Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Increase the conductive contact area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

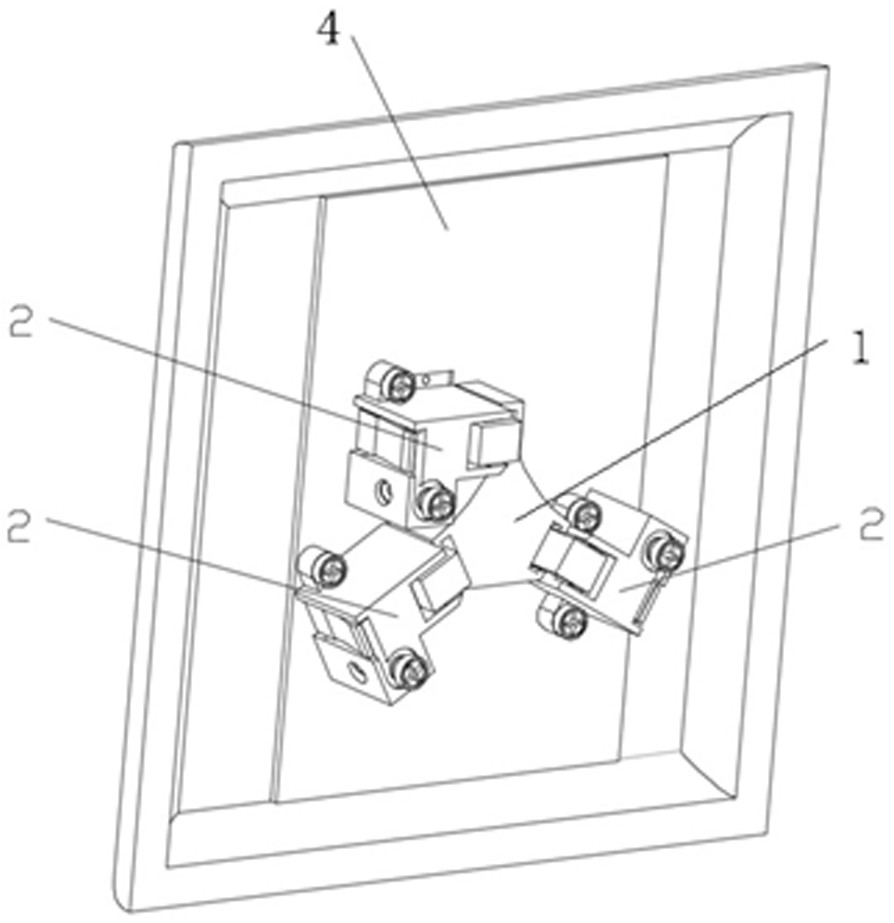

A terminal connection structure

The present invention relate to the field of power tool, in particular to a terminal connection structure, comprises a connecting seat and a two-action chuck, A plug hole is arranged on the connectingseat, A movable chuck comprises a splint and an elastic pressing member, the splints of the two moving chucks are respectively articulated with the connecting seat, As that two end of the two elasticpressing member abut on the connecting seat and the corresponding splint respectively, the clam ends of the two splints are pressed against each other to clamp the terminal, the clamping end includessuccessively arranged inlet segments, a flat pressure section and an anti-disengagement section, wherein the inlet section is raised in the opposite direction to the pressing direction so as to facilitate insertion of the terminal, the flat pressure section is a planar structure capable of abutting against the pressing of the terminal and forming an electrically conductive contact surface with the terminal, and the anti-disengagement section is provided with barbs inclined in the insertion direction of the terminal for hooking the terminal to prevent disengagement of the terminal; The terminal connection structure has the advantages of convenient operation, firm connection, tight contact of the conductive contact surface and no gap.

Owner:GUANGZHOU PANYU CABLE WORKS

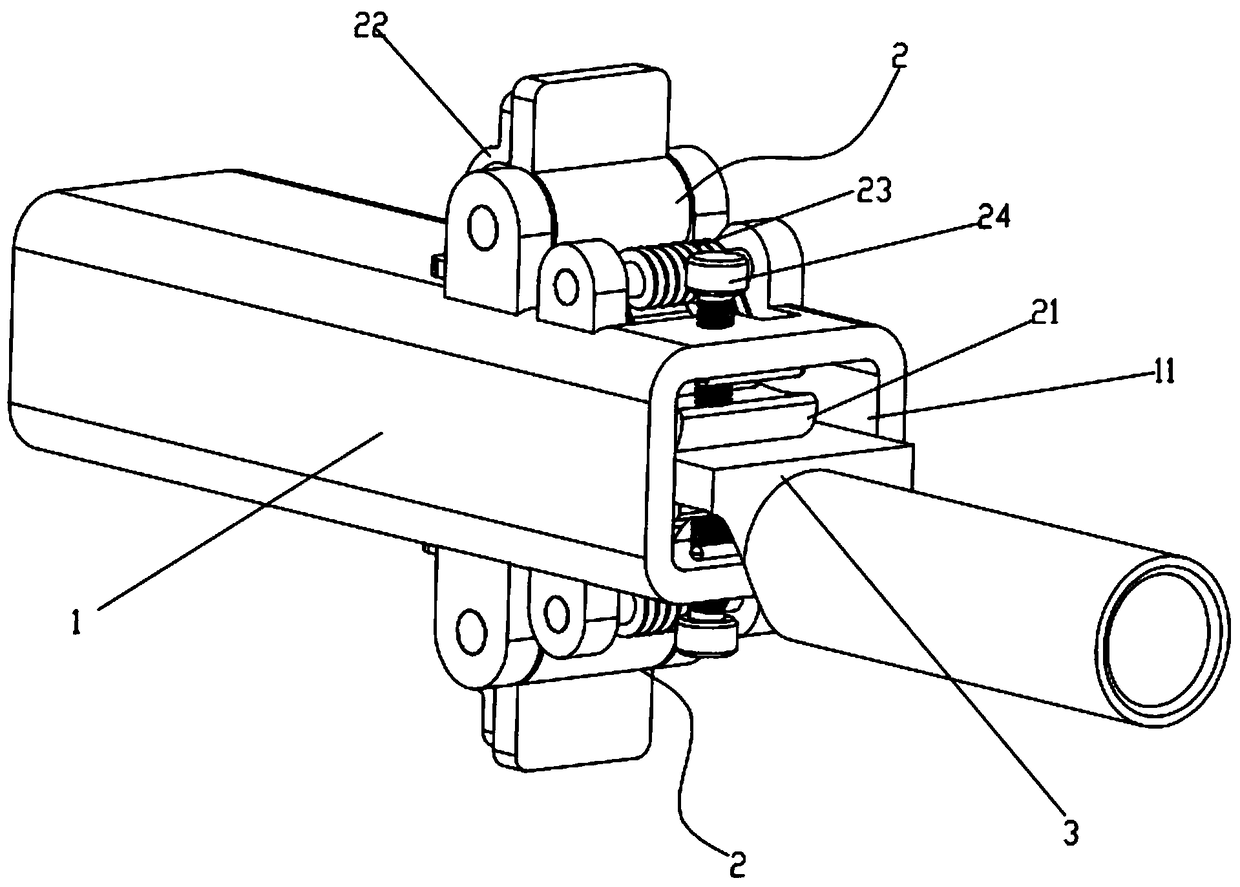

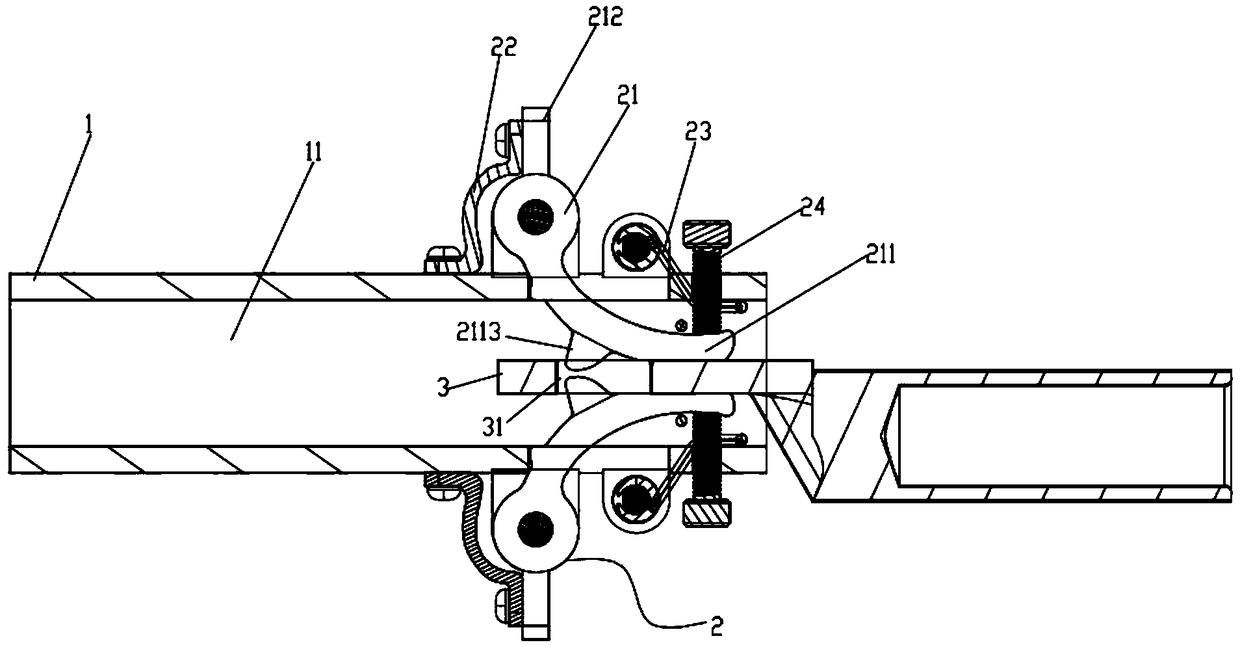

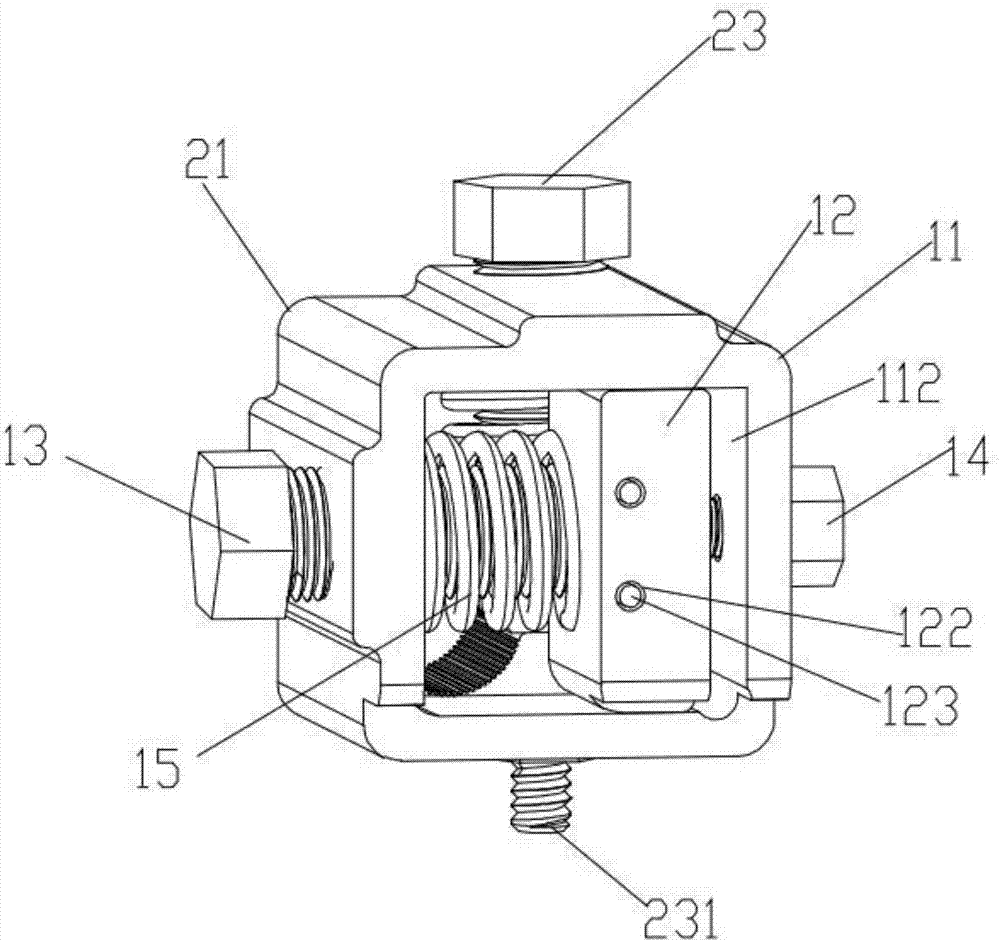

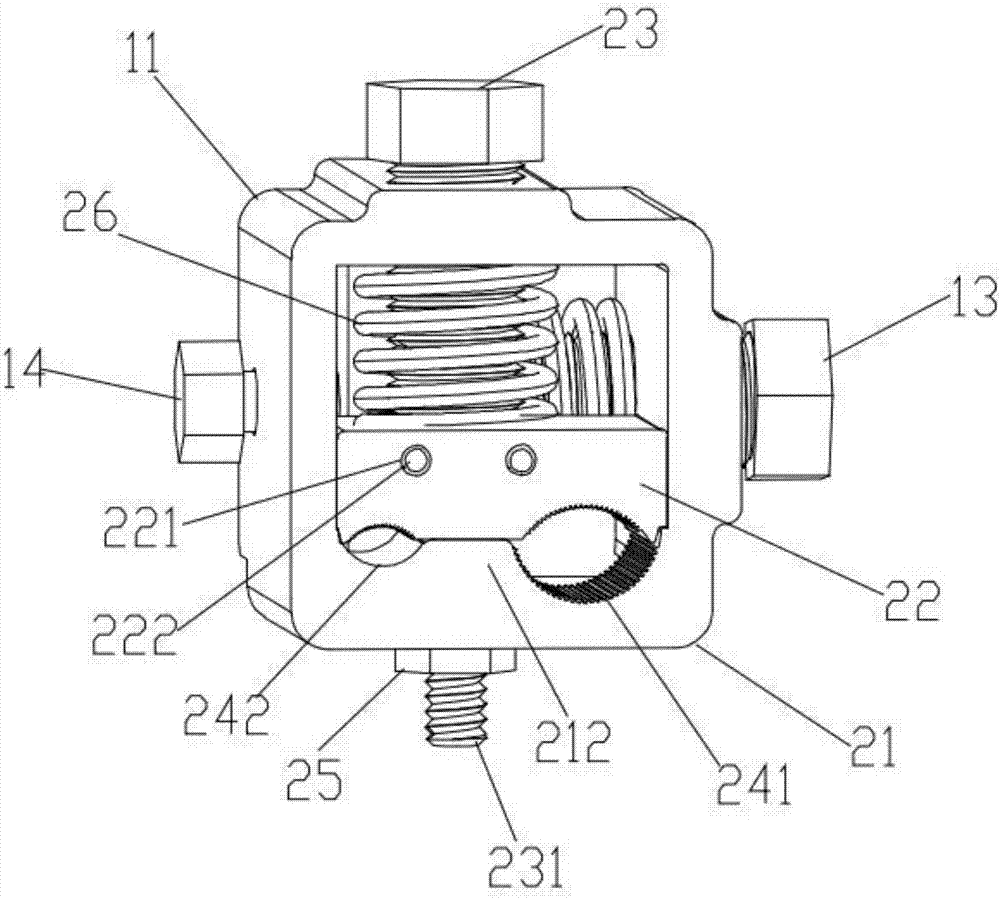

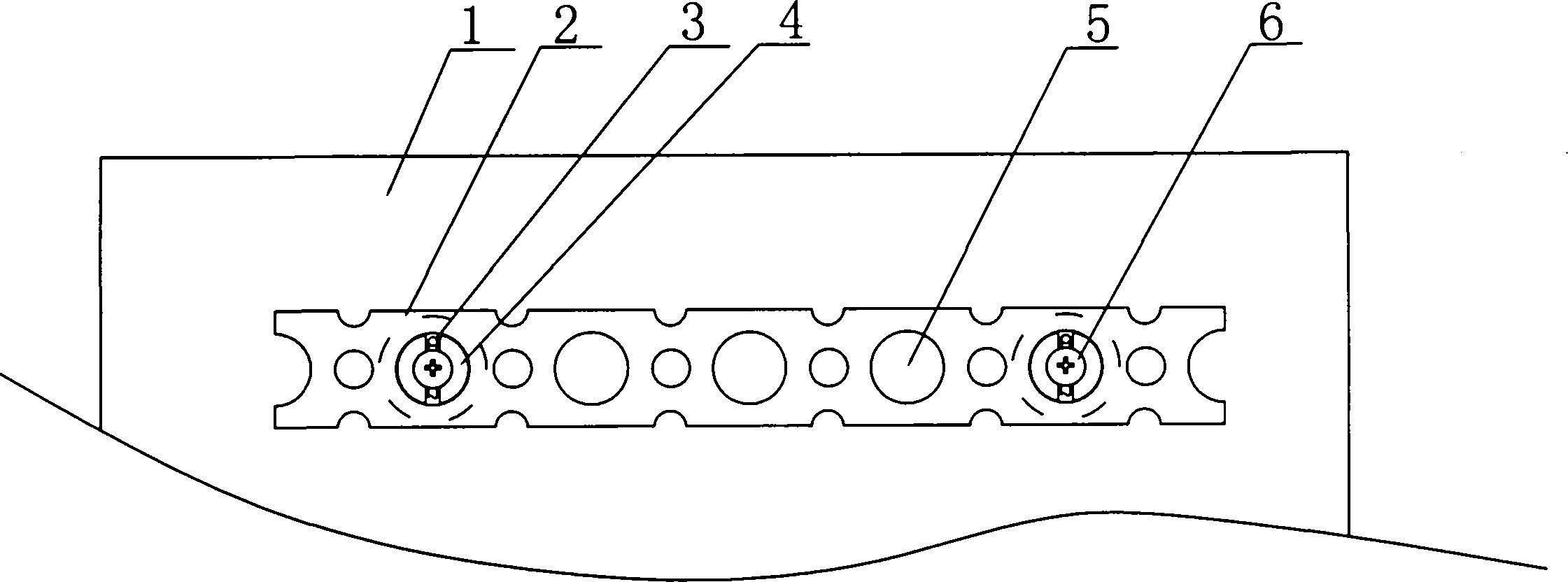

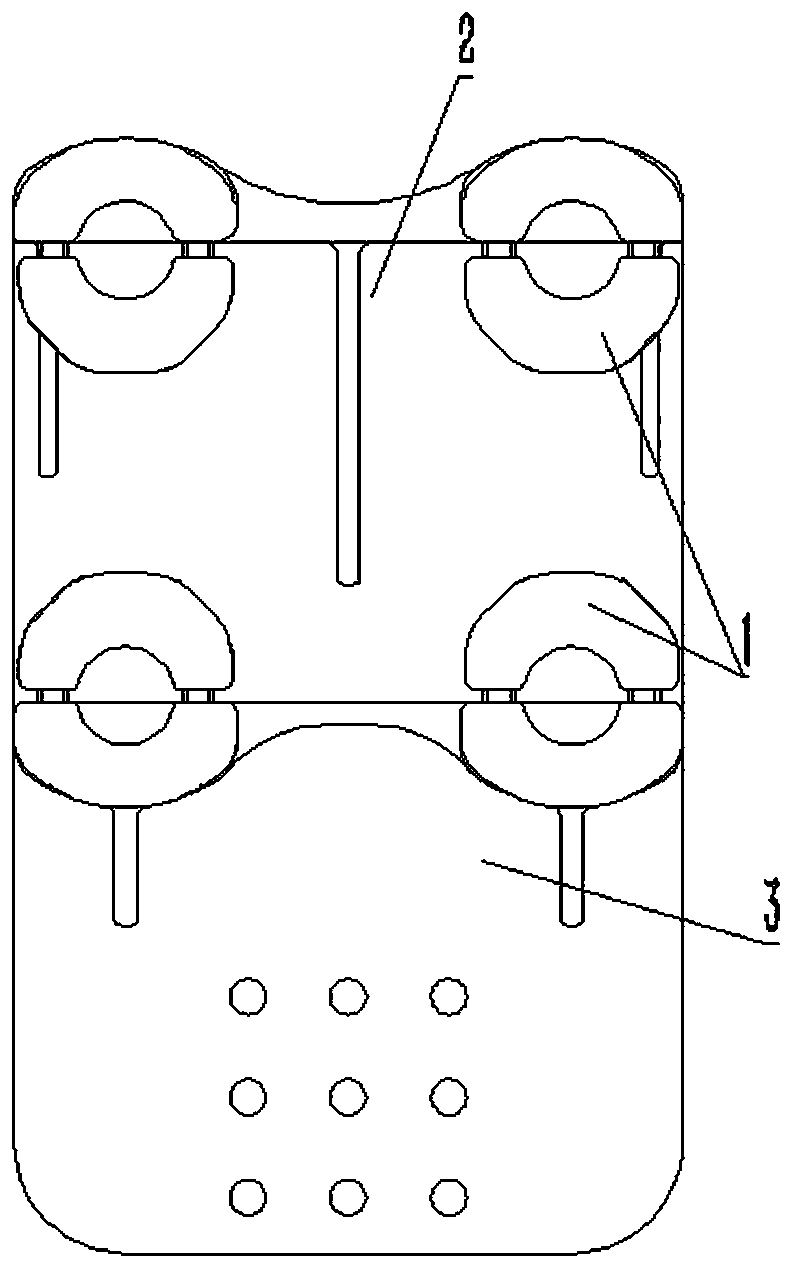

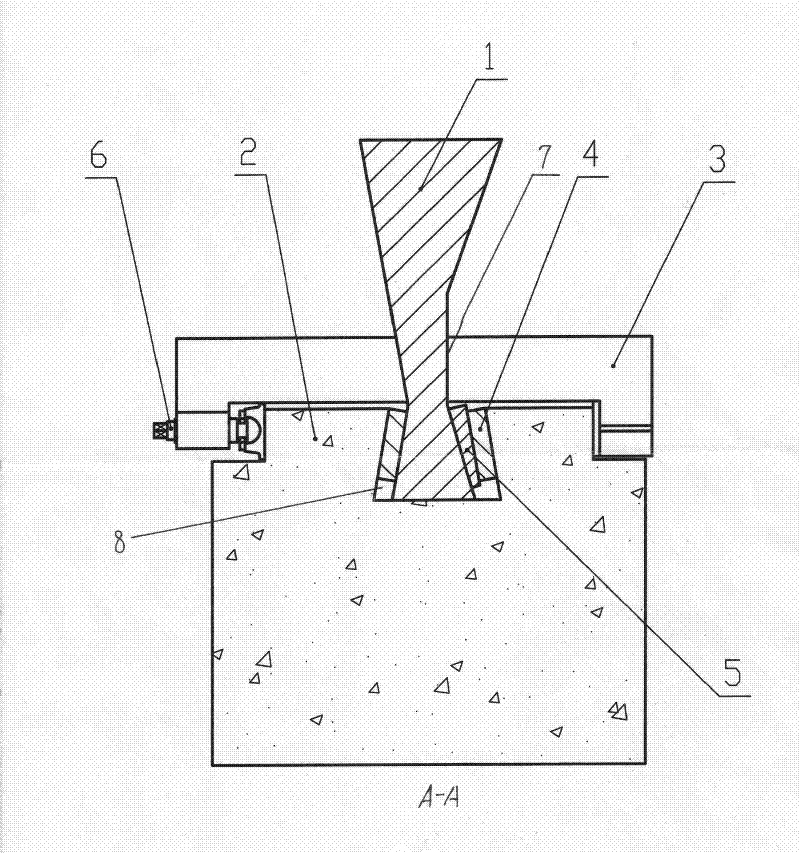

Anti-loose type equipment clamp

ActiveCN107404014APrevent looseningPrevent slipping outClamped/spring connectionsMultiple conductors connectorScrew threadElectric cables

The present invention relates to the technical field of the equipment clamp, in particular to an anti-loose type equipment clamp. The anti-loose type equipment clamp comprises an equipment clamp and a cable clamp. The equipment clamp comprises an equipment clamp body, a dynamic pressure plate, a fastening bolt and a check bolt; the fastening bolt is also provided a reverse internal thread hole; the check bolt is provided with a reverse external thread; the equipment clamp body is provided with a fastening thread hole and a static pressure plate that are arranged opposite to each other; the fastening bolt passes through the fastening thread hole and is rotatably connected with the dynamic pressure plate; and the check bolt is inserted into the fastening bolt and connected with the reverse thread of the fastening bolt. The cable clamp comprises a cable clamp body, a dynamic clamp head and a locking bolt; the cable clamp body is provided with a locking thread hole and a static clamp head that are arranged opposite to each other; the locking bolt passes through the locking thread hole and is rotatably connected with the movable clamp head; and the dynamic clamp head and the static clamp head are provided with pressure grooves. Beneficial effects of the loose type equipment clamp provided by the present invention are that the conductive contact area between the equipment terminal and the equipment clamp is large, installation is firm, the contact surface is hard to generate a gap, and the safety and reliability are ensured.

