Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Low moisture content requirement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

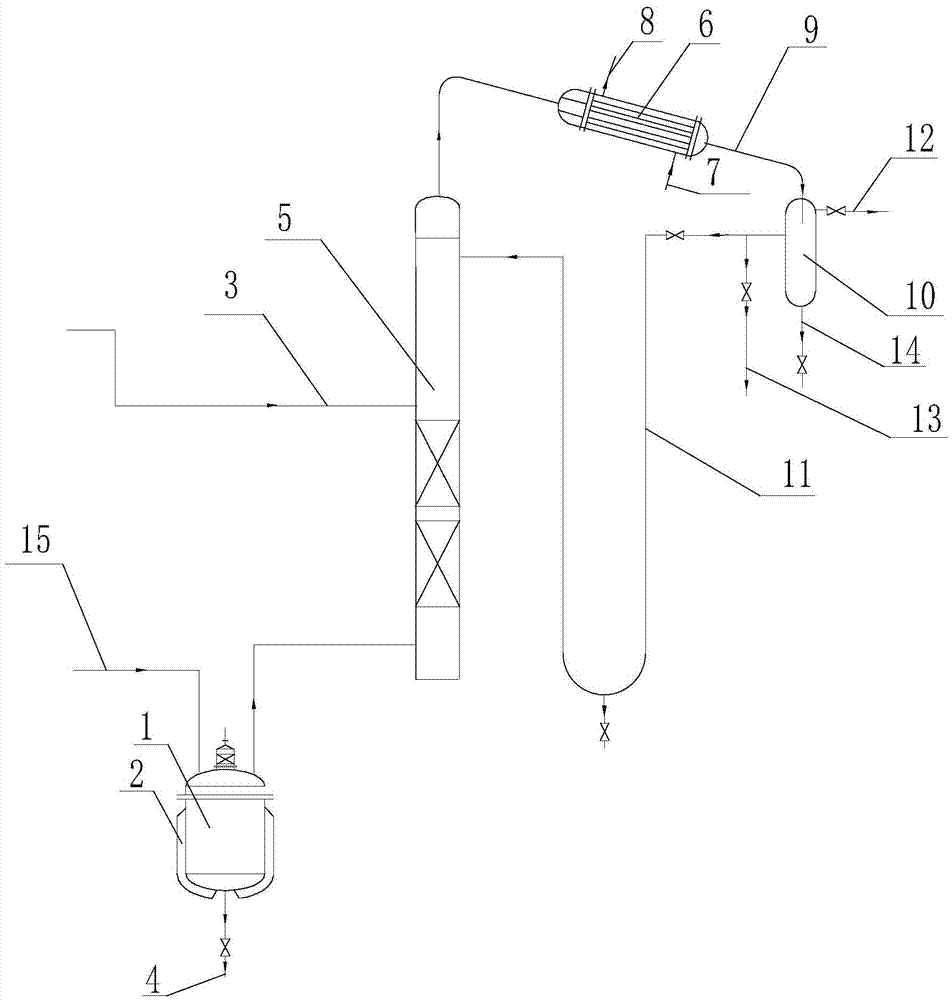

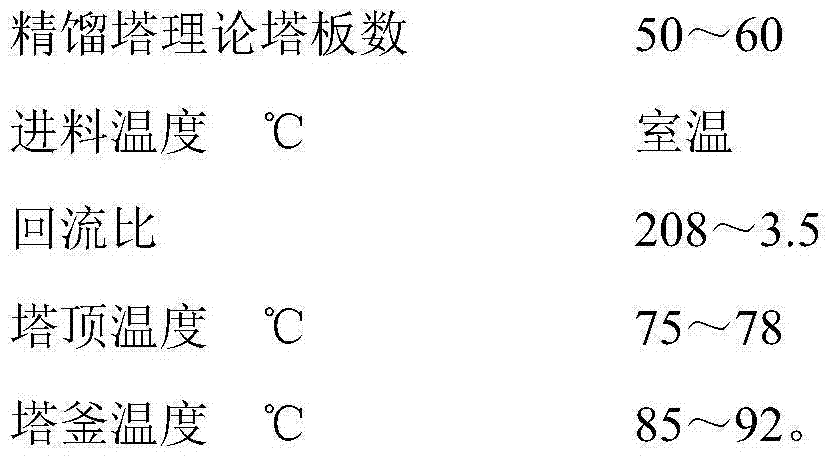

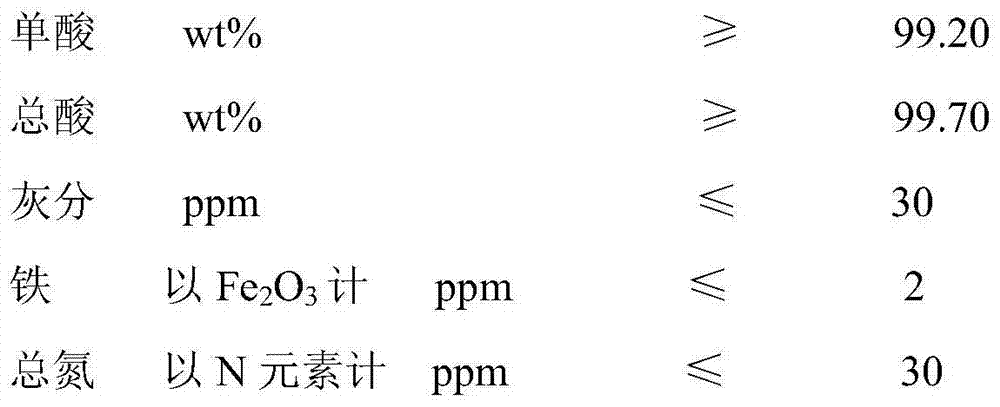

Method for refining long-carbon chain dicarboxylic acid

ActiveCN104496793AMeet the technical requirements of useLess investmentCarboxylic compound separation/purificationEngineeringCarboxylic acid

The invention relates to a method for refining long-carbon chain dicarboxylic acid. A long-chain dicarboxylic acid crude product prepared by a fermentation method is used as a raw material, acetic acid is used as a solvent, and the refining and purification are performed by recrystallization treatment. The method comprises the process steps of bleaching filtration, cooling crystallization, centrifugal separation, centrifugal material washing, secondary centrifugation and drying, and is characterized in that a. the long-chain dicarboxylic acid crude product to be refined does not need to be dried; b. the acetic acid solvent is recycled by an azeotropic distillation method, and isopropyl acetate is used as an azeotropic dehydrating agent; and c. the isopropyl acetate is used as a centrifugal material washing solvent for replacing the acetic acid. The purification method of the long-carbon chain dicarboxylic acid provided by the invention has the advantages of distillation equipment investment conservation, low operating power consumption, good product color, high purity, high refining yield and low production cost, the long-carbon chain dicarboxylic acid to be refined does not need to be dried and dehydrated, and the acetic acid solvent is completely recyclable. The quality of the refined product can meet the technical requirements of use of condensed monomer raw materials used by synthesis of high polymer materials.

Owner:山东广通新材料有限公司

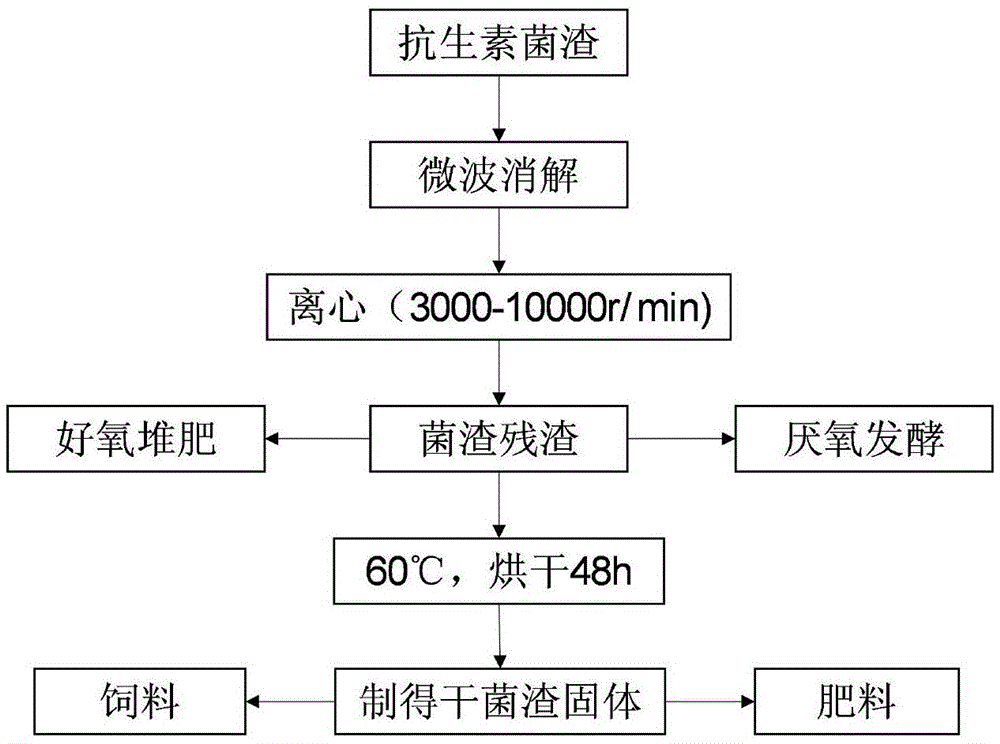

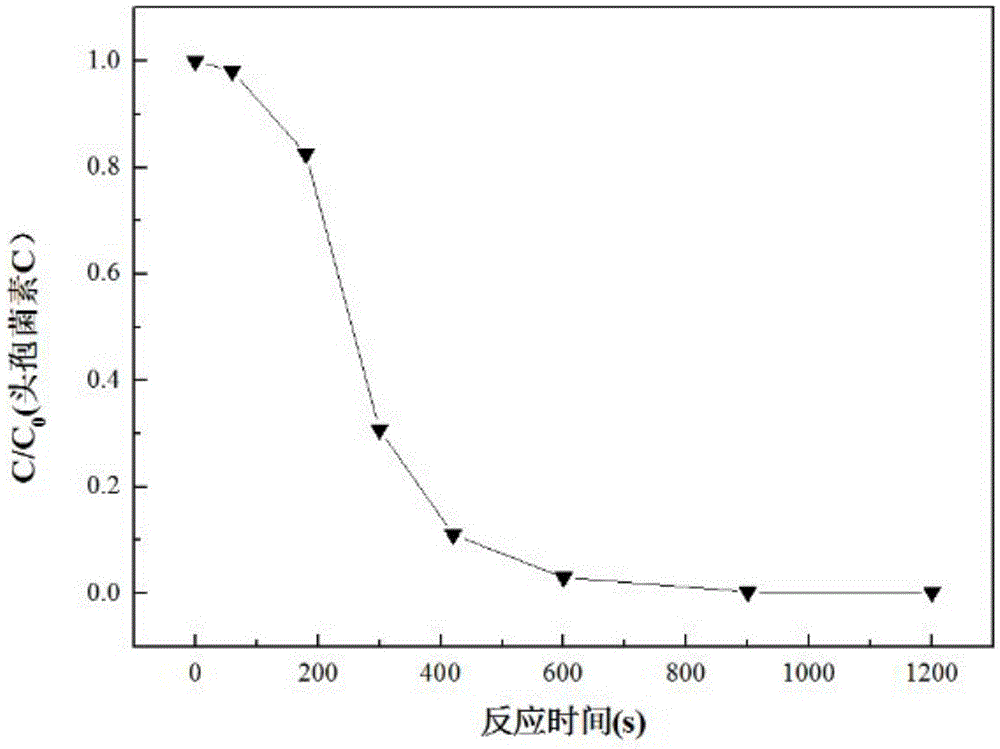

Treatment method and application of antibiotic bacterial residues

InactiveCN105537251ALow moisture content requirementRealize resourcesTransportation and packagingSolid waste disposalAfter treatmentAntibiotic Y

The invention relates to a treatment method and an application of antibiotic bacterial residues, and aims to solve problems that existing bacterial residue treatment methods are long in period, still have the environmental risk after treatment and the like. The method comprises steps as follows: 1) fresh bacterial residues are placed in a reaction tank, the moisture content is controlled between 85% and 95%, and the bacterial residues are evenly mixed; 2) the reaction tank containing the bacterial residues is placed in a microwave reactor, heated to 100 DEG C by a microwave generator with the microwave power of 100-900 W and kept for 10 min; 3) the antibiotic bacterial residues after the reaction are subjected to centrifugal separation, and obtained bacterial residues are precipitated and dried. With the adoption of the method, antibiotic residues in the bacterial residues can be removed quickly, and harmless treatment and recovery of the bacterial residues are realized.

