A preparing method of a ternary-material lithium battery saggar

A ternary material and lithium battery technology, applied in the field of refractory materials, can solve the problems of high technical performance requirements, high cost, and few use cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation of a ternary material lithium battery sagger according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. , preparation method, steps, features and effects thereof, detailed descriptions are as follows.

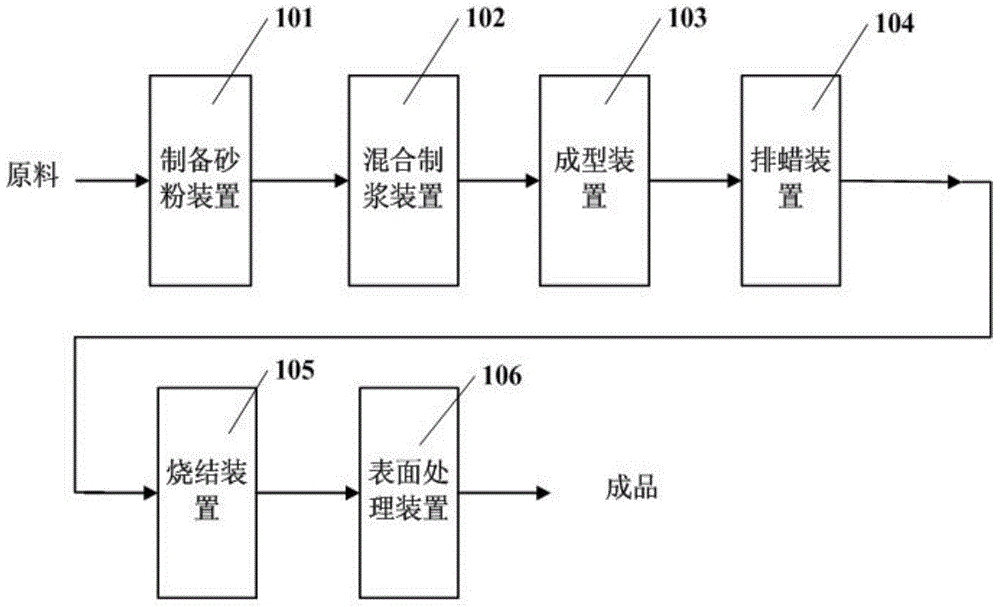

[0038] A preparation method of a ternary material lithium battery containing a sagger, such as figure 1 As shown, the raw materials are sequentially passed through the sand powder preparation device 101, the mixing and pulping device 102, the molding device 103, the wax removal device 104, the sintering device 105, and the surface treatment device 106; finally, the finished product is produced after being processed by the surface treatment device 106.

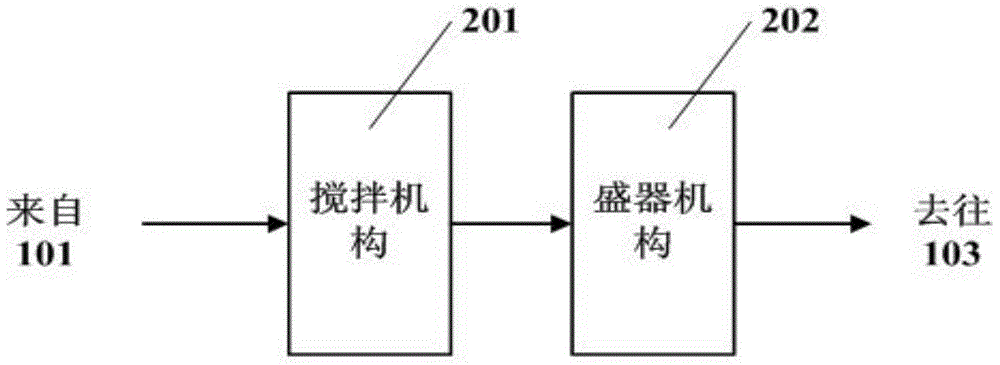

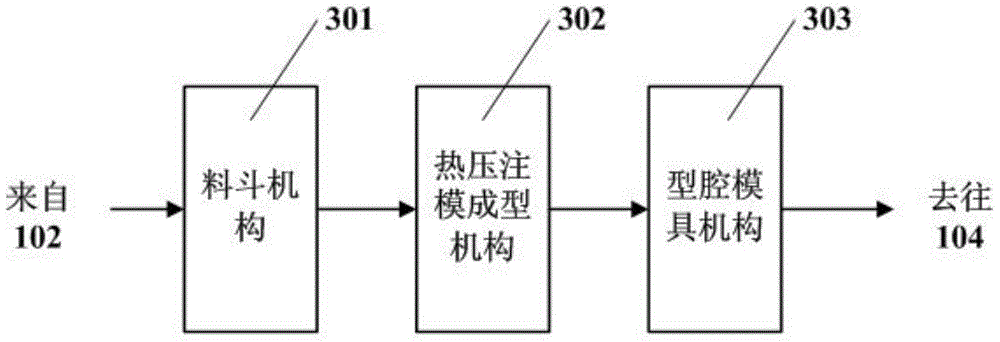

[0039] The various devices used in the preparation method of a ternary material lithium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com