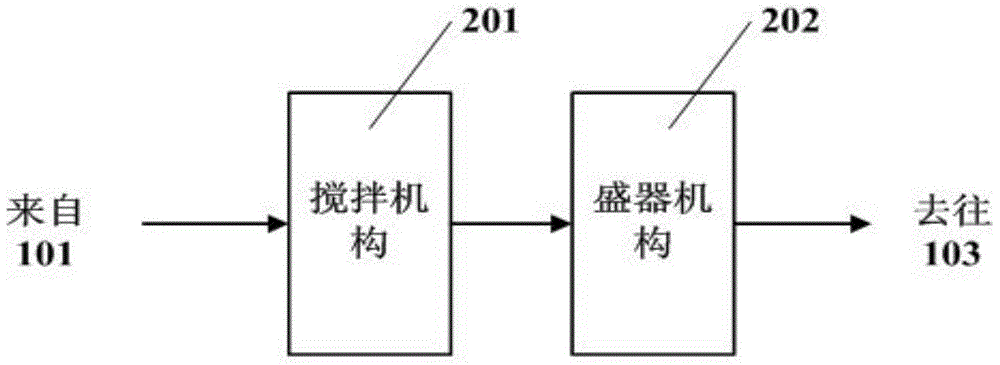

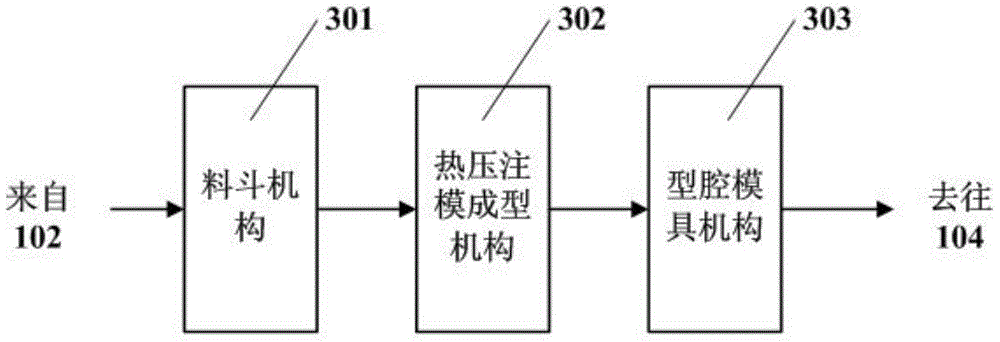

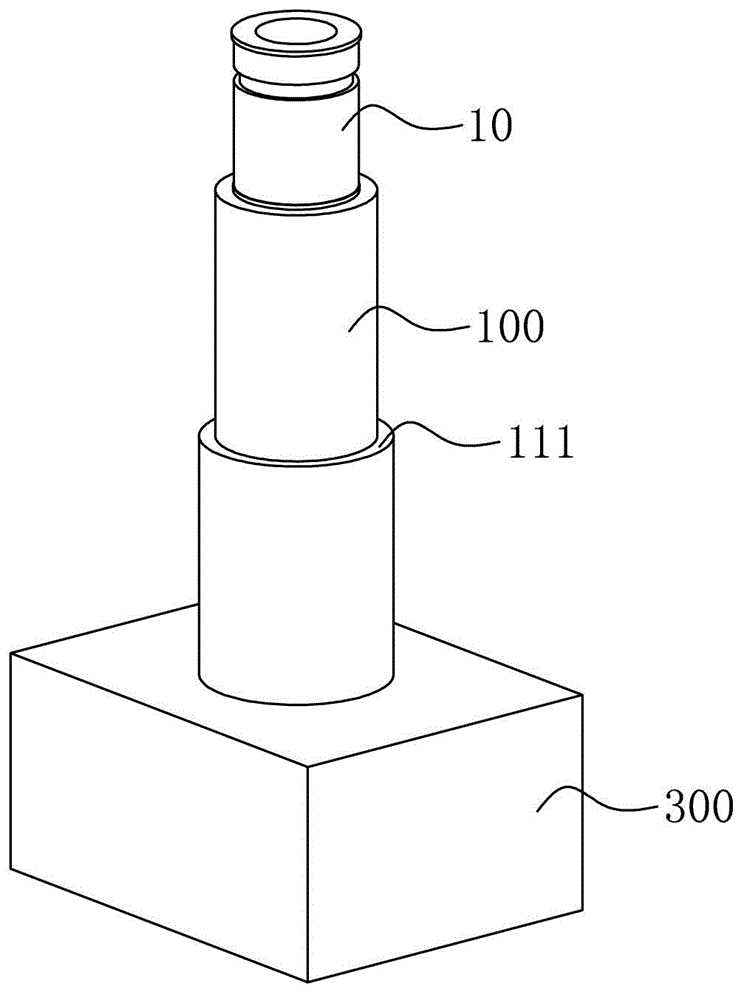

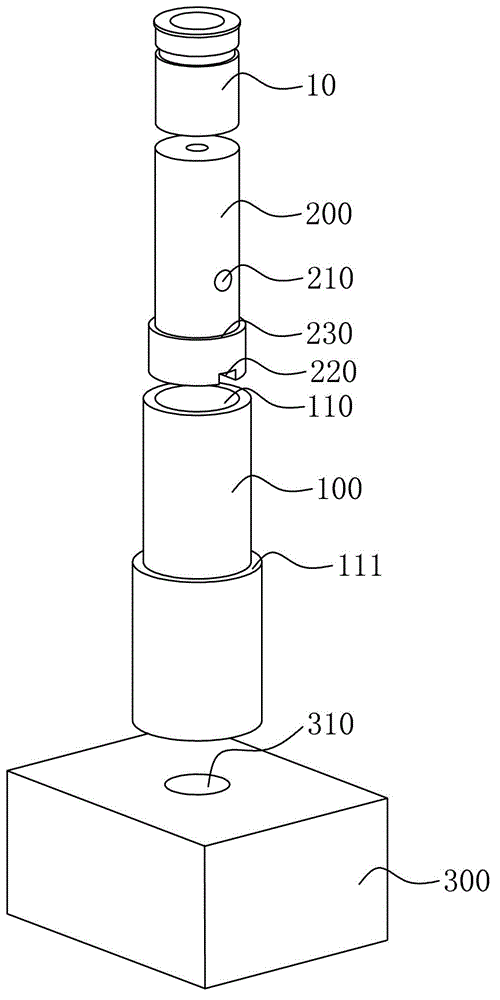

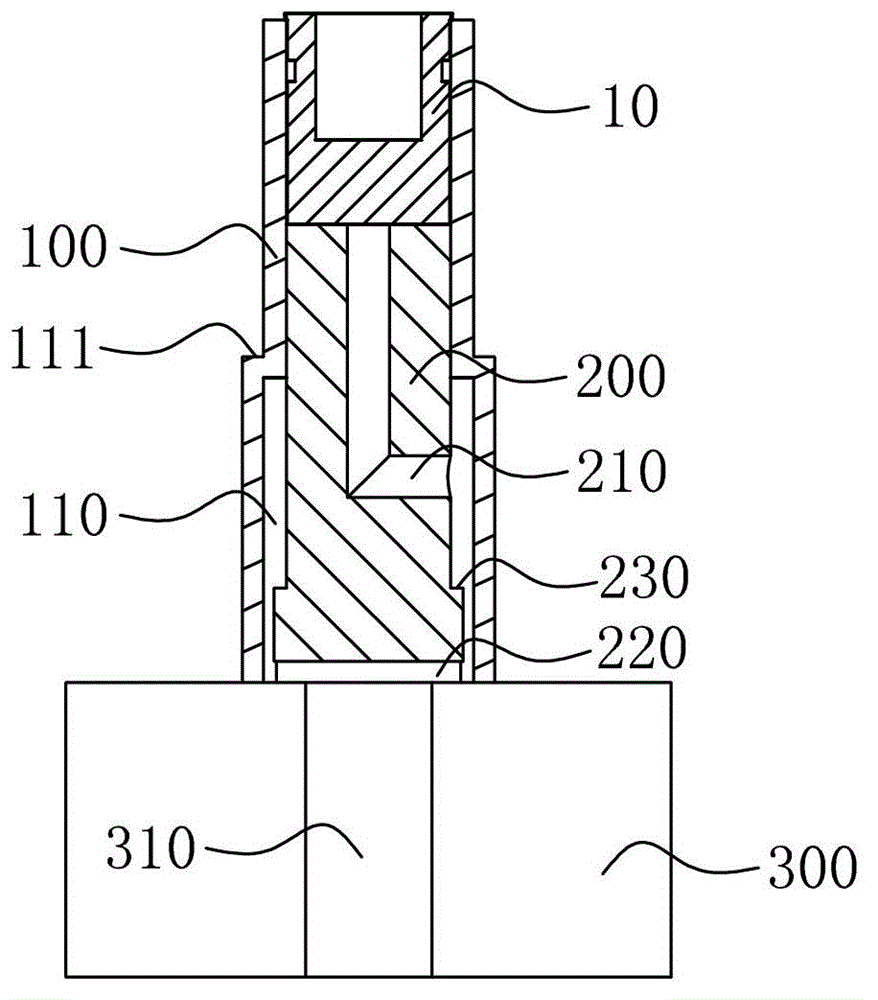

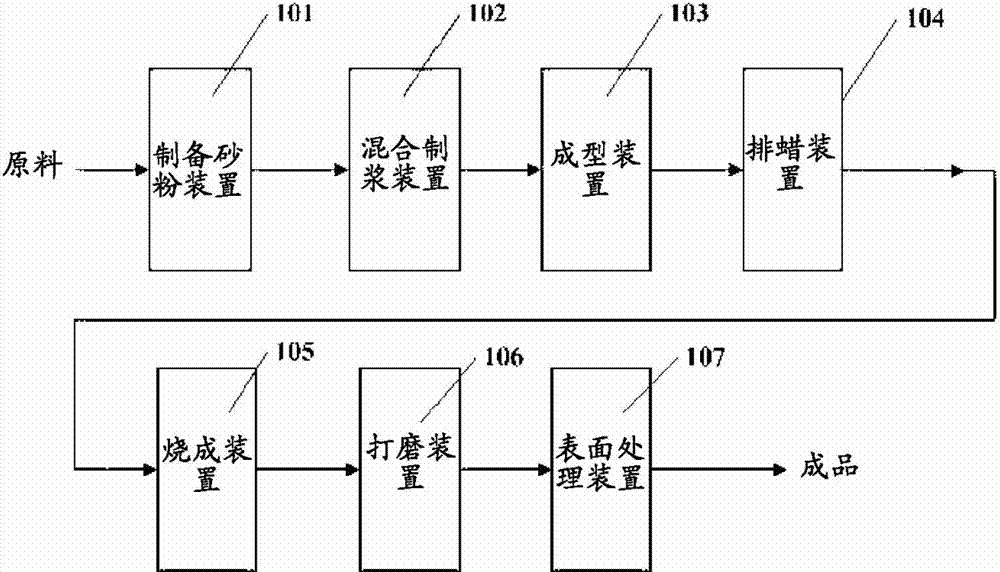

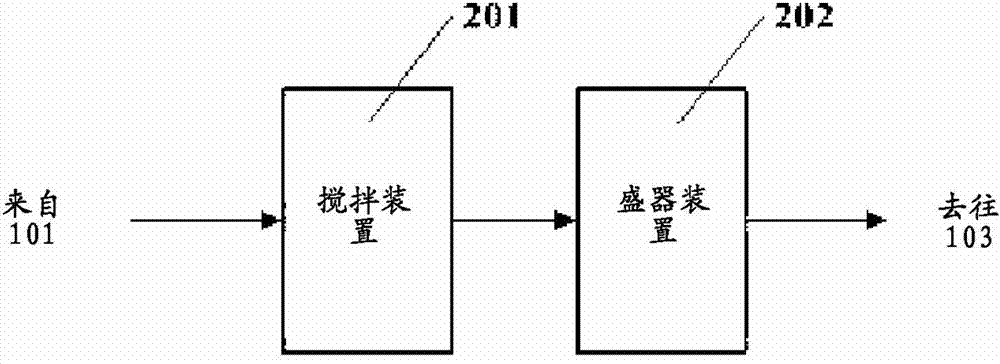

A preparing method of a ternary-material lithium battery saggar

The invention relates to a preparing method of a ternary-material lithium battery saggar. Synthetic mullite is adopted as a main raw material, and the mass of the synthetic mullite accounts for 70% of the total mass. Synthetic cordierite is adopted as a main auxiliary material, a wax mixing agent is added, and the mass of the synthetic cordierite and the wax mixing agent accounts for 30% of the total mass. The ternary-material lithium battery saggar is prepared by subjecting the main raw material and the main auxiliary material to granule smashing and graduation in order by a sand powder preparing device, mixing and fully stirring by a mixing and pulping device into which the wax mixing agent is added in advance so as to complete preparation of pulp used for a product blank, further stirring by a molding device, vacuumizing, removing bubbles, cooling, molding, discharging components of the wax mixing agent in the product blank by a wax discharging device, firing the product blank by a firing device, subjecting the product blank to external and internal surface treatment by a surface treatment device, and drying. The technical scheme of the method can effectively reduce the saggar cost, improve product quality and prolong service lifetime of the product.

Owner:SHENZHEN MEIJINGSHI CERAMICS

Intra-mode automatic nut assembling structure

The invention discloses an intra-mode automatic nut assembling structure applied to mold injection molding. The structure comprises a guide block, a pneumatic push block and a base, wherein the guide block is provided with a first channel communicated with the top and bottom ends of the guide block; a vacuum air channel communicated with the top end and the side face of the pneumatic push block and a groove which penetrates through the bottom end of the pneumatic push block are arranged in the pneumatic push block; the pneumatic push block is movably arranged in the first channel; the base is arranged at the bottom end of the guide block; the base is provided with a second channel communicated with the top end and the bottom end; and the second channel is communicated with the first channel. The intra-mode automatic nut assembling structure is matched with a vacuum generator, the nut is pressed in the mold through drive of the mechanical arm, the automatic operation of assembling the nut into the mold can be realized, the production efficiency is greatly improved, and the intra-mode automatic nut assembling structure is simple in structure, high in universality and suitable for large-scale production.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Manufacturing method for quartz ceramic crucible used for polycrystalline silicon ingot