Owner:GUANGZHOU PANYU CABLE WORKS

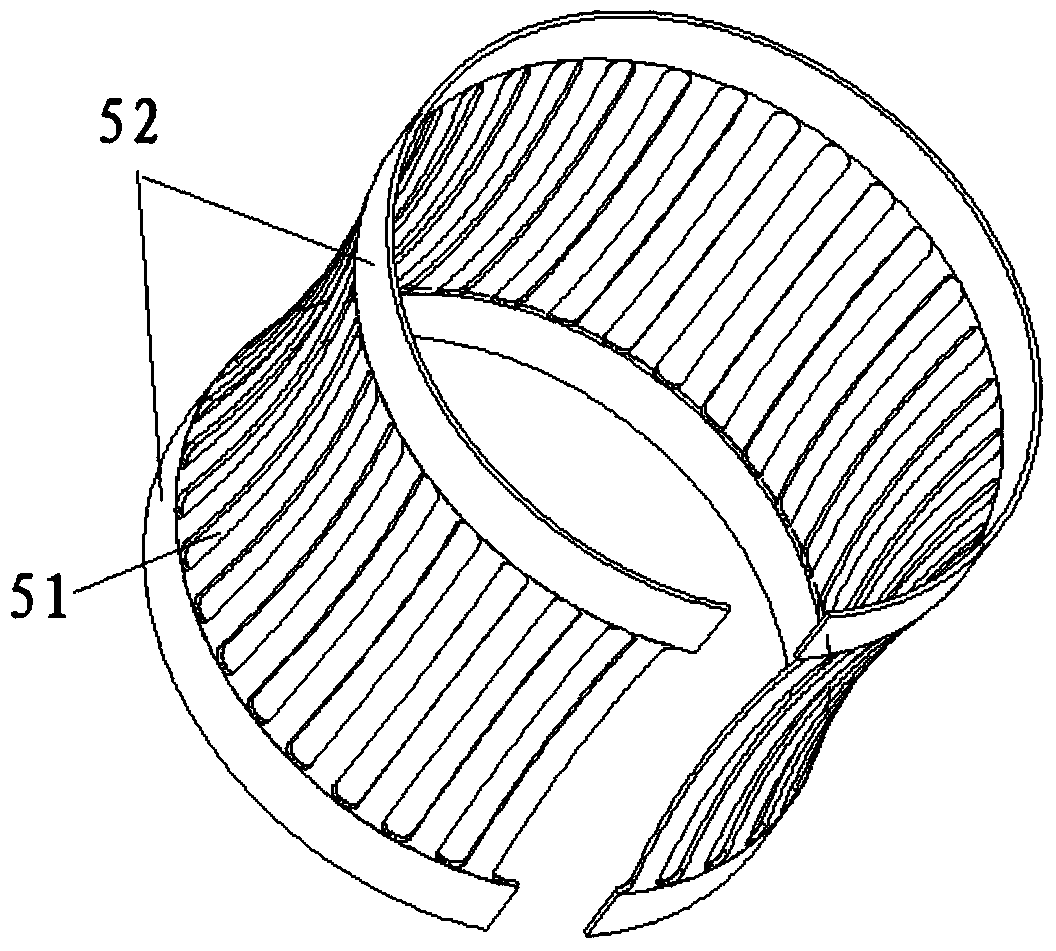

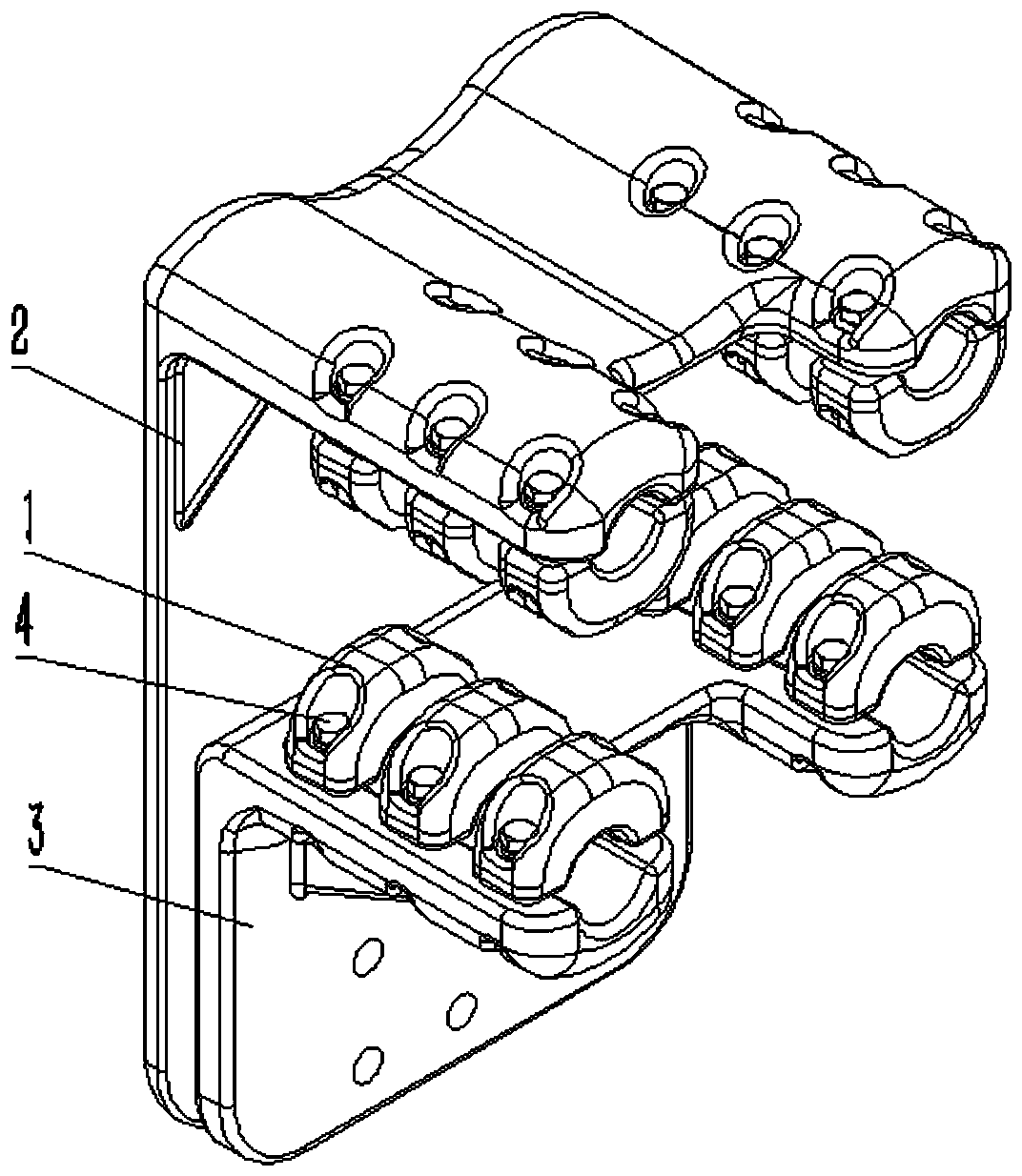

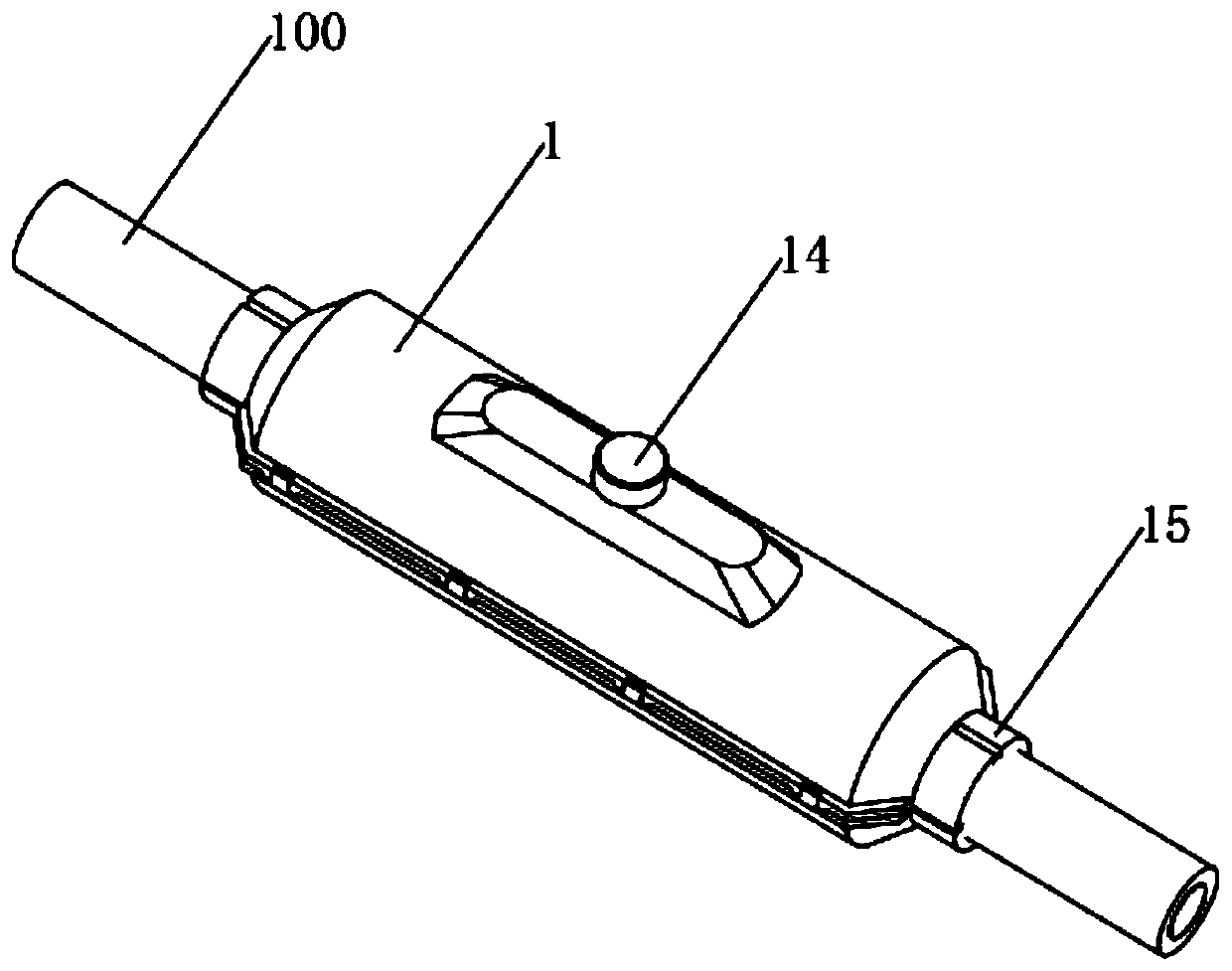

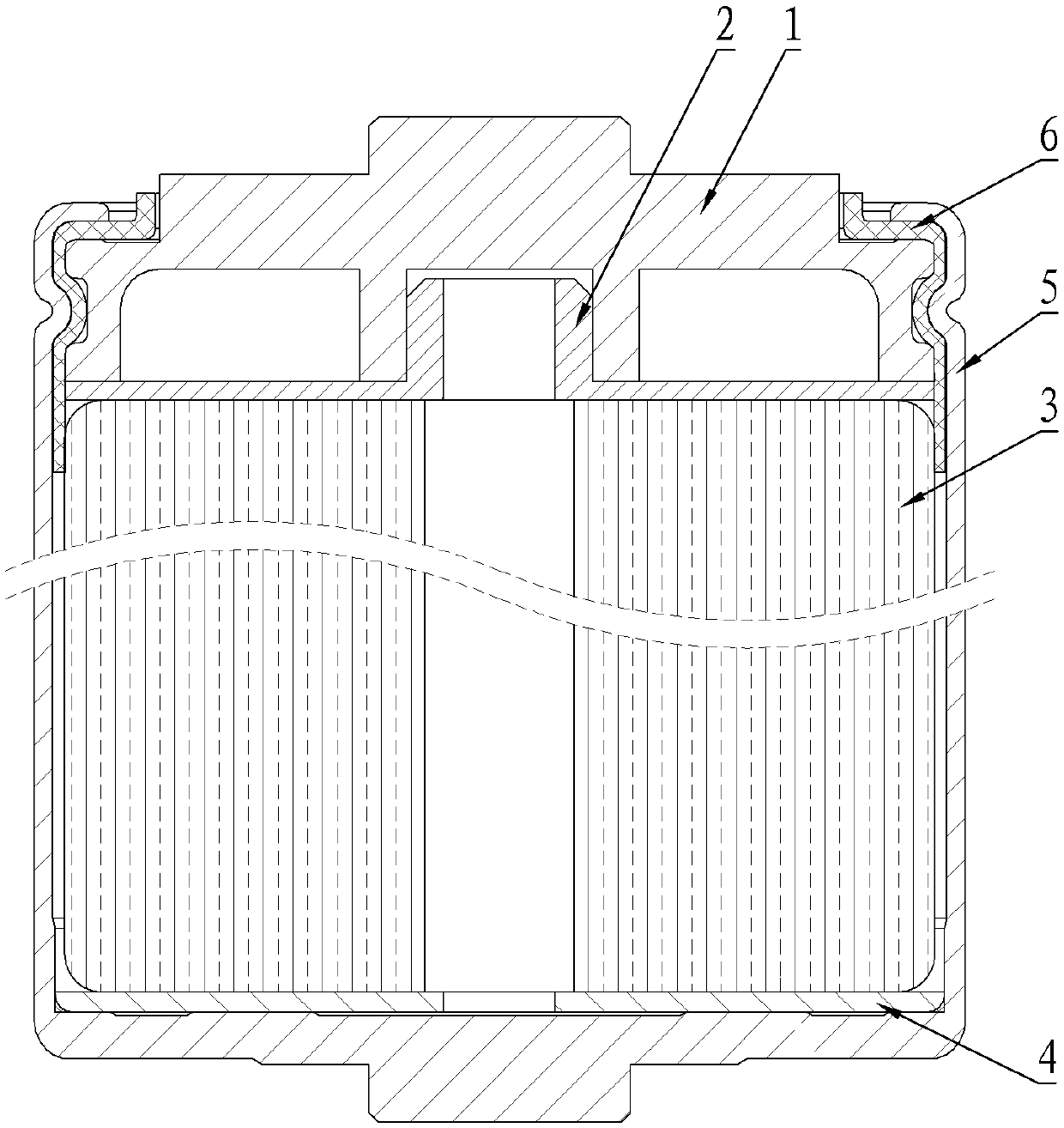

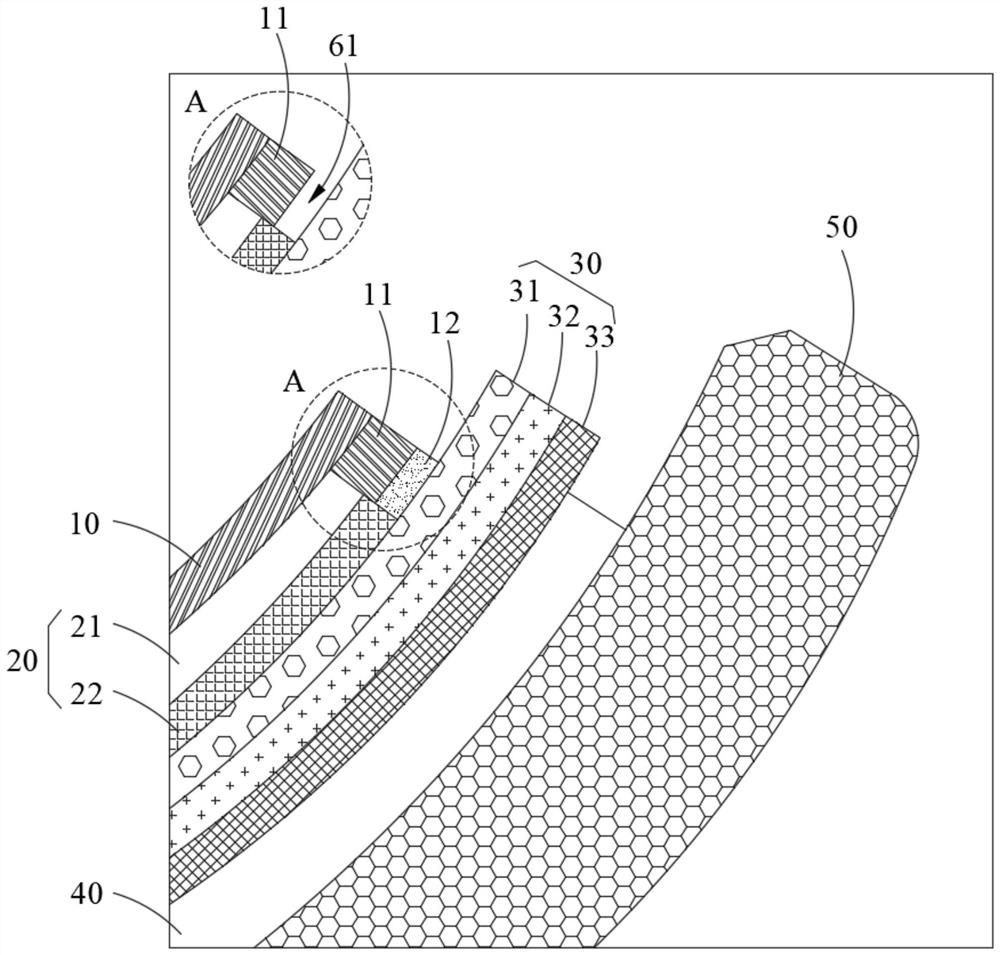

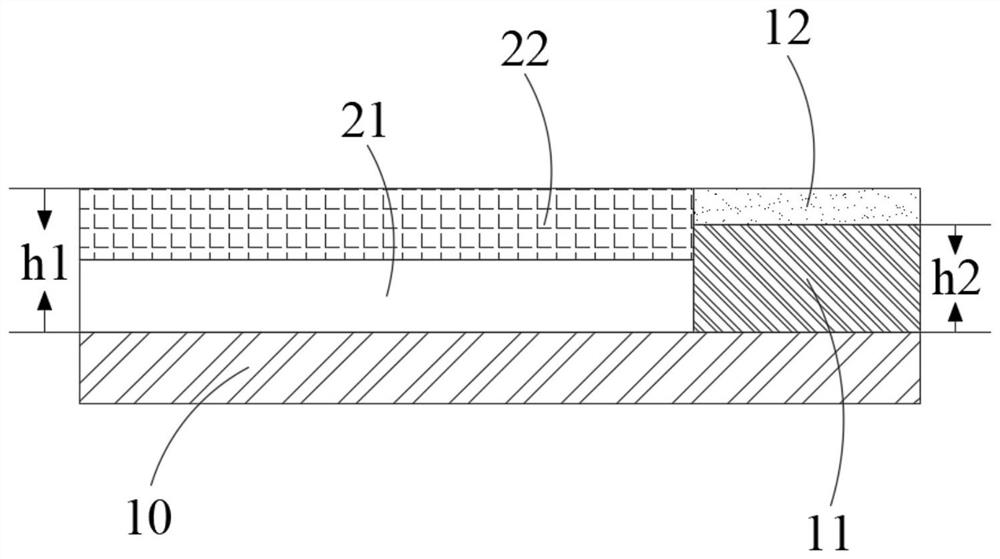

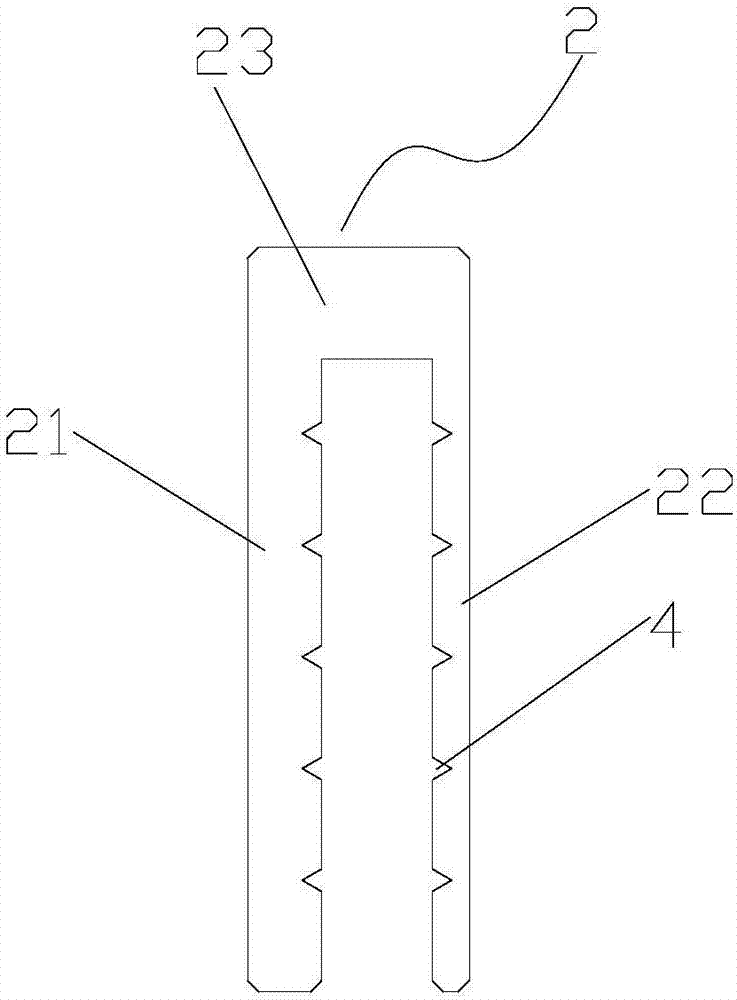

Leaf spring and electric connector

InactiveCN103545637AImprove overcurrent capabilitySmall sizeCoupling contact membersEngineeringLeaf spring

The invention provides a leaf spring. The leaf spring comprises two connecting plates and a plurality of elastic pieces. Each elastic piece comprises an inner contact plate, a transition plate and an outer contact plate which are connected in sequence, wherein the two ends of the transition plate are fixedly connected with the two connecting plates respectively, a space exists between every two adjacent elastic pieces, and the first circumferential face where the inner contact plates of all the elastic pieces are located and the second circumferential face where the outer contact plates of all the elastic pieces are located are coaxially arranged. The leaf spring increases the conductive contact area, and has better current passing capacity.

