Sponge powder feeding roller grinding machine

A technology of powder feeding roller and grinding machine, which is applied in the direction of grinding frame, parts of grinding machine tool, machine tool designed for grinding workpiece rotating surface, etc. Low efficiency, increased product defect rate and other problems, to achieve the effect of reducing labor costs and defective product rate, good machine versatility, and avoiding defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

[0028] The directional terms mentioned in the following embodiments, such as "horizontal, vertical, left, right", etc., are only referring to the directions of the drawings, therefore, the directional terms are used for illustration and not for limiting the present invention.

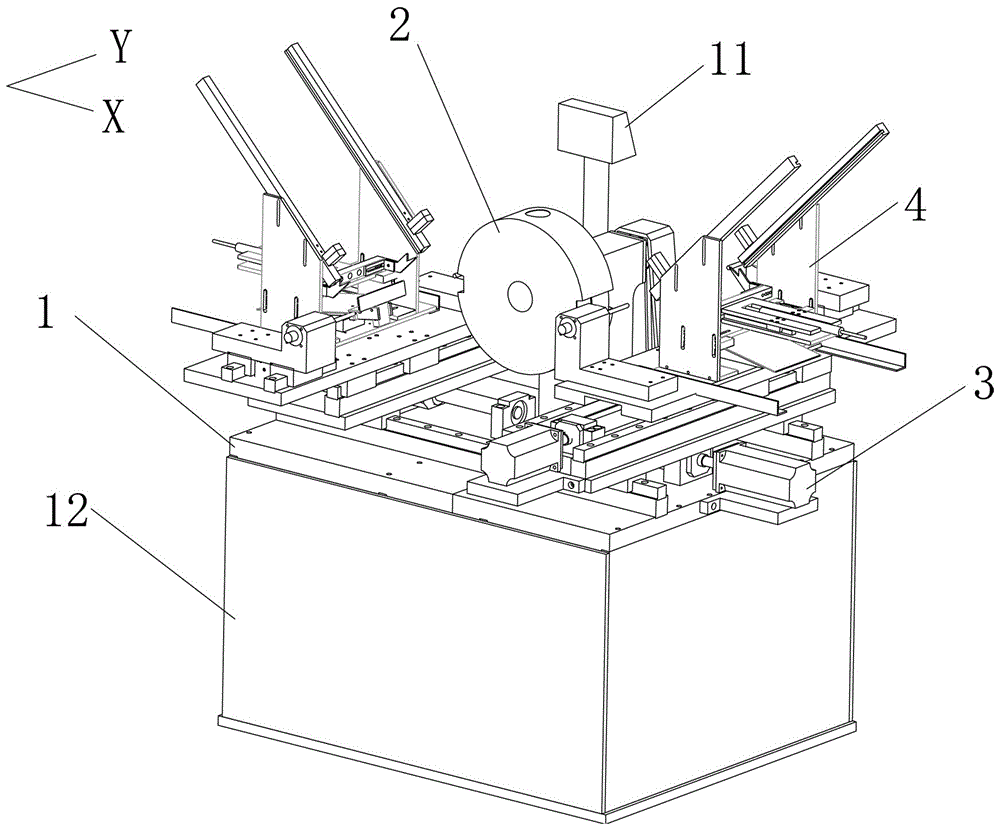

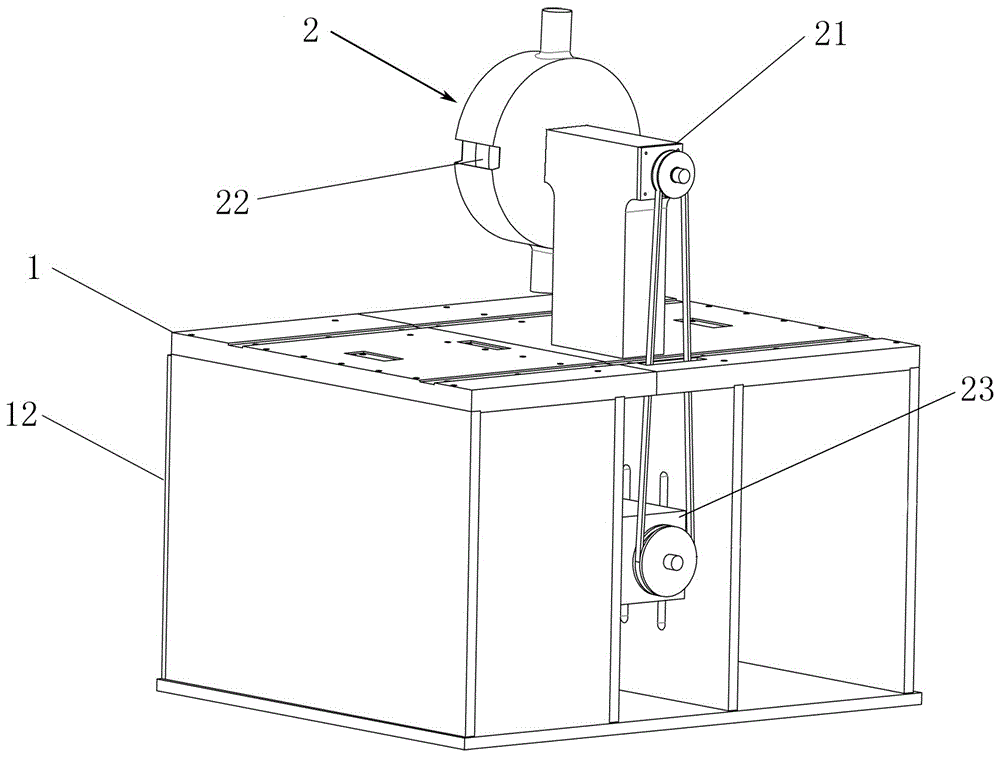

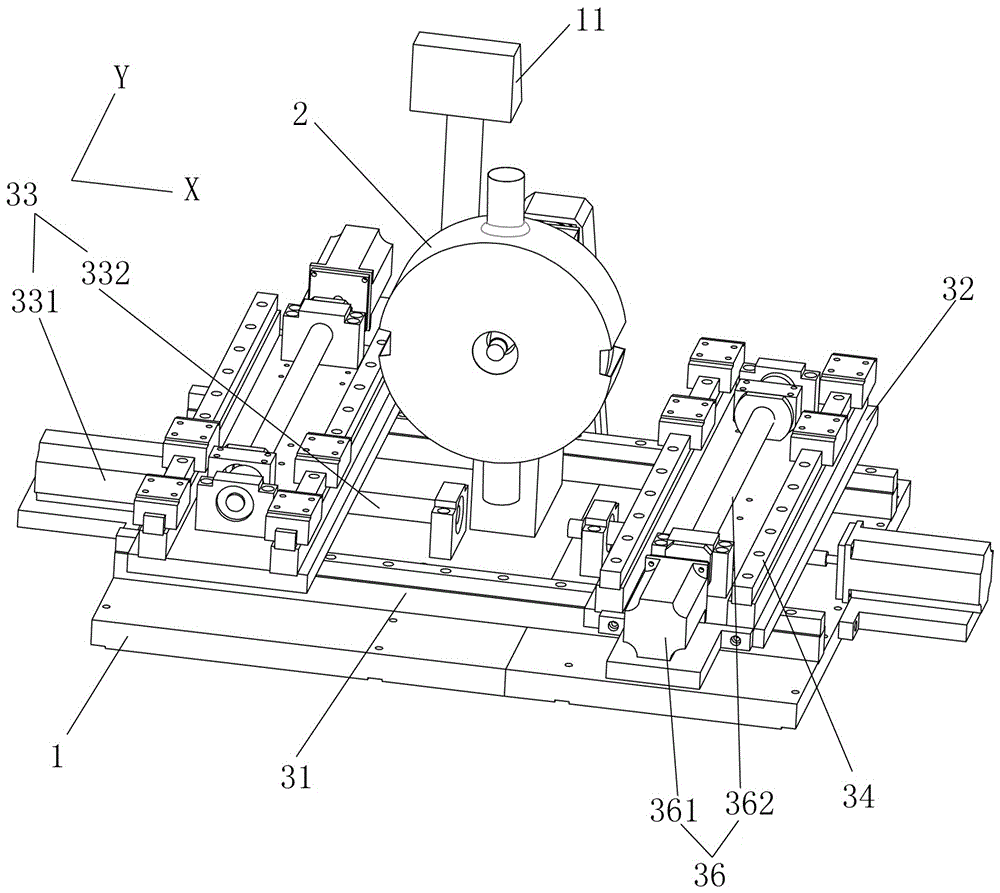

[0029] Such as Figure 1 to Figure 7 Shown, a kind of sponge powder-feeding roller grinder comprises workbench 1, emery wheel mechanism 2, conveying mechanism 3, automatic loading and unloading mechanism 4 and control system; Described emery wheel mechanism 2 is installed on workbench 1, and described working Also be provided with electric control box 12 below platform 1.

[0030] The control system includes a storage module and a control module, the grinding wheel mechanism 2, the conveying mechanism 3 and the automatic loading and unloading mechanism 4 are respectively electrically connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com