Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

154results about "Circuit masks application/removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Touch screen sensor

Owner:3M INNOVATIVE PROPERTIES CO

Methods of patterning a conductor on a substrate

InactiveUS20090218310A1Decorative surface effectsNanoinformaticsElectrical conductorSelf-assembled monolayer

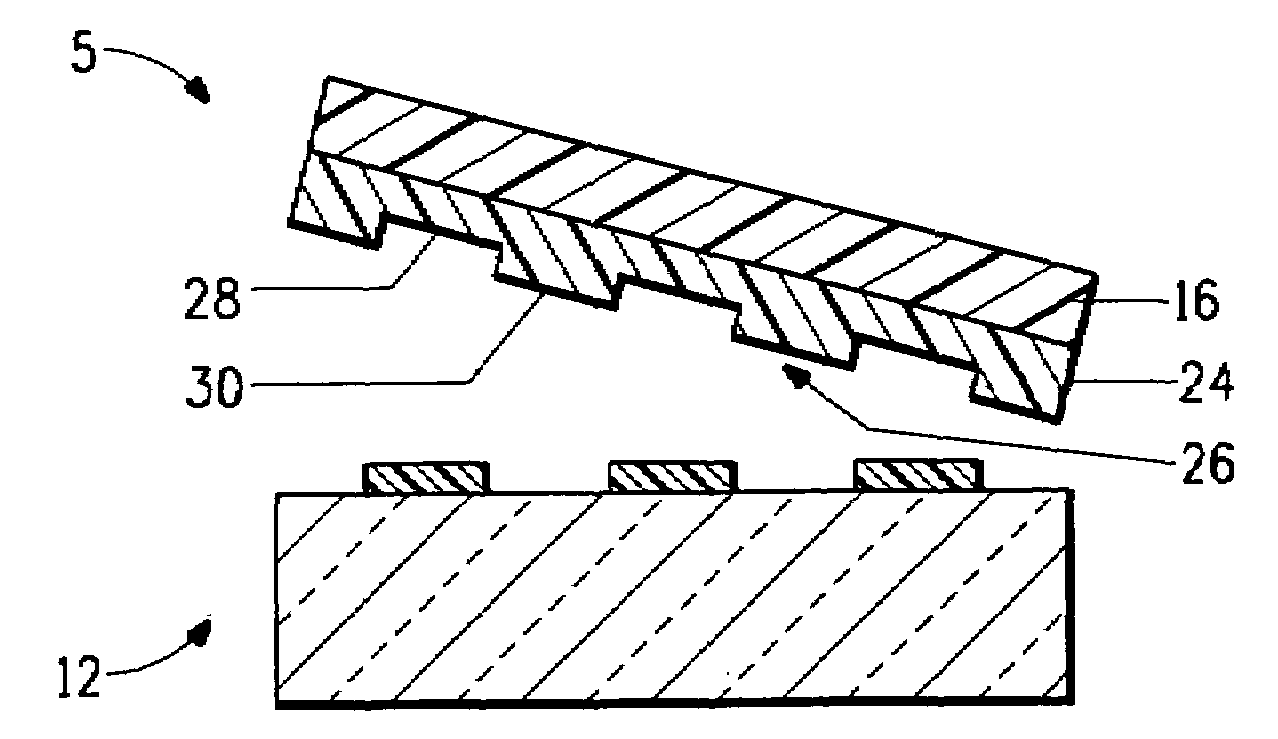

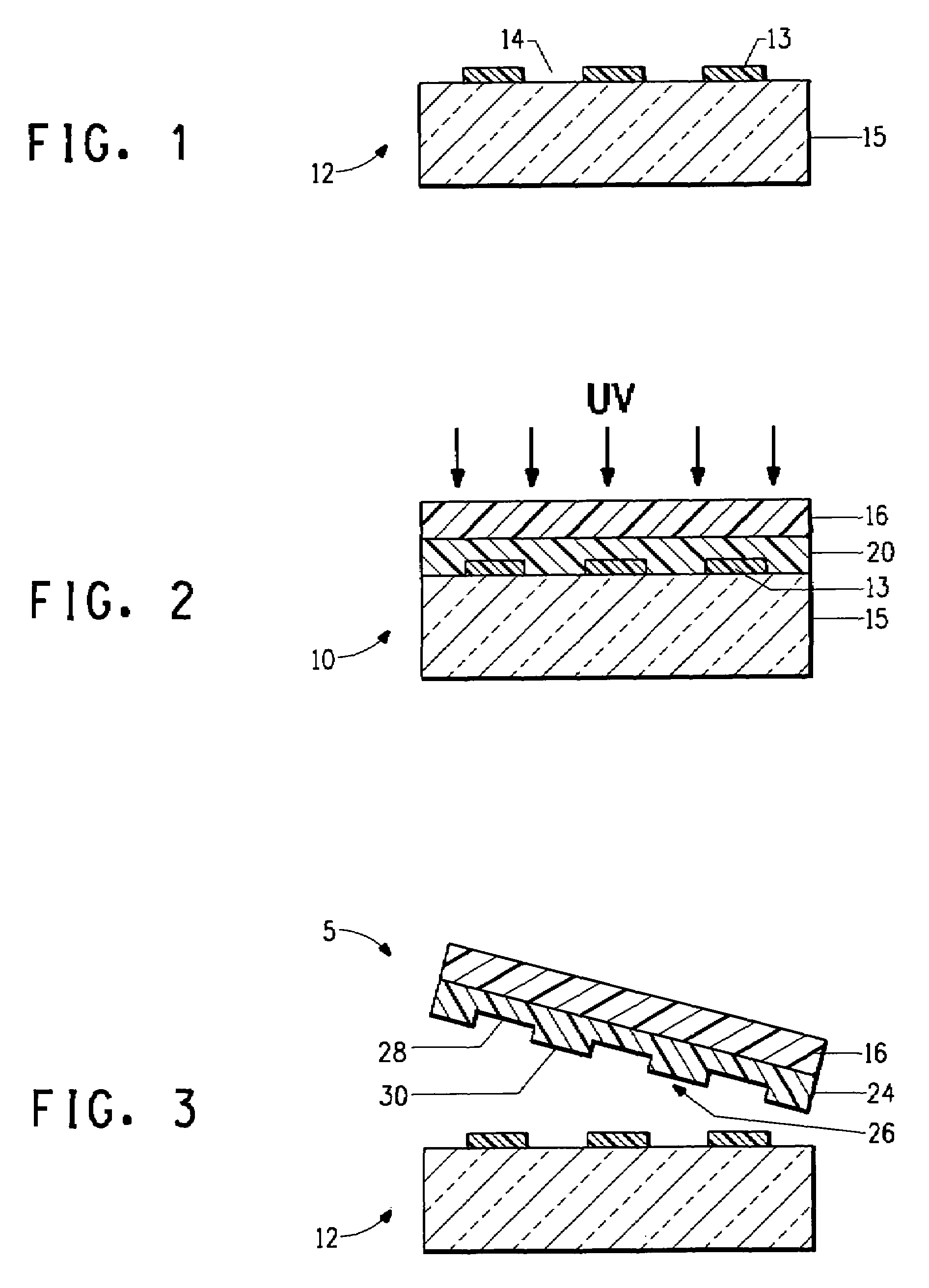

A method of patterning a conductor on a substrate includes providing an inked elastomeric stamp inked with self-assembled monolayer-forming molecules and having a relief pattern with raised features. Then the raised features of the inked stamp contact a metal-coated visible light transparent substrate. Then the metal is etched to form an electrically conductive micropattern corresponding to the raised features of the inked stamp on the visible light transparent substrate.

Owner:3M INNOVATIVE PROPERTIES CO

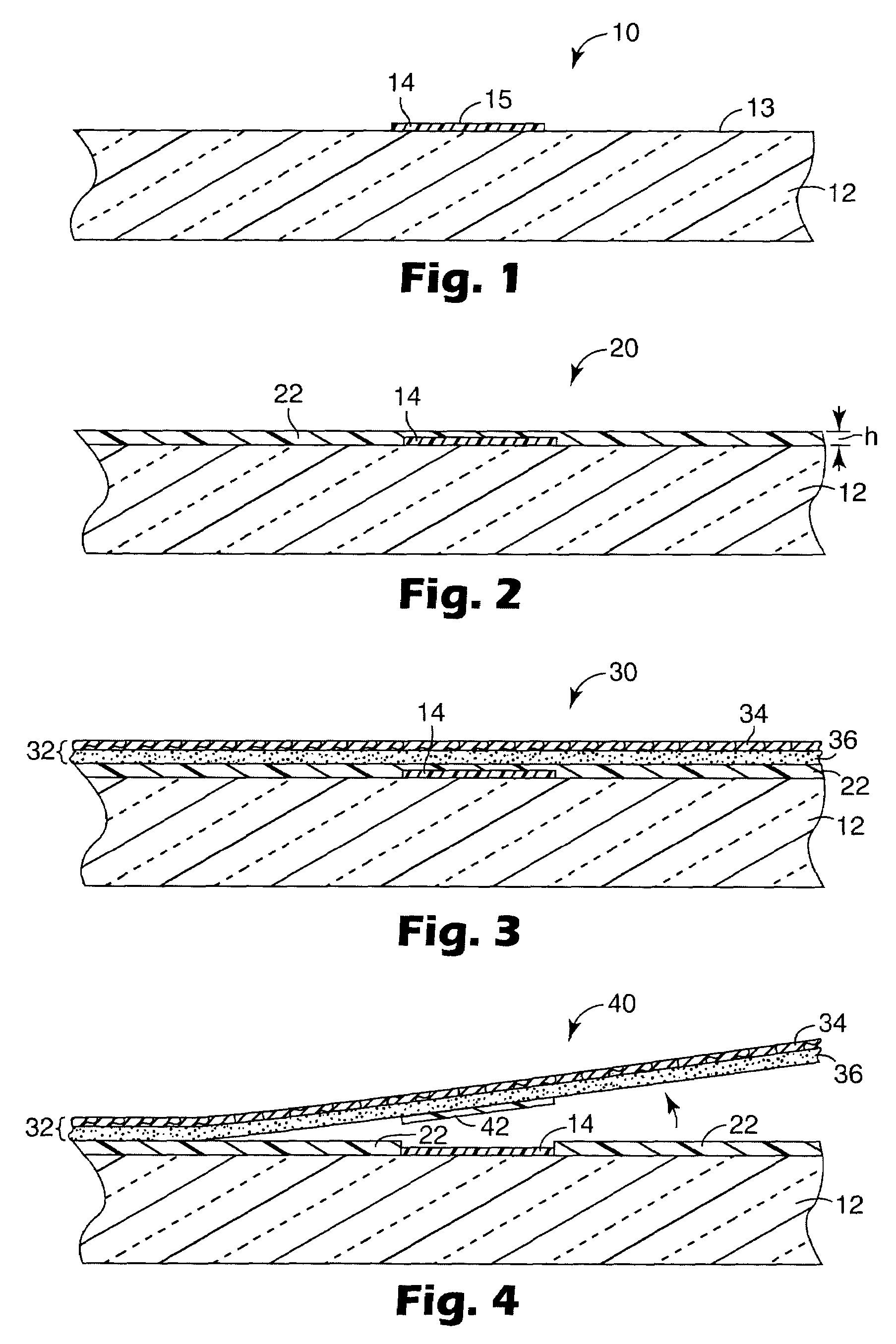

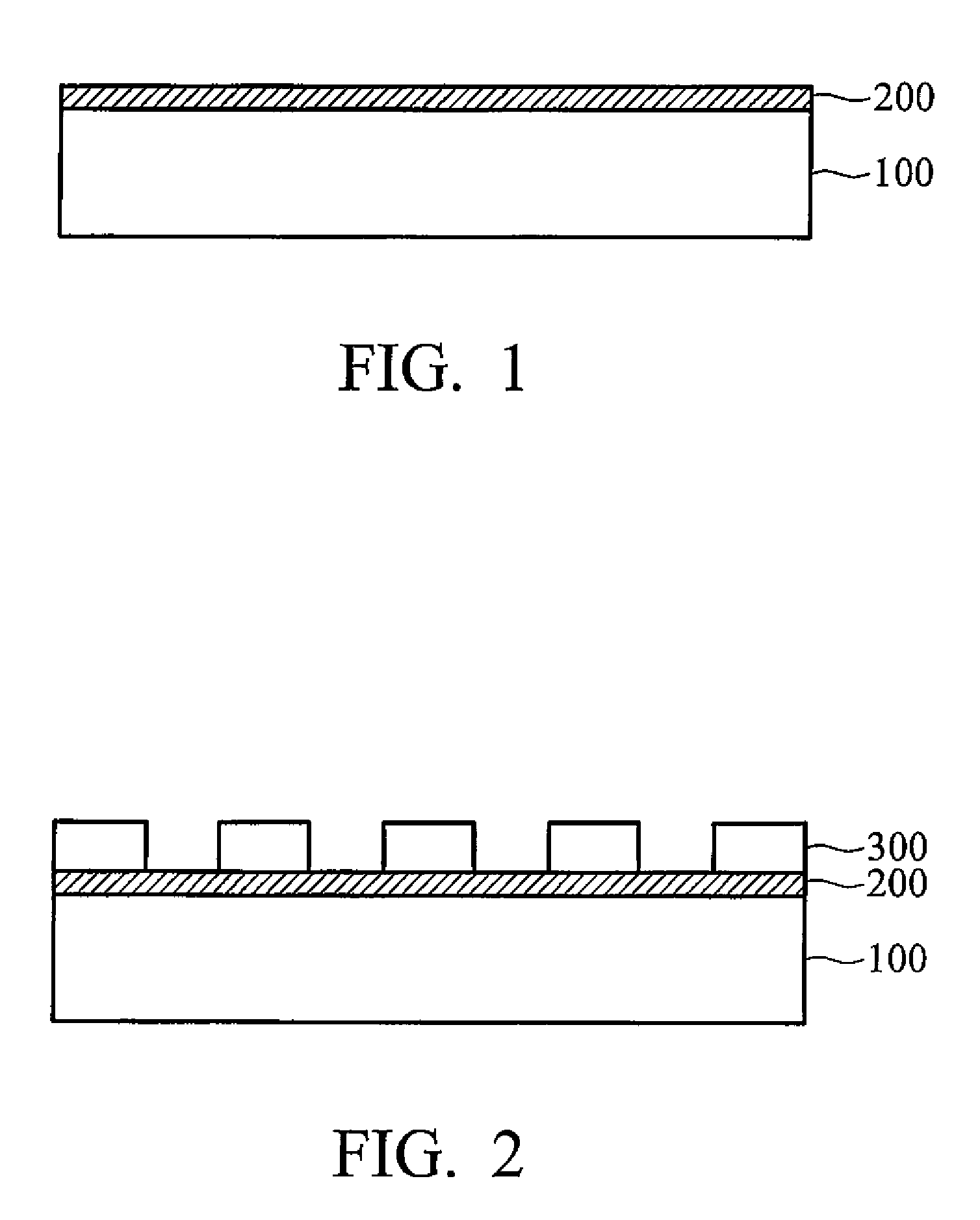

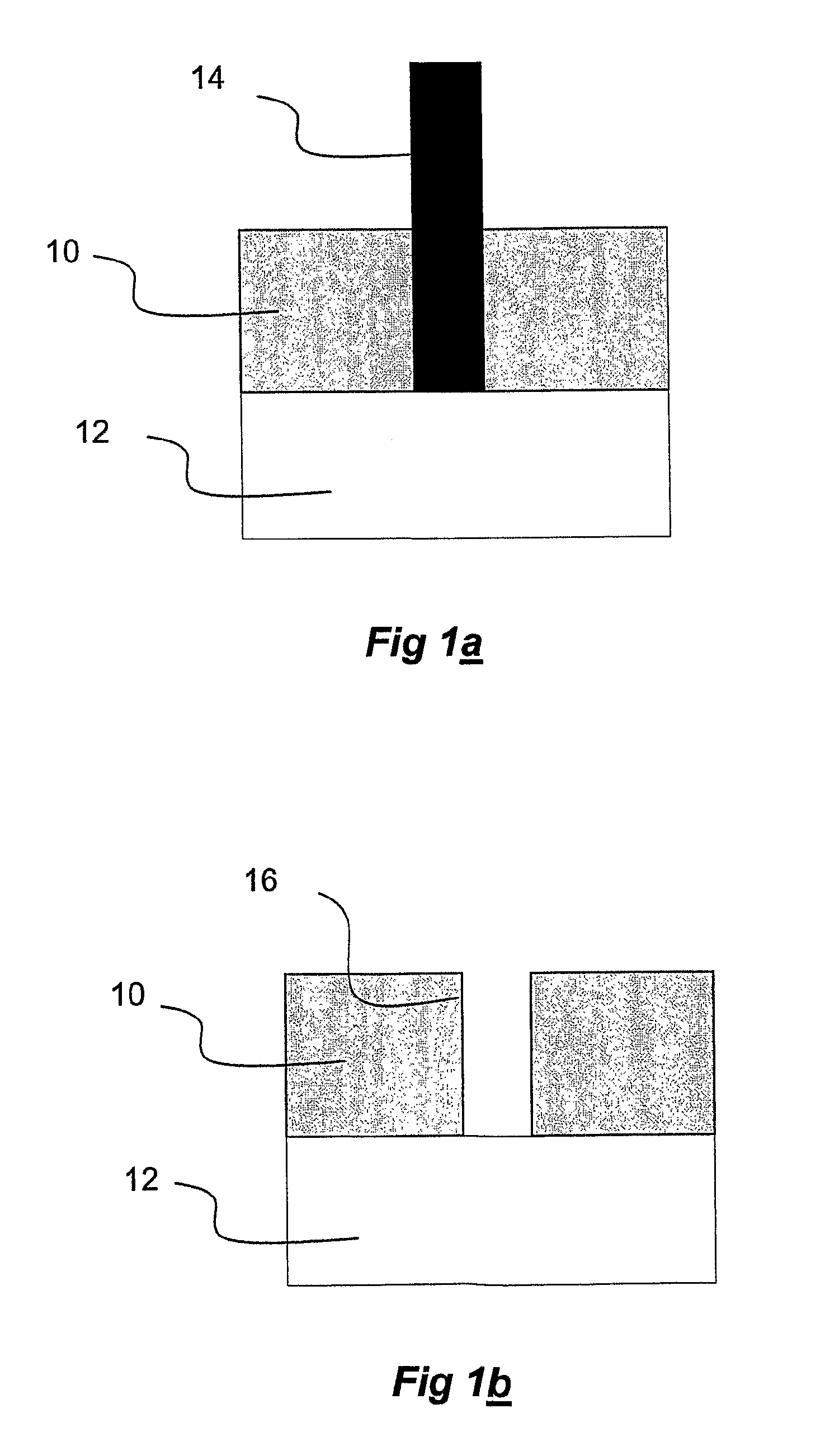

Method to form a pattern of functional material on a substrate

InactiveUS20080047930A1Excellent conductive silver pattern formationEliminates possibility of shortingDecorative surface effectsNanoinformaticsOptoelectronicsMaterial transfer

The invention provides a method to form a pattern of a functional material on a substrate for use in electronic devices and components. The method uses a stamp having a relief structure to transfer a mask material to a substrate and form a pattern of open area on the substrate. The functional material is applied to the substrate in at least the open area. The mask material is removed from the substrate, forming the pattern of functional material on the substrate. The method is suitable for the fabrication of microcircuitry for electronic devices and components.

