Flexible circuit board for demisting car lamp and manufacturing process of flexible circuit board

A technology for flexible circuit boards and car lights, which is applied in the directions of flexible printed circuit boards, printed circuit manufacturing, use/removal methods of circuit masks, etc., can solve the problems of poor defogging effect, complex production process and high cost, and achieve The effect of saving production costs, simple production process, and thin and light products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

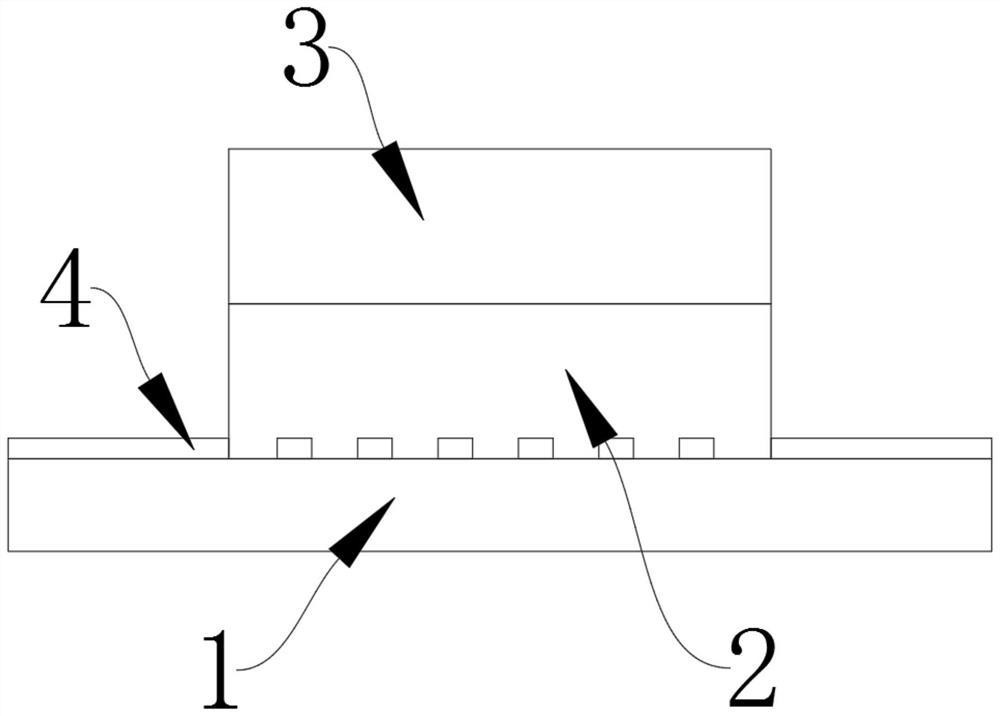

[0039] see Figure 1-3 As shown, the present invention is a flexible circuit board for car lamp defogging, including a substrate 1, the size of the substrate 1 is 100mm×100mm, the substrate 1 is composed of a first PET board and a CU, and the first PET board The thickness is 75 μm, and the thickness of CU is 1 μm;

[0040] The upper end of the substrate 1 is laminated with a dry film, the material of the dry film can be resin, and the thickness of the dry film is 5um-15um;

[0041] Here, the dry film is pressed on the surface of the substrate by using a dry film pressing machine, and the parameters for pressing the dry film are: temperature 95°C, speed 1.50m / min, pressure 6kg;