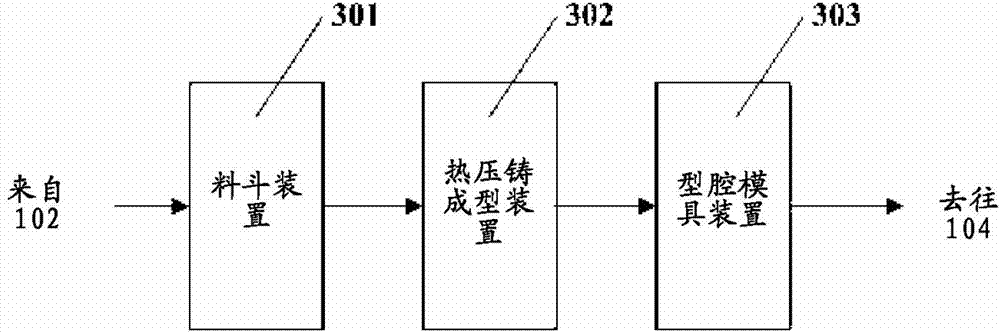

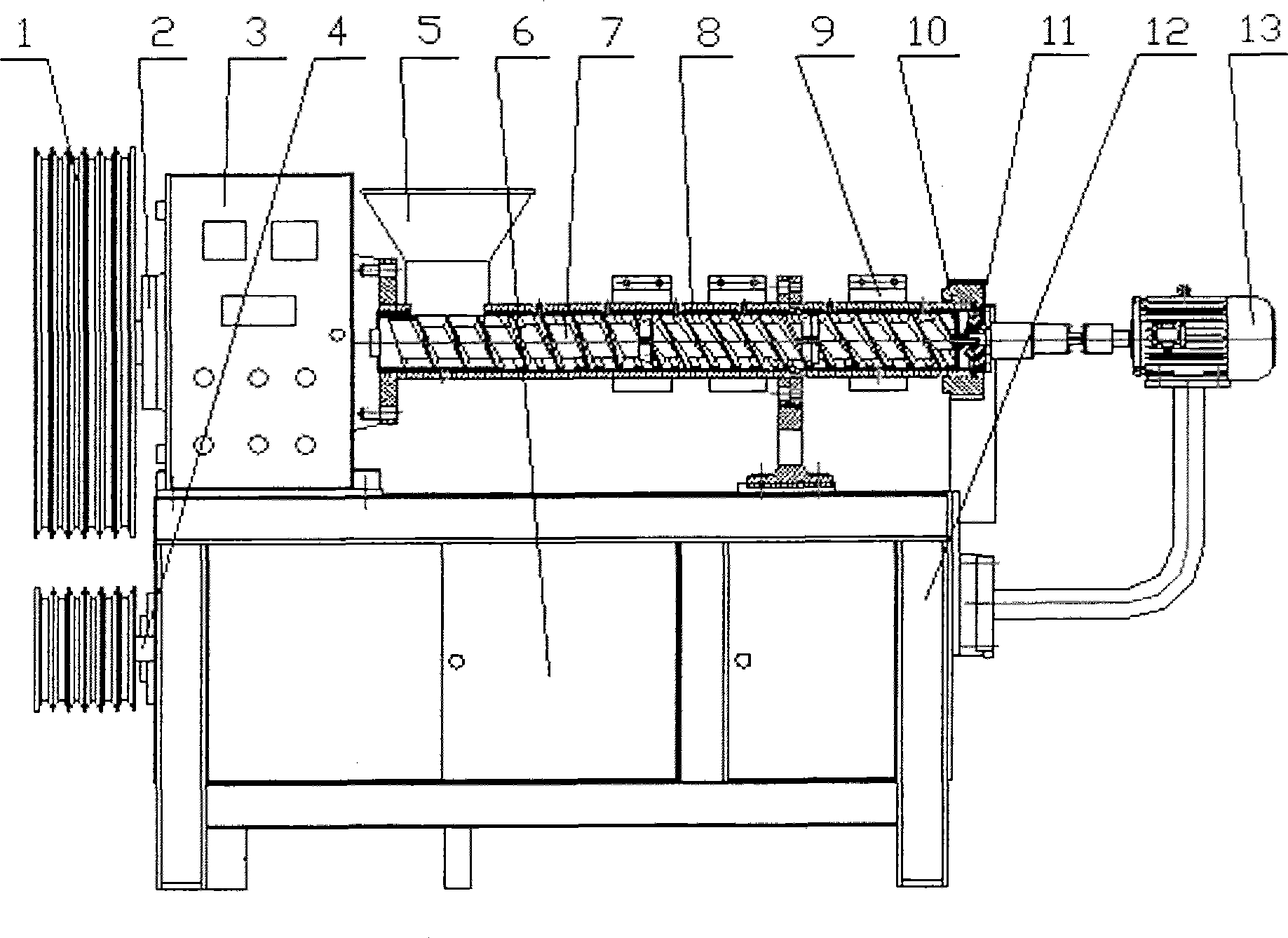

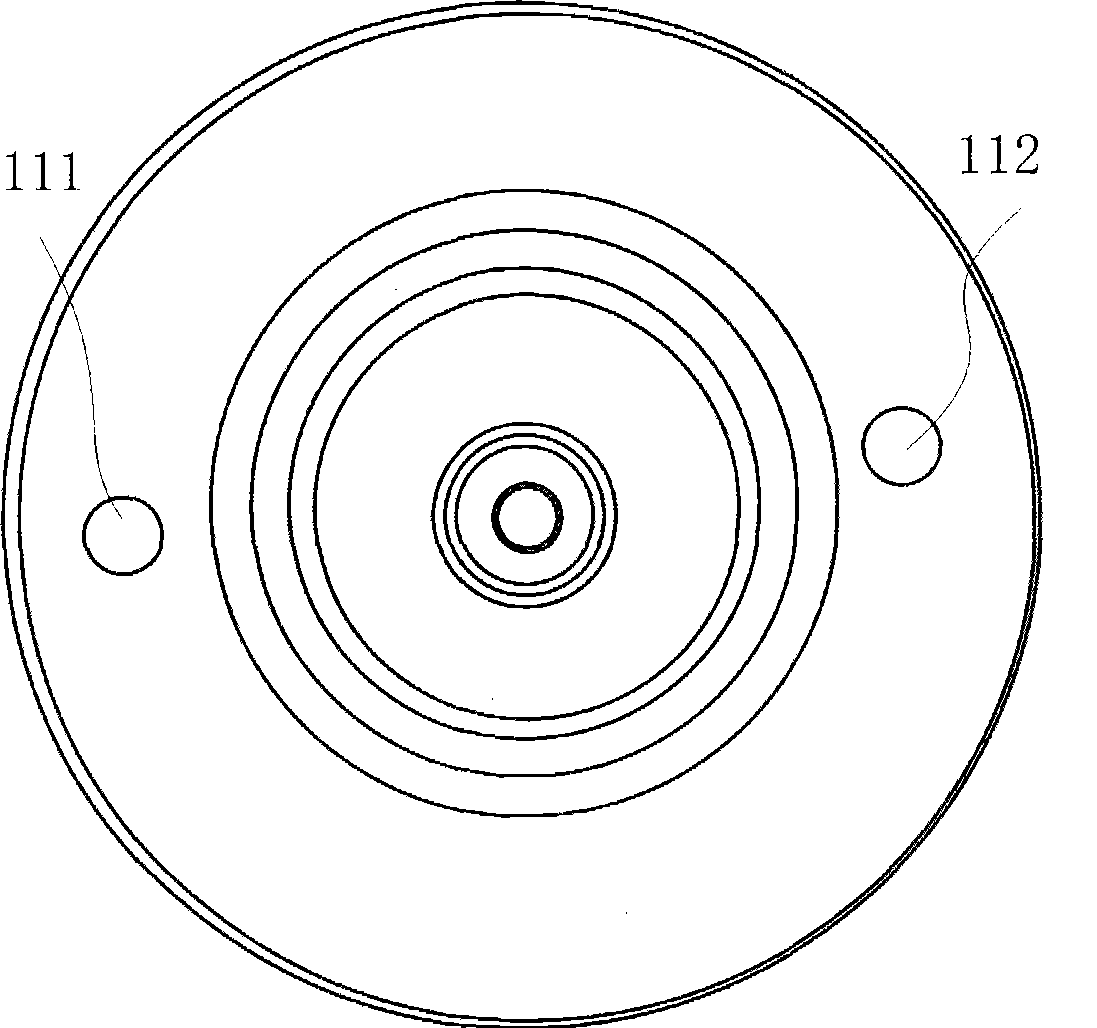

The invention relates to a manufacturing method for a quartz ceramic crucible used for a polycrystalline silicon ingot. The manufacturing method comprises the following steps: with fused silica with purity of 99 to 99.9 wt% as a raw material, crushing particles of the raw material by using a sand powder preparation device 101, screening prepared fused silica sand powder and preparing, by weight, 15% of 0-mesh to 400-mesh fused silica sand powder, 15% of 400-mesh to 200-mesh fused silica sand powder, 25% of 200-mesh to 100-mesh fused silica sand powder, 30% of 100-mesh to 40-mesh fused silica sand powder and 15% of 40-mesh to 20-mesh fused silica sand powder; putting the prepared fused silica sand powder materials in different containers for subsequent usage in a sequence from fine fused silica sand powder material to coarse fused silica sand powder material; and subjecting the prepared fused silica sand powder materials to treatment by a mixed slurrying device 102, a forming device 103, a wax discharging device 104, a sintering device 105, a polishing device 106 and a surface treatment device 107 so as to produce the finished quartz ceramic crucible used for the polycrystalline silicon ingot. The manufacturing method provided by the invention can effectively reduce product cost, improve the qualified rate of the crucible and realize large scale production and has wide application prospects.

Owner:SHENZHEN MEIJINGSHI CERAMICS

Equipment and technique for puffing foodstuff

InactiveCN101375734AAchieve food grade puffingLow moisture content requirementFood shapingFood gradeAdditive ingredient

The invention discloses equipment and a technology for food puffing. The equipment comprises a main electric motor and a puffing formation cavity, wherein, the puffing formation cavity is composed of a screw, a sleeve and a die head, the screw is arranged inside the sleeve, the die head is fixedly connected with one end of the sleeve, and double die holes are formed on the die head. The invention can achieve the purpose of puffing rice at food grade. According to the invention, the requirement for moisture content of rice is relatively low, and ingredients are not crushed in advance unnecessarily, so that the production efficiency is greatly improved. As the invention improves the adaptability of the prior art, the puffing rate increases, and a better puffing effect is achieved. Puffed rice produced by adopting the technology has the advantage that a heavy decline in the volume weight of powder made from the puffed rice is brought about. Therefore, according to the fact that the smaller volume weight can enable the rice powder to be more soluble and also can enable the taste to be better, the powder made from the puffed rice is taken as the main ingredient for rice powder for babies to ensure that the rice powder can be easily digested by babies and is good in taste.

Owner:杨小静 +1

Method for removing ferric trichloride from chlorination reaction liquid with styrene type macroporous anion exchange resin

ActiveCN103058819AQuality improvementReduce water consumptionHalogenated hydrocarbon preparationBenzeneDesorption

The invention provides a method for removing ferric trichloride from chlorination reaction liquid with styrene type macroporous anion exchange resin, the method includes the following steps: (a) filtering the chlorination reaction liquid and removing suspended impurities and tar in the chlorination reaction liquid; (b) absorbing the ferric trichloride in the filtered chlorination reaction liquid with the styrene type macroporous anion exchange resin; (c) desorbing the styrene type macroporous anion exchange resin which reaches saturated in absorption with a desorption reagent to obtain desorption solution; and (d) the fully desorbed styrene type macroporous anion exchange resin entering into absorption in the next period, and using the ferric trichloride after water evaporation in the desorption solution as flocculant for water treatment engineering. The technical defects that a traditional method is large in workload, and the water is difficult to separate are overcome, the removal method of the ferric trichloride in the chlorination reaction liquid with the styrene type macroporous anion exchange resin is good in quality, small in water consumption, high in removal efficiency, low in cost and more suitable for large-scale production, and automated operation is easier to achieve.

Owner:SUNRESIN NEW METERIALS CO LTD XIAN

Vacuum loading switch

ActiveCN101030500AAvoid pollutionSmall form factorHigh-tension/heavy-dress switchesAir-break switchesEngineeringSwitchgear

The invention is concerned with a kind of vacuum load switch for high voltage fixed type switchboard, relating to upside wire of switch, insulated switch, insulated knife frame, vacuum interrupter, downside move contactor, downside wire frame, united terminal, cable leading line plank, insulated knife insulated perch assemblage, interrupter insulated perch assemblage, operation frame and grounding equipment. The insulated switch connects with vacuum interrupter, the insulated knife insulated perch assemblage and interrupter insulated perch assemblage connect with operation frame, and the insulated knife frame, vacuum interrupter and downside wire frame are closed together. The hinge end of insulated switch has contact spring that connects with insulated switch and insulated knife frame. The move end of vacuum interrupter has contact spring that connects with downside move contactor and downside wire frame. This invention has large insulated strength and modularization level, and the simple using is fit for production on scaled.

Owner:江苏德春电力科技股份有限公司

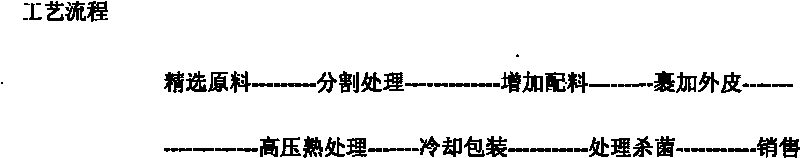

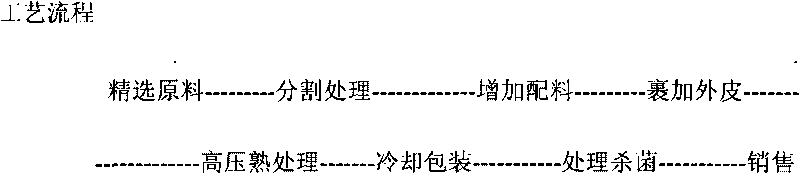

Method for preparing fried roll

InactiveCN101756309AUnique flavorStrong fragranceBakery productsFood preparationMonosodium glutamateLean meat

The invention relates to food preparation, and in particular discloses a method for preparing a fried roll. The method comprises the following process flows: fine selection of raw materials, cutting treatment, addition of ingredients, wrapping by using outer sheet jelly, high-pressure curing treatment, cooling, sterilization and vacuum packaging; and the method comprises the following steps: selecting fat meat and lean meat manually, slicing the fat meat and the lean meat into fine strips, adding onion, ginger, aniseed, pepper, refined salt and monosodium glutamate into the fine strips, matching mung bean flour, grated carrot, starch and other ingredients, mixing mixture into a pasty stuffing, wrapping the pasty stuffing by using a sheet jelly into a roll shape, and after high-pressure steaming, cooling and sterilization treatment, performing vacuum packaging. The fried roll prepared by the method has the characteristics of unique flavor, mellow scent, fine mouthfeel, softness, rich nutrition and the like.