Owner:HARBIN INST OF TECH

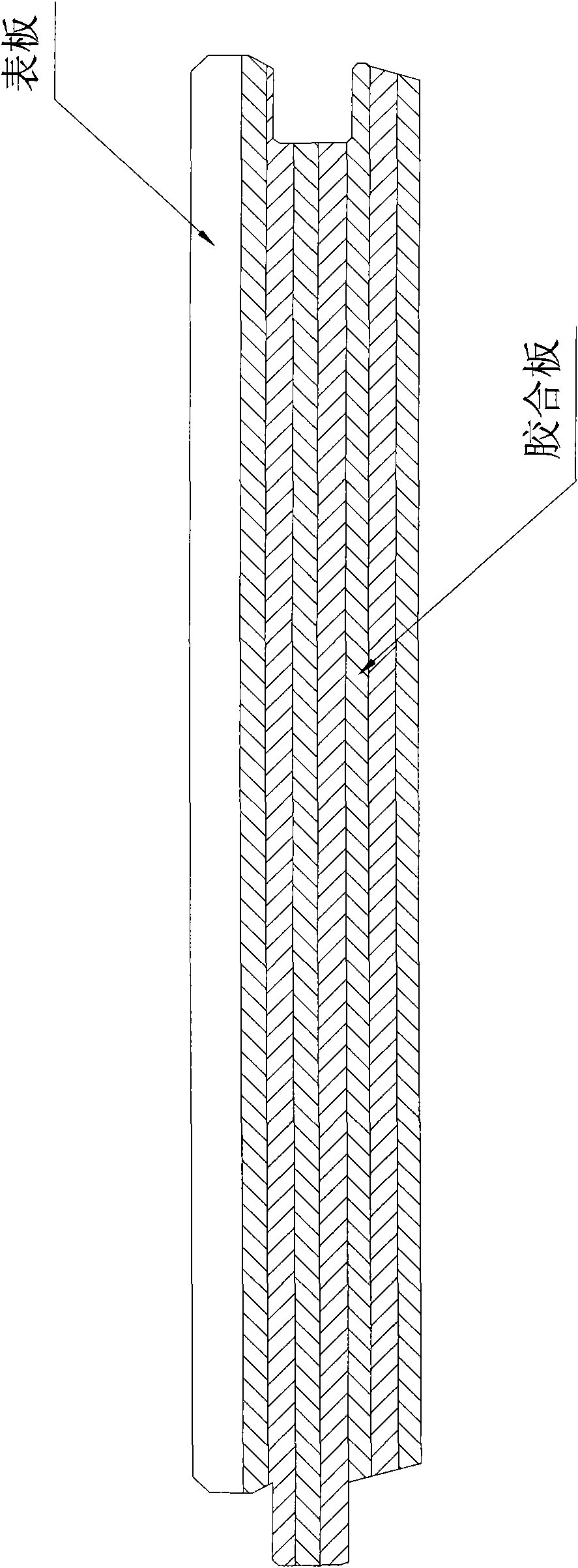

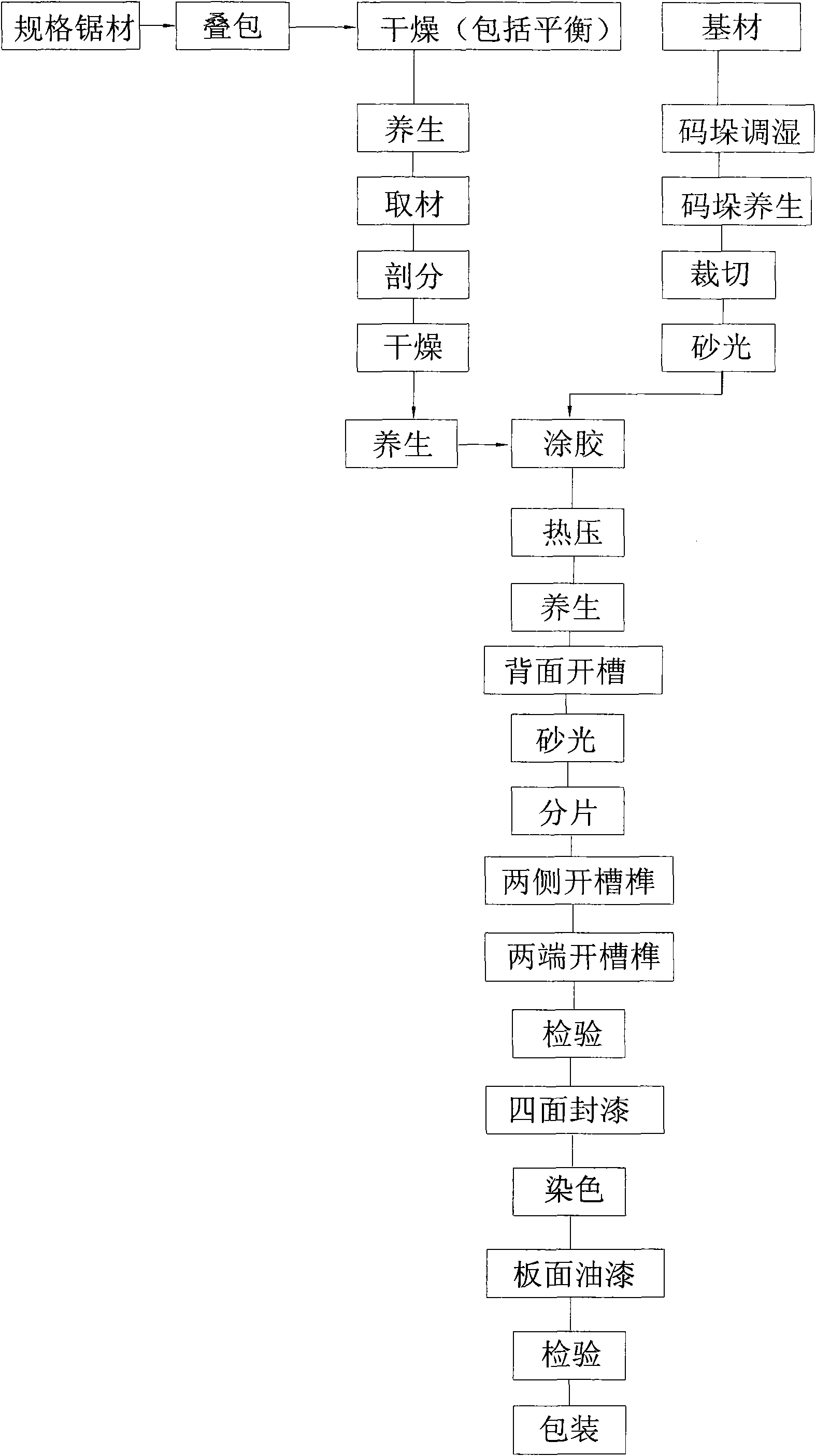

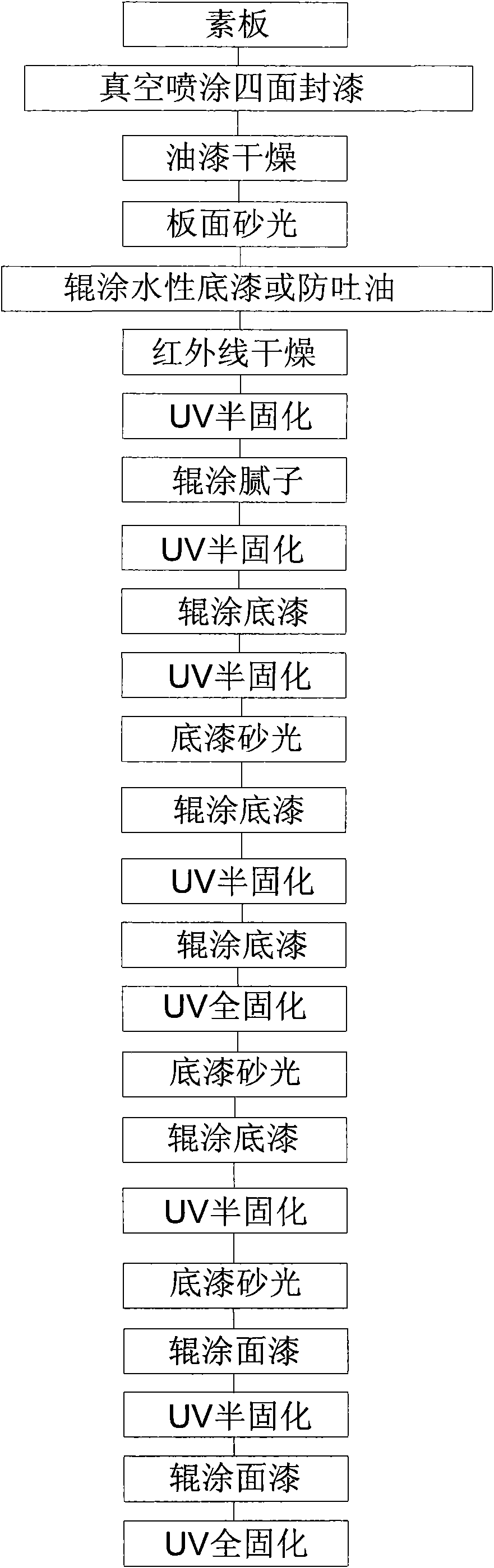

Production method of weather-proof multilayer composite wood floor

ActiveCN101628440AReduce water lossReduce stressWood veneer joiningWood dampingPulp and paper industryWater content

The invention discloses a production method of weather-proof multilayer composite wood floor, comprising the following steps: after normal procedures of drying, balancing and nourishing life, the water content of a wood panel is lowered to 12-16% from originally more than 16%; after sawn into face veneers with thickness being 1-4mm, the water content of the wood panel is lowered to 6-9% by low temperature drying, balancing and nourishing life; then the water content of plywood basal material with water content being 9-14% is lowered to 10-8% by lower temperature drying, balancing and nourishing life; then, plywood basal material which conforms to water content requirement is cut, sanded and glued to assemble with the face veneers, and hot-pressing or cold-pressing procedure is adopted to glue into a floor blank; and finally, the floor blank is nourished, processed with a mortise and decorated by painting on the surface so as to form the weather-proof multilayer composite wood floor. The multilayer composite wood floor produced with the method has small warping degree and deformation ratio when used, has small possibility of cracking, has strong weather-proof performance and can be used as heating wood floor.

Owner:SHANDONG YIHUA FURNITURE CO LTD

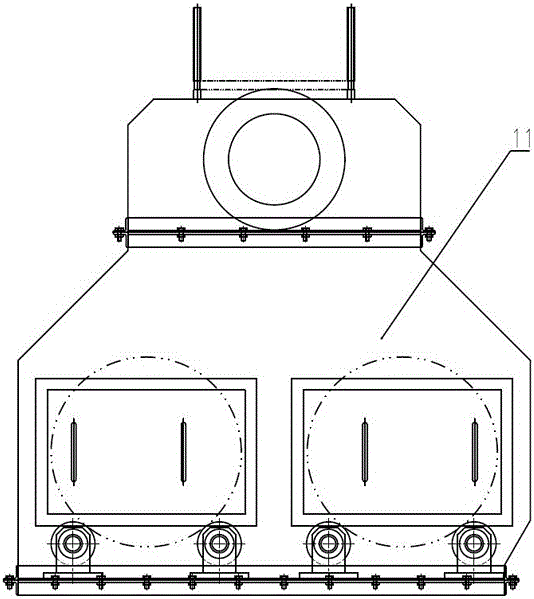

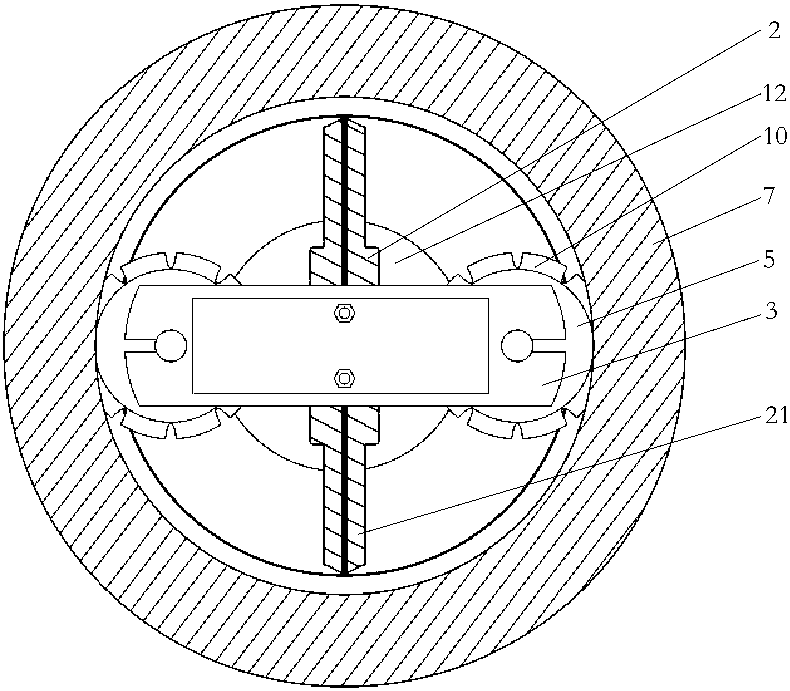

Treatment apparatus and process for in-kiln balling and firing ceramsite from industrial waste residue and sludge

InactiveCN103030376ASimplify and optimize the production processLow moisture content requirementClaywaresCombustionSludge

The invention discloses a treatment apparatus and process for in-kiln balling and firing ceramsite from industrial waste residue and sludge. The treatment apparatus is characterized by comprising a bidirectional axial stirrer, a double-shaft kneader, a combustion device, a ceramsite rotary kiln and a mobile feeding screw conveyor for conveying materials to the ceramsite rotary kiln, wherein an in-kiln balling device is arranged in the ceramsite rotary kiln. According to the invention, the structure is simple, the treatment capacity of the ceramsite kiln apparatus on agglomerate, high-moisture, high-viscosity and pasty industrial solid waste and sludge is greatly improved, and the waste treatment cost is low, thereby achieving favorable popularization values.