Owner:EI DU PONT DE NEMOURS & CO

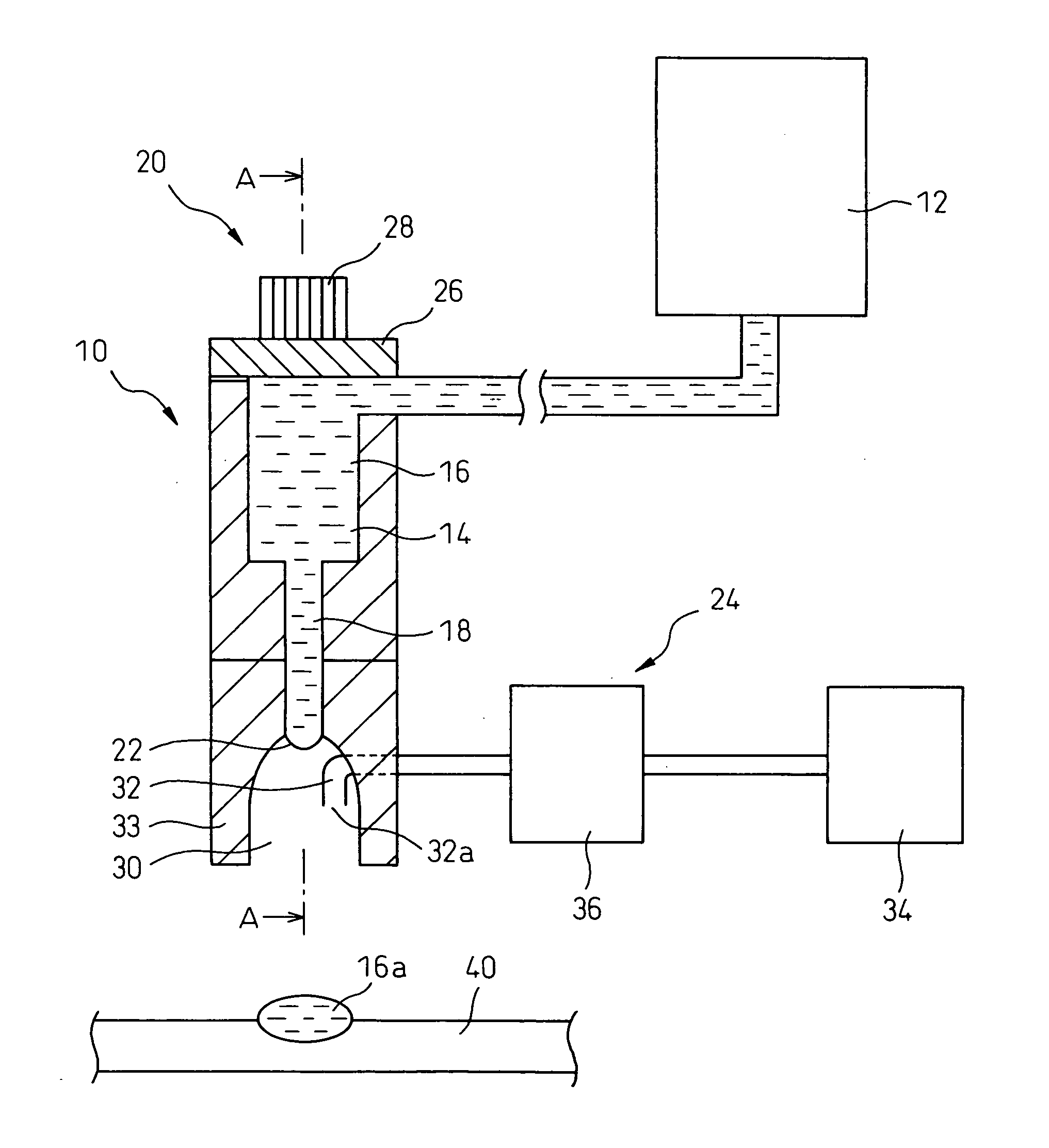

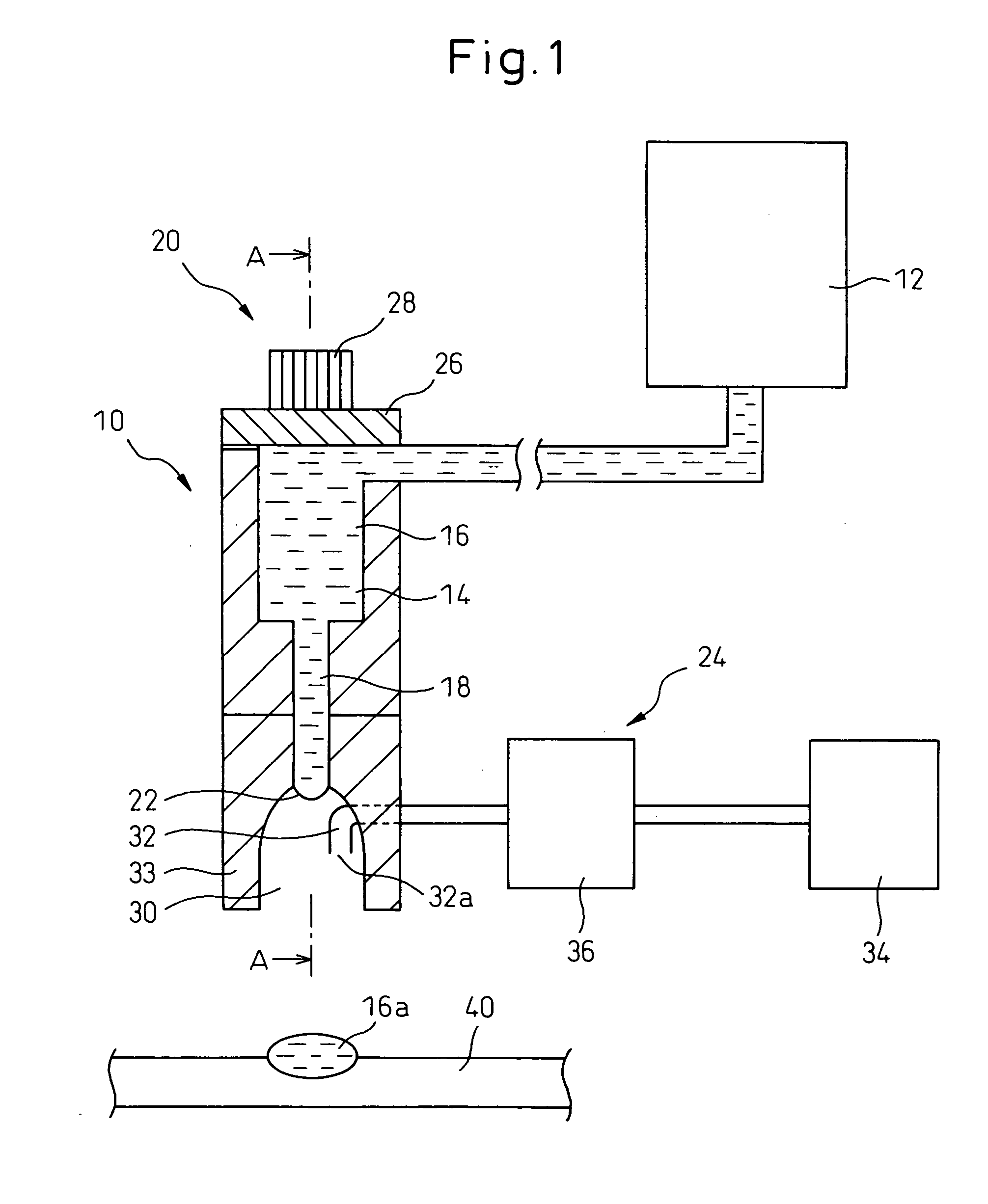

Liquid ejection apparatus and resist pattern forming method

InactiveUS20080158278A1Liquid surface applicatorsMovable spraying apparatusResistElectrical and Electronics engineering

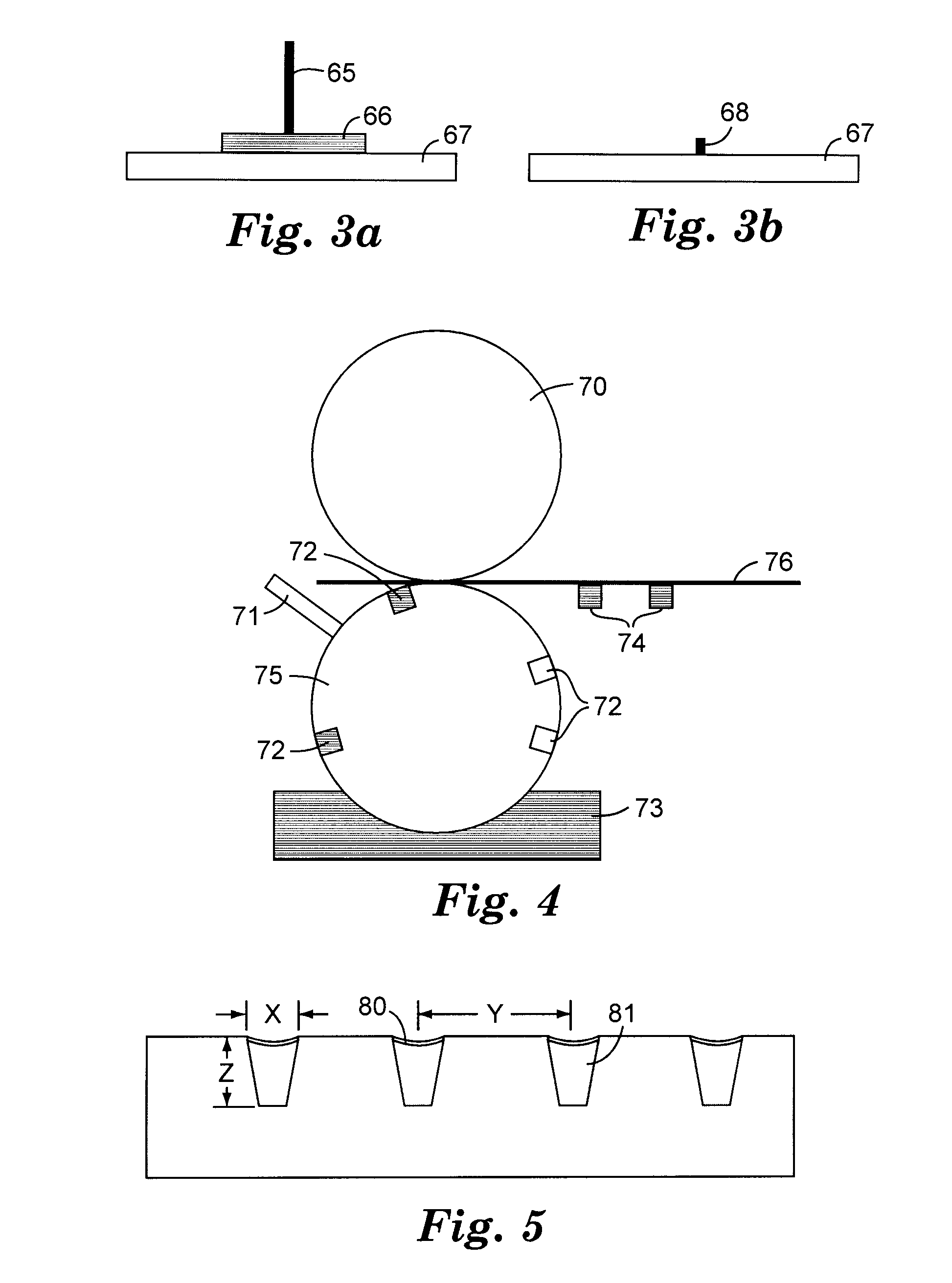

The liquid ejection apparatus has: a head having a nozzle group including a plurality of nozzles which are aligned in a first direction and performs ejection of resist liquid onto a wiring substrate; a scanning device which causes the head and the wiring substrate to move relatively in the first direction; an ejection control device which controls the ejection of the resist liquid from the head; and a scanning control device which controls the scanning device in such a manner that the head and the wiring substrate are relatively moved only once in the first direction, through a region of the wiring substrate which corresponds to one relative movement in the first direction of the wiring substrate and the scanning device, wherein the ejection control device controls the ejection of the resist liquid from the head to cause the resist liquid to be ejected onto a same position of the wiring substrate sequentially, at prescribed time intervals, from different nozzles of the nozzle group, to deposit the resist liquid ejected onto the same position of the wiring substrate sequentially from the different nozzles of the nozzle group, in such a manner that a resist pattern having a prescribed thickness and a prescribed pattern is formed on the wiring substrate.

