Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about "Lithographic masks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for Fabricating Blackened Conductive Patterns

ActiveUS20140377455A1High resolutionImprove conductivityLight absorption dielectricsLithographic masksResistConductive materials

The present invention relates to a method for fabricating blackened conductive patterns, which includes (i) forming a resist layer on a non-conductive substrate; (ii) forming fine pattern grooves in the resist layer using a laser beam; (iii) forming a mixture layer containing a conductive material and a blackening material in the fine pattern grooves; and (iv) removing the resist layer remained on the non-conductive substrate.

Owner:INKTEC CO LTD

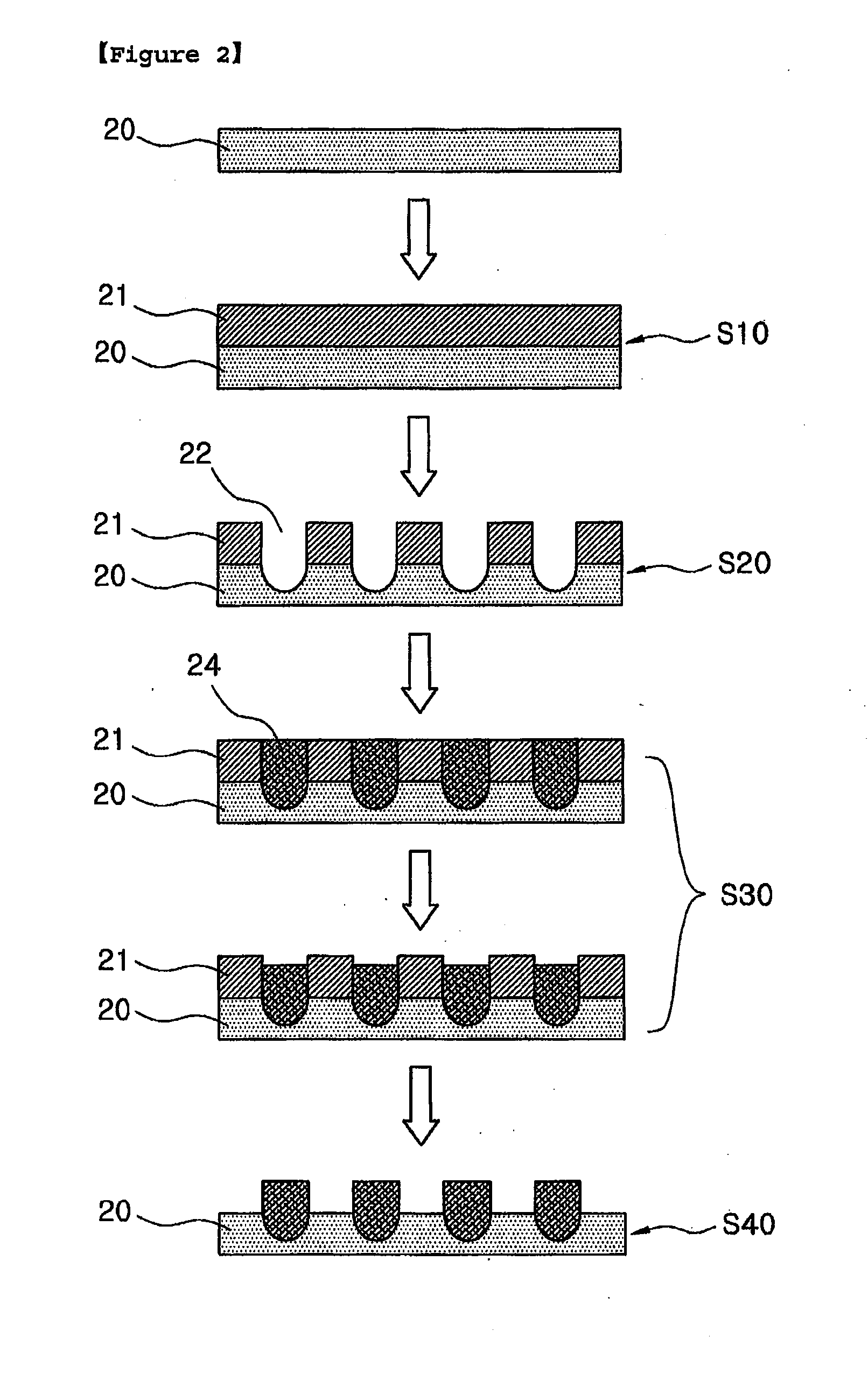

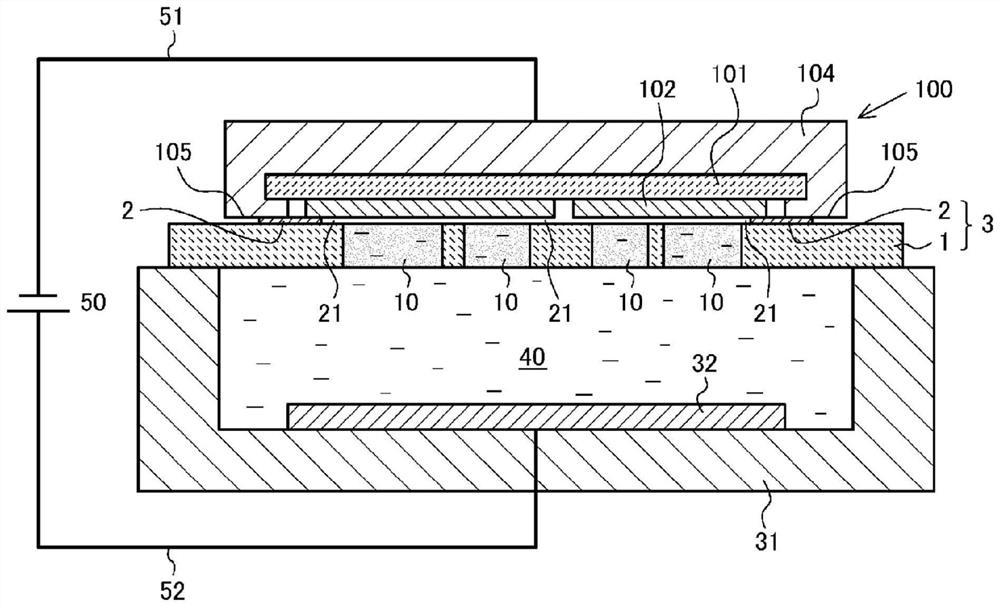

Ink application apparatus and method for applying ink

InactiveCN110505762AHigh resolutionFast scanningLithographic masksConductive material chemical/electrolytical removalEngineeringEdge region

The invention provides an ink application apparatus capable of shortening the processing time during ink coating. A moving mechanism moves one of the object to be coated and the inkjet head relative to the other so as to move a landing point of the ink with respect to the object to be coated on a surface of the object to be coated. A control device controls the inkjet head and the moving mechanism. One of the object to be coated and the inkjet head is moved relative to the other, and the ink is landed on an edge region along the edge of the region to be coated, thereby forming an edge portionmade of the ink in the edge region. In addition, after the edge portion is formed, one of the object to be coated and the inkjet head is moved relative to the other at a movement speed higher than a movement speed when the edge portion is formed, and the ink is applied to an inner region surrounded by the edge portion.

Owner:SUMITOMO HEAVY IND LTD

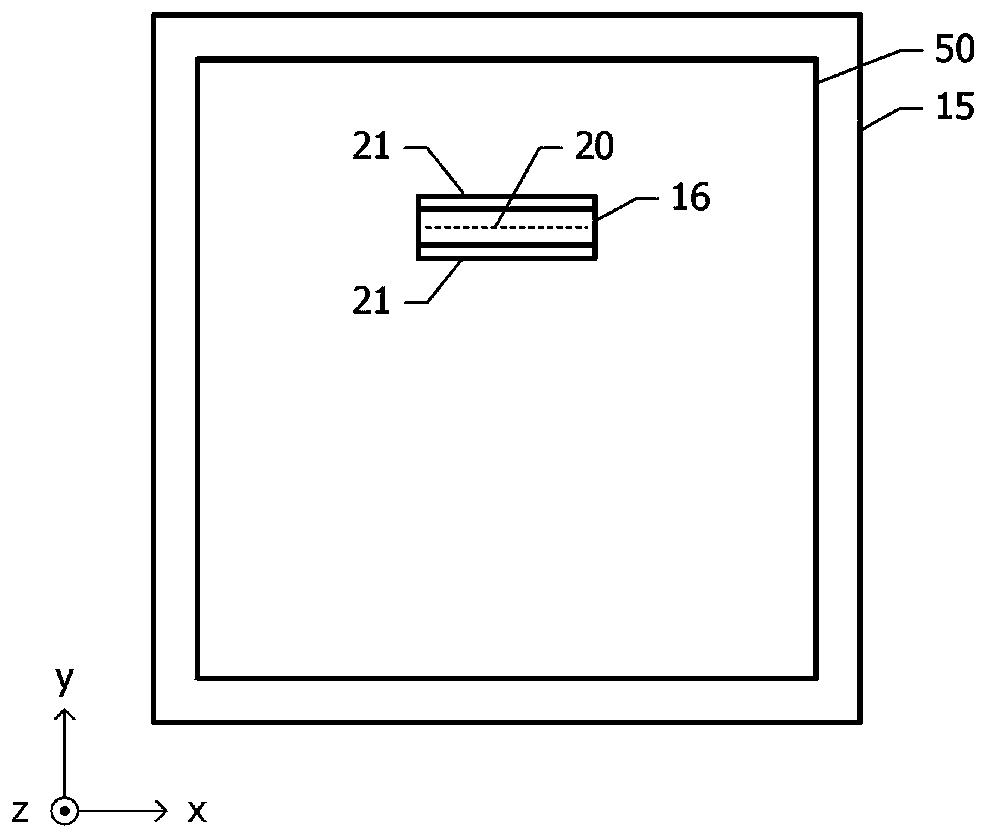

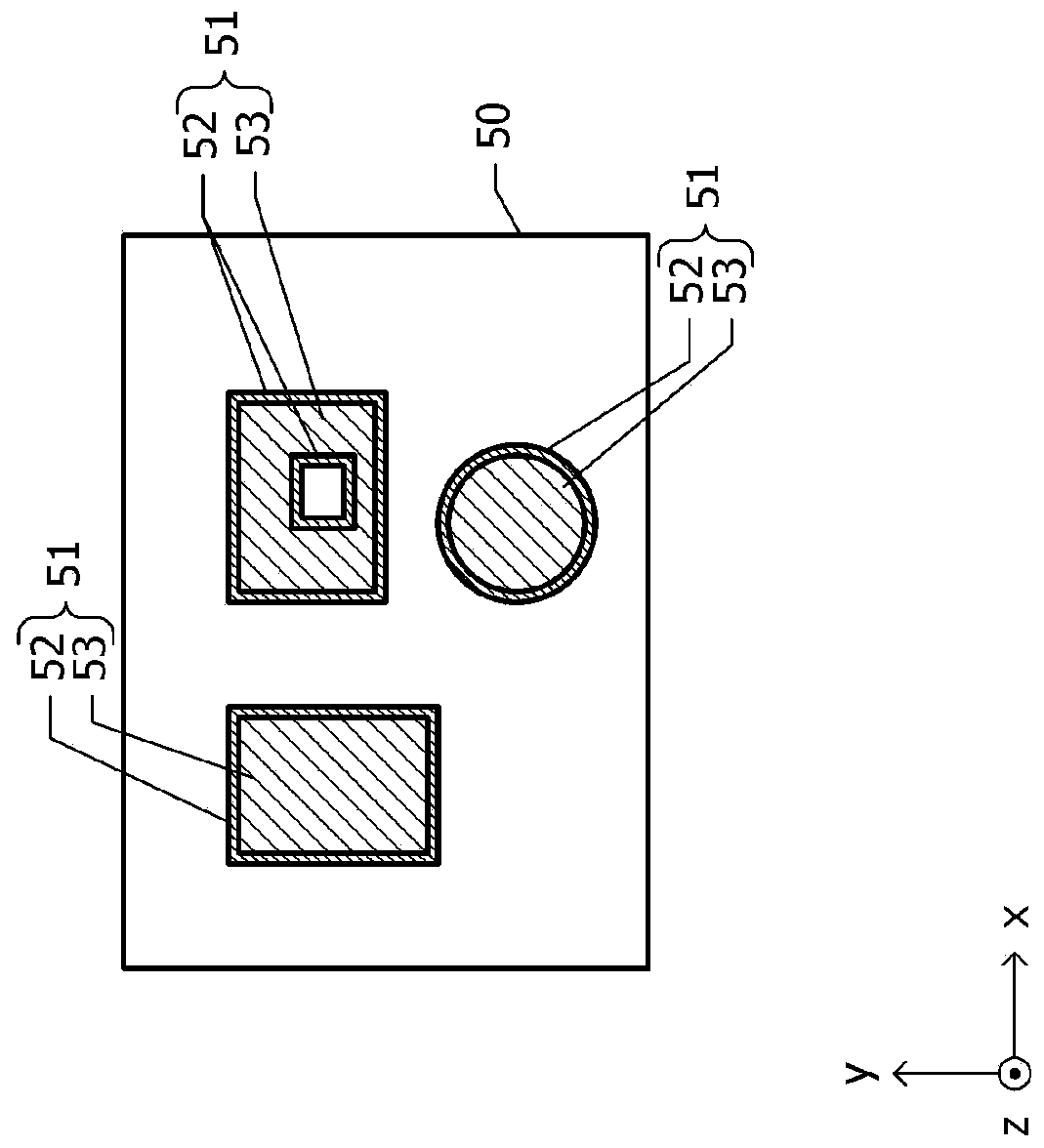

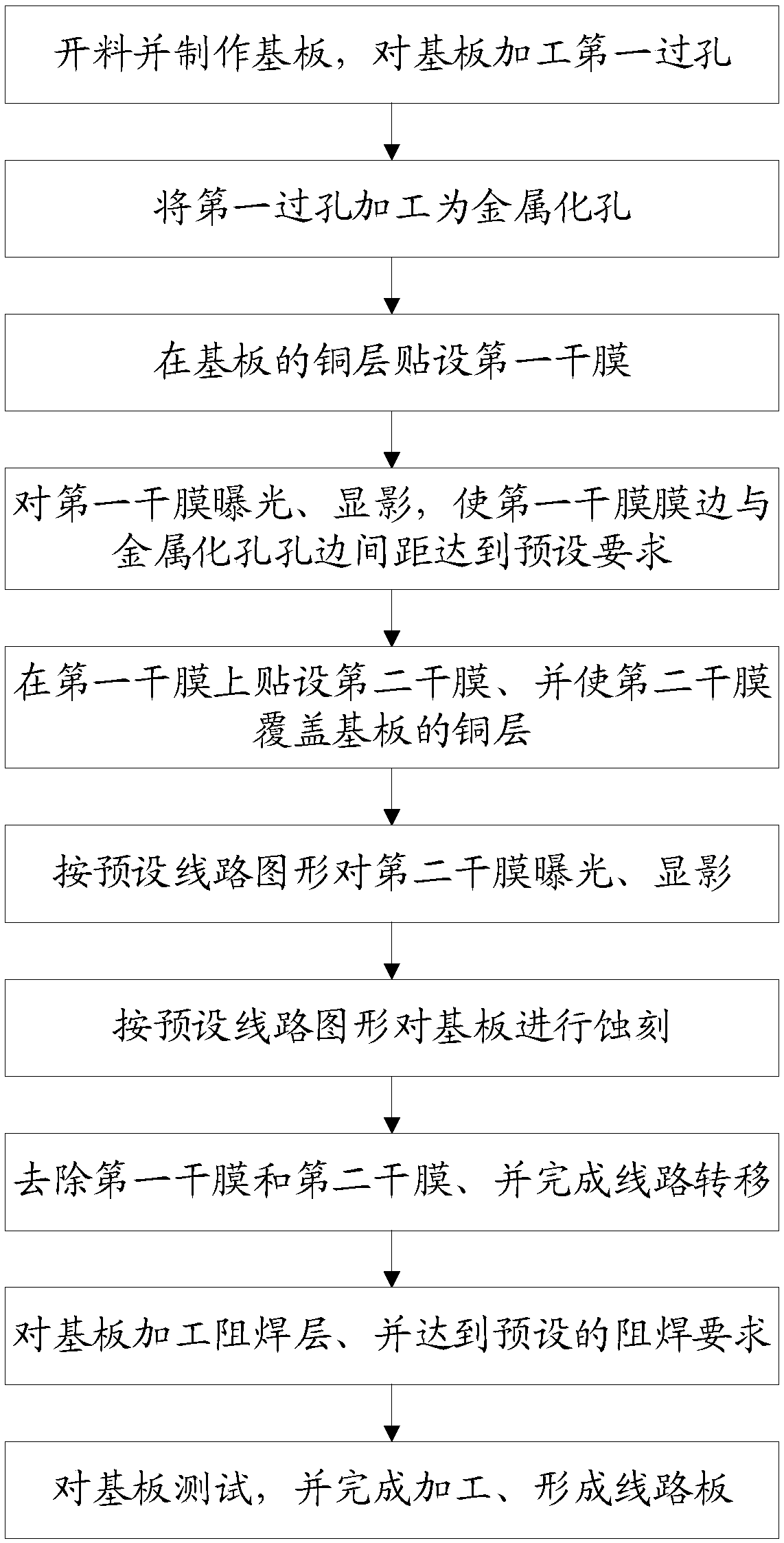

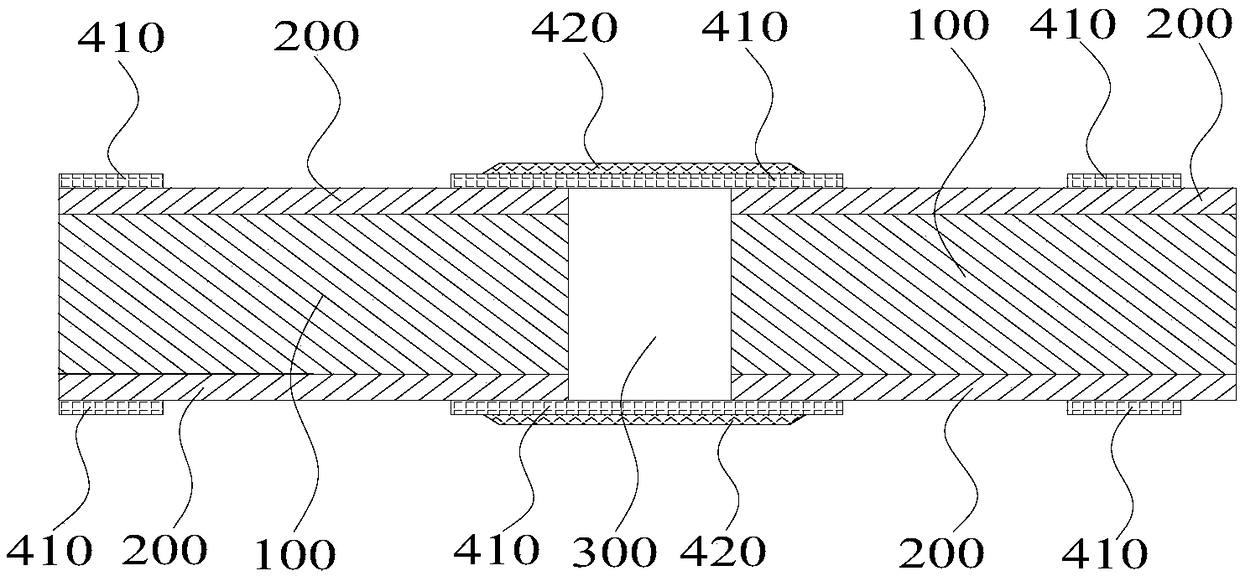

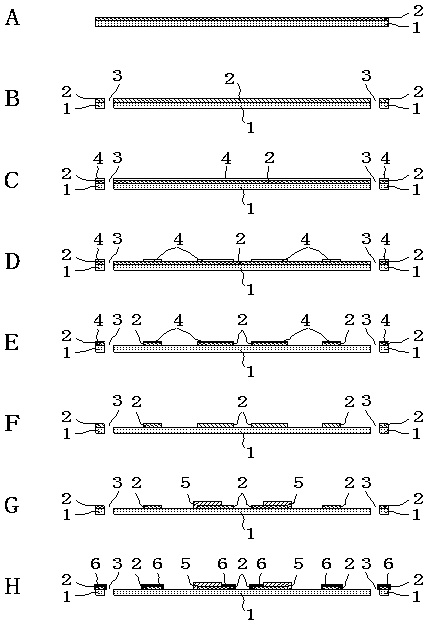

Circuit board, production method thereof and pattern transfer method

InactiveCN108124386AImprove yieldReduce manufacturing costLithographic masksElectrical connection printed elementsEtchingEngineering

The invention relates to a pattern transfer method, which comprises the steps of taking a substrate, and attaching a first dry film to the substrate; performing exposure and development on the first dry film, covering a plated through hole by the first dry film retained after the development, and enabling the spacing between the edge of the first dry film and the edge of the plated through hole toreach a preset spacing requirement; laying a second dry film on the retained first dry film, and enabling the second dry film to be attached to the whole substrate; performing exposure and development on the second dry film according to a preset circuit pattern; etching the substrate according to the preset circuit pattern, and completing the etching; and removing the first dry film and the second dry film to complete the pattern transfer. According to the invention, exposure and development are performed on the first dry film so as to protect the plated through hole in advance, the attachment of the second dry film forms a thicker dry film, thereby playing a role of protecting the plated through hole, avoiding damages imposed on the dry film by the subsequent etching process, thus improving the processing finished product rate of the circuit board, and reducing the production cost.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

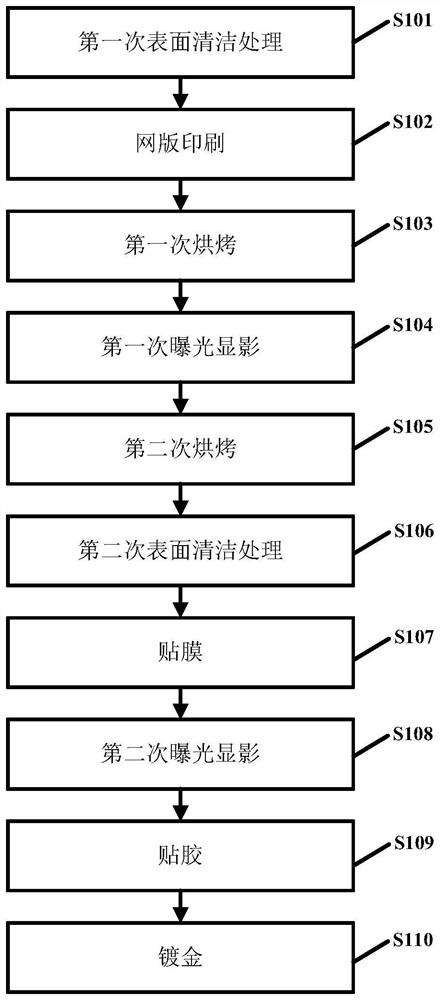

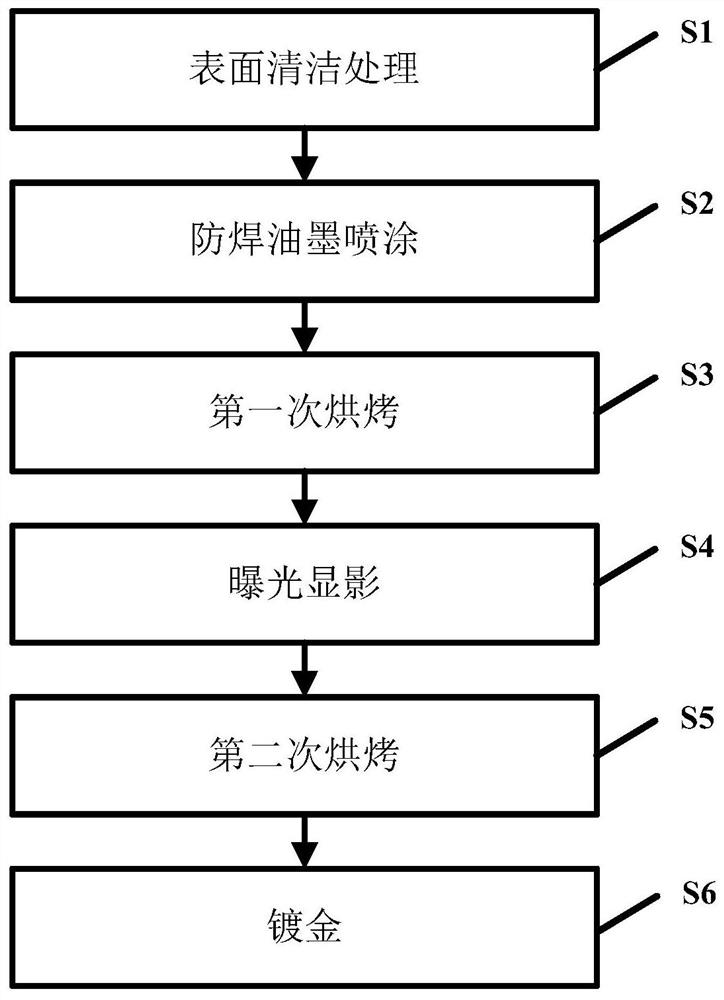

Manufacturing method of printed circuit board

InactiveCN112040655APlay anti-soldering effectQuality assuranceLithographic masksPrinted circuit dryingSolder maskMechanical engineering

The invention discloses a manufacturing method of a printed circuit board, and relates to the field of circuit board manufacturing. The method comprises the following steps: removing impurities on thesurface of a metal layer of the printed circuit board; performing solder mask ink spraying on the printed circuit board to form a solder mask layer; and sequentially carrying out primary baking, exposure and development, secondary baking and gold plating on the printed circuit board. On the basis of ensuring the quality of the printed circuit board, the manufacturing period of the printed circuitboard is greatly shortened, and the manufacturing cost of the printed circuit board is remarkably reduced.

