Biomass toothed pressing wheel rolling-type forming machine and forming method

A molding machine and biomass technology, applied in the direction of material molding presses, presses, manufacturing tools, etc., can solve the problems of short mold life, low production efficiency, high production cost, etc., and achieve convenient maintenance and replacement of parts, mold Long life and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

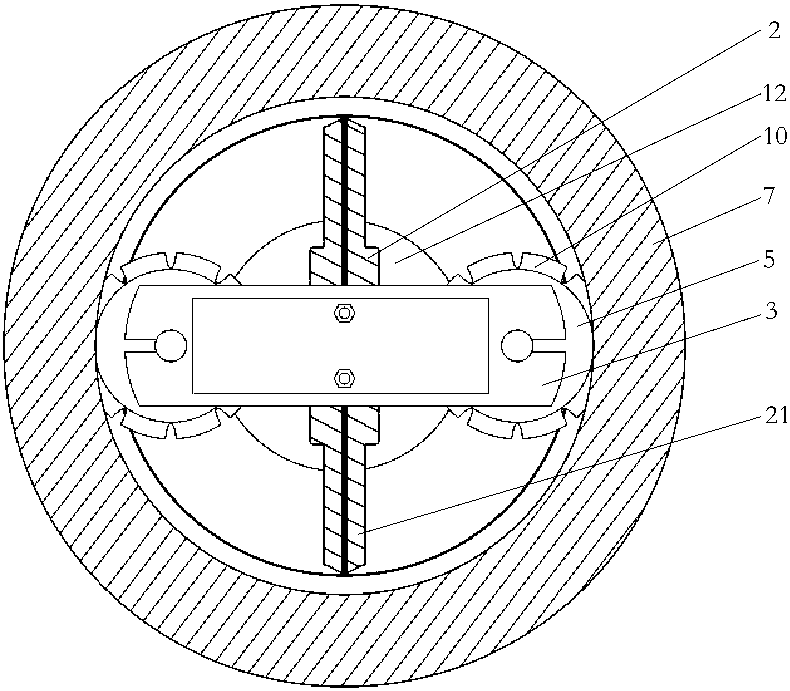

[0036] Embodiment 1: The present invention includes a machine base (13), a feed bin (1), a transmission spindle (12), an extrusion device, an annular fixed mold (7) and a driving device, and a driving device is provided in the hollow of the machine base (13). The drive device is mainly composed of a reducer (8) and a drive motor (9). One end of the reducer (8) is connected to the drive shaft (12) through the second coupling (16), and the other end is connected through the first The shaft coupling (15) is connected with the driving motor (9);

[0037] A silo (1) is arranged above the machine base (13), and the transmission main shaft (12) is fixed in the hollow of the machine base (13) through at least two sets of bearings (11) in the axial and radial directions to ensure that the transmission main shaft (12) ) operates stably when subjected to two-way force;

[0038] The lower end of the transmission spindle (12) is connected with the reducer (8), and the upper end is connect...

Embodiment 2

[0044] Embodiment 2: A water jacket (4) can also be provided on the outside of the silo (1) of the present invention. The water jacket (4) is located on the upper part of the annular fixed mold (7). The water jacket (4) passes through the through hole and feeds The area is connected; it is to prevent the dense raw material from clogging the cavity (6) when the machine is shut down, that is, to send an appropriate amount of water into the material area through the water jacket (4) before the machine is shut down, so that the raw material that is about to enter the cavity contains excessive water To ensure that the raw material staying in the mold cavity (6) is in a loose state with high moisture content and cannot be molded in the mold cavity, so that the mold cavity (6) will not be blocked during the next startup. If it is not used for a long time, the raw materials in the cavity (6) need to be cleaned up, and the loose raw materials are easy to clean.

Embodiment 3

[0045] Embodiment three: the outlet of the mold cavity (6) of the outer circumference of the ring-shaped fixed mold (7) can also be provided with a fixed-length baffle, and the fixed-length baffle is arranged on the outer circumference of the ring-shaped fixed mold in a ring. Keep compression molded products at a uniform length. That is, when the main shaft (12) rotates, the rotating bracket (3) and the toothed pressure wheel (5) start to roll, and the raw material in front of each pressure wheel tooth (10) is pressed into the front cavity (6), and the feeding device ( 2) Continuously feed the raw material into the gap between the pinch wheel teeth (10) and the annular fixed mold (7), the rotating bracket (3) and the toothed pinch wheel (5) run continuously, and the annular fixed mold (7) Stable extrusion of dense straw blocks at the outlet of the die cavity on the outer circumference. In order to prevent the straw blocks from automatically falling due to their own weight, a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com