Electrode lead-out structure

An electrode extraction and cell technology, applied in structural parts, hybrid capacitor electrodes, circuits, etc., can solve problems such as affecting the production efficiency of energy storage devices, sudden changes in performance of energy storage devices, and increasing processing difficulty, saving assembly time and extending Service life, the effect of increasing the conductive contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

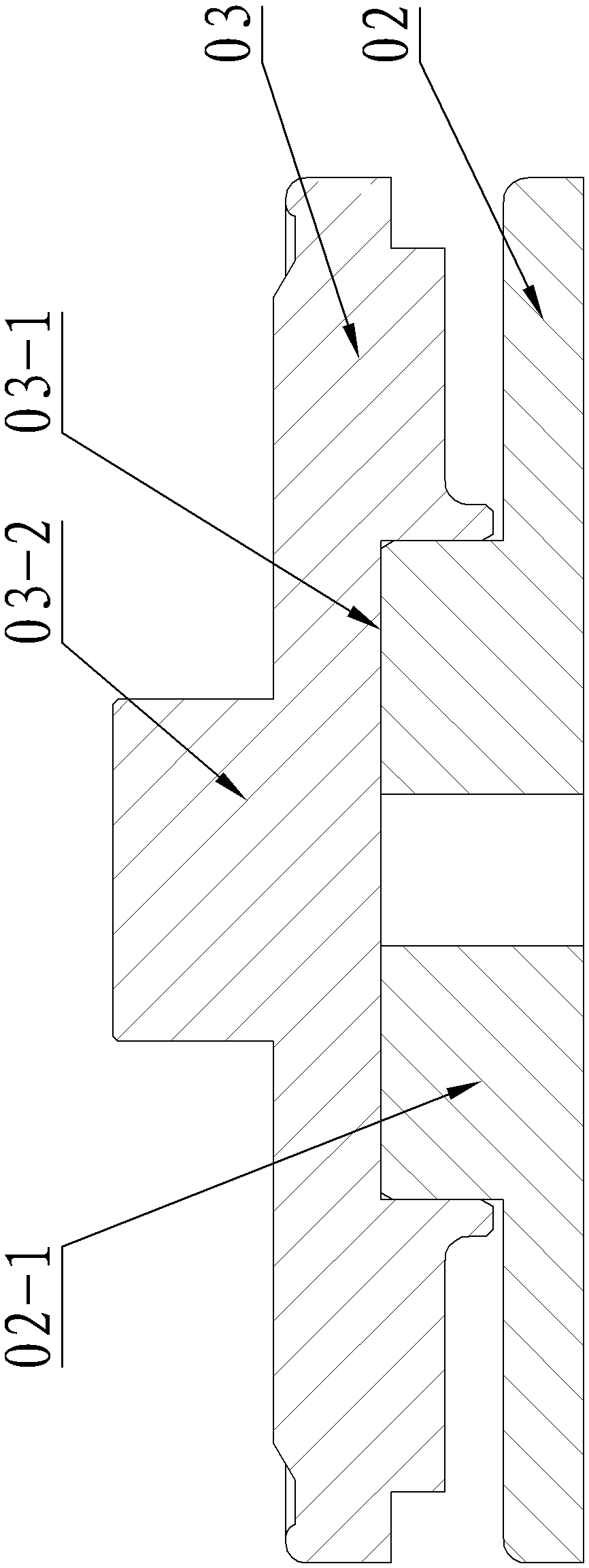