Owner:JIANDING HUBEI ELECTRONICS CO LTD

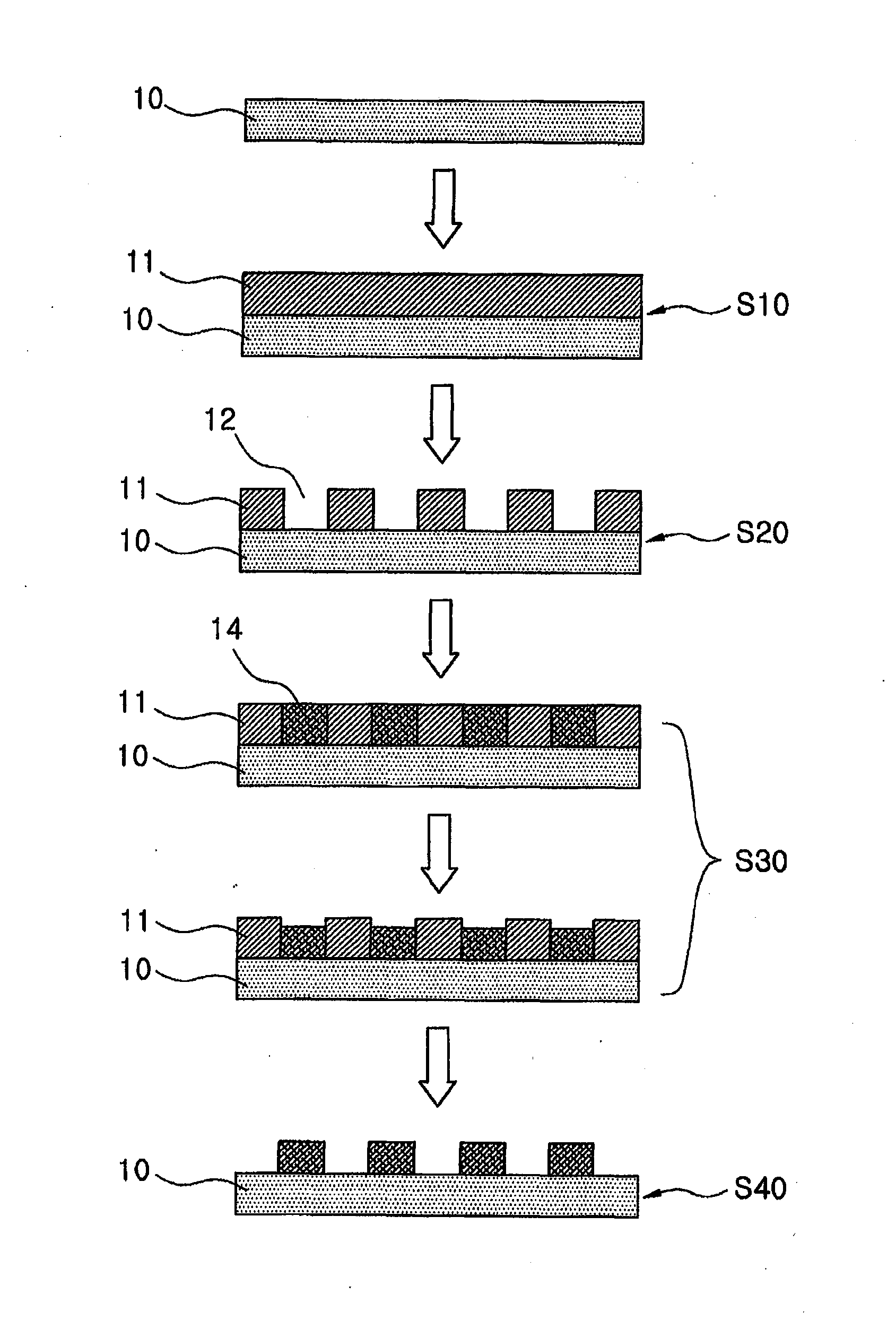

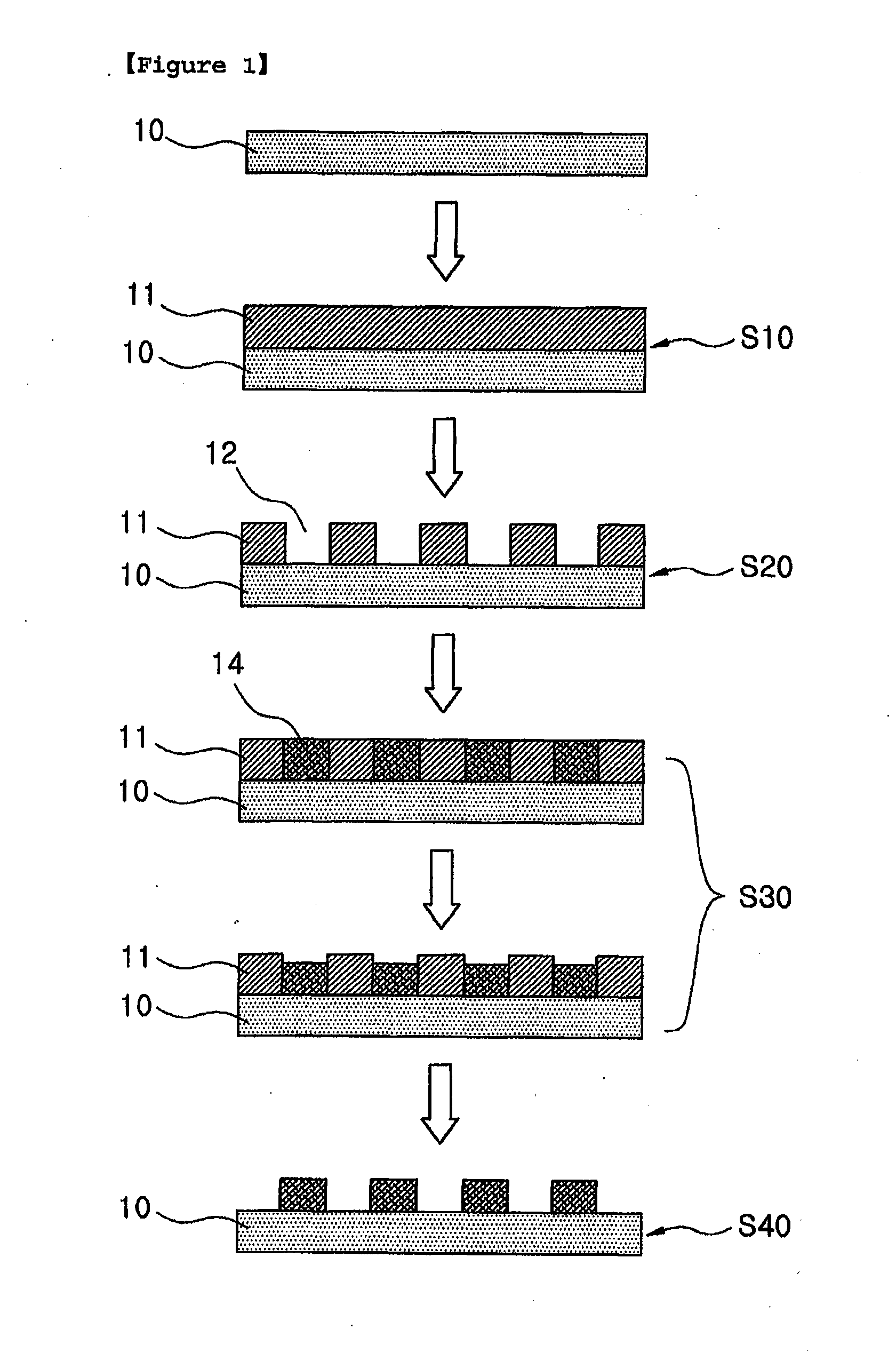

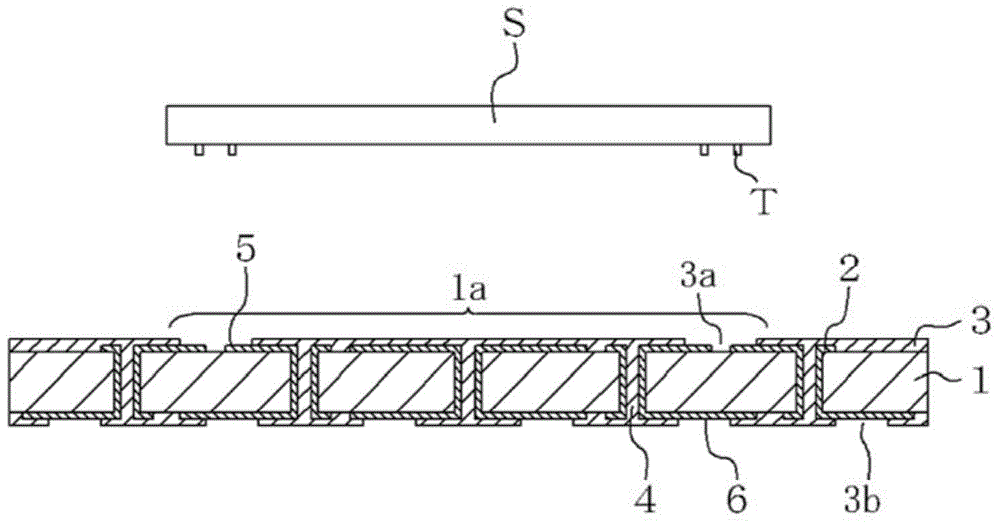

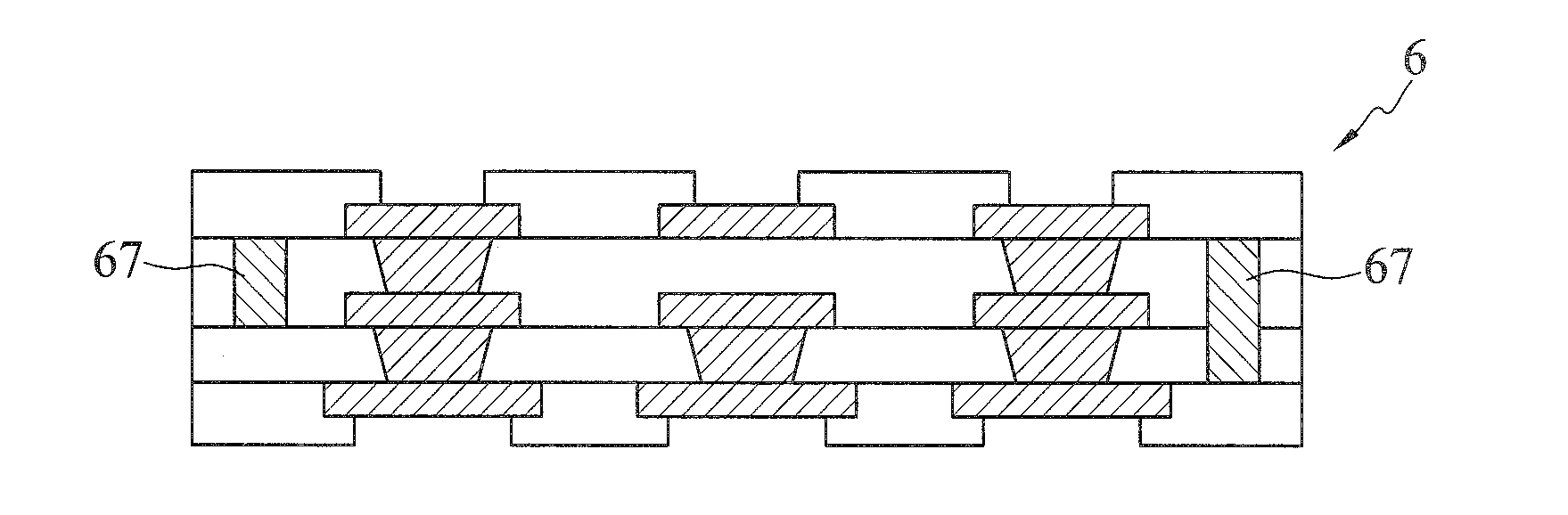

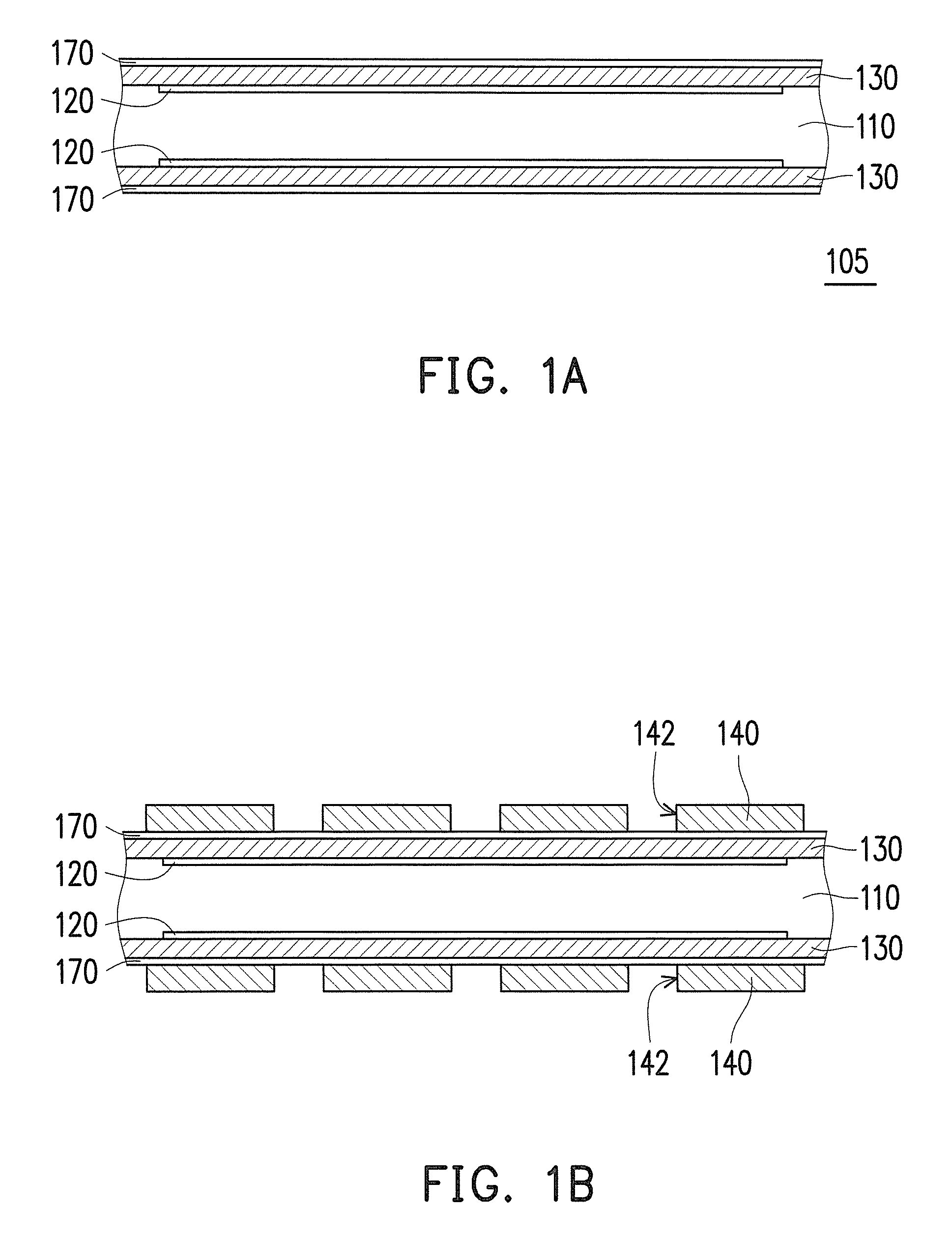

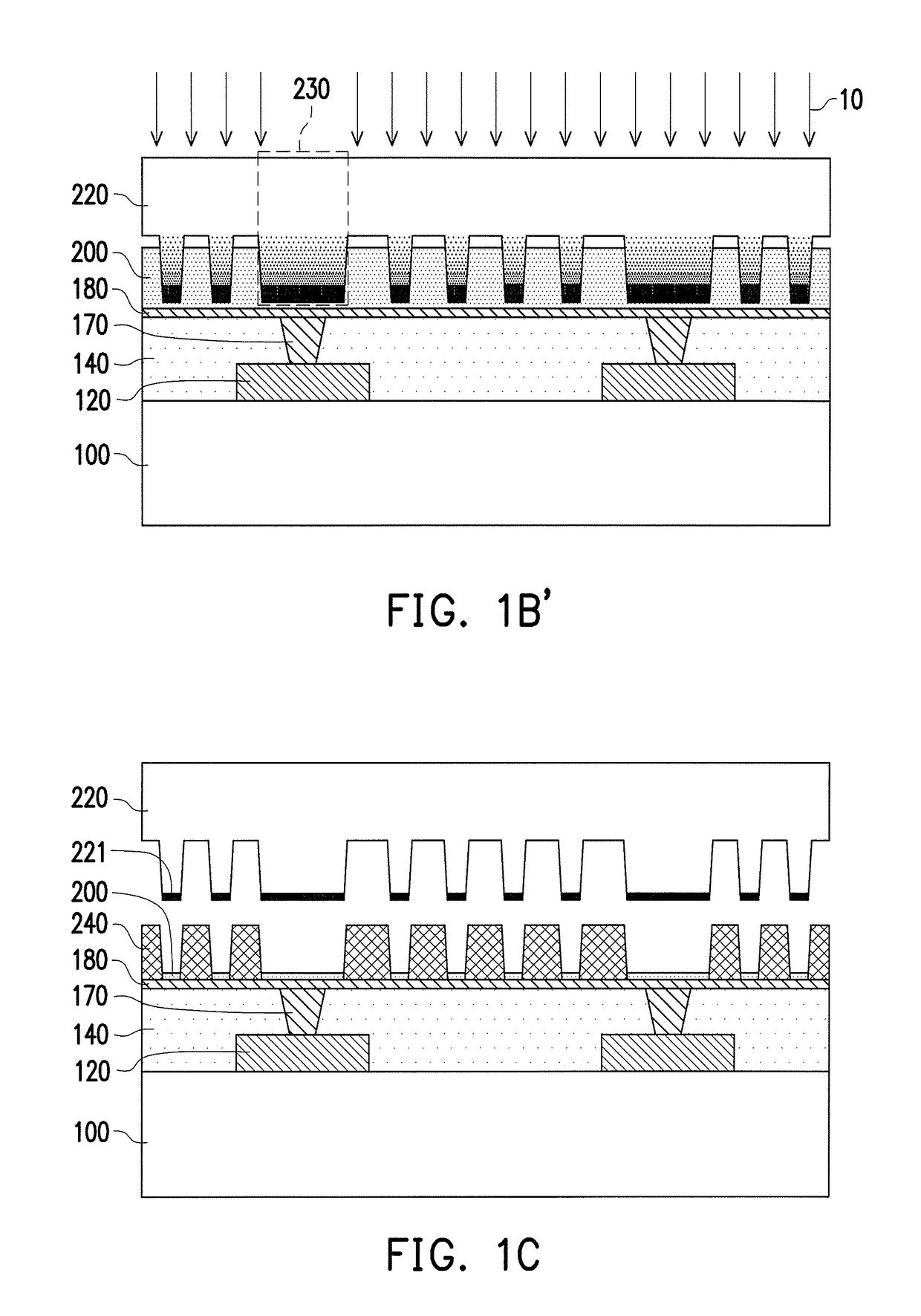

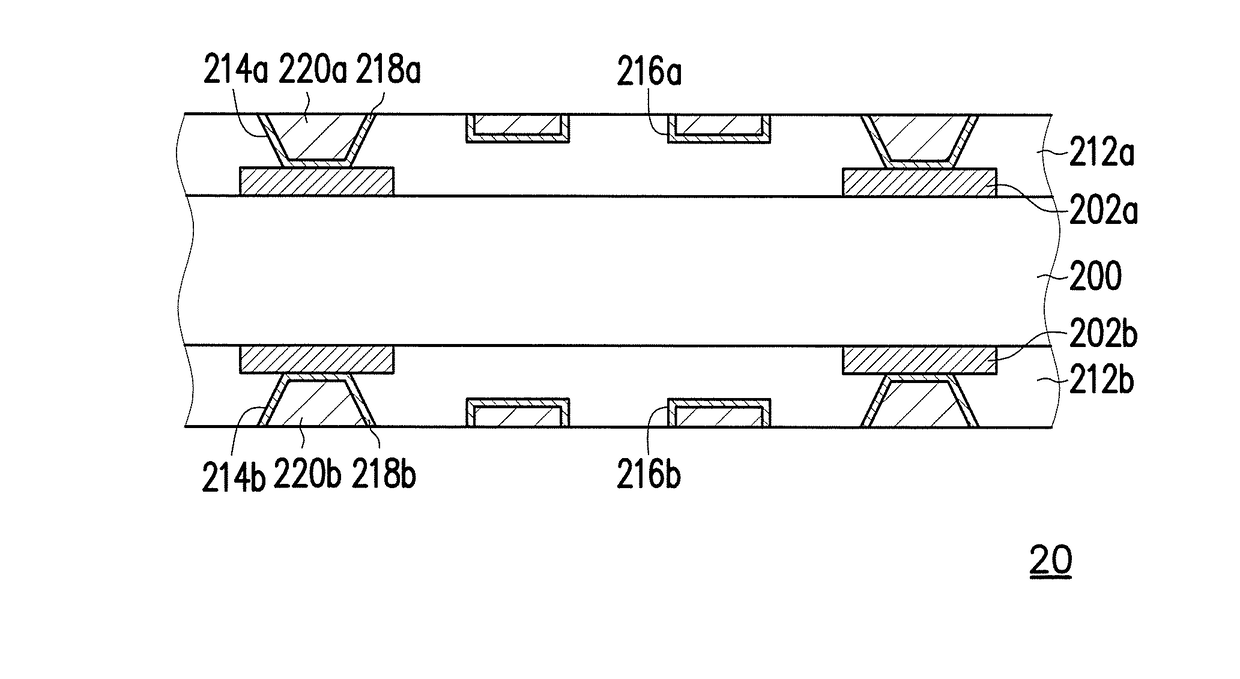

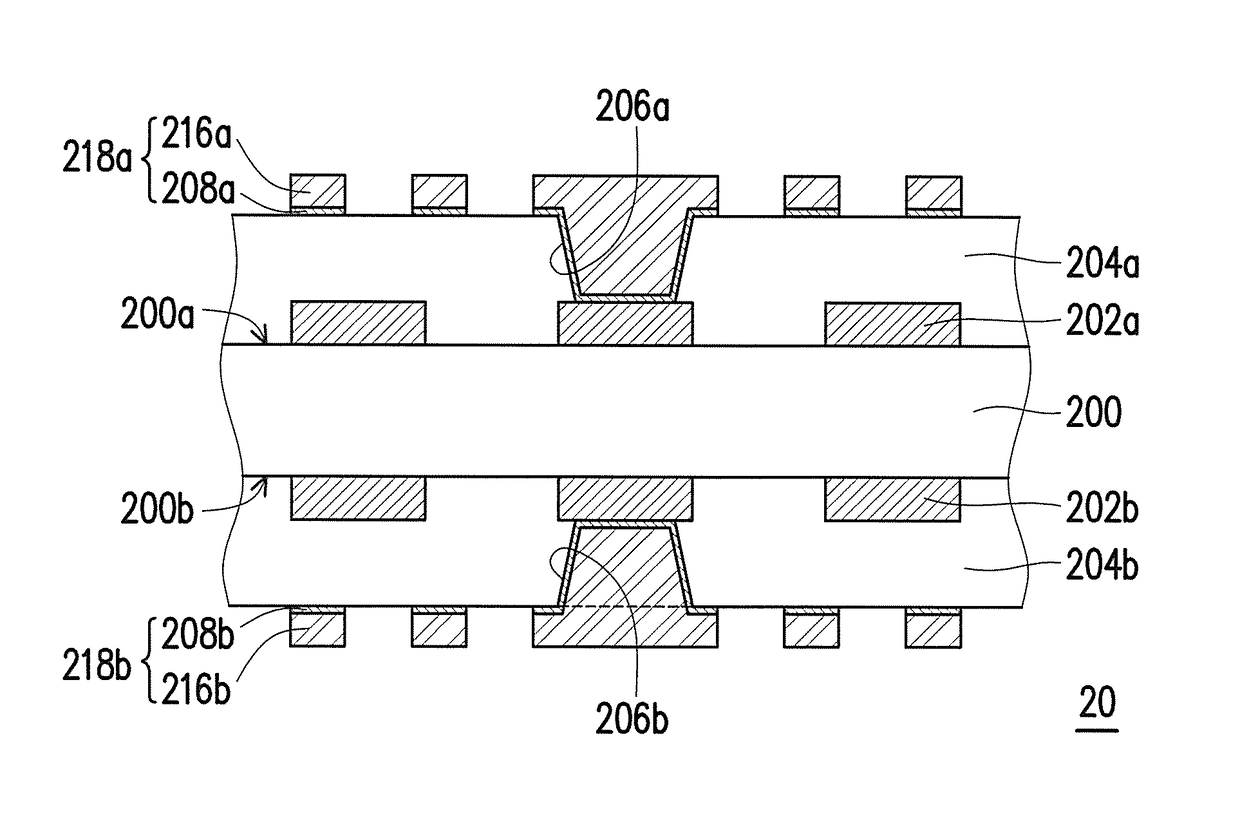

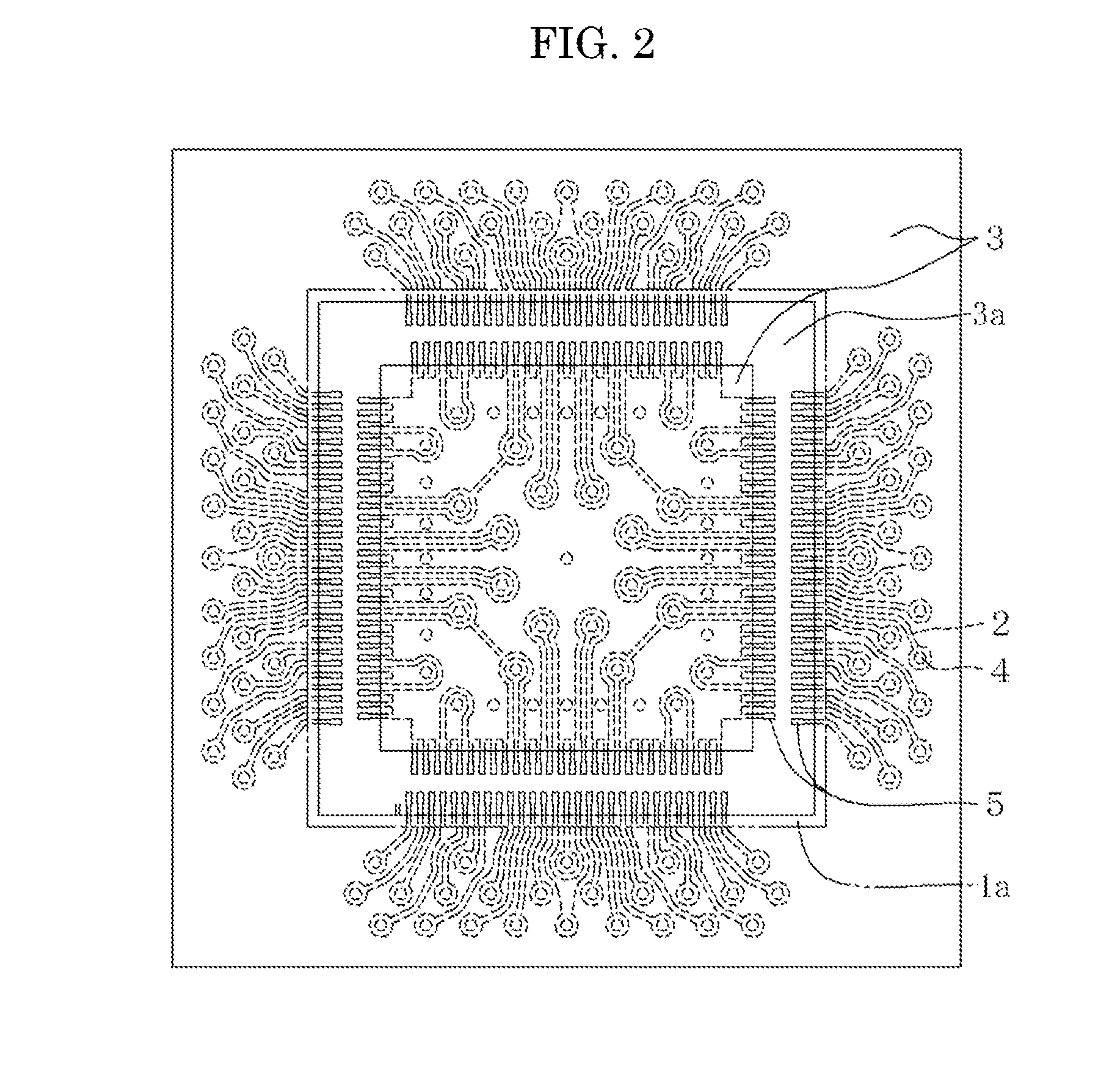

Methods of fabricating package substrates having embedded circuit patterns

InactiveUS20170053813A1Lithographic masksSemiconductor/solid-state device detailsEngineeringDielectric layer

There is provided a method of fabricating a package substrate. The method may include forming an isolation trench in a conductive layer, and forming a first dielectric layer on the conductive layer to provide an isolation wall portion filling the isolation trench. The method may include recessing the conductive layer to form circuit patterns in circuit trenches defined and separated by the isolation wall portion. The method may include forming a second dielectric layer covering the circuit patterns, and patterning the first and second dielectric layers to expose portions of the circuit patterns. The exposed portions of the circuit patterns may act as connectors.

Owner:SK HYNIX INC

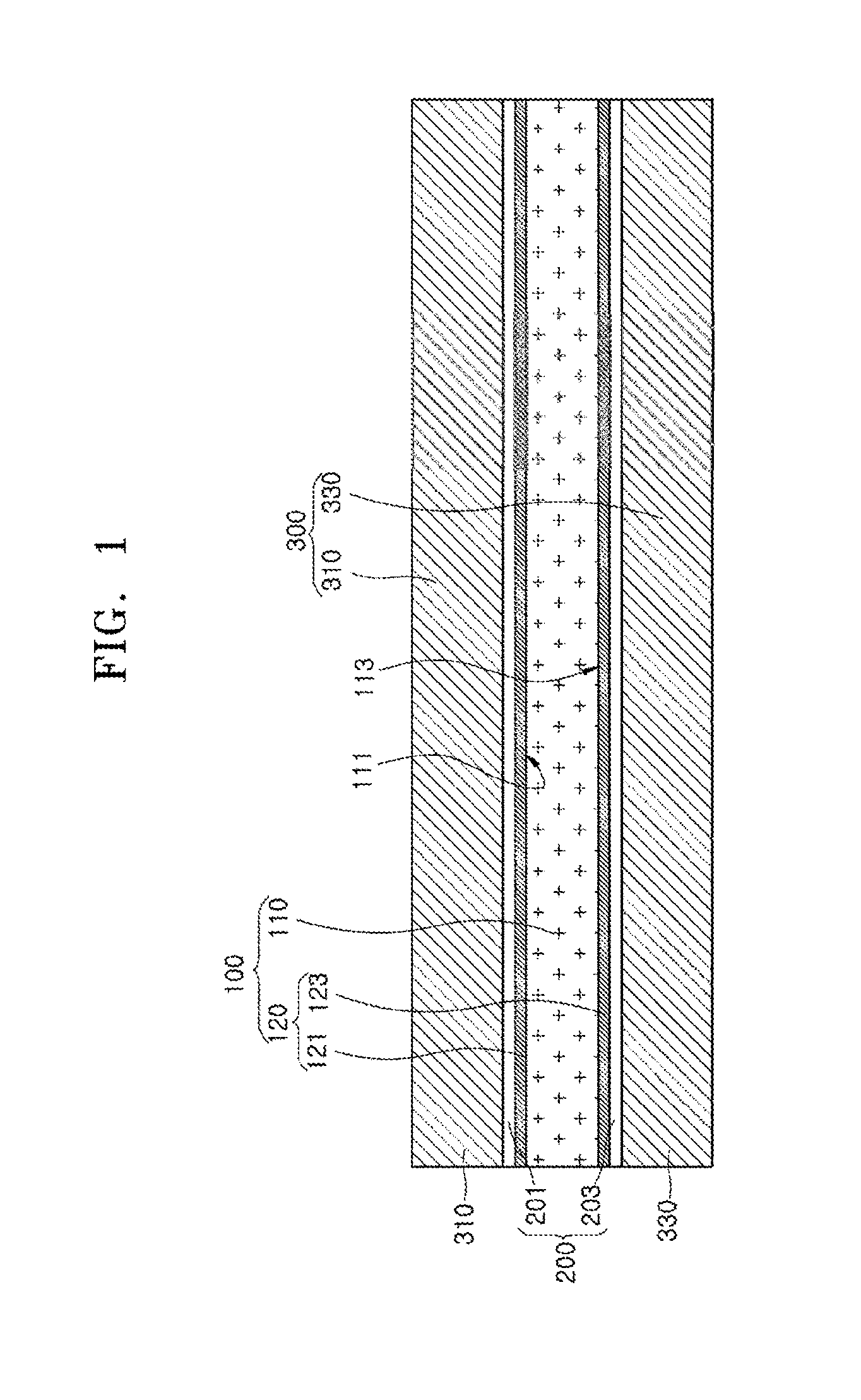

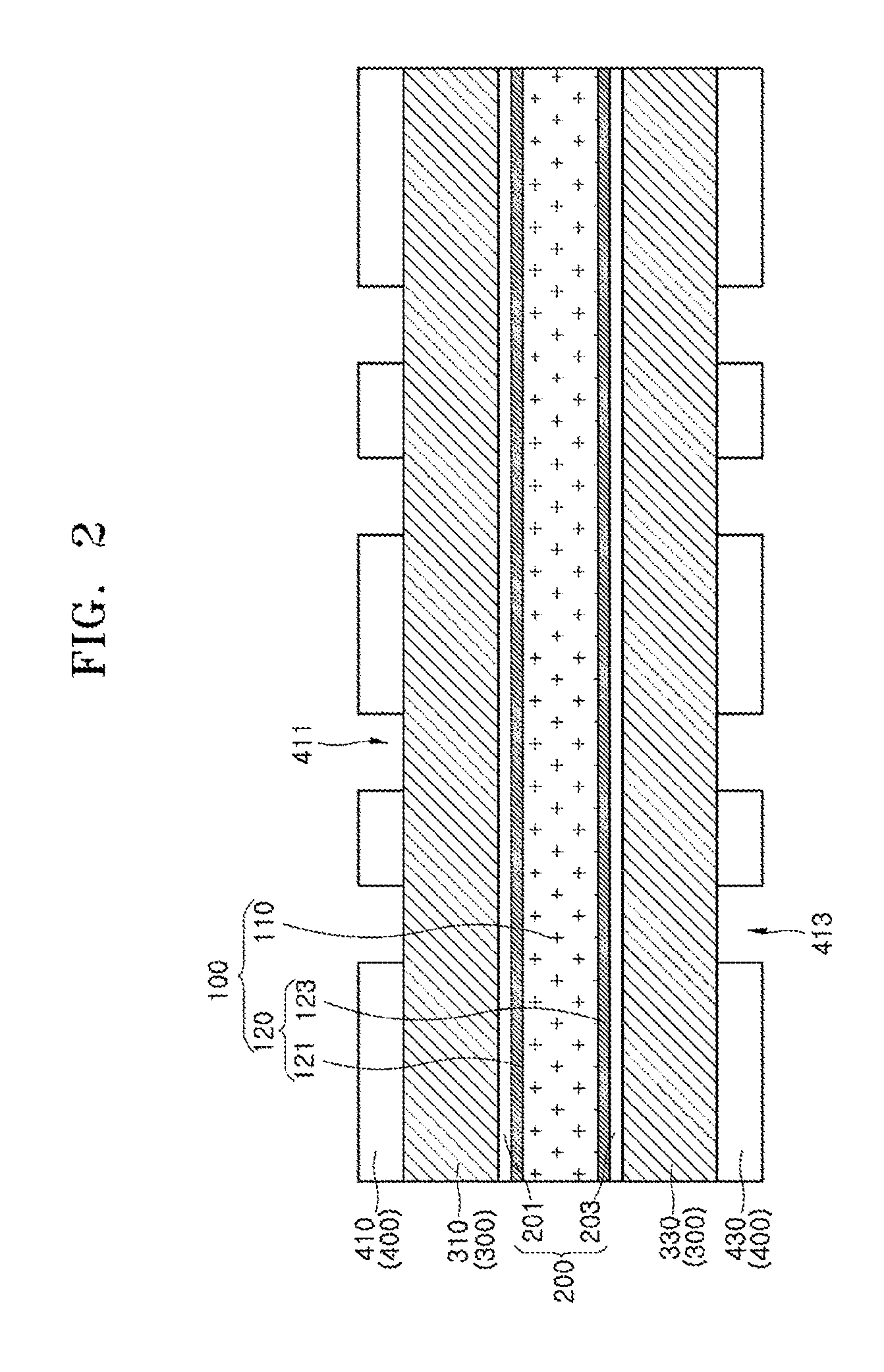

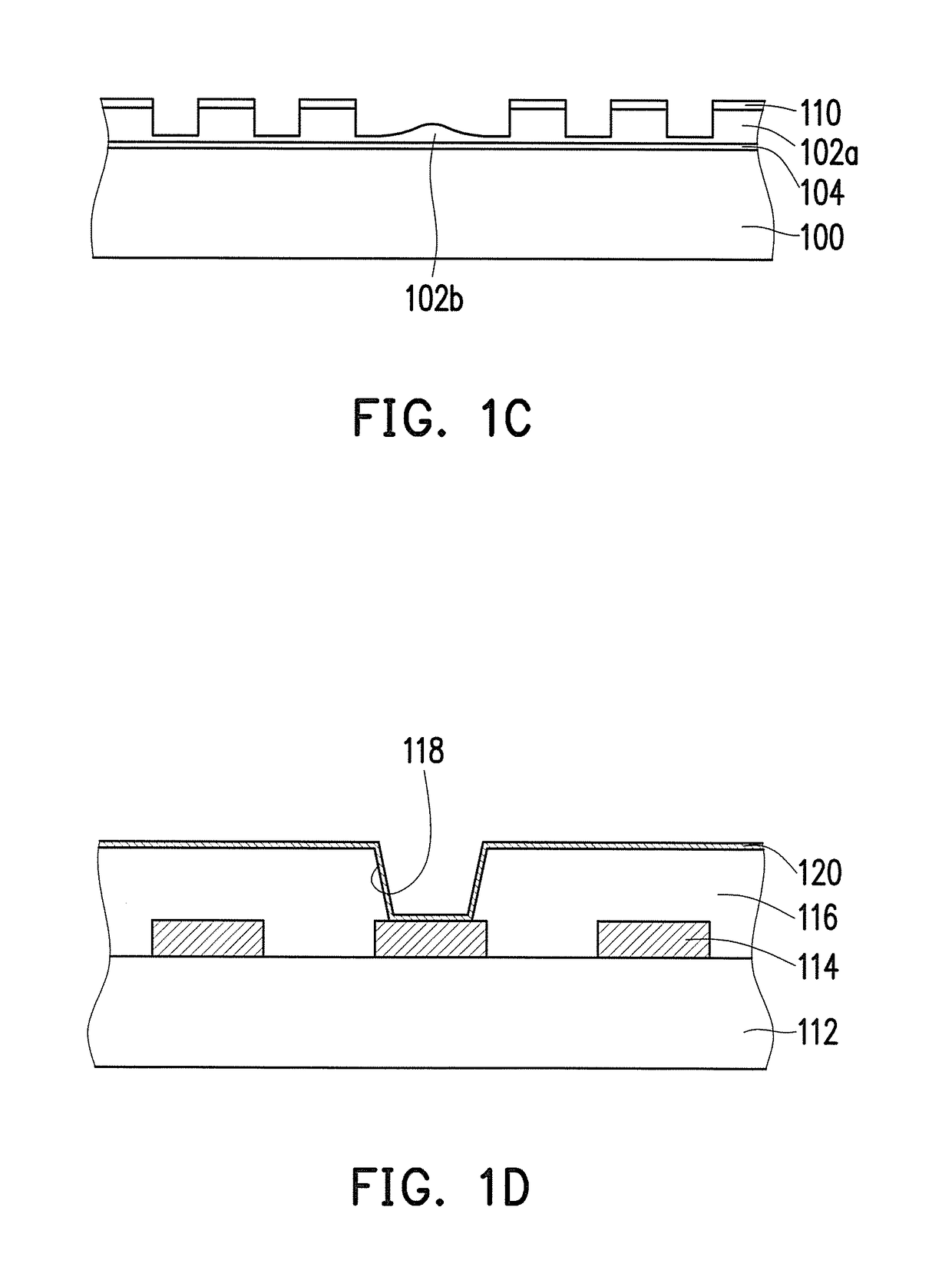

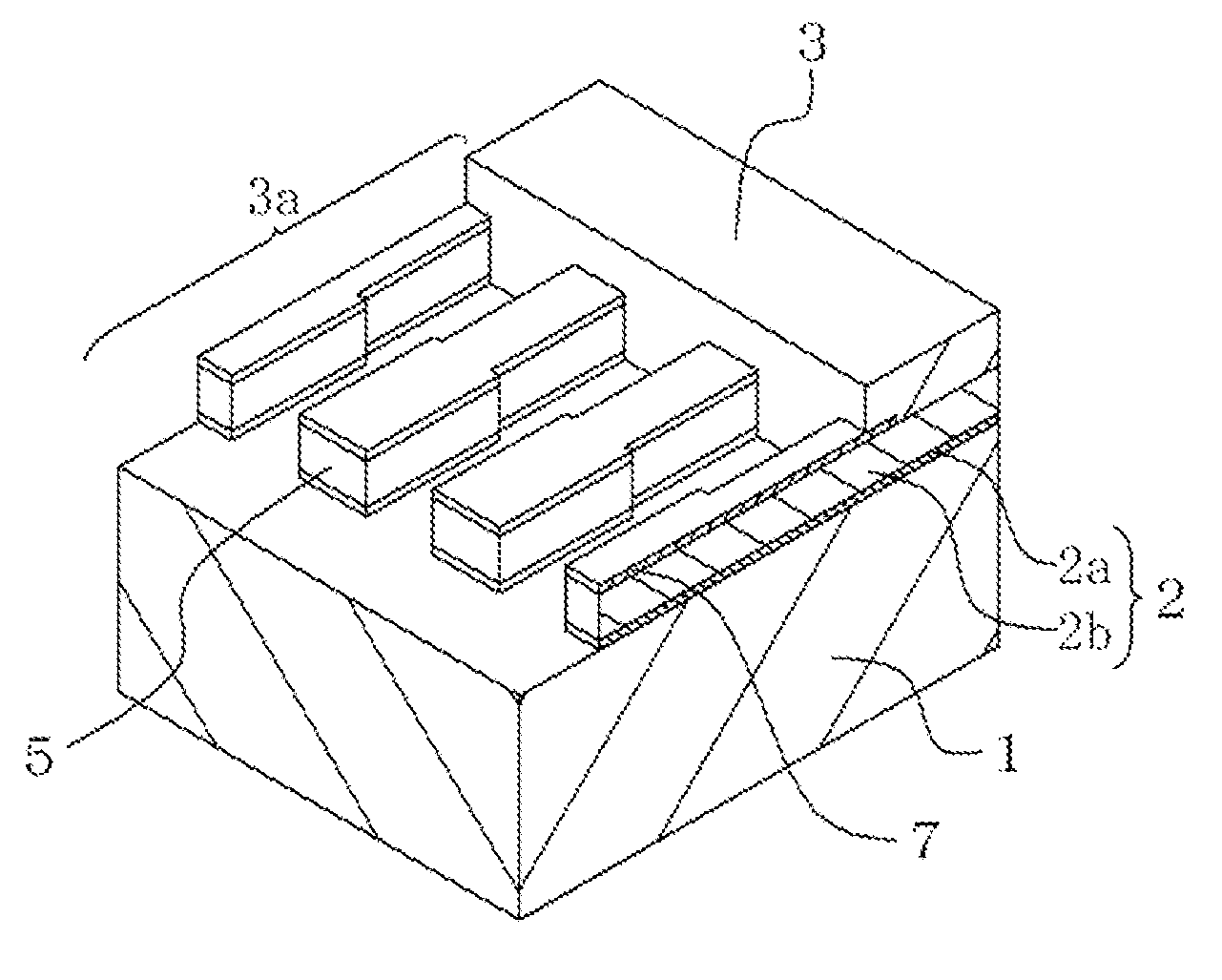

Substrate structure and manufacturing method thereof

InactiveUS20150296618A1High bonding strengthEasy to separateLaminating printed circuit boardsSolid-state devicesEngineeringDielectric layer

A substrate structure including a carrier and a substrate is provided. The carrier includes a release layer, a dielectric layer and a metal layer. The dielectric layer is disposed between the release layer and the metal layer. The substrate includes a packaging region and a peripheral region. The peripheral region