A method for manufacturinga three-dimensional thin film electrode by using an abrasive

A thin-film electrode and abrasive technology, which is applied in the manufacturing of circuits, electrical components, cables/conductors, etc., can solve the problems of difficult control of deformation effect, troublesome deformation processing, long manufacturing cycle and low efficiency, etc., and achieves simple and convenient processing and short manufacturing cycle. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

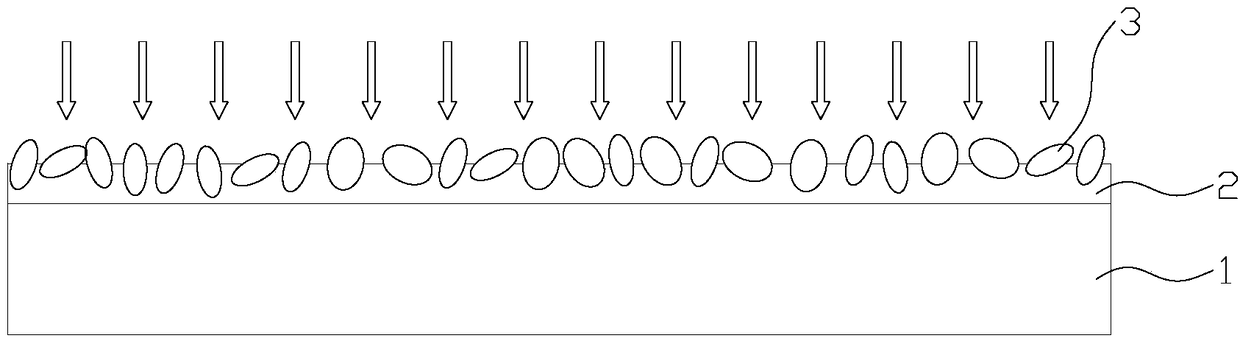

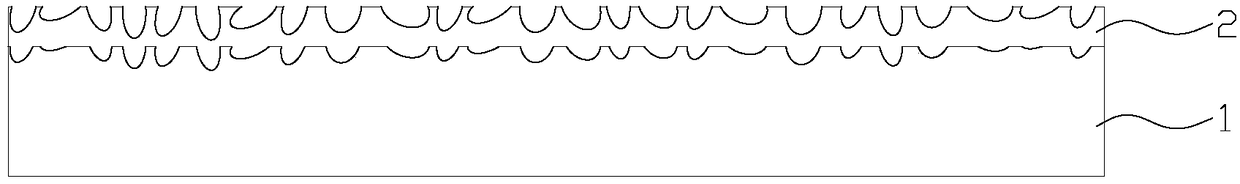

[0020] Example 1 as figure 1 As shown, a method for making a three-dimensional thin film electrode using abrasives is characterized in that solid abrasive 3 particles are placed on the surface of the thin film electrode for grinding and pressing, and the grinding pressure is to apply pressure to the solid abrasive 3 to partially embed the surface of the thin film electrode so that The surface layer of the thin film electrode is deformed to produce indentations, and the indentations form corresponding uneven three-dimensional undulations on the surface layer of the thin film electrode. After the pressure is released, the solid abrasive 3 is removed to obtain a three-dimensional thin film electrode. The thin film electrode consists of the base layer 1 and the device. The thin film electrode layer 2 is formed on it, and the thin film electrode layer 2 is the surface layer of the thin film electrode.

[0021] The present invention grinds and presses the surface layer of the thin f...

Embodiment 2

[0026] Example 2 as image 3 As shown, a method for making a three-dimensional thin film electrode using abrasives, the difference from Example 1 is that the base layer 1 is a single-layer rigid layer, and the rigid layer is a single material layer, and the rest are the same as in Example 1. Similarly, during processing, the rigid layer does not deform with the shape change of the thin film electrode layer 2 during the grinding and pressing process of the solid abrasive 3 and maintains a planar state. In addition, the base layer 1 can also be a multi-layer structure, the multi-layer structure is a plurality of layers of different materials, in the multi-layer structure, the layer next to the thin film electrode layer 2 is a rigid layer, and the rigid layer is formed during the grinding and pressing process of the solid abrasive 3 The center still does not deform with the shape change of the thin film electrode layer 2 and maintains a planar state.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com