System for continuously monitoring temperature and pressure during steam injection and soaking process

A temperature and pressure monitoring system technology, applied in measurement, wellbore/well components, earthwork drilling, etc., can solve the problems of high use and maintenance cost, high measurement cost, difficult to move flexibly, etc., to achieve the manufacturing process and equipment structure. Simple, low-cost, flexible mobile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

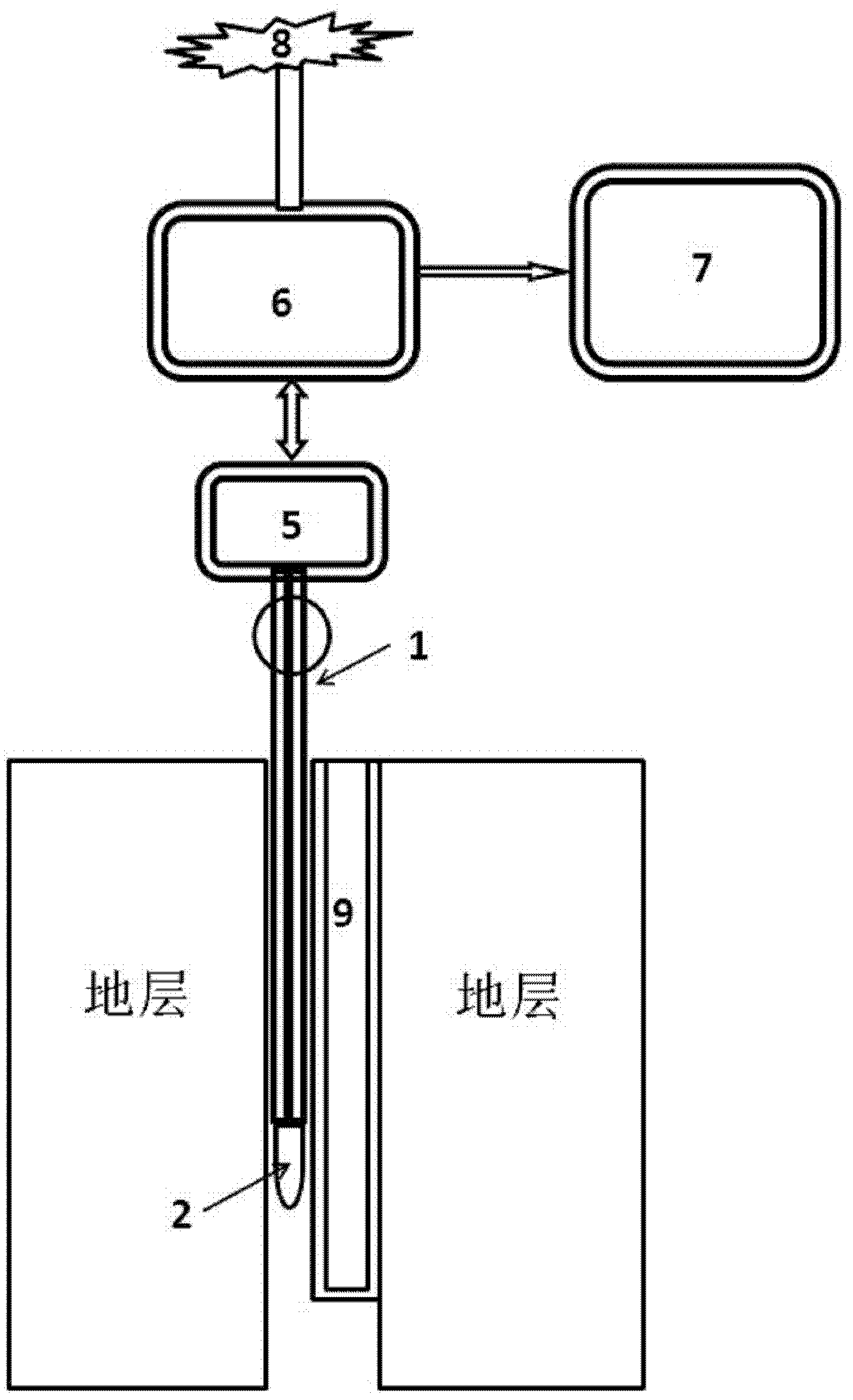

[0027] Figure 1a It is a schematic diagram of the system structure of "Embodiment 1" of the present invention. This system is driven downhole by the power of the lower pipe string, and it can be used for permanent monitoring in vertical wells. from Figure 1a It can be seen from the figure that the armored cable 1 containing a pair of capillary tubes is fixed on the downhole string, and goes down to the measurement well section along with the string 9, and the capillary tube is directly connected to the ground data converter 5. The downhole pressure is introduced into the capillary 4 filled with high-temperature pressure-guiding medium through the clean pipe, and the pressure at the measured place is transmitted to the surface data processor 5 through the pressure-guiding medium. The pressure temperature sensor 2 is a constant-volume container filled with a high-temperature pressure-guiding medium. There is a linear relationship between the temperature and pressure of the hig...