Owner:沙永庆

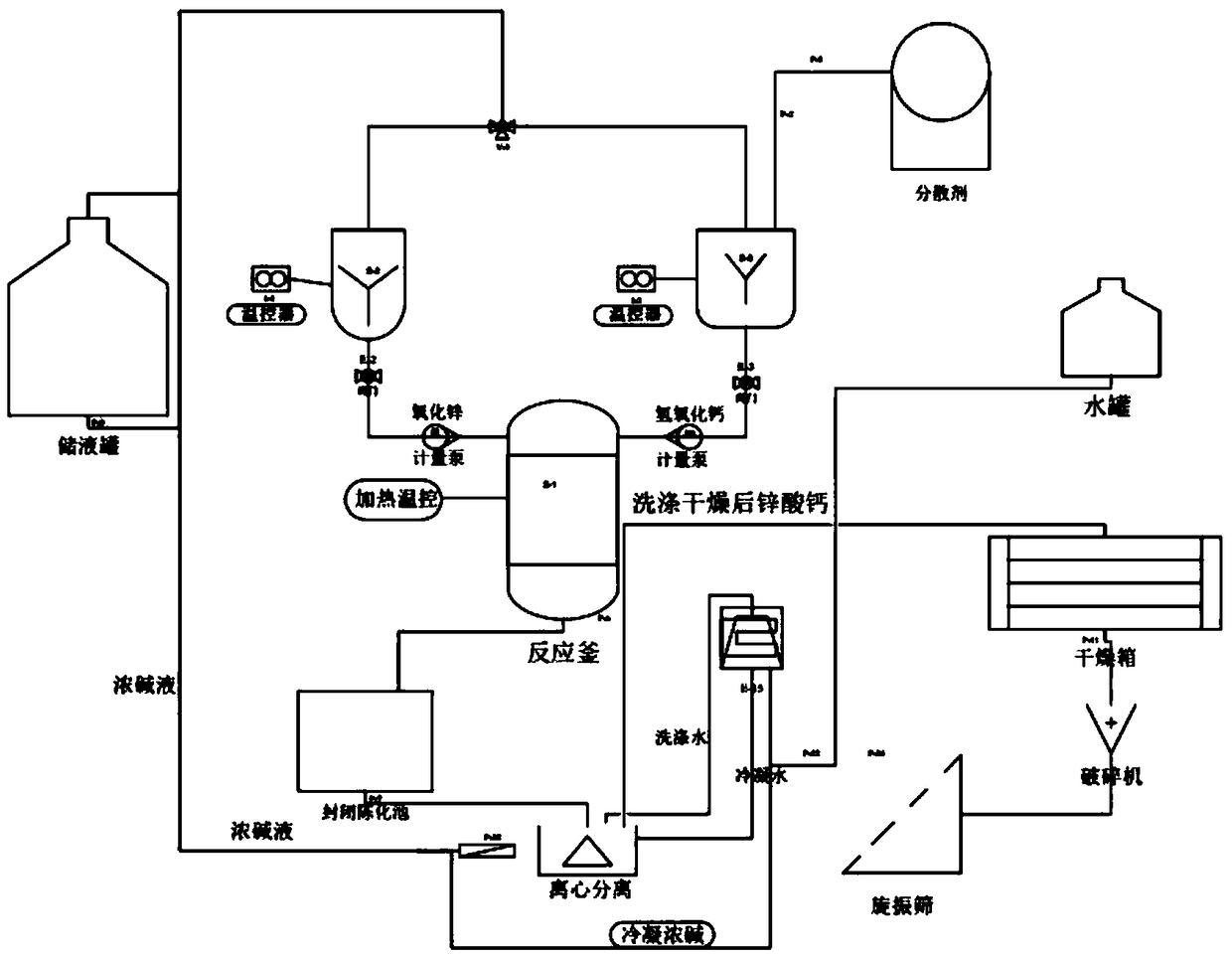

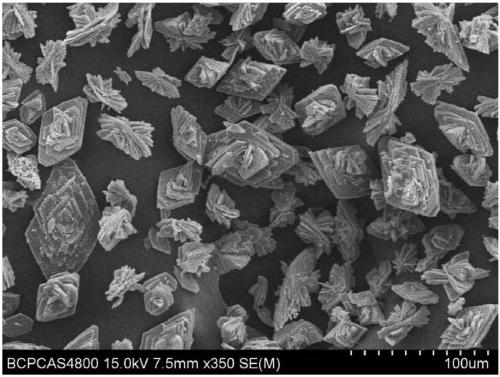

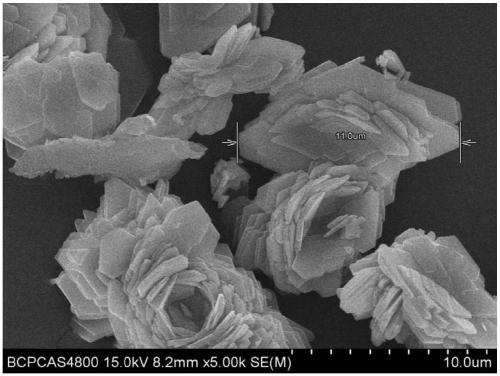

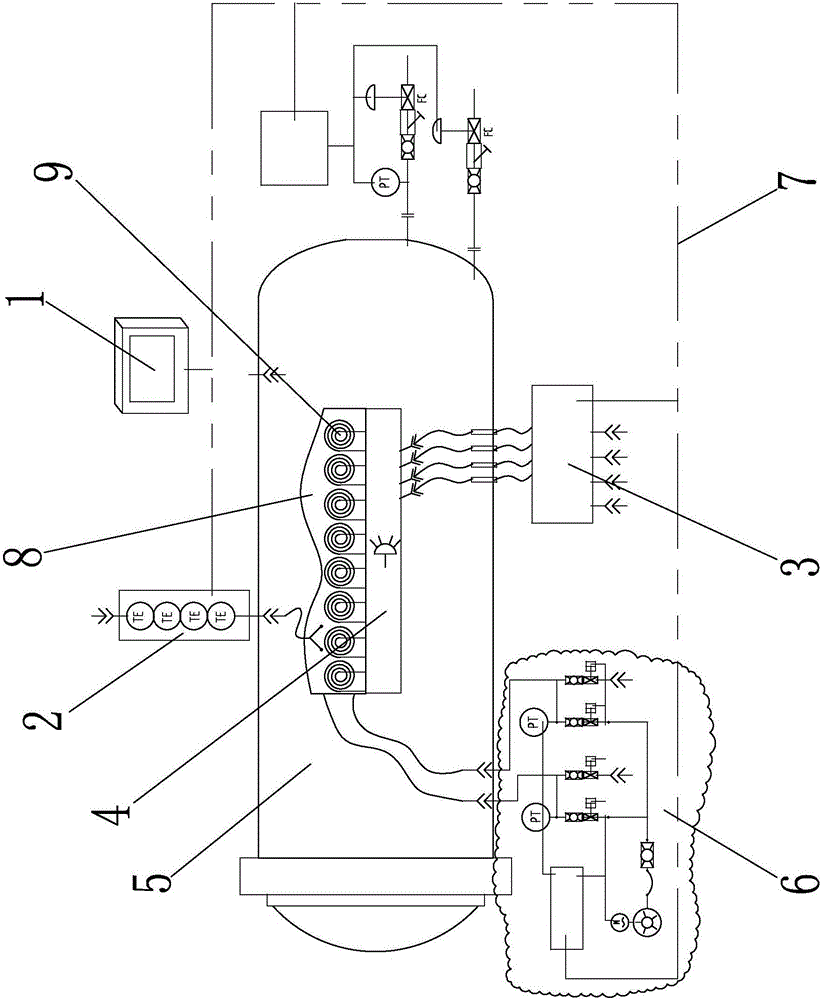

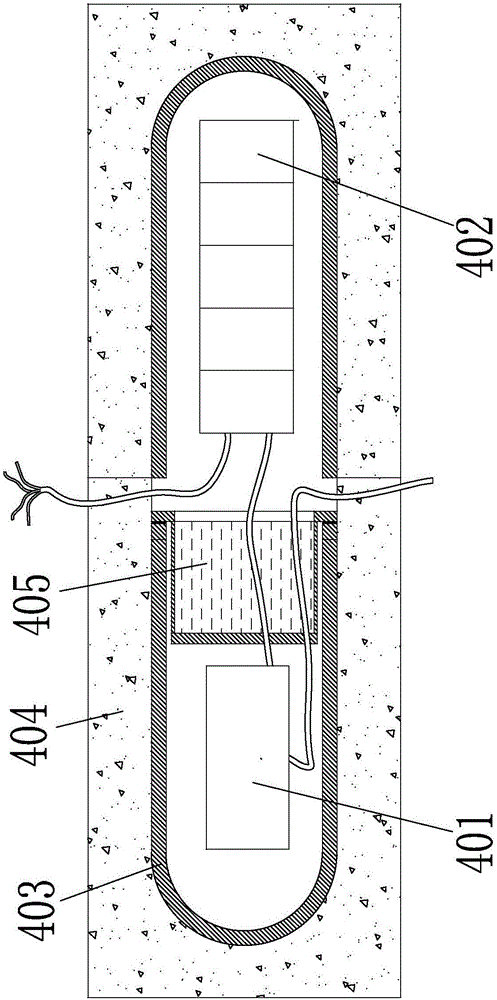

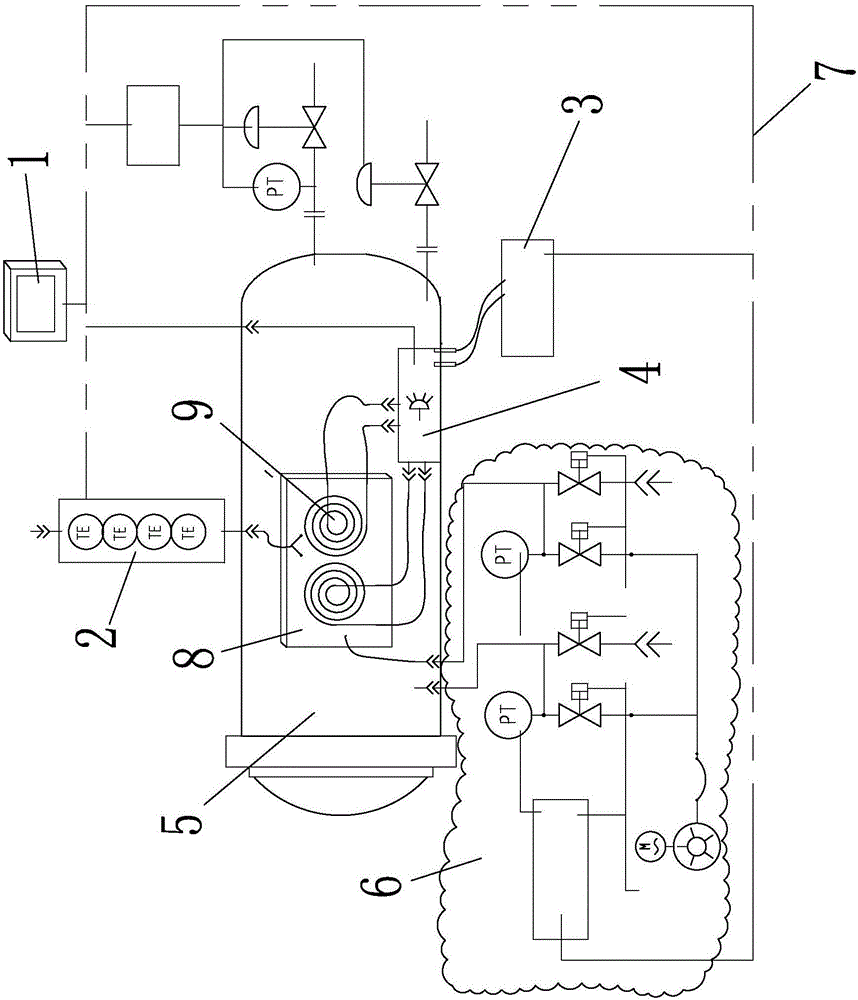

Synthetic process and equipment for calcium zincate as zinc-nickel battery negative electrode material

ActiveCN109455754AHigh purityAvoid the phenomenon of different shapes and uneven particle sizesCell electrodesZinc compoundsCalcium hydroxideOrganic acid

The invention relates to the technical field of calcium zincate synthesis and discloses a synthetic process for calcium zincate as a zinc-nickel battery negative electrode material. The synthetic process comprises the following steps of 1, mixing zinc oxide with organic acid, performing full reaction, performing filtering to remove impurities, then adding a certain quantity of strong alkaline solution, and performing mixing reaction to form a zincate solution; 2, (1) performing reaction on the organic acid and calcium hydroxide to produce an organic acid calcium solution, then dropwise addinga dispersant to form a mixed solution; or (2) adding the calcium hydroxide in a certain quantity of water, then dropwise adding the dispersant to form suspension liquid; 3, mixing products prepared instep 1 and step 2; 4, transferring reaction liquid obtained in step 3 into an ageing groove, performing still standing for 2-48 h, then performing centrifugal treatment, washing and drying filter residues, and performing crushing and sieving to obtain a product; and 5, recovering filtrate obtained in step 4 as a reaction medium for recycling use. The process realizes recycling of alkaline liquorand reduces pollution.

Owner:森克创能(天津)新能源科技有限公司

Soy sauce flavored duck tongue preparation method

InactiveCN104856079ANot prone to corruptionExtended shelf lifeFood preparationBiotechnologySoya sauce

The present invention discloses a soy sauce flavored duck tongue preparation method which relates to the technical field of food processing and includes the following processes: duck tongue selecting, washing, marinating, air-drying duck base, baking and packaging. The processing has simple processes, strong operability and well controllable various process parameters, the product has beautiful and full appearance and modeling, and bright color and luster, the meat quality is full of chewiness and has unique flavor, and through an ultraviolet disinfection, the duck tongue is not easy to be corrupted, has long shelf life, and is suitable for a large-scale production.

