Method for refining long-carbon chain dicarboxylic acid

A long-chain dibasic acid and dibasic carboxylic acid technology, which is applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of harsh moisture requirements, large steam consumption, acetic acid loss, etc., and reduce the moisture content of raw materials Requirements, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

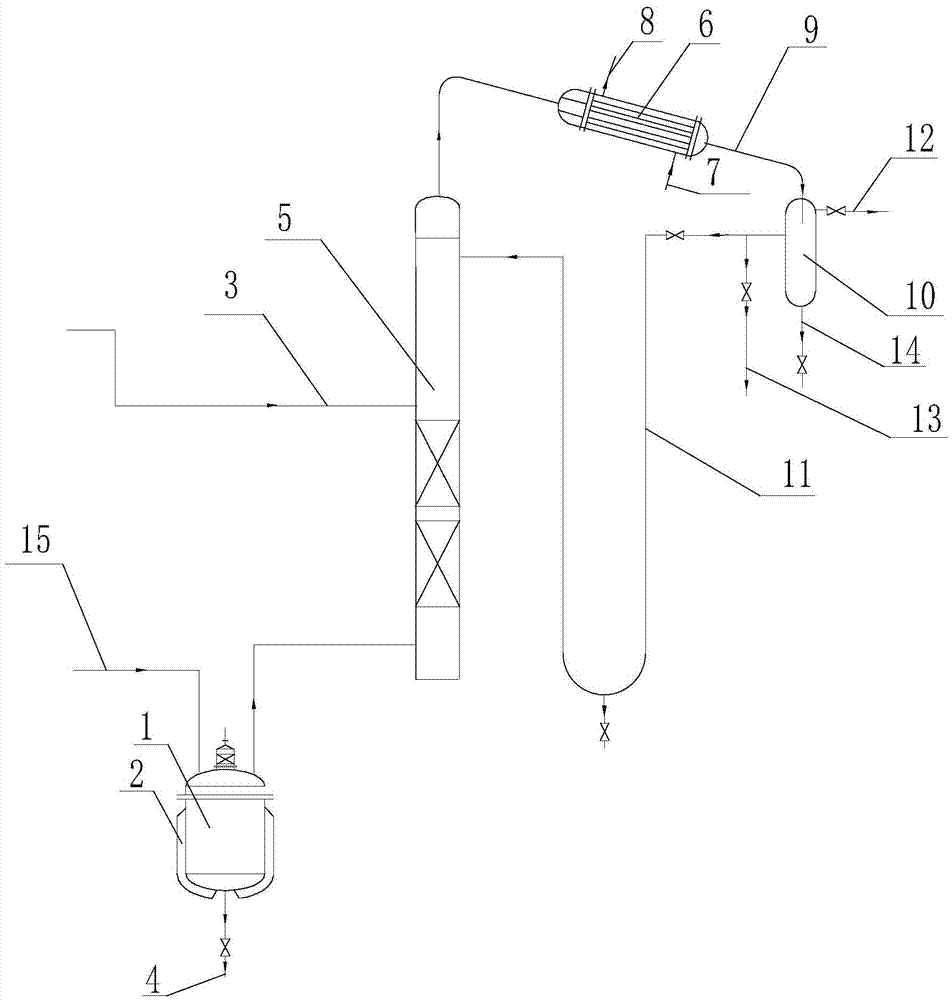

Method used

Image

Examples

Embodiment 1

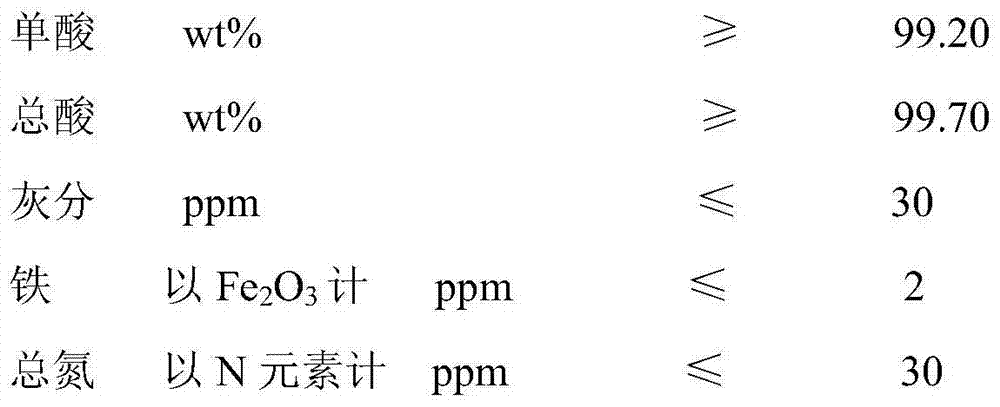

[0073] A kind of refining method of dodecanedioic acid of the present invention

[0074] Add 700kg of dodecanedioic acid (water content 23%) and 4kg of activated carbon into 2000L of acetic acid solution with a purity of 98%, stir and heat up to 95°C, keep warm for half an hour for decolorization, and the dibasic acid solution obtained by plate and frame filtration enters the crystallization kettle , quickly and uniformly cool down to 85°C in the crystallization tank, control the cooling time for 1 hour, turn off the cooling water, and naturally cool down for 1 hour, the temperature in the crystallization tank reaches 80°C, turn on the cooling water and cool down to 25°C, the cooling speed gradually increases from slow, Control the cooling time for 4-5 hours. The crystal liquid is centrifuged and separated, and the material in the centrifuge is rinsed with 1800L of isopropyl acetate with a purity of 98%. After the rinse is completed, it is centrifuged for 15 minutes to obtain ...

example 2

[0076] A kind of recycling method of dodecanedioic acid refining solvent of the present invention

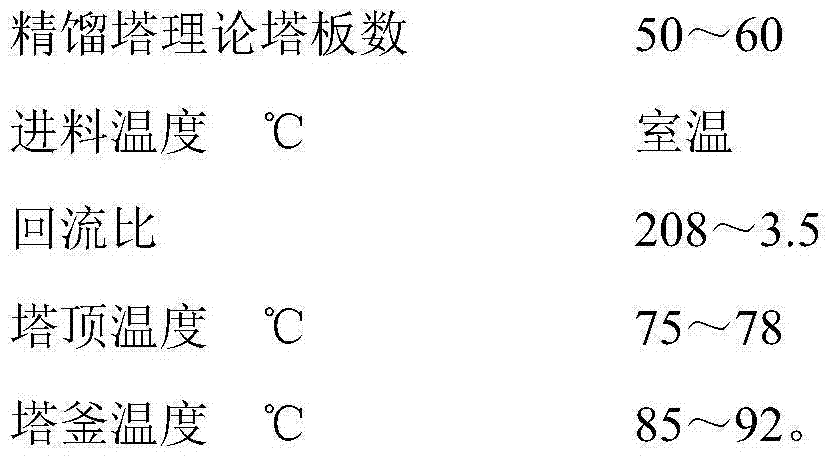

