Novel copper electric-conducting bar

A copper conductive row, a new type of technology, applied in the direction of electrodes, electrolysis process, electrolytic components, etc., can solve the problems of increased resistance of conductive row, large usage of conductive row, small current flow area, etc., and achieve the increase of conductive contact area , Significant energy-saving effect, and the effect of reducing heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

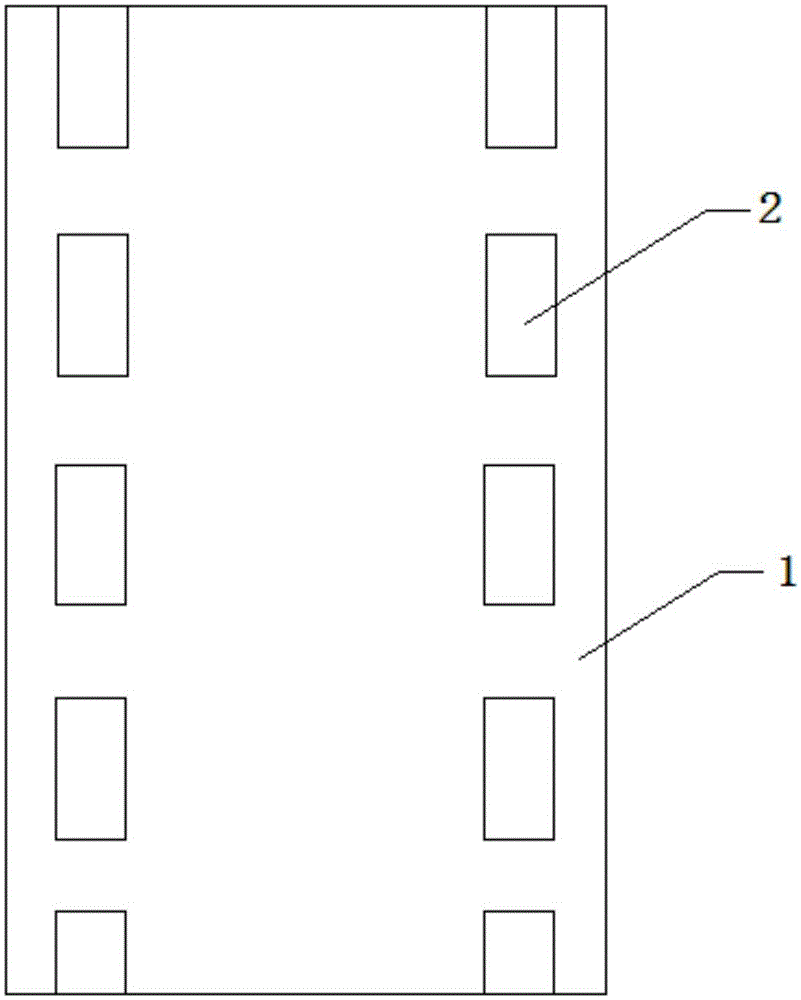

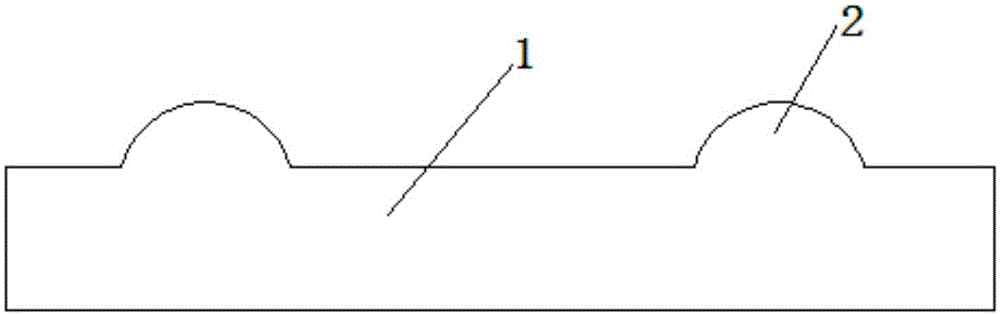

[0008] figure 1 , figure 2 As shown, a new type of copper conductive row is provided, which includes a copper substrate 1, and the two sides of the copper substrate 1 are respectively provided with a plurality of sections of conductive contact protrusions with a solid structure in a continuous arrangement. The distance between the contact protrusions is between 6-15mm. Since the conductive contact point of the traditional copper conductive row is changed to a multi-segment solid conductive contact raised part 2, the conductive contact area of the copper conductive row increases during use, thereby increasing the current flow area and reducing the resistance . Setting the distance between adjacent conductive contact protrusions 2 between 5-12 cm is more conducive to increasing the conductive contact area.

[0009] In addition, when the cross section of the conductive contact protrusion 2 is set as a semicircular structure, the maximum conductive performance of the conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com