Intra-mode automatic nut assembling structure

An automatic, nut-to-nut technology, applied in the field of injection molding industrial equipment, to achieve the effects of improved production efficiency, good versatility, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

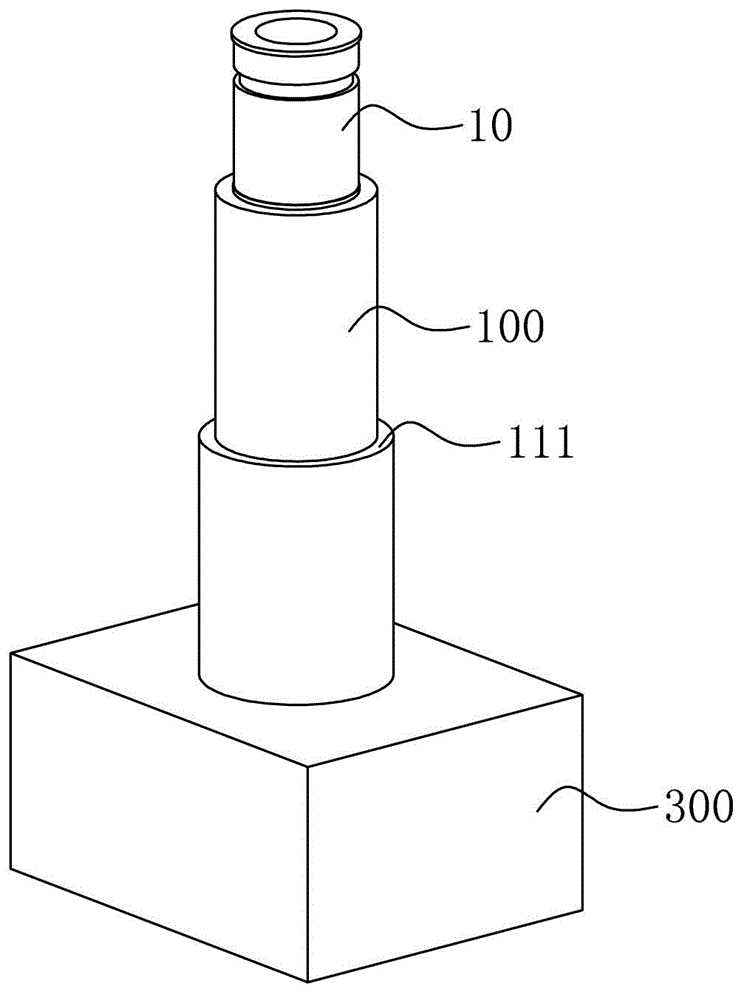

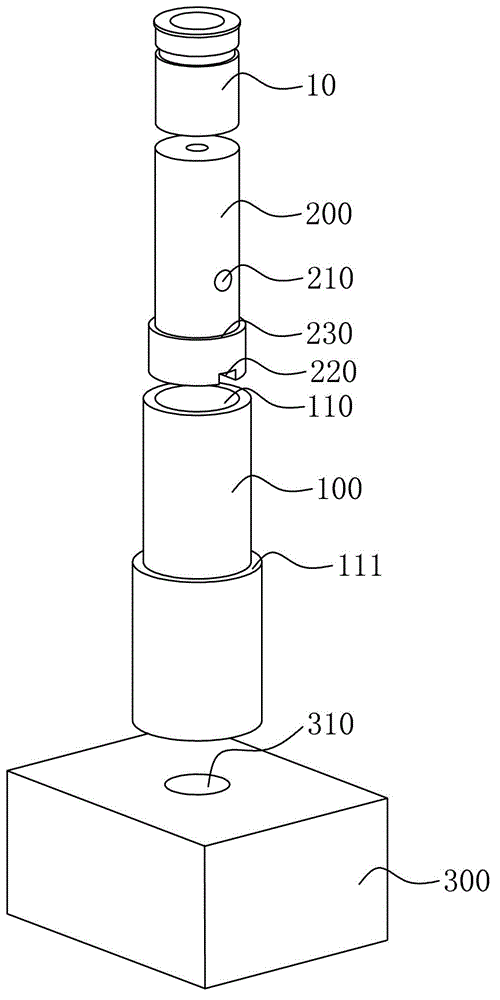

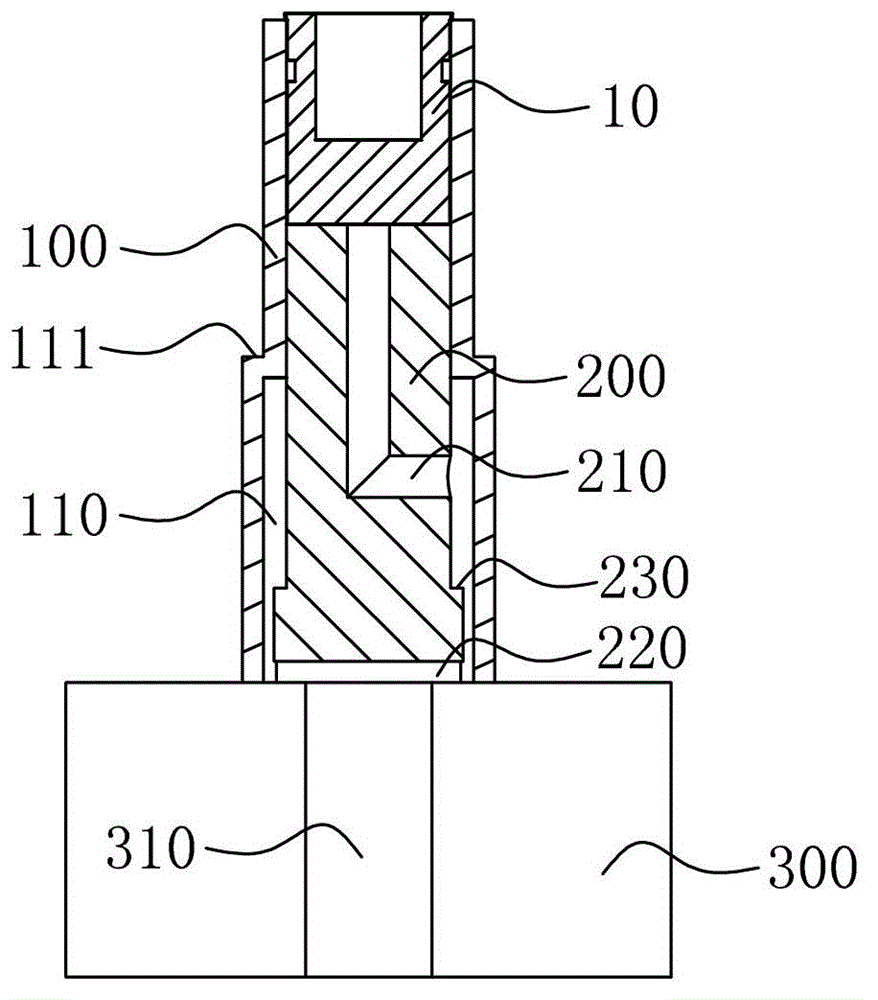

[0020] Such as figure 1 and figure 2 As shown, the structure of automatic nut loading in the mold provided by the present invention is applied in mold injection molding, and the structure includes:

[0021] The guide block 100 is provided with a first passage 110 connecting the top end and the bottom end of the guide block;

[0022] The pneumatic push block 200 has a vacuum air path 210 connecting the top and side of the pneumatic push block 100 and a groove 220 running through the bottom of the pneumatic push block. The pneumatic push block 200 is movable in the first channel Medium 110;

[0023] The base 300 is disposed at the bottom of the guide block 100 . The base 300 defines a second passage 310 communicating with the top and bottom thereof. The second passage 310 communicates with the first passage 110 .

[0024] Where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com