is connected to the packaging region and surrounds the packaging region. The peripheral region or the packaging region has a plurality of through holes. The substrate is disposed on the carrier. The release layer is located between the substrate and the dielectric layer. The release layer and the dielectric layer are filled in the through hole such that the substrate is separably attached to the carrier.

Owner:SUBTRON TECH

Method of manufacturing wiring board

A manufacturing method includes a step of forming a first plating mask on a base metal layer, a step of forming a main conductor layer on the base metal layer exposed from the first plating mask, a step of forming a second plating mask on them, a step of attaching a metal plating layer to an upper surface of the main conductor layer exposed from the second plating mask, a step of removing the first and second plating masks, a step of etching away a portion of the base metal layer to which the main conductor layer is not attached, and a step of forming a solder resist layer.

Owner:KYOCERA CORP

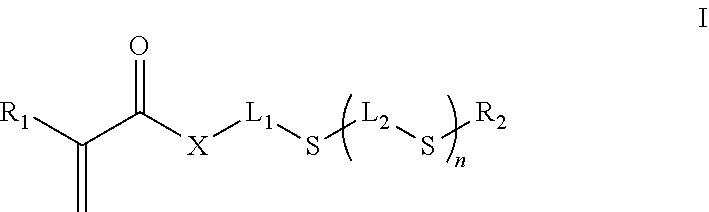

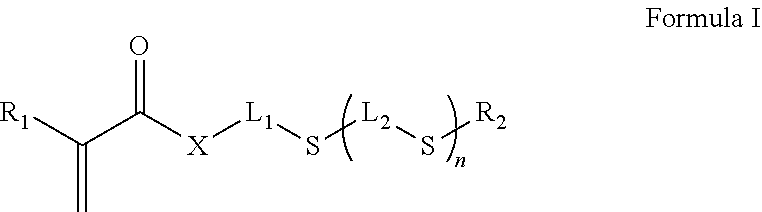

Compound, photocurable composition, and methods for producing patterned film, optical component, circuit board, electronic component by using the photocurable composition, and cured product

ActiveUS9593170B2Improve responseHigh reaction conversion ratePrinted circuit assemblingOrganic chemistryHydrogen atomElectronic component

A compound that increases the photocuring rate of a photocurable composition and reduces the force for releasing a cured product from a mold is provided.A compound is represented by general formula (1):where Rf represents an alkyl group at least part of which is substituted with fluorine, RO represents an oxyalkylene group or a repeated structure of an oxyalkylene group, N represents a nitrogen atom, RA represents an alkyl group, and RB represents an alkyl group or a hydrogen atom.

