Manufacturing method of printed circuit board

A technology for printed circuit boards and manufacturing methods, which is applied in the directions of printed circuit manufacturing, printed circuit, printed circuit drying, etc., can solve the problems of reducing printed circuit board production costs, shortening the production cycle of printed circuit boards, etc., so as to reduce material costs and save the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Conjunction with the drawings and embodiments of the present invention is described in further detail.

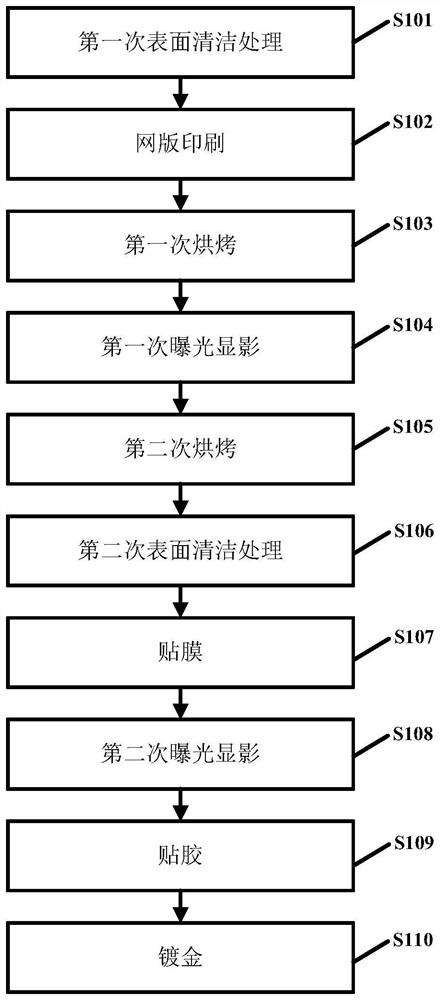

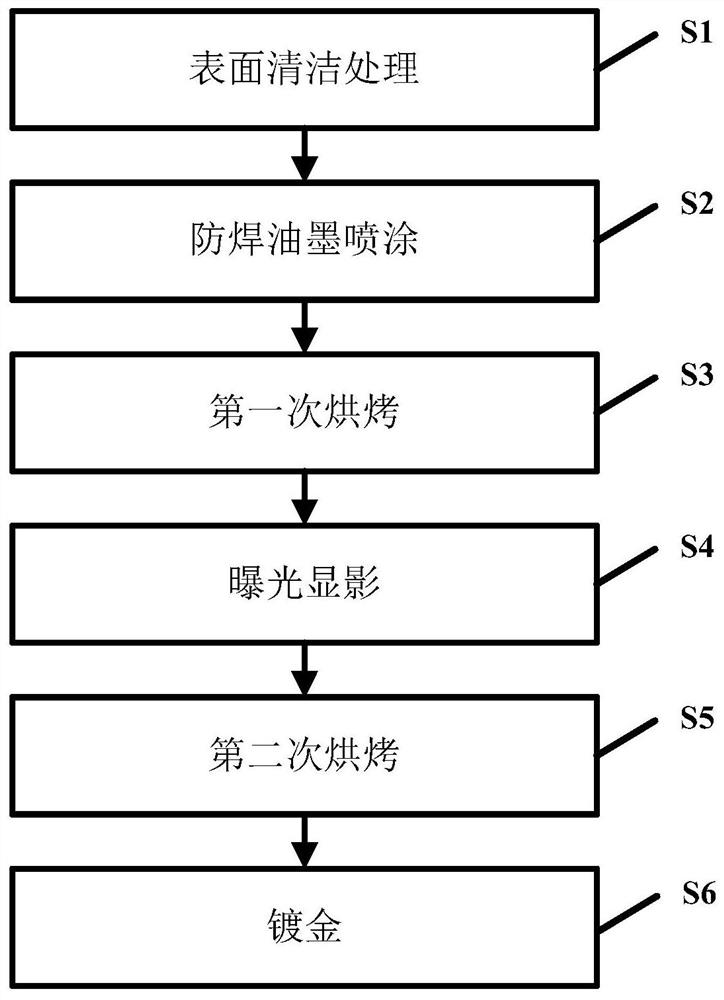

[0041] See image 3 As shown in the embodiment of manufacturing method of a printed circuit board embodiment of the present invention, comprising the steps of:

[0042] S1: cleaning the surface; and a printed circuit board through the metal plating layer (e.g., copper) surface oxide film, the removal of grease and other debris, and the roughened metal layer; performed prior to this step, the printed circuit board may according to need treatment or ultra-roughening treatment by sand blasting (Pumice).

[0043] S2: resist ink spray; cleaning the surface of the completed printed circuit board carried into the resist ink coating spraying equipment to form a solder resist layer; the thickness of the solder resist layer according to the forward speed of the printed circuit board, and spray equipment the amount of ink spray decision.

[0044] Preparation of the solder resist ink...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com