Owner:甘永雄 +2

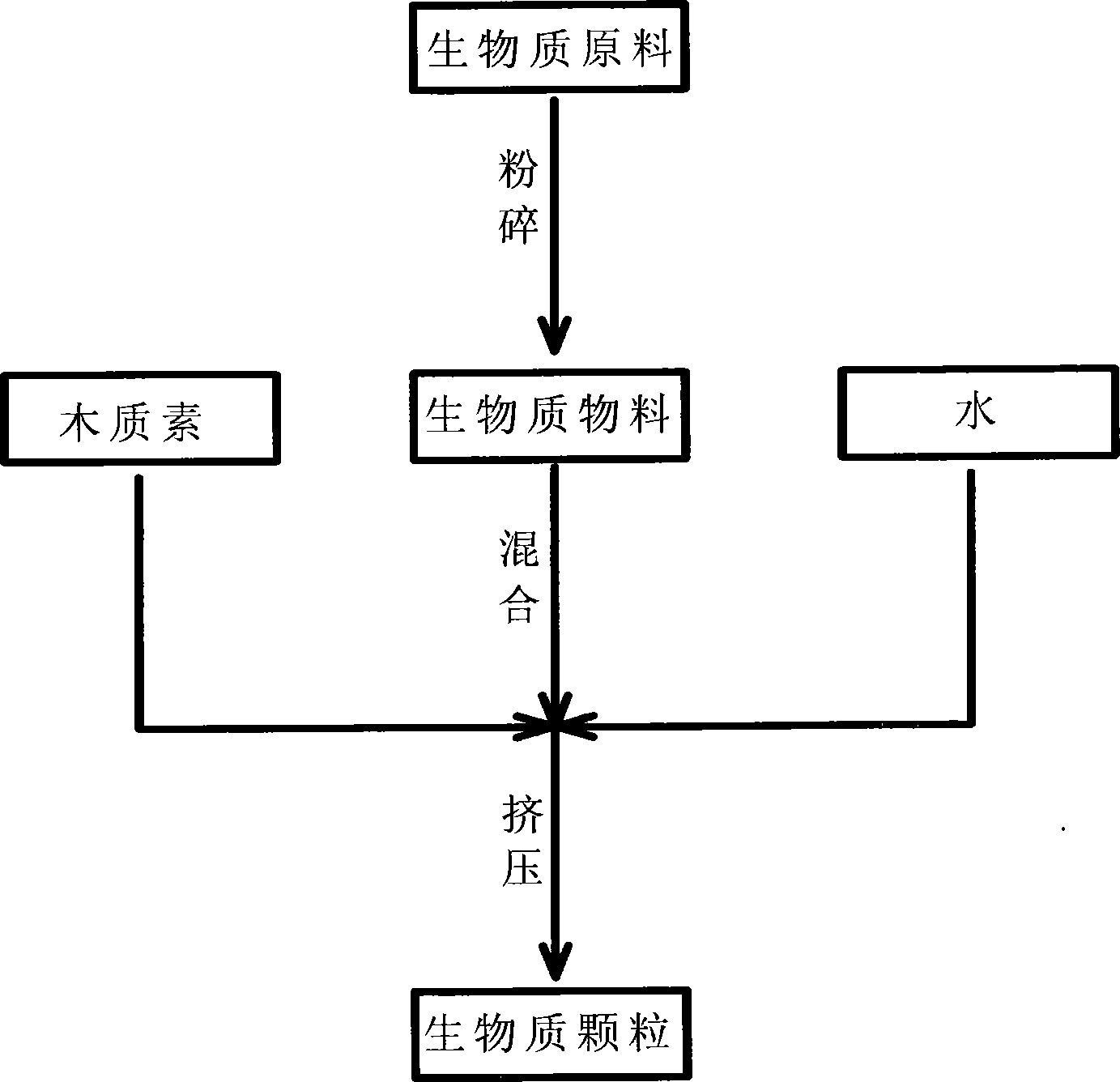

Method for processing biological particles using lignin in paper-making waste liquid

InactiveCN101069977AIncreased durabilityHigh densityWood working apparatusDomestic articlesLiquid wasteHusk

A method to process biomass pellets by using lignin in pulping waste liquor relates to molding technique of biomass pellets. It takes grinding matters of barks, branches, genus aralias, sawdust, straw, rice husk and bagasse as materials and adopts lignin distilled from pulping waste liquor as bond. They are mixed and pressed under normal temperature and low pressure for molding. The weight ratio of them is: biomass materials 40%-98% and lignin 1%-50%. Mix them and add some water. The pellets in this invention take natural and renewable crops as main materials and add combustibles-lignin as bond, which increases the burning heat and reduces the environmental pollution and energy consumption.

Owner:SHENYANG INST OF ENG +1

Collision type shell breaking machine

ActiveCN107772497AReduce breakage rateImprove the efficiency of breaking upPlastic recyclingHuskingBreakage rateCentrifugal force

The invention discloses a collision type shell breaking machine, which comprises a frame, an outer shell installed on the frame and an inner barrel installed in the outer shell; the inner barrel has an inner cavity and a material inlet located at the top part of the inner cavity; the bottom part of the inner cavity is equipped with a rotary driving device for making the material generate centrifugal force and perform throwing movement towards four side walls of the inner cavity; several discharging openings for guiding the material to the outer shell are arranged on the four side walls of theinner cavity, and the bottom part of the outer shell is provided with a material outlet; the collision type shell breaking machine further comprises a feeding device for feeding materials in the innercavity. The collision type shell breaking machine has the advantages of being simple and compact in structure, low in cost, stable and reliable in work, high in breaking rate, low in grain breakage rate, and convenient to install and maintain.

Owner:HUNAN AGRICULTURAL UNIV

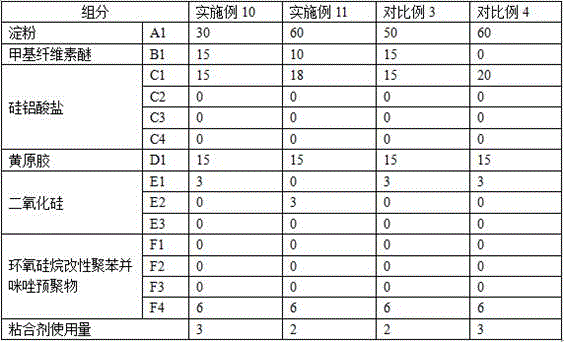

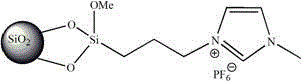

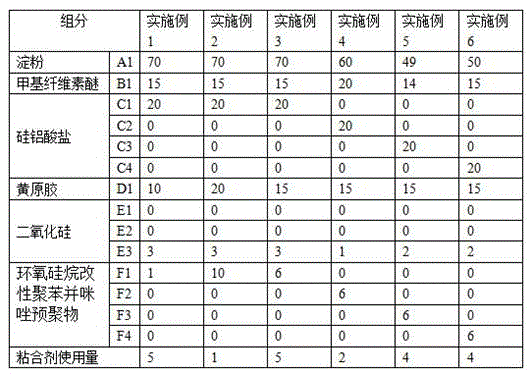

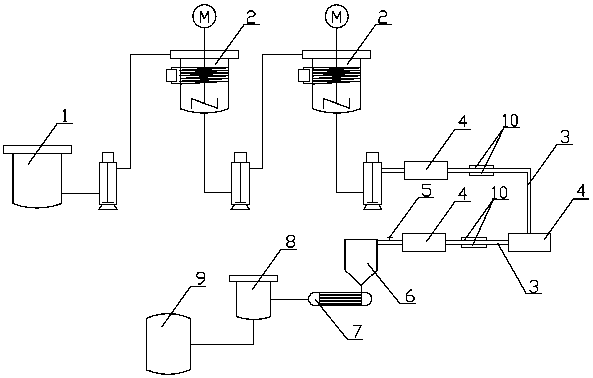

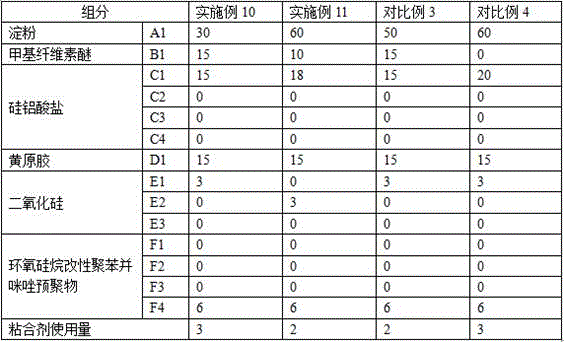

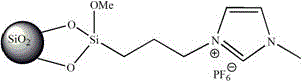

Drying-free bonding agent for iron powder cold pressing pellets

The invention discloses a drying-free bonding agent for iron powder cold pressing pellets. The drying-free bonding agent comprises, by weight, 30-70 parts of starch, 5-20 parts of methyl cellulose ether, 15-25 parts of aluminosilicate, 10-20 parts of xanthan gum, 1-5 parts of silica and 1-10 parts of epoxy silane modified polybenzimidazole prepoly. The bonding agent is suitable for the iron ore powder and iron-containing dust cold pressing pellet field.

Owner:LUANXIAN YONGHENG ADHESIVE CO LTD

Process of preparing biological diesel oil

InactiveCN101058743AHigh catalytic activityEasy to makeFatty acid esterificationBiofuelsBiodieselPhysical chemistry

The invention discloses a making method of biological diesel coproducted glycerine and magnesium oxide through catalyzing plant oil by magnesium carbinol, which is characterized by the following: adopting non-refined plant oil as raw material; using magnesium carbinol as non-even phase catalyst; reacting through ester exchange to obtain the product and glycerine and magnesium oxide as by-product without neutralizing and processing; improving the receiving rate of magnesium oxide without discharging waste liquid.

Owner:EAST CHINA UNIV OF SCI & TECH

Preparation method and application of activated biogas residue hydrothermal carbon

InactiveCN110371971ALarge specific surface areaSmall specific surface areaCarbon compoundsWaste based fuelBiogas productionFermentation system

The invention discloses a preparation method and application of activated biogas residue hydrothermal carbon. The activated biogas residue hydrothermal carbon serves as an additive and is added in theanaerobic fermentation process taking fecal residue and waste water as a fermentation substrate, biogas residue is recycled, and the biogas production efficiency in the anaerobic fermentation processis improved. The preparation method and application of the activated biogas residue hydrothermal carbon have the beneficial effects that the biogas residue is recycled and used for anaerobic fermentation engineering, material circulation is achieved, and meanwhile the high value utilization path of biogas residue is developed; the cost of the preparation method is low, the technology is simple, extra raw material purchasing is not needed, and in the preparation process, the condition is mild, energy consuming is small, and the cost is low; and in addition, the biogas production in the anaerobic fermentation system and the content of methane in the biogas can further be improved, thus the fermentation efficiency is high, the fermentation system is stable, and the problems that existing biogas residue is difficult to consume, and the anaerobic fermentation efficiency of the fecal residue and waste water is low are solved.

Owner:广东广垦畜牧工程研究院有限公司

Modified red mud filling master batch for plasticizing industry and special material

The invention relates to a modified red mud filling master batch for plasticizing industry and a special material for modified red mud, and belongs to the technical field of chemical industry. The modified red mud filling master batch is prepared from the following raw materials in percentage by weight: 80%-90% of red mud, 5%-15% of carrier resin, 3%-10% of auxiliary agents and 0.5%-2% of surface modification agents. The modified red mud filling master batch disclosed by the invention has no need of early dealkalization treatment, excessive drying, grinding and screening and is large in red mud usage amount and reduced in cost because the red mud usage amount is increased in a formula; and in addition, a prepared product has more excellent property and especially increases other characteristics of flame retardance, weather resistance and the like.