Owner:CANON KK

Method for manufacturing PCBs through serial numbers

The invention relates to a method for manufacturing PCBs through serial numbers. The method includes the following steps that film files of all the circuit boards to be produced in a batch mode are manufactured, the film files correspond to the serial numbers in a one-to-one mode; the serial numbers corresponding to the circuit boards to be produced are obtained, and circuit graphs and serial number layers of the circuit boards are manufactured according to the film files corresponding to the serial numbers. By means of the method for manufacturing the PCBs through the serial numbers, the film graphs of all the circuit boards can be concentrated together, all the corresponding circuit boards are produced through a serial number identifying method by bumbering the serial numbers, the circuit boards can be produced in the batched mode, batched production of the circuit boards can be achieved, the production error probability of the circuit boards can be greatly reduced, and the production efficiency of the PCBs is improved.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

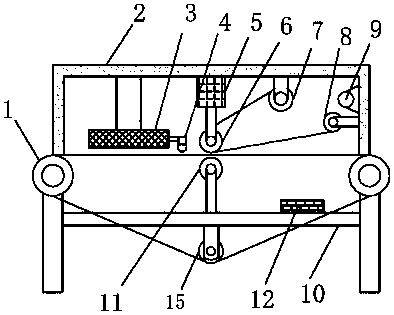

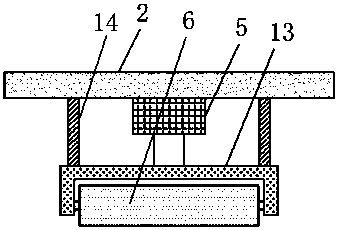

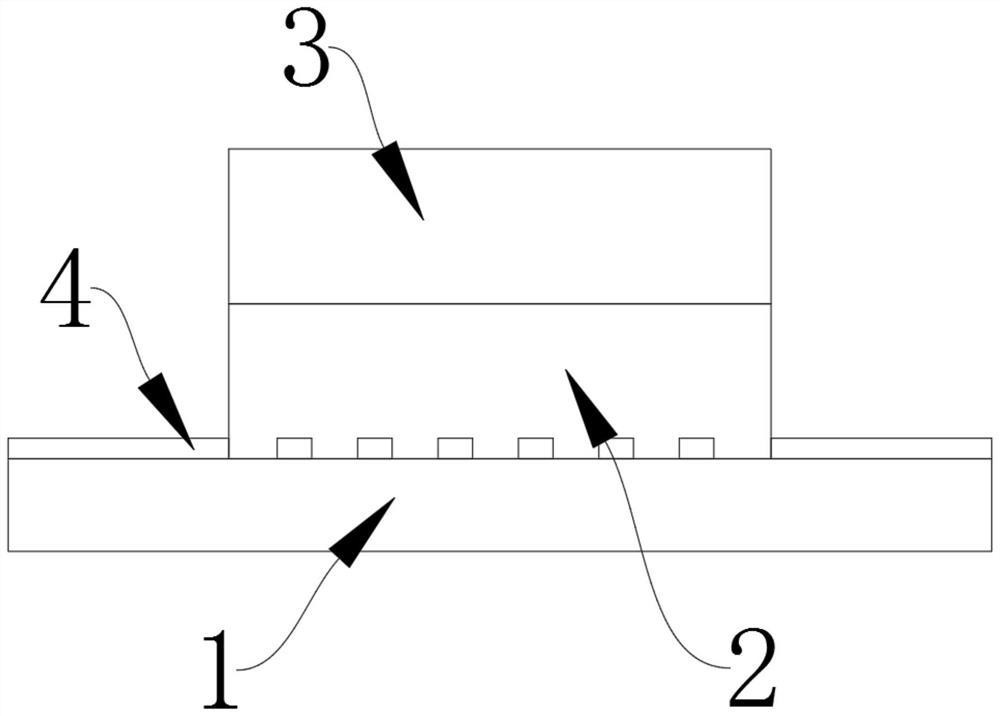

Multifunctional film pasting machine for circuit board

InactiveCN108243566AReasonable structurePracticalLithographic masksLaminating printed circuit boardsEngineeringConveyor belt

The invention discloses a multifunctional film pasting machine for a circuit board. A door type rack is installed at the upper end of a conveyor belt. The lower end opening of a heating box faces thebelt surface of the conveyor belt; and a sensor is installed at one side of the heating box. A cylinder is arranged in the middle of the door type rack. A roller rack is connected with an upper hot-pressing roller in a rotation manner; a film paying-off roller is arranged at the right side of the upper hot-pressing roller; and a film take-up roller is arranged at the right side of the film paying-off roller. A lower hot-pressing roller is fixed in the middle of a cross beam by a fulcrum bar. The lower hot-pressing roller and the upper hot-pressing roller are arranged at the upper side and thelower side of the belt surface of the conveyor belt symmetrically. According to the multifunctional film pasting machine having advantages of reasonable structure and high practicability, the lower hot-pressing roller and the upper hot-pressing roller enable a film to be pasted on a circuit board; and heating devices are arranged in the lower hot-pressing roller and the upper hot-pressing roller,so that the pasting effect is improved by heating during the film pasting process; with the sensor, sensing of passing of a circuit board is realized; and the cylinder can drive the upper hot-pressingroller to move downwardly. The multifunctional film pasting machine has high practicability.

Owner:惠州市源名浩科技有限公司

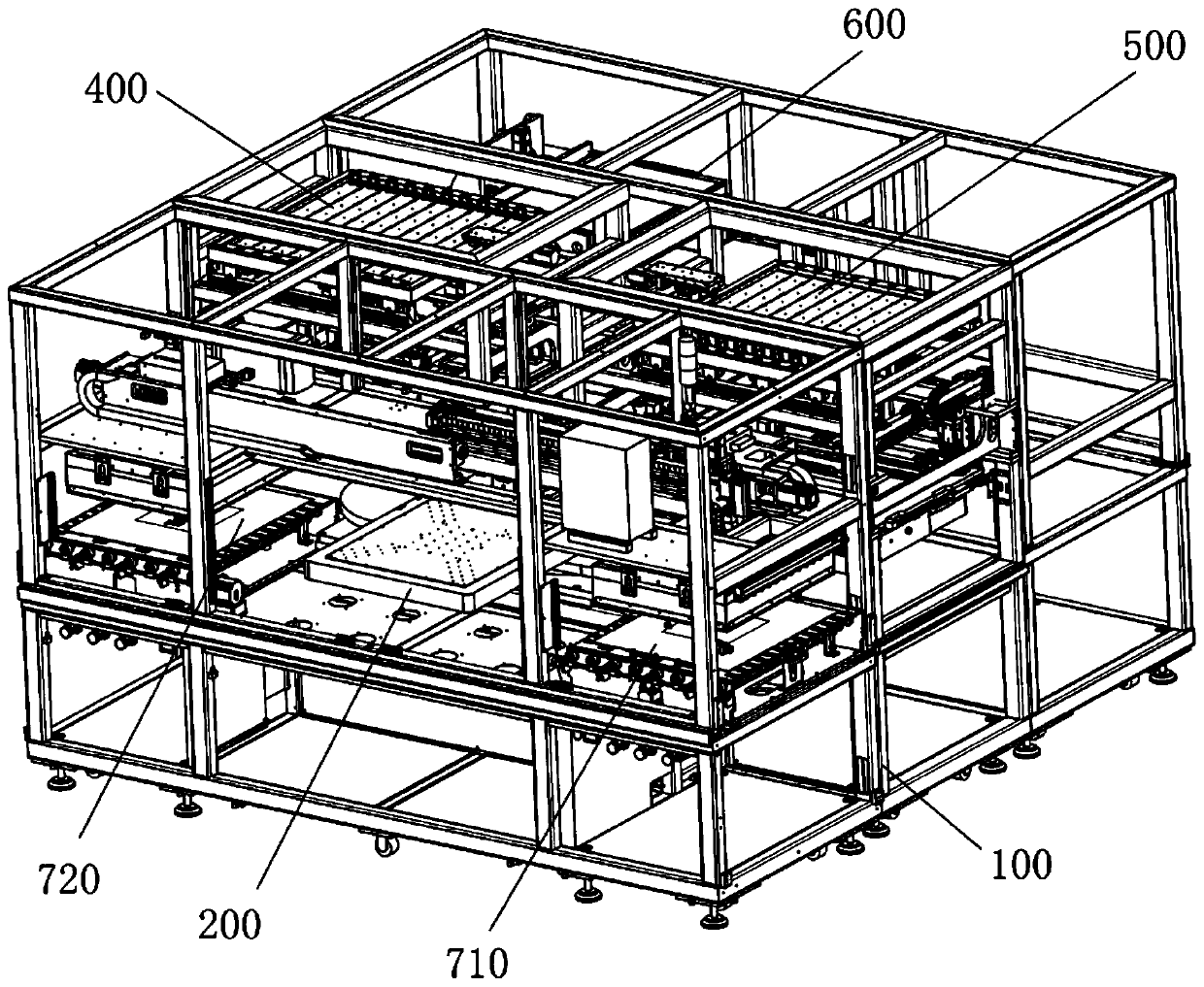

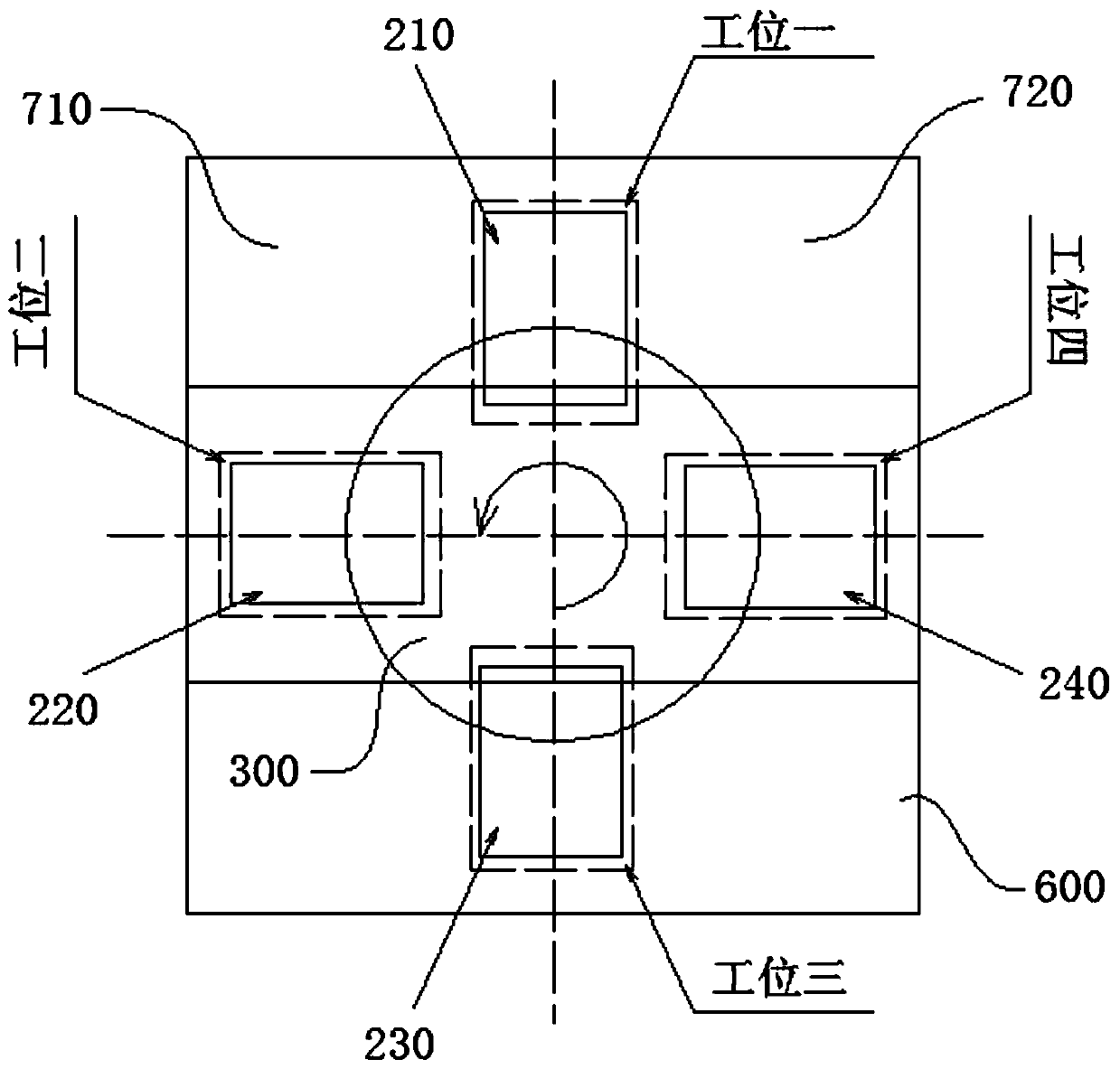

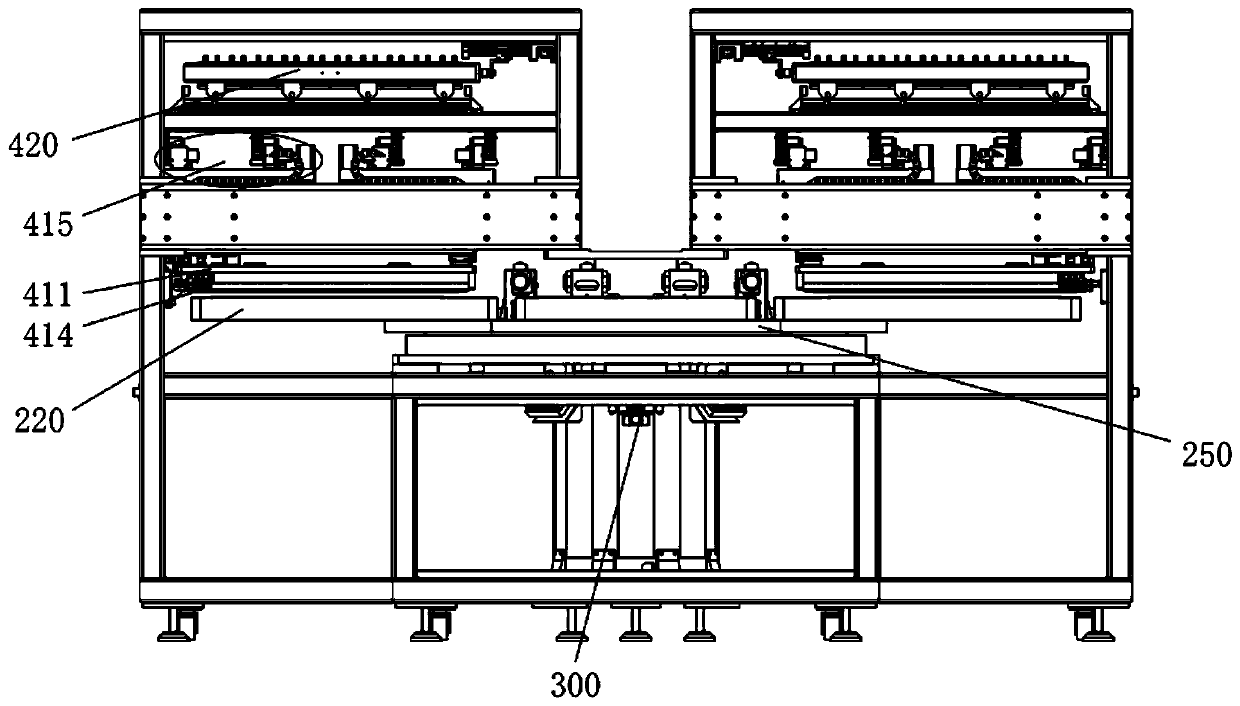

Rotary high-speed automatic alignment exposure equipment

PendingCN111522205AShorten the lengthSimple structureLithography/patterningLithographic masksControl engineeringMachine

A rotary high-speed automatic alignment exposure equipment comprises a rack, a rotary platform, a platform driving module, a first alignment exposure module, a second alignment exposure module, a turning plate module and a feeding and discharging module. The rotating platform is provided with four stations, the four stations are arranged around the center of the rotating platform, and the center of the rotating platform is connected with the platform driving module. The first alignment exposure module, the second alignment exposure module, the turning plate module and the loading and unloadingmodule are respectively positioned on the four stations and are fixed on the rack. The first alignment exposure module and the second alignment exposure module are located on the two opposite stations, and the turning plate module and the feeding and discharging module are located on the other two opposite stations. The length of the whole machine is shortened, the occupied area is reduced, the structure of the whole machine is simplified, the fault probability and cost are reduced, and meanwhile the productivity and precision of the machine are effectively improved.

