Mounting device and structure for semiconductor component, electro-optical device and producing method thereof

An installation method and installation structure technology, which are applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, and semiconductor/solid-state device components, etc., can solve problems such as poor short circuits, reduced reliability of conductive joints, and deterioration of product yields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Embodiments of a semiconductor device mounting method, a semiconductor device mounting structure, an electro-optical device, and an electronic device according to the present invention will be described in detail below with reference to the accompanying drawings.

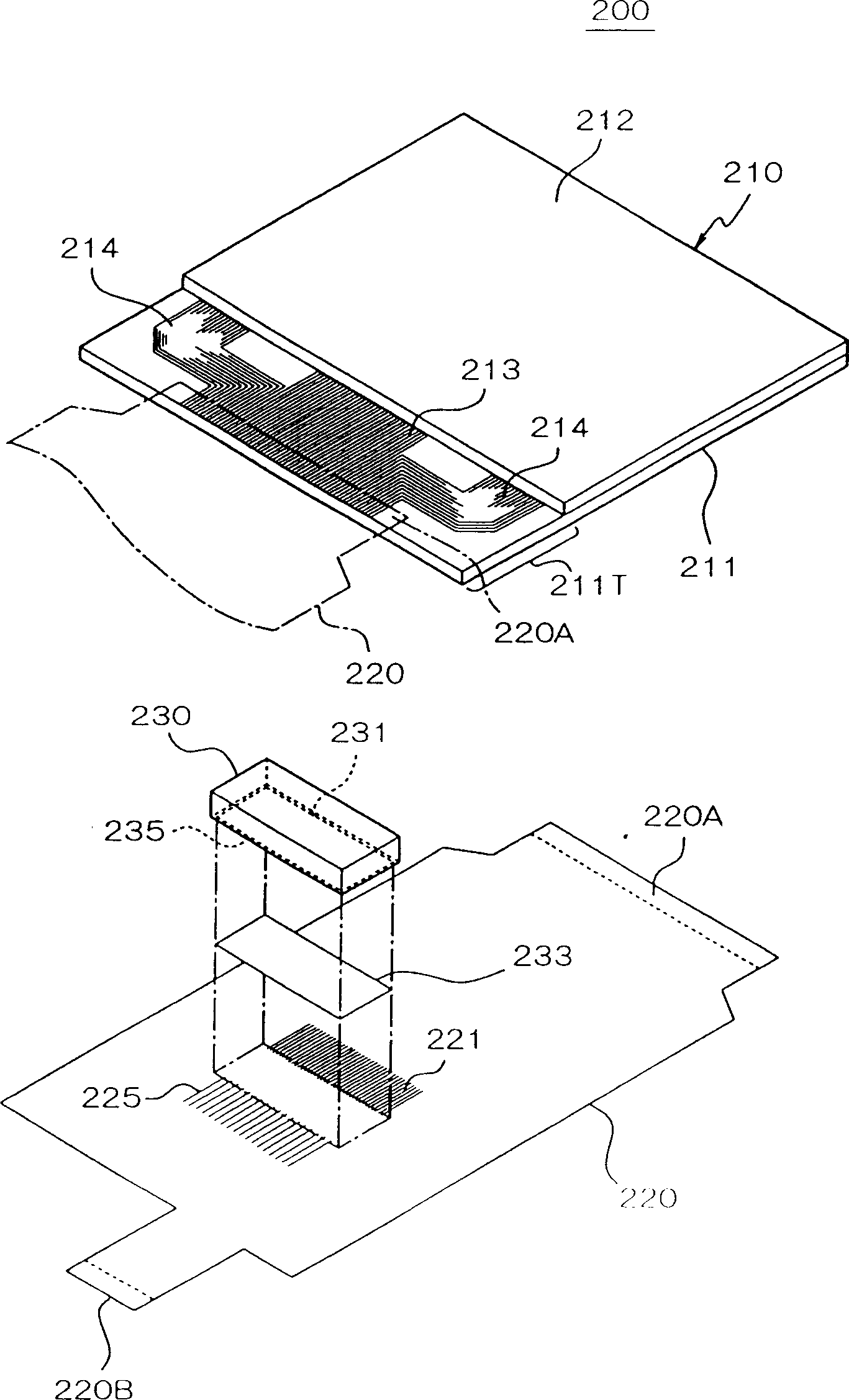

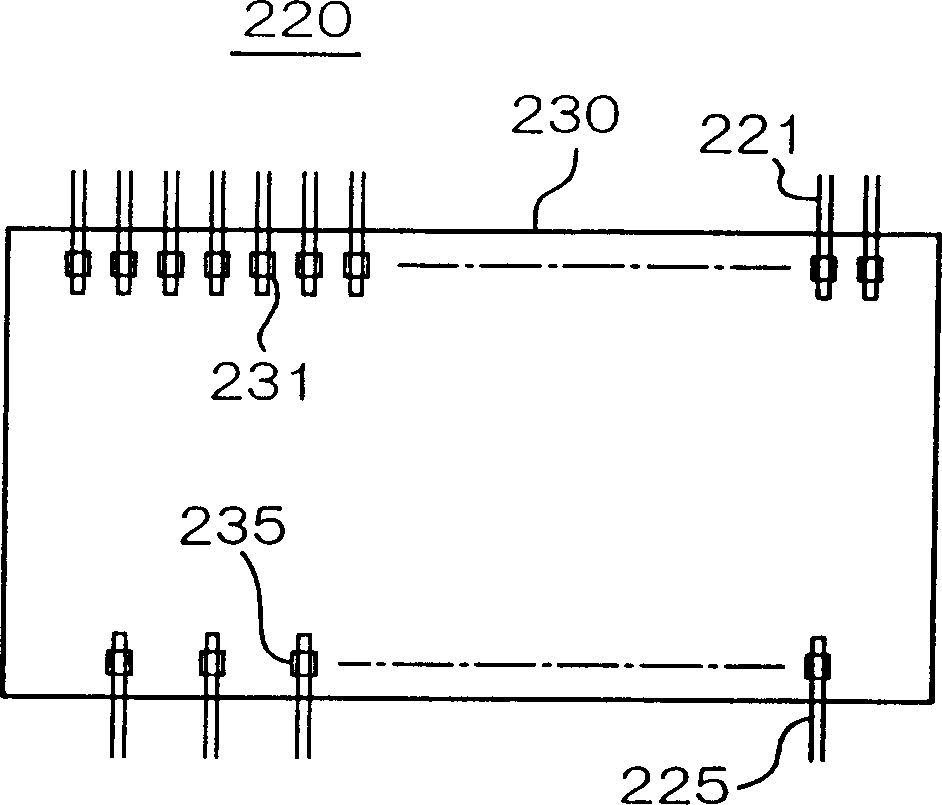

