Technique for treating sewage sludge into soil

A treatment process and sludge treatment technology, applied in the fields of sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of inadequate treatment, transportation difficulties, threats to the surrounding environment, etc., and achieve labor costs. The effect of reduction, simple process flow and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1. Design of sludge soil tank:

[0050] (1) Process flow

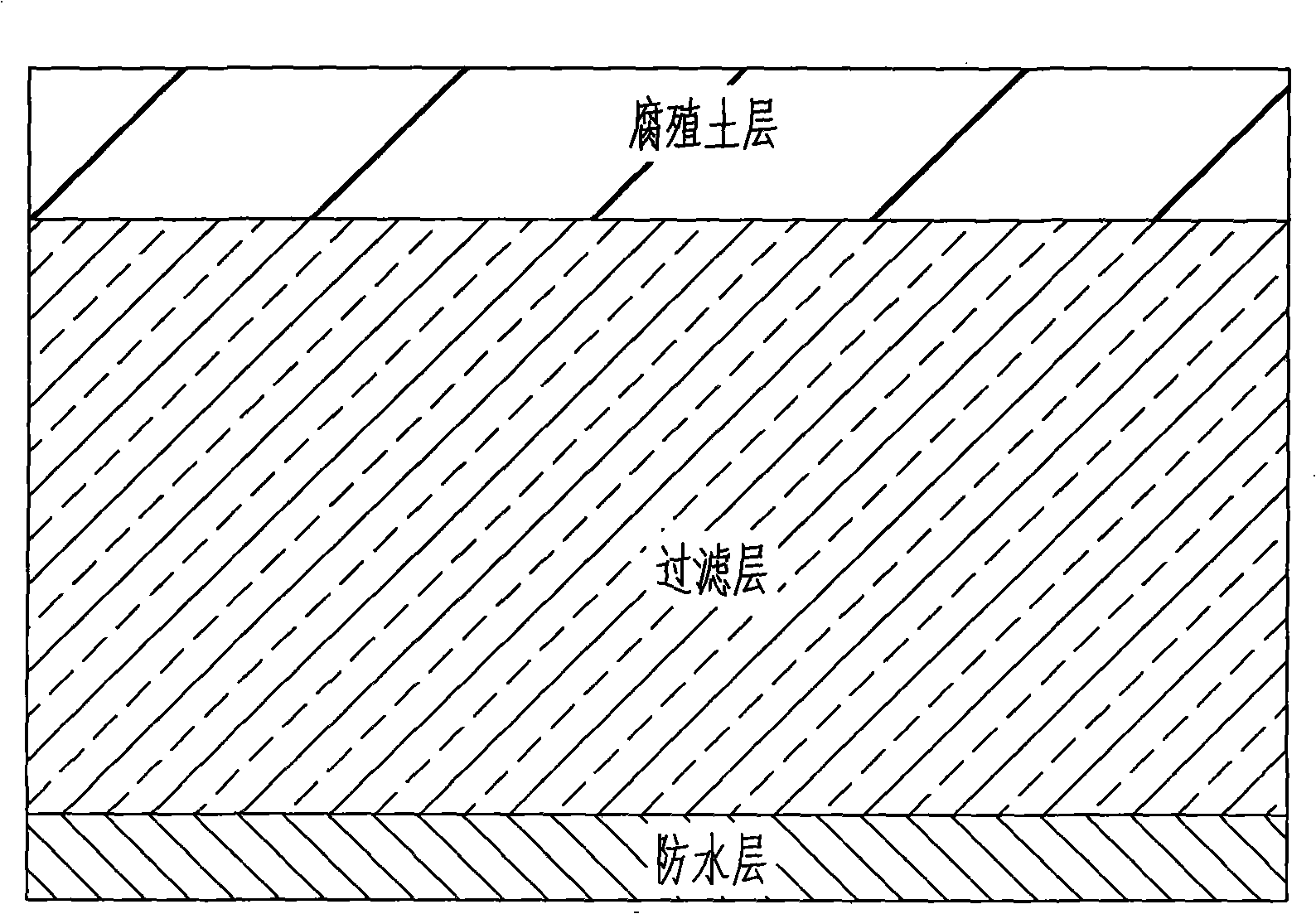

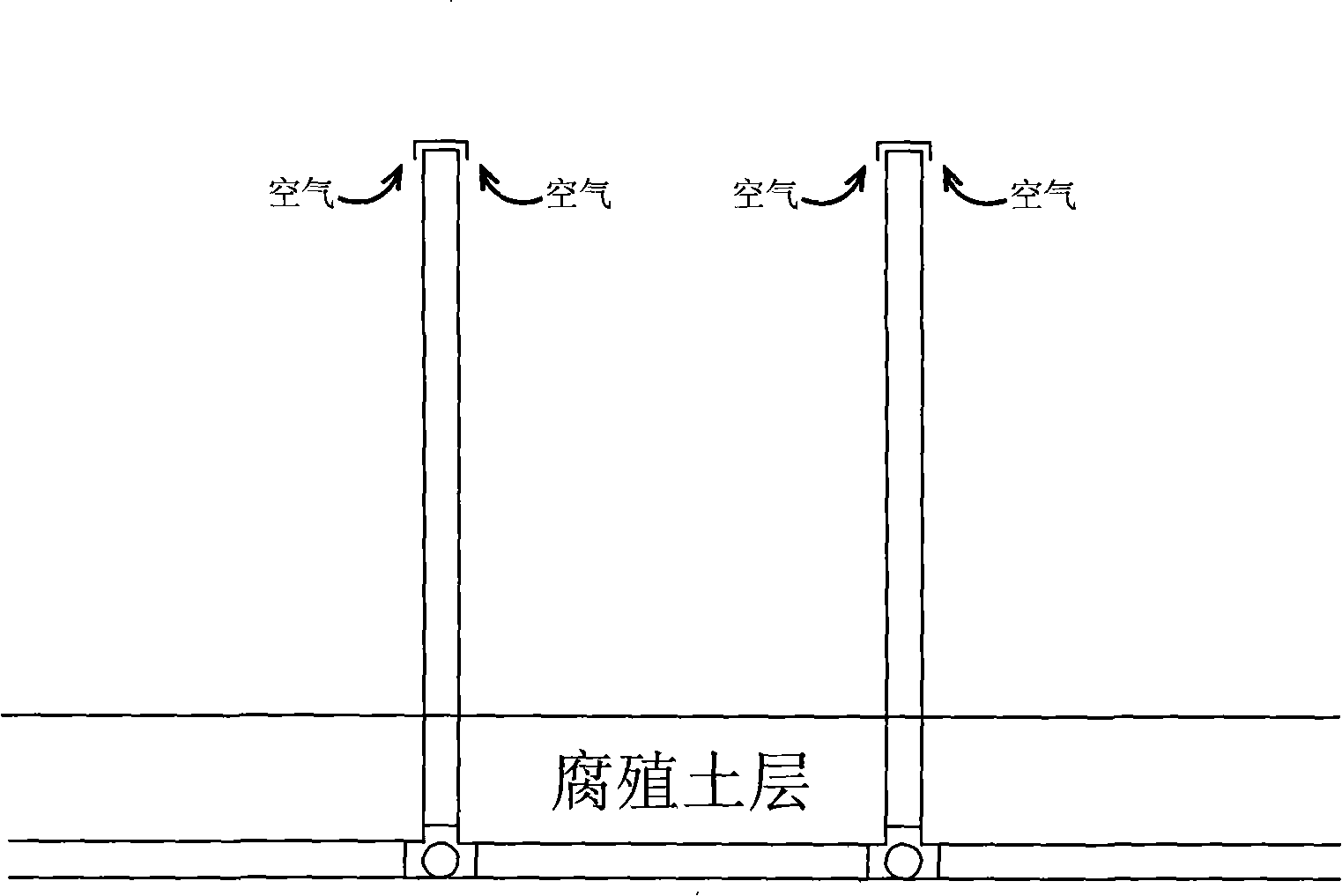

[0051] Such as figure 1 As shown, the sludge soilization tank is divided into 10 pools, and the sludge is discharged into the sludge soilization tank from the sludge storage tank through the pipe belt. The bottom of the sludge soilization tank is a waterproof layer, and the filter layer is above it. Including sand layer, gravel layer and geotextile layer, laying leachate collection pipes on the filter layer, connected with the leachate storage tank, and humus layer on the filter layer (such as figure 2 shown), the humus layer is laid with an air delivery pipe, which runs through the humus layer and contacts with the outside world in a vertical manner (such as image 3 shown). After the laying is completed, from top to bottom are as follows:

[0052] Humus layer (5.10m -4 / s): 100mm

[0053] Geotextile layer: 3.0mm

[0054] Sand layer: 200mm (sand particle size 0.5~3mm)

[0055] Geotextile layer: 3.0mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com