Owner:FUJIFILM CORP

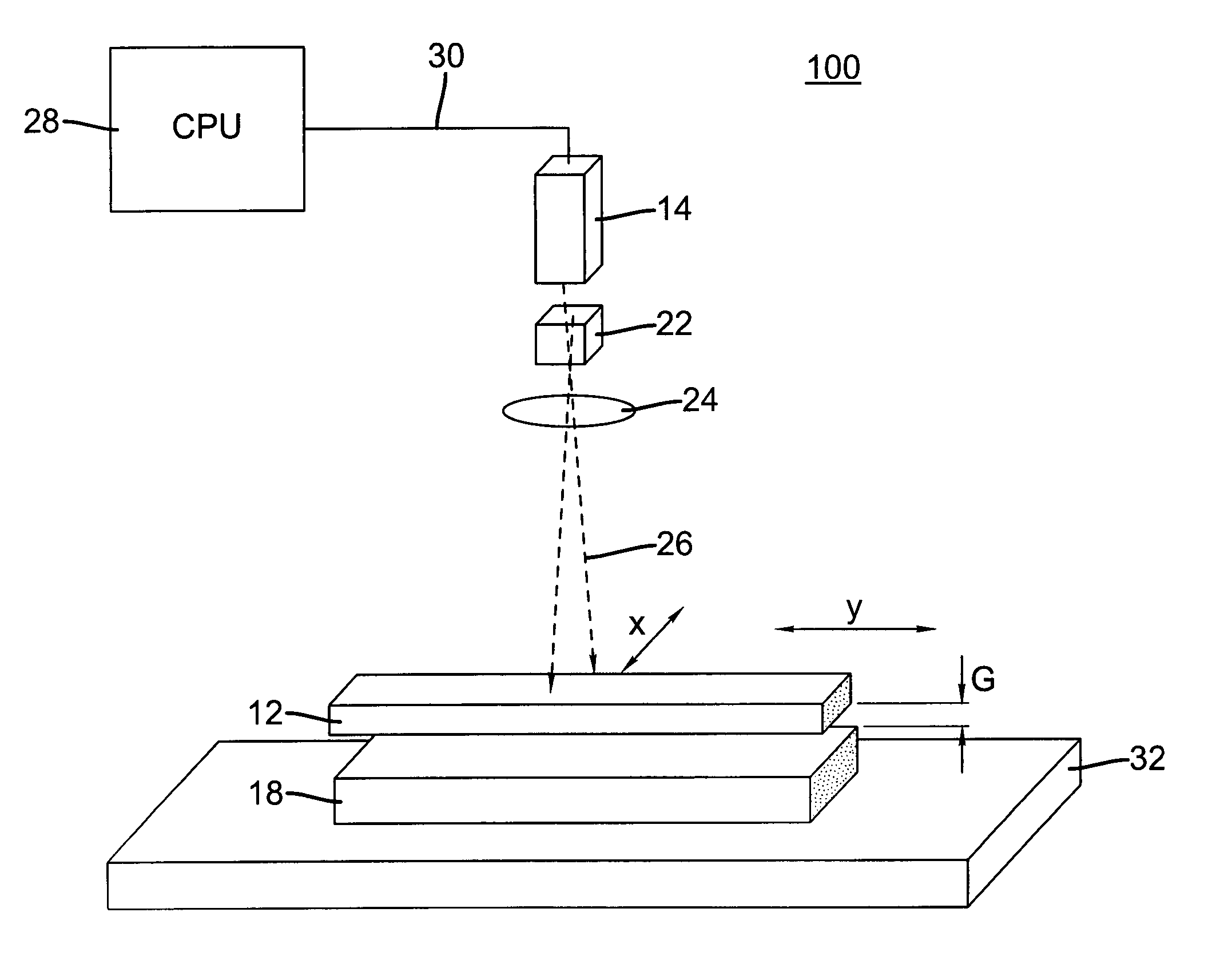

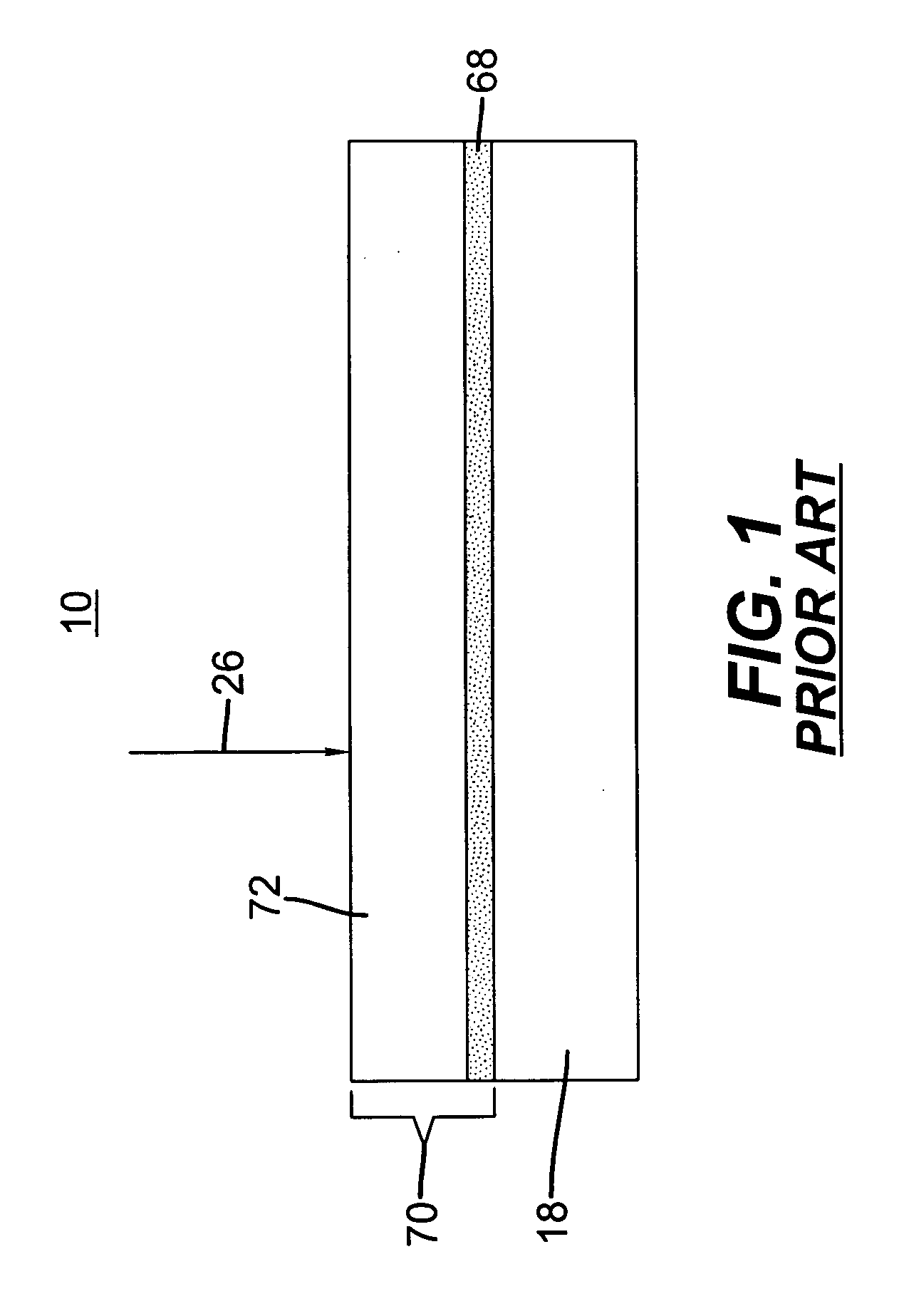

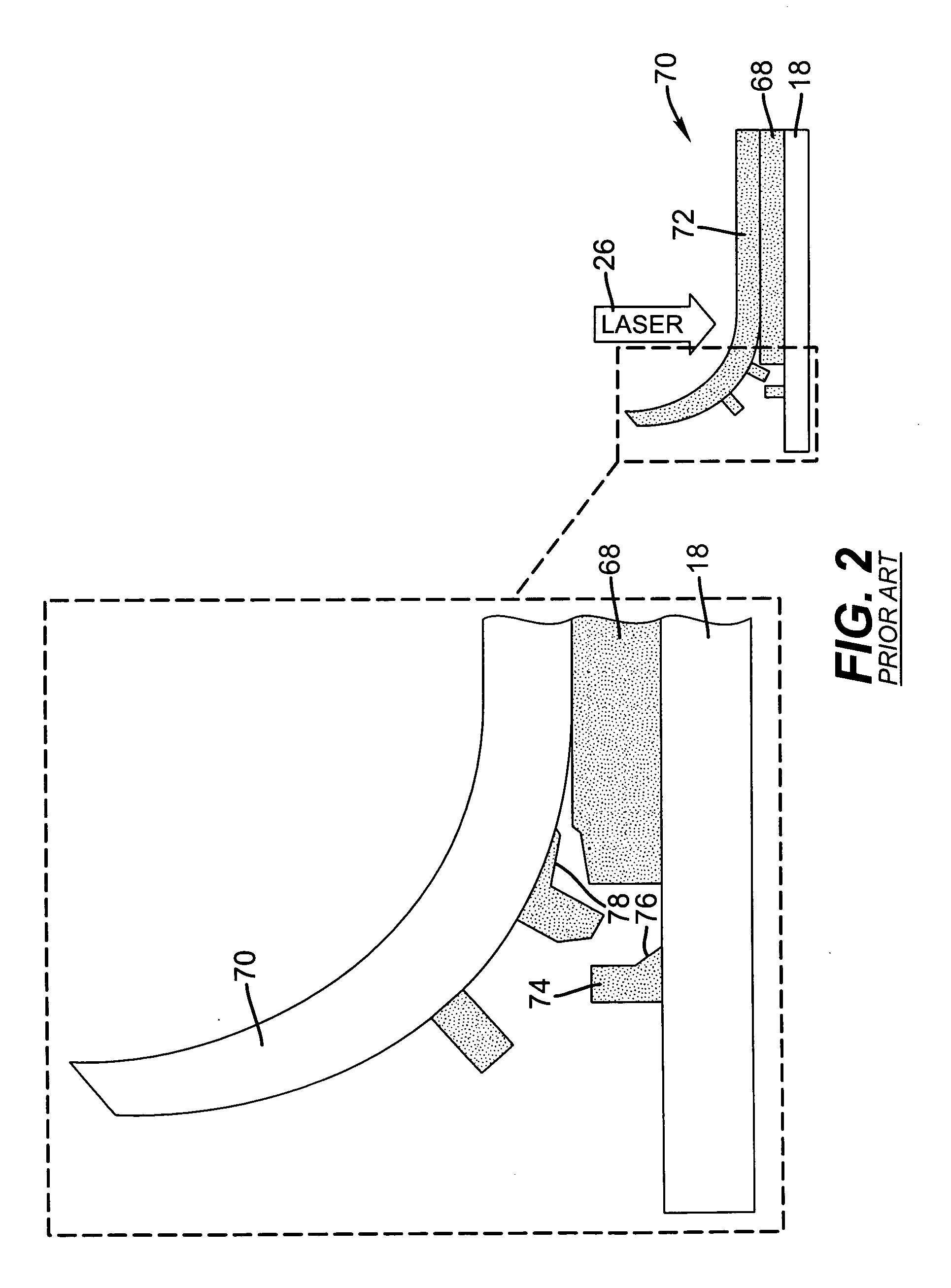

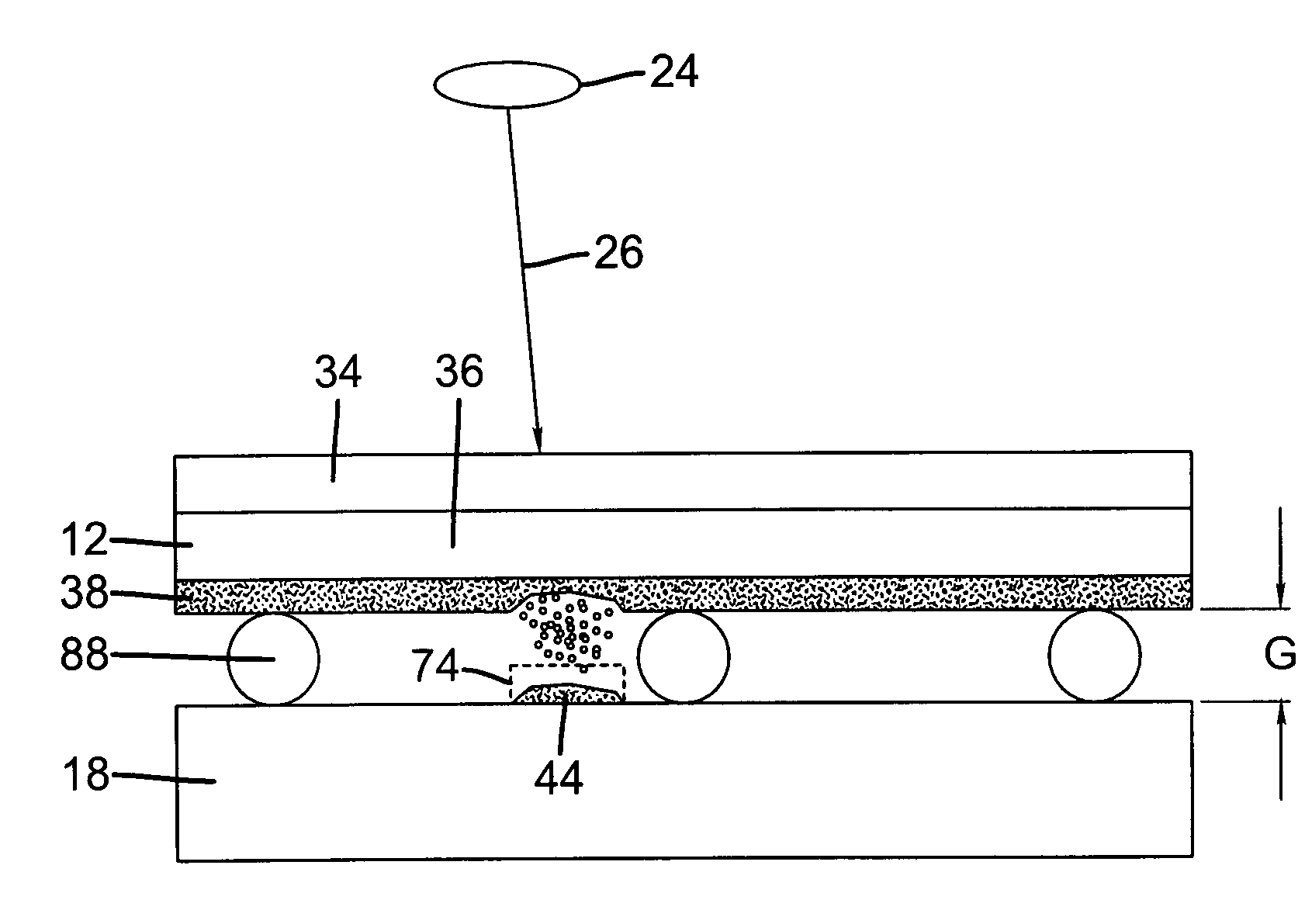

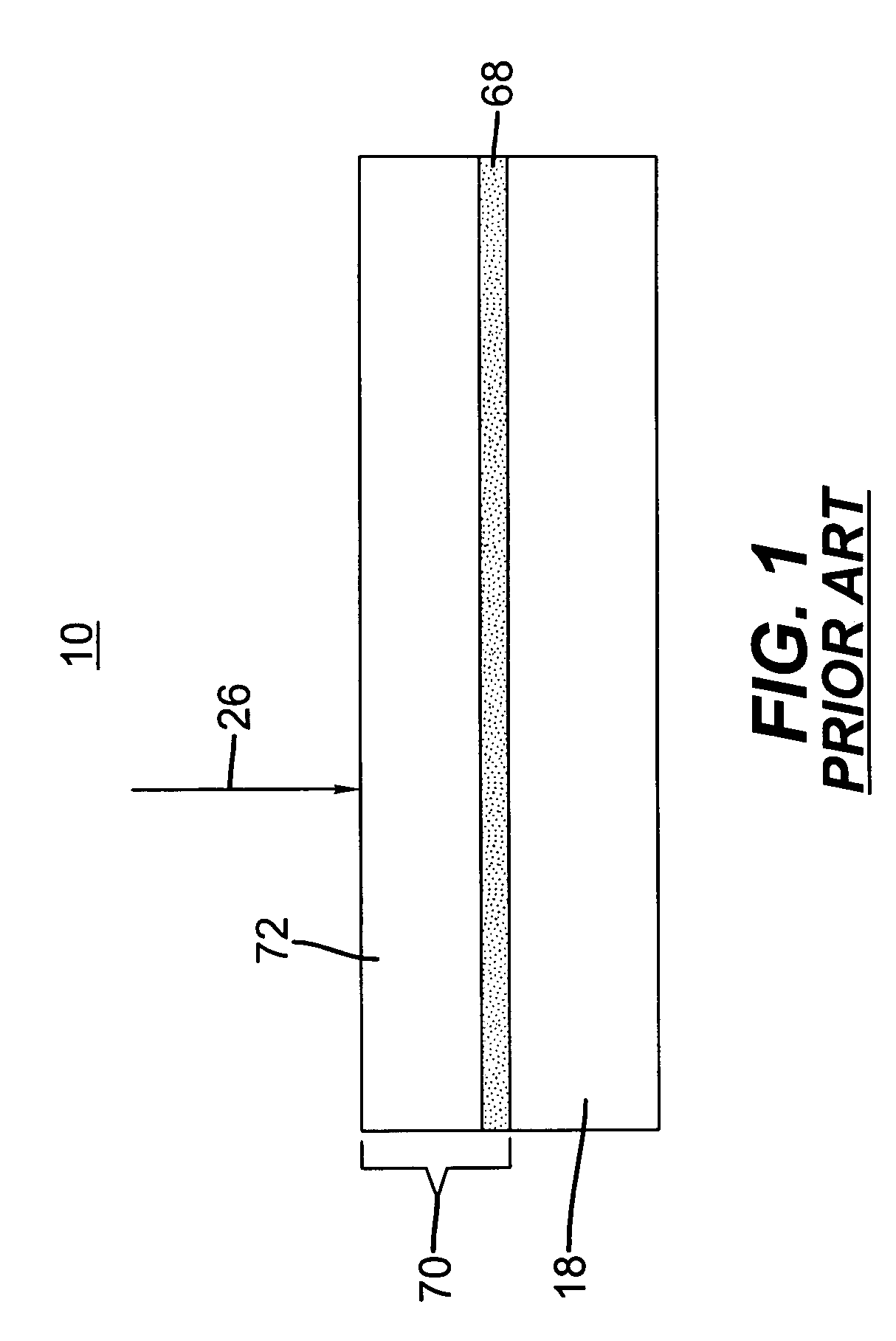

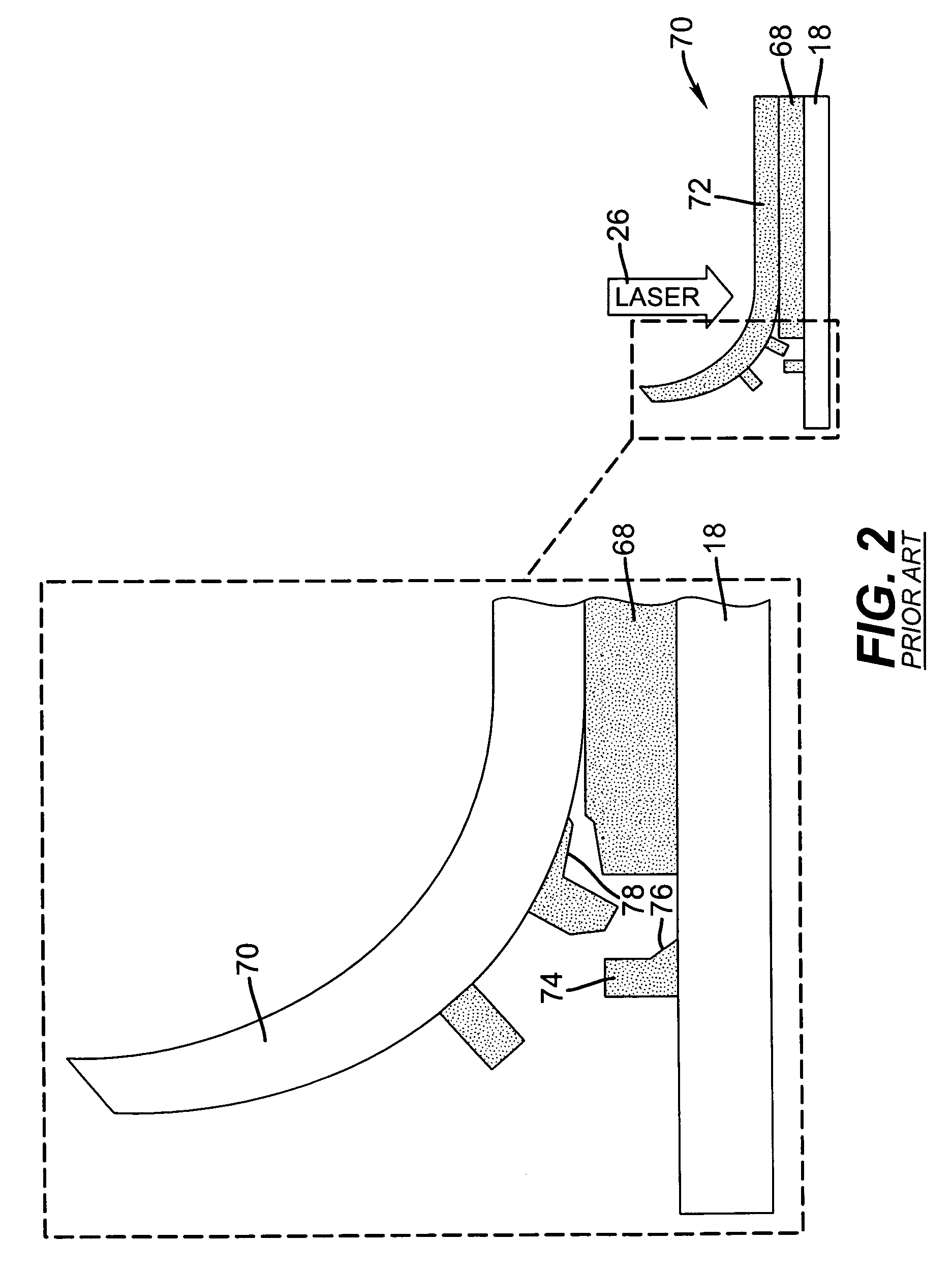

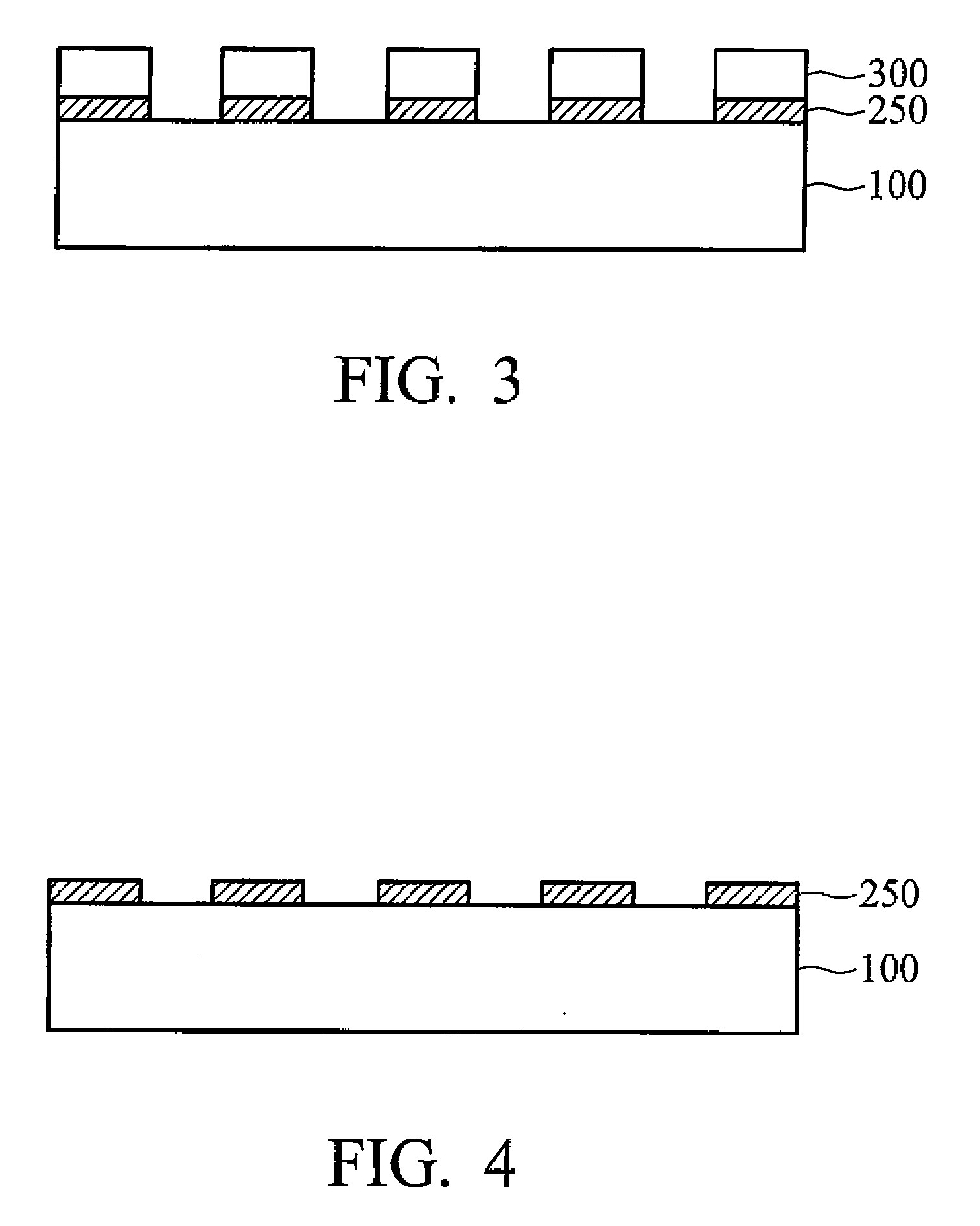

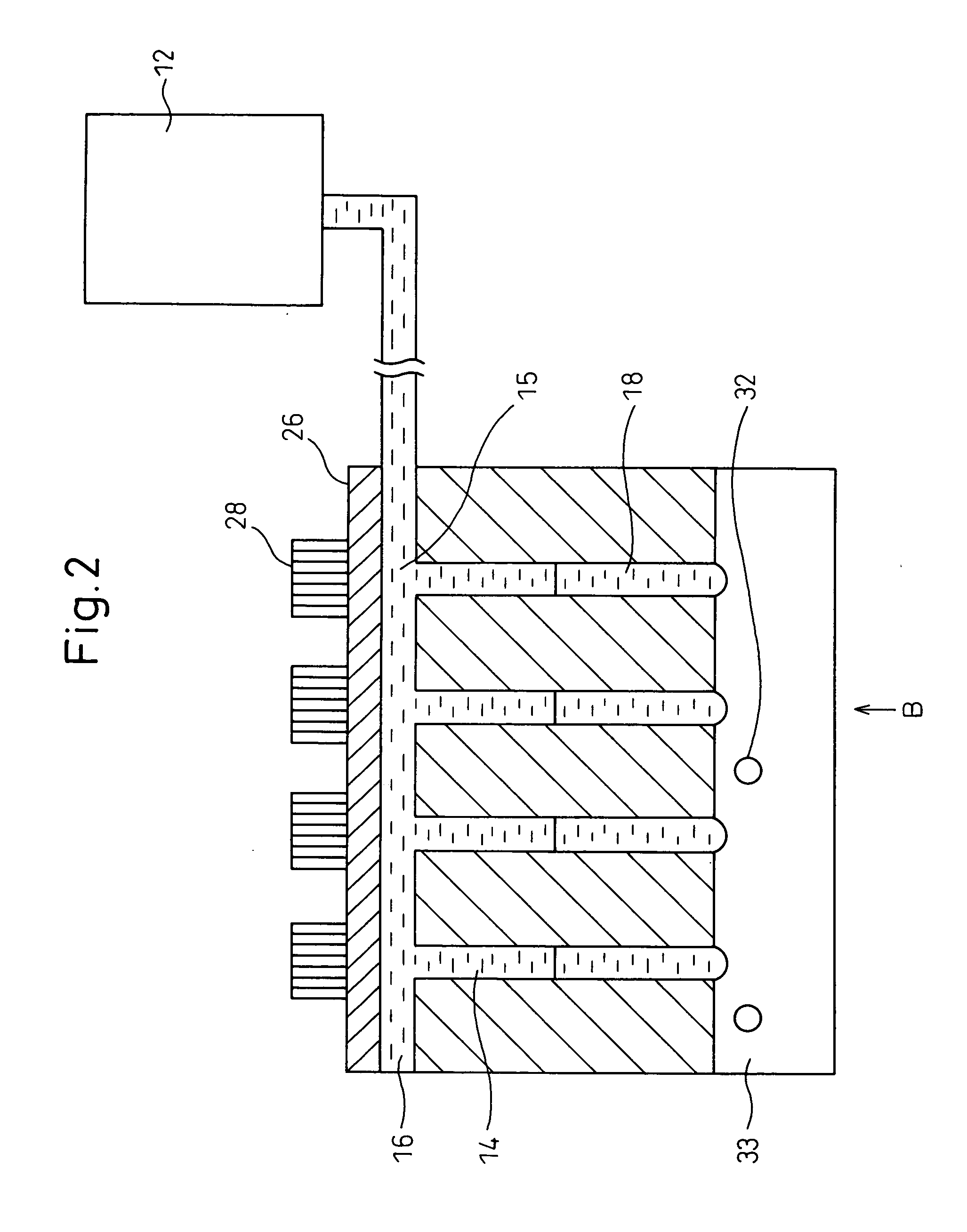

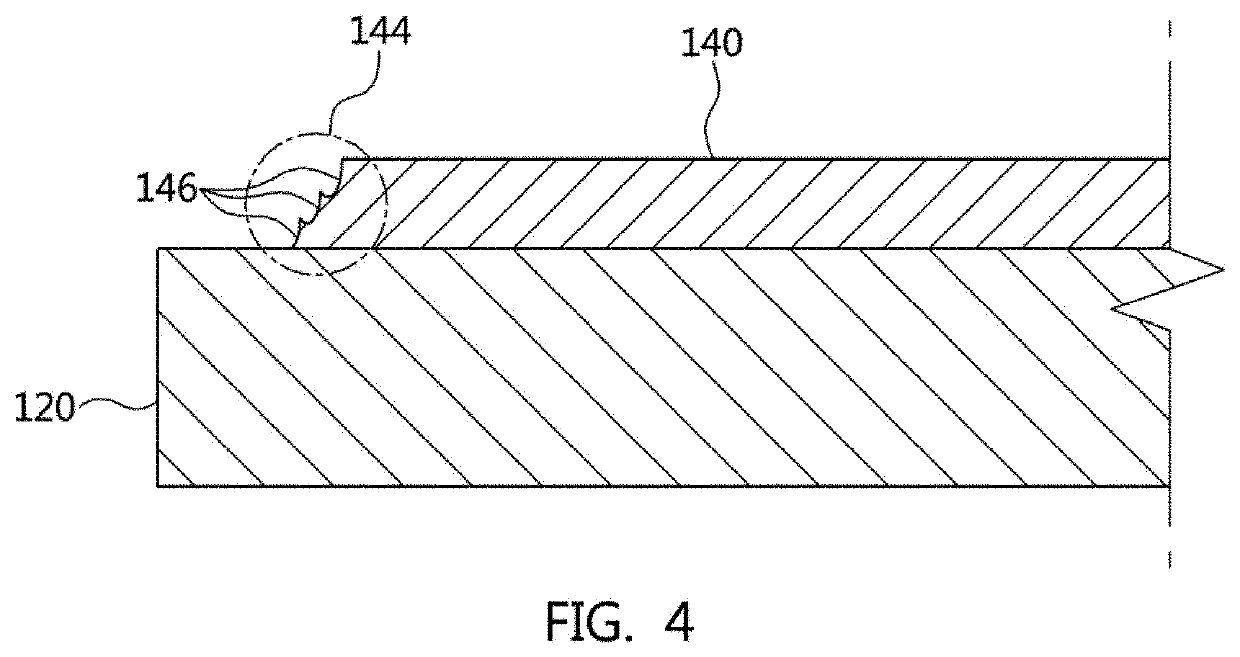

Laser resist transfer for microfabrication of electronic devices

A method for forming a resist pattern on a substrate (18) places a donor element (12) having a layer of thermoresist material proximate the substrate. A gap is maintained such that the surface of the layer of thermoresist material is spaced apart from the surface of the substrate by a number of spacing elements. Thermal energy is directed toward the donor element (12) according to the resist pattern, whereby a portion of thermoresist material is transferred from the donor element (12) across the gap by ablative transfer and is deposited onto the substrate (18) forming the resist pattern.