Owner:ANHUI XIANZHIYUAN FOOD

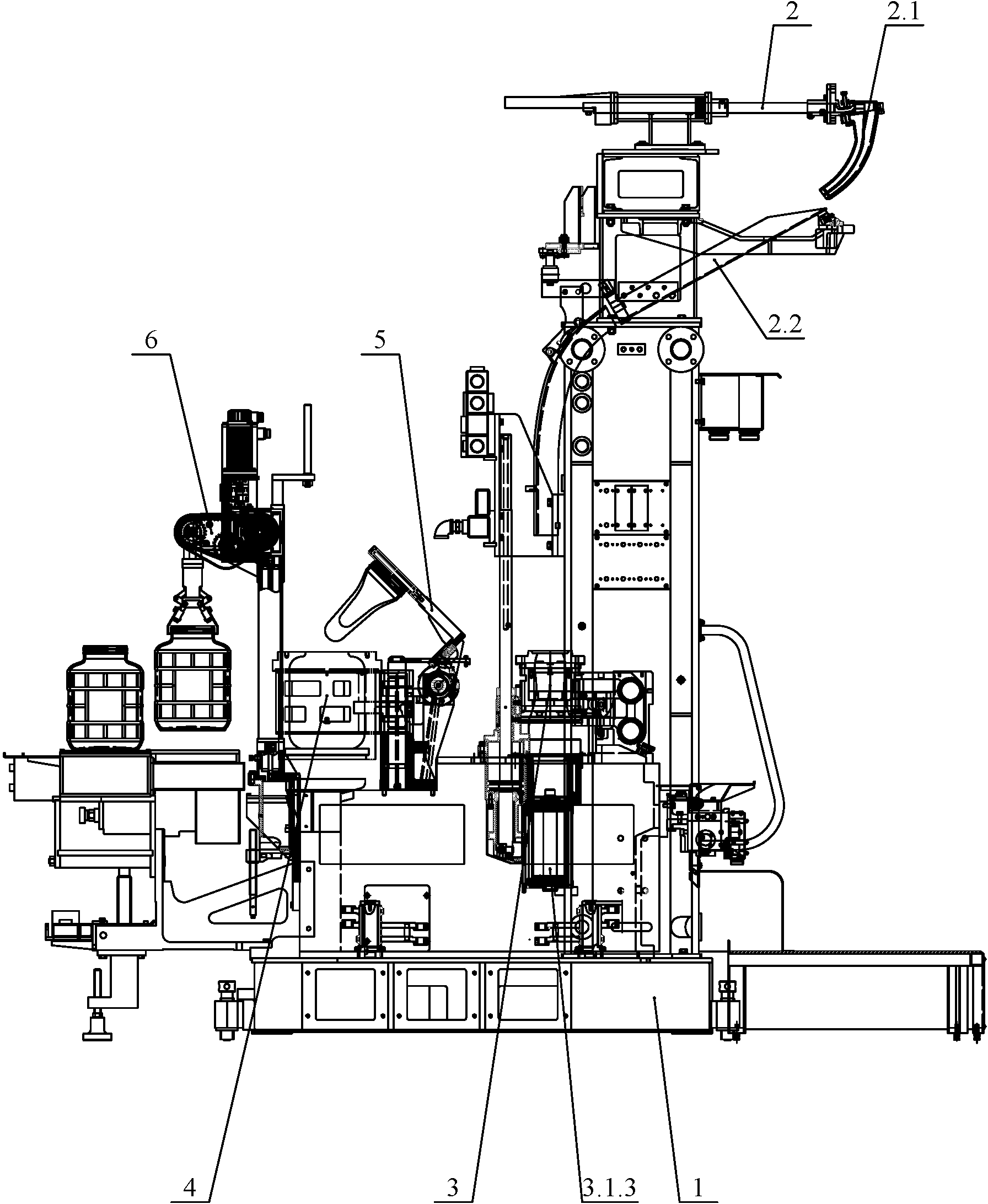

Equipment and process for forming composite material

InactiveCN105965916AReduce energy consumptionShort process cycleElectromagnetic inductionEngineering

The invention discloses equipment for forming a composite material. A master control system is connected with a controller provided for each module via a network, and used for sending running commands to the modules to run the modules; an electromagnetic output module receives the running commands sent by the master control system, and outputs electromagnetically induced current in a pulse mode; an electromagnetic power distribution and heating module distributes the current output by the electromagnetic output module to each heating module, so that the heating module heats a composite material forming mold in a specific combination manner and timing sequence; a pressurizing device is a pressure vessel or a mechanical pressurizing device; the composite material forming mold is placed in the pressurizing device, so that pressure can be exerted on the composite material laid on the composite material forming mold; and a vacuum control module having a vacuuming function is connected with the composite material mold via a pipeline, receives the commands of the master control system, and is used for vacuuming the composite material forming mold. The equipment has the advantages that the curing formation process cycle of the composite material is greatly shortened; and the transportation cost and the energy consumption are reduced.

Owner:山东中航泰达复合材料有限公司

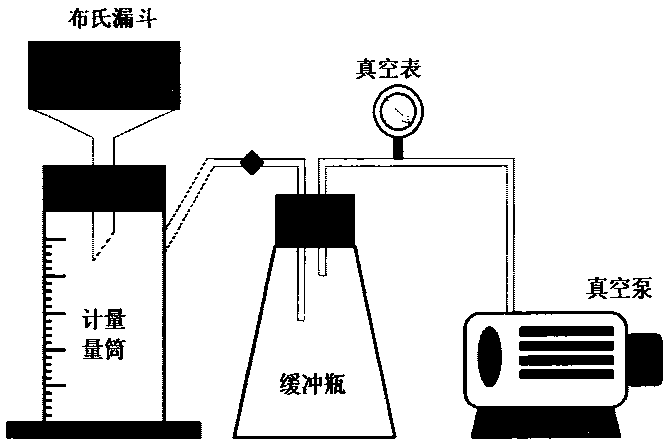

Filtering separation method for nanometer molecular sieve slurry

ActiveCN103752083AImproved solid phase purityHigh purityMolecular sieve catalystsFiltration separationMolecular sieveSlurry

The invention relates to a filtering separation method for nanometer molecular sieve slurry, and belongs to the field of nanometer molecular sieve materials. The filtering separation method for the nanometer molecular sieve slurry is as follows: the pH value of the nanometer molecular sieve slurry is adjusted to be less than or equal to 5 by utilizing an acid material, and pressure filtering is carried out for at least one time. The nanometer molecular sieve filtered by the method provided by the invention has the equivalent catalytic reaction performance to that of the nanometer molecular sieve obtained by the common filtering process. The method has the advantages that the operation is simple; the used raw materials are low in price, and easy to obatin; the special equipment is not needed; the nanometer molecular sieve particles can be completely recovered by a common filtering machine; the method is suitable for the scaled production of the nanometer molecular sieve.

