Line repairing device

A line and wire technology, which is applied in the field of line repair devices, can solve problems such as increasing the workload of staff, failure to ensure connection reliability, and failure of overcurrent capacity to meet requirements, so as to improve operating efficiency, improve connection reliability, and avoid random effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

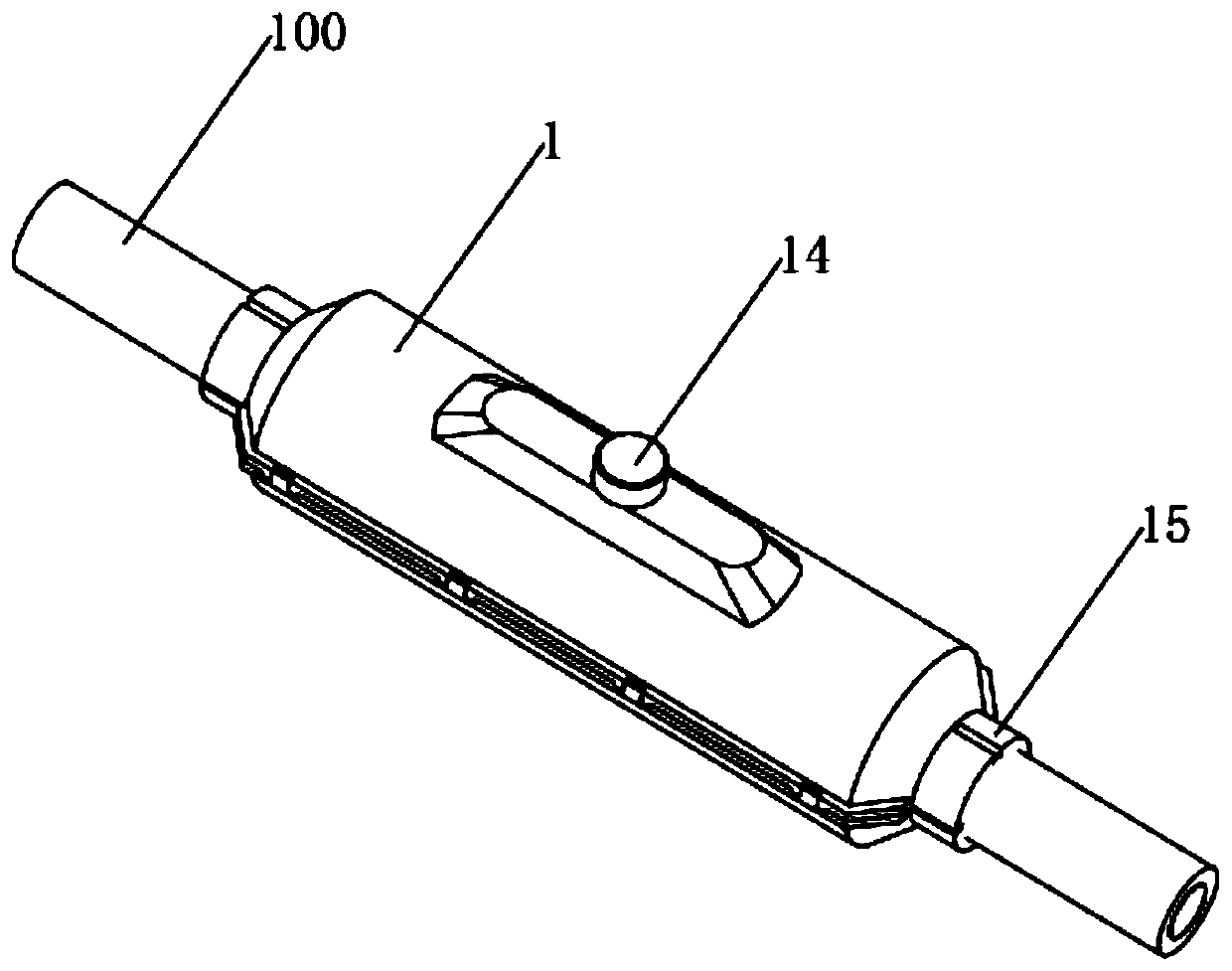

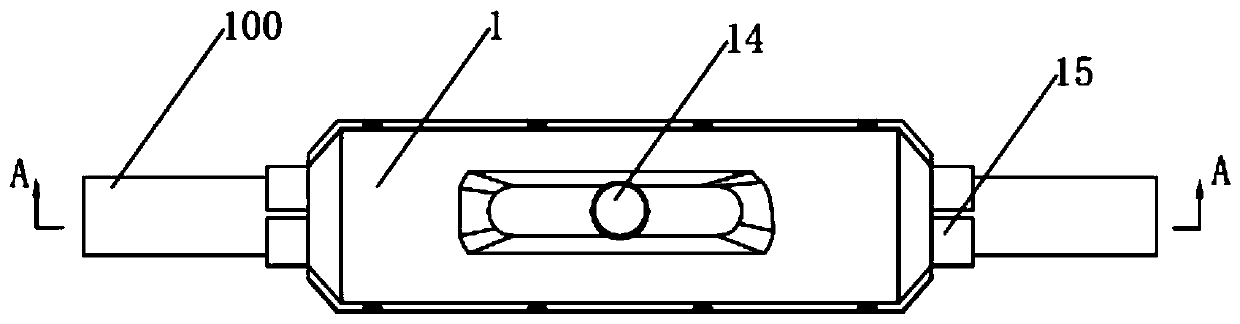

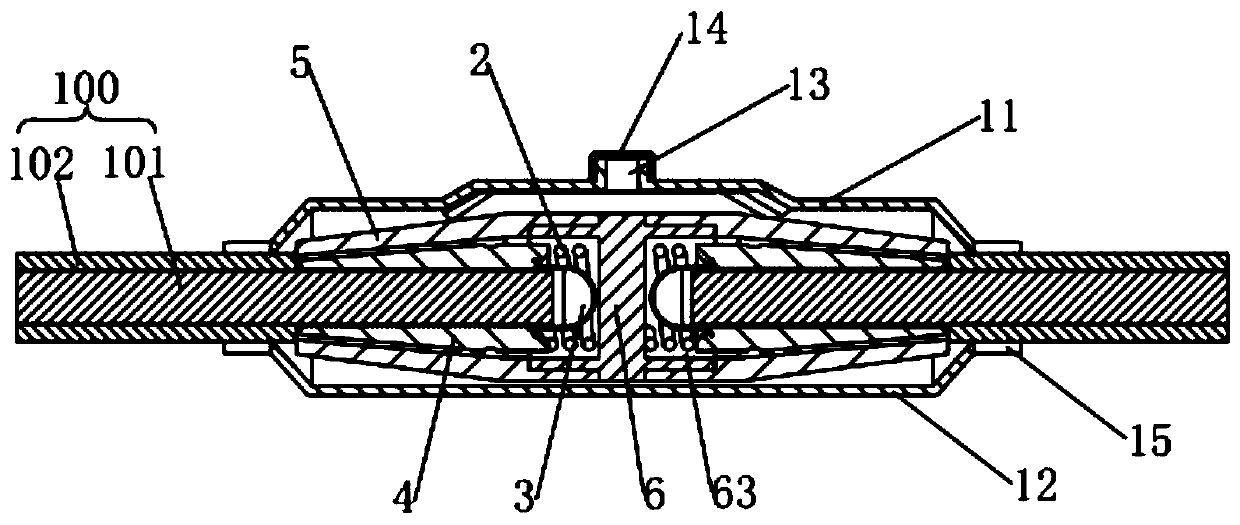

[0045] This embodiment provides a line repair device, such as Figure 1-4 As shown, it includes a connecting conductor 6, two elastic compression members 2, two expansion members 4, and two spin caps 5 respectively arranged on both sides of the connecting conductor 6. Reference image 3 with Figure 4 Specifically, the two ends of the connecting conductor 6 are provided with mounting holes 63, and the two wires 101 are respectively arranged in the two mounting holes 63 and can be electrically connected with the connecting conductor 6; the two expansion members 4 are respectively sleeved on the two wires 101 Above, the expansion member 4 is in the shape of a conical column and its large diameter end is close to the connecting conductor 6; the two compression elastic members 2 are respectively arranged in the two mounting holes 63, and their two ends are respectively abutted on the large diameter end of the expansion member 4 And the connecting conductor 6; two screw caps 5 are r...

Embodiment 2

[0067] The difference between this embodiment and the first embodiment is that a two-wire system or a multi-wire system is formed. In this embodiment, the line repairing device includes a plurality of insulating housings 1, and the plurality of insulating housings 1 are connected by an insulating plate 16; other embodiments In this case, a plurality of accommodating cavities may also be opened on the insulating housing 1, and each accommodating cavity is used to connect two wires 101.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com