Owner:广东科视光学技术股份有限公司

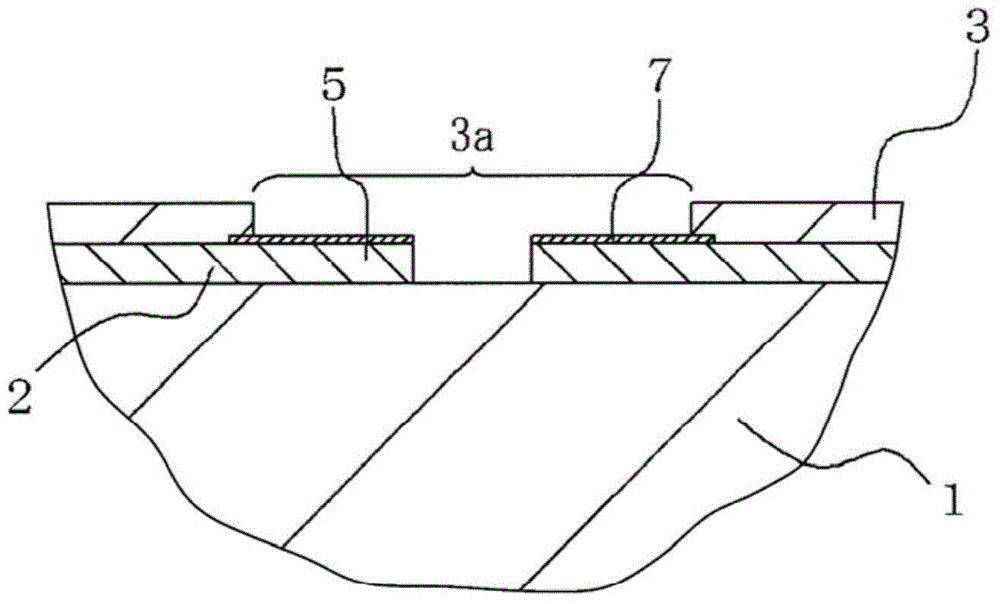

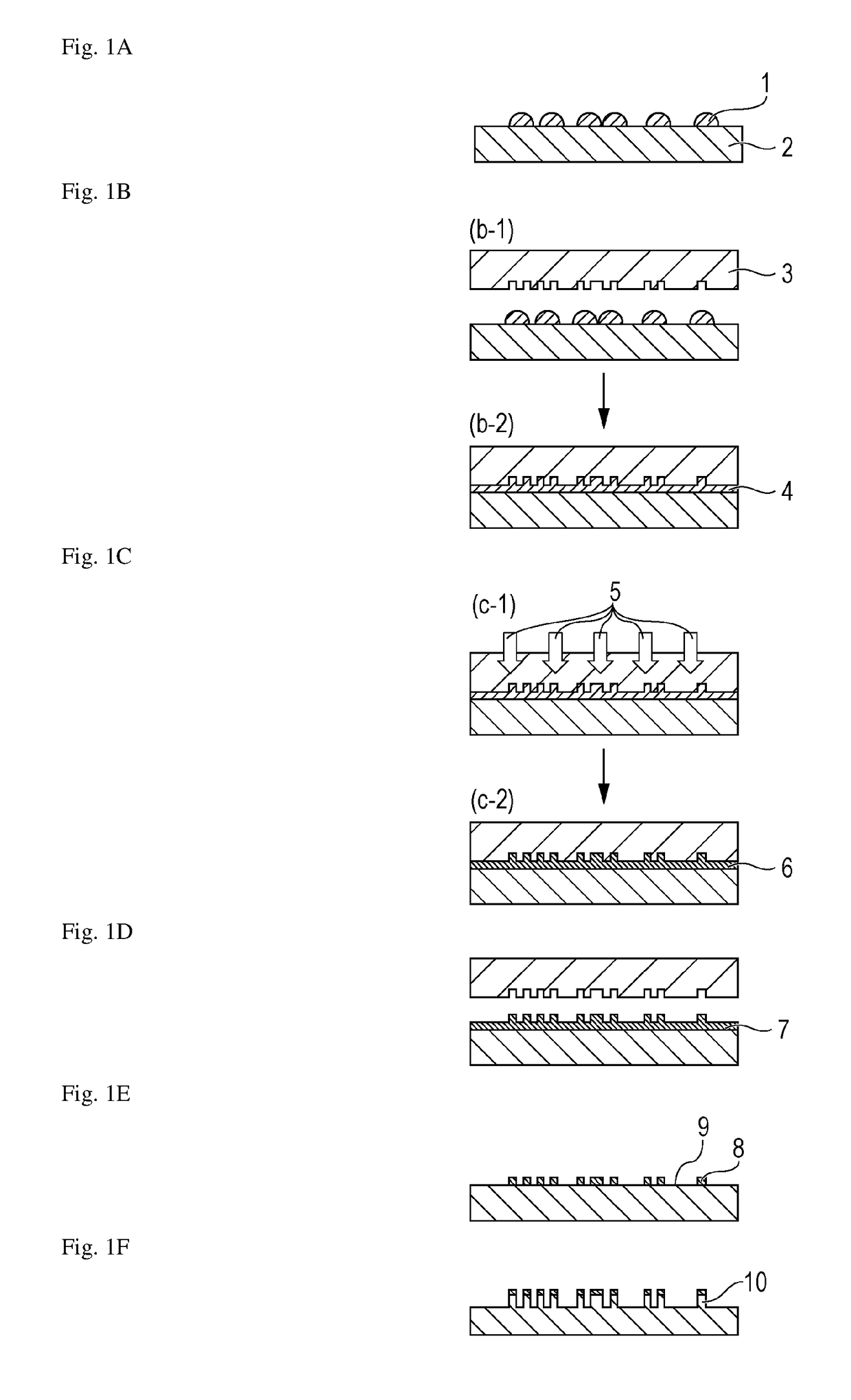

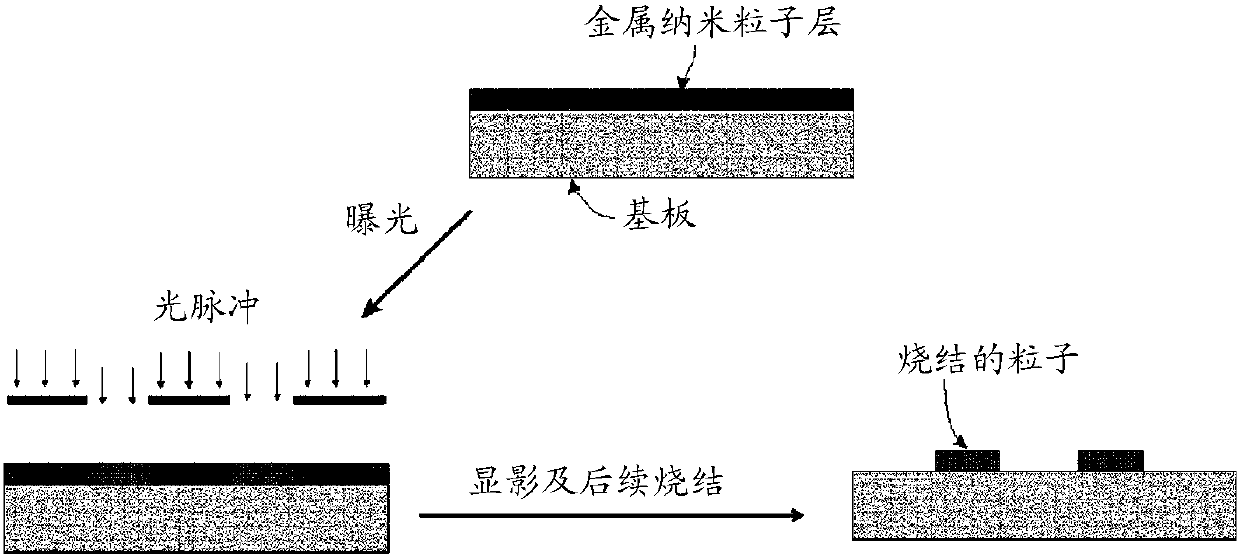

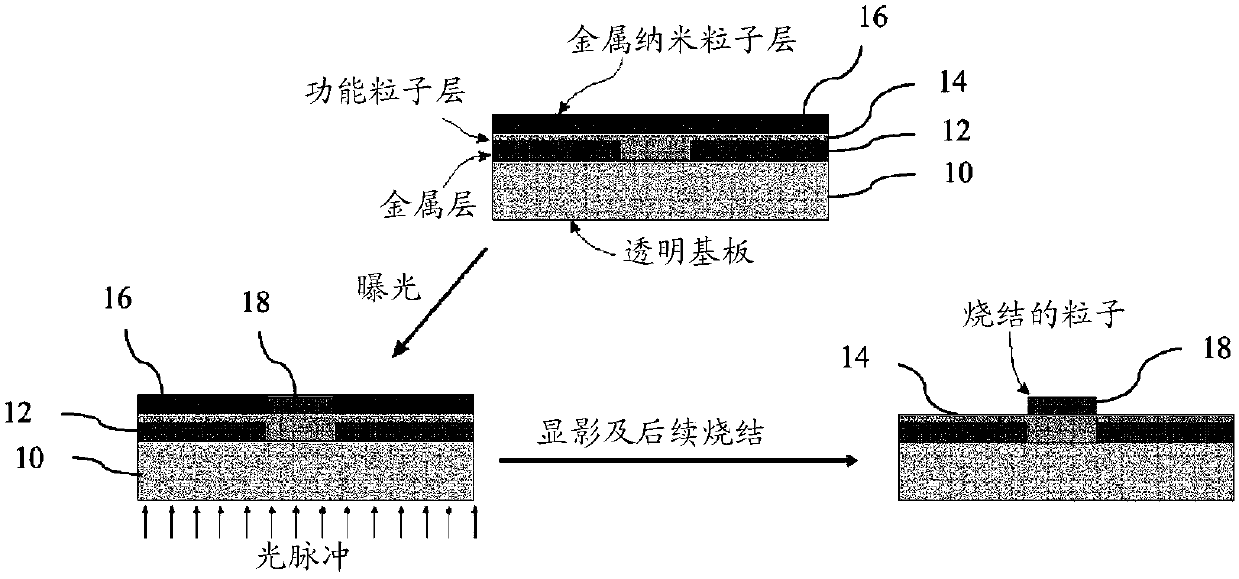

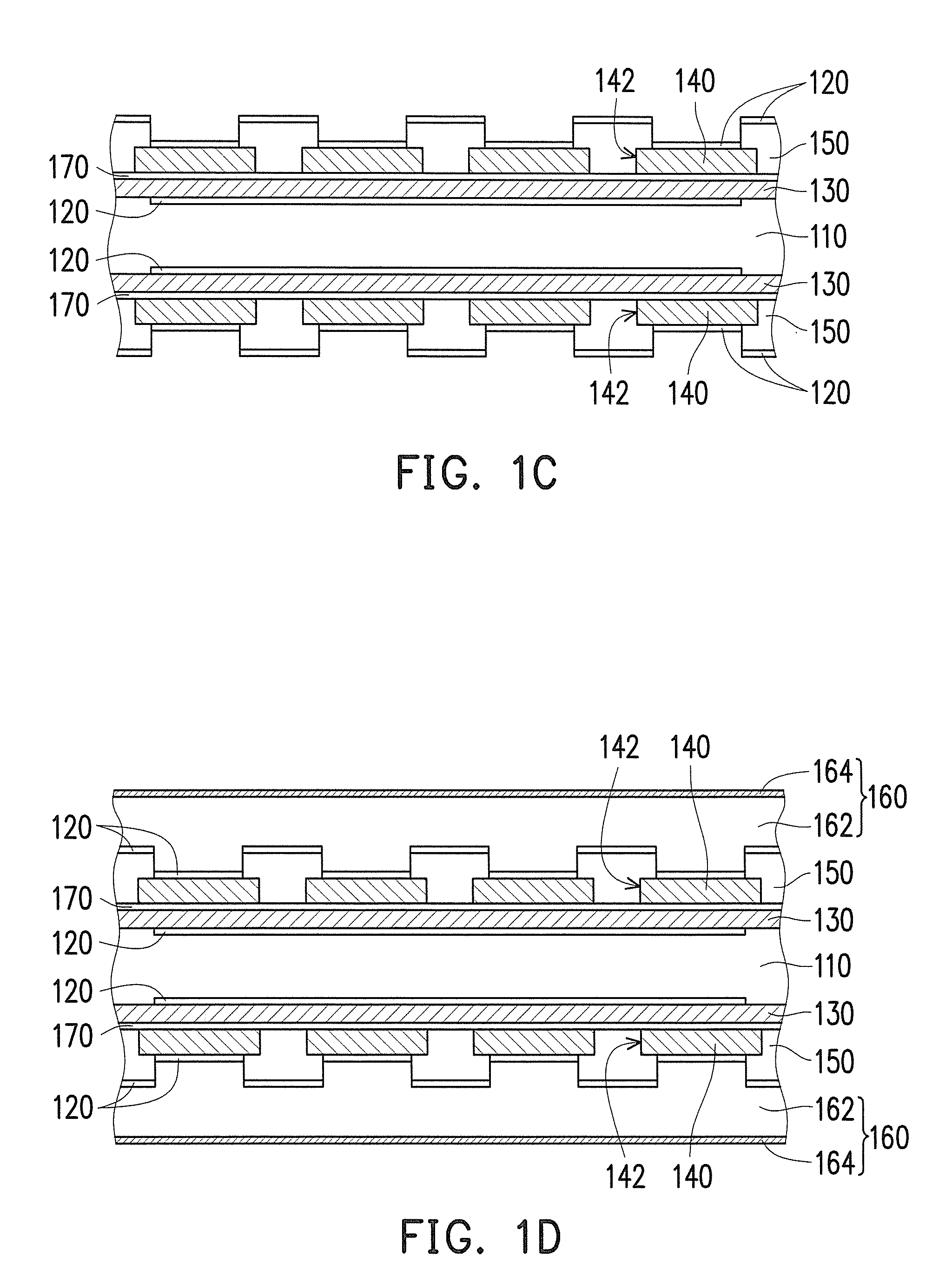

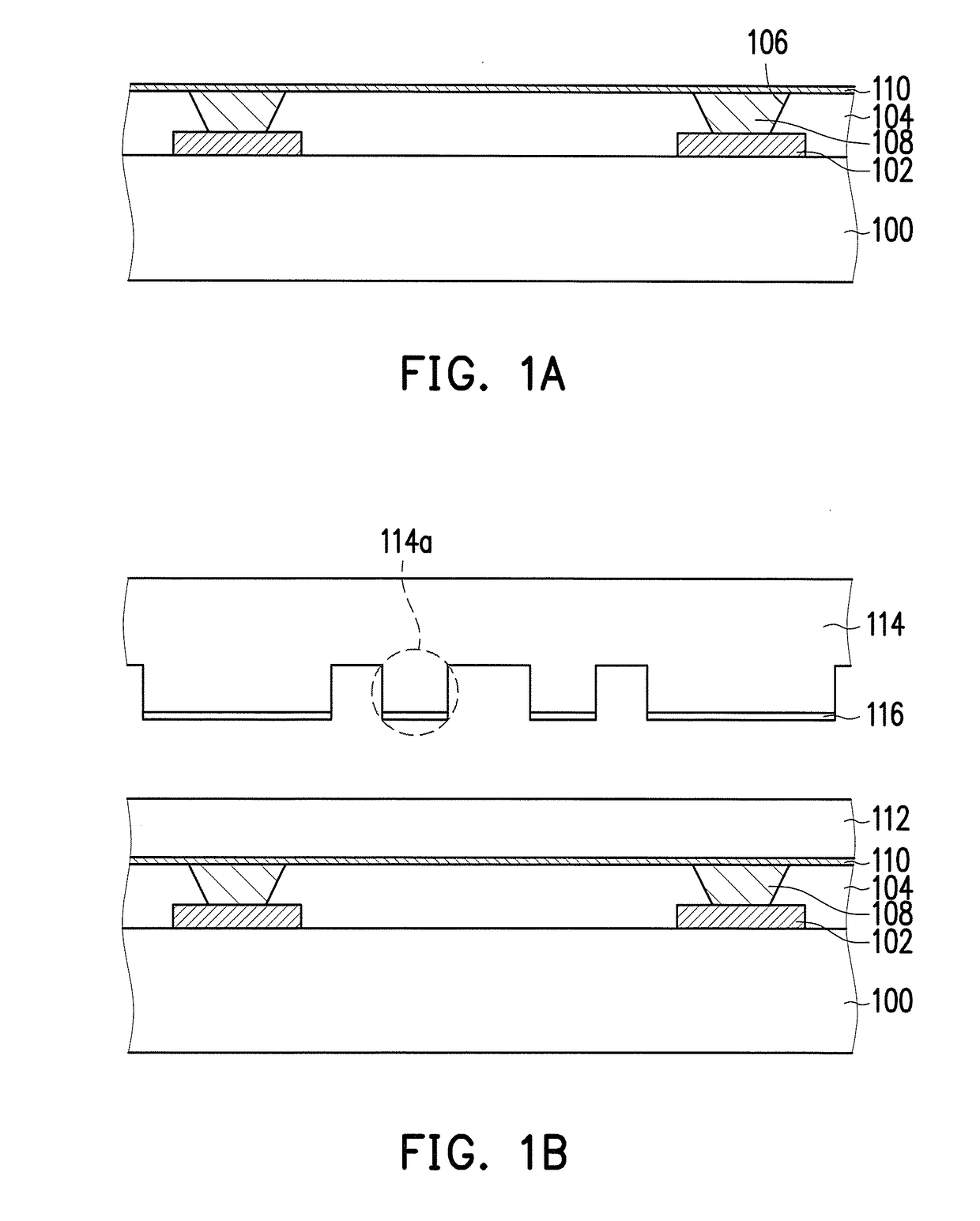

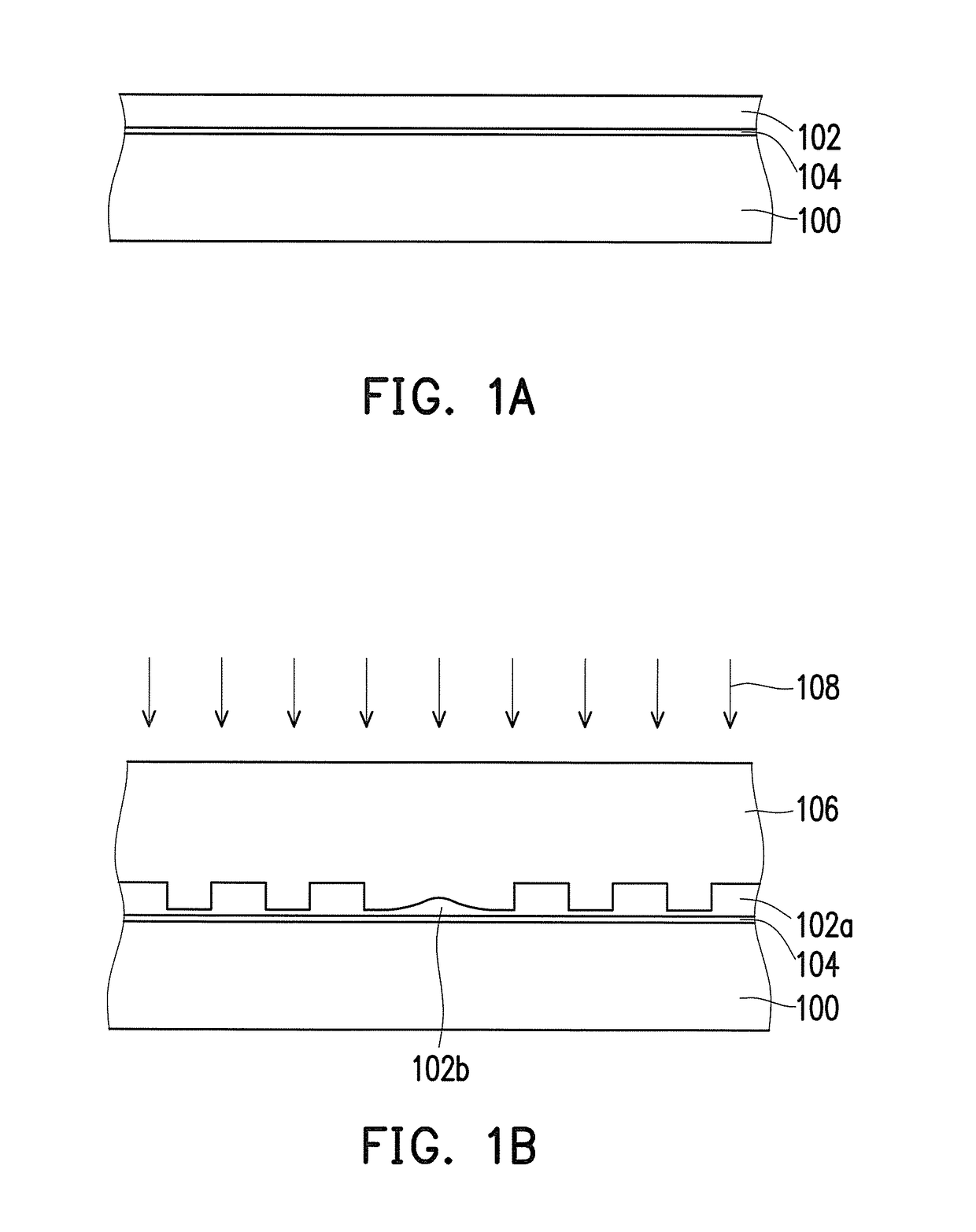

Self-aligning metal patterning based on photonic sintering of metal nanoparticles

A method is disclosed for aligning layers in fabricating a multilayer printable electronic device. The method entails providing a transparent substrate upon which a first metal layer is deposited, providing a transparent functional layer over the first metal layer, depositing metal nano particles over the functional layer to form a second metal layer, exposing the metal nano particles to intense pulsed light via an underside of the substrate to partially sinter exposed particles to the functional layer whereby the first metal layer acts as a photo mask, and washing away unexposed particles using a solvent to leave partially sintered metal nano particles on the substrate.

Owner:NAT RES COUNCIL OF CANADA

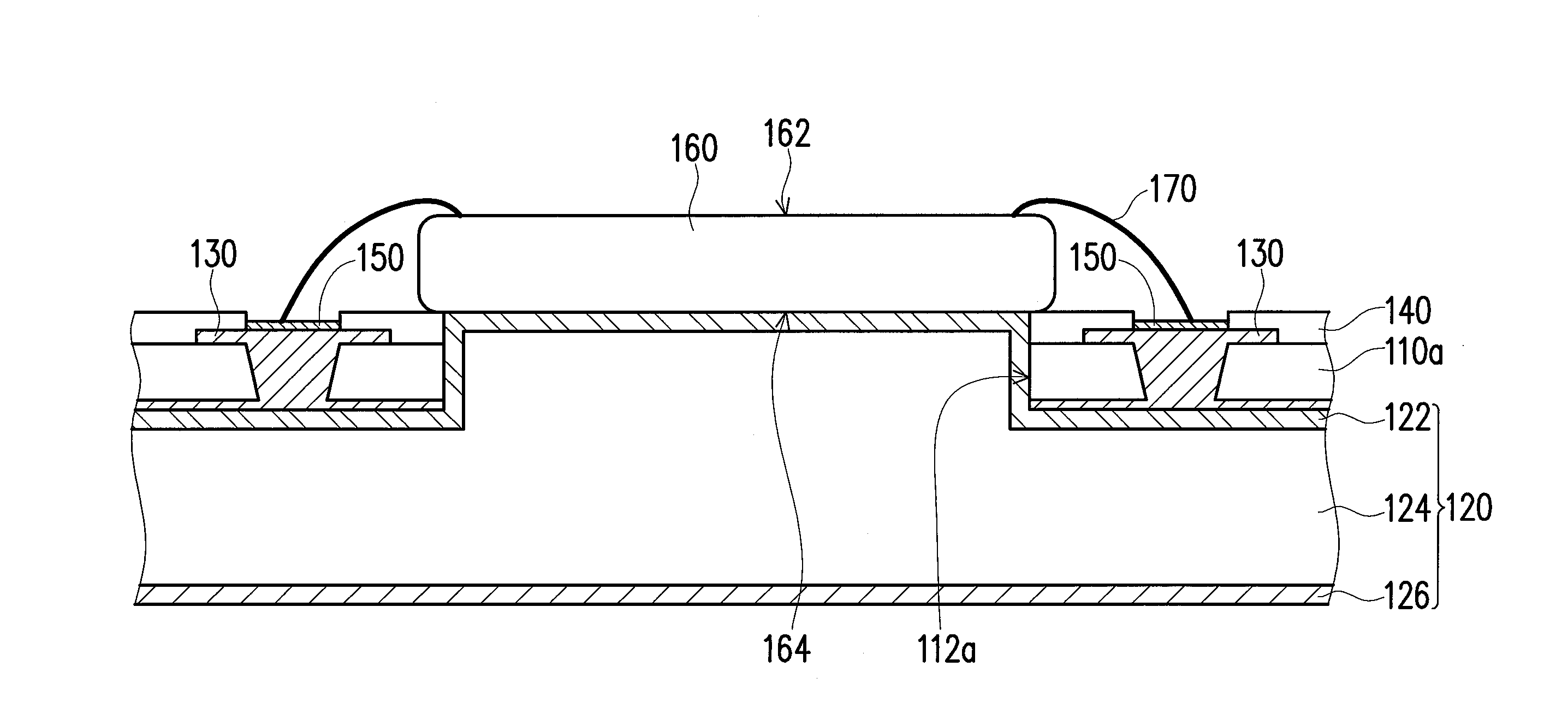

Substrate structure and fabrication method thereof

ActiveUS20160128184A1Substrate structureSmall sizeLithographic masksPrinted circuit aspectsEngineeringDielectric layer

A method for fabricating a substrate structure is provided, which includes the steps of: disposing at least a strengthening member on a carrier; sequentially forming a first circuit layer and a dielectric layer on the carrier, wherein the strengthening member is embedded in the dielectric layer; forming a second circuit layer on the dielectric layer; removing the carrier; and forming an insulating layer on the first circuit layer and the second circuit layer. The strengthening member facilitates to reduce thermal warping of the substrate structure.

Owner:SILICONWARE PRECISION IND CO LTD

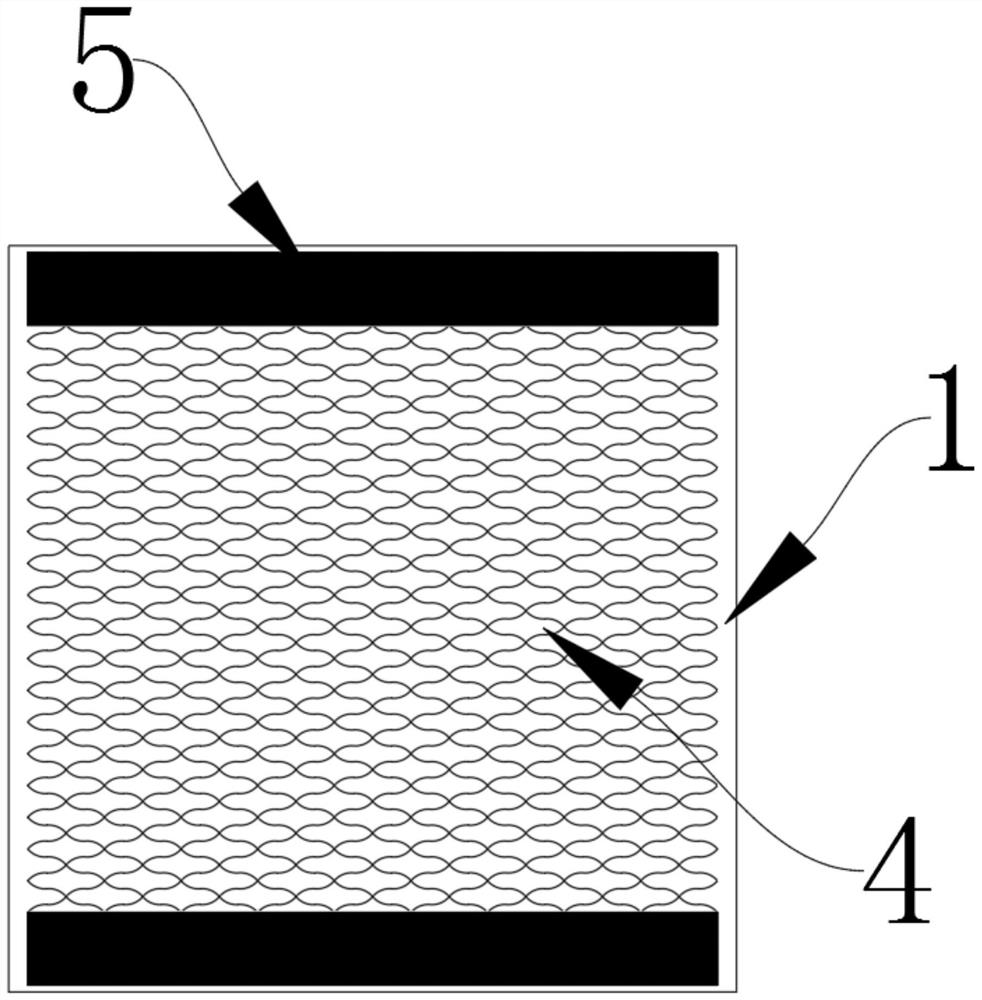

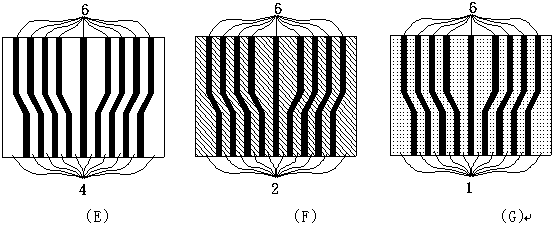

Flexible circuit board for demisting car lamp and manufacturing process of flexible circuit board

PendingCN112969276AThe production process is simpleLow costCircuit thermal detailsFlexible printed circuitsUV curingFlexible circuits

The invention discloses a flexible circuit board for demisting an automobile lamp and a manufacturing process of the flexible circuit board, and belongs to the technical field of automobile parts. The flexible circuit board comprises a substrate; the substrate is composed of a first PET board and a CU; a dry film is pressed at the upper end of the substrate; the dry film is sequentially subjected to exposure, development and etching film stripping to form a circuit pattern; the circuit pattern is composed of a wire network and two buses, the two buses are located on the two sides of the wire network, and the wire network is electrically connected with the buses; a cover film is pressed at the upper end of the dry film through a vacuum pressing machine; the cover film is composed of a UV curing transparent adhesive tape and a second PET plate; the second PET plate is located at the upper end of the UV curing transparent adhesive tape; and the dry film and the second PET plate are connected through the UV curing transparent adhesive tape in a gluing mode. Through cooperation of all accessories, demisting can be well conducted on the front lamp and the rear lamp of an automobile; the product is light and thin, is wide in application range, simple in manufacturing process, low in cost, is easy to introduce to mass production and can greatly save the production cost.