Owner:大连龙缘化学有限公司

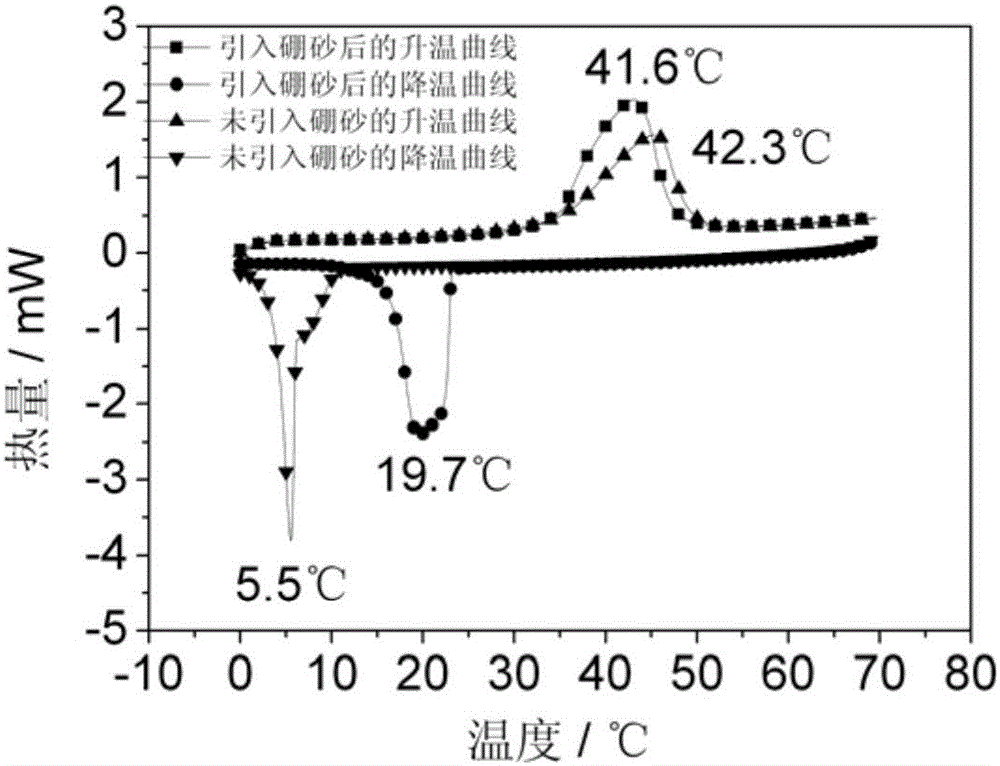

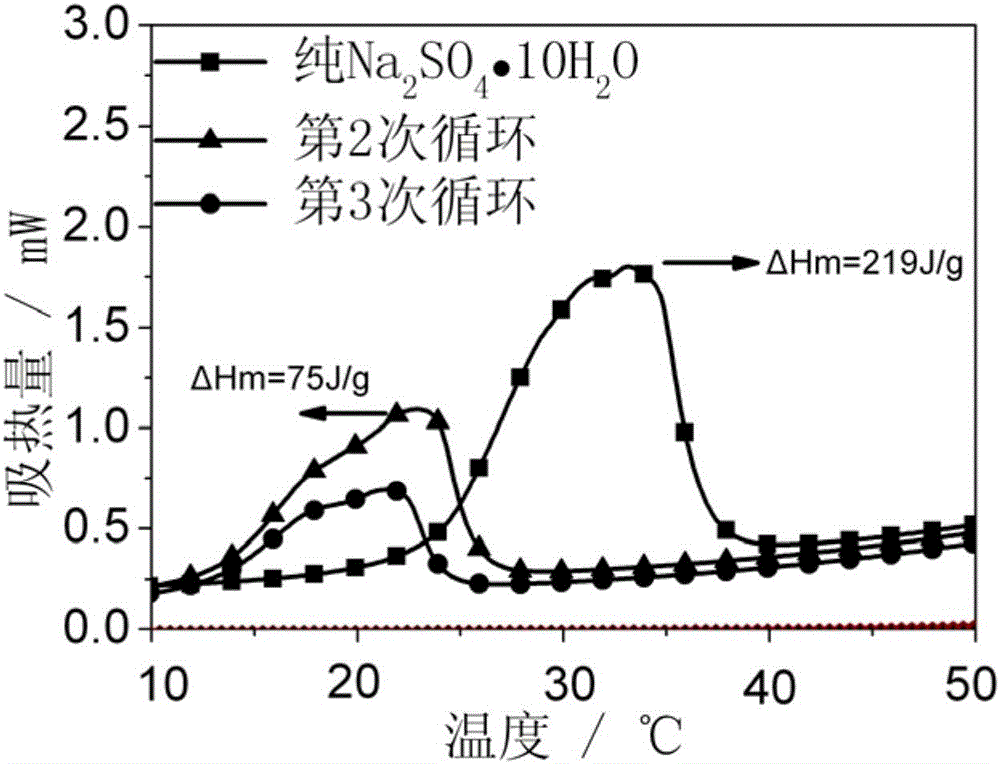

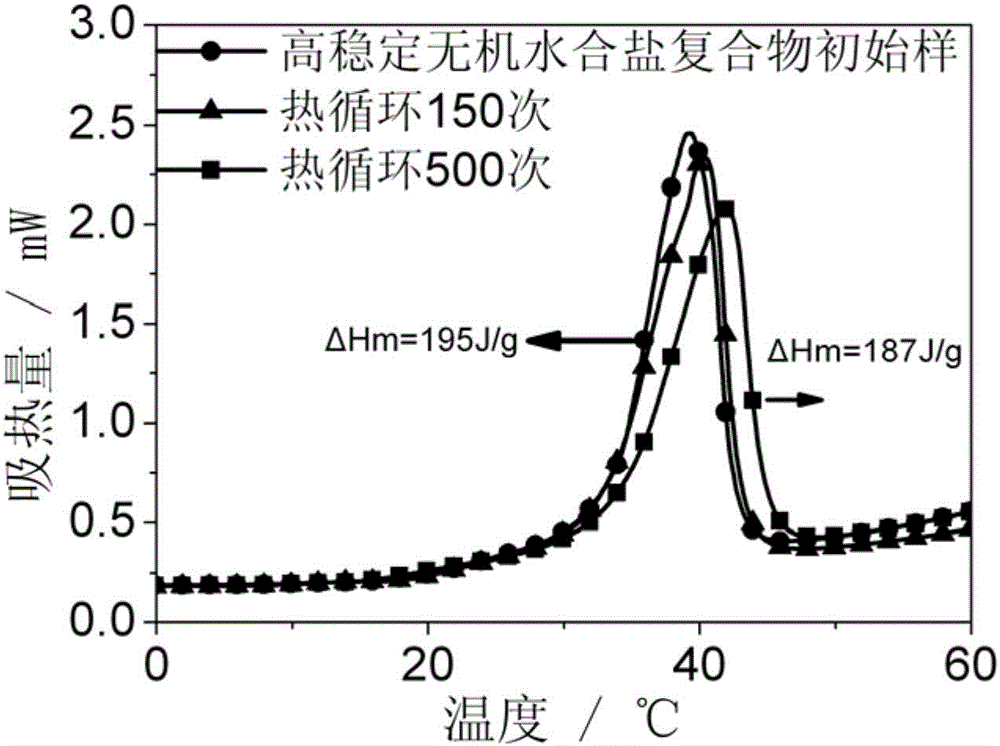

High-stability composite phase-change material and preparation method

ActiveCN106367033AImprove stabilityReduce equipment investmentHeat-exchange elementsCyclic stabilityComposite phase change material

A high-stability composite phase-change material is prepared from, by mass, 60-94wt.% of inorganic salt hydrate, 1-3wt.% of a nucleating agent and 5-37wt.% of a polymer. The high-stability composite phase-change material has the advantages of being good in cycling stability and high in phase-change latent heat.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Technique for preparing berberine hydrochloride by microwave-enzyme method

InactiveCN103435607AReduce energy consumptionCheap implementationOrganic chemistryPhysical chemistryBerberis empetrifolia

The invention relates to a technique for preparing berberine hydrochloride by a microwave-enzyme method, which comprises the following steps: a. pulverization and screening of berberis root; b. acidic cellulase enzymolysis; c. microwave-assisted extraction; d. high-temperature and adjusted pH inactivation; and e. near-saturation precipitation of berberine hydrochloride with diluted acid and sodium chloride. The berberis root is used as the raw material, thereby fully utilizing the cellulase to destroy the cell walls of the plant; and the cavitation of ultrasonic is utilized to increase the molecular motion frequency and speed of the substance and enhance the penetrating power of the solvent, thereby enhancing the leaching speed and leaching frequency of the effective component, and further enhancing the leaching rate of berberine. The invention has the advantages of simple technique, mild reaction conditions, high selectivity, short extraction time and the like, and maximizes the extraction yield.

Owner:NANJING TONGZE AGRI SCI & TECH

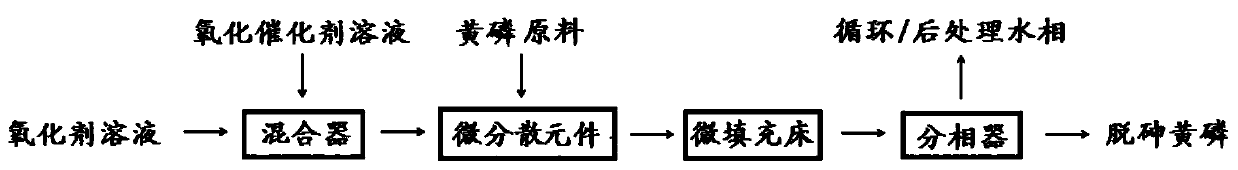

Method for oxidizing yellow phosphorus to remove arsenic

InactiveCN111533097AImprove recycling ratesEfficient mixingPhosphorus compoundsPtru catalystIodide potassium

The invention provides a method for oxidizing yellow phosphorus to remove arsenic, and belongs to the technical field of chemical engineering. The method for oxidizing yellow phosphorus to remove arsenic comprises the following steps of: premixing an oxidant solution and an oxidation catalyst solution by using a mixer, introducing the obtained mixed fluid into a micro-dispersion element to be mixed with a yellow phosphorus raw material, carrying out an oxidation-reduction reaction in a micro-packed bed, and carrying out phase splitting to obtain arsenic-removed yellow phosphorus, wherein the oxidation catalyst solution comprises a potassium iodide solution or a hydrogen iodide solution. Through efficient mixing of the oxidant solution and the oxidation catalyst solution, effective formation of I2 can be ensured, and meanwhile, I2 is prevented from being separated out of the solution; the yellow phosphorus raw material and the mixed fluid keep a huge liquid-liquid phase interface in themicro-dispersion element and the micro-packed bed, shuttling of I2 between a yellow phosphorus phase and a water phase is effectively enhanced, the arsenic removal reaction speed is increased, the high arsenic removal rate and the high phosphorus yield can be achieved at the same time, operation is easy, consumed time is short, and the method is suitable for large-scale production.