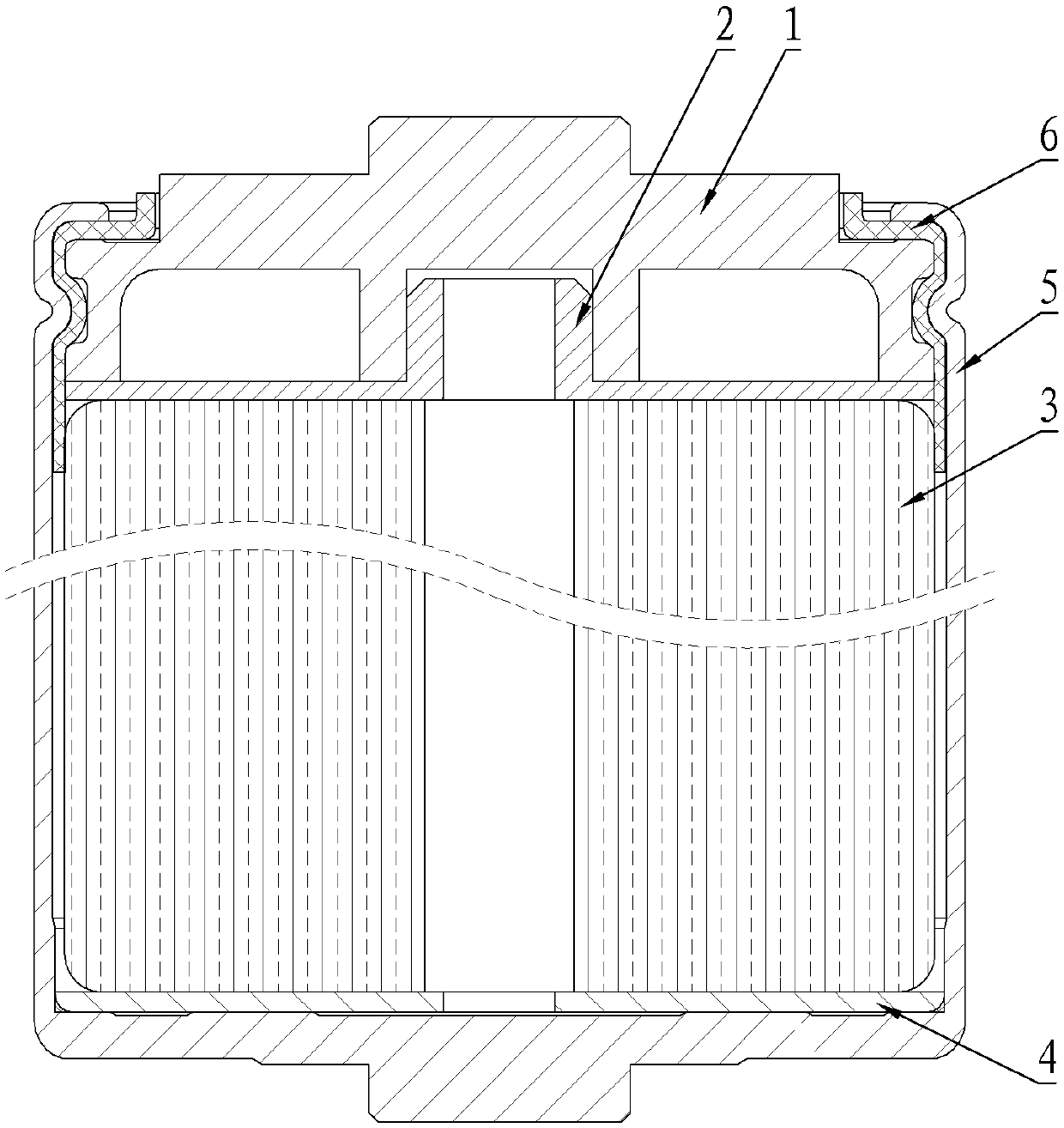

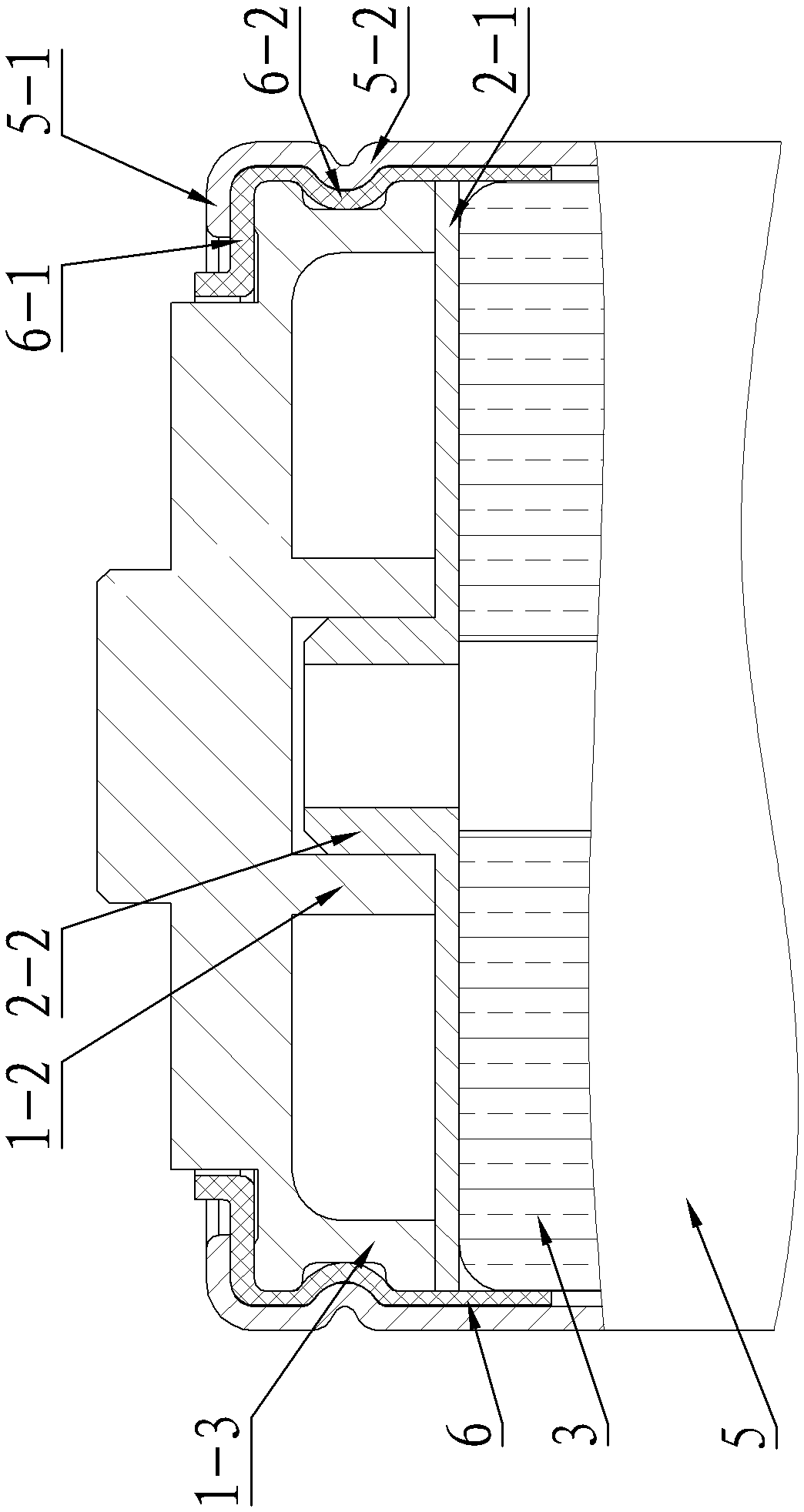

[0032] Embodiment 3 of the electrode lead-out structure of the present invention: as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the upper collector plate 32 is composed of a plate body 32-1 and a collector plate protrusion 32-2 protruding from the upper edge of the plate body 32-1. 32-2 is a sleeve shape, the inner peripheral surface of the collector plate protrusion 32-2 and the part of the plate body 32-1 in the collector plate protrusion form a blind hole-like positioning hole, and the end cover 31 is formed by the end cover The disc body 31-1 and the end cap protrusion 31-4 protruding from the lower end surface of the end cap disc body 31-1 are formed, the end cap protrusion 31-4 is solid columnar, and the end cap protrusion 31-4 is transitionally inserted in The upper end of the positioning hole has a retaining edge surrounding the end cap protrusion 31-4 on the lower end surface of the end cap disc body 31-1, and the retaining edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com