Owner:北京格林吉能源科技有限公司

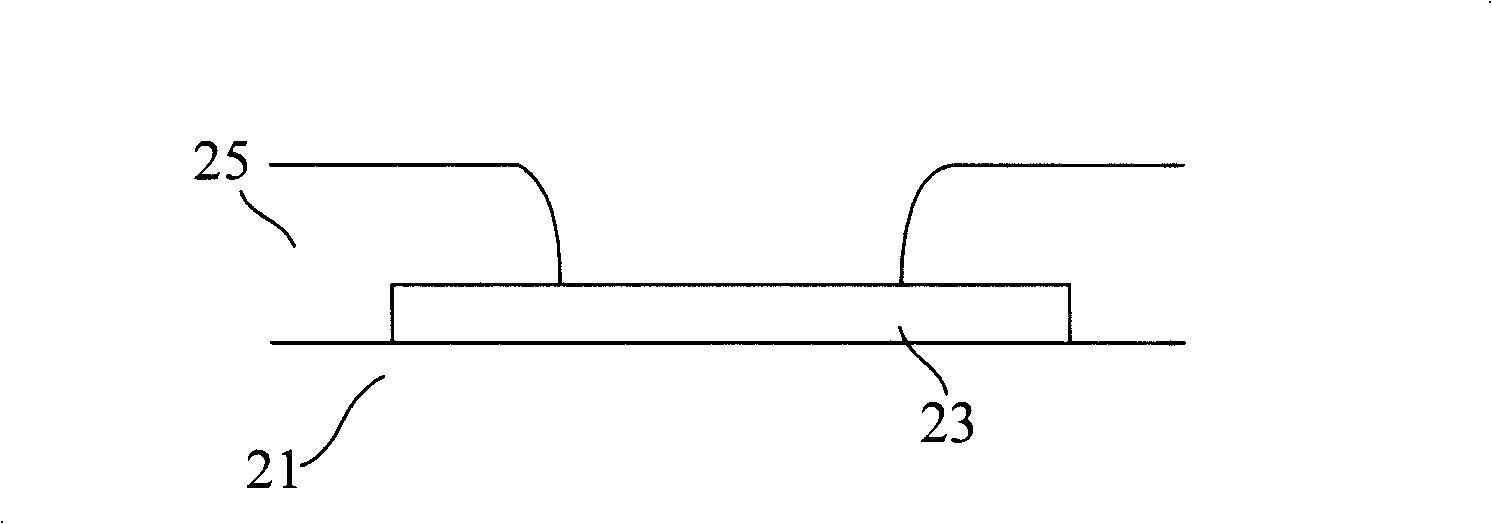

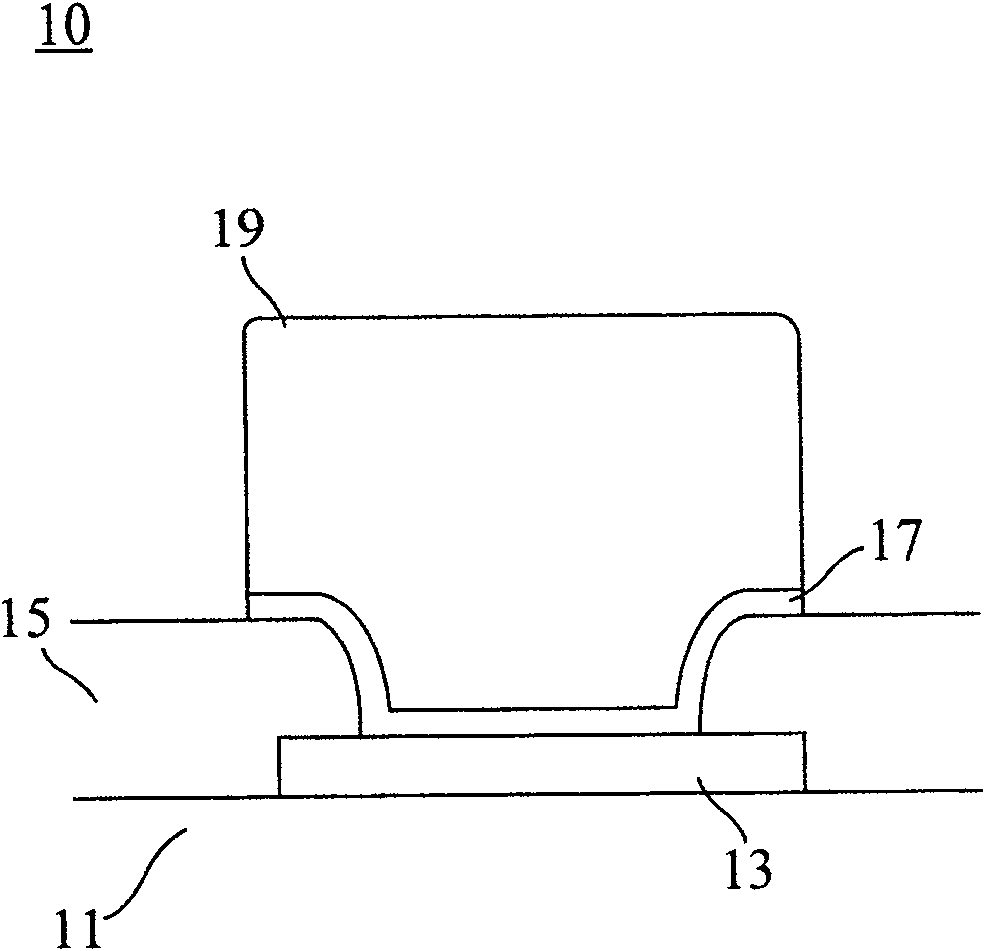

Packaging conductive structure and its manufacturing method

ActiveCN101246865AIncrease contact areaReduced risk of open circuitSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

The invention relates to an encapsulated conducting structure for a semiconductor substrate and the forming method thereof. The encapsulated conducting structure consists of a under bump metal layer covering the liner of the semiconductor substrate, at least one auxiliary part is arranged on the under bump metal layer, and then a bump metal layer is covered, and finally a bump is arranged on a bump conducting layer. Thereby, the bump can electrically connect with the lining of the semiconductor substrate by the under bump metal layer and the bump conducting layer, and provide better connecting buffer capacity and conduction property.

Owner:CHIPMOS TECH INC

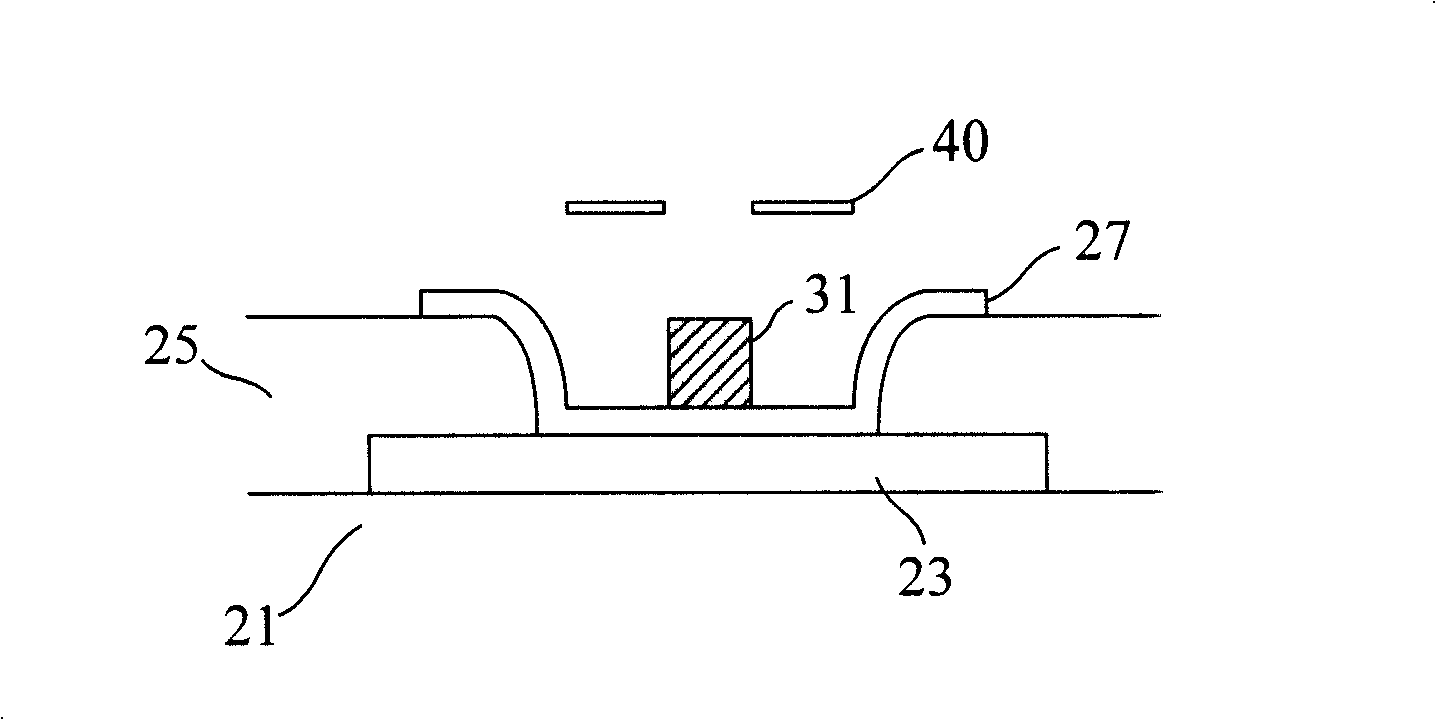

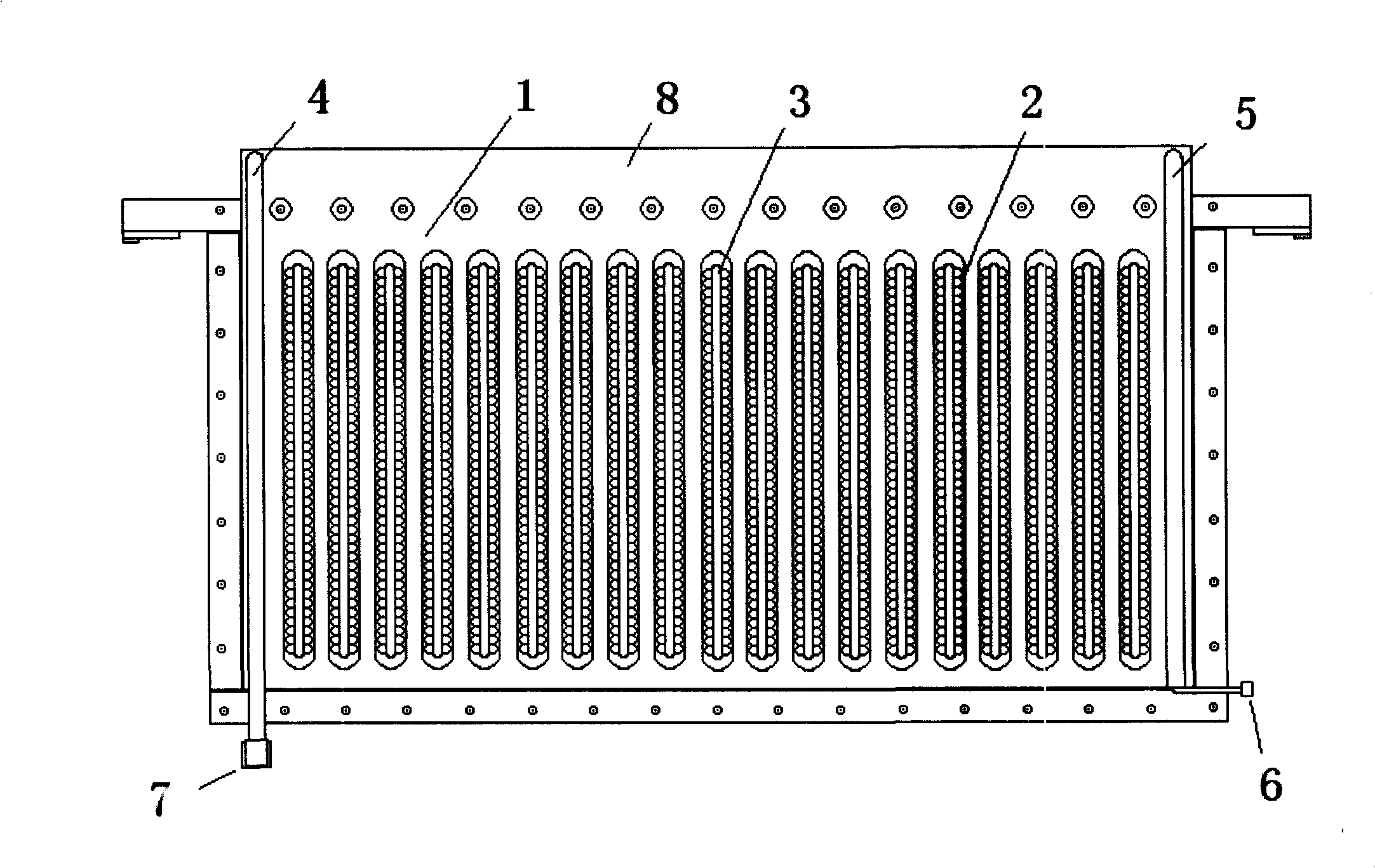

Electrode structure for electrochemical device

InactiveCN101265587AIncrease the conductive contact areaReduce contact currentCellsElectrode shape/formsEngineeringChemical property

An electrode component used for an electrochemical appliance comprises a tray-shaped trough main body; a sealing edge extending outwards on the periphery of the tray; a porous electrode covering the tray surface and on the same level as the periphery; and an electric supporting element for connecting the electrode with the back wall of the tray. The technical points are as follows: as an anode component, the anode tray is provided with leading grooves protruding inwards, the leading grooves are provided with electric springs on the inner walls, the two ends of the anode tray are respectively provided with a guide slot equipped with a communicating tube; as a cathode component, the cathode tray is provided with tongues protruding outwards, the two ends of the cathode tray corresponding to the anode tray are respectively provided with a guide slot equipped with a communicating tube, each tongue of the cathode tray are corresponding to the leading grooves on the anode component side; the communicating tubes arranged in the guide slots on the two sides of the trays are connected with a gas-liquid separation chamber on the upper part of the tray, the lower parts of the communicating tubes are connected with an outlet at the bottom of the tray. The structure can protect physical and chemical properties of the film to a greatest extent and prolong the service life of the film and the trough.

Owner:刘国桢

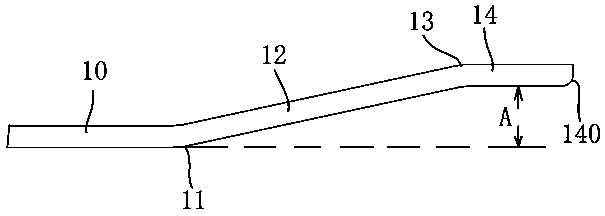

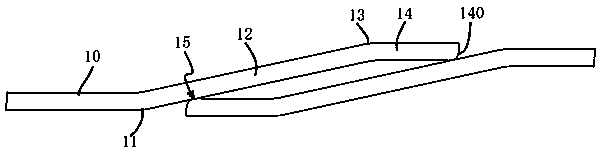

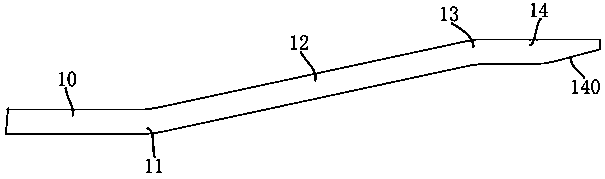

Electric conduction contact component and electric connector using same

ActiveCN105977678AAvoid stub radiation effectReduce insertion lossCoupling contact membersElectricityMechanical engineering

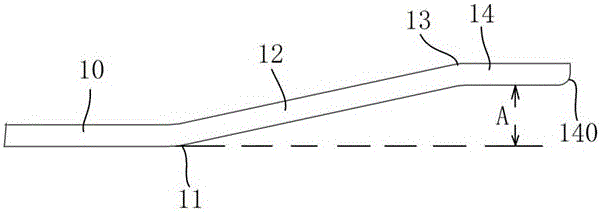

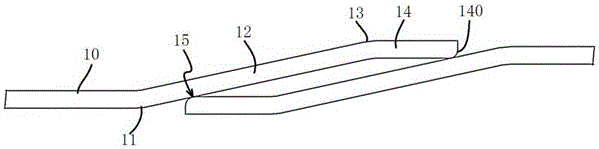

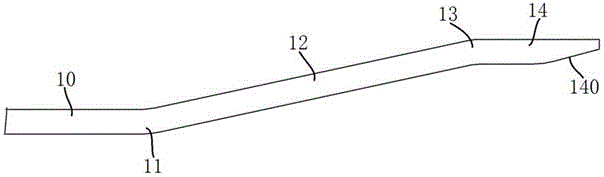

The present invention provides an electric conduction contact component and an electric connector using the same. The electric conduction contact component comprises a base body which extends flatly and straightly; the front end of the base body is connected with a first connecting section which is arranged in an upwards tilting manner through a first bent section; the front end of the first connecting section is connected with a contact section through a second bent section; the contact section is provided with a front contact portion which is in electric conduction contact with a matched electric conduction contact component; the lower side surface of the first connecting section is provided with a rear contact point which is in electric conduction contact with the front contact portion of the matched electric conduction contact component; and the front contact portion and space at the upper side and lower side of the base body form an insertion space into which the matched electric conduction contact component can be inserted. The electric conduction contact component provided by the invention is simple in structure. With the electric conduction contact component adopted, multi-point contact can be realized, the radiation effect of a short pile can be eliminated, and insertion loss can be decreased.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Solar cell and module group thereof

InactiveCN103985769AIncrease the conductive contact areaReduced series resistancePhotovoltaic energy generationSemiconductor devicesPower flowEngineering

A solar cell and a module group thereof are disclosed. The cell comprises a substrate having a light receiving face and a back face that are opposite to each other, a passivation layer which is arranged on the back face and is provided with an opening part, and a back face electrode which is positioned on the passivation layer and contacts with the back face through the opening part, wherein the opening part is provided with a first opening pattern and a second opening pattern, wherein the first opening pattern extends along the circumferential edge of the substrate and is annular in shape, the second opening pattern is surrounded by the first opening pattern and is provided with a plurality of sub-openings, and distance between the first opening pattern and the circumferential edge of the substrate is smaller than 5 mm. The first opening pattern is arranged at the outer periphery of the second opening pattern, the first opening pattern is arranged close to the circumferential edge of the substrate, an electric conduction area between the back face electrode and the substrate can be improved, and thus electric current collection effects and photoelectric conversion efficiency can be improved.