Owner:EASTMAN KODAK CO

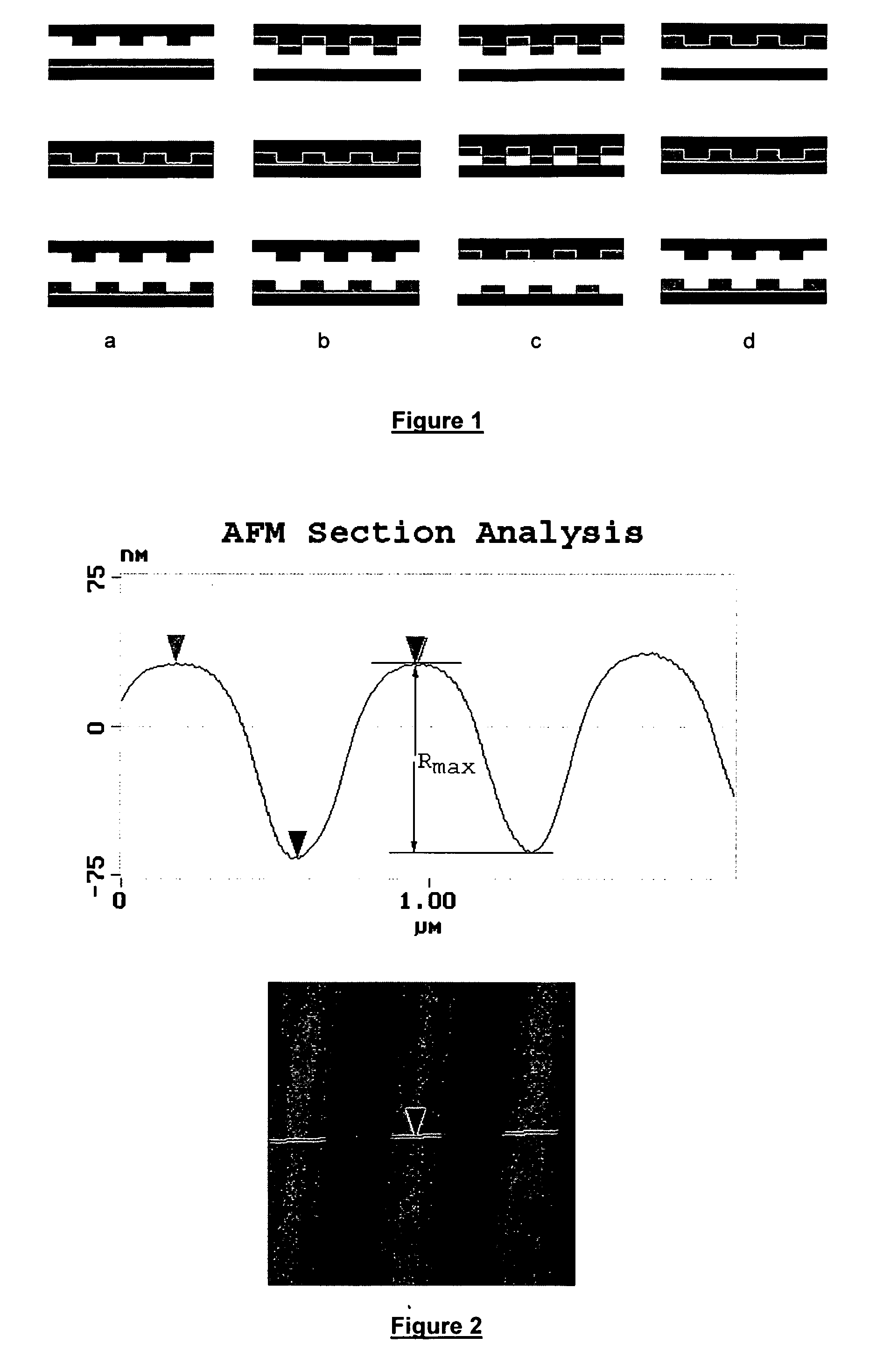

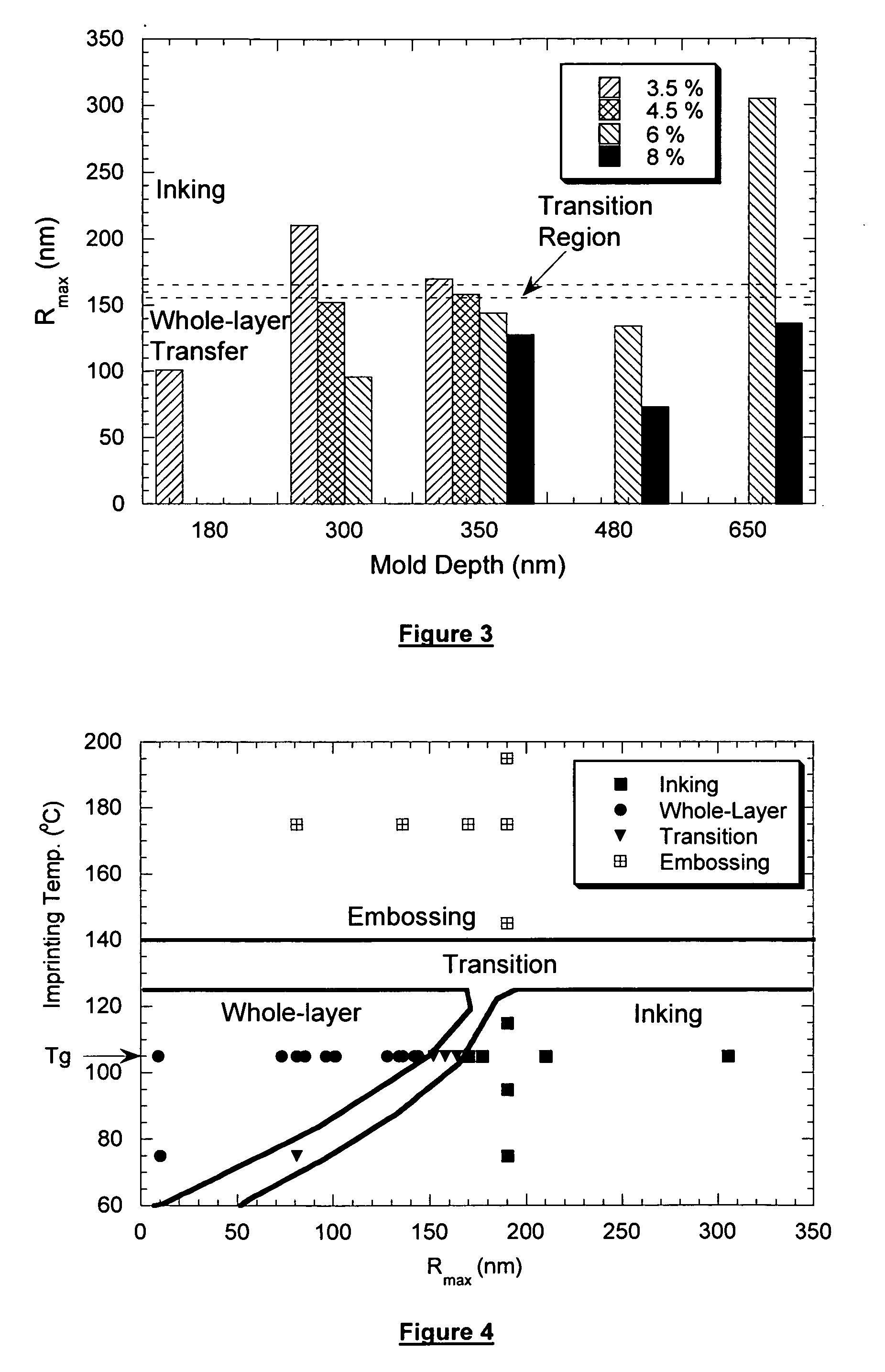

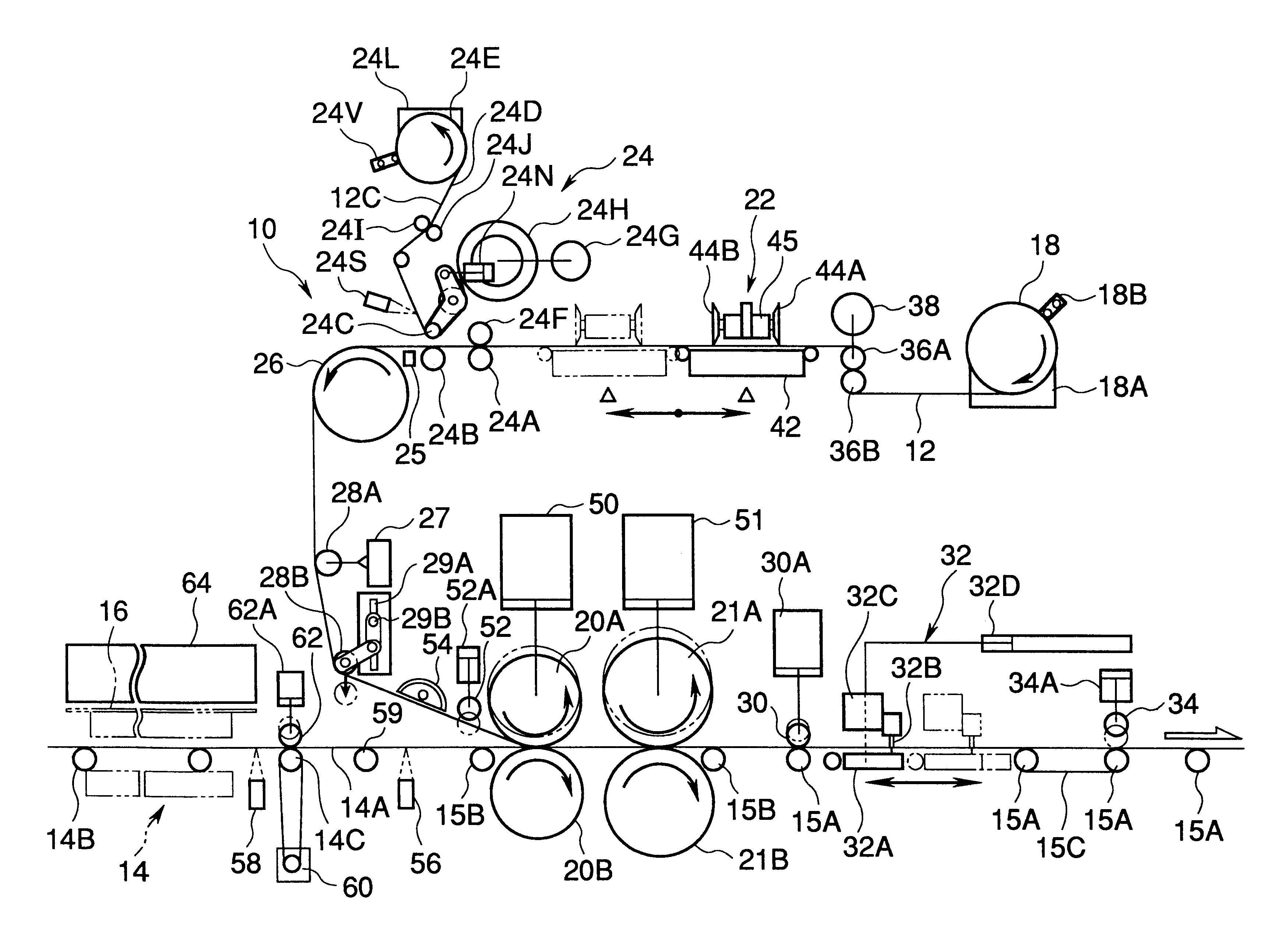

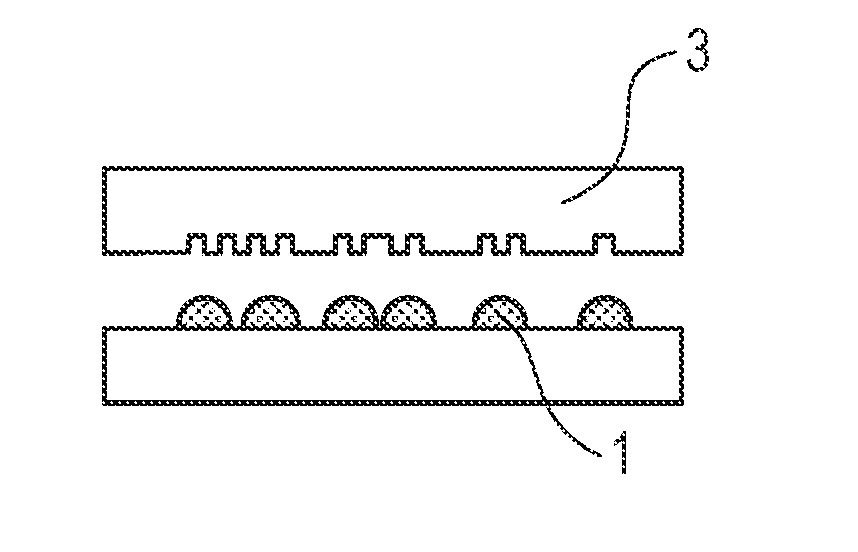

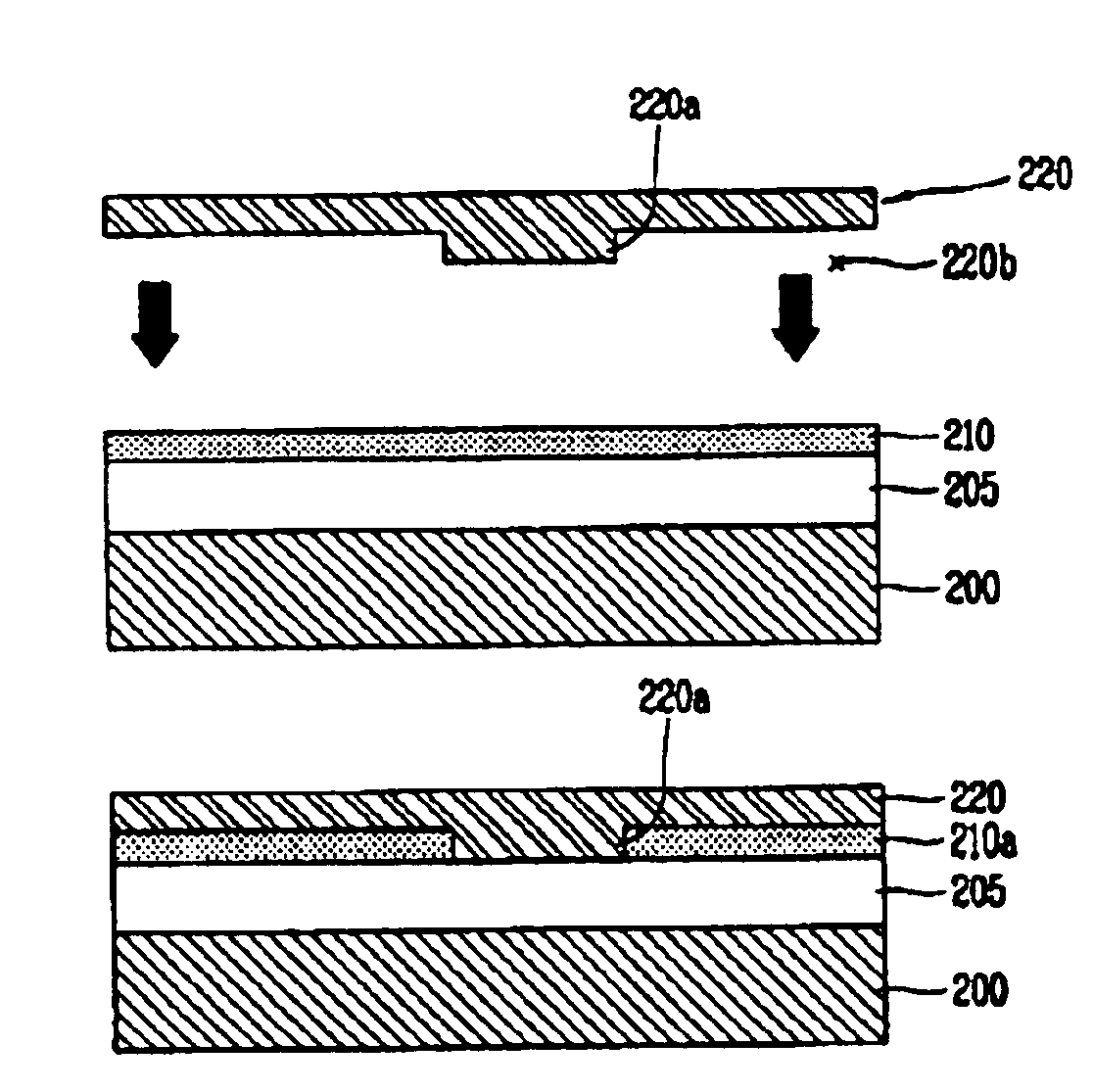

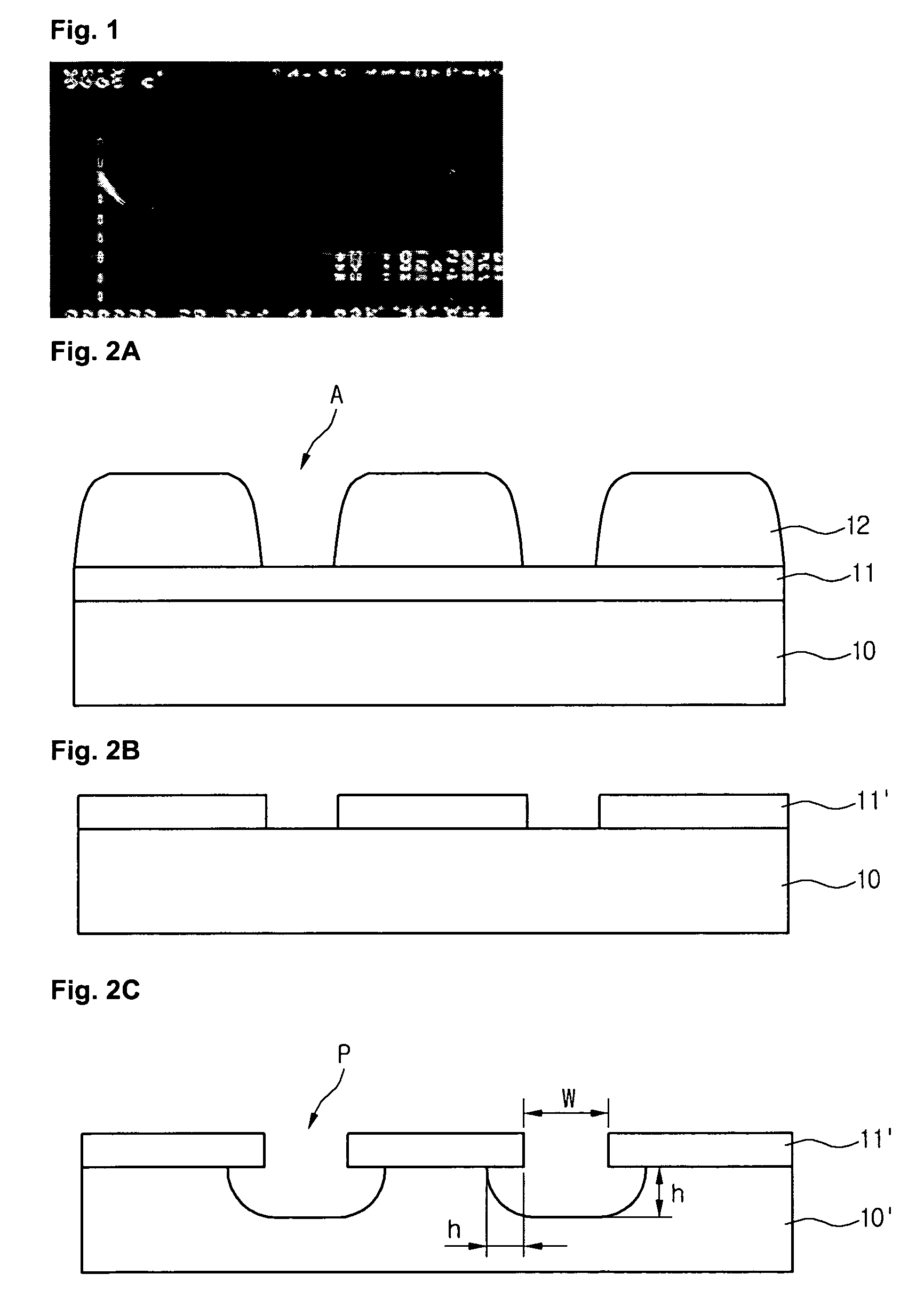

Reversal imprint technique

InactiveUS20070059497A1Reduce thicknessDecorative surface effectsDuplicating/marking methodsPolymer coatingsNanostructure

The present invention relates to a method for imprinting a micro- / nano-structure on a substrate, the method comprising (a) providing a mold containing a desired pattern or relief for a microstructure; (b) applying a polymer coating to the mold; and (c) transferring the polymer coating from the mold to a substrate under suitable temperature and pressure conditions to form an imprinted substrate having a desired micro- / nano-structure thereon.