Owner:淄博龙沙高分子材料科技有限公司

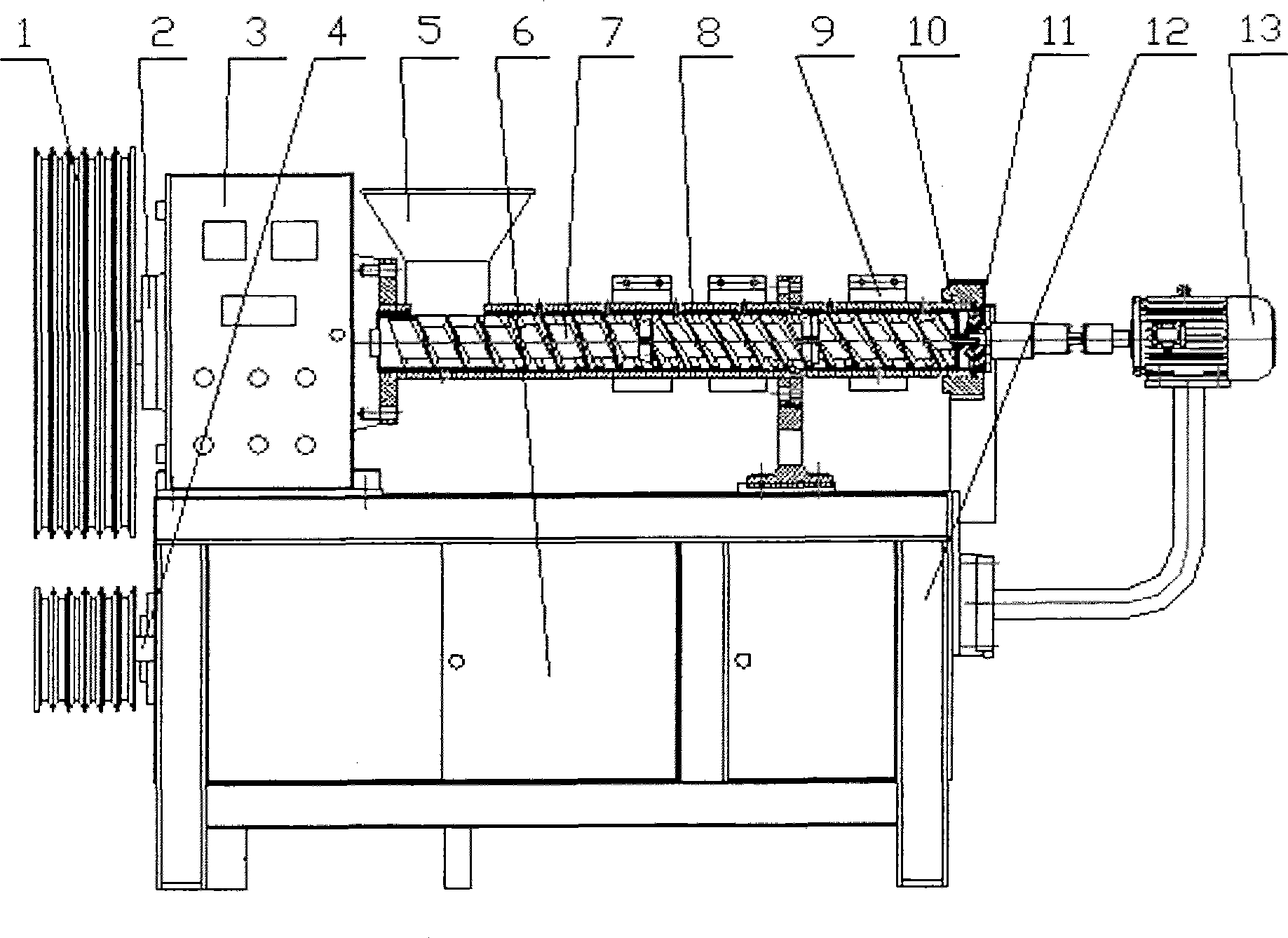

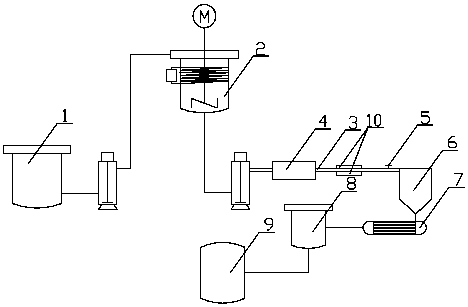

Equipment and technique for puffing foodstuff

InactiveCN101375734AAchieve food grade puffingLow moisture content requirementFood shapingFood gradeAdditive ingredient

The invention discloses equipment and a technology for food puffing. The equipment comprises a main electric motor and a puffing formation cavity, wherein, the puffing formation cavity is composed of a screw, a sleeve and a die head, the screw is arranged inside the sleeve, the die head is fixedly connected with one end of the sleeve, and double die holes are formed on the die head. The invention can achieve the purpose of puffing rice at food grade. According to the invention, the requirement for moisture content of rice is relatively low, and ingredients are not crushed in advance unnecessarily, so that the production efficiency is greatly improved. As the invention improves the adaptability of the prior art, the puffing rate increases, and a better puffing effect is achieved. Puffed rice produced by adopting the technology has the advantage that a heavy decline in the volume weight of powder made from the puffed rice is brought about. Therefore, according to the fact that the smaller volume weight can enable the rice powder to be more soluble and also can enable the taste to be better, the powder made from the puffed rice is taken as the main ingredient for rice powder for babies to ensure that the rice powder can be easily digested by babies and is good in taste.

Owner:杨小静 +1

Preparation process of sludge electrical coal

InactiveCN103146453AIncrease calorific valueReduce the blending ratioSludge treatmentBiofuelsBiomassChemistry

The invention relates to a preparation process of sludge electrical coal. The preparation process comprises the following steps of: (1) stirring and mixing dewatered sludge and water decomposing agents, and spraying a deodorant during the process to remove odor; and (2) crushing the dewatered sludge after treatment in the step (1), combustion-supporting additives, a biomass auxiliary fuel and raw coal powder, and then mixing to obtain the sludge electrical coal, wherein the water decomposing agents are of red mud, a sodium salt, bentonite and an organic flocculant; the combustion-supporting additives are of an organic strong oxidant, a magnesium salt, rare earth and sodium humate; the deodorant is of a Bacillus natto preparation; and the sludge electrical coal comprises the following components in percentage by weight: 20-30% of dewatered sludge, 1-5% of water decomposing agents, 1-5% of combustion-supporting additives, 30-40% of biomass auxiliary fuel and 30-40% of raw coal. The whole set of the method disclosed by the invention has the advantages of simple process, low cost and low requirement for water content in the sludge, the sludge electrical coal is prepared by using the sludge, the caloric value of the sludge is fully utilized, and the resource utilization purpose is achieved.

Owner:GUANGXI LIUZHOU POWER GENERATION COMPANY

Method for preparing cement additive by taking titanium gypsum as raw material

The invention provides a method for preparing a cement additive by taking titanium gypsum as the raw material. The main raw materials comprise titanium gypsum and causticized white sludge; titanium gypsum and causticized white sludge are by-products of chemical production and are mixed, so that industrial waste residue can be reduced, and acid-base neutralization can be realized to fix heavy metalelements including lead, zinc, copper, cadmium, mercury, arsenic, chromium and the like in titanium gypsum; trace graphene is added and ground to improve the reaction effect of titanium gypsum and causticized white sludge and improve the fixing effect of the heavy metal elements; after grinding, the mixture is poured in an extruding machine to be extruded into brick fragments; the material required by forming has low water content requirement and is then naturally piled and aired to be normally transported and meet the unloading requirement of a cement plant.

Owner:DANYANG LANSI INFORMATION TECH CO LTD

Alkoxy silane-terminiated polymer and production technology thereof

InactiveCN105085864AHigh mechanical strengthAddressing Moisture SensitivityCross-linkPolymer science

The invention relates to the technical field of an alkoxy silane-terminiated polymer, especially to a high-strength and low-toxicity alkoxy mixed silanes modified polymer for RTV sealants and adhesives and a production technology thereof. The polymer comprises polyurethane, polyether, polyacrylate or any other linear or cross-linked polymer containing free reactive hydroxyl groups which can react. The ratio of methyl dimethoxy to triethoxy is between 2:8 and 8:2. By controlling quantity of carbamic acid ester to minimize hydrogen bonds, viscosity of the polymer at 25 DEG C is within 20000-30000. In comparison with a trimethoxy silane gamma-silane-terminated polymer, the novel alkoxy silane-terminiated polymer has higher mechanical strength. The problem that a trimethoxy silane-terminated product is sensitive to moisture and has short shelf life is solved.

Owner:泰州瑞洋立泰新材料科技有限公司

Screw propelling type solid waste continuous carbonization equipment and continuous carbonization method

The invention provides screw propelling type solid waste continuous carbonization equipment and a continuous carbonization method. The screw propelling type solid waste continuous carbonization equipment is characterized by comprising a feeding system, a material distributing system, a carbonization system, a product collecting system and a discharging system which are successively connected with one another, wherein a sealed connected screw propelling material channel is formed from a feeding opening of the feeding system to a discharging opening of the discharging system; and the carbonization system is connected with a deodorization system. The feeding system comprises a feeding screw conveyer, a feeding gear motor, a first stirring motor and the feeding opening, the feeding opening of the feeding system is an inverted-cone-shaped feeding hopper, the first stirring motor drives a stirring shaft to rotate, blades are mounted on the stirring shaft, and the stirring shaft is positioned in the inverted-cone-shaped feeding hopper of the feeding system. The screw propelling type solid waste continuous carbonization equipment is high in universality, the generated carbonization products are used extensively, and secondary pollution is avoided. The screw propelling type solid waste continuous carbonization equipment is reasonable and compact in structure, good in airtightness, relatively low in manufacturing cost, high in degree of automation and high in working efficiency.

Owner:CHENGHE ENVIRONMENTAL PROTECTION SCIEN TECH CO LTD

Oil mud two-stage thermal desorption system with high water content and integrated skid-mounted equipment

ActiveCN109354375AReduce energy consumptionIncrease heat absorptionSludge treatmentDispersed particle separationSteam condensationSludge

The invention discloses an oil mud two-stage thermal desorption system with a high water content and integrated skid-mounted equipment, and belongs to the technical field of oil mud treatment devices.The system includes a feeding system, a first-stage thermal desorption system, a second-stage thermal desorption system, a discharge system, a steam condensation and oil-water separation system and anitrogen protection system, which are integrated in the integrated skid-mounted equipment. The system aims at deficiencies of high energy consumption and limited treatment capacity in the oil mud thermal desorption method treatment process, reduces the water content of the oil mud through microwave thermal desorption pretreatment of first-stage thermal radiation, uses the indirect thermal desorption of second-stage heat conduction to separate oil from the soil, and improves the thermal efficiency and the processing capacity of the equipment by a first-stage thermal desorption distributor, a second-stage thermal desorption flame retardant plate and a fire blocking wall to increase the flue gas residence time. The system solves the problem that a microwave belt discharge belt adheres to theoil sludge, a steam releases on the discharge port and the sealing and the safety concern people, the structure is reasonable and compact, and the system is convenient to relocate and install, and has good application prospects.