Owner:MOTECH INDUSTRIES

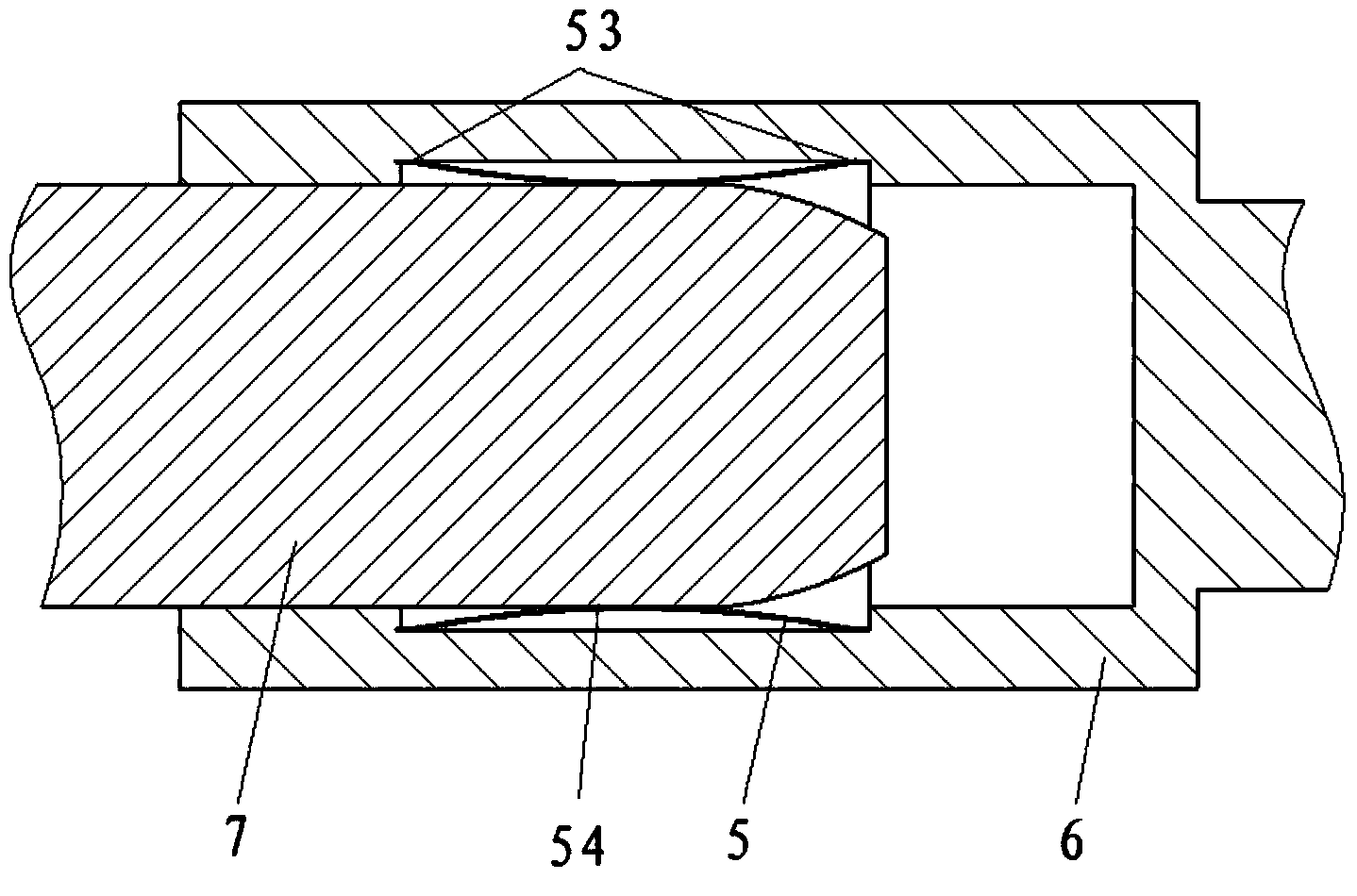

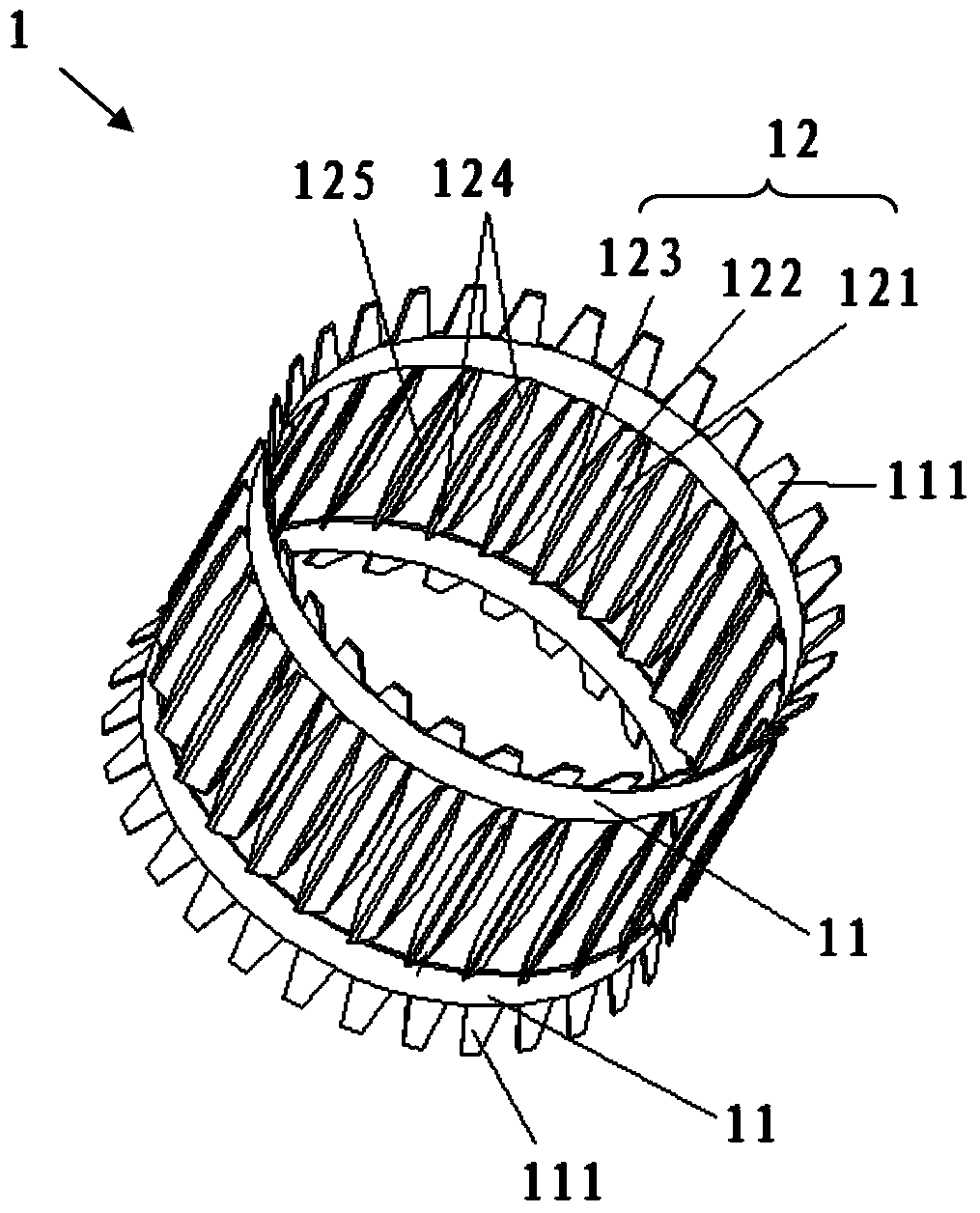

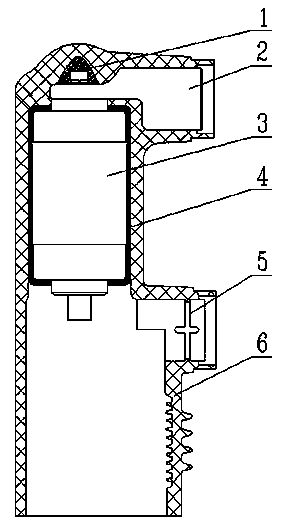

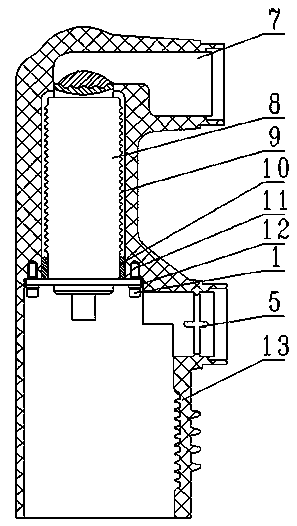

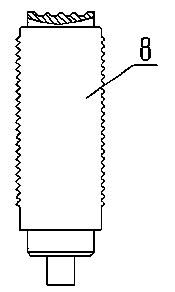

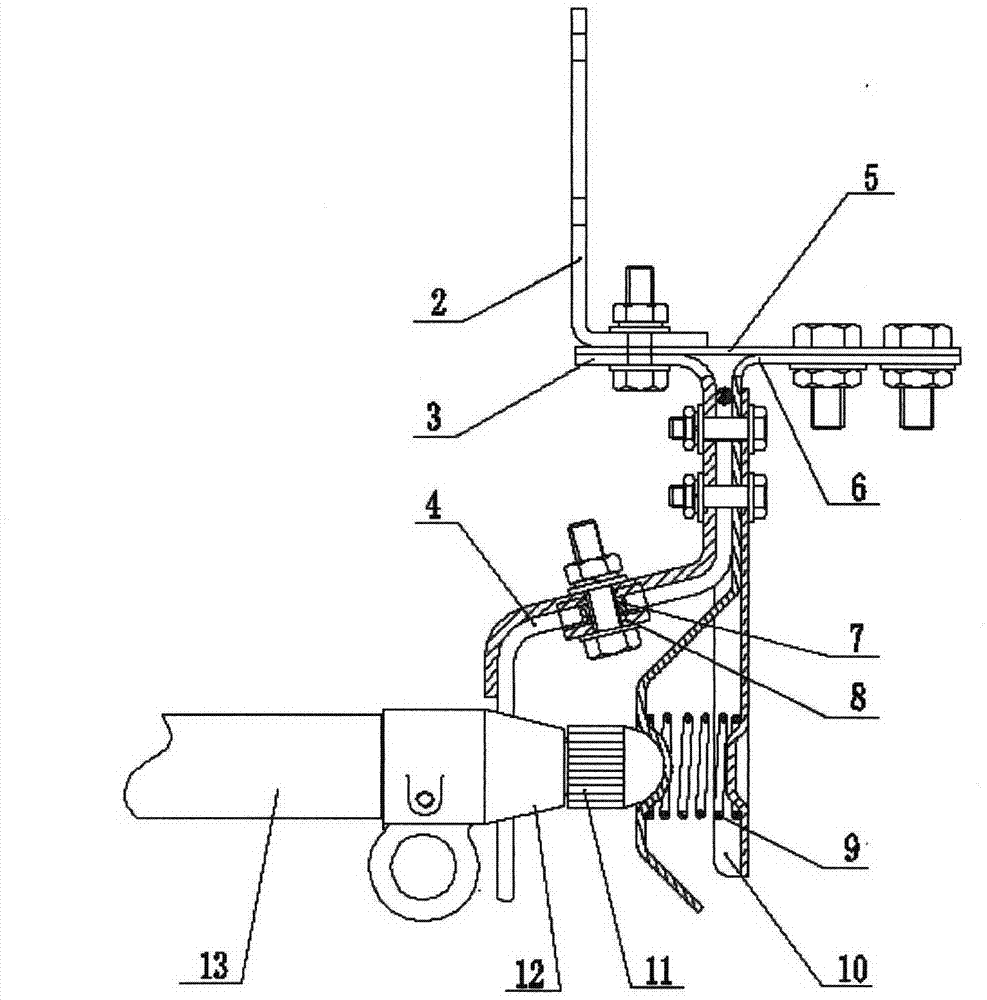

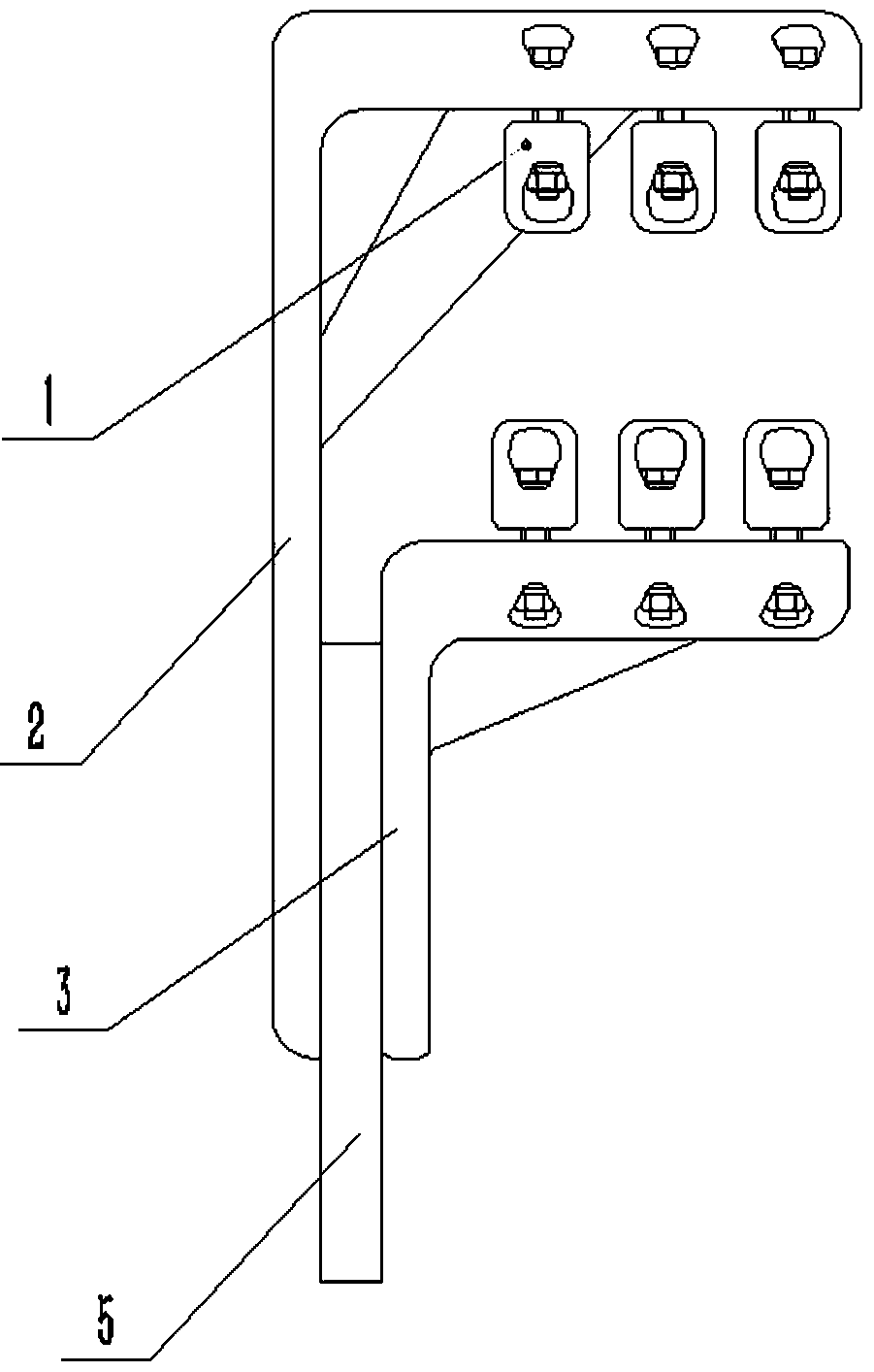

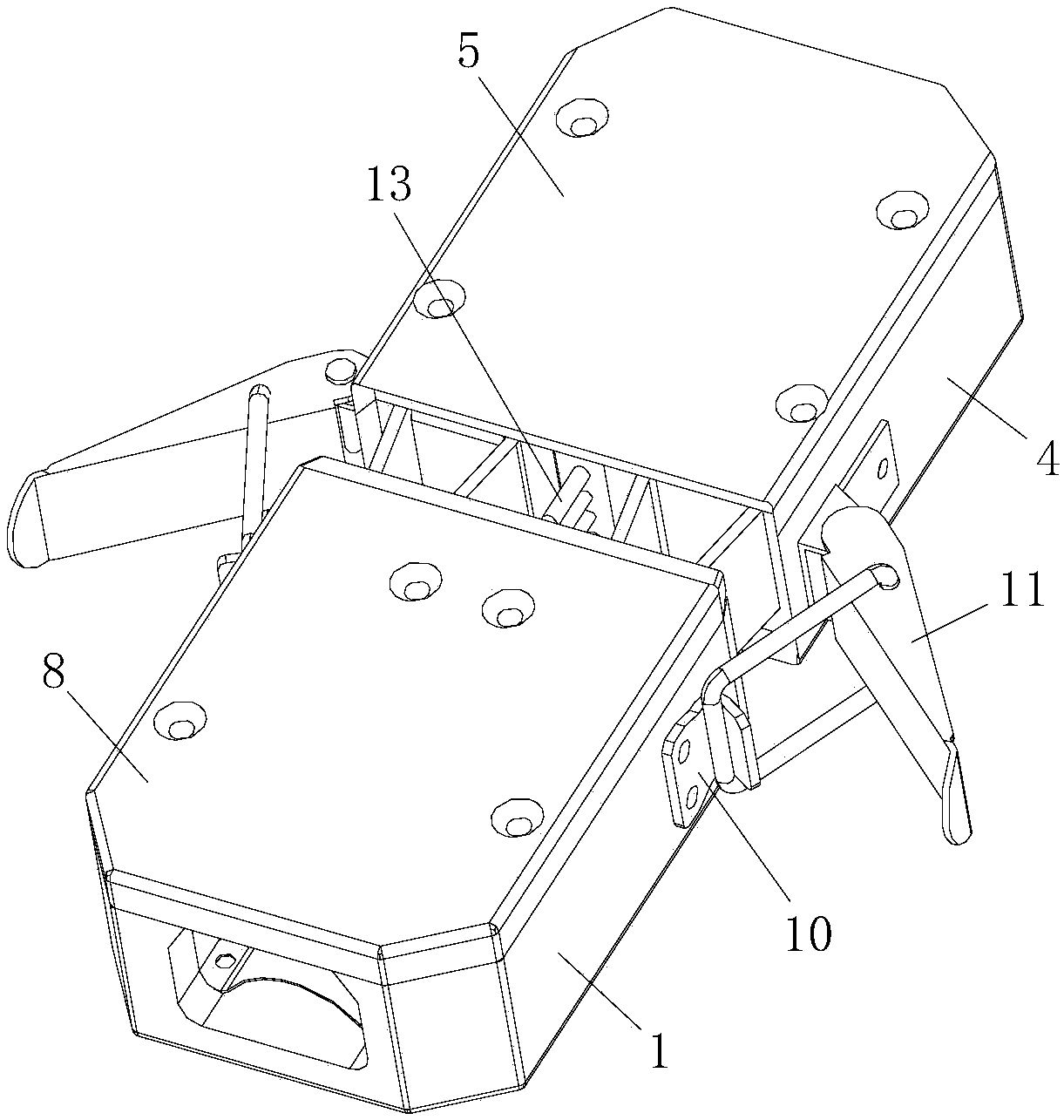

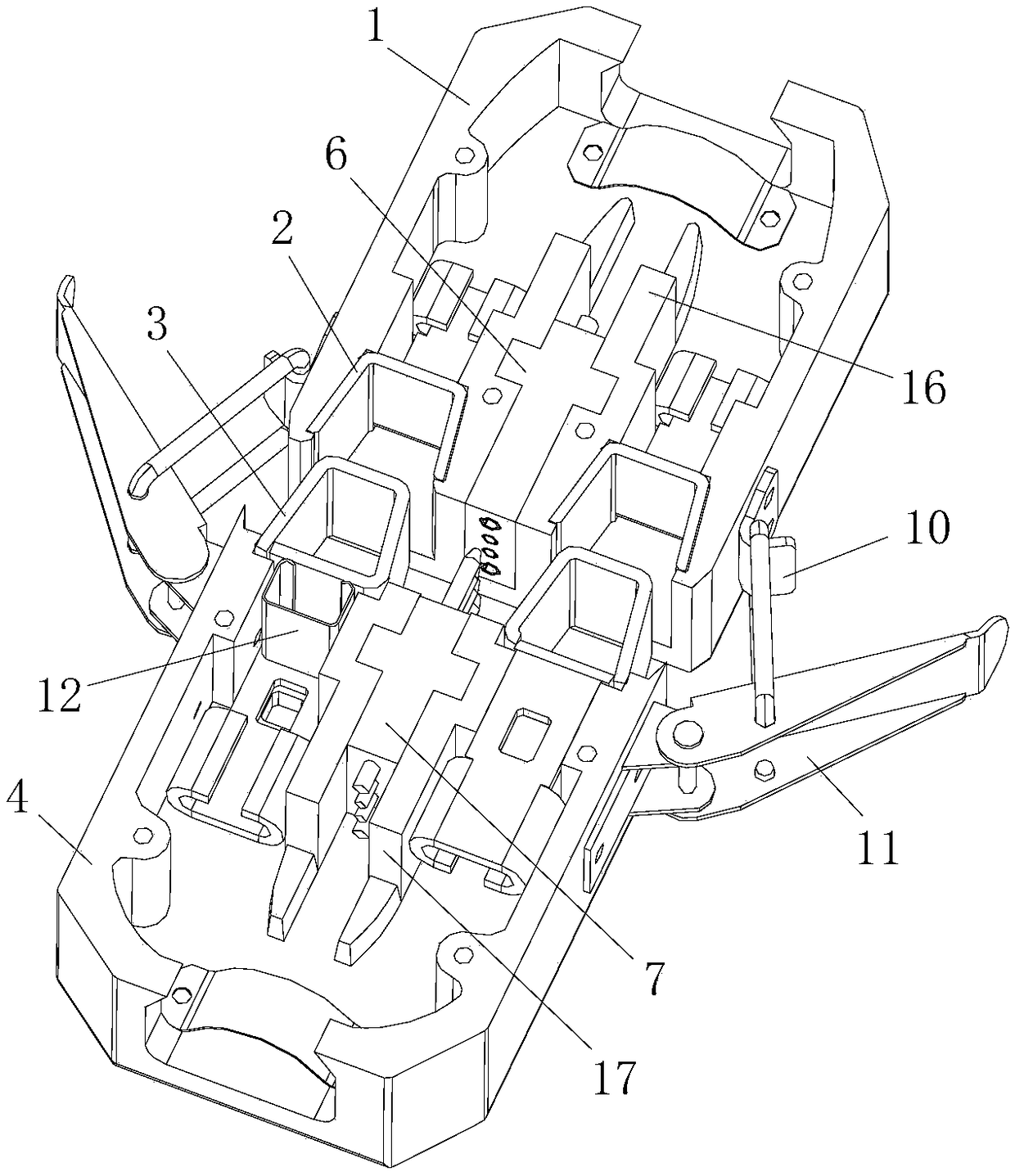

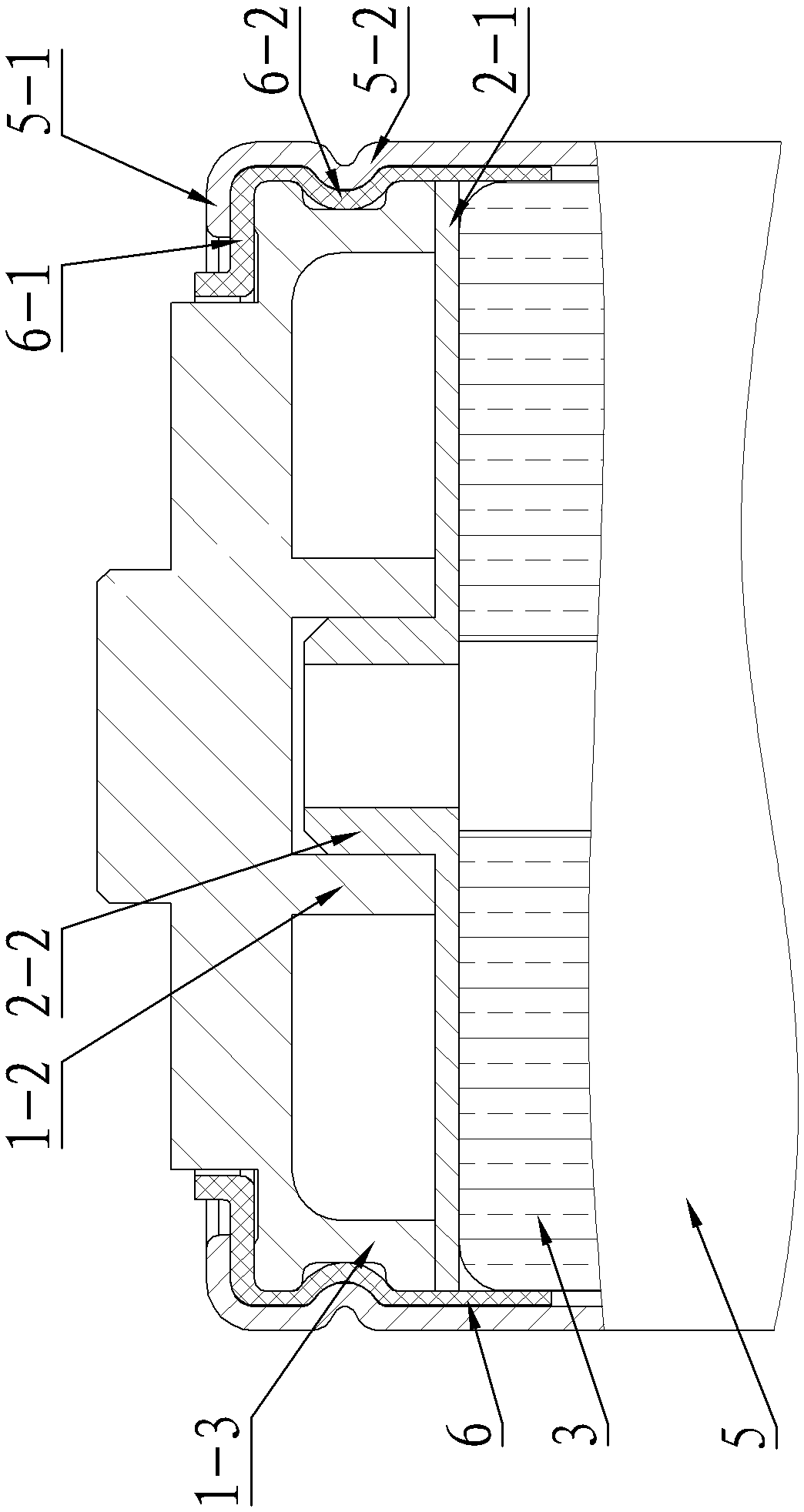

Vacuum circuit breaker solid-sealed polar pole

ActiveCN104319162AEasy to replaceImprove insulation performanceHigh-tension/heavy-dress switchesAir-break switchesContact pressureSilica gel

The invention discloses a vacuum circuit breaker solid-sealed polar pole which structurally comprises a bolt 1, silicone rubber 4, a lower leading-out terminal 5, an upper leading-out terminal 7, a vacuum arc extinguish chamber 8, an insert 11, a fixing flange 12 and an insulating body 13. The vacuum circuit breaker solid-sealed polar pole has the advantages that the vacuum arc extinguish chamber is convenient to replace, and the defect that the whole solid-sealed polar pole is scrapped when the solid-sealed polar has a problem; the upper leading-out terminal and the vacuum arc extinguish chamber are in contact and connected in a tooth-shaped meshed and contact mode, the vacuum arc distinguish chamber is fixed to the insert of the insulating body by the bolt through the fixing flange, the contact pressure of the upper leading-out terminal and the conduction contact face of the vacuum arc extinguish chamber is ensured, the conduction contact area and the current carrying capacity of a conduction circuit are improved, and the resistance of the conduction circuit is reduced; a vacuum layer is arranged between the insulating body and the vacuum arc extinguish chamber, it is ensured that the external insulation of the vacuum arc extinguish chamber is not affected by the external environment, the insulation performance of the solid-sealed polar pole is improved, and compared with the technology that the whole vacuum arc extinguish chamber is wrapped by silicon, more production cost is lowered.