Owner:贵州新天鑫化工有限公司 +1

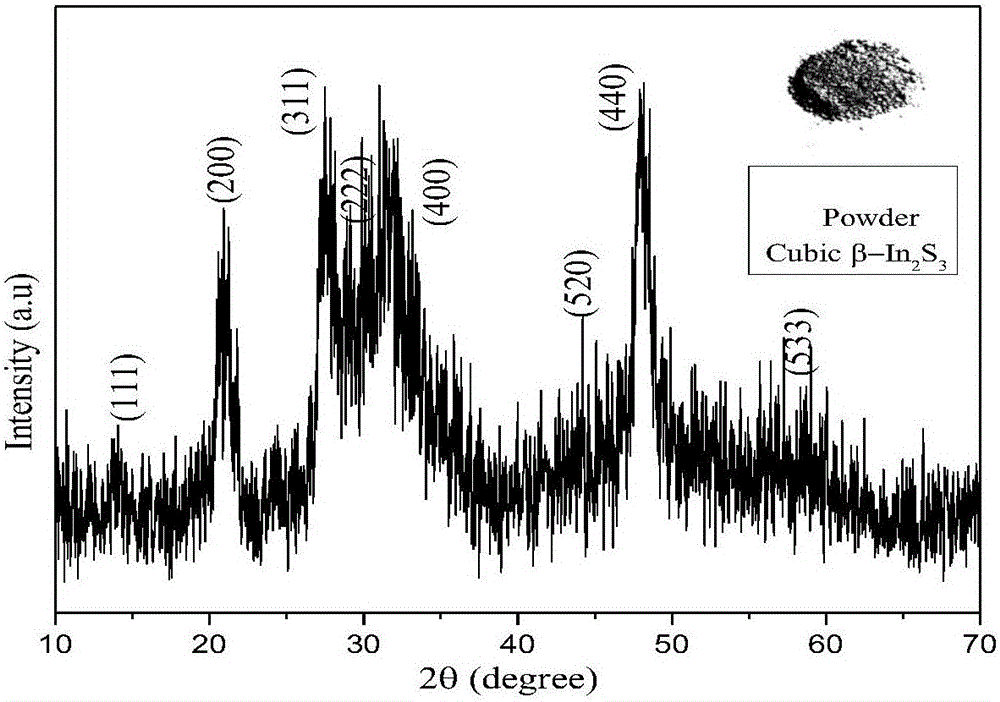

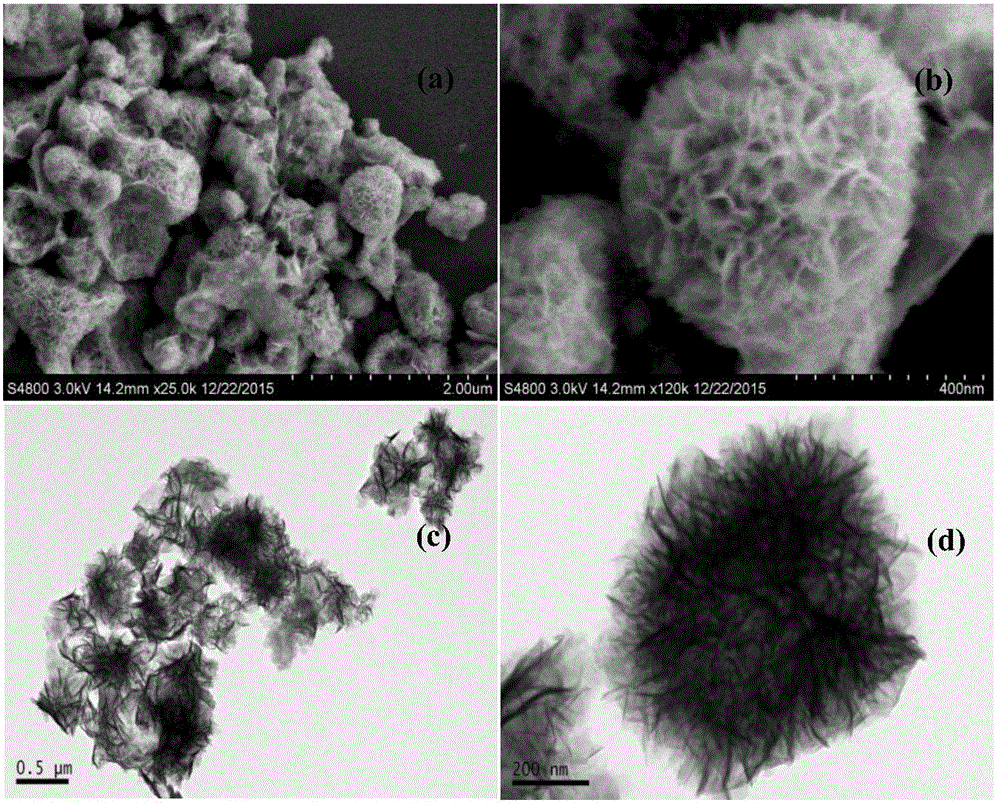

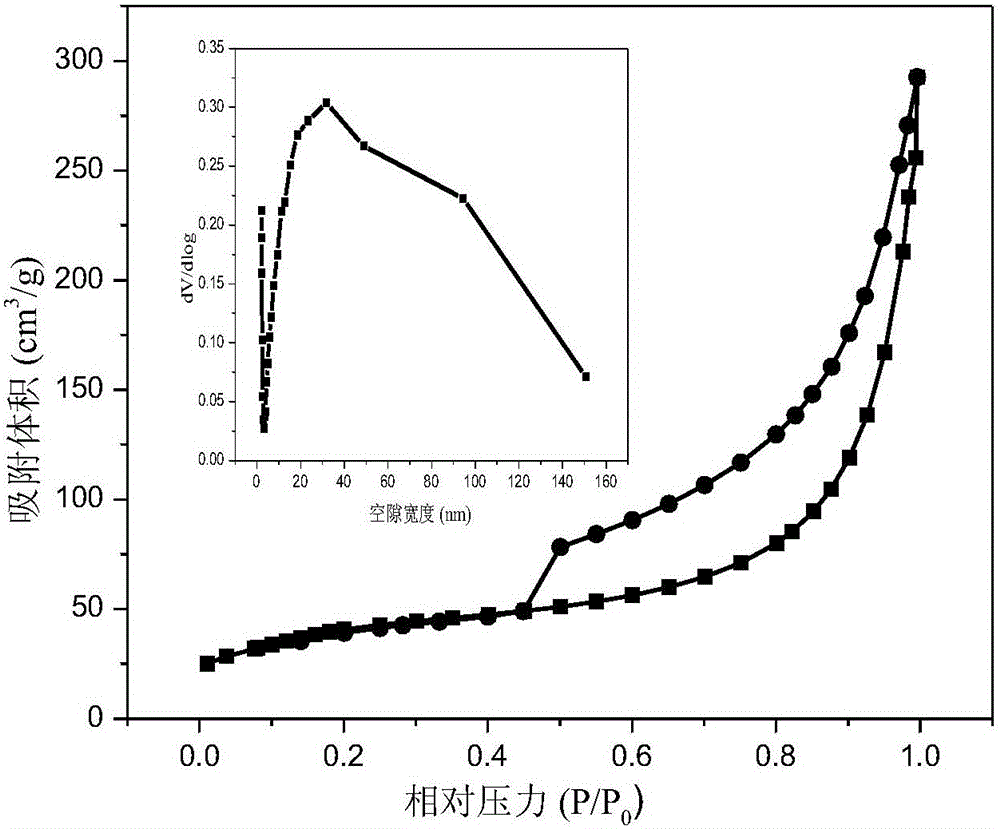

Indium sulfide photocatalyst with ultrahigh photocatalytic activity and preparation method and application thereof

InactiveCN106000424AHigh activitySimple manufacturing methodPhysical/chemical process catalystsWater/sewage treatment by irradiationIndium nitrate hydrateMethyl orange

The invention discloses an indium sulfide photocatalyst with ultrahigh photocatalytic activity and a preparation method and application thereof, and belongs to the technical field of photocatalytic degradation. Indium sulfide nanometer materials are stimulated by visible light to be used for catalyzing and degrading wastewater. Indium nitrate aquo-complex is used as an indium source, sodium diethyl dithiocarbamate is used as a sulphur source, and a hydrothermal method is adopted for preparing a target product. The indium sulfide photocatalyst has the advantages that the preparation process is simple and easy to operate, reaction conditions are mild, and large-scale production can be achieved; the prepared indium sulfide photocatalyst with ultrahigh photocatalytic activity has high specific area and provides a large number of active sites, and photoproduction electron hole overlapping is restrained. The nanometer material is applied for photocatalytic degradation of methyl orange, the degradation rate within 15 min is 99.6%, and stability is good; the degradation rate can still reach 98.8% after 16 cycles of photocatalytic degradation of methyl orange; the degration rate reaches 90.1% after 60 min of visible light catalytic degradation oxytetracycline.

Owner:牛和林

Method for producing liquid microbial drip irrigation fertilizer from waste

InactiveCN108503422AAvoid pollutionAdapt to large-scale productionBio-organic fraction processingBioloigcal waste fertilisersFiltrationDrip irrigation

The invention provides a method for producing liquid microbial drip irrigation fertilizer from waste. The method comprises the following concrete steps: step 1, sterilization of a liquid raw material;step 2, nutritional formulation of the liquid raw material; step 3, addition of a bacterial agent into the liquid raw material; step 4, fermentation; step 5, filtration; and step 6, inspection and discharging. According to the invention, the leftovers and emissions of large food enterprises are subjected to sterilization, pH value regulation and nutrient regulation; the method makes full use of nutrients consisting of 15-20% of original organic matters, 10% of N, P and K and 6-8% of amino acid in waste, and functional bacteria capable of meeting the demands of production raw materials and soil are cultured and applied to fermentation; and then, filtering with a 100-mesh filter screen is carried out to produce the qualified composite microbial drip irrigation fertilizer. The method provided by the invention solves the problem of pollution caused by emission; the microbial organic fertilizer is applied to soil through drip irrigation, so energy is saved, and emission is reduced; and themethod is simple, convenient and economical to operate and suitable for large-scale production.