Owner:广安铭鸿环保科技有限责任公司

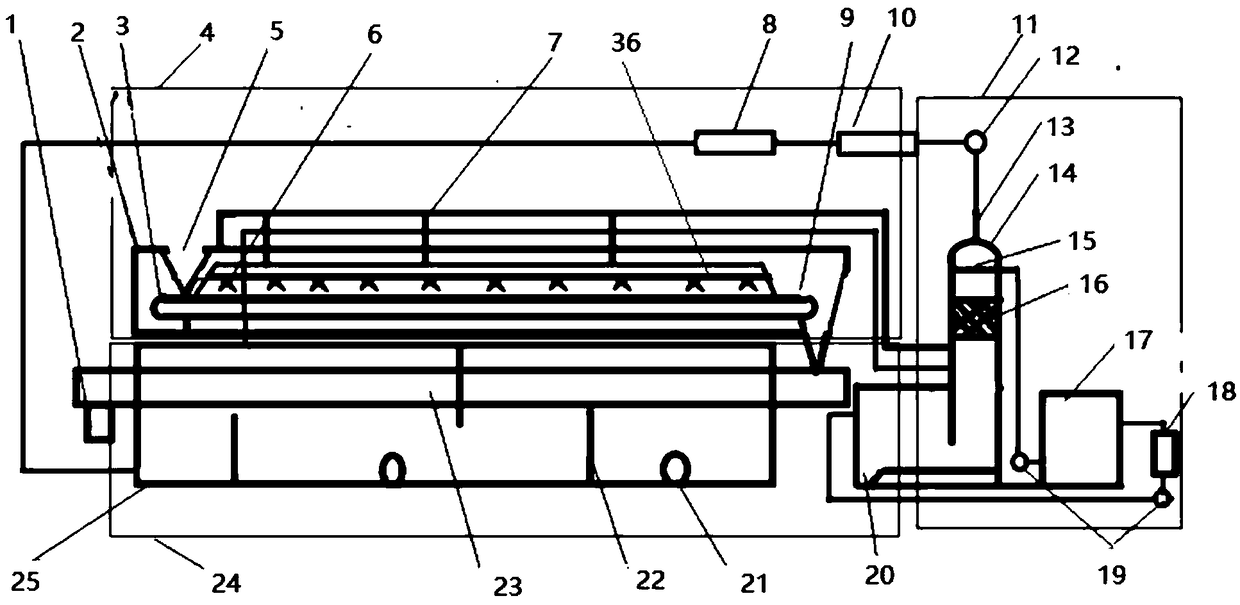

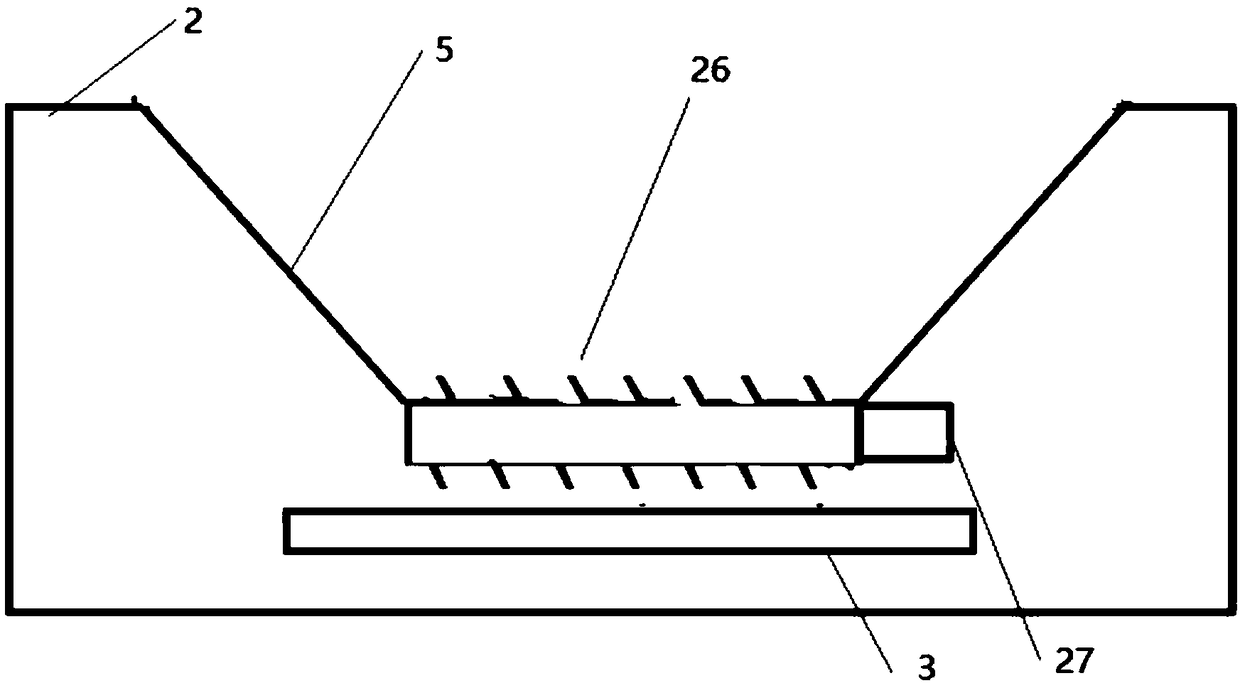

Purification method for straw gasified gas and equipment thereof

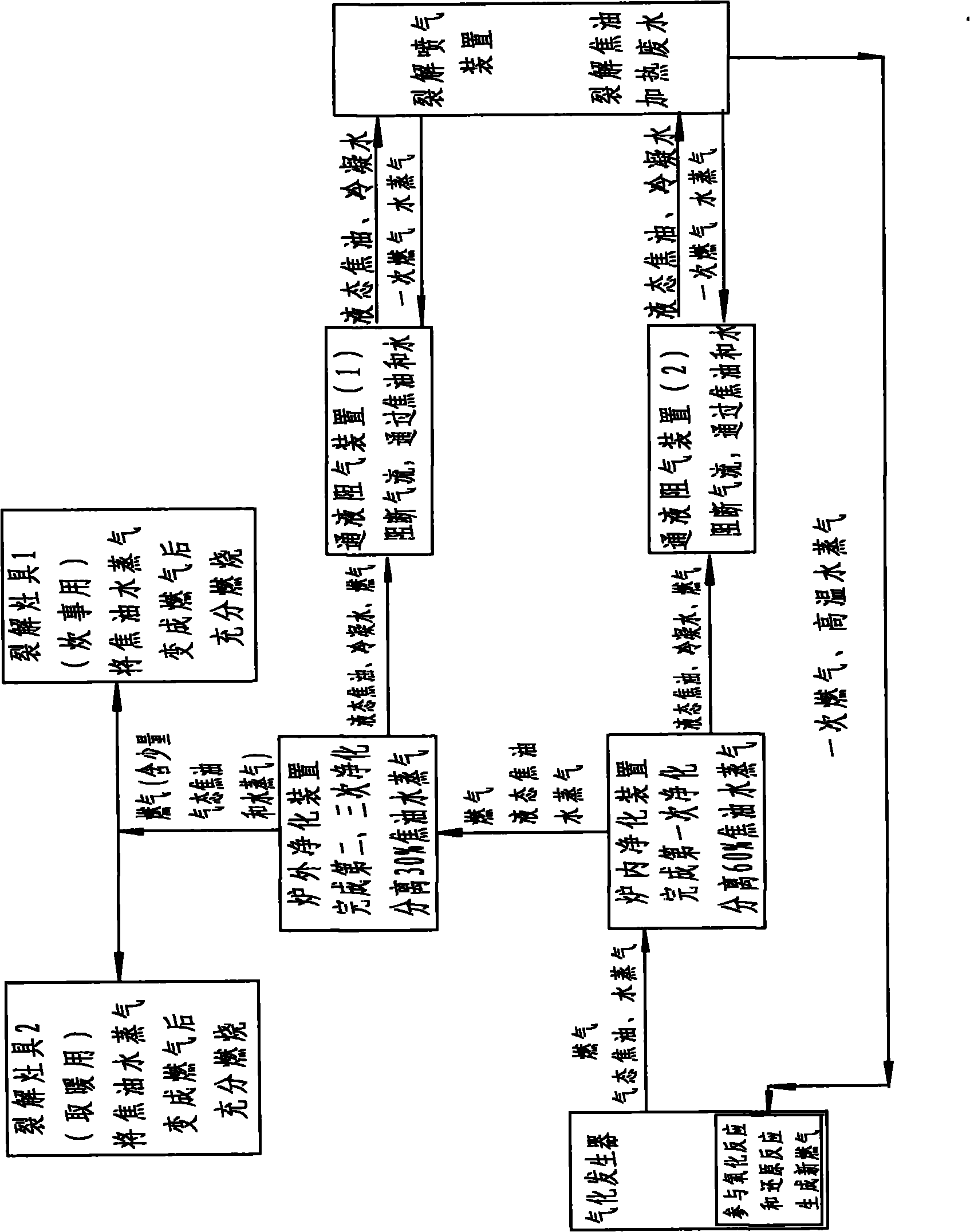

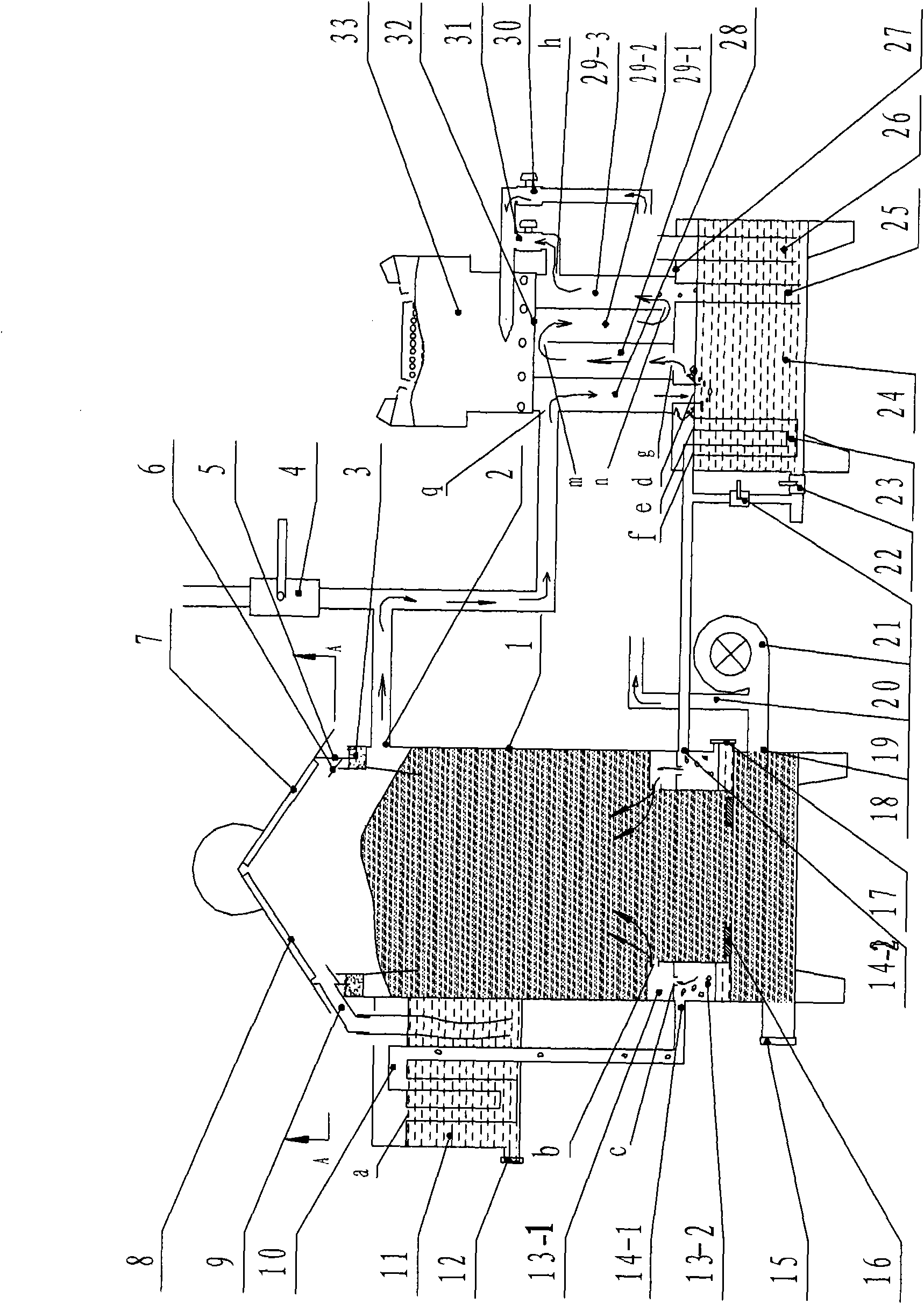

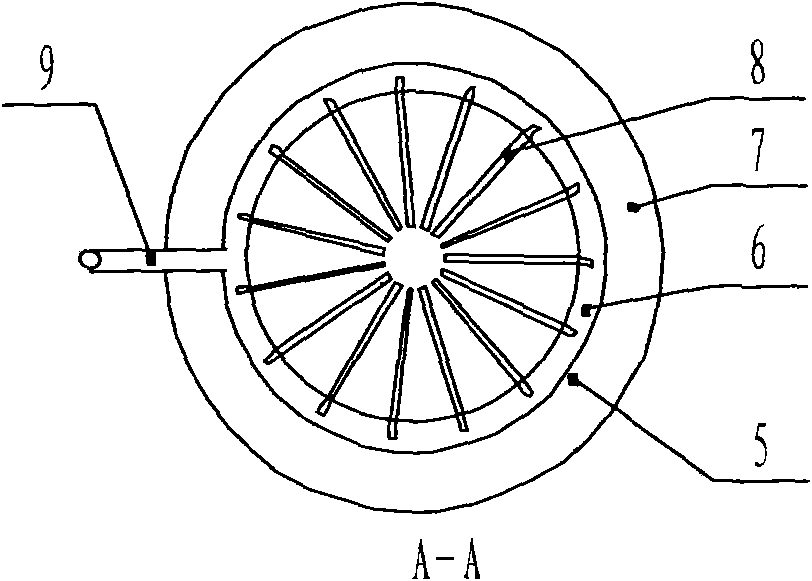

InactiveCN102003721AAchieving zero emissionsHigh thermal efficiencyThermal non-catalytic crackingDomestic stoves or rangesCombustion chamberPurification methods

The invention relates to a purification method for straw gasified gas and equipment thereof. Equipment for separating, recycling and converting tar-containing wastewater is designed and installed on a gas producer and a purification device of the current gasifier; the equipment separates most of tar from water in crude gas firstly; and the separated tar-containing wastewater is not discharged but fully converted into combustible gas to be sufficiently combusted in a cooking stove. In the invention, a tar-containing wastewater converting device and a three-dimensional oxygen supply device are installed on the cooking stove; a small amount of tar-containing wastewater which is not separated after the gas passes through the purification device is fully converted into the combustible gas by the tar-containing wastewater converting device, and the combustible gas is delivered with other gas into a combustion chamber and combusted in three-dimensional oxygen supply environment, thus realizing zero discharge of the tar-containing wastewater in the gasified gas; the calorific value of the gas is as high as 5100KJ / Nm<3>, and the gasification efficiency is greater than or equal to 72%; and the combustion temperature is 100-200 DEG C higher than that of the current cooking stove, fuel is saved by 10-15% compared with common gasifiers, and the gas is to easy ignite, has the advantages of sufficient combustion, no release of harmful gas and energy saving and is environmental friendly.