Owner:HENAN SENYUAN ELECTRIC CO LTD

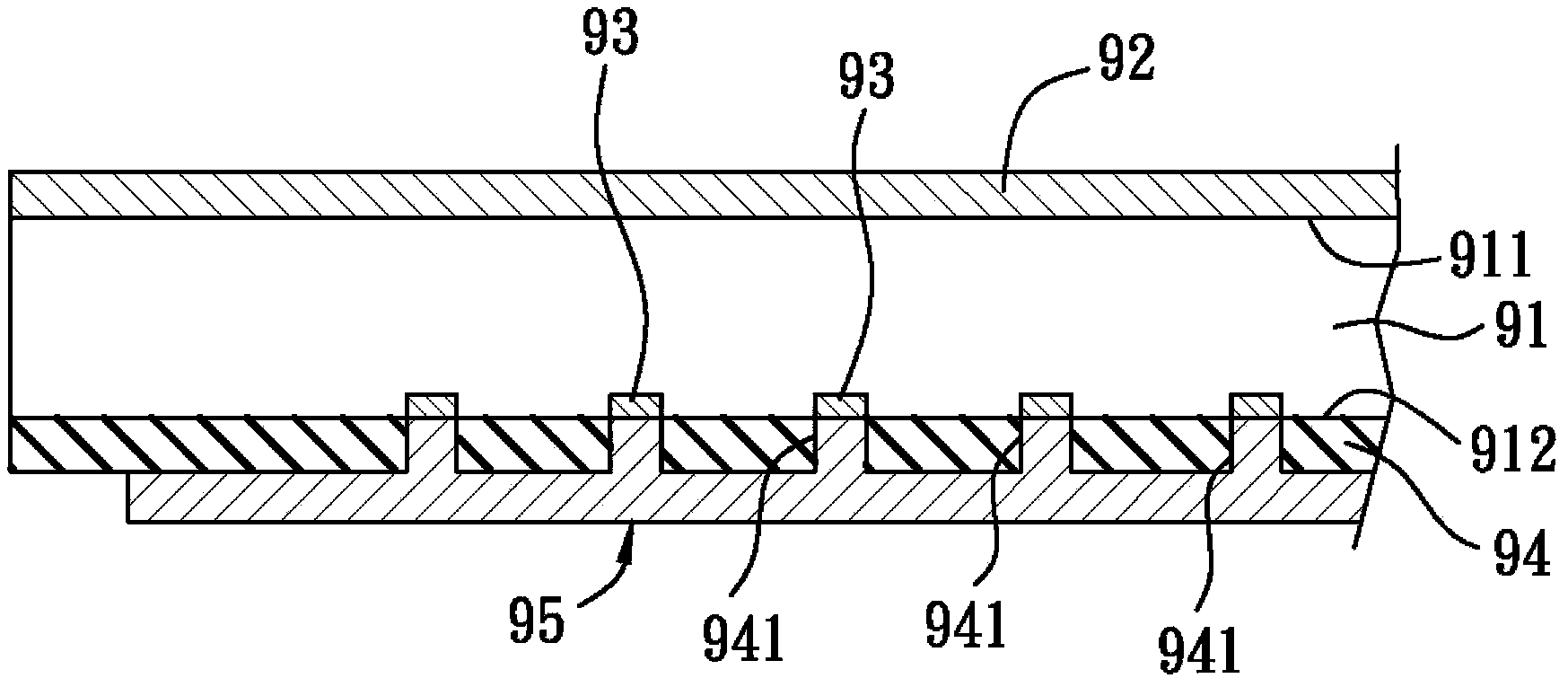

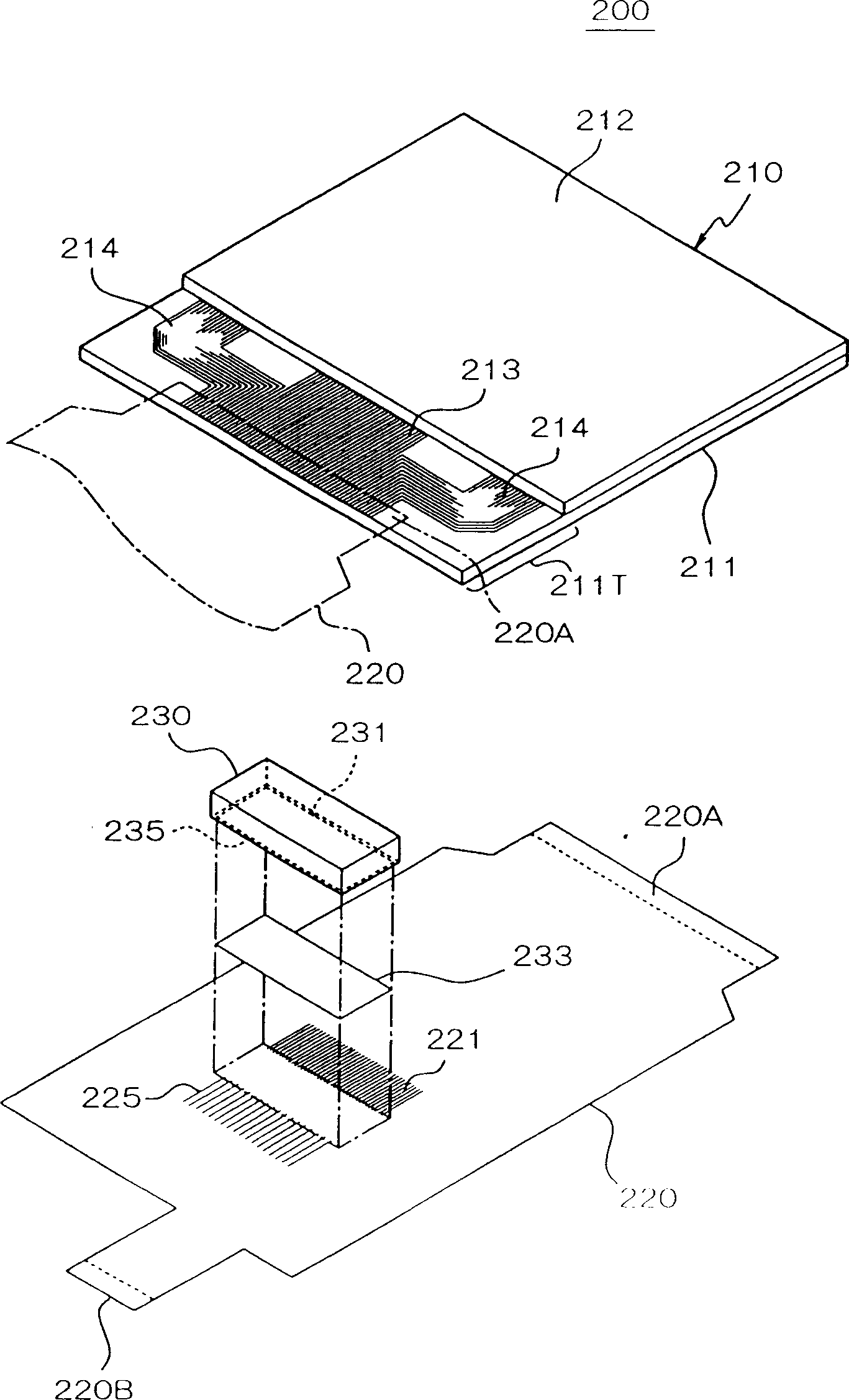

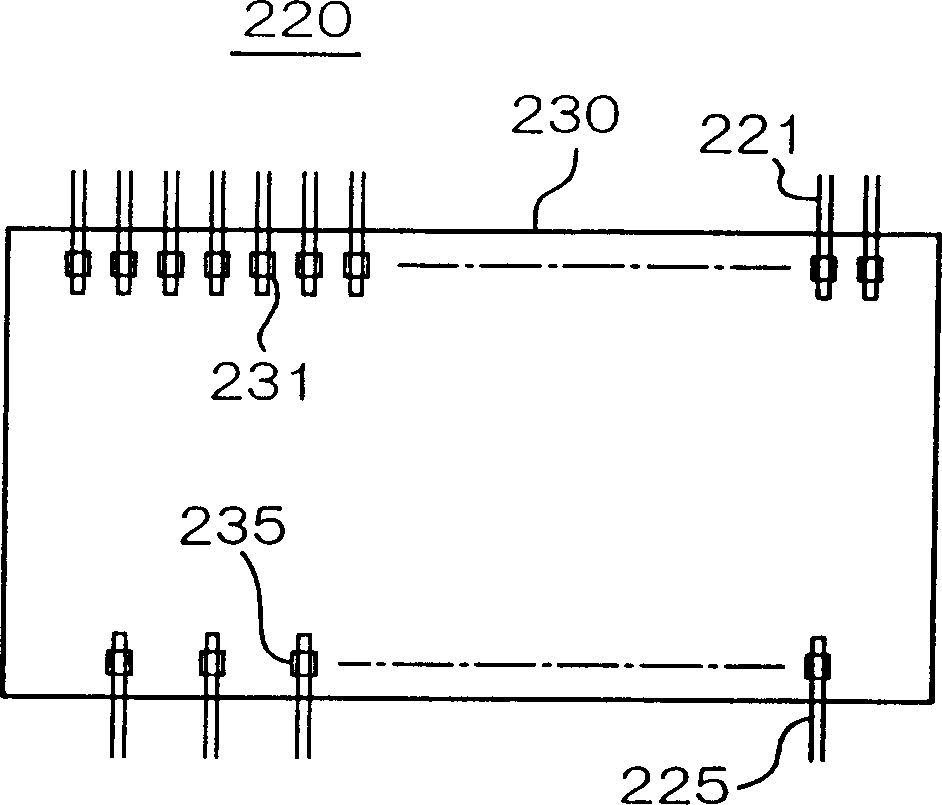

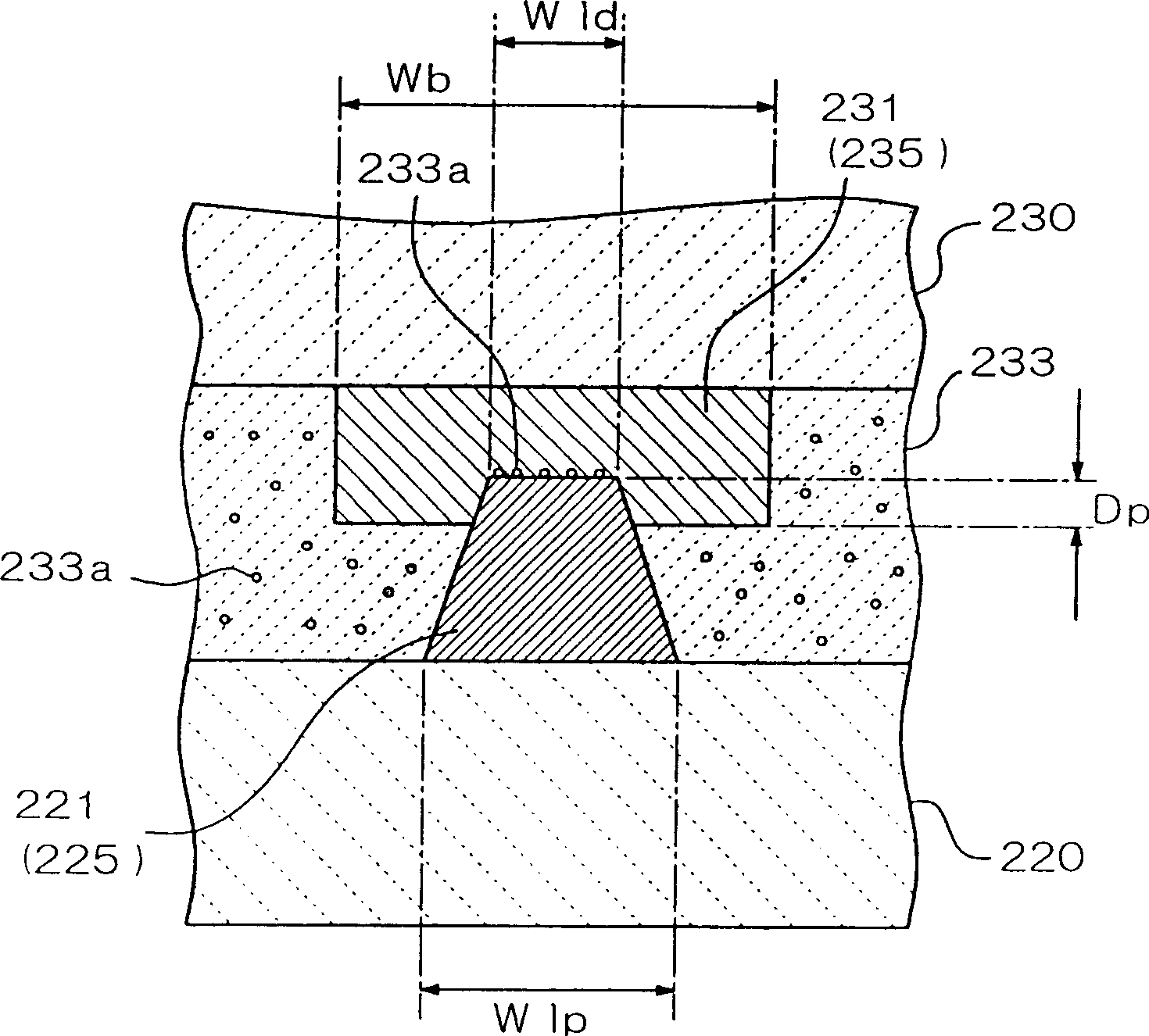

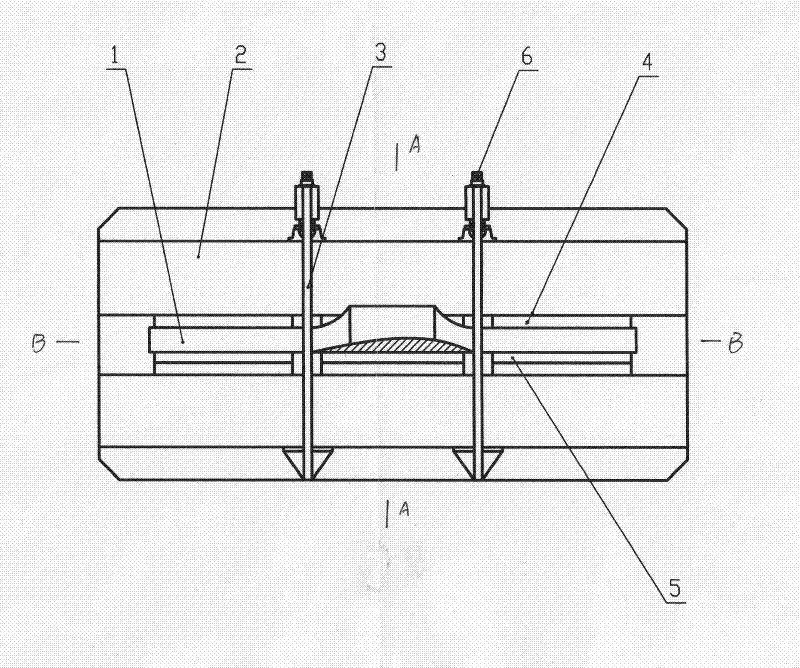

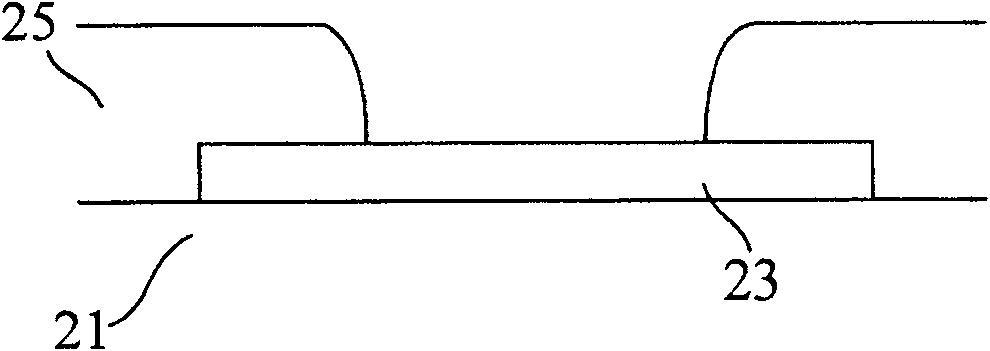

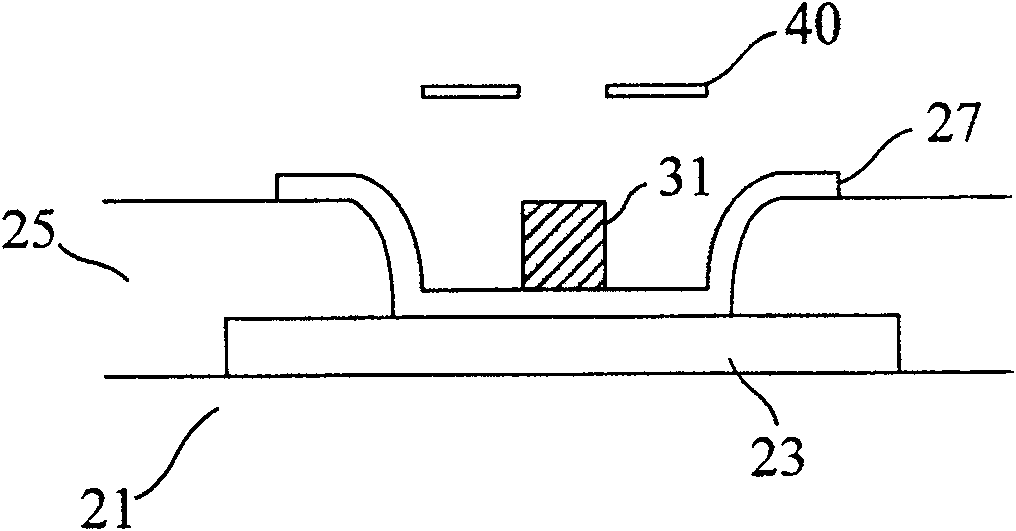

Mounting device and structure for semiconductor component, electro-optical device and producing method thereof

InactiveCN1490646AImprove reliabilityReduce the bias of falling into resistancePrinted circuit assemblingStatic indicating devicesElectronSemiconductor device

The invention seeks to provide a new semiconductor device mounting method, a semiconductor device mounting structure, an electro-optical device and an electronic device that can improve the reliability of conductively joined portions, even if the numbers of wiring terminals and electrodes increases and intervals therebetween are narrowed. A wiring terminal is formed on a wiring substrate, and an electrode is formed on a semiconductor device. Here, the width of the wiring terminal is formed so that it becomes smaller than the width of the electrode. When the semiconductor device is mounted on the wiring substrate, the wiring terminal becomes embedded in the electrode due to applied pressure. It is preferable for the embedding amount of the wiring terminal to be within the range of about 1 µm to 5 µm.

Owner:BOE TECH GRP CO LTD

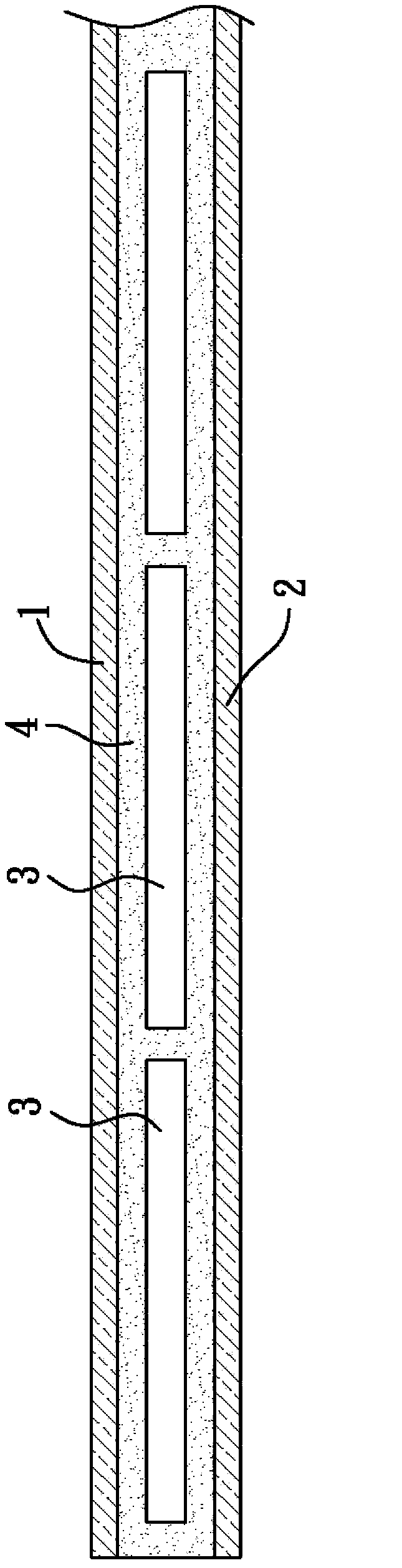

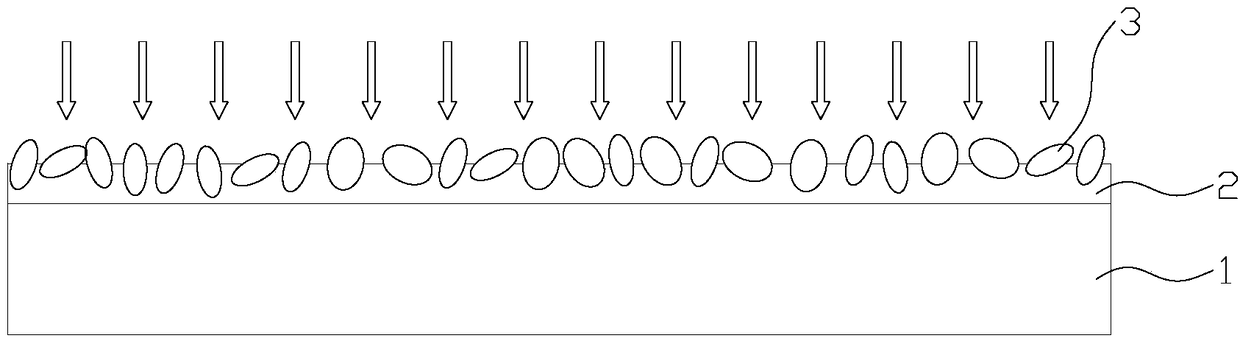

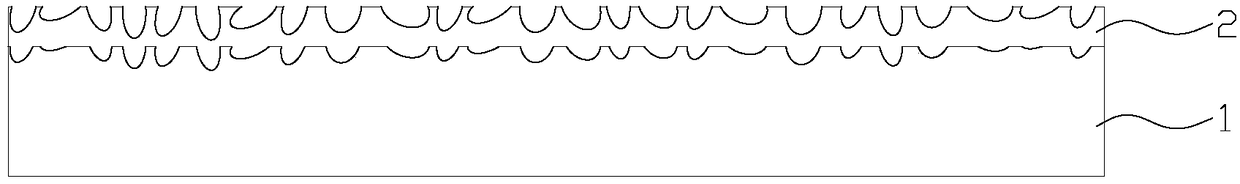

Embedding method of conducting metal plate for heating floor

InactiveCN103644593AIncrease bonding areaHigh bonding strengthLighting and heating apparatusElectric heating systemFiberCarbon fibers

The invention discloses an embedding method of a conducting metal plate for a heating floor, and belongs to the technical field of wood floor manufacture. According to the method, a platy metal plate serving as a conductor directly contacts with far-infrared carbon fiber heating paper and is parallelly connected with a connection terminal at high temperature and under high pressure through resin, and the metal plate and the connection terminal are combined into one and embedded into the heating floor to form an internal power supply system. The embedding method includes the specific implementation steps: firstly, punching; secondly, mounting the conducting metal plate for the heating floor; thirdly, mounting the connection terminal for the heating floor; fourthly, mounting the far-infrared carbon fiber heating paper; fifthly, mould pressing; sixthly, fixing electric wires. The embedding method has the advantages that resin gluing area is enlarged, the gluing strength of an upper plate blank and a lower plate blank is enhanced, the physical performance of bonding strength in the floor is ensured, the conducting metal plate can normally conduct, conducting contact area is increased, and the quality of the floor cannot be reduced.

Owner:欧邦智能家居(武汉)有限公司

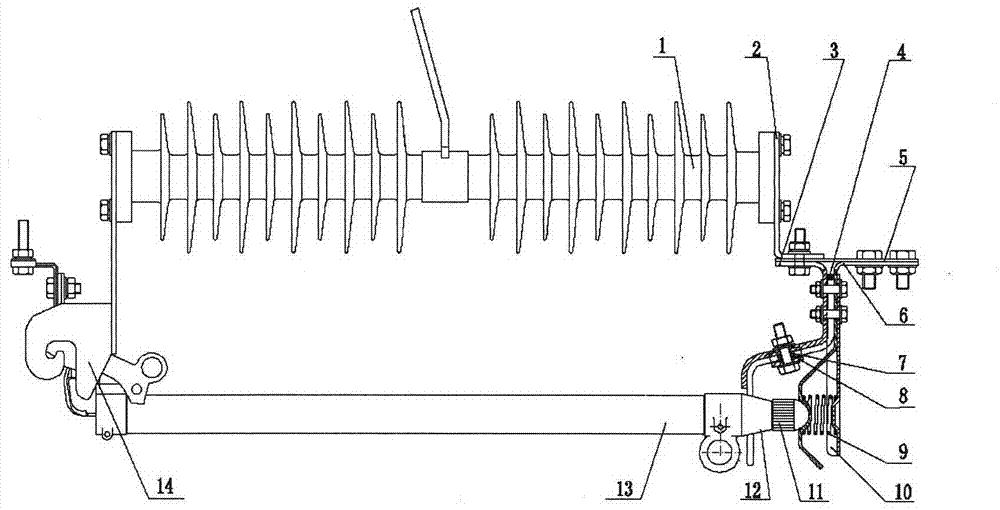

Falling-type fuse

ActiveCN103367071AEasy to dropFall quicklyProtective switch operating/release mechanismsElectricityElectric power system

The invention discloses a falling-type fuse which comprises a fuse tube assembly and a conductive plate electrically connected with the fuse tube assembly. The end of an upper moving contact of the fuse tube assembly is provided with a spherical surface of a contact nut. Correspondingly, the conductive plate is provided with a ball socket surface and the ball socket surface is matched with the spherical surface. The middle part of the upper moving contact of the fuse tube assembly is provided with a conical surface which is connected with the spherical surface. A conductive rod made of a beryllium-bronze rod is fixed around the conical surface. An insulating tube of the fuse tube assembly is coated with a silicon rubber. The falling-type fuse can be widely applicable to the power systems with voltage levels of 10KV, 35KV, 66KV, and the like. The falling-type fuse is characterized by large current capacity, high wind resistance, good resistance to uncleanness, quick falling during overload, stable and reliable operation, long service life, low cost of maintenance, and the like.

