Embedding method of conducting metal plate for heating floor

A conductive metal sheet and metal sheet technology, applied in the field of wood floor manufacturing, can solve problems such as poor contact, exposure, and safety discounts, and achieve the effects of increasing the conductive contact area, increasing the resin bonding area, and increasing the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

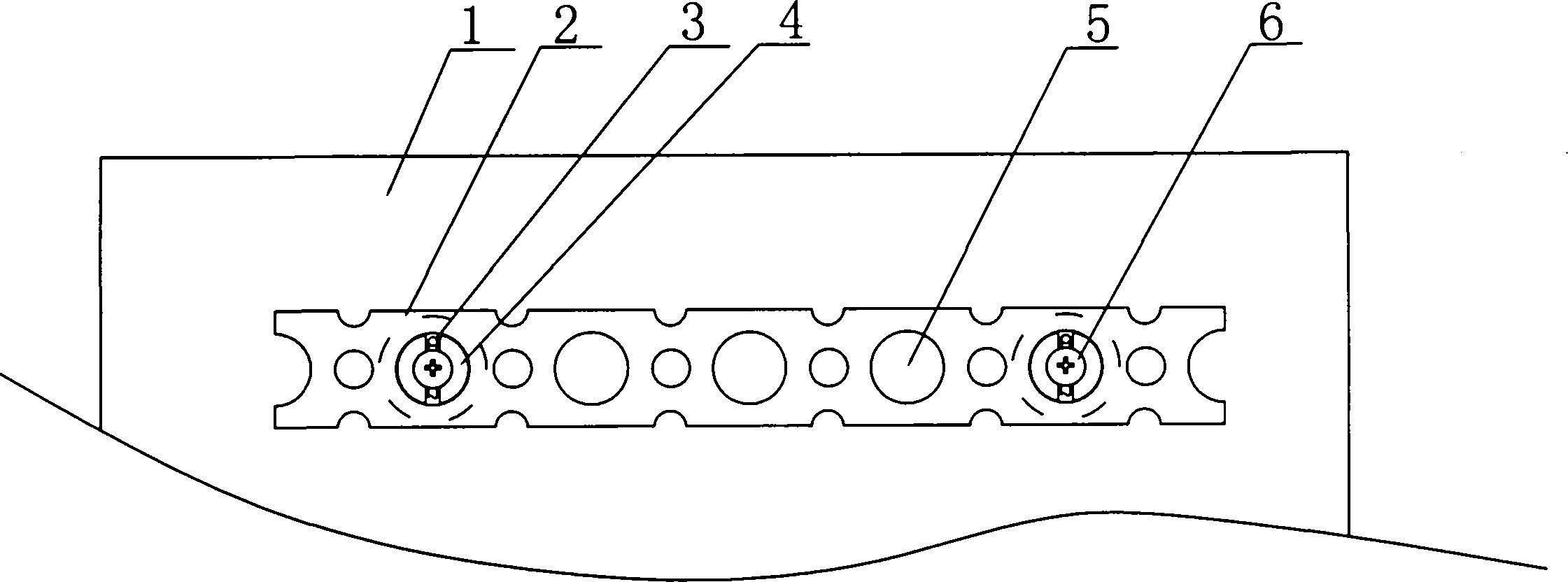

[0010] Embodiment 1, as figure 1 As shown, a method for implanting a conductive metal sheet for heating floors, the method is to use a sheet metal sheet as a conductor to directly contact the far-infrared carbon fiber heating paper 1, and connect the terminal 4 in parallel through high temperature and high pressure of the resin to make it two. It is implanted into the heating floor to form an internal power supply system; the specific implantation method is: 1. Drilling, when molding the heating floor, take a substrate with milled horizontal grooves and drilled holes, and the milled grooves One side facing up, spread a piece of impregnated paper, and punch holes on the impregnated paper through the mold holes, and cover the base material after the impregnated paper is punched; 2. Install the conductive metal sheet 2 for the heating floor. The conductive metal sheet 2 is installed on the perforated rubber-impregnated paper, and the conductive metal sheets 2 are installed in par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com