Owner:北票市圣光秸杆气化炉具厂

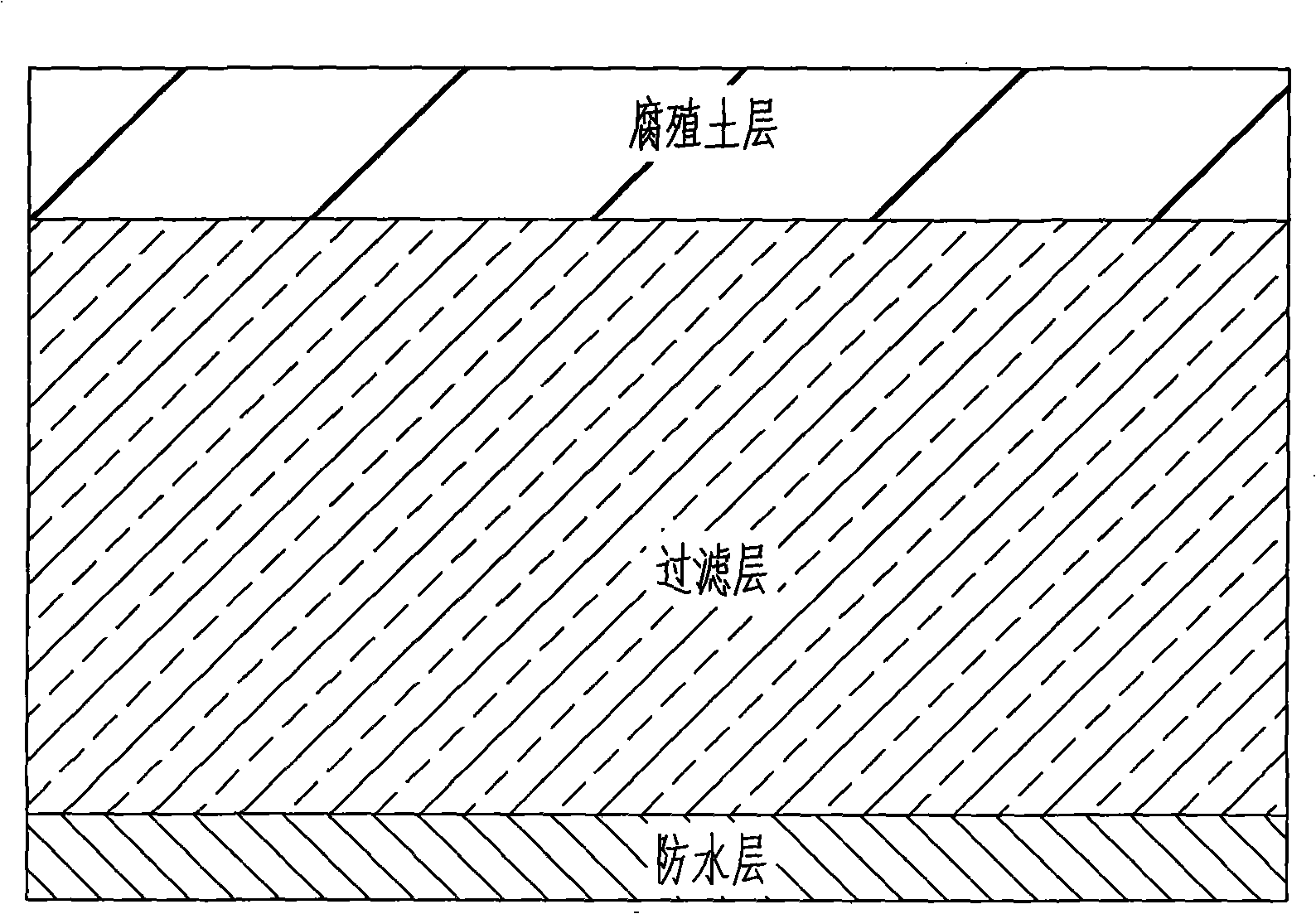

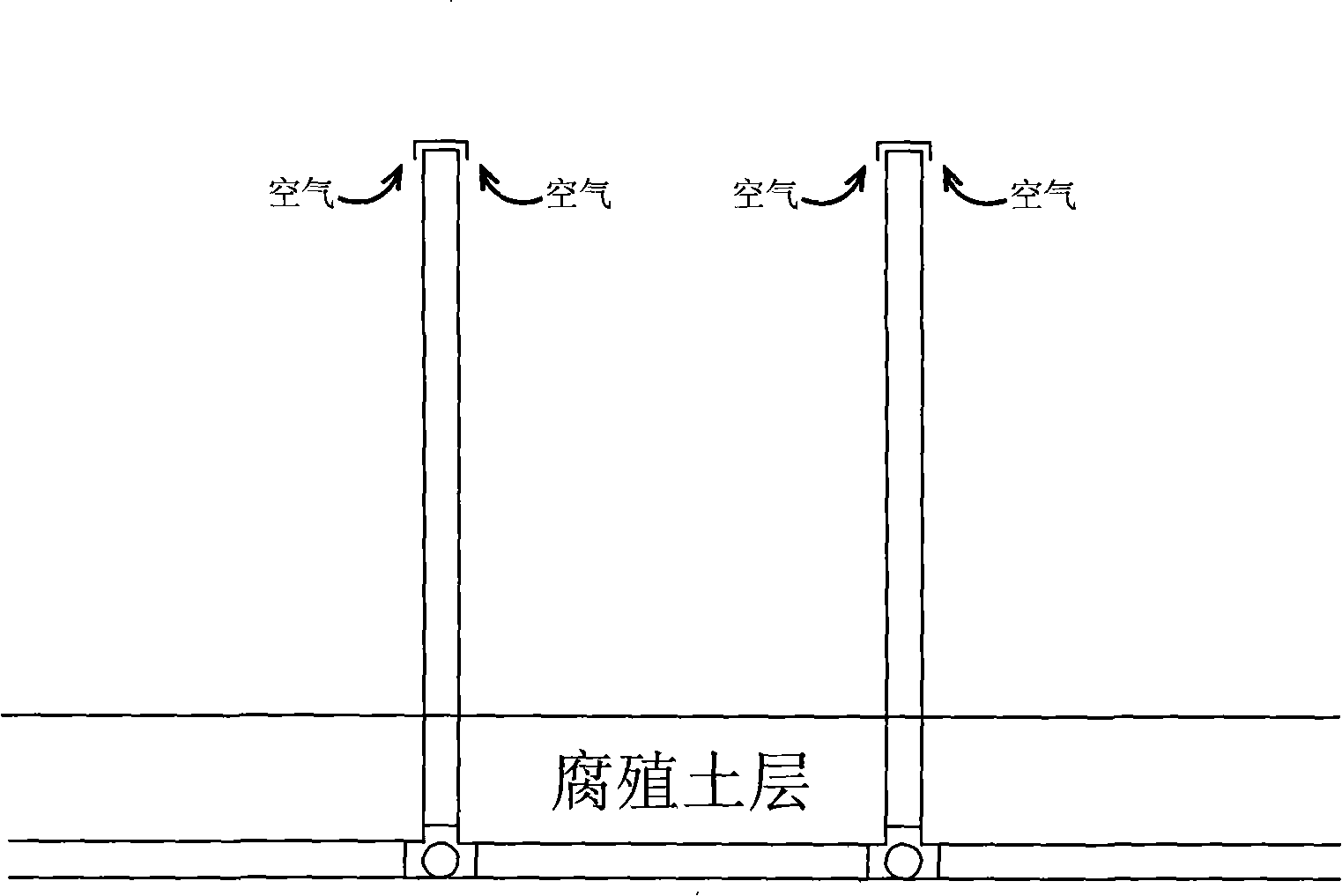

Technique for treating sewage sludge into soil

The invention relates to a sludge treatment process, which discloses a sludge soil-oriented treatment process adopting a sludge soil-oriented pond for sludge treatment, a bottom layer of the sludge soil-oriented pond is a waterproof layer, an upper layer thereof is a filtering layer, the filtering layer includes a sand layer, a sandstone layer and an earthwork cloth layer, a humus soil layer is arranged on the filtering layer, reeds are planted on the humus soil layer, the filtering layer of the sludge soil-oriented pond is provided with a leachate collecting pipeline, and the sludge treatment process comprises the following steps of: discharging the sludge onto the humus soil layer of the sludge soil-oriented pond, stopping the discharge of sludge to the sludge soil-oriented pond after the sludge soil-oriented pond is saturated, and finishing the soil building after the sludge discharged into the sludge soil-oriented pond experiences the stabilization period. The process has advantages of simple process flow, easy management and operation, meanwhile realizing the sludge resource utilization.

Owner:SHANGHAI LIEXING ENVIRONMENTAL PROTECTION TECH

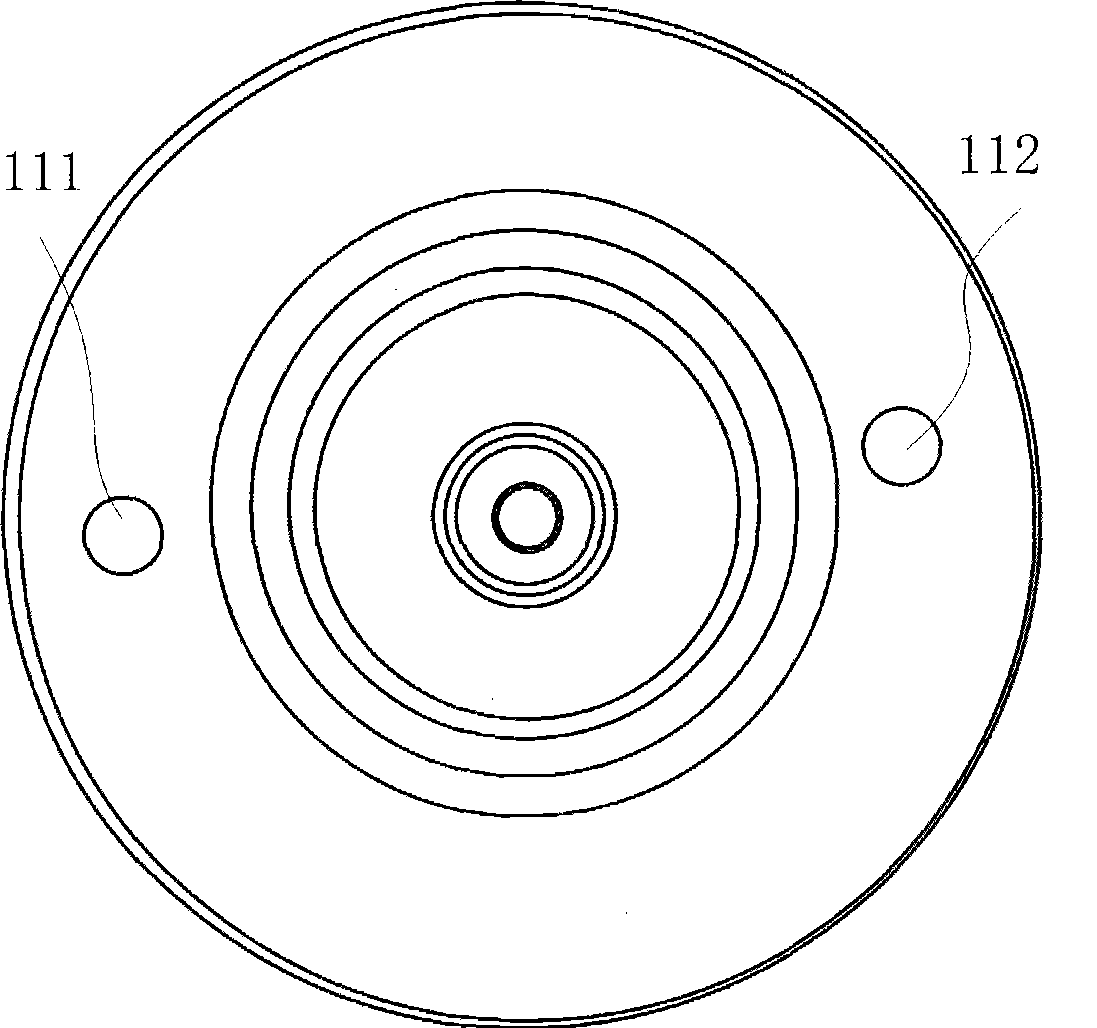

Special-shaped quartz crucible

InactiveCN102011179AReduced shrinkage requirementsLow moisture content requirementBy pulling from meltShrinkage rateAbnormal shaped

The invention provides a special-shaped quartz crucible, comprising a crucible wall and a crucible bottom, wherein the crucible wall and the crucible bottom are integrated, the crucible bottom is of a plane shape, and the cross section of the crucible wall is of regular polygon. In the invention, because of regular hexagon design, the single surface area of a regular hexagon is lessened as compared with the single surface area of a quadrangle in the same volume, and the requirement of the shrinkage rate of a gypsum mould is reduced; and simultaneously because the area of the single surface is lessened, the requirement of the water-containing rate of a green body is relatively reduced, the requirement on the shrinkage rate of a heating plate is also reduced, and the heat conversion rate is improved.