Owner:吉林市能兴电力设备有限公司

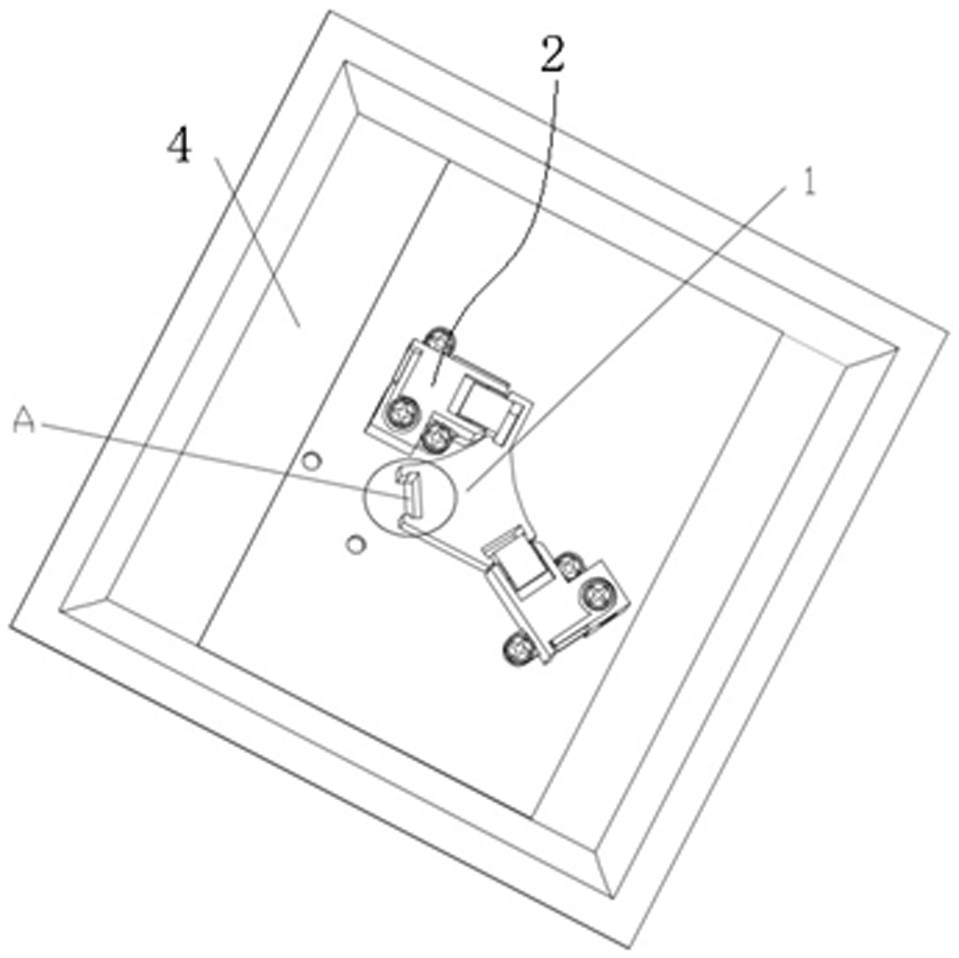

A kind of split wire clamp hardware

ActiveCN105048130BSolve the problem of unstable conduction and flow performanceTo achieve diversionElectric connection structural associationsEngineeringClose contact

Owner:PINGGAO GRP +1

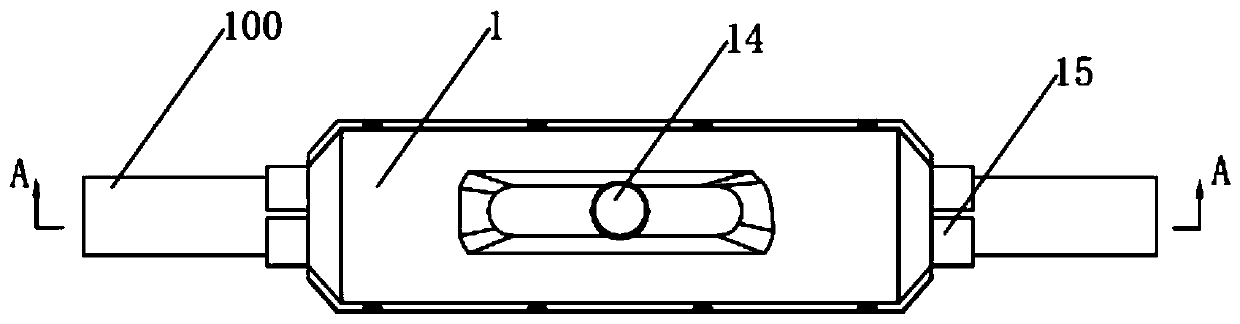

Line repairing device

InactiveCN111541061AImprove gripPrevent looseningElectric connection structural associationsClamped/spring connectionsElectrical conductorStructural engineering

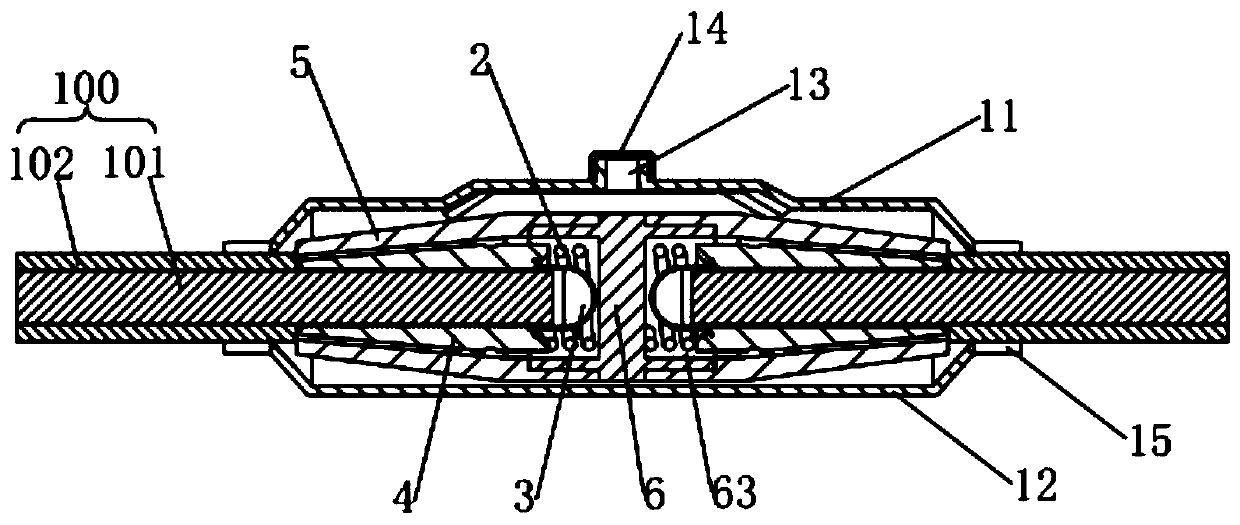

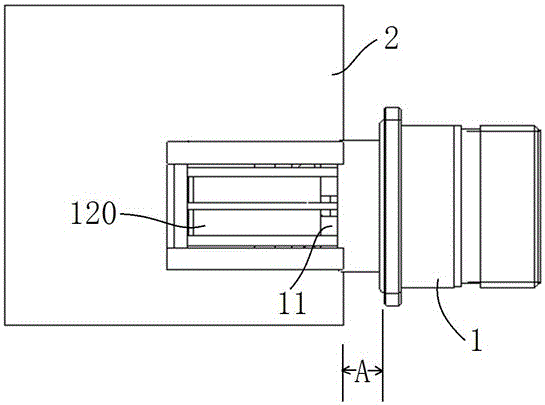

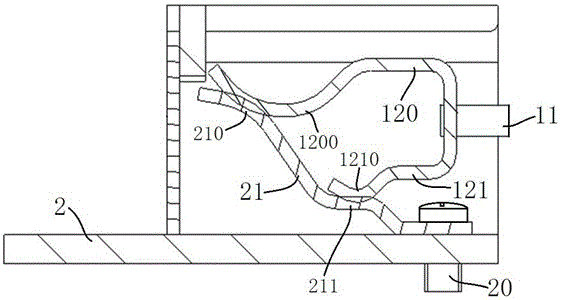

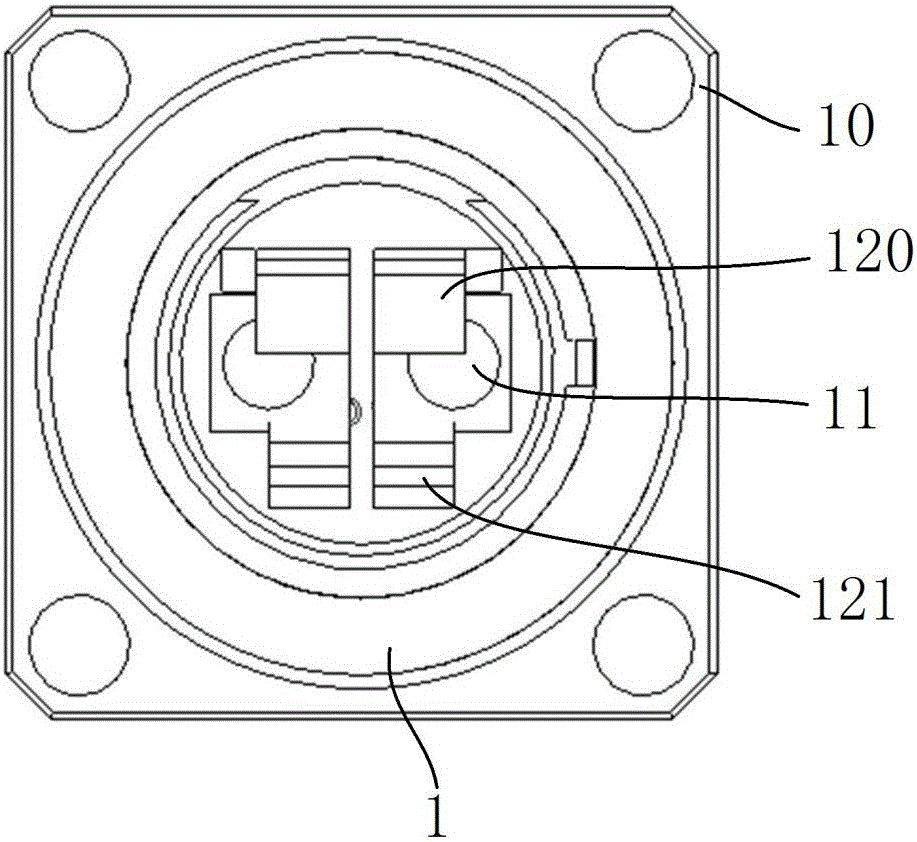

The invention discloses a line repairing device, and belongs to the technical field of power maintenance tools. The line repairing device comprises a connecting conductor, two packing elastic pieces,two expansion pieces and two turncaps, mounting holes are formed in the two ends of the connecting conductor, and two wires are arranged in the two mounting holes respectively and can be electricallyconnected with the connecting conductor; and the two expansion pieces respectively sleeve the two wires, the expansion pieces are in a conical column shape, and the large-diameter ends of the expansion pieces are close to the connecting conductor. The two packing elastic pieces are arranged in the two mounting holes respectively, and the two ends of each packing elastic piece abut against the large-diameter end of the expansion piece and the connecting conductor respectively; and the two turncaps are connected to the two ends of the connecting conductor respectively, the turncaps are arrangedon the expansion piece in a sleeving mode, and inner cavities of the turncaps are in a conical hole shape matched with the appearance of the expansion piece. According to the line repairing device provided by the invention, the expansion piece is compressed from the two ends by the compression elastic piece and the turncap, so that the expansion piece is tightly attached to the wire, the overcurrent capacity is improved, the wire is prevented from loosening, and the connection reliability is improved.

Owner:GUANGDONG POWER GRID CO LTD +1

Connector, printed board assembly and wafer assembly

ActiveCN106099565AIncrease elasticityImprove deformation abilityCoupling parts mountingEngineeringMechanical engineering

The invention provides a connector, a printed board assembly and a wafer assembly. The connector comprises a connector shell, wherein the connector shell is internally provided with a front contact piece extending forwards and backwards; a rear contact piece is fixedly arranged at the rear end of the front contact piece; and a connecting contact end for mutual pressing and contact with the adapting contact end of an adapting contact piece to realize elastic deformation in a plug connection process is arranged at the rear end of the rear contact piece. Through the arrangement of the connecting contact end in contact with the adapting contact end in a pressing manner to realize elastic deformation, the floating quantity of the contact piece in the plug connection process is increased, and the contact piece in the plug connection process is prevented from being damaged by forced mounting.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Fast connecting device realizing heavy current charge and discharge

InactiveCN108511986AGuaranteed stabilityOvercoming large repulsionVehicle connectorsCoupling contact membersElectricityFast charging

The invention discloses a fast connecting device realizing heavy current charge and discharge; the fast connecting device comprises a fixed seat and a movable seat; the fixed seat comprises a fixed pedestal; a wedge form female end is fixed in the fixed pedestal; the movable seat comprises a movable pedestal; a wedge form male end is fixed in the movable pedestal; the wedge form male end inserts the wedge form female end, the wedge form female end wraps left, right and front end faces of the wedge form male end so as to form a mutually attached electric connecting structure; a buckling mechanism is arranged between the movable seat and the fixed seat, and pulled to push the movable seat to move to the fixed seat so as to form firm connection. The wedge form female end and the wedge form male end can realize multi-aspect electric connections via an insertion and matching mode, thus providing a much greater conductive contact area when compared with a conventional spring form; a spring buckle is arranged outside the connecting device so as to keep firm connection, thus enabling the wedge form female end to always firmly wrap the wedge form male end, keeping the electric connection stability, and realizing fast charging / discharging connection of heavy currents above 100A.

Owner:DONGGUAN YINGZHIBAO ELECTRONICS TECH

Electrode lead-out structure

ActiveCN103199212BImprove stability and reliabilityExtended service lifeHybrid capacitor electrodesCell component detailsEngineeringLead structure

The invention discloses an electrode lead-out structure. According to the electrode lead-out structure, a positioning projection and a positioning hole are arranged on the opposite end faces of an end cover and a current collecting plate respectively; the positioning projection is inserted into the positioning hole in a transitional mode; a combining part is arranged at the periphery of the positioning projection and the positioning hole and in the combining position of the end faces of the end cover and the current collecting plate; and a welding structure fixedly connected with the end cover and the current collecting plate is arranged on the combining part. By virtue of transitional insertion and welding modes, the positioning projection is inserted into the positioning hole by pressing or knocking, and the end cover and the current collecting plate do not need to be subjected to pretreatment of cooling or heating, so that the assembling time is saved, the production efficiency is improved, and the cost is reduced.

Owner:ZHENGZHOU SINO CRYSTAL DIAMOND

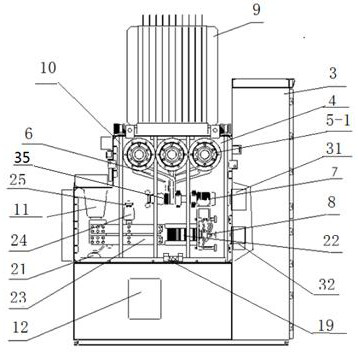

12kV/4000A high-current gas-insulated metal-enclosed switchgear

PendingCN113363860ADoes not take up internal spaceReduce heating powerBus-bar/wiring layoutsSwitchgear arrangementsElectrical conductorNatural convection

A 12kV / 4000A high-current gas-insulated metal-enclosed switchgear overcomes the problems of complex structure, large size and low heat dissipation efficiency in the prior art, and is characterized in that a heat dissipation pipe is mounted on a gas tank shell to form a natural convection heat exchange structure, a top heat dissipation box is mounted at the top of the gas tank shell, and a top heat dissipation box is mounted at the bottom of the gas tank shell; the lower end of the main bus in the gas tank shell is connected with a direct-acting three-station double-set disconnecting switch, and the lower part of the direct-acting three-station double-set disconnecting switch is connected with an arc extinguish chamber moving end flexible connector. The beneficial effects of the utility model are that through the heat dissipation structure design of a plurality of components with large heat productivity, the temperature in the air chamber is reduced through natural convection in the closed air chamber, and the problem of large-current temperature rise is solved; the conductive contact area is multiplied through the plurality of flexible connection conductors, and the through-current capability is improved; the size of a single conductive part is reduced through double sets of isolating switches of each phase, and the requirement of 12 kV / 4000 A large-current gas insulated metal-enclosed switchgear for the through-current capability is met.

Owner:SHENYANG HUADE HIGH TECH ELECTRIC CO LTD

Method for connecting electrolytic aluminum anode without pouring

The invention provides a method for connecting an electrolytic aluminum anode without pouring. In the method, a steel talon is manufactured into a wedge shape with a big end down cross section; the cross section of an anode carbon block is made into a boss shape, and a dovetail through slot is formed in the middle of the upper plane of the anode carbon block along the vertical direction; after the steel talon is put in the dovetail through slot, steel plates with the same number and same thickness are filled in gaps on two sides of the steel talon correspondingly, so that the two sides of thesteel talon and the copper plates are closely jointed, and the two steel plates and the anode carbon blocks on two sides are closely jointed. The pouring connecting method of melting ferro-phosphorusis changed into a wedge plate compacting connecting method, an intermediate frequency furnace for melting ferro-phosphorus and pressure-disengaging equipment for disengaging a phosphorus iron hoop bypressure are canceled, so that the equipment investment is reduced, the labor intensity is reduced, and the working environment is improved; the profile steel talon is put in the dovetail through slot of the carbon block and compacted by a wedge-shaped stainless steel plate without pouring, so the operation is easy and convenient; and the conventional mode of combining the anode steel talon and the anode carbon block is changed, a transitional connecting mode of combining copper and carbon is adopted, so that the conductive contact area is enlarged, and the anode conductive drop can be effectively reduced.

Owner:商丘市鑫科节能技术服务有限公司

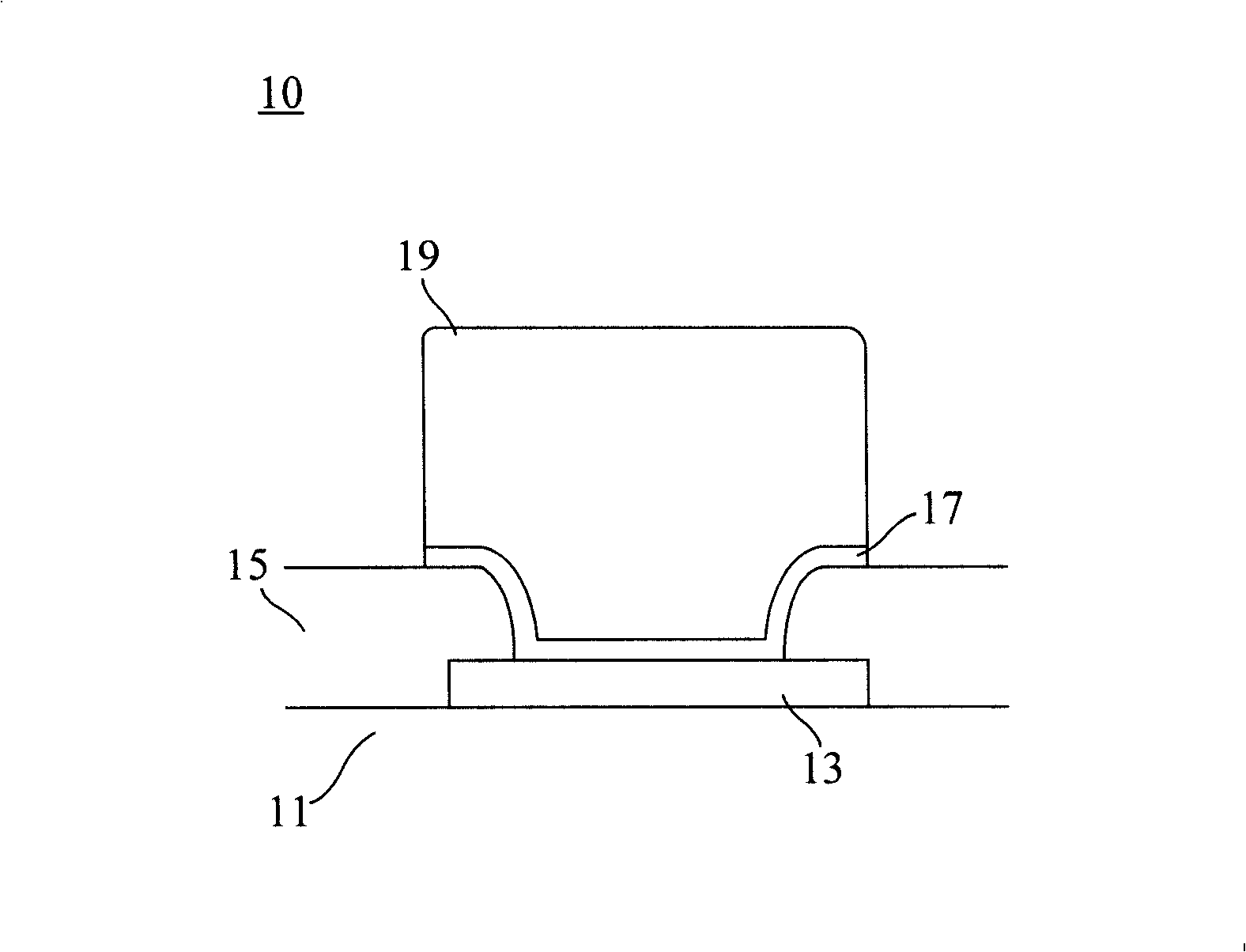

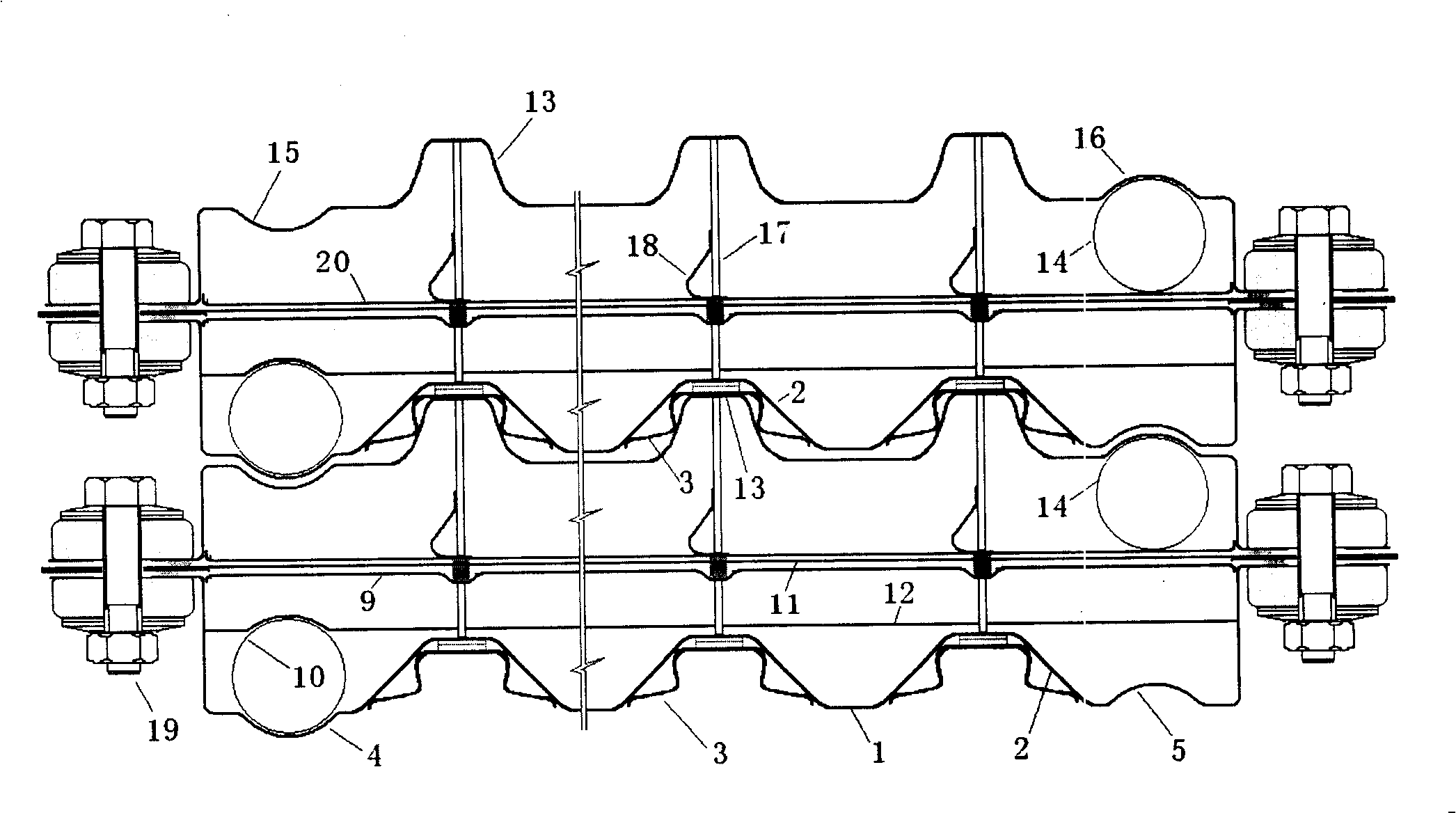

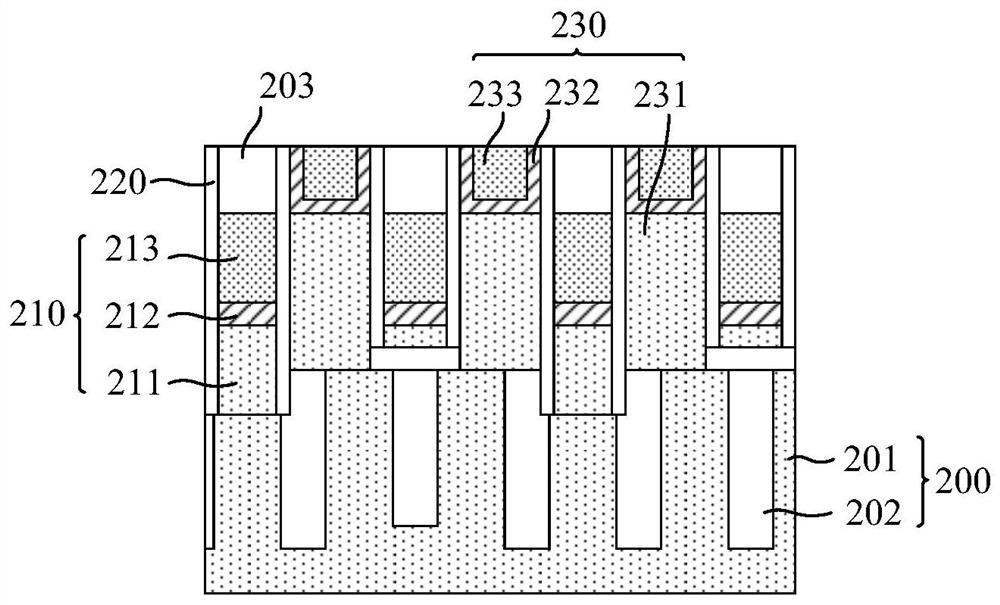

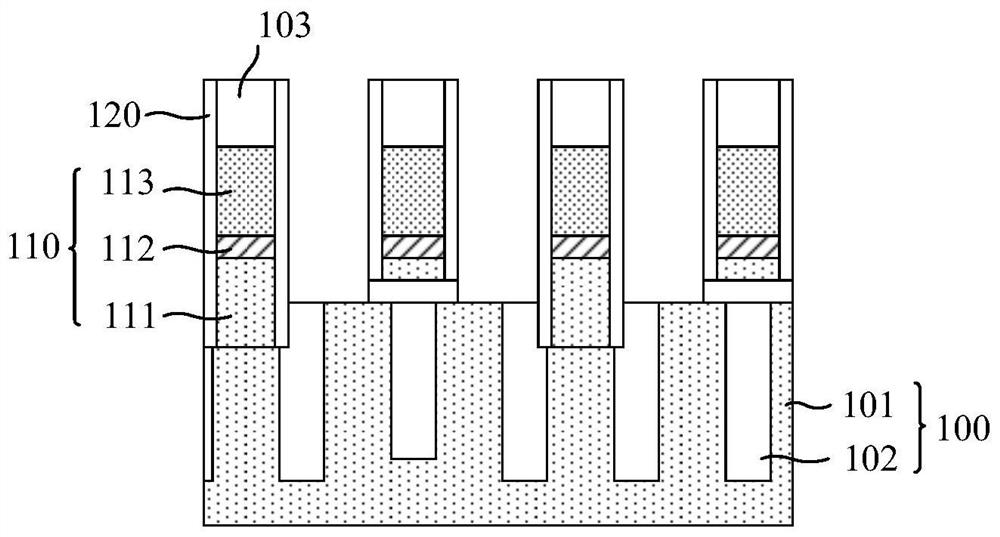

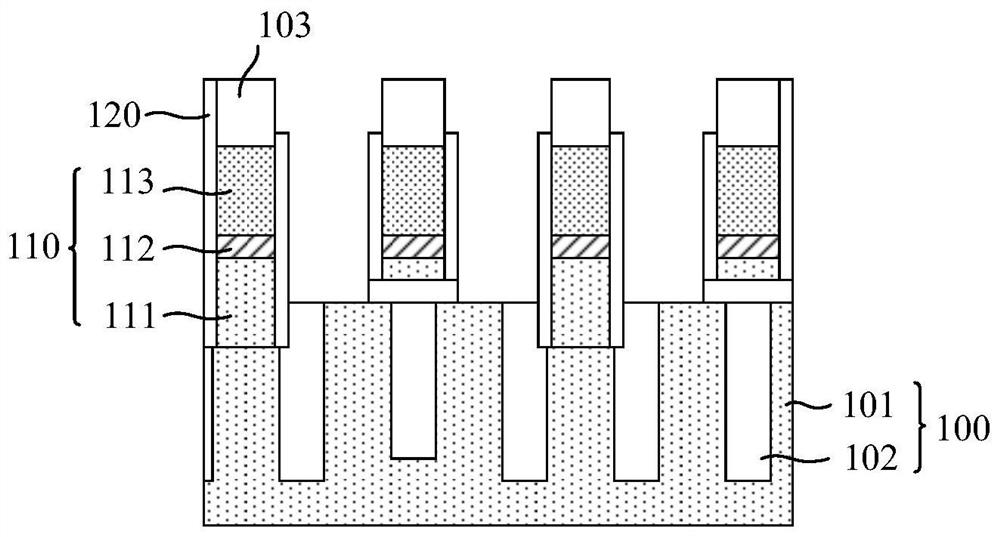

Semiconductor structure and forming method thereof

ActiveCN113078115AIncrease the conductive contact areaReduce contact resistanceTransistorSemiconductor/solid-state device manufacturingSemiconductor structureStructural engineering

The embodiment of the invention provides a semiconductor structure and a forming method thereof. The semiconductor structure comprises the following steps: providing a substrate and a plurality of mutually separated conductive structures located on the substrate; forming an insulating layer on the upper surface of each conductive structure; forming an isolation structure, wherein the isolation structure is located on the side wall of each conductive structure and the side wall of each insulating layer; removing part of the isolation structure on the side wall of the insulating layer, wherein the upper surface of the residual isolation structure is higher than the upper surface of the conductive structure; removing part of the insulating layer away from the conductive structure, and in the direction perpendicular to the side wall of the insulating layer, the width of the top of the remaining insulating layer being smaller than that of the bottom of the remaining insulating layer; the surface of the substrate, the side wall of the isolation structure and the side wall of the insulating layer defining a groove, and the width of an opening of the groove being larger than that of the bottom of the groove in the direction perpendicular to the side wall of the groove. The embodiment of the invention is beneficial to improving the performance of the semiconductor structure.