Owner:隽美经纬电路有限公司

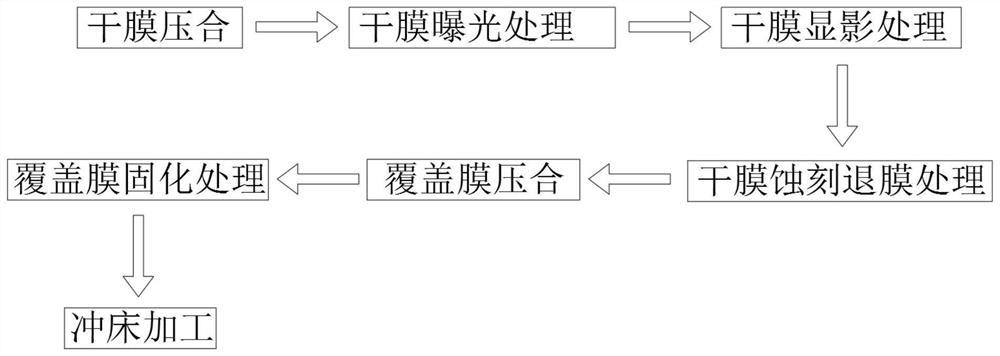

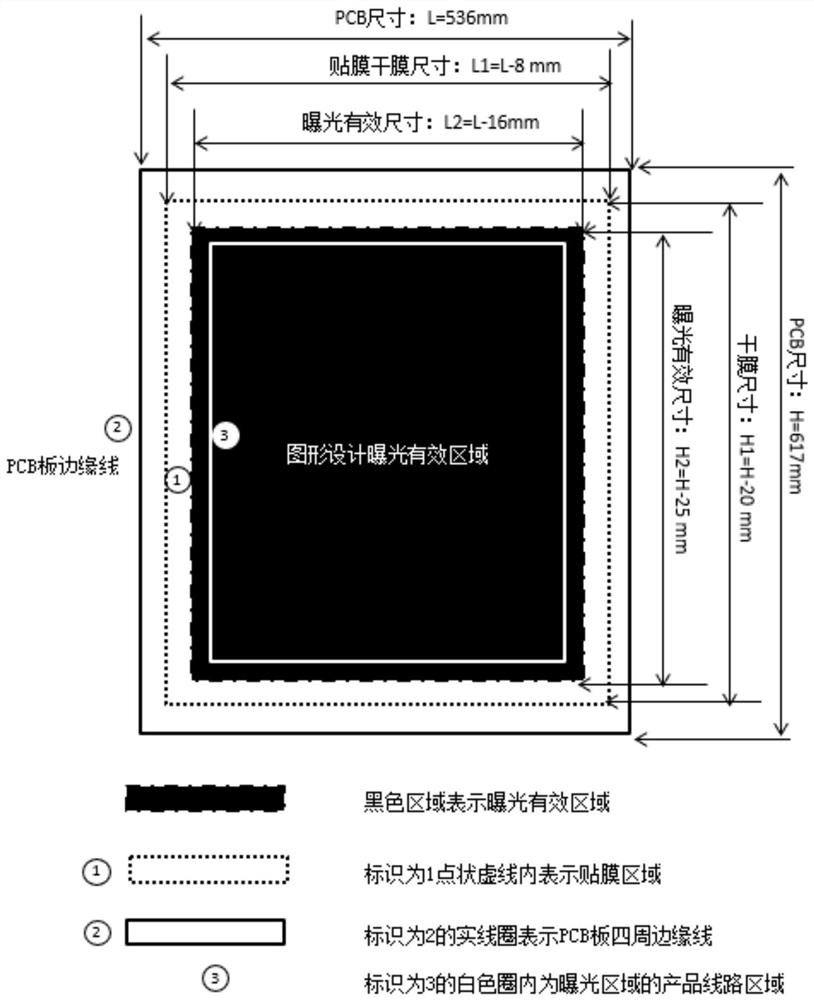

Graphic design method for reducing dry film breakage of fine circuit board

PendingCN114867220AGuarantee product qualityEnsure copper thickness uniformityLithographic masksConductive pattern formationGraphical designComposite material

A graphic design method for reducing dry film breakage of a fine circuit board relates to the technical field of fine circuit board manufacturing, and a dry film on a PCB (printed circuit board) after the dry film is pasted needs to be a certain distance away from the edge of the circuit board so as to ensure that enough space is reserved around the dry film to reserve various mold positions. And dry film breakage caused by the fact that the clamp is clamped on the plate edge dry film is avoided. According to the graphic design method for reducing the dry film fragments of the fine circuit board, generation of the dry film fragments can be avoided and controlled from the source, and the quality influence of circuit open circuit or notch caused by the fact that the dry film fragments adhere to the board surface to hinder electroplating is avoided.

Owner:GUANGZHOU MEADVILLE ELECTRONICS

Substrate structure and manufacturing method thereof

ActiveUS9313886B2Easy to disassembleShorten the timeLithography/patterningLithographic masksResistMetal foil

Owner:SUBTRON TECH

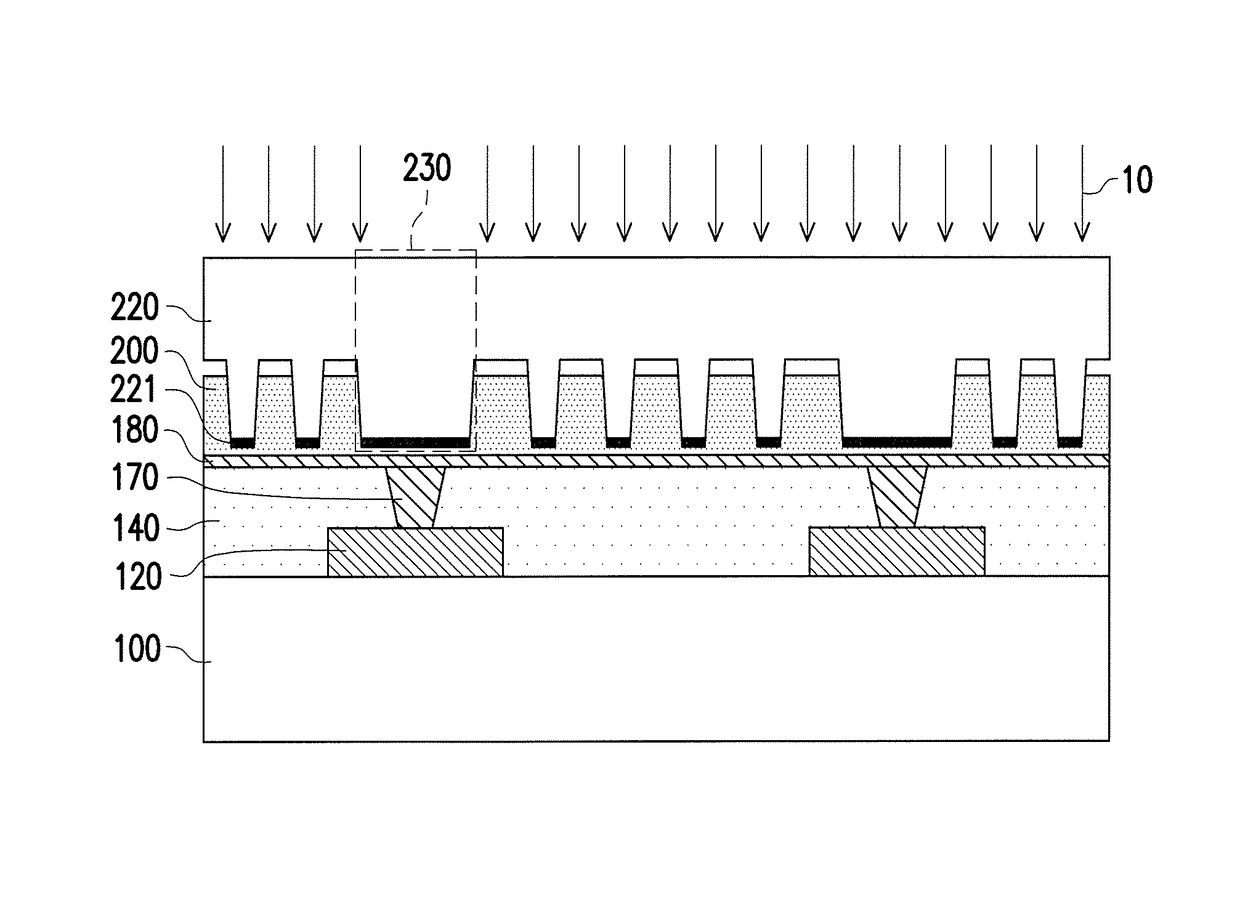

Manufacturing method of circuit board

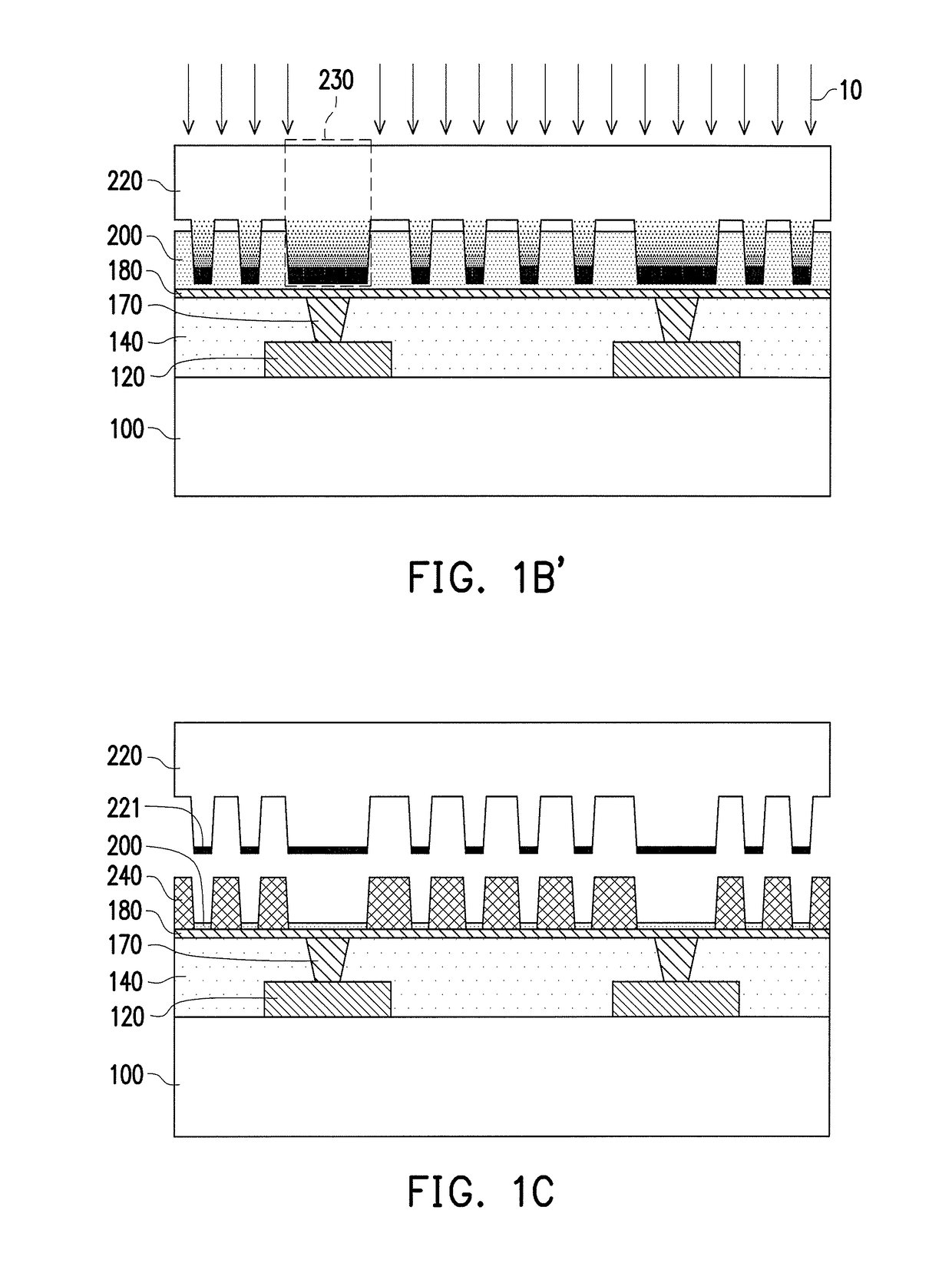

ActiveUS10098234B2Improve reliabilityHigh yieldLithography/patterningResist detailsDielectric substrateTransmittance

A manufacturing method of a circuit board and a piezochromic stamp are provided. A circuit pattern is formed on a dielectric substrate. A dielectric layer having a hole or a conductive via and covering the circuit pattern is formed on the dielectric substrate. A conductive seed layer is formed on the dielectric layer. A photoresist layer is formed on the conductive seed layer. A piezochromic stamp is imprinted on the photoresist layer, wherein when the pressing side of the piezochromic stamp is in contact with the conductive seed layer, the light transmittance effect thereof is changed to blocking or allowing light having a specific wavelength to pass through. A patterned photoresist layer is formed by using the piezochromic stamp as a mask. A patterned metal layer is formed on the exposed conductive seed layer. The patterned photoresist layer and the conductive seed layer are removed.

Owner:UNIMICRON TECH CORP

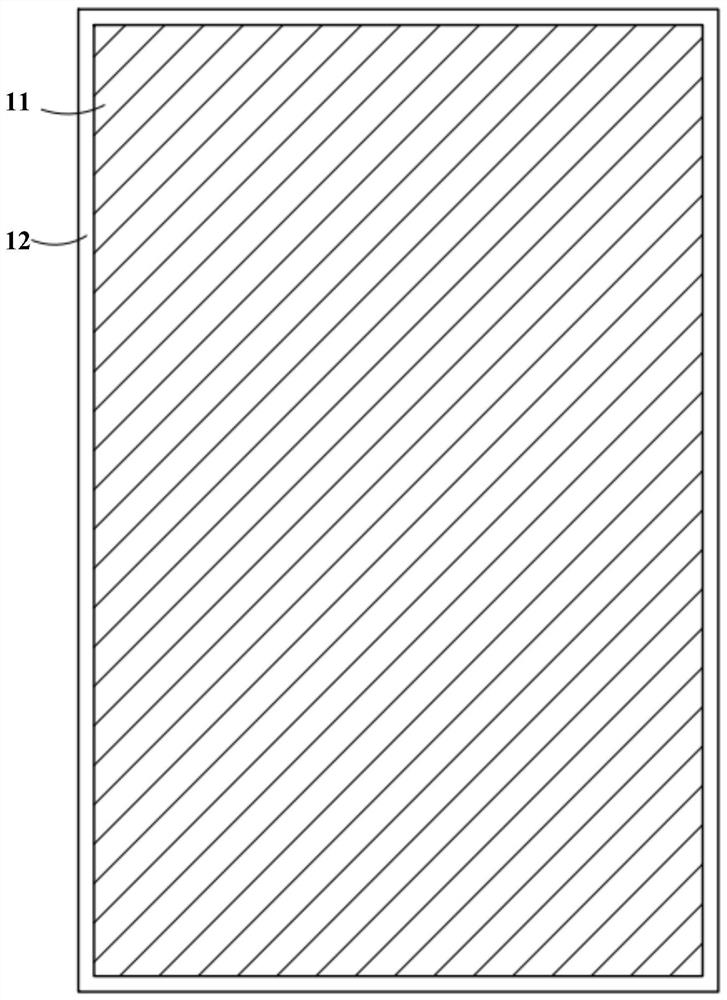

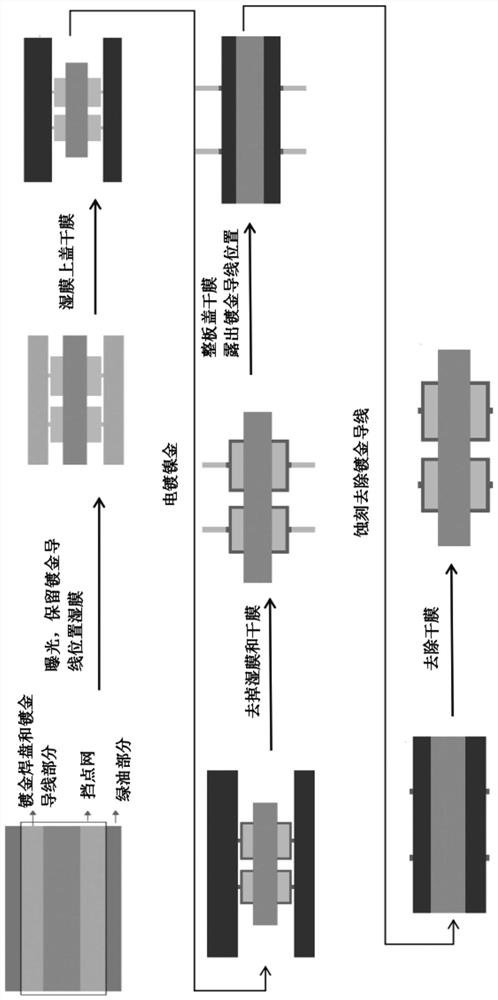

Method for plating gold on surface of circuit board

PendingCN112954907AResidue reductionLess residue and uniformLithographic masksConductive material chemical/electrolytical removalEngineeringElectrical performance

The invention belongs to the technical field of circuit board manufacturing, and discloses a method for plating gold on the surface of a circuit board. According to the method, a wet film and a dry film are covered on the prefabricated circuit board covered with a solder resist, and then a method of etching a gold-plated wire is adopted, so that the gold-plated wire residue of the manufactured circuit board is less than 3.8 mil, the gold-plated wire residue is few and uniform, and the gold-plated part is flat and free of scratches. The surface of the solder resist of the circuit board is clean and free of dirt, and the solder resist is not easy to fall off; and the circuit board is good in binding and welding performance and excellent in electrical performance.

Owner:珠海杰赛科技有限公司 +1

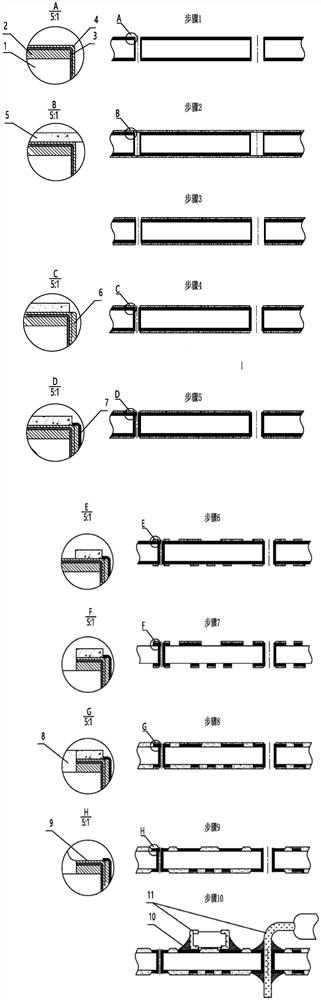

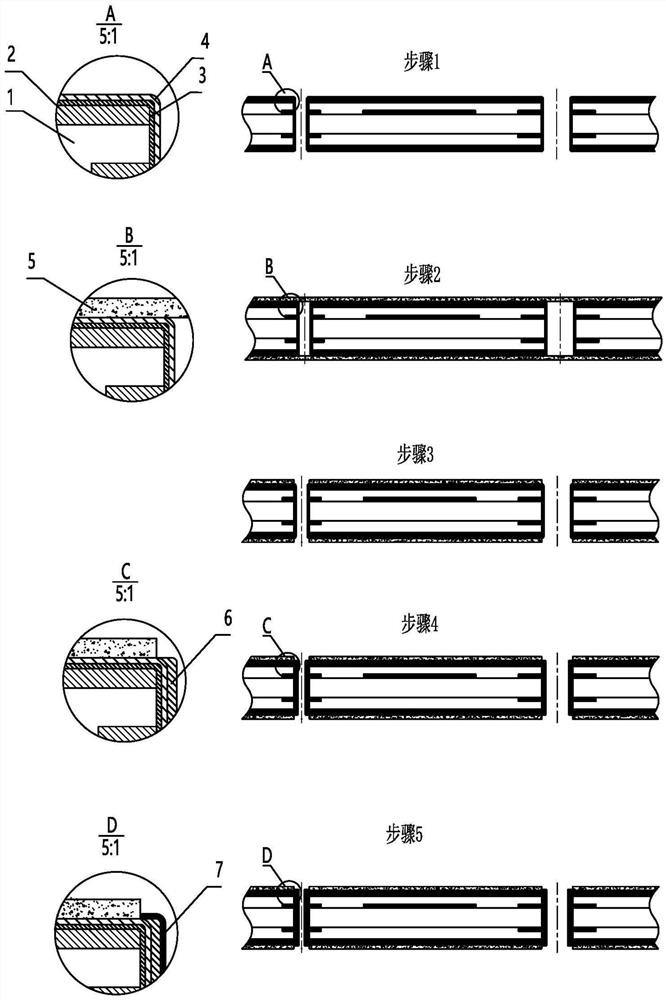

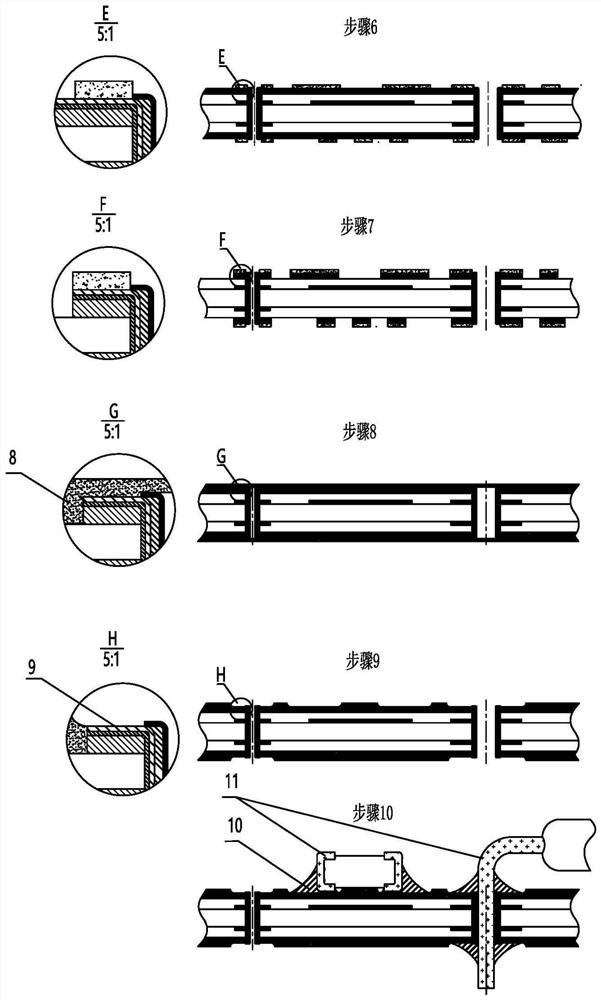

Circuit forming method of circuit board

InactiveCN110493970AFast updateReduce varianceLithographic masksConductive material chemical/electrolytical removalEtchingCopper foil

The invention discloses a circuit forming method of a circuit board, and belongs to the technical field of photolithography technique. The method comprises steps: A) combining a base material and copper foil to serve as a substrate; B) punching a required hole; C) arranging a film on the surface of the copper foil; D, developing the film; E, performing graphical surface treatment on the surface ofthe copper foil to form a surface treatment layer on the surface of the copper foil; F, stripping the film; G, performing differential etching on the surface of the copper foil; and H, performing inkprinting at the corresponding position. The surface-treated non-copper substance thinner than the wet film or the dry film is adopted for differential etching, so that the updating speed of the etching solution on the surface of the to-be-etched part is higher during etching, the difference of contact between the etching solution and a copper surface is reduced, and finer circuit etching is realized. Compared with the traditional process, the surface treatment process in the method avoids long-time contact between the base material at the bottom edge of the circuit and the surface treatment liquid medicine before etching, and improves the binding force between the copper surface circuit and the base material.

Owner:江苏上达半导体有限公司

Circuit board manufacturing method for processing electroplated hole and anti-corrosion pattern by laser

PendingCN113766767AOptimize and shorten the manufacturing processSuitable for mass productionLithographic masksConductive material chemical/electrolytical removalChemistryPhysics

The invention relates to a circuit board manufacturing method for processing an electroplated hole and an anti-corrosion pattern by laser, which comprises the following steps of: drilling, depositing a thin metal layer on the hole and a board surface, pasting a non-photosensitive masking film, removing the masking layer covering the hole wall by using laser to expose the hole wall, only electroplating and thickening a conductive layer in the hole, only electroplating a metal anti-corrosion agent in the hole, and manufacturing the anti-corrosion pattern by using the laser. A conductive pattern is etched, a non-photosensitive solder resist is coated on a non-circuit area, a solder resist pattern is manufactured by laser on an assembly site, and cleaning and weldability treatment are carried out on the surface of a welding area; the manufacturing process of the circuit board can be integrally optimized and shortened, a non-photosensitive material is used as an anti-electroplating material, only a conductive layer in the hole is electroplated and thickened, only anti-corrosion and weldable metal is electroplated on the hole wall, and an electroplating hole pattern, an anti-etching pattern and a solder mask pattern are manufactured step by step by using laser, so that the steps are few, the cost is low, and a finer circuit board is manufactured; the quality and the efficiency are improved. The method is suitable for large-batch or small-batch and multi-variety manufacturing of various circuit boards or circuit board samples.