Owner:VESUVIUS SOLAR CRUCIBLE SUZHOU

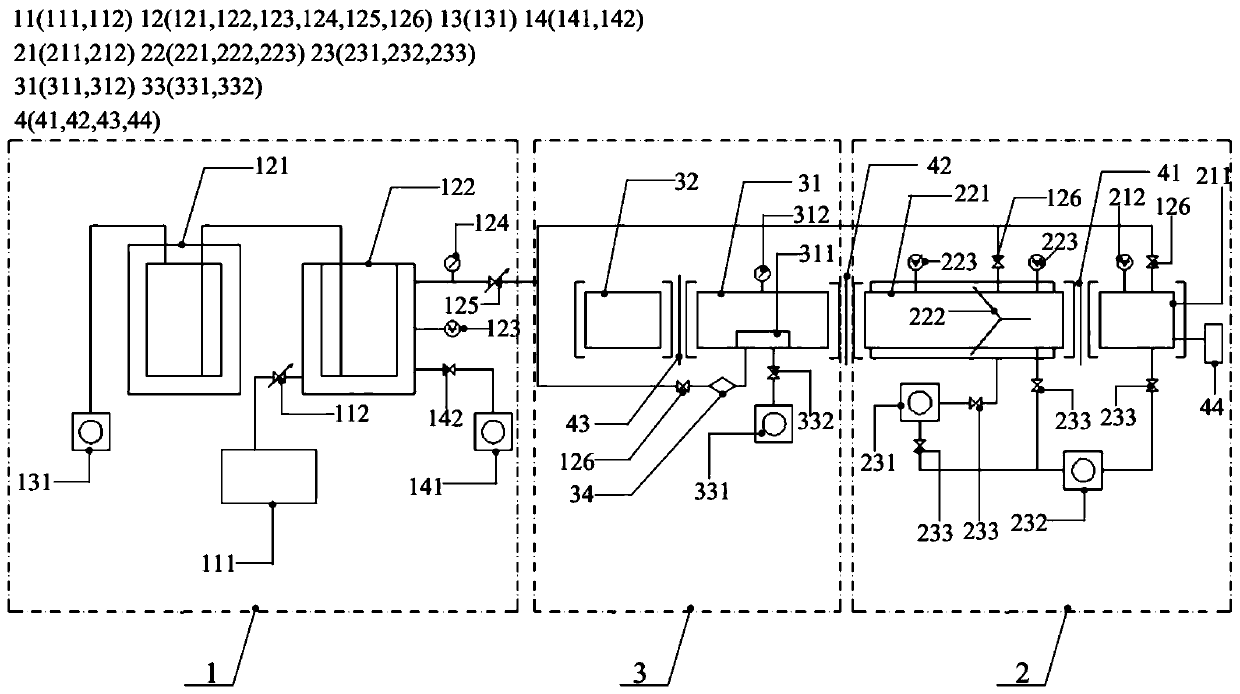

Welding sealing system and welding sealing process

ActiveCN111302299AControl air pressureHigh purityDecorative surface effectsSemiconductor/solid-state device manufacturingThermodynamicsProcess engineering

The invention discloses a welding sealing system. The device comprises a gas filling module, a baking module, a welding module and a conveying module, the vapor content of less than 100PPM in the device can be realized, the internal gas pressure of the packaging body can be controlled within + / -500Pa, the purity of the backfill process gas is ensured to be higher than 99.5%, and the sealing requirements of military special processes such as energy storage welding sealing and the like are met. The four modules of the welding sealing system can operate independently and can also work cooperatively, the automation degree is high, and the mass production requirement can be met. The invention further discloses a welding sealing process, and the welding sealing system is applied, so that energystorage welding sealing of low-water-vapor and high-purity process gas can be realized.

Owner:BEIJING CHENJING ELECTRONICS

Formaldehyde-free membranous wood adhesive and preparation and using methods thereof

ActiveCN103467769BImprove production environmentSimple processFilm/foil adhesivesLaminationSocial benefitsPolymer science

The invention discloses a formaldehyde-free membranous wood adhesive and a preparation method and using method thereof. According to the preparation method, surface grafting modification is carried out on a polymer resin membrane so as to graft various polar groups on a molecular chain, thus obtaining the formaldehyde-free membranous wood adhesive. The adhesive has the advantages of no formaldehyde pollution, simple process, high adhesive strength and the like, is easy to spread, easy to transport and store, and has remarkable economic and social benefits.

Owner:FUZHOU HANYANG ENVIRONMENTAL PROTECTION TECH CO LTD

Method for preparing vegetarian dried meat floss product from cordyceps millitaris fermented glycine max dregs

InactiveCN111374305ASolve the problem of extremely low levelsImprove biological activityFood ingredient as mouthfeel improving agentBiotechnologyCellulose

The invention discloses a method for preparing a vegetarian dried meat floss product from cordyceps millitaris fermented glycine max dregs. A glycine max processing byproduct, namely glycine max dregs, is adopted as a raw material, through solid fermentation, flavor blending and frying with cordyceps millitaris, contents of two soy isoflavones, namely daidzein and glycitein, can be remarkably increased, the content of insoluble cellulose can be reduced, and the vegetarian dried meat floss product which is rich in aglycone isoflavones, proteins and edible fungi, is cotton-like and fluffy and has sensitive, physical and chemical and microorganism indexes similar to those of dried meat floss is prepared. The product prepared by using the method is "natural, nutrient and low-grease", and expectation of different customers on nutrient and healthy foods can be met. Solid fermentation used in the method is a traditional and modern biological technology, is efficient and low-carbon, good in applicability and simple to operate, and is free of secondary sterilization; the cordyceps millitaris can be used as an edible fungus, the mycelia of the cordyceps millitaris is rich in nutrition, and the flavor and the drawing feeling of the product can be also improved. By adopting the method, the nutrition and functional value of the vegetarian dried meat floss leisure food can be effectively intensified, and great significances in increasing additional values of the vegetarian dried meat floss product and promoting comprehensive utilization of the glycine max dregs can be achieved.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

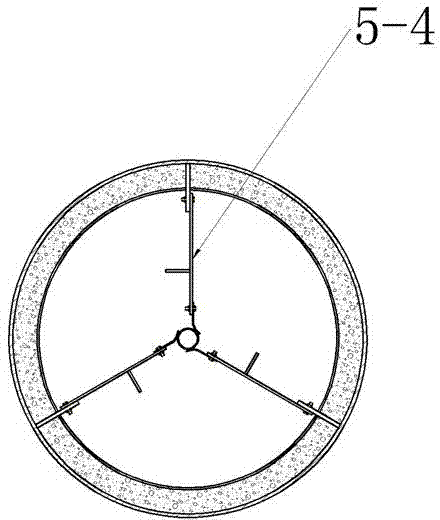

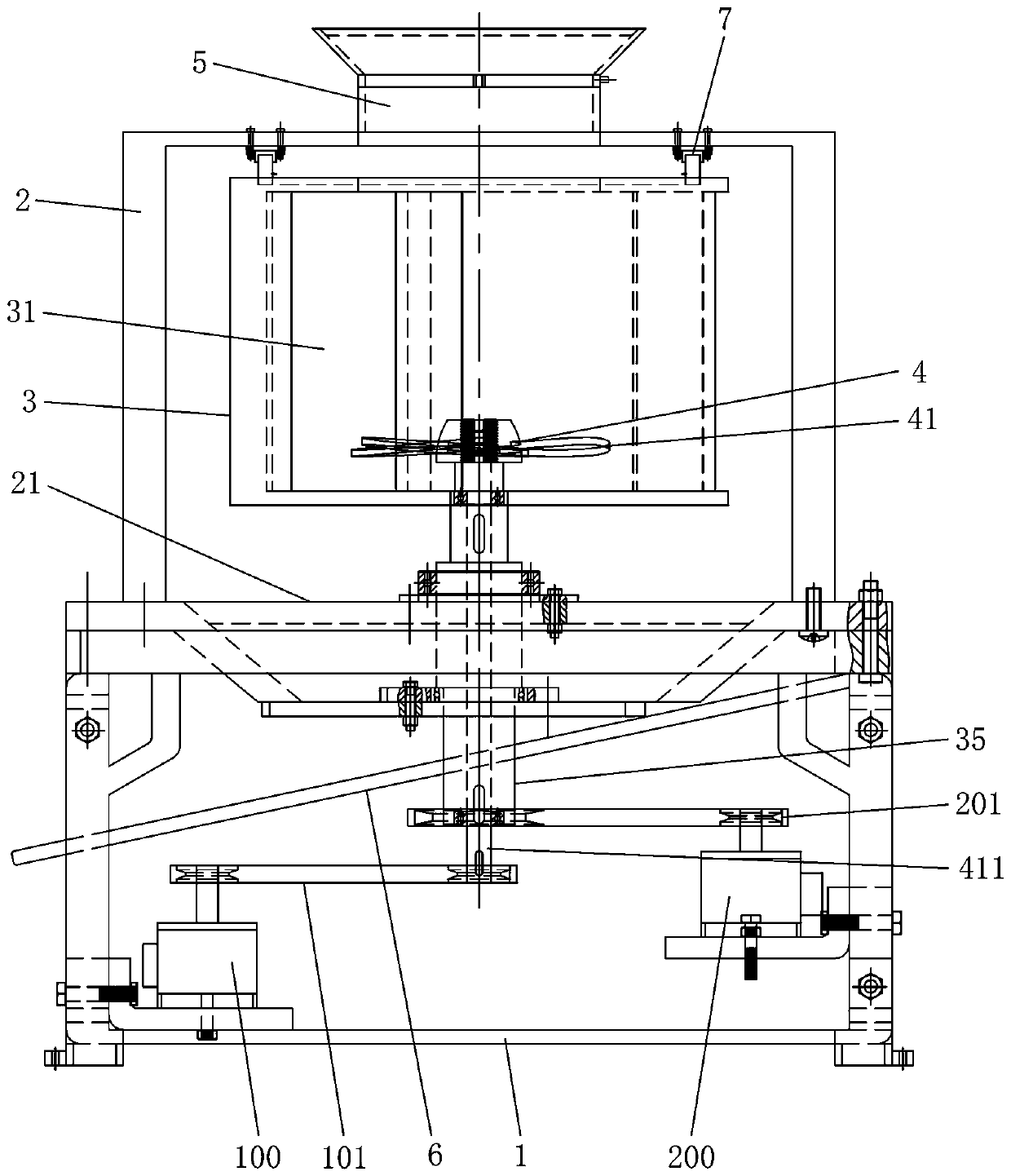

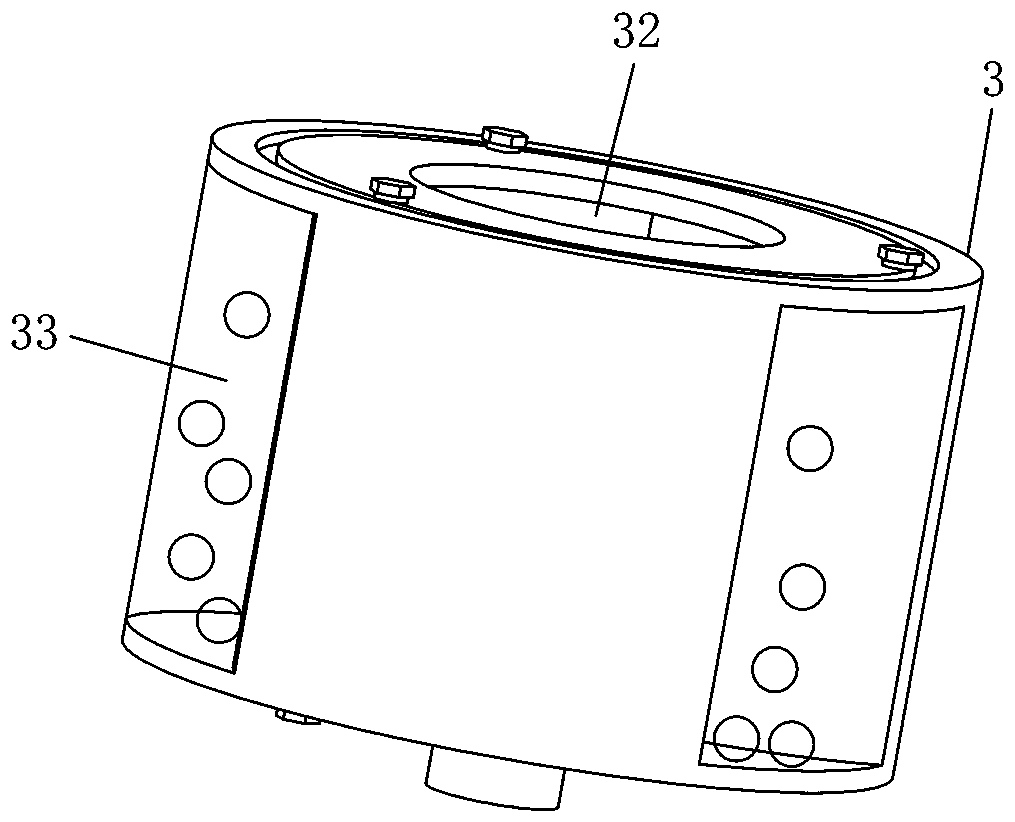

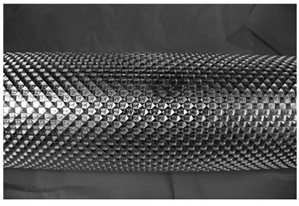

Biomass toothed pressing wheel rolling-type forming machine and forming method

PendingCN109895442ASimple equipment structureEasy to maintainShaping pressBiomassMechanical engineering