Owner:CHANGXIN MEMORY TECH INC

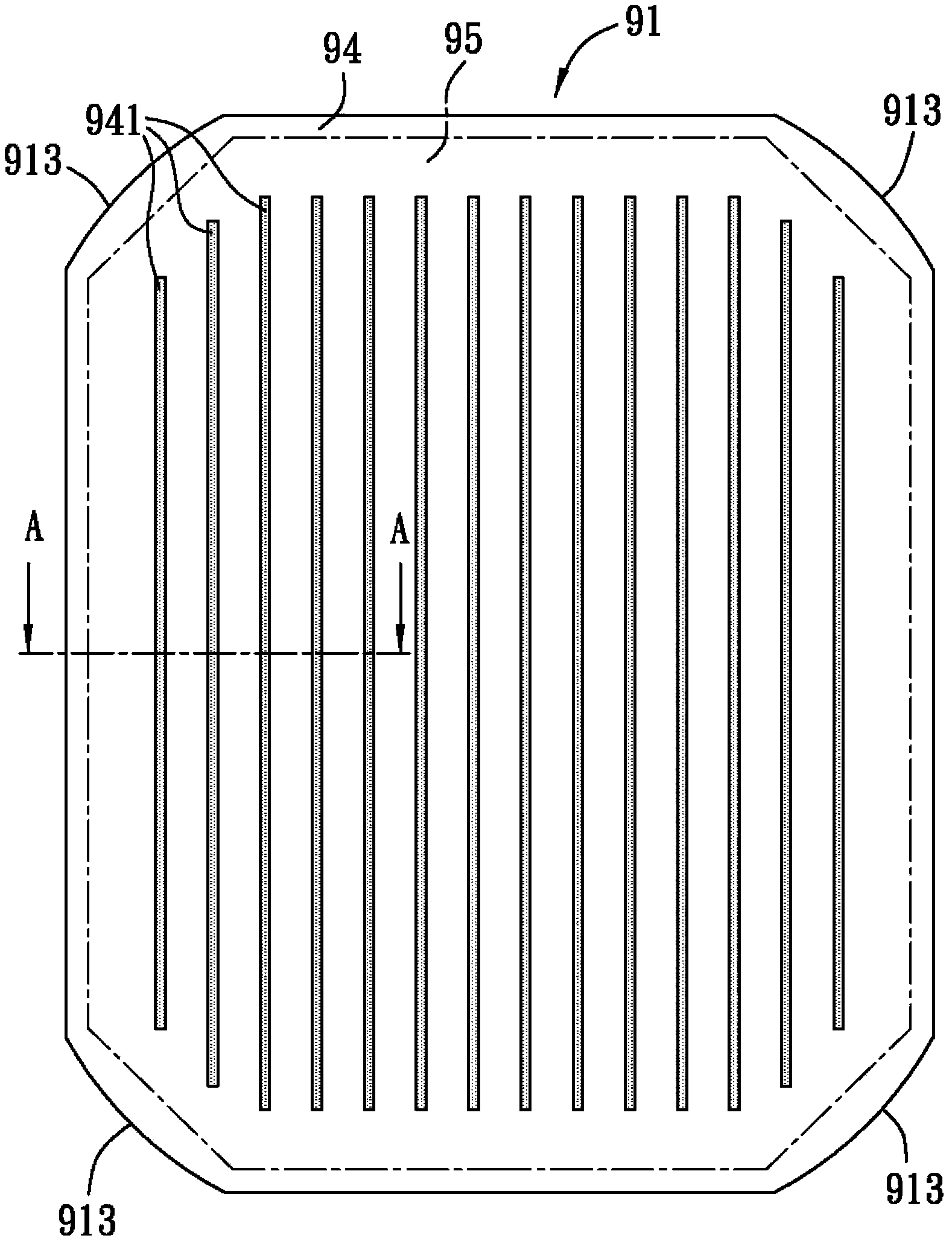

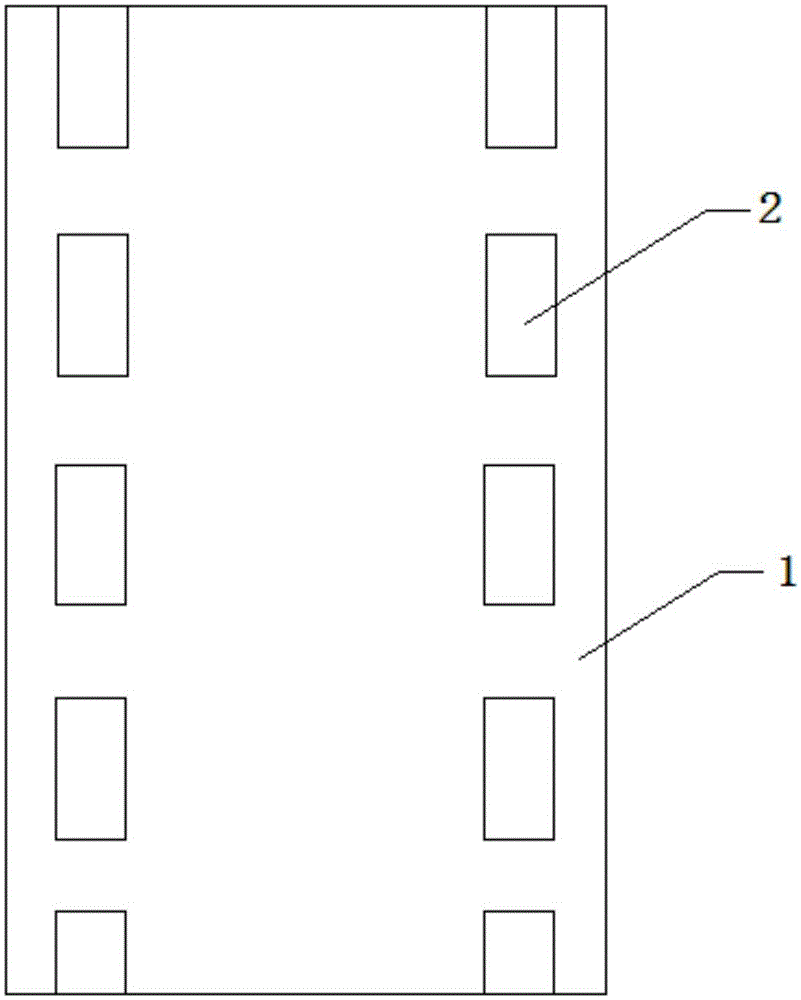

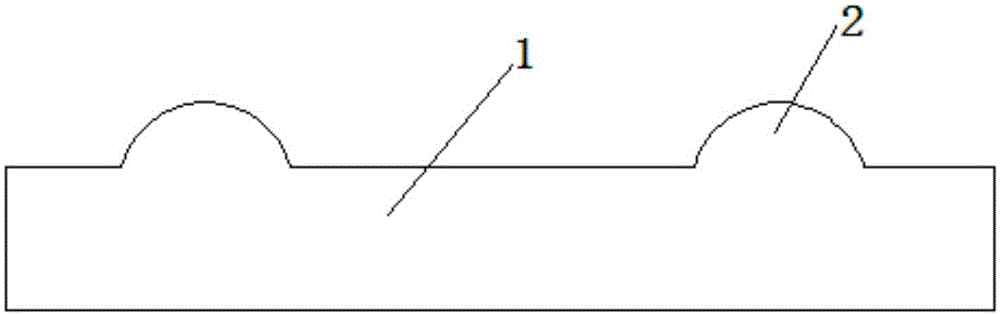

Novel copper electric-conducting bar

InactiveCN105063668ALarge flow areaSimple structurePhotography auxillary processesProcess efficiency improvementElectrical resistance and conductanceSolid structure

The invention discloses a novel copper electric-conducting bar which comprises a copper substrate, wherein both sides of the copper substrate are respectively provided with a plurality of solid-structure electric-conducting contact bulges which are arranged in a continuous mode, and the distance between every two adjacent electric-conducting contact bulges is 5-12cm. The novel copper electric-conducting bar is simple in structure; and the electric-conducting contact points of the electric-conducting bar adopt the plurality of solid-structure electric-conducting contact bulges, so that the electric-conducting contact area of the electric-conducting bar is increased in the use process, thereby increasing the current passage area, reducing the resistance, relieving the heating phenomenon in the equipment use process, and having obvious energy-saving effect.

Owner:无锡斯普流体设备有限公司

A conductive contact piece and an electrical connector using the conductive contact piece

ActiveCN105977678BAvoid stub radiation effectReduce insertion lossCoupling contact membersElectricityElectrical connector

The present invention provides an electric conduction contact component and an electric connector using the same. The electric conduction contact component comprises a base body which extends flatly and straightly; the front end of the base body is connected with a first connecting section which is arranged in an upwards tilting manner through a first bent section; the front end of the first connecting section is connected with a contact section through a second bent section; the contact section is provided with a front contact portion which is in electric conduction contact with a matched electric conduction contact component; the lower side surface of the first connecting section is provided with a rear contact point which is in electric conduction contact with the front contact portion of the matched electric conduction contact component; and the front contact portion and space at the upper side and lower side of the base body form an insertion space into which the matched electric conduction contact component can be inserted. The electric conduction contact component provided by the invention is simple in structure. With the electric conduction contact component adopted, multi-point contact can be realized, the radiation effect of a short pile can be eliminated, and insertion loss can be decreased.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Display panel and display equipment

InactiveCN113112927AMeet electrostatic discharge requirementsMeet structural design requirementsElectrostatic discharge protectionIdentification meansMechanical engineeringElectrostatic discharge

The embodiment of the invention provides a display panel and display equipment. The display panel comprises an electrostatic discharge layer, an electrostatic discharge connecting part and a composite functional film layer which are located on the same side of the electrostatic discharge layer, and a display substrate located on the side, away from the electrostatic discharge layer, of the composite functional film layer. A first accommodating space formed in the side, close to the display substrate, of the electrostatic discharge layer can accommodate at least part of the electrostatic discharge connecting part, and the display substrate is conducted with the electrostatic discharge layer through the electrostatic discharge connecting part, so that the conductive contact area between the display substrate and the electrostatic discharge layer can be increased; therefore, electrostatic charges gathered at the display substrate quickly and timely flow into the electrostatic discharge layer through the electrostatic discharge connecting part, so that the electrostatic discharge requirement of the display panel is met. An orthographic projection, on the electrostatic discharge layer, of the electrostatic discharge connecting part contained in the first accommodating space is located in the electrostatic discharge layer, so that the structure of the display panel does not need to be greatly adjusted, and the structural design requirement of the display panel can be met.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

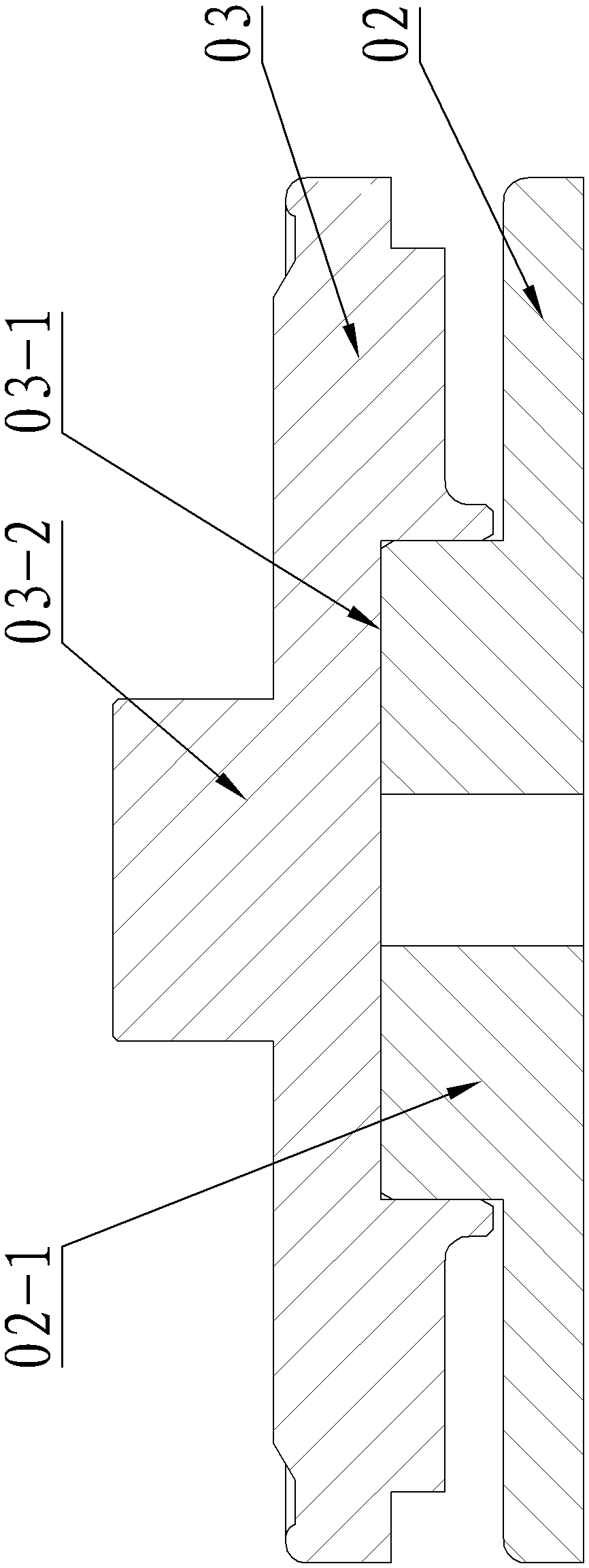

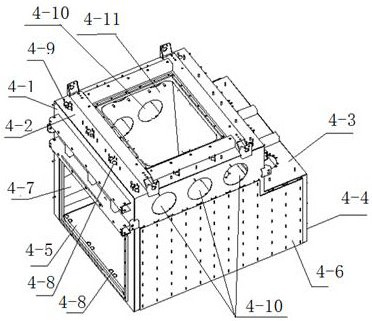

Embedded copper bar connector

ActiveCN106953216AAchieve connectionIncrease the conductive contact areaCoupling device connectionsButt jointEngineering

The present invention discloses an embedded copper bar connector. The embedded copper bar connector comprises a connector main body and an embedding body. The connector main body has a U-shaped structure with a U-shaped neck, the connector main body comprises a main body front plate, a main body rear plate and a main body bottom plate, the inner side surface of the main body front plate is provided with a front caulking groove, the inner side surface of the main body rear plate is provided with a rear caulking groove, the embedding body is a U-shaped structure with a U-shaped neck, the embedding body comprises an embedding front plate, an embedding rear plate and an embedding top plate, the thickness of the embedding front plate is larger than the thickness of the embedding rear plate, two copper rows are butt joint and inserted into the U-shaped neck of the connector main body, the embedding body is buckled with the connector main body, the embedding front plate is inserted into the front caulking groove of the connector main body, the embedding rear plate is inserted into the rear caulking groove of the connector main body, and the embedding body and the connector main body are commonly matched to perform clamping connection of the two copper rows. The structure is simple, the connection of the copper rows are reliable, and the connection operation is convenient, and other tools and screws are not needed.

Owner:SUZHOU A RACK INFORMATION TECH CO LTD

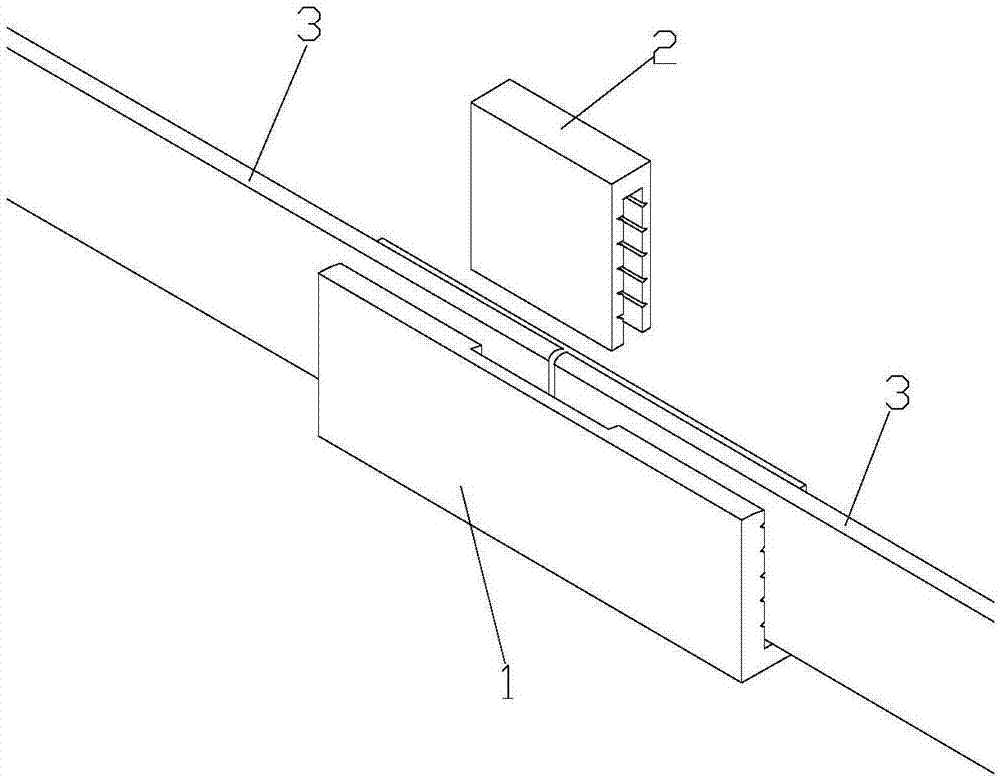

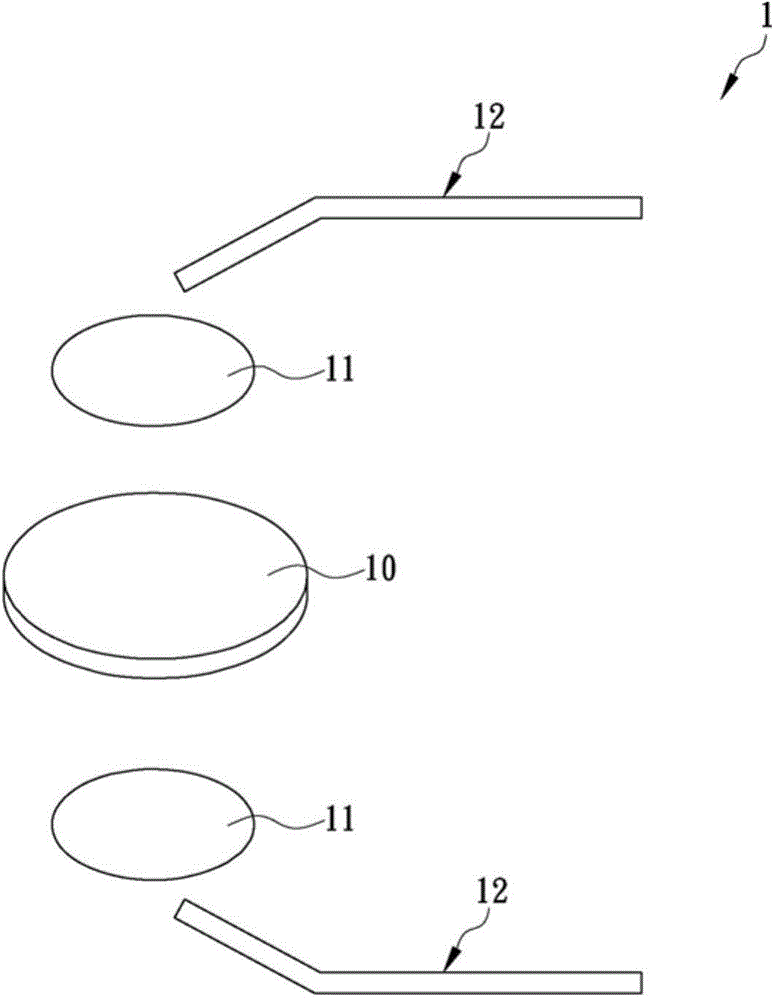

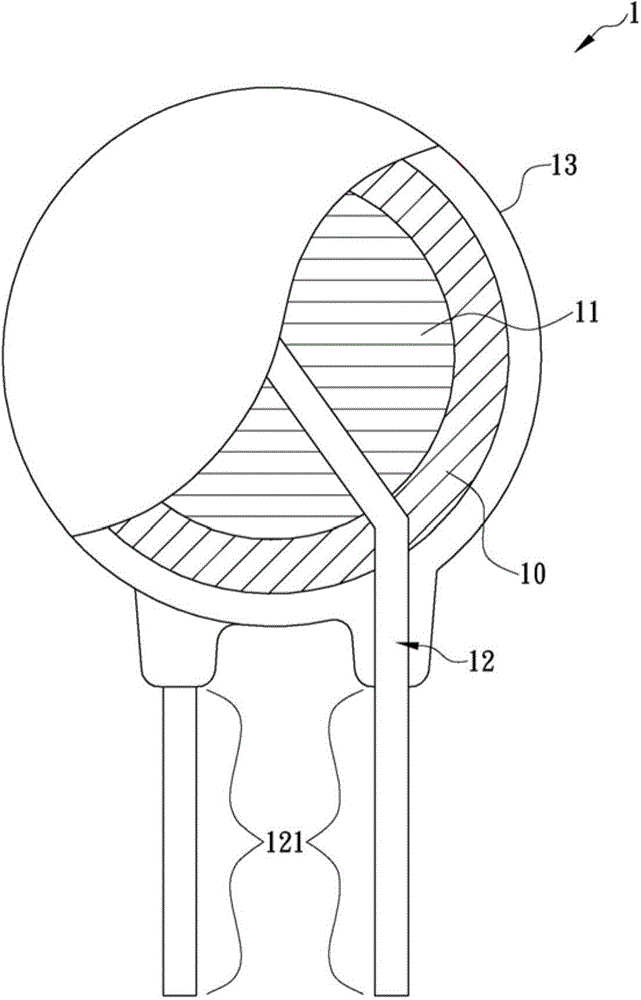

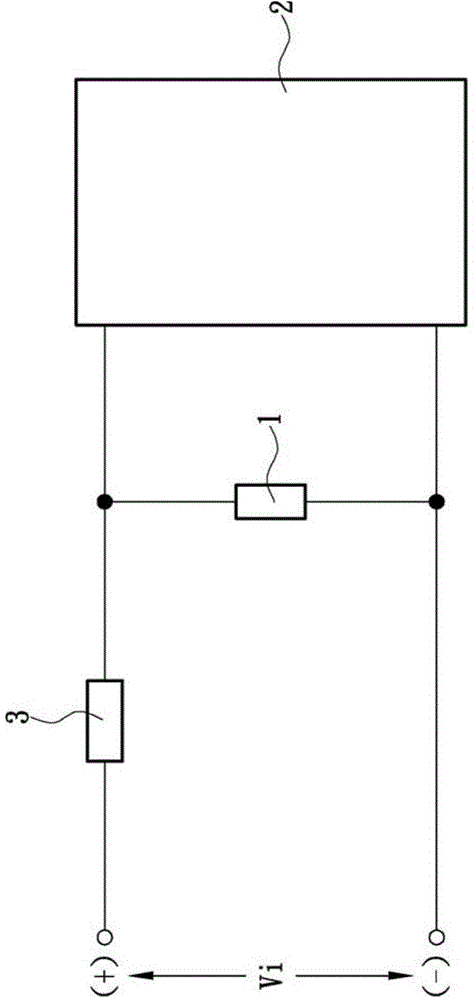

Surge discharge device with fuse and warning mechanism

InactiveCN104867795AIncrease the conductive contact areaEnsure the release effectEmergency protective arrangements for automatic disconnectionEmergency protective arrangements for limiting excess voltage/currentElectricityConductive materials