Owner:新疆巨康生物科技有限公司

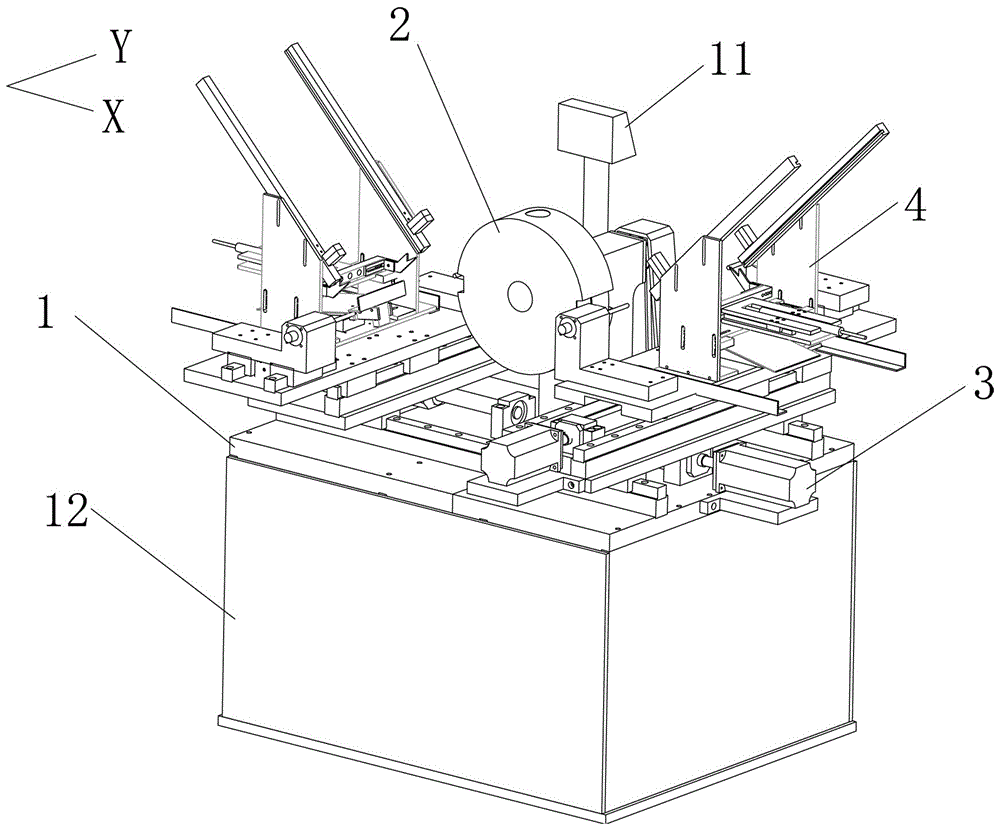

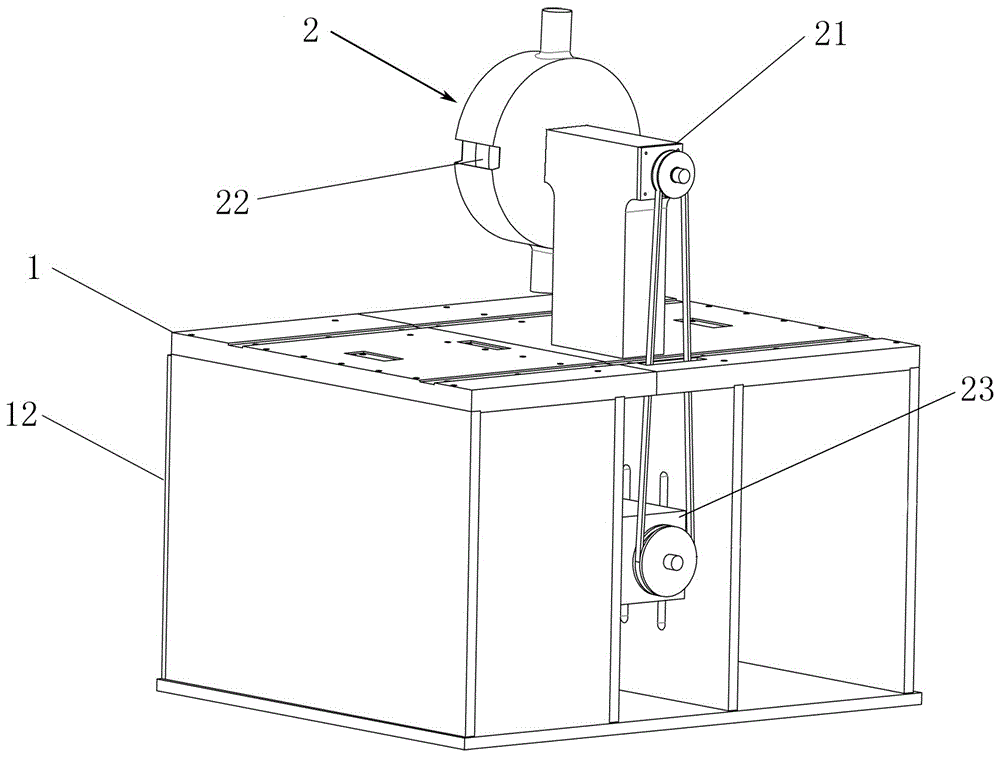

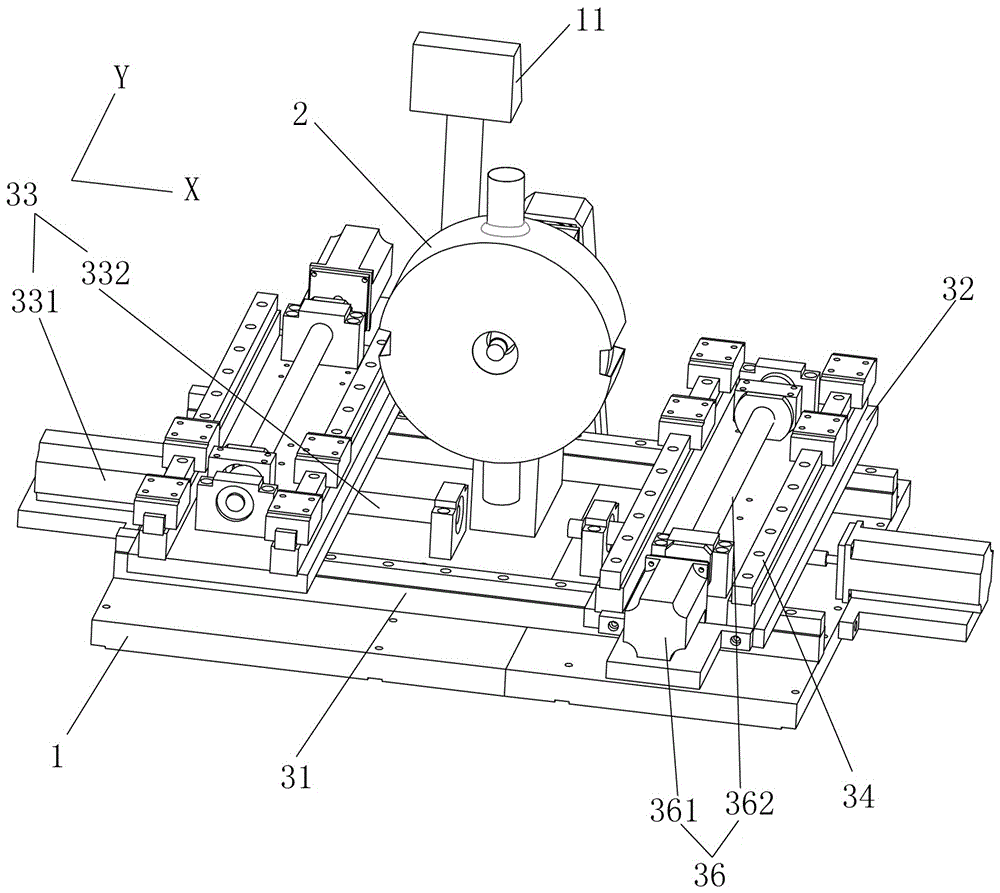

Sponge powder feeding roller grinding machine

InactiveCN106217147AIncrease production speedIncrease productivityGrinding carriagesRevolution surface grinding machinesControl systemEngineering

The invention relates to the technical field of sponge grinding, in particular to a sponge powder feeding roller grinding machine. The sponge powder feeding roller grinding machine comprises a workbench, a grinding wheel mechanism, two groups of conveying mechanisms, automatic feeding and discharging mechanisms and a control system, wherein X-direction guide rails are arranged on the workbench, the grinding wheel mechanism is mounted on the workbench, the conveying mechanisms are positioned on two sides of the grinding wheel mechanism, and the automatic feeding and discharging mechanisms are mounted on the conveying mechanisms. The sponge powder feeding roller grinding machine has the advantages that the conveying mechanisms are arranged on two sides of the grinding wheel mechanism respectively, two sponge powder feeding rollers can be produced once, and accordingly high efficiency is achieved, and the sponge powder feeding roller grinding machine is applicable to large-scale production; by the aid of the automatic feeding and discharging mechanisms, labor cost and defect rate are decreased; the sponge powder feeding roller grinding machine is high in universality, so that labor hours wasted due to debugging of the machine are reduced.

Owner:东莞市亚煌电子科技有限公司

A kind of filtration and separation method of nano molecular sieve slurry

ActiveCN103752083BImproved solid phase purityHigh purityMolecular sieve catalystsFiltration separationMolecular sieveFiltration

The invention relates to a filtering separation method for nanometer molecular sieve slurry, and belongs to the field of nanometer molecular sieve materials. The filtering separation method for the nanometer molecular sieve slurry is as follows: the pH value of the nanometer molecular sieve slurry is adjusted to be less than or equal to 5 by utilizing an acid material, and pressure