Owner:AGENCY FOR SCI TECH & RES +1

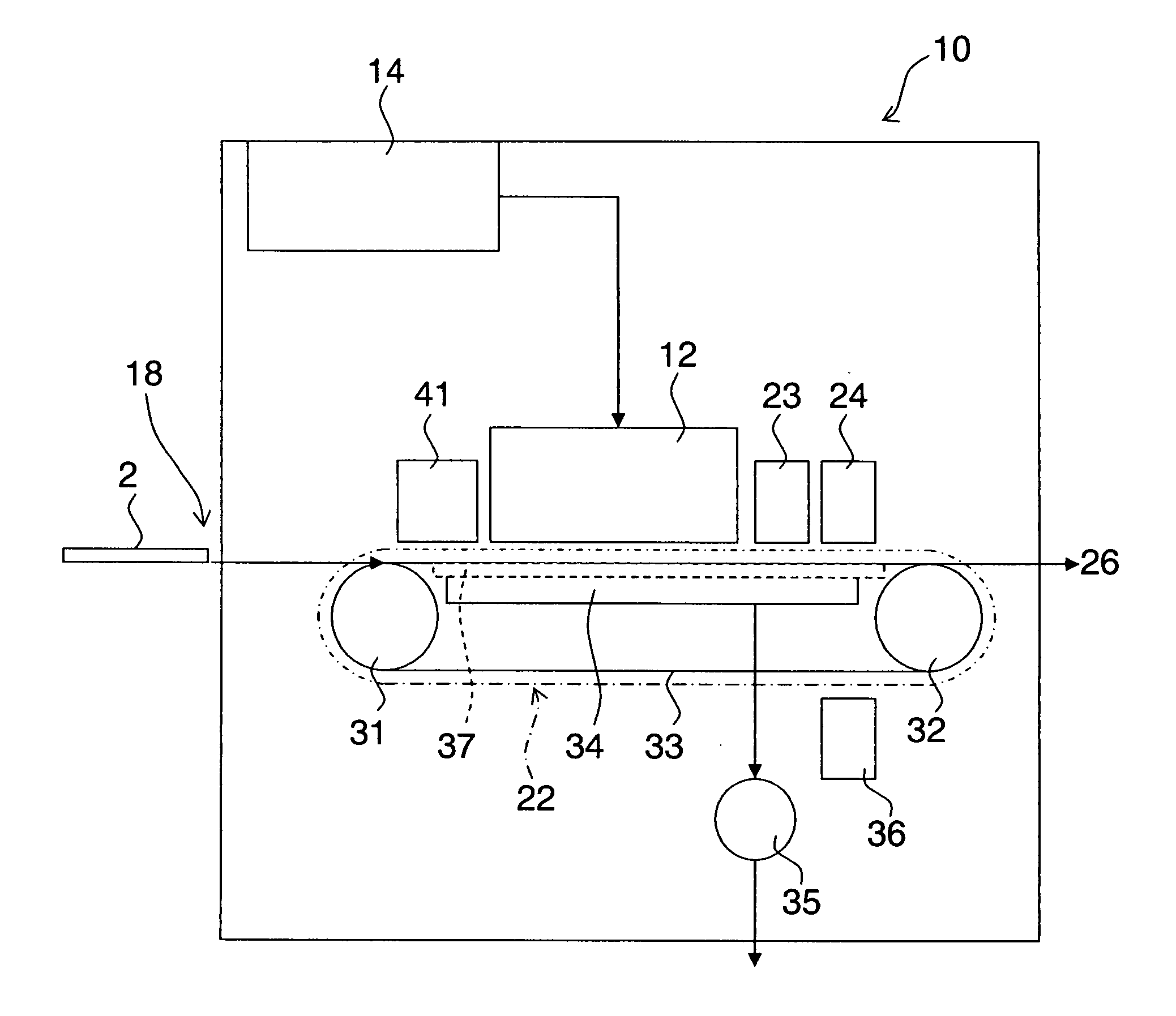

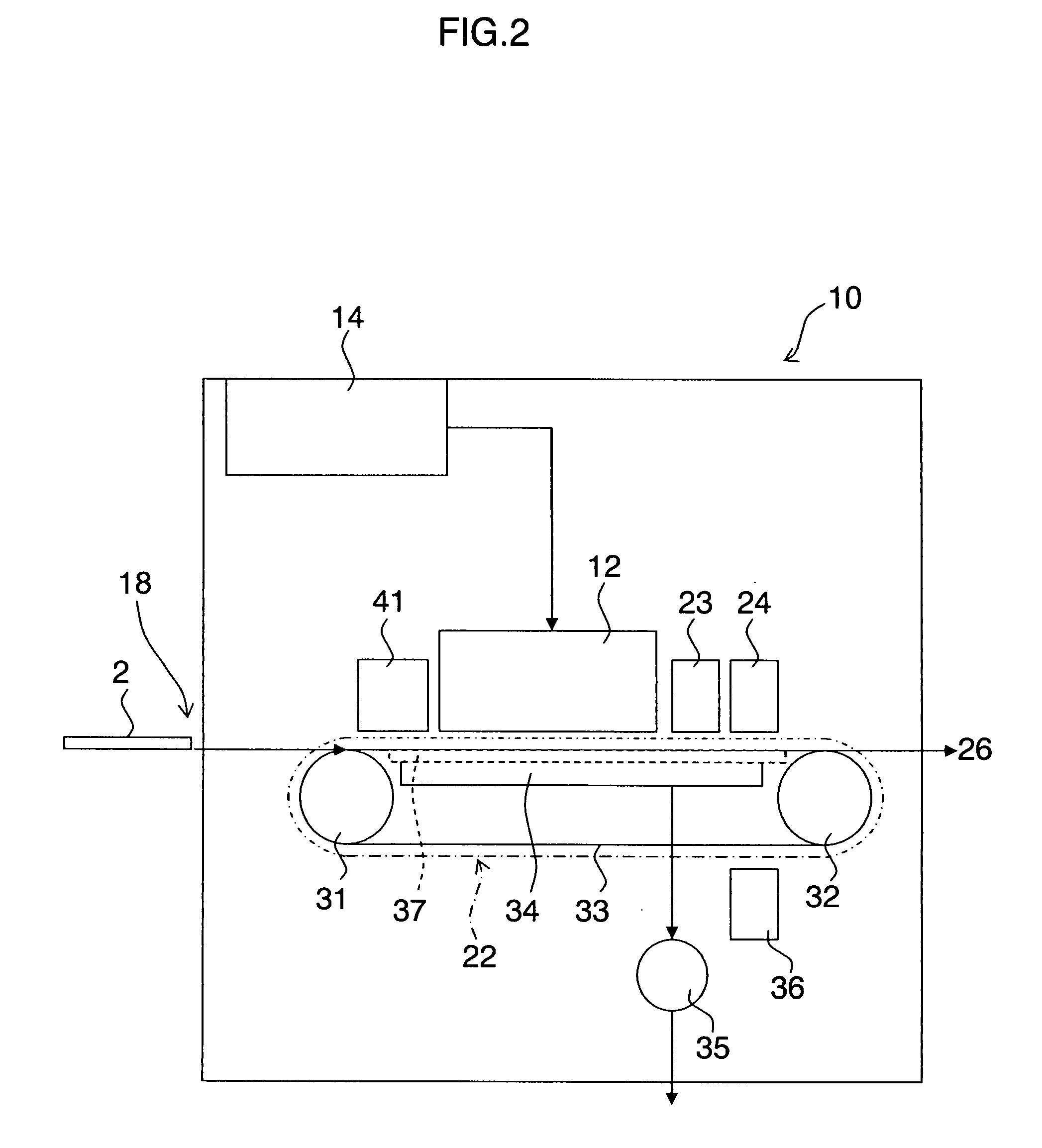

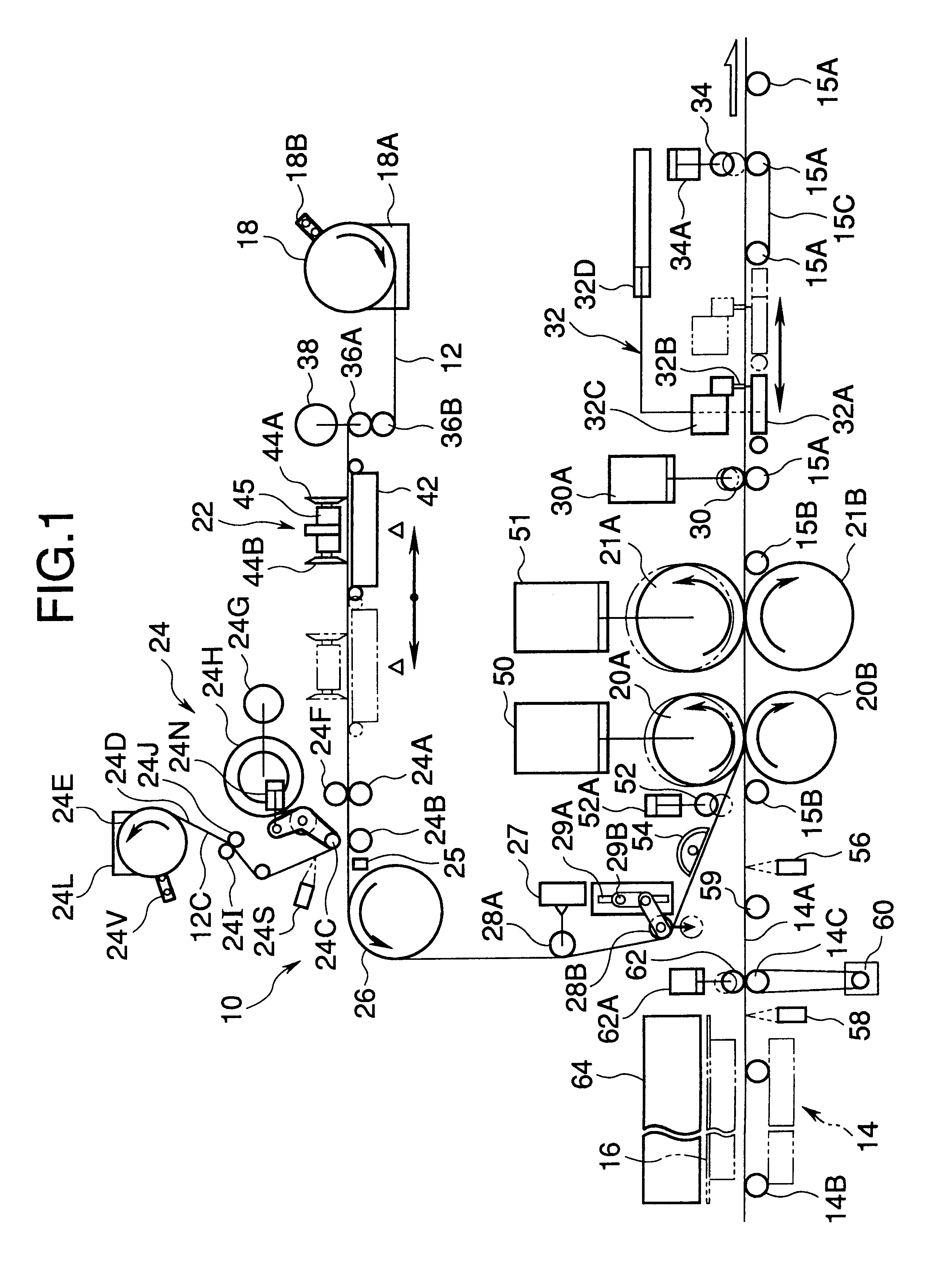

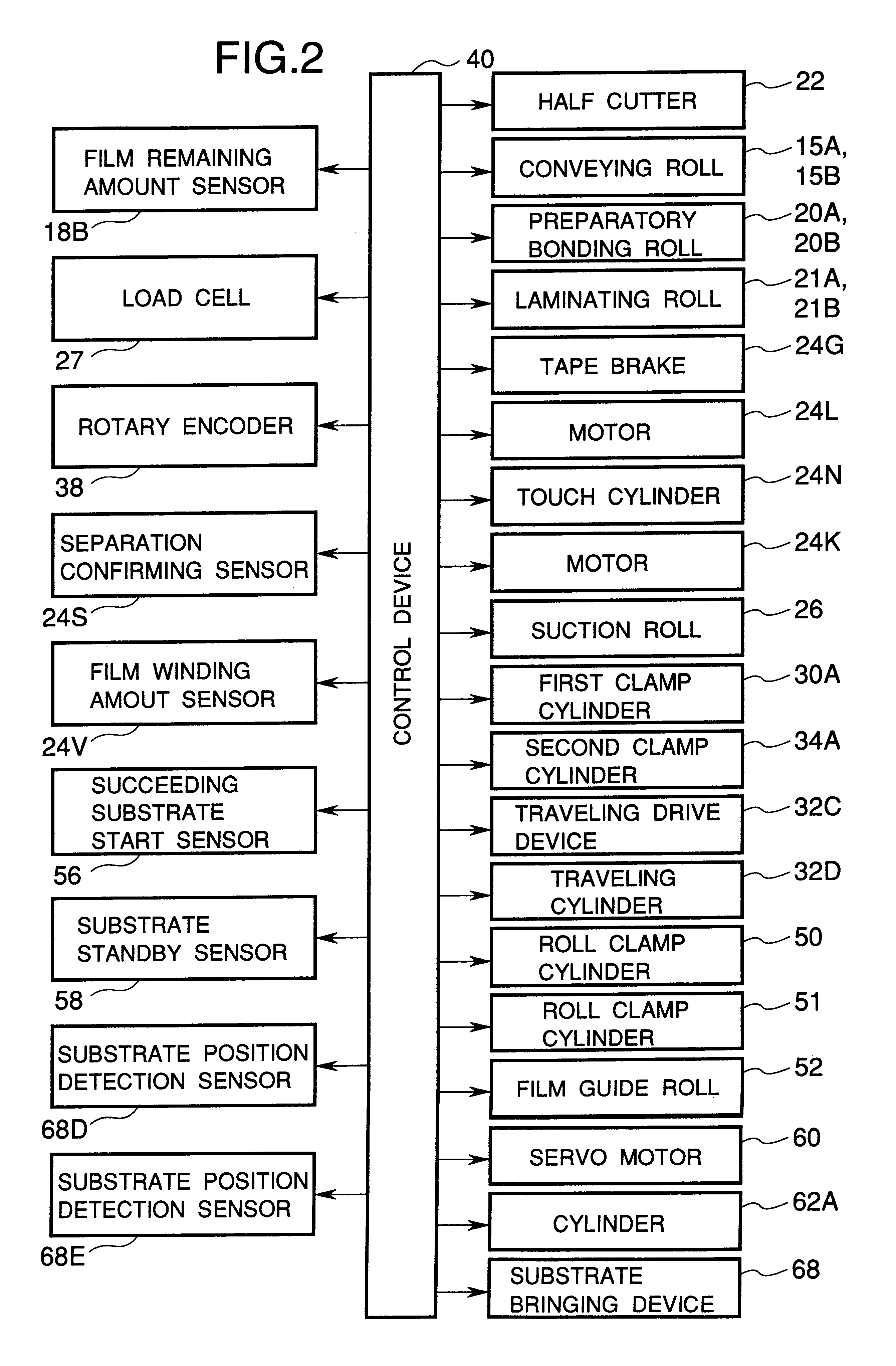

Film applying apparatus

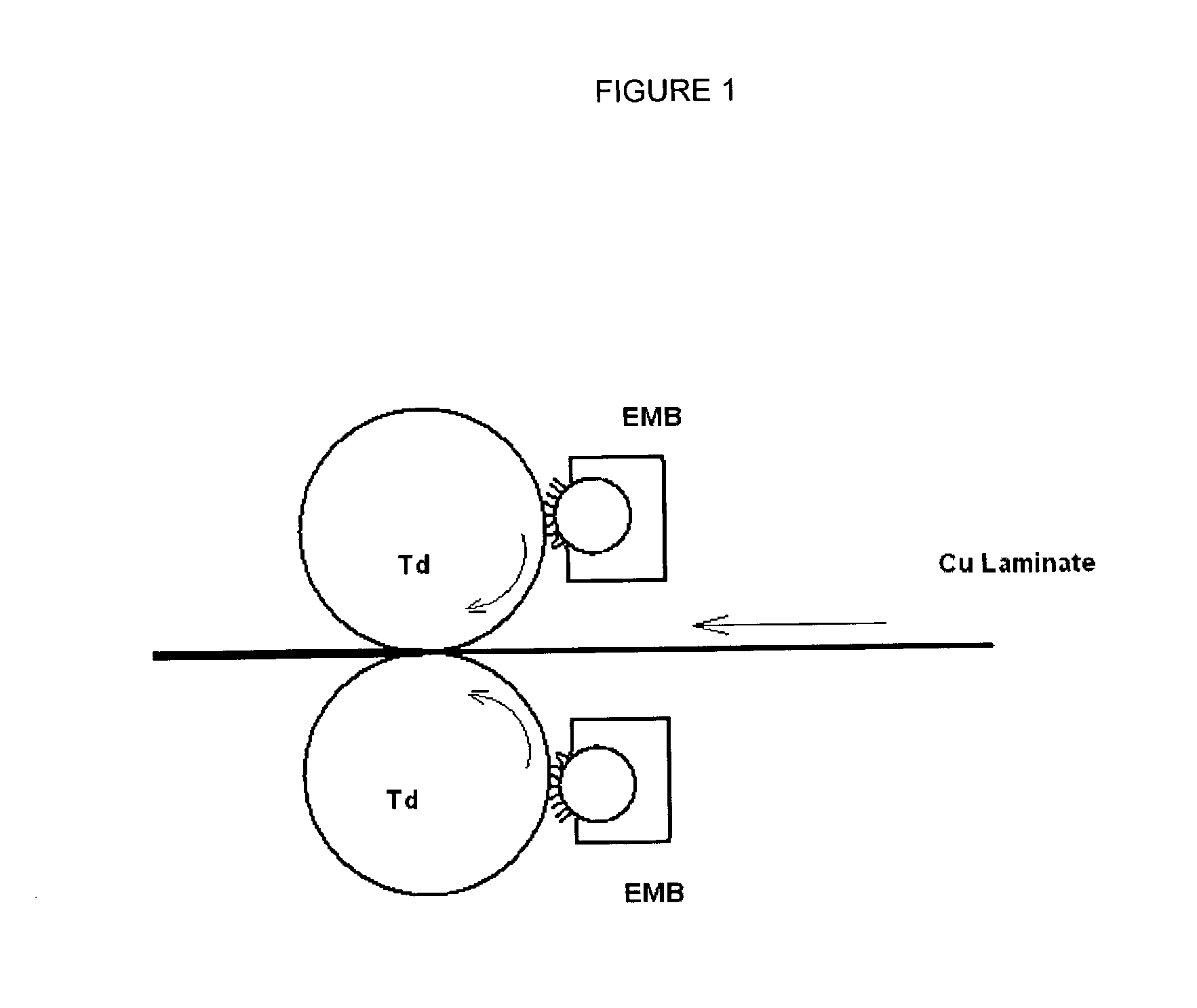

InactiveUS6176286B1Small rangeSecure bondingMechanical working/deformationLamination ancillary operationsSheet filmEngineering