The invention discloses a biomass toothed pressing wheel rolling-type forming machine. The biomass toothed pressing wheel rolling-type forming machine comprises a machine seat, a material bin, a transmission spindle, an extrusion device, an annular fixed mold and a driving device, the machine seat is provided with a hollow part, the hollow part of the machine seat is internally provided with the driving device, the material bin is arranged above the machine seat, the transmission spindle is fixed into the hollow part of the machine seat through two or more sets of bearings in axially and radially positioned modes, the lower end of the transmission spindle is connected with the driving device, the upper end of the transmission spindle is connected with the extrusion device, the extrusion device is connected to the transmission spindle in a sleeving mode and located on the upper part of the machine seat, both a feeding device and the extrusion device rotate along with the transmission spindle, the annular fixed mold is arranged at the position, corresponding to the extrusion device, of the lower part of the material bin, the annular fixed mold is fixed to the position above the machine seat, and the annular fixed mold and the extrusion device are connected in an engaged mode. The biomass toothed pressing wheel rolling-type forming machine is simple in structure, convenient to maintain, convenient to operate, stable in product quality, capable of realizing energy saving, long in mold life, and a forming method of the biomass toothed pressing wheel rolling-type forming machineis wide in raw material applicability.

Owner:沈阳燃料设备制造安装有限公司

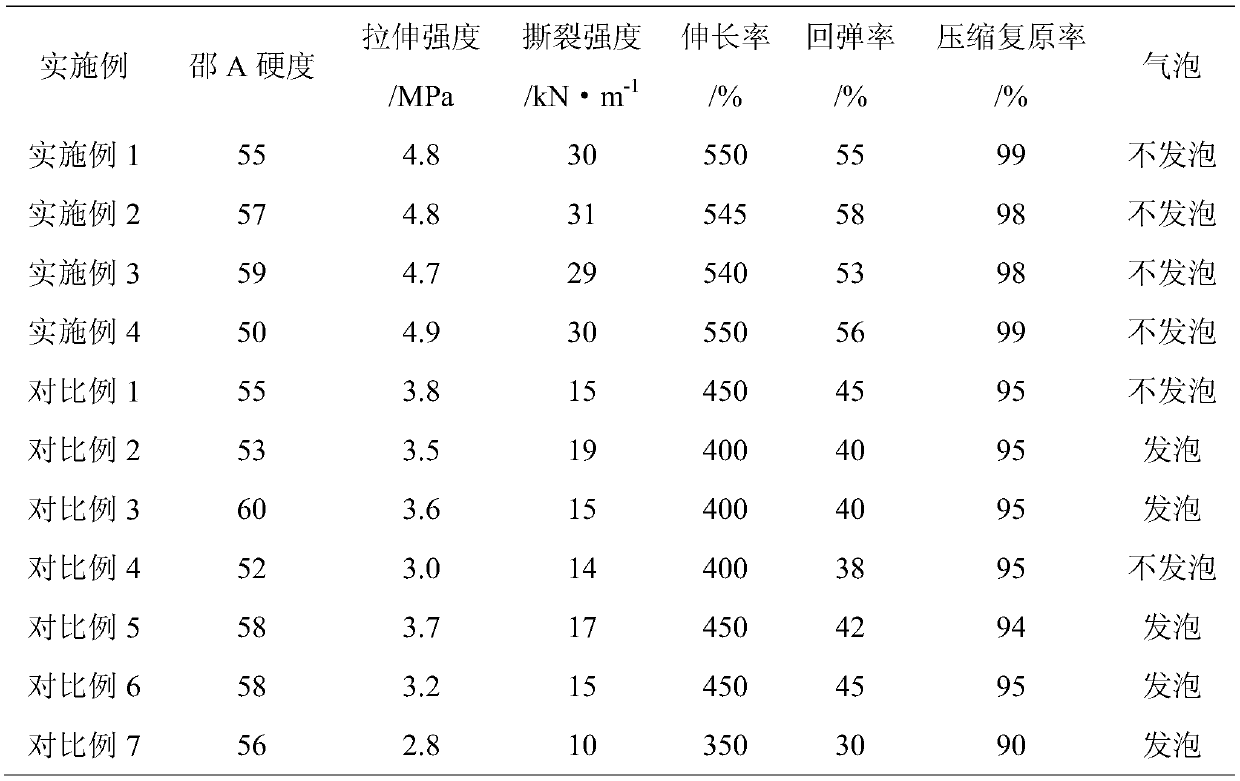

Polyurethane track made of polyurethane fiber waste and preparation method thereof

The invention provides a polyurethane track which is composed of a prepolymer component A and a curing agent component B. The prepolymer component A is prepared from, by weight, 25-40 parts of MDI and 45 parts of polyether polyol. The curing agent component B is prepared from, by weight, 5-15 parts of polyether binary alcohol, 10-20 parts of polyether-tribasic alcohol, 5-10 parts of a chain extender, 15-30 parts of a plasticizer, 15-30 parts of filling, 5-10 parts of pigment, 0.5-2 parts of a catalyst, 1-5 parts of an additive and 50-60 parts of polyurethane fiber waste. By adding the polyurethane fiber waste in the formula, sport injuries caused by tumbling can be avoided, the polyurethane track is good in compatibility and strong in adhesive strength, avoids the phenomena of bubbles, stripping and the like, resists impact force, is high in elastic recovery rate, has the wear resistance smaller than 2.5%, meets the requirements for long-time and high-frequency using, absorbs impact force rapidly and is suitable for long-time training and competition. Due to the fact that the polyurethane fiber waste is added in the preparation process, the requirement for the water content in components of a curing agent is low, and the requirement for technological conditions is low and not harsh.

Owner:JIANGSU QIAOXIN FIBER

A kind of film adhesive and its preparation method and application

ActiveCN112646500BNo pollution in the processDegradable excellentWood veneer joiningFilm/foil adhesives without carriersPolymer scienceAdhesive

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

A method for preventing sticking of tobacco sheets

ActiveCN110742298BEasy to shapeIncrease pressure resistanceTobacco preparationTobacco treatmentEngineeringBiology

A method for preventing sticking of tobacco sheets disclosed in the present invention comprises the following steps: spraying a protective agent on the tobacco sheets and drying them, shaping the tobacco sheets, reducing the contact area of the sheets, increasing the pressure resistance elasticity of the sheets, and increasing the The film-forming properties between the sheets block the molecular movement of the contact surface of the tobacco sheets, and can also reduce the moisture content in the tobacco sheets to reduce adhesion.

Owner:HUBEI CHINA TOBACCO IND +1

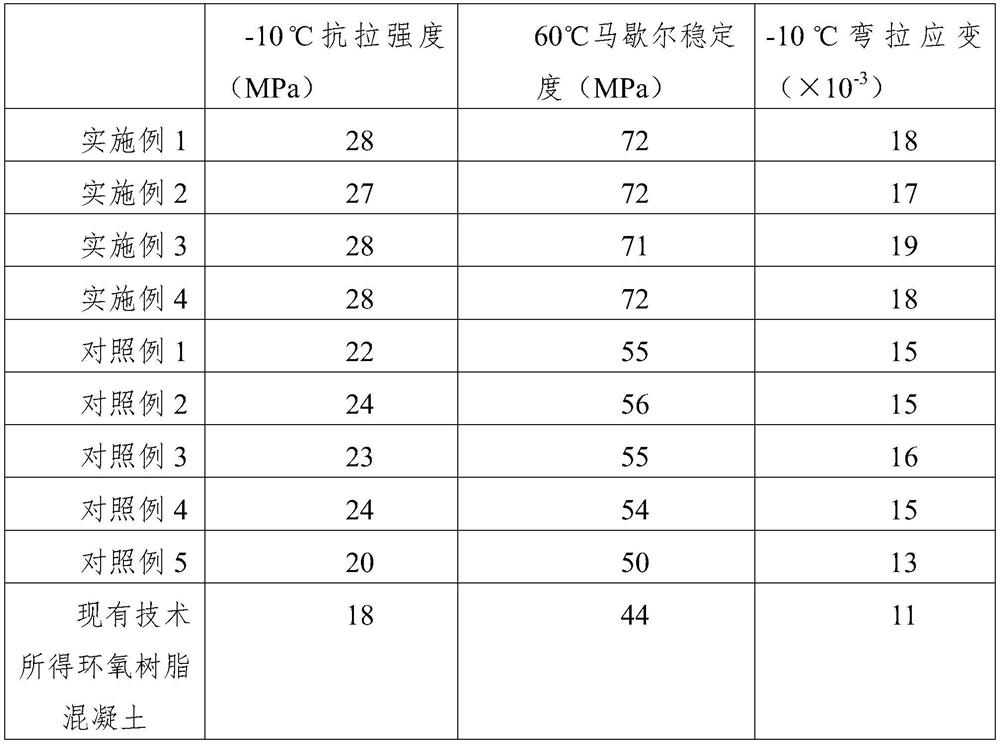

Epoxy resin concrete for grouting of bridge expansion joints and road-bridge joints

Owner:石家庄广科新材料有限公司

A kind of polyurethane runway using spandex waste silk as raw material and its preparation method

The invention provides a polyurethane track which is composed of a prepolymer component A and a curing agent component B. The prepolymer component A is prepared from, by weight, 25-40 parts of MDI and 45 parts of polyether polyol. The curing agent component B is prepared from, by weight, 5-15 parts of polyether binary alcohol, 10-20 parts of polyether-tribasic alcohol, 5-10 parts of a chain extender, 15-30 parts of a plasticizer, 15-30 parts of filling, 5-10 parts of pigment, 0.5-2 parts of a catalyst, 1-5 parts of an additive and 50-60 parts of polyurethane fiber waste. By adding the polyurethane fiber waste in the formula, sport injuries caused by tumbling can be avoided, the polyurethane track is good in compatibility and strong in adhesive strength, avoids the phenomena of bubbles, stripping and the like, resists impact force, is high in elastic recovery rate, has the wear resistance smaller than 2.5%, meets the requirements for long-time and high-frequency using, absorbs impact force rapidly and is suitable for long-time training and competition. Due to the fact that the polyurethane fiber waste is added in the preparation process, the requirement for the water content in components of a curing agent is low, and the requirement for technological conditions is low and not harsh.

Owner:JIANGSU QIAOXIN FIBER

A kind of continuous production process of 3,6-dichlorosalicylic acid

ActiveCN105801397BReduced moisture requirementsImprove one-way yieldOrganic compound preparationCarboxylic compound preparationReaction systemOrganic chemistry

The invention relates to a continuous production process of 3,6-dichlorosalicylic acid, and belongs to the technical field of the synthesis of a herbicide dicamba intermediate. A specific continuous production process and a specific continuous production system are adopted, harsh requirements on the water content of a reaction system can be lowered, coking is reduced, equipment investment cost is lowered, efficiency is high, and continuous production is realized. The process disclosed by the invention lowers the harsh requirements on the water content of the reaction system, can meet reaction requirements if the water content is below 2000ppm, and has the advantages of high once through yield, high selectivity and little coking. When the process disclosed by the invention is adopted, the yield is above 55%, and the selectivity is above 96%.

Owner:SICHUAN FOURSTAR BIOTECH RANDD CORP

Iron powder cold-pressed pellets non-drying adhesive

The invention discloses a drying-free bonding agent for iron powder cold pressing pellets. The drying-free bonding agent comprises, by weight, 30-70 parts of starch, 5-20 parts of methyl cellulose ether, 15-25 parts of aluminosilicate, 10-20 parts of xanthan gum, 1-5 parts of silica and 1-10 parts of epoxy silane modified polybenzimidazole prepoly. The bonding agent is suitable for the iron ore powder and iron-containing dust cold pressing pellet field.

Owner:LUANXIAN YONGHENG ADHESIVE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com