filtering is carried out for at least one time. The nanometer molecular sieve filtered by the method provided by the invention has the equivalent catalytic reaction performance to that of the nanometer molecular sieve obtained by the common filtering process. The method has the advantages that the operation is simple; the used raw materials are low in price, and easy to obatin; the special equipment is not needed; the nanometer molecular sieve particles can be completely recovered by a common filtering machine; the method is suitable for the scaled production of the nanometer molecular sieve.

Owner:大连龙缘化学有限公司

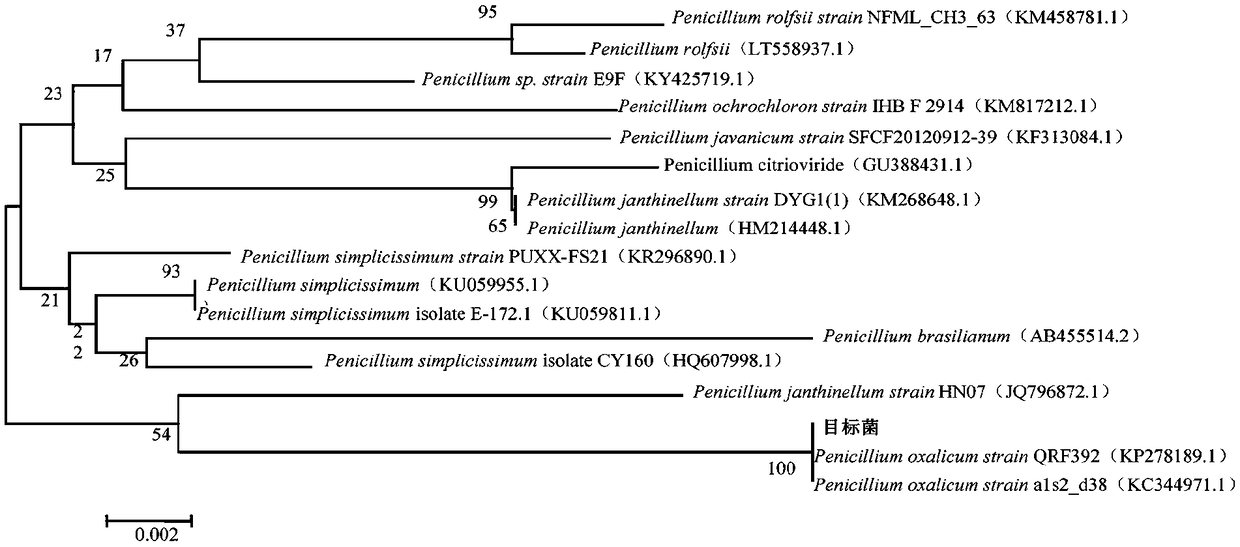

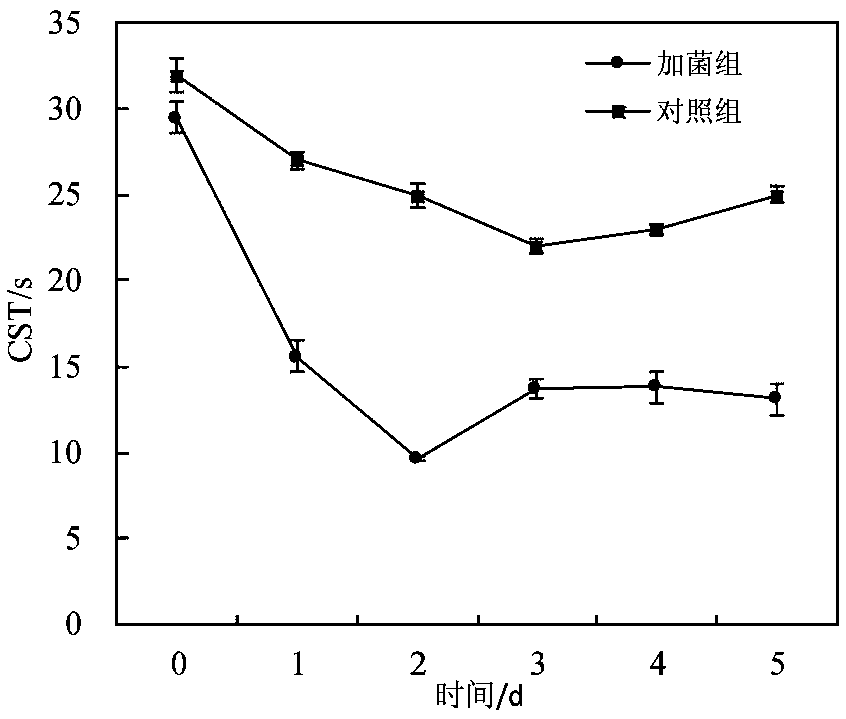

Method for improving dehydration performance of citric acid wastewater sludge by using penicillium oxalicum

ActiveCN108911452AFast growth metabolismShort separation and purification cycleSludge treatment by de-watering/drying/thickeningBiological sludge treatmentSludgePenicillium oxalicum

The invention discloses a method for improving dehydration performance of citric acid sludge by using penicillium oxalicum and belongs to the field of treatment of wastewater sludge of citric acid industry. According to the method, the penicillium oxalicum with an extracellular polymer degradation function is separated, purified and screened out from the citric acid wastewater sludge, a fungal spore suspension with a concentration of 1.0*10<7> / mL to 1.0*10<8> / mL is prepared from the penicillium oxalicum, and then, a Martin liquid culture medium is inoculated with the fungal spore suspension for culture for 2 to 4 days, so that stable mycelia are formed. The mycelia are added into the citric acid wastewater sludge with a total suspended solid content of 1% to 4% according to a volume ratioof 5% to 20%, culture is carried out for 2 to 4 days after uniform mixing, the sludge specific resistance SRF and capillary water absorption time CST of the citric acid wastewater sludge can be separately lowered to (1-6)*10<13>m / kg and 6-12 seconds from (1-3)*10<14>m / kg and 25-43 seconds, and the dehydration performance is remarkably improved.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com