Embodiment 2

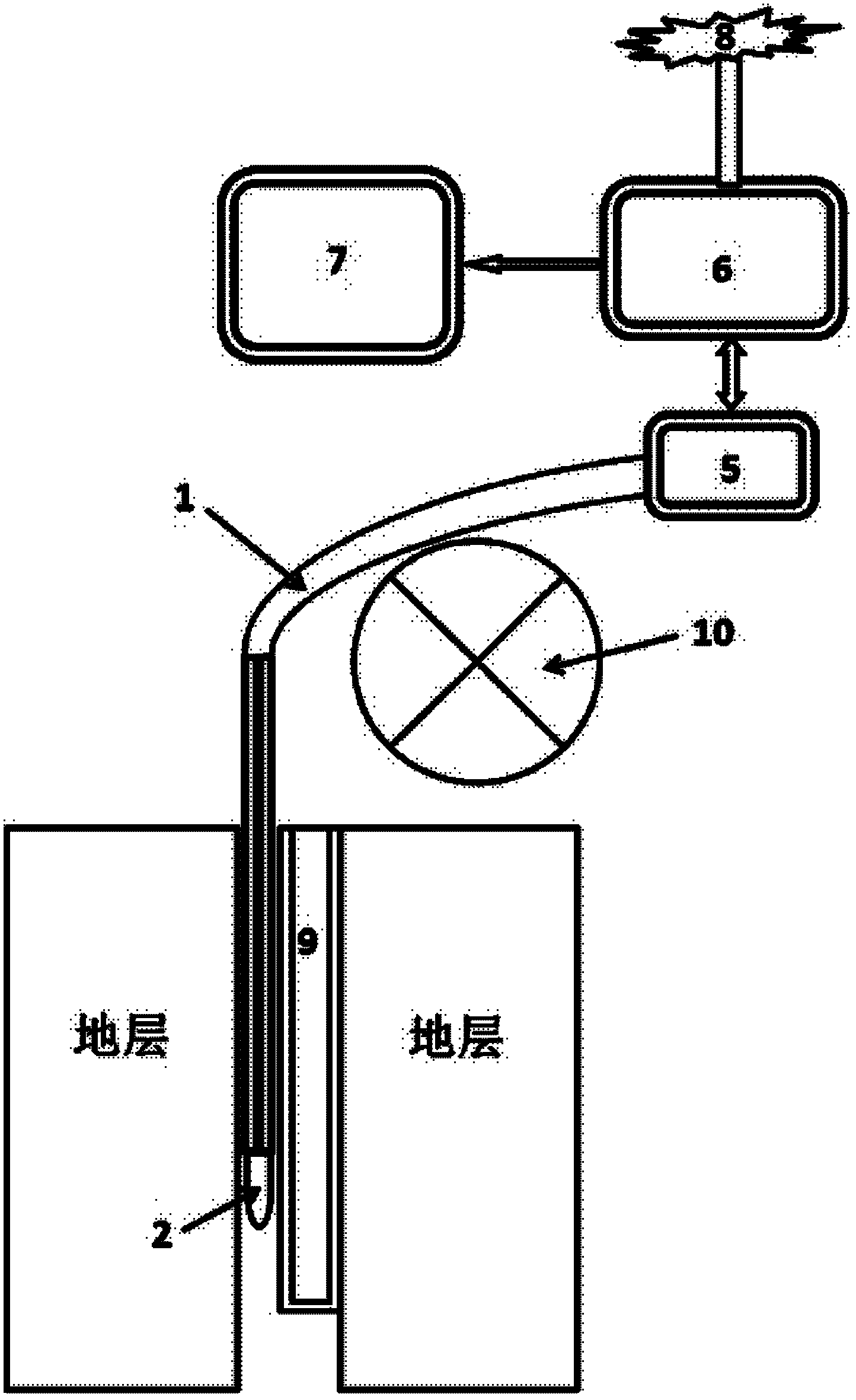

[0030] figure 2 It is a schematic diagram of the system structure of "Embodiment 2" of the present invention. This system is based on the action of winch power and gravity, and it can be used in vertical wells for permanent or temporary monitoring. Its characteristic is that it is easy to move. from figure 2It can be seen from the figure that the armored cable 1 containing a pair of capillary tubes is coiled on the logging drawworks 9, the pressure temperature sensor 2 and the measuring capillary tubes 3 and 4 are lowered to the measuring well section by the power of the winch and gravity, and the capillary tubes are directly connected to the ground data converter 5 on. The downhole pressure is introduced into the capillary 4 filled with high-temperature pressure-guiding medium through the clean pipe, and the pressure at the measured place is transmitted to the surface data processor 5 through the pressure-guiding medium. The pressure temperature sensor 2 is a constant-v...

Embodiment 3

[0032] The temperature and pressure continuous monitoring system of the present invention can also lower a group or groups of capillary armored cables to the measurement well section of the horizontal well by means of the power of the flexible tubing, and it can be used for permanent monitoring of the horizontal well SAGD.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com