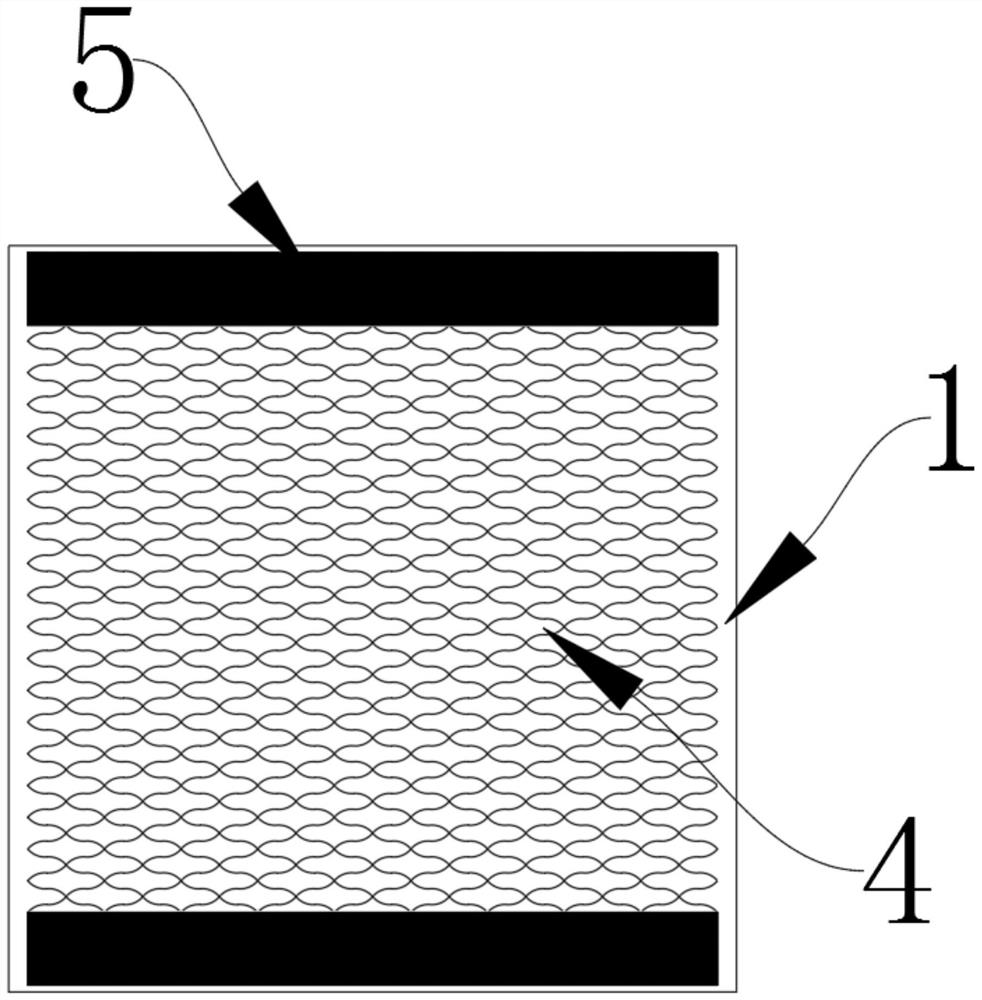

[0042] The dry film is sequentially exposed, developed and etched to form a circuit pattern. The circuit pattern is composed of a wire network 4 and two bus bars 5. The two bus bars 5 are located on both sides of the wire network 4. The wire network 4 and the bus bar 5 are electrically connected. , t...

Embodiment 2

[0053] On the basis of Embodiment 1, a method for using a flexible circuit board for defogging vehicle lights is disclosed, and the steps are as follows:

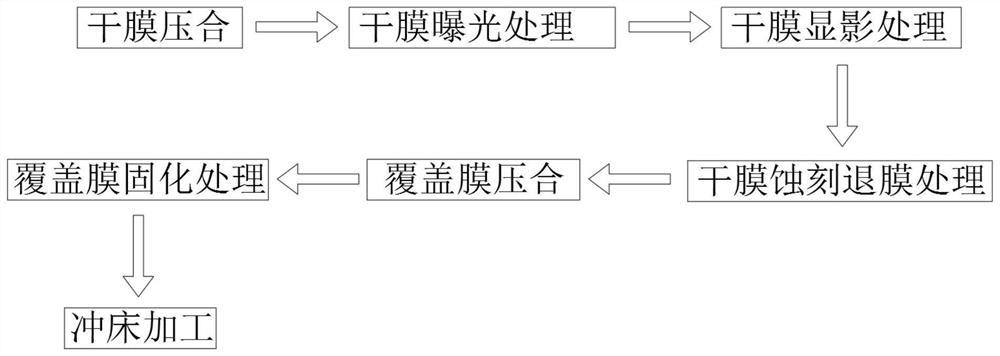

[0054] The first step: use a dry film pressing machine to press the dry film on the surface of the substrate 1;

[0055]Step 2: Expose the dry film, use the exposure machine to radiate ultraviolet light to irradiate the dry film and the negative film pattern, let the dry film undergo polymerization reaction, and the ultraviolet light emitted by the exposure machine irradiates the light-transmitting part of the negative film pattern When the film graphics are transferred to the photosensitive dry film;

[0056] The third step: developing the dry film, using Na at a concentration of 1.0% (w / v) 2 CO 3 The solution removes the photosensitive dry film that has not undergone polymerization, and the photosensitive dry film that undergoes polymerization remains on the substrate 1 to complete the pattern transfer;

[0057] Step 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com