Owner:德中(天津)技术发展股份有限公司

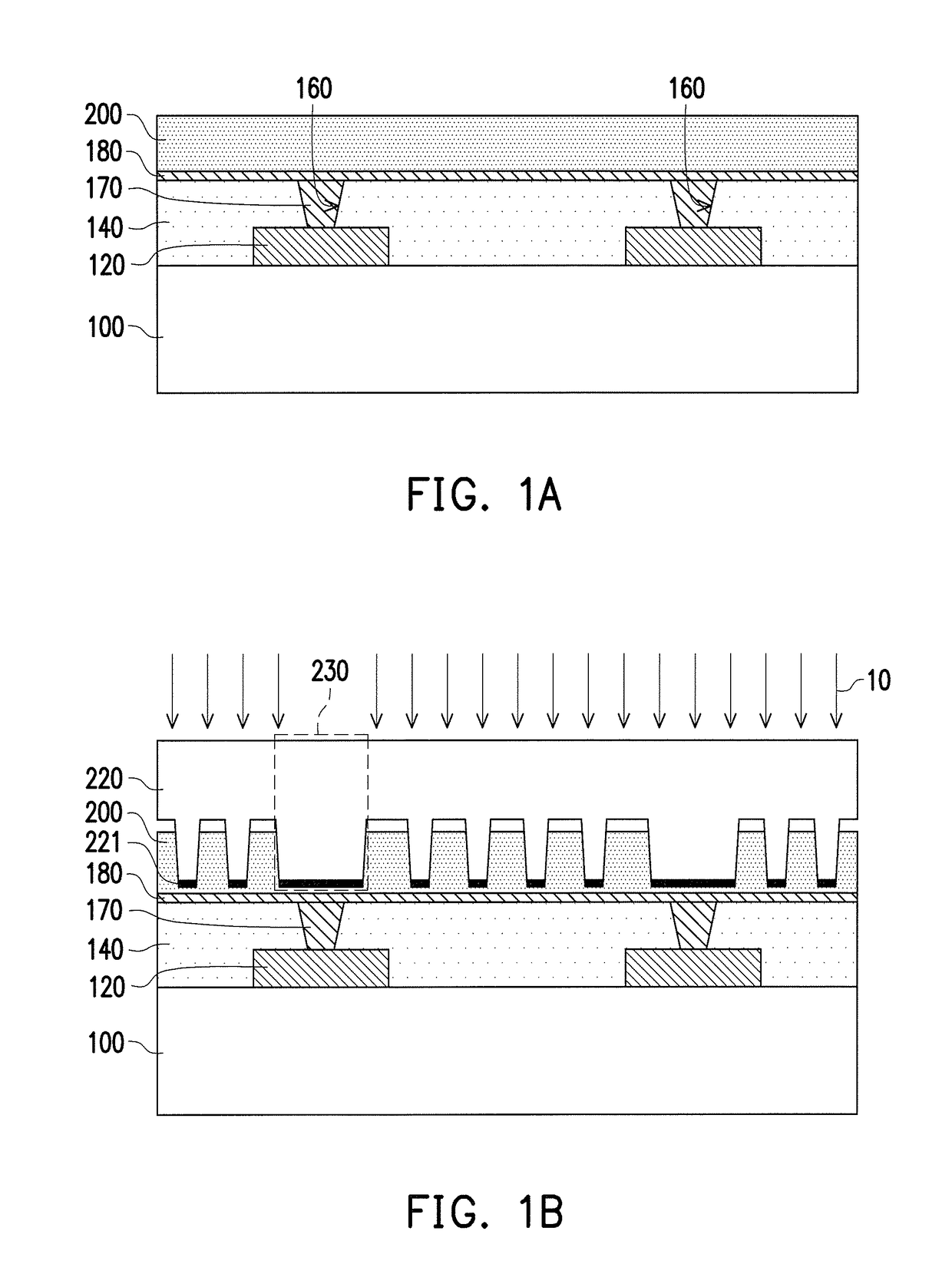

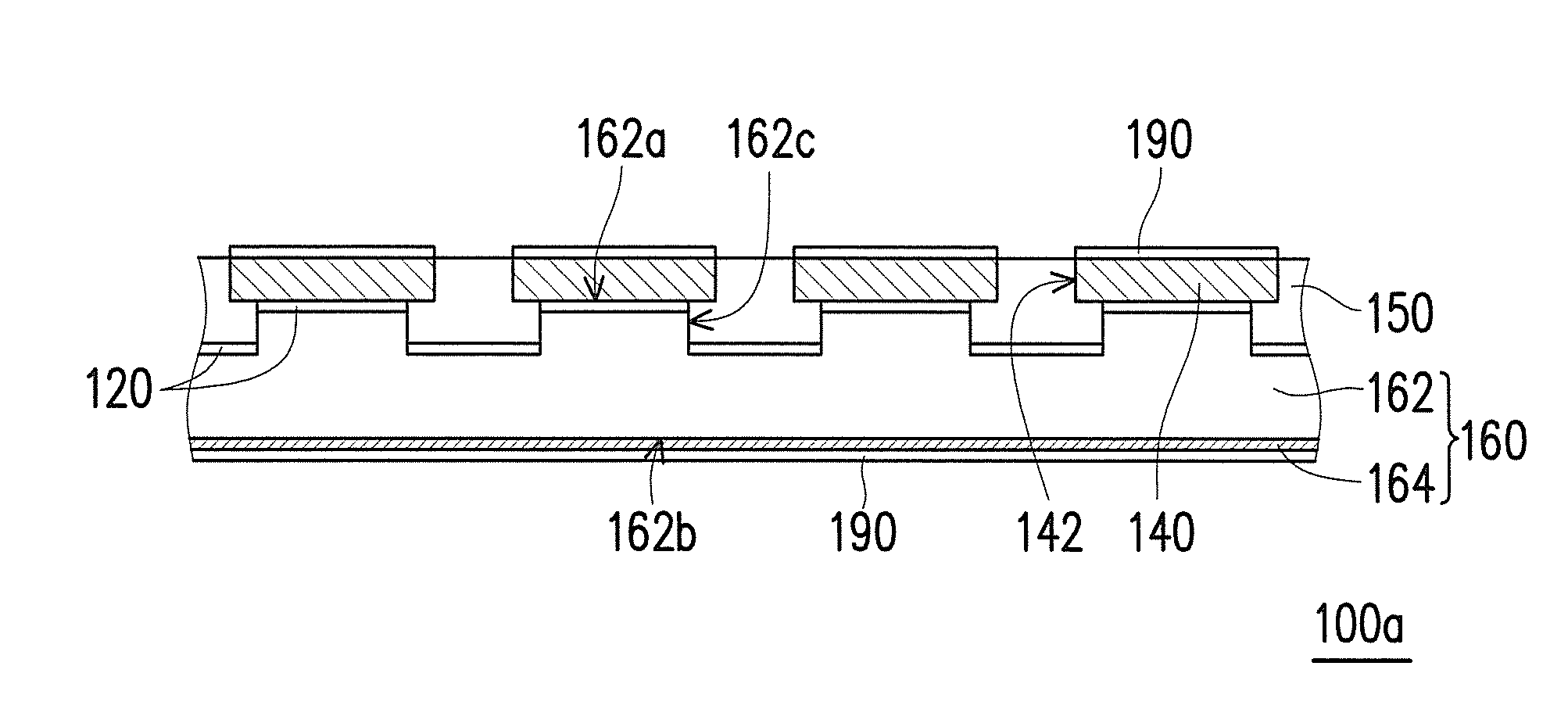

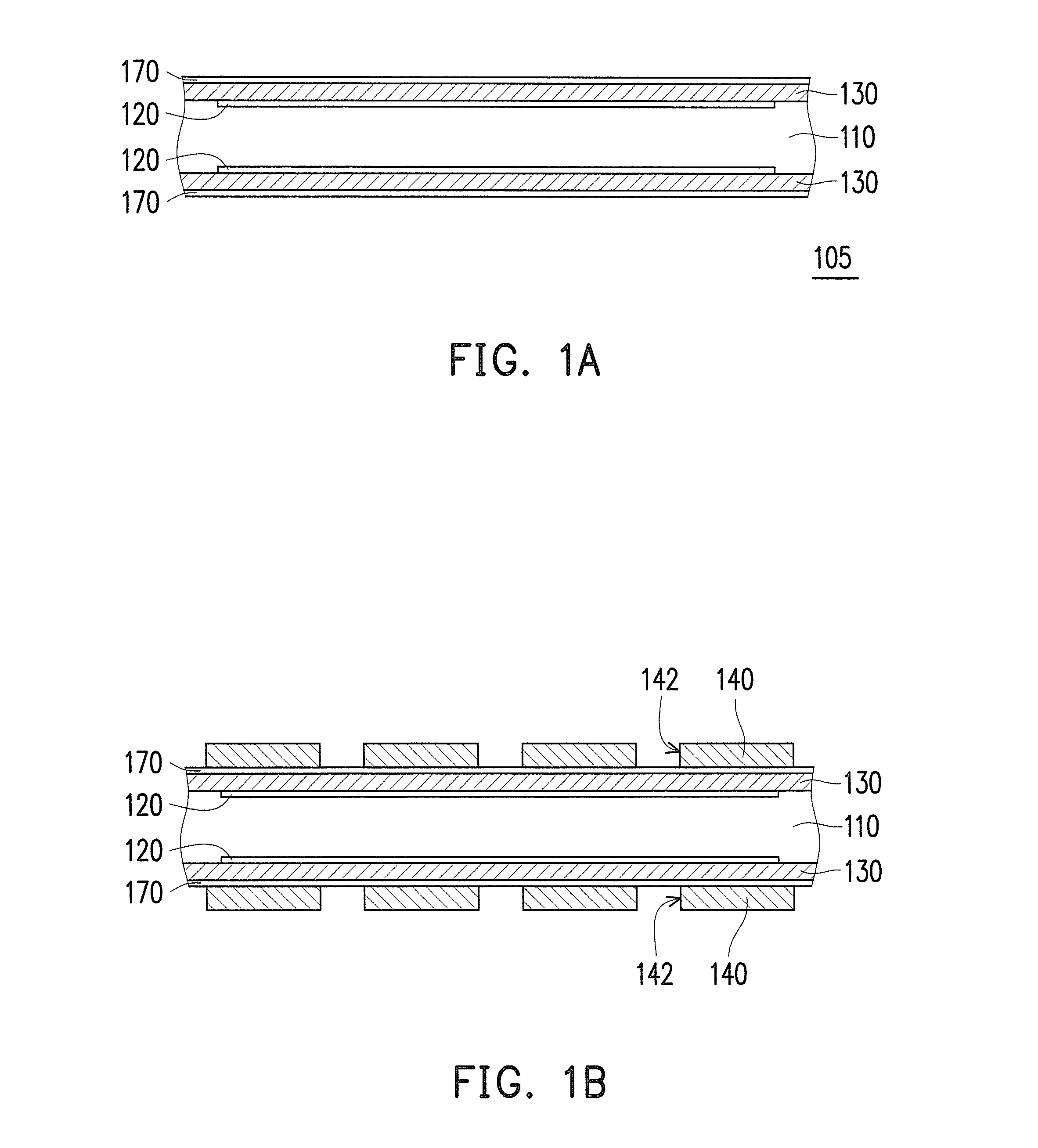

Manufacturing method of circuit board and stamp

ActiveUS20170273191A1Easy to disassembleLithography/patterningLithographic masksDielectric substratePhotoresist

A manufacturing method of a circuit board and a stamp are provided. The method includes the following steps. A circuit pattern and a dielectric layer covering the circuit pattern are formed on a dielectric substrate. A conductive via connected to the circuit pattern is formed in the dielectric layer. A photoresist material layer is formed on the dielectric layer. An imprinting process is performed on the photoresist material layer using a stamp to form a patterned photoresist layer, wherein the pressing side of the stamp facing the circuit pattern becomes sticky when subjected to pressure so as to catch photoresist residue from the photoresist material layer in the imprinting process. A patterned metal layer is formed on a region exposed by the patterned photoresist layer. The patterned photoresist layer is removed.

Owner:UNIMICRON TECH CORP

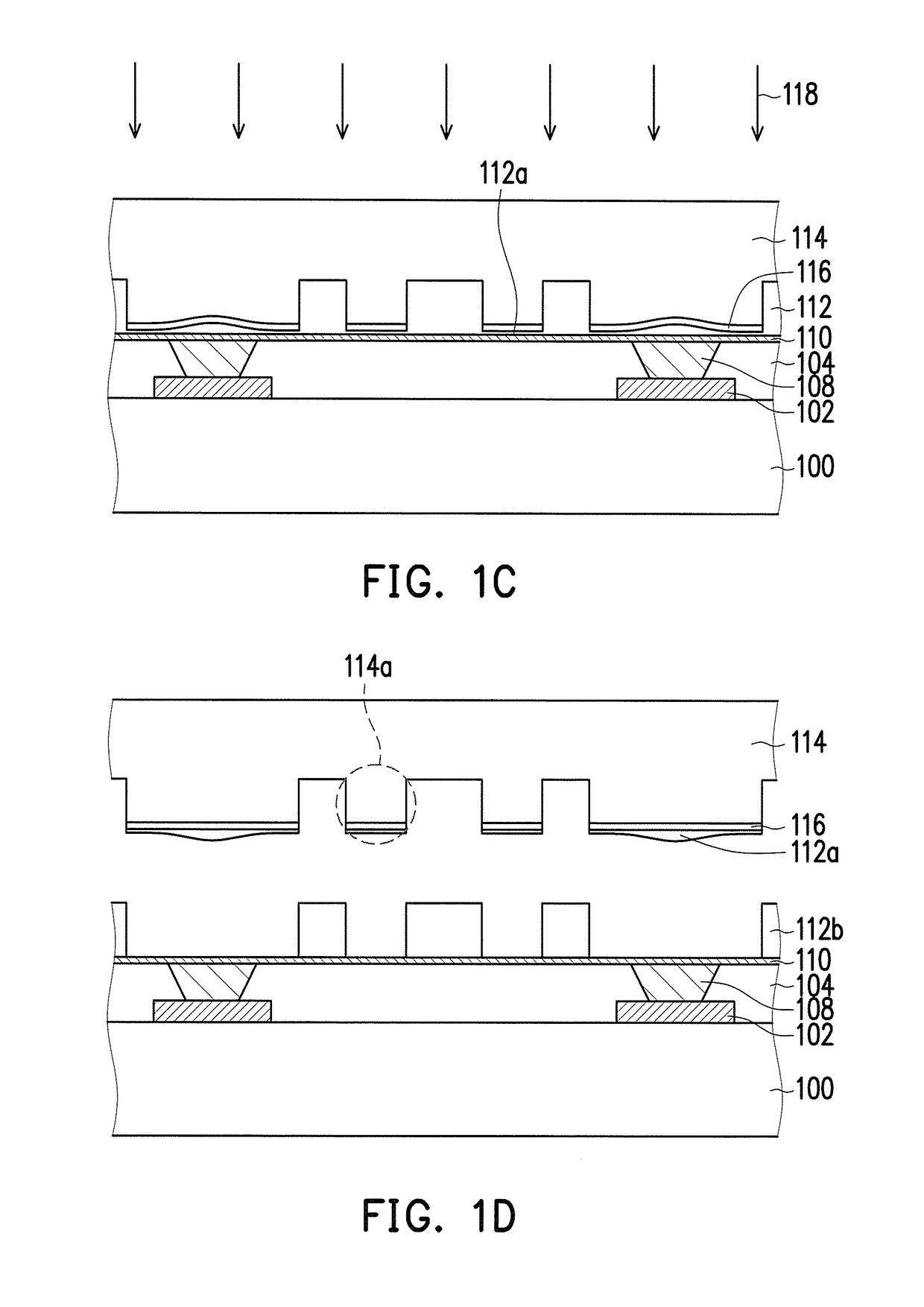

Mask for partial plating, method for manufacturing insulated circuit board using said mask, and partial plating method

PendingCN114438561AEasy to manufactureIncrease production capacityLithographic masksSemiconductor/solid-state device manufacturingAdhesiveHemt circuits

The invention discloses a mask for partial plating, a method for manufacturing an insulated circuit board using the mask, and a partial plating method. Provided is a mask for partial plating, which is capable of selectively performing partial plating on a predetermined portion of the surface of an electrically isolated metal member provided on an insulating substrate, and which has a more simple structure than in the prior art. Also provided are a method for manufacturing an insulated circuit board using the mask, and a partial plating method. The problem is solved by a mask for partial plating having a structure in which a partial region of a surface on one side in the thickness direction of an insulating sheet member in which an opening having a shape corresponding to a portion to be plated is formed is covered by one or a plurality of conductive sheet members attached to the region. The conductive sheet member is adhered to the surface of the insulating sheet member, for example, via an adhesive or an adhesive member. In addition, the conductive sheet member may be embedded in a recess formed in the surface of the insulating sheet member.