[0077] After mixing the centrifugal mother liquor 1800L obtained in Example 1 and the washing liquid 1750L, feed continuously to the middle part of the rectification column for rectification operation. During the rectification process, the temperature at the top of the tower was controlled at 77°C, and the reflux ratio was 3.2. After the azeotrope extracted from the top of the rectification tower is stratified, 1700L of the oil phase is recycled into the azeotrope storage tank. The measured purity of isopropyl acetate is 97.00%, the water content is 2.48%, and the acetic acid content is 0.52%, which can be continued. Detergent: get 200L of water phase, go to the evaporator for treatment, evaporate 5.8L of azeotrope, return it to the azeotrope storage tank, and the measured cod value of the wastewater in the evaporator is 62. The heavy component of acetic acid in the rectificati...

example 3

[0079] A kind of refining method of dodecanedioic acid of the present invention

[0080] 700kg of dodecanedioic acid (water content 22%) and 4kg of activated carbon were added in the 1780L acetic acid solution obtained in Example 2, stirred and heated up to 95°C, kept for half an hour for decolorization, and the dibasic acid solution obtained by plate and frame filtration entered the crystallization kettle , quickly and uniformly cool down to 85°C in the crystallization tank, control the cooling time for 1 hour, turn off the cooling water, and naturally cool down for 1 hour, the temperature in the crystallization tank reaches 80°C, turn on the cooling water and cool down to 25°C, the cooling speed gradually increases from slow, Control the cooling time for 4-5 hours. The crystallization liquid is centrifuged, and the 1705.8L isopropyl acetate solution recovered by Example 2 is used to rinse the material in the centrifuge. After the rinse is completed, it is centrifuged for 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com