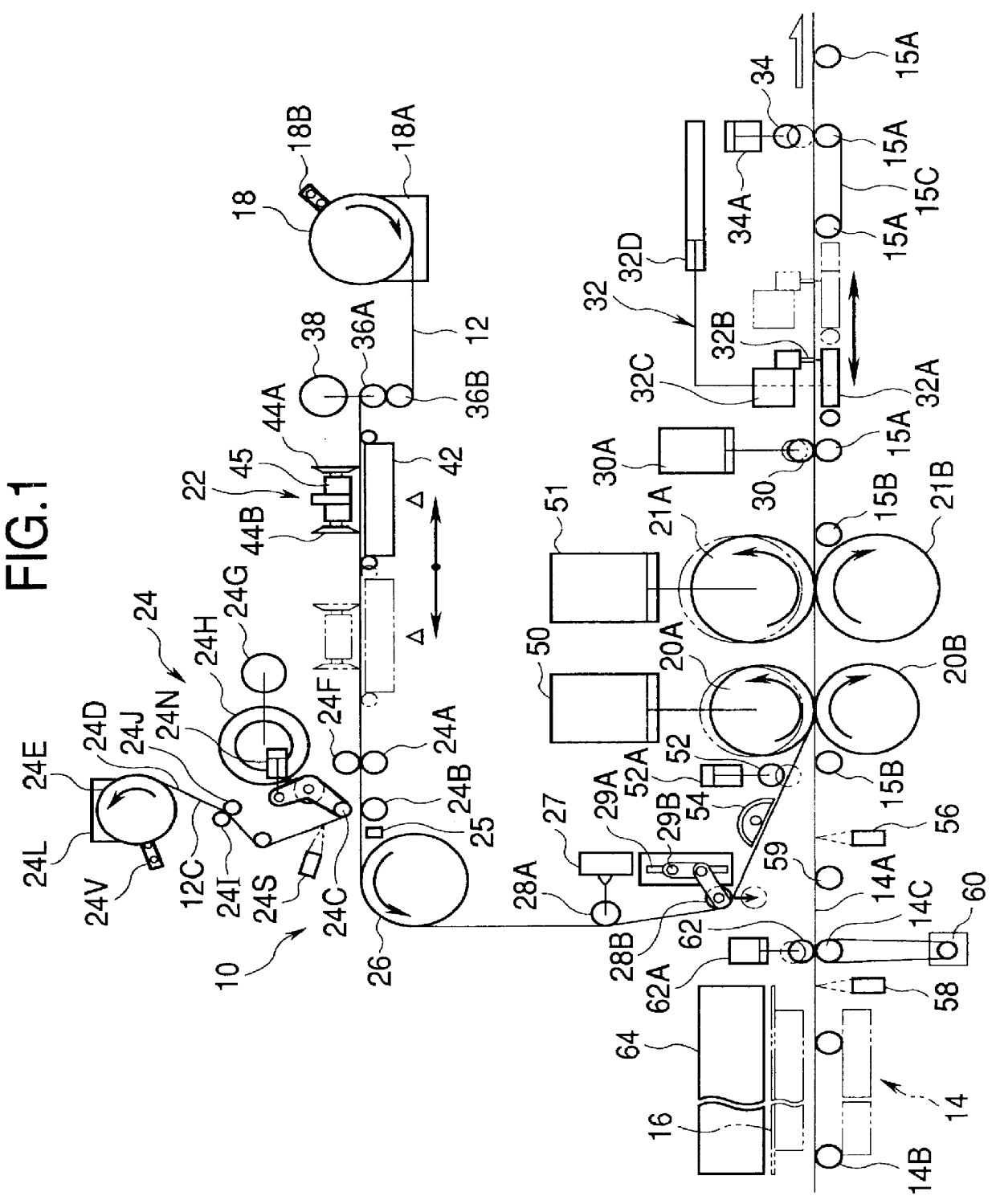

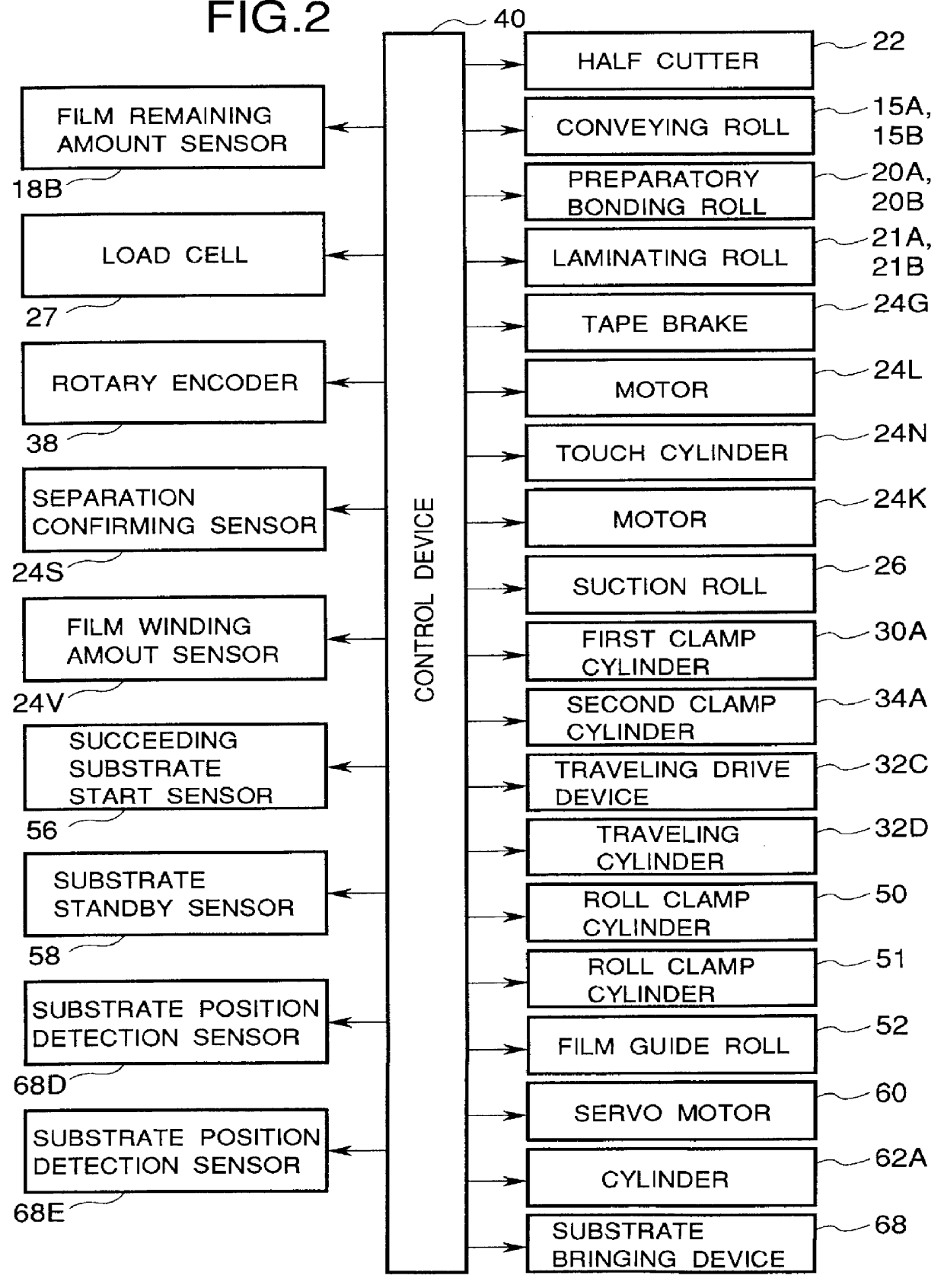

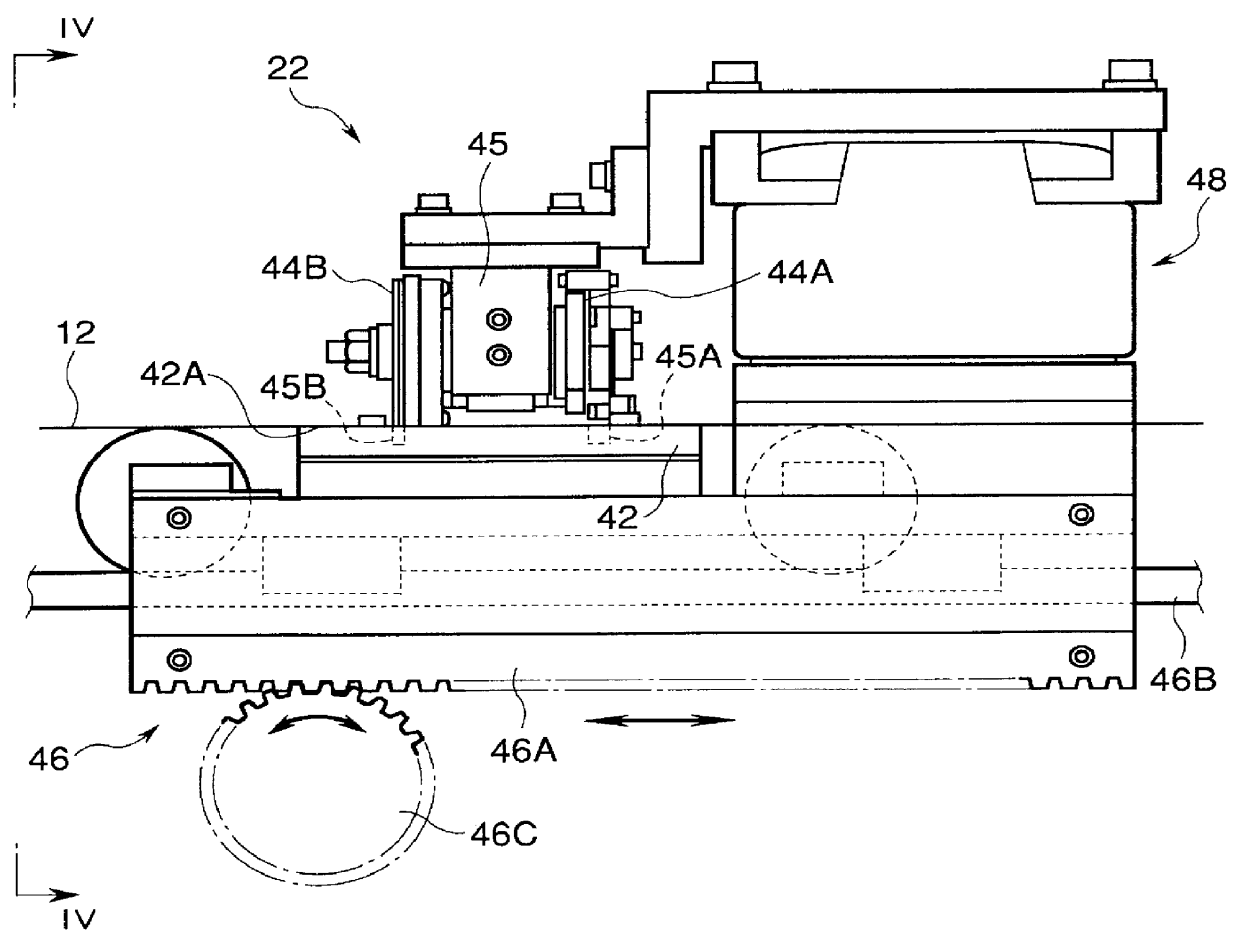

A film applying apparatus 10 is provided with preparatory bonding rolls 20A, 20B and laminating rolls 21A, 21B, and a laminated film 12 wound out from a film roll 18 and a substrate 16 conveyed by a substrate conveying device 14 pass between these rolls and pressure bonding is performed. Diameter of the preparatory bonding rolls 20A, 20B is made smaller than diameter of the laminating rolls 21A, 21B and range of elastic deformable area S1 at the roll surface at grasping starting of the substrate and the laminated film 12 by the preparatory bonding rolls 20A, 20B is made small thereby range of generating, air holding or the like is limited to small.