Owner:DOWA METALTECH CO LTD

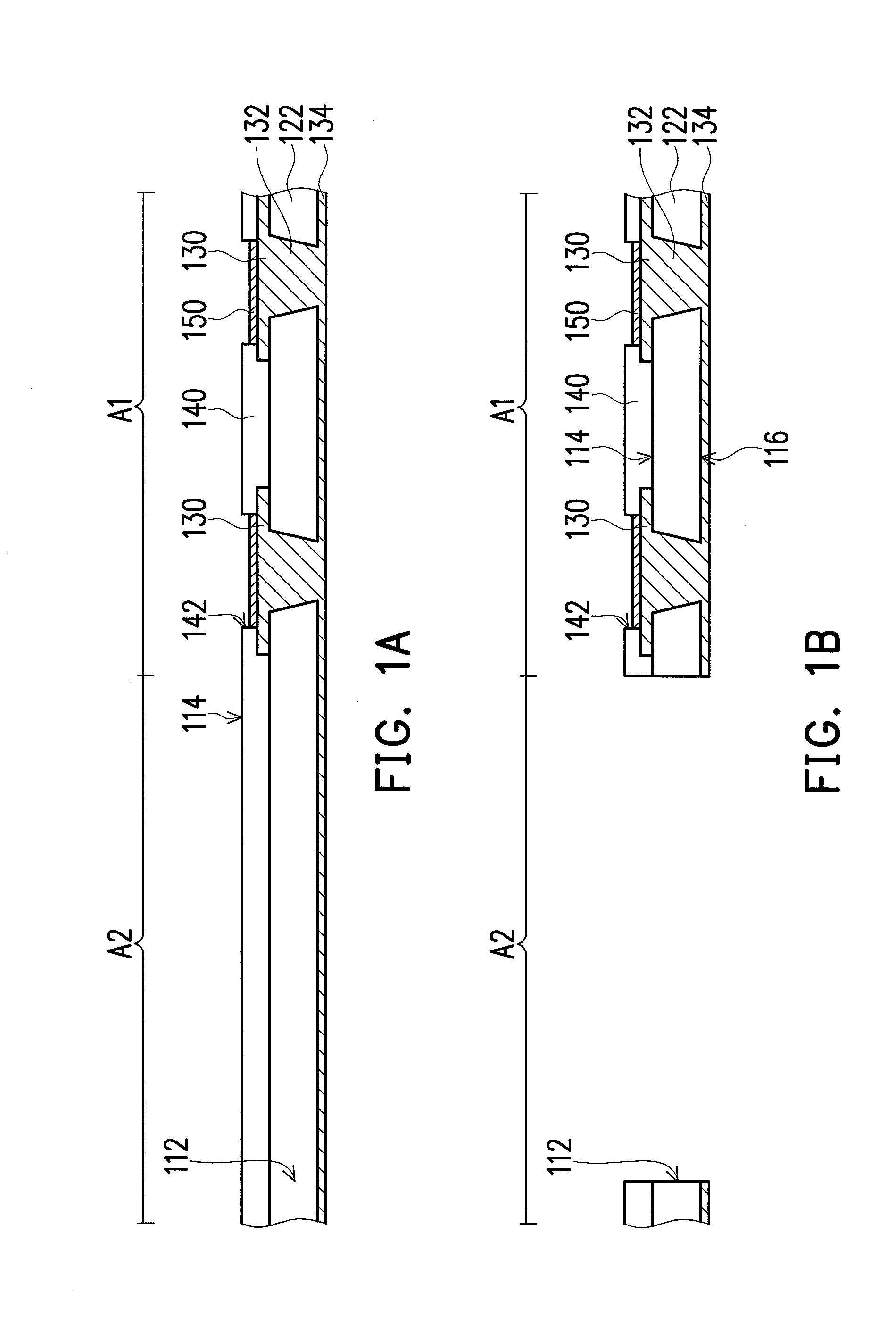

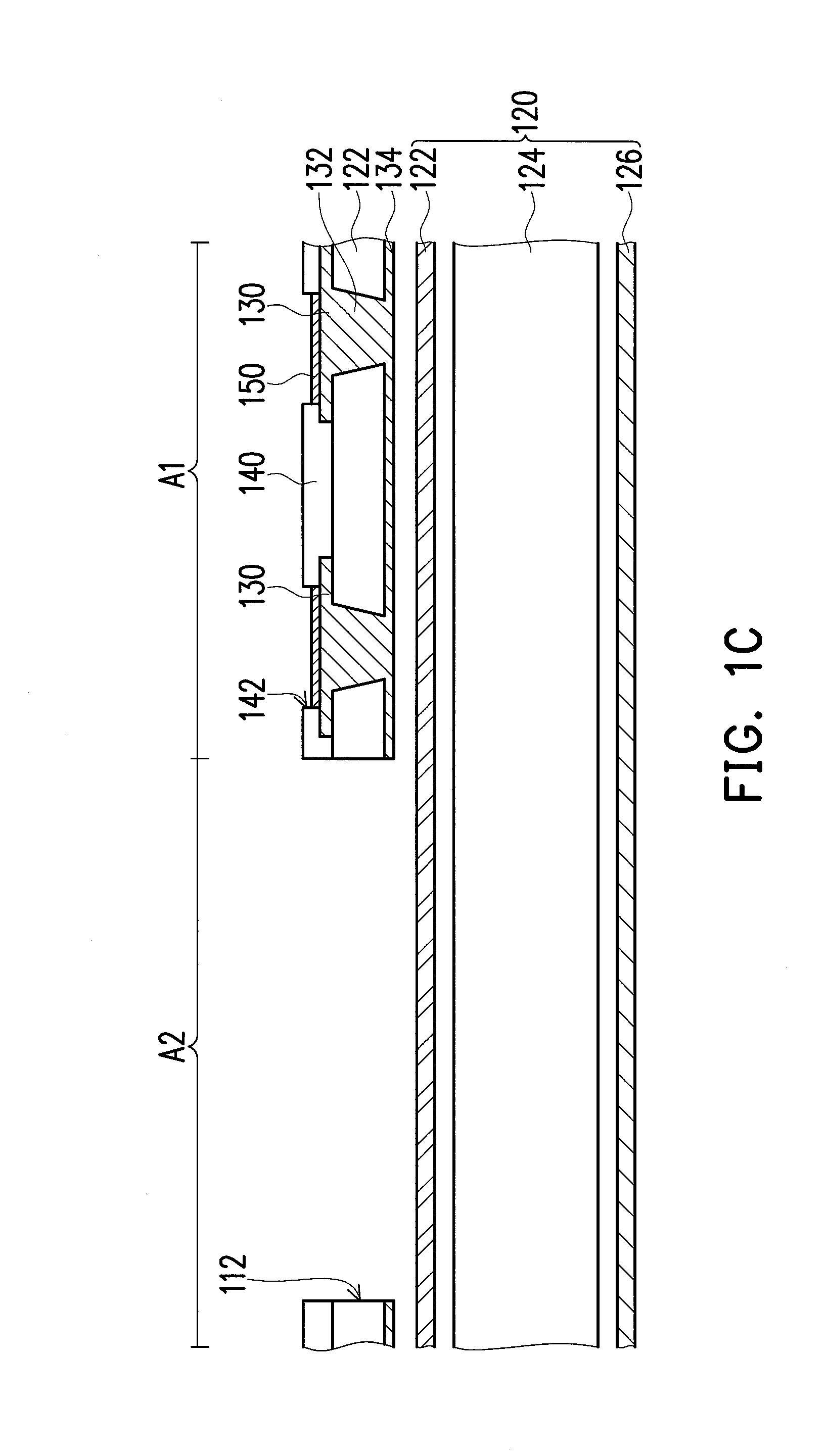

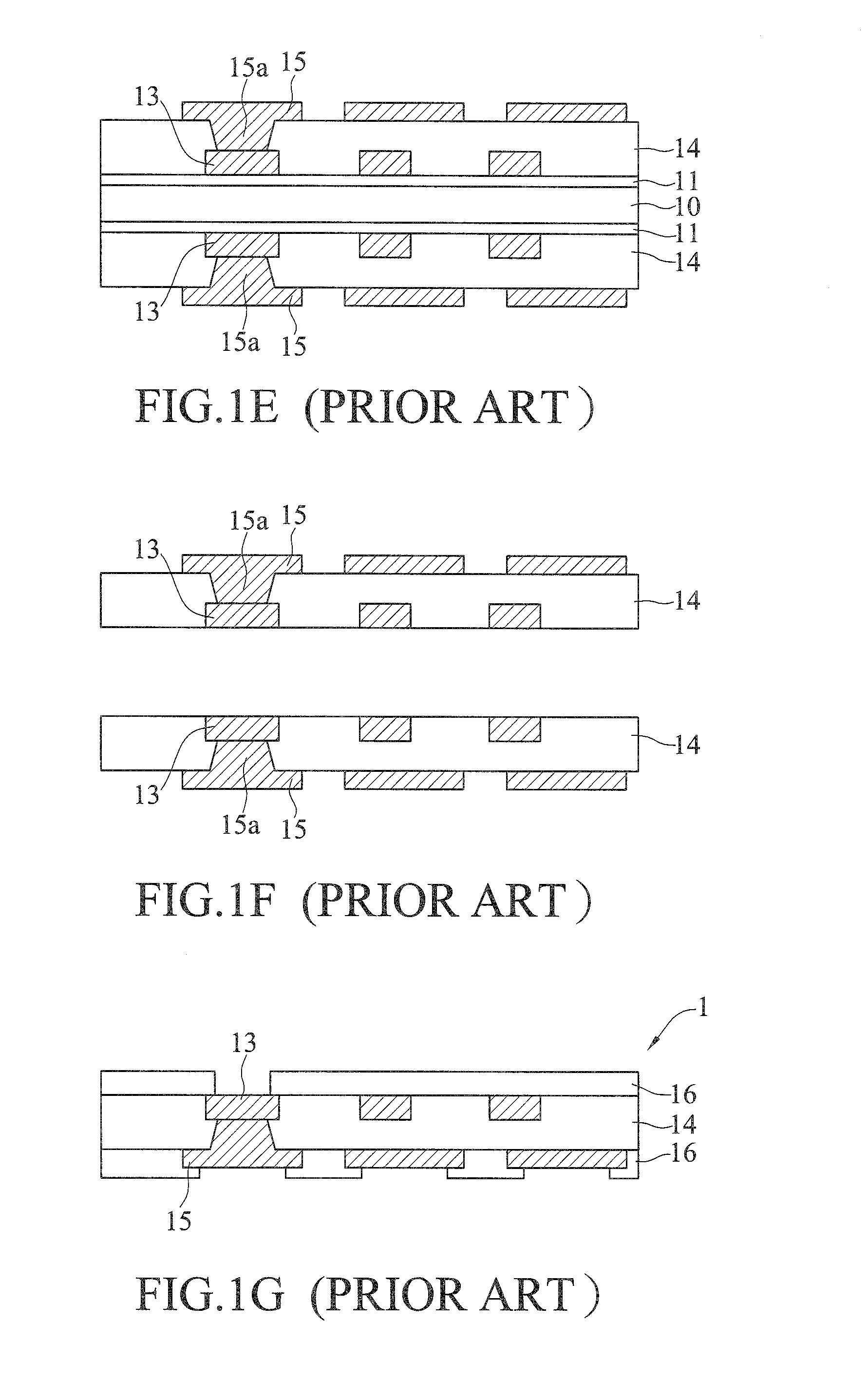

Substrate structure and manufacturing method thereof

ActiveUS20150313007A1Saving manufacturing timeIncrease productivityLithography/patterningSemiconductor/solid-state device detailsResistSolder mask

A manufacturing method of a substrate structure includes the following steps. A substrate including a supporting layer, two release layers and two base metal layers is provided. The release layers are disposed on two opposite surfaces of the supporting layer respectively. Each base metal layer covers each of the release layers. A first patterned solder-resist layer is formed on each of the base metal layers. A stacking layer is laminated on each of the base metal layers to cover each of the first patterned solder-resist layers. Each stacking layer includes a dielectric layer and a metal foil. Each dielectric layer is disposed between the corresponding base metal layer and the corresponding metal foil. Each base metal layer is separated from the supporting layer. Each base metal layer is patterned to form a patterned metal layer on each stacking layer. Each patterned metal layer exposes the corresponding first patterned solder-resist layer.

Owner:SUBTRON TECH

Manufacturing method of circuit board

ActiveUS20170273186A1Flexible choiceLess adhesiveLithography/patterningLithographic masksDielectric substrateEngineering

A manufacturing method of a circuit board including the following steps is provided. A carrier substrate is provided. A patterned photoresist layer is formed on the carrier substrate. An adhesive layer is formed on the top surface of the patterned photoresist layer. A dielectric substrate is provided. A circuit pattern and a dielectric layer covering the circuit pattern are formed on the dielectric substrate, wherein the dielectric layer has an opening exposing a portion of the circuit pattern. The adhesive layer is adhered to the dielectric layer in a direction that the adhesive layer faces of the dielectric layer. The carrier substrate is removed. A patterned metal layer is formed on a region exposed by the patterned photoresist layer. The patterned photoresist layer is removed. The adhesive layer is removed.

Owner:UNIMICRON TECH CORP

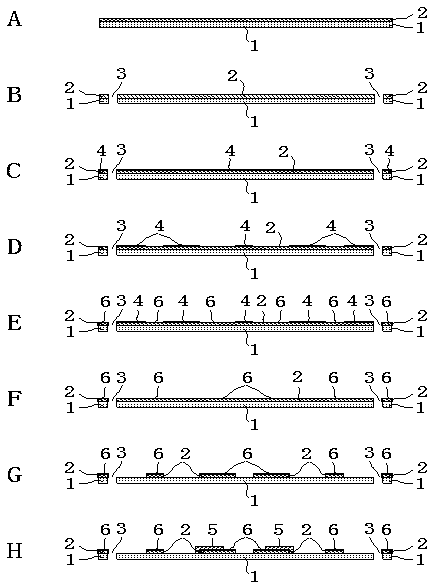

A kind of fpc circuit figure making method

ActiveCN108124387BReduce dry filmImprove efficiencyLithographic masksConductive material chemical/electrolytical removalGraphicsEngineering

The invention provides an FPC circuit pattern making method, and the method comprises the steps: employing UV light curing ink for replacing a conventional dry film and other photoresists, carrying out the UV light curing of an FPC sheet material after ink printing, enabling a UV light curing ink to be hardened but not completely solidified, and forming a protection film layer with a pattern; enabling the protection film layer to be hardened but not transferred (not to be solidified on an FPC), forming a temporary anti-corrosion protection film layer, thereby enabling the protection film layerto be easily peeled off after etching, reducing the steps of dry film pasting, silent standing and hardening and development, enabling the efficiency to be high, enabling the flow to be simple, saving the manufacturing cost of equipment and development auxiliary materials, and reducing the cost. The FPC can be directly transferred out of a yellow region for operation after the UV light curing, sothe time is short and the impact on employees is small.

Owner:XIAMEN BOLION CIRCUIT

Method of manufacturing wiring board

InactiveUS20150027977A1Improve reliabilityInferior in solder wettabilityResist coatingLithographic masksResistSolder mask

A manufacturing method includes a step of forming a first plating mask on a base metal layer, a step of forming a main conductor layer on the base metal layer exposed from the first plating mask, a step of forming a second plating mask on them, a step of attaching a metal plating layer to an upper surface of the main conductor layer exposed from the second plating mask, a step of removing the first and second plating masks, a step of etching away a portion of the base metal layer to which the main conductor layer is not attached, and a step of forming a solder resist layer.

Owner:KYOCERA CIRCUIT SOLUTIONS

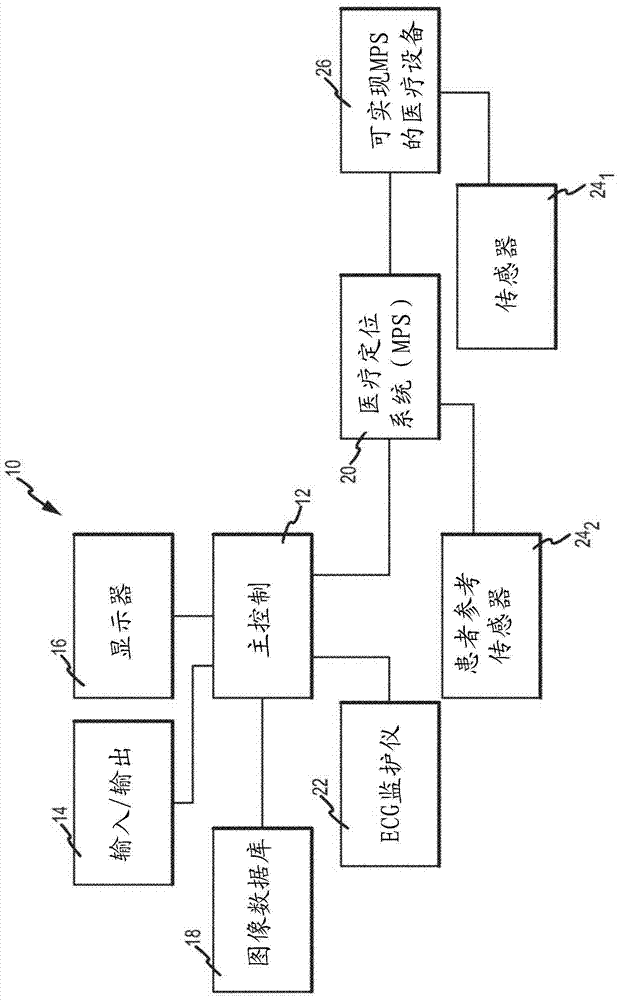

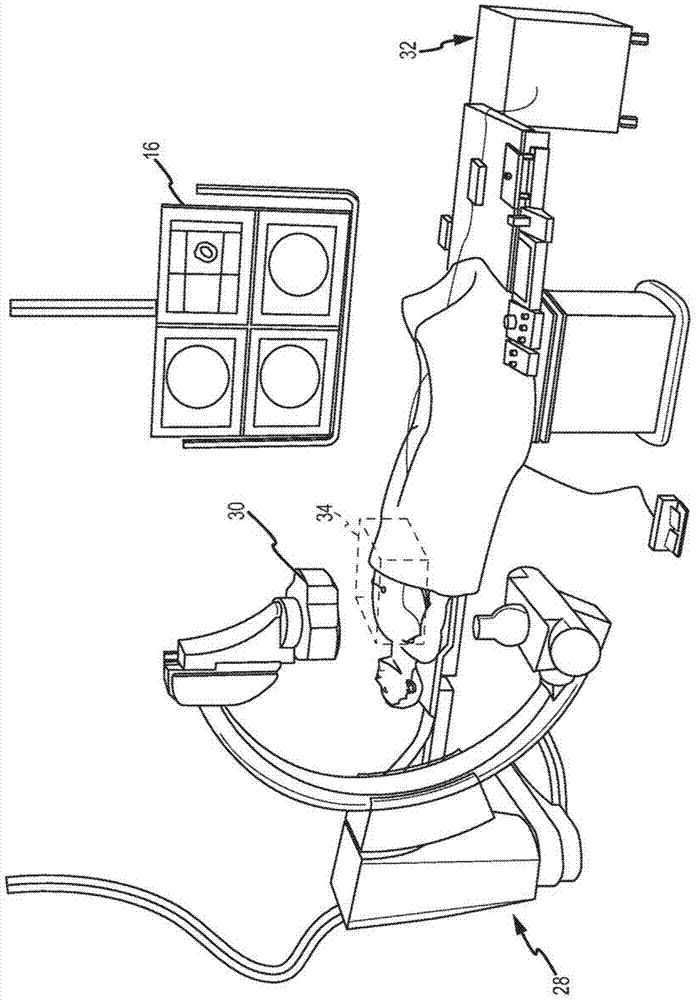

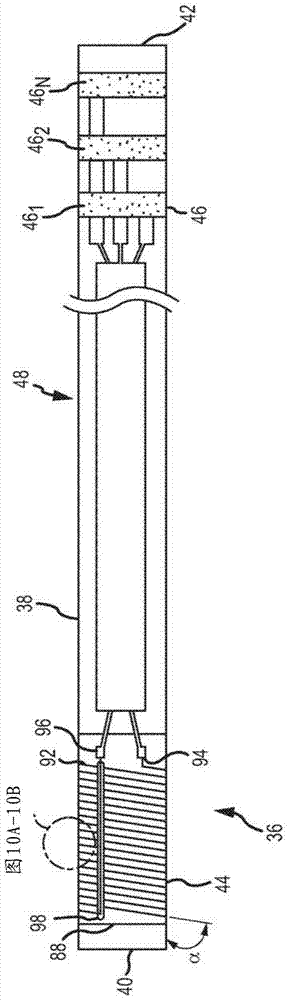

Shielded twisted pair conductors using conductive ink

InactiveCN104918548BShielding materialsAdditive manufacturing apparatusConductive materialsTwisted pair

A device for transmitting electrical signals is disclosed. The device includes a base and twisted-pair conductors on the base. The twisted pair conductors include a first layer comprising a conductive material, a second layer comprising a non-conductive material, and a third layer comprising a conductive material. The first layer has a plurality of sections separated by a plurality of gaps. The second layer is located within the gap and electrically insulates portions of the segment located within the gap. The third layer is located on the second layer. The third layer is configured to electrically connect one end of one segment to one end of the other segment. The twisted-pair conductor formed by the three-dimensional structure comprises two electrically isolated conductors twisted to each other.

Owner:ST JUDE MEDICAL INT HLDG SARL

PCB negative film production process

InactiveCN113194617AIncrease production capacityReduce use costLithographic masksConductive material chemical/electrolytical removalRough surfacePunching

The invention discloses a PCB negative film production process. The production process comprises the following steps of: fixing a PCB and then drilling the PCB by using a punching machine; carrying out electroless copper plating: depositing a layer of thin chemical copper on the drilled non-conductive PCB by using a chemical method; conducting DVCP thickening, specifically, depositing metal or alloy on the surface of a workpiece through DVCP by means of current to form a uniform and compact metal layer with good binding force; plugging a hole: plugging printing ink or resin into a VIA hole used for conduction of the PCB through machine printing; polishing the board: polishing the rough surface of the PCB to be smooth; and drying the film; The invention aims to provide a PCB negative film production process which can improve the negative film production capacity. The production ratio of the negative film is increased from 10% to 40%, the productivity matching is more reasonable, the productivity is maximized, the tin use and recovery treatment cost is reduced by 30%, the energy is saved, the waste is reduced, and the problems that the production productivity of the PCB negative film is reduced, the tin use and recovery treatment cost is higher, and resources are wasted are solved.

Owner:江门市奔力达电路有限公司

Inkjet inks for manufacturing printed circuit boards

ActiveUS20210002500A1Improve adhesionExcellent jettingOrganic chemistryLithographic masksArylEngineering

A method of manufacturing a Printed Circuit Board (PCB) wherein an inkjet printing step is used, characterized in that in the inkjet printing step a radiation curable inkjet ink comprising an adhesion promoter having a chemical structure according to Formula I is jetted and cured on a substrate, wherein X is selected from the group consisting of O and NR3, L1 and L2 independently represent a divalent linking group comprising from 2 to 20 carbon atoms, R1 is selected from the group consisting of hydrogen, a substituted or unsubstituted alkyl group and a substituted or unsubstituted aryl group, R2 is selected from the group consisting of a substituted or unsubstituted alkyl group, a substituted or unsubstituted alkenyl group, a substituted or unsubstituted alkynyl group, a substituted or unsubstituted alkaryl group, a substituted or unsubstituted aralkyl group and a substituted or un-substituted (hetero)aryl group, R3 is selected from the group consisting of hydrogen, a substituted or unsubstituted alkyl group, a substituted or unsubstituted alkenyl group, a substituted or unsubstituted alkynyl group, a substituted or unsubstituted alkaryl group, a substituted or unsubstituted aralkyl group and a substituted or unsubstituted (hetero)aryl group, n represents an integer from 0 to 4, any of L1, L2 and R2 may represent the necessary atoms to form a 5 to 8 membered ring.

Owner:AGFA GEVAERT AG

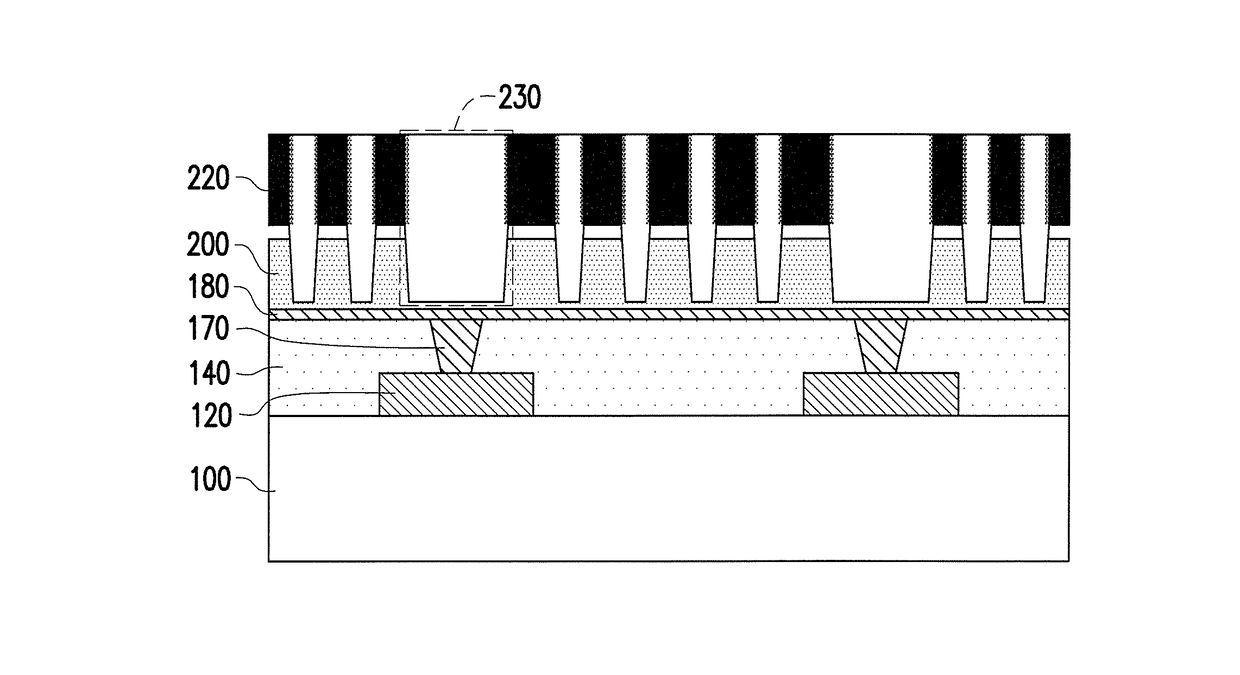

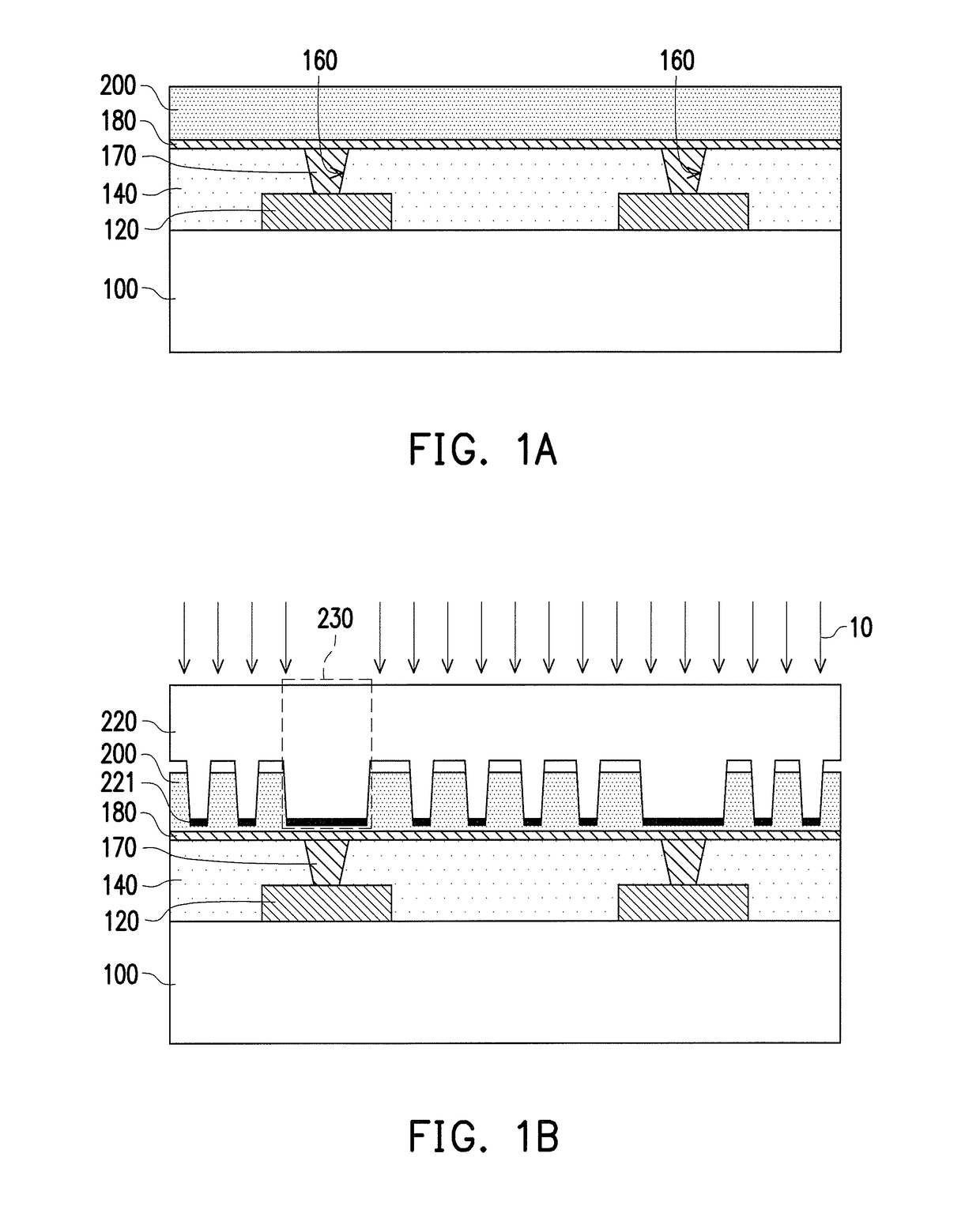

Manufacturing method of circuit board and piezochromic stamp

ActiveUS20170273189A1Improve circuit reliabilityHigh yieldLithography/patterningResist detailsTransmittanceDielectric substrate

A manufacturing method of a circuit board and a piezochromic stamp are provided. A circuit pattern is formed on a dielectric substrate. A dielectric layer having a hole or a conductive via and covering the circuit pattern is formed on the dielectric substrate. A conductive seed layer is formed on the dielectric layer. A photoresist layer is formed on the conductive seed layer. A piezochromic stamp is imprinted on the photoresist layer, wherein when the pressing side of the piezochromic stamp is in contact with the conductive seed layer, the light transmittance effect thereof is changed to blocking or allowing light having a specific wavelength to pass through. A patterned photoresist layer is formed by using the piezochromic stamp as a mask. A patterned metal layer is formed on the exposed conductive seed layer. The patterned photoresist layer and the conductive seed layer are removed.

Owner:UNIMICRON TECH CORP

Popular searches

Nanotechnology Liquid/solution decomposition chemical coating Solid/suspension decomposition chemical coating Paste/ink/powder application resist Special surfaces Surface layering apparatus Superimposed coating process Resistive material coating Printed circuit coating Conductive pattern polishing/cleaning

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com