Graphic design method for reducing dry film breakage of fine circuit board

A graphic design and fine circuit technology, applied in the direction of conductive pattern formation, etc., can solve the problems of circuit open circuit, gap, dry film broken resistance plating, etc., to achieve the effect of ensuring completeness, reducing dry film broken, and avoiding film clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below with reference to the specific embodiments. It should be noted that, on the premise of no conflict, the embodiments or technical features described below can be arbitrarily combined to form new embodiments.

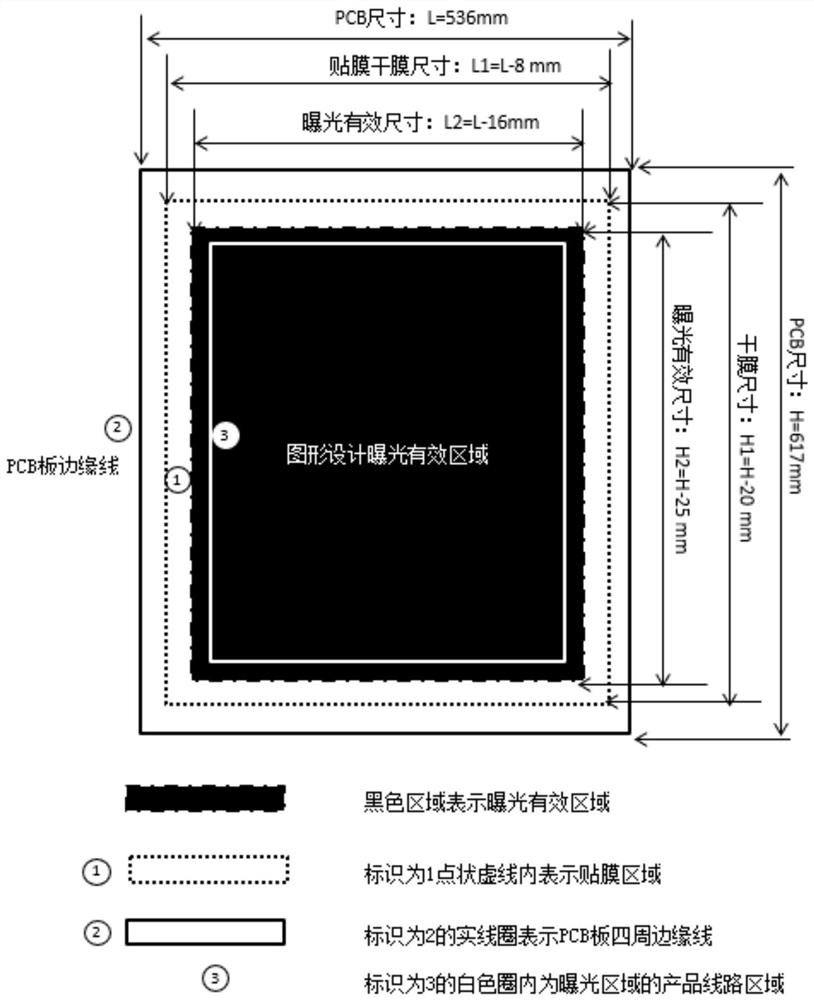

[0028] Please see attached Figures 4 to 7 The present invention provides a graphic design method for reducing dry film breakage of fine circuit boards. Specifically, on the PCB board after the dry film is attached, the dry film needs to have a certain distance from the edge of the circuit board to ensure that there is a certain distance around the dry film. Sufficient space is reserved for auxiliary alignment holes, test mold positions, test coupon positions, equipment fixture clip positions and board edge flow grooves, from Figure 4 It can be seen from the schematic diagram that after the development of the circuit board provided by the present invention, there is no dry film residue on the clip position on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com