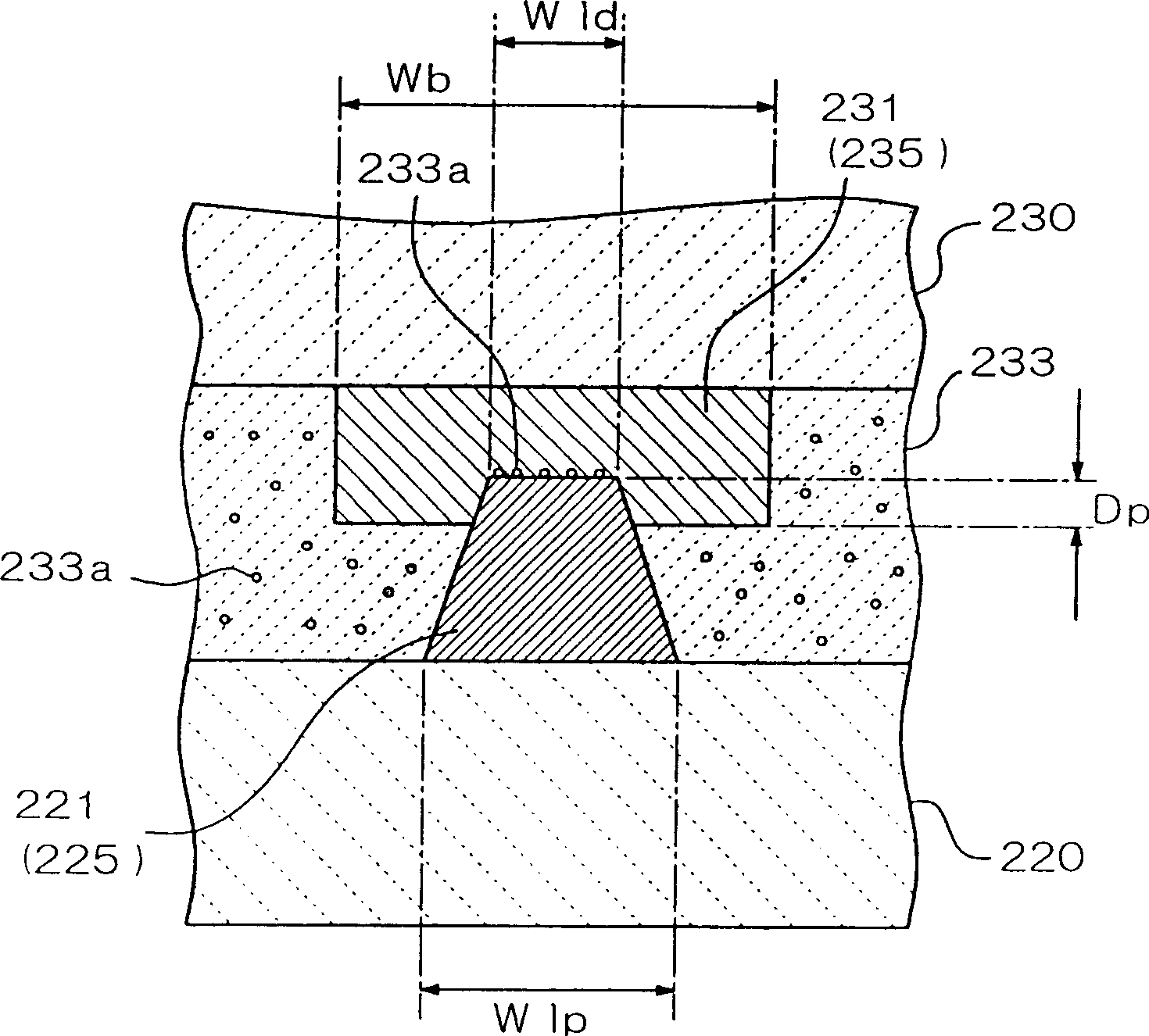

[0067] figure 1 It is an exploded perspective view showing the overall configuration of the liquid crystal device 200 as the electro-optical device of the present embodiment. This liquid crystal device 200 includes a liquid crystal panel 210 , a wiring board (wiring board) 220 connected to the liquid crystal panel 210 , and a semiconductor device (semiconductor bare chip) 230 mounted on the wiring board 220 .

[0068] In the liquid crystal panel 210 , substrates 211 and 212 made of transparent glass, plastic, or the like are bonded together with a sealing material (not shown), and liquid crystal (not shown) is sealed therein. In this liquid crystal panel 210, depending on the liquid crystal mode, a polarizi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com