Owner:陈赞棋

A method for manufacturinga three-dimensional thin film electrode by using an abrasive

ActiveCN108986986AIncrease the conductive contact areaIncrease productivityGrapheneCarbon nanotubesThin film electrodeSurface layer

The invention relates to the field of manufacturing thin film electrodes, in particular to a method for manufacturing a three-dimensional thin film electrode by using an abrasive. Aiming at defects including the troubles of deformation machining, difficult-to-control deformation effect, long manufacturing period, low efficiency and the like of the thin film electrode layer on the surface of the existing three-dimensional thin film electrode, the method for manufacturing the three-dimensional thin film electrode by using the abrasive is provided. Solid abrasive particles are placed on the surface layer of the thin film electrode for grinding and pressing so as to press the solid abrasive from top to bottom so that part of the solid abrasive is embedded in the surface layer of the thin filmelectrode to deform the surface layer of the thin film electrode and indentation is generated. The indentation forms corresponding rugged three-dimensional undulation on the surface layer of the thinfilm electrode, then the pressure is released and the solid abrasive is removed to obtain the three-dimensional thin film electrode, the thin film electrode is composed of a base layer and a thin filmelectrode layer arranged on the base layer, and the thin film electrode layer is the surface layer of the thin film electrode. Surface layer deformation processing operation of the three-dimensionalthin film electrode manufactured by the method is simple, the deformation effect is easy to control, and the manufacture period is short and the production efficiency is high.

Owner:ZHEJIANG ZHENENG TECHN RES INST

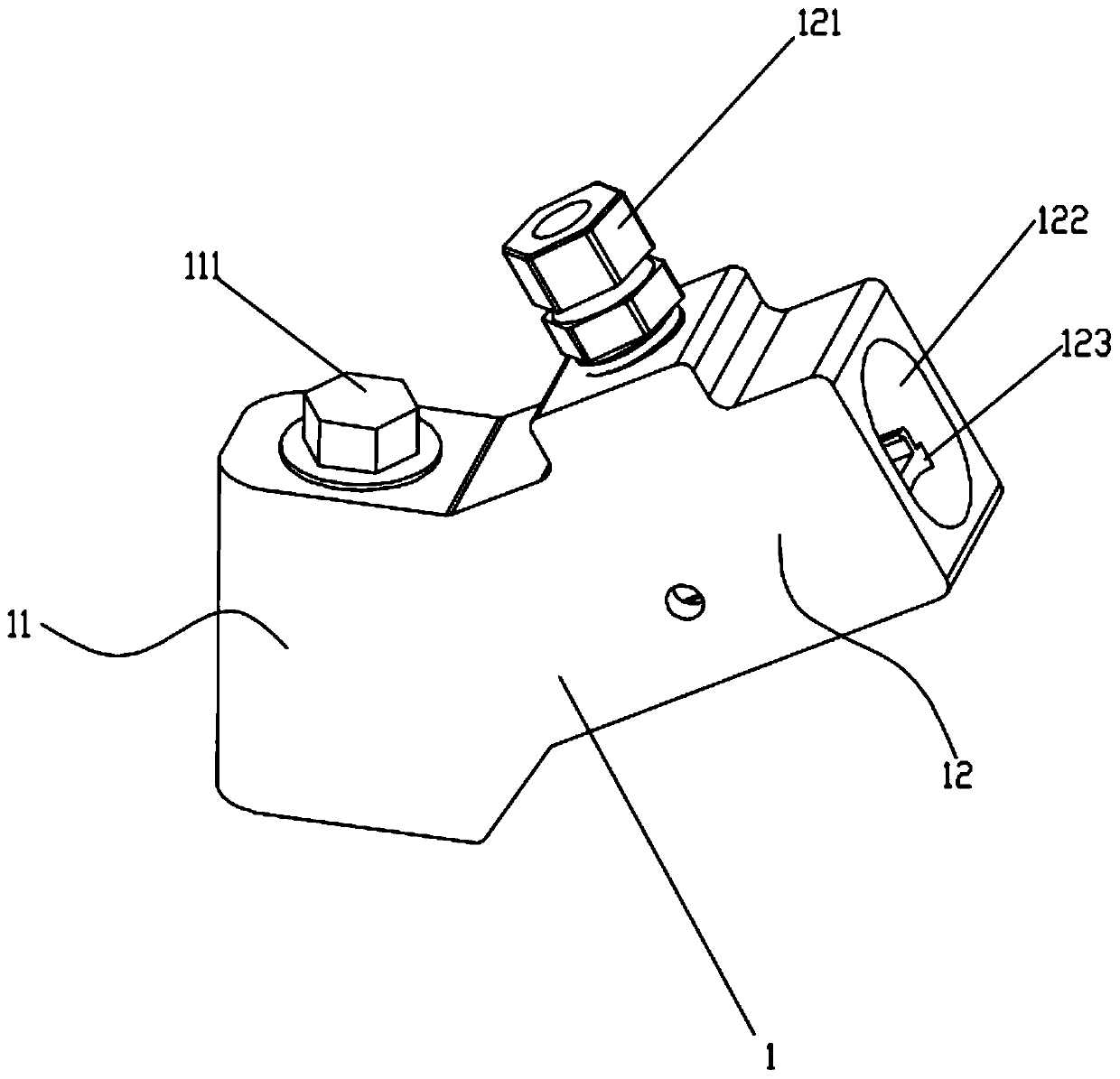

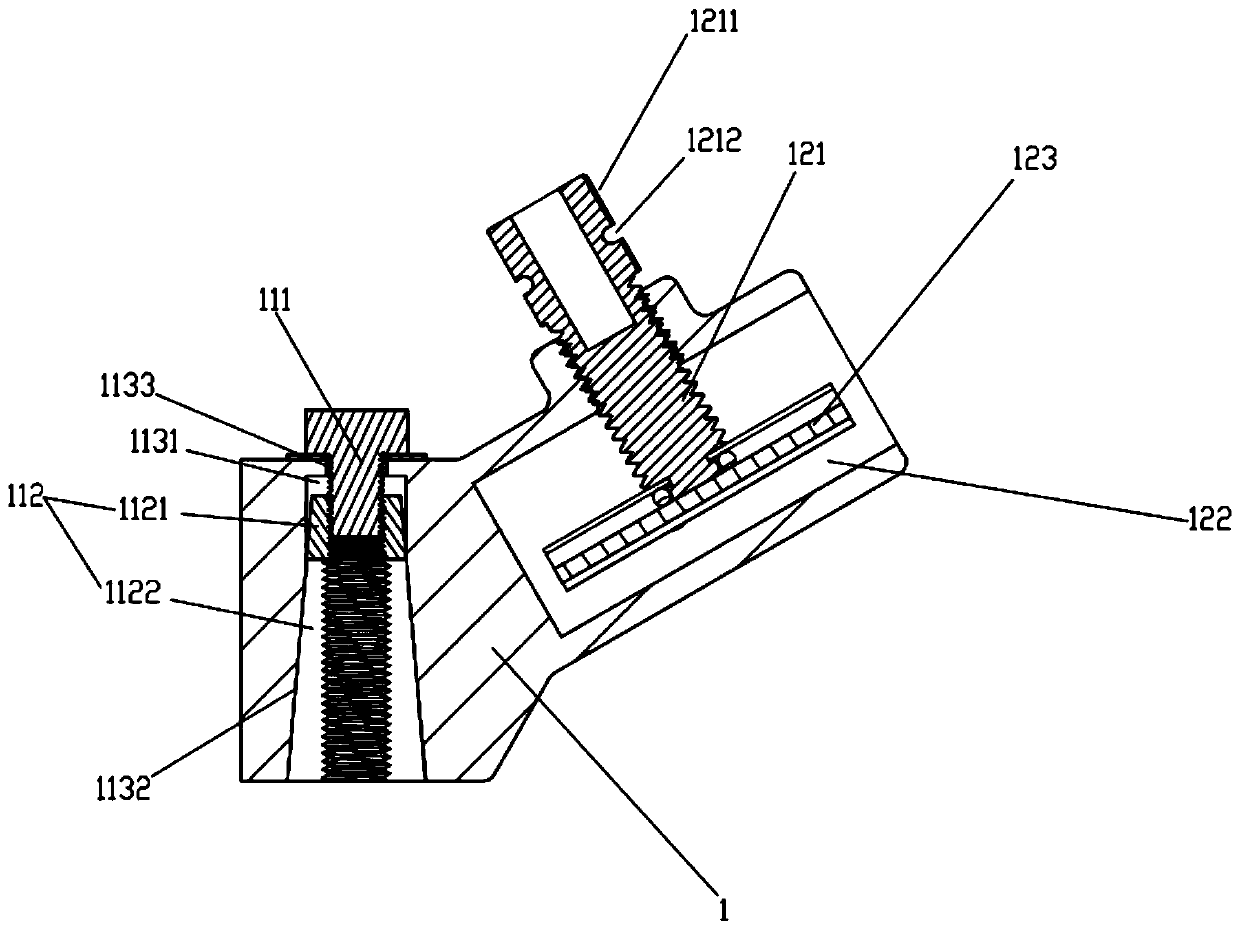

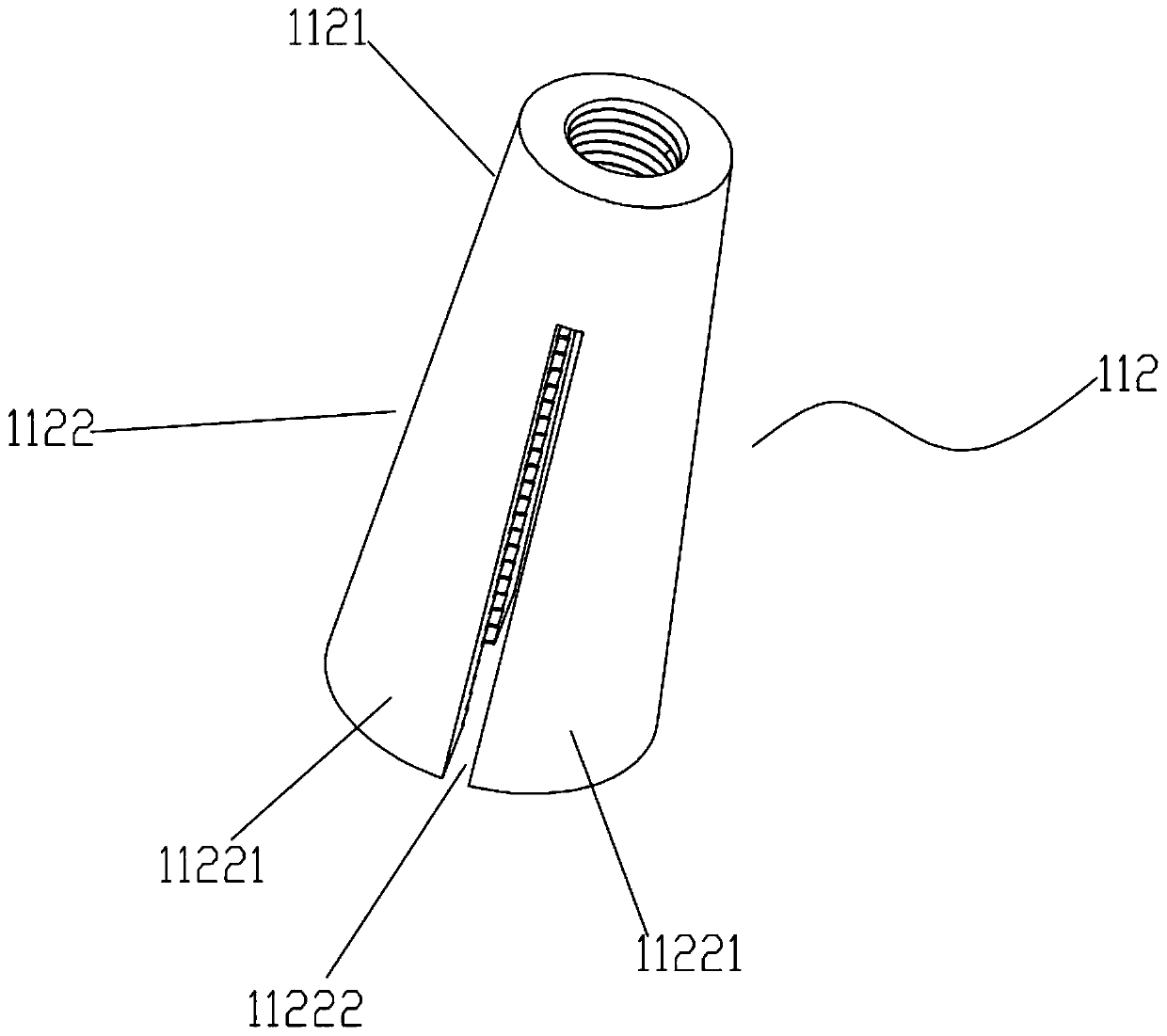

Transformer wiring device

PendingCN110611179AAvoid damageFirmly connectedTransformers/inductances coils/windings/connectionsClamped/spring connectionsTransformerScrew head

The invention relates to the technical field of power tools and particularly relates to a transformer wiring device. The transformer wiring device comprises a wiring device body provided with a fastening mechanism and a wiring mechanism. The fastening mechanism comprises a tension bolt, a conical crimping sleeve and a conical tightening hole formed in the wiring device body; the crimping sleeve iscoaxially arranged in the tightening hole; the conical crimping sleeve is attached to the conical tightening hole, and both small-diameter ends face upwards; the conical side wall of the lower part of the crimping sleeve is enclosed by at least two elastic crimping sheets; an inner hole of the crimping sleeve is a screw hole; one end of the tension bolt is hung outside the wiring device body through a screw head, and the other end is in threaded connection with the upper part of the crimping sleeve; and the lower part of the crimping sleeve is in threaded connection with the transformer wiring stud. The transformer wiring device provided by the invention is firmly connected with the transformer wiring stud, is convenient to assemble and disassemble, and occupies small space during assembly and disassembly.

Owner:GUANGZHOU PANYU CABLE WORKS

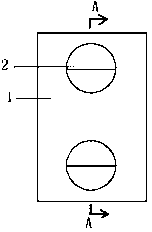

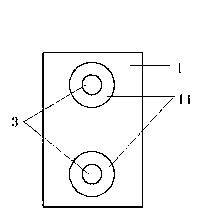

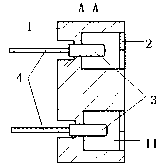

Cylindrical socket

InactiveCN103078202AOvercome bad contactIncrease the conductive contact areaCoupling contact membersEngineeringBody positions

The invention discloses a cylindrical socket. The cylindrical socket comprises a socket body, a safe cover and socket columns, wherein two or more socket jacks are formed in the socket body; the cylindrical socket columns are arranged on the socket body positioned in the socket jacks; the front ends of the socket columns can be chamfered into smooth ends without corners according to specific requirements; and one socket column is arranged in each socket jack. The cylindrical socket has the beneficial effects that due to the match between the cylindrical socket and a pipe type plug, the conduction contact area is increased, the requirement of a high-power electric appliance can be met, and the defect that the plug and the socket are not well contacted and are easy to loosen in the traditional socket can also be overcome.

Owner:郑福建

Packaging conductive structure and its manufacturing method

ActiveCN100580915CIncrease contact areaReduced risk of open circuitSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

Owner:CHIPMOS TECH INC

Socket

PendingCN111653887AIncrease the conductive contact areaLow calorific valueSecuring/insulating coupling contact membersCoupling contact membersElectrical connectionStructural engineering

The invention discloses a socket, which is provided with a socket panel and an electric connection system. The socket panel is provided with a bolt fixing frame. The electric connection system is provided with a mounting seat, a power connection sheet and a spring jacking mechanism, and the mounting seat is provided with a power connection sheet mounting groove and a spring groove. Through arranging the bolt fixing frame, when the plug and the plug pin are inserted into the socket, the plug pin is inserted into the plug pin fixing frame, the plug pin fixing frame can fix the plug pin, and whenthe plug pin makes contact with the conductive contact plane of the power connection piece, under the action of the jacking spring and the plug pin fixing frame, tight combination of the plug pin andthe conductive contact plane can be guaranteed, and the plug pin can be prevented from being bent or deformed. The conductive contact planes of the power connection sheets are in surface-to-surface contact with the conductive sheets of the plug, so that the conductive contact area is increased, and the heat productivity during electrification is reduced. Because the power connection sheet moves left and right under the acting force of the spring jacking mechanism, the power connection sheet does not deform in the moving process.

Owner:苏茂均

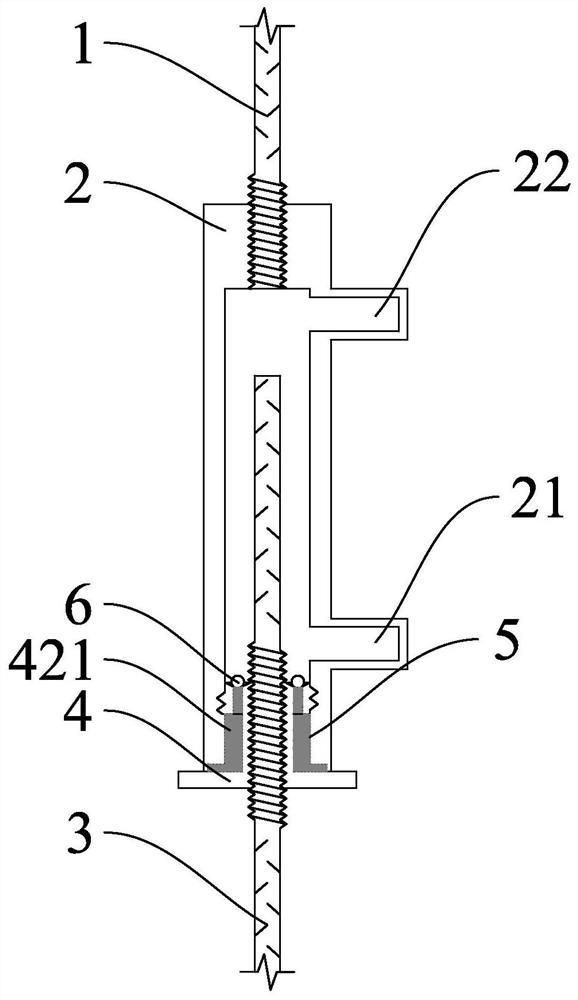

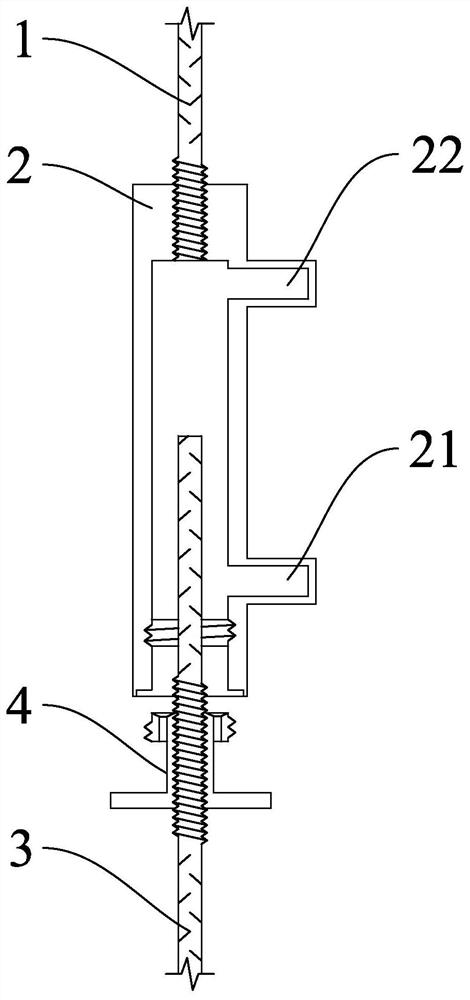

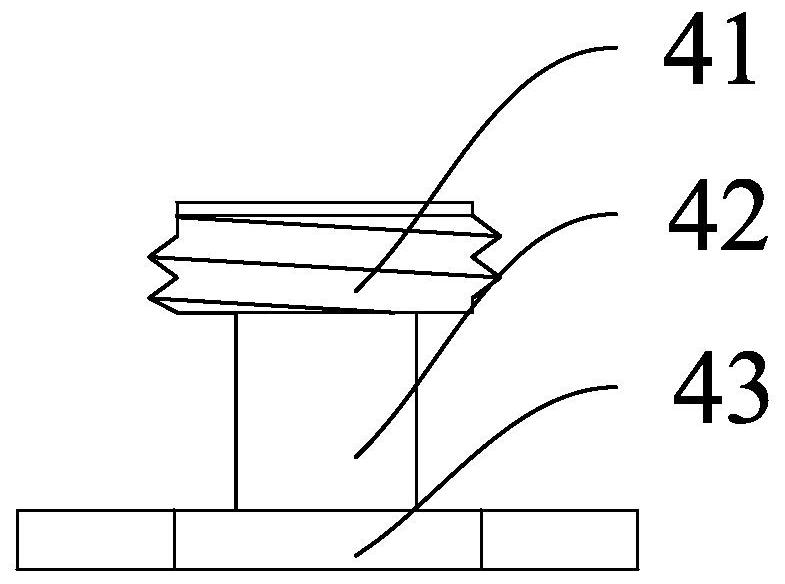

Sleeve connection device and construction method for lightning protection and grounding of prefabricated buildings

PendingCN111677191AEasy accessEasy to operateBuilding reinforcementsConnection contact member materialArchitectural engineeringRebar

The invention discloses a sleeve connection device for lightning protection and grounding of prefabricated buildings. The connection device comprises an upper reinforcement structure, a grouting sleeve and a lower reinforcement structure, one end of the upper reinforcement structure is connected with one end of the grouting sleeve, the sleeve connection device further comprises a connecting pieceextending into one end of the grouting sleeve away from the upper reinforcement structure, the connecting piece sleeves the lower reinforcement structure, and a conductive medium is filled between theconnecting piece and the grouting sleeve. The invention also discloses a construction method. The construction method comprises the following steps that (1) the end of the upper reinforcement structure is connected with the end of the grouting sleeve; (2) the connecting piece sleeves the lower reinforcement structure, and the connecting piece is connected with the grouting sleeve; (3) the conductive medium is filled between the connecting piece and the grouting sleeve; and (4) the grouting sleeve is grouted. Through filling the conductive medium between the connecting piece and the grouting sleeve, the conductive contact area of the connecting piece and the grouting sleeve is increased, and stable electrical conduction between the upper reinforcement structure and the lower reinforcementstructure is ensured.

Owner:THE ARCHITECTURAL DESIGN & RES INST OF ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com