Owner:SOMAR CORP

Touch screen sensor

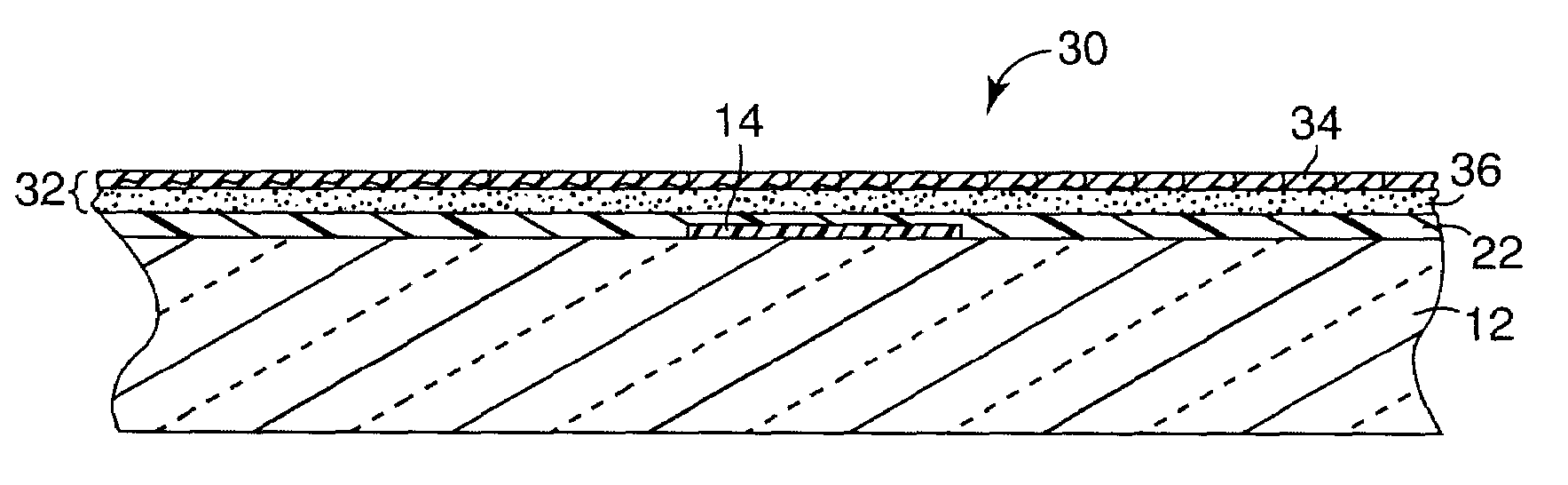

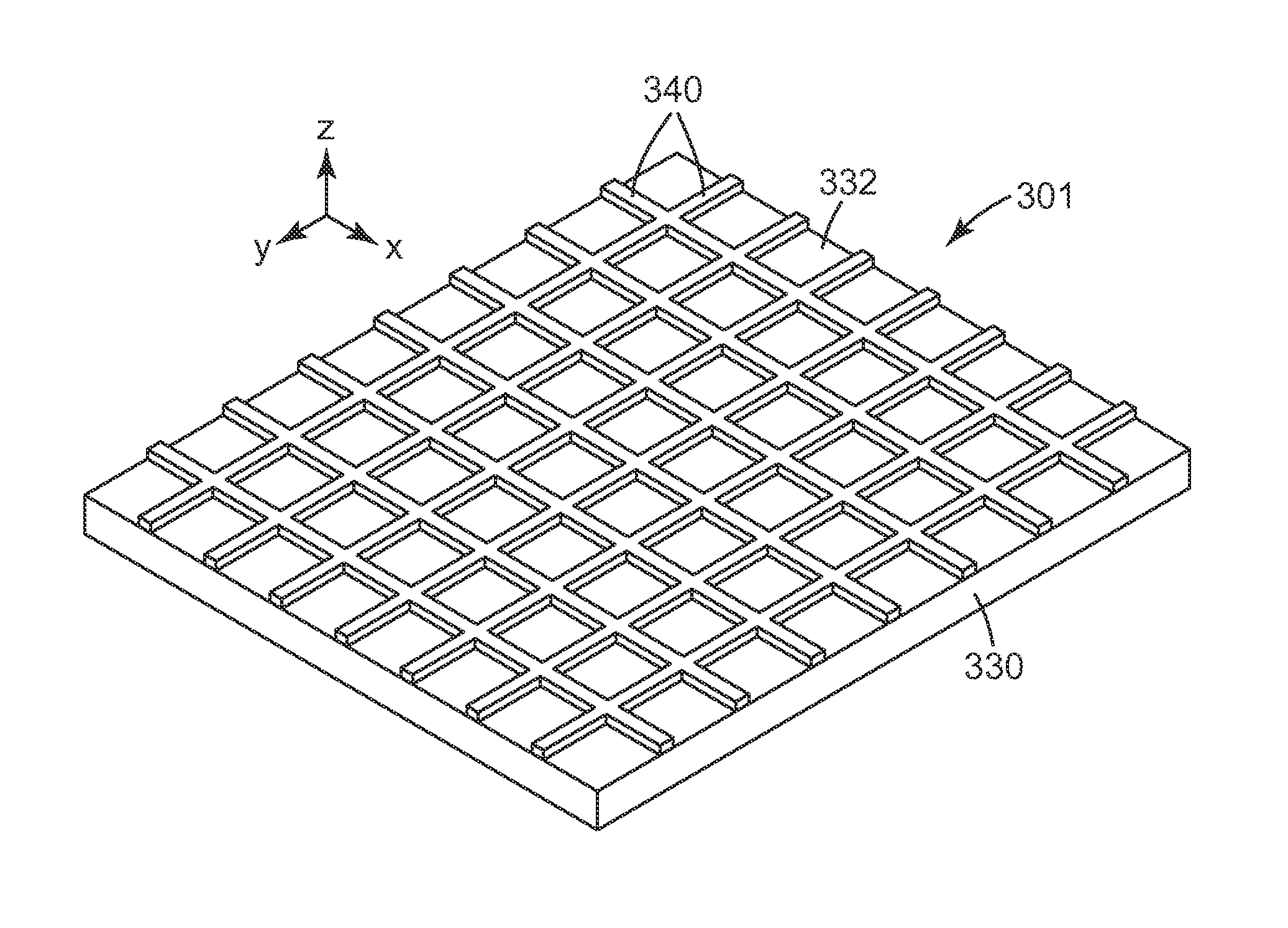

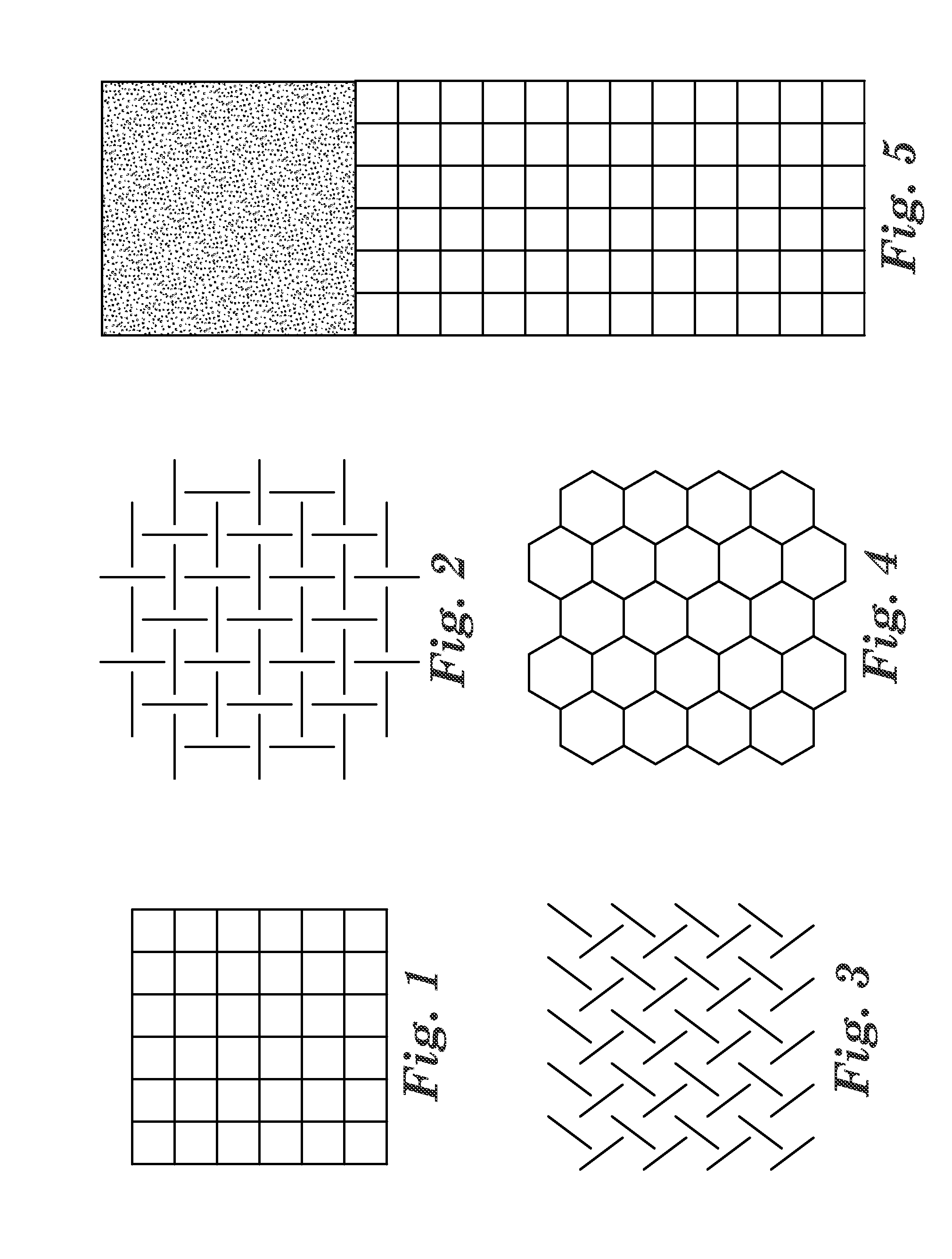

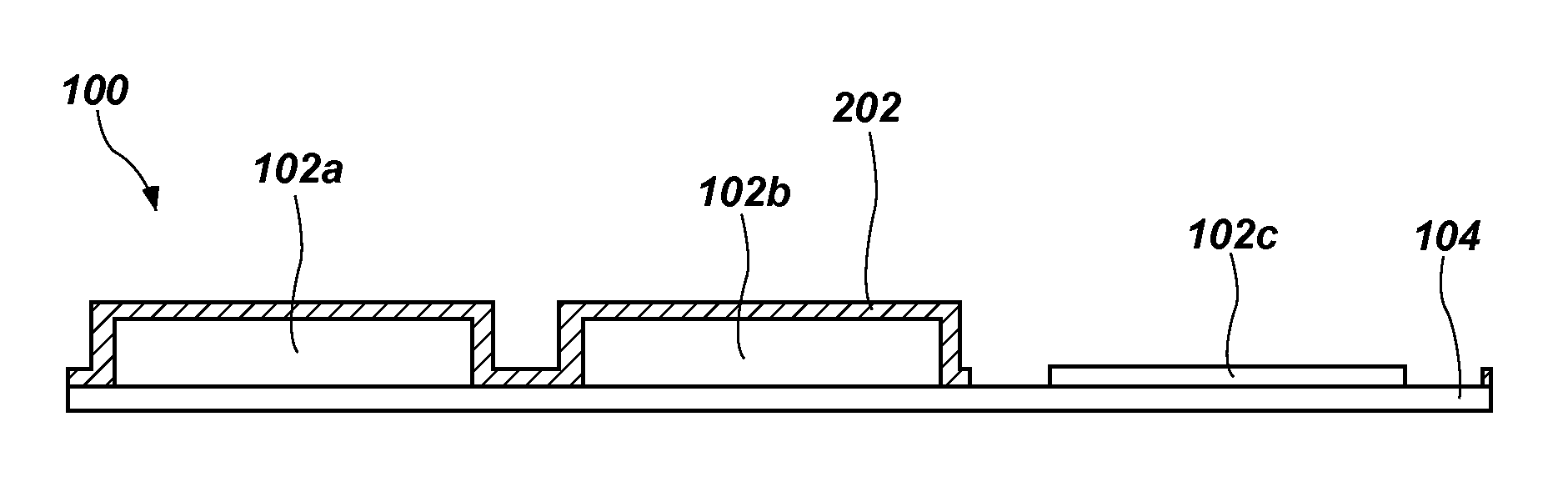

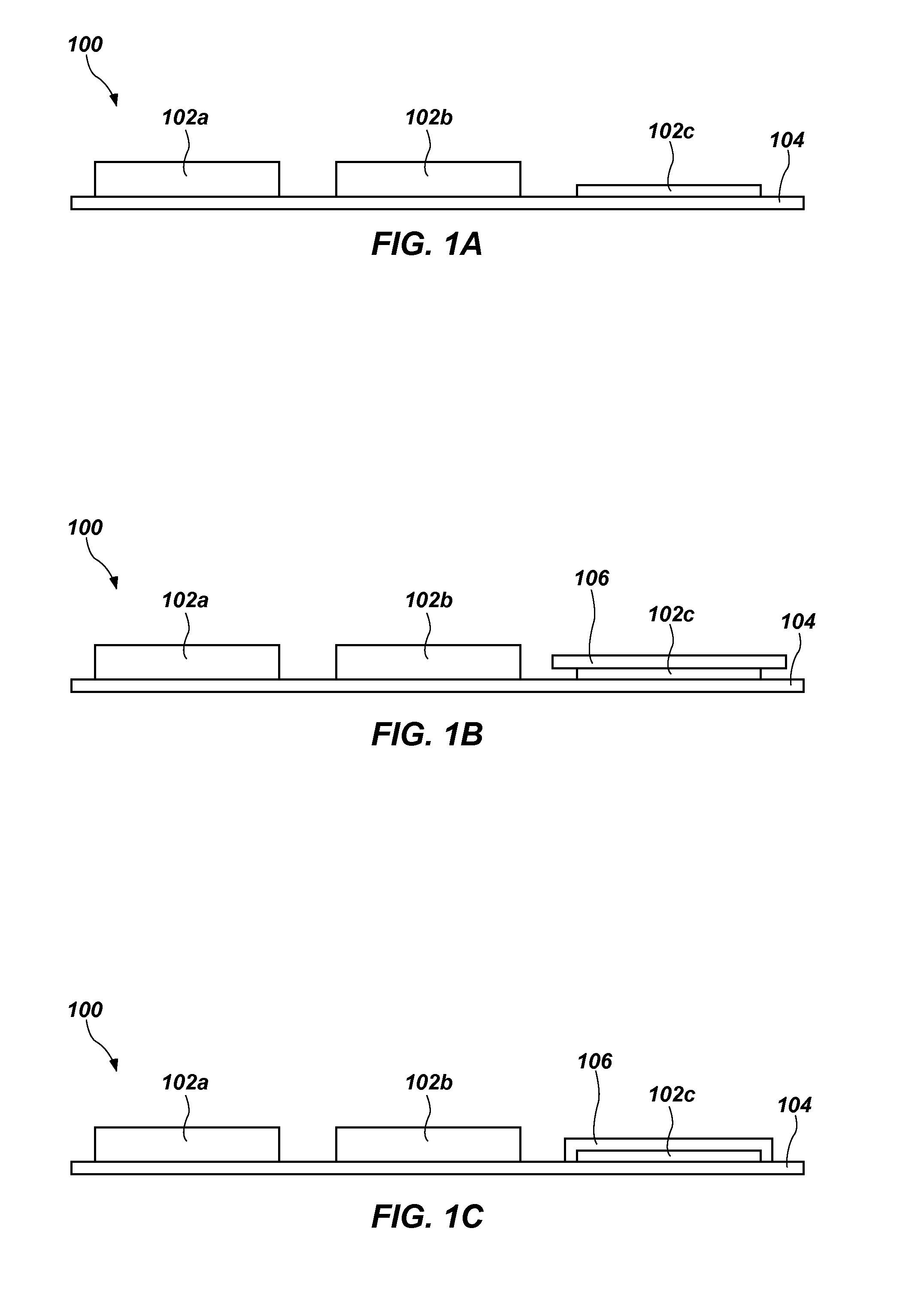

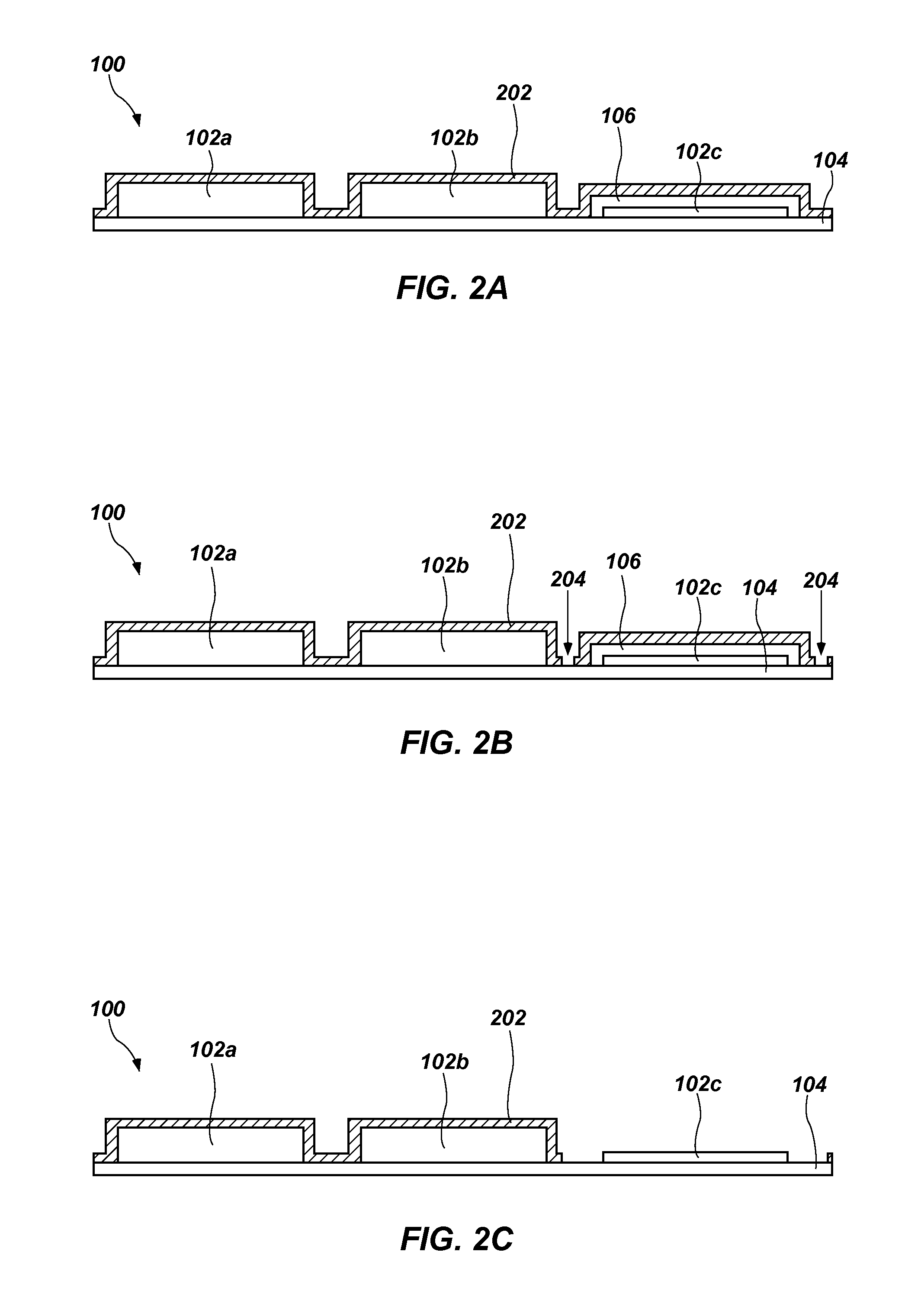

ActiveUS20120194481A1Conductive layers on insulating-supportsNanoinformaticsElectrical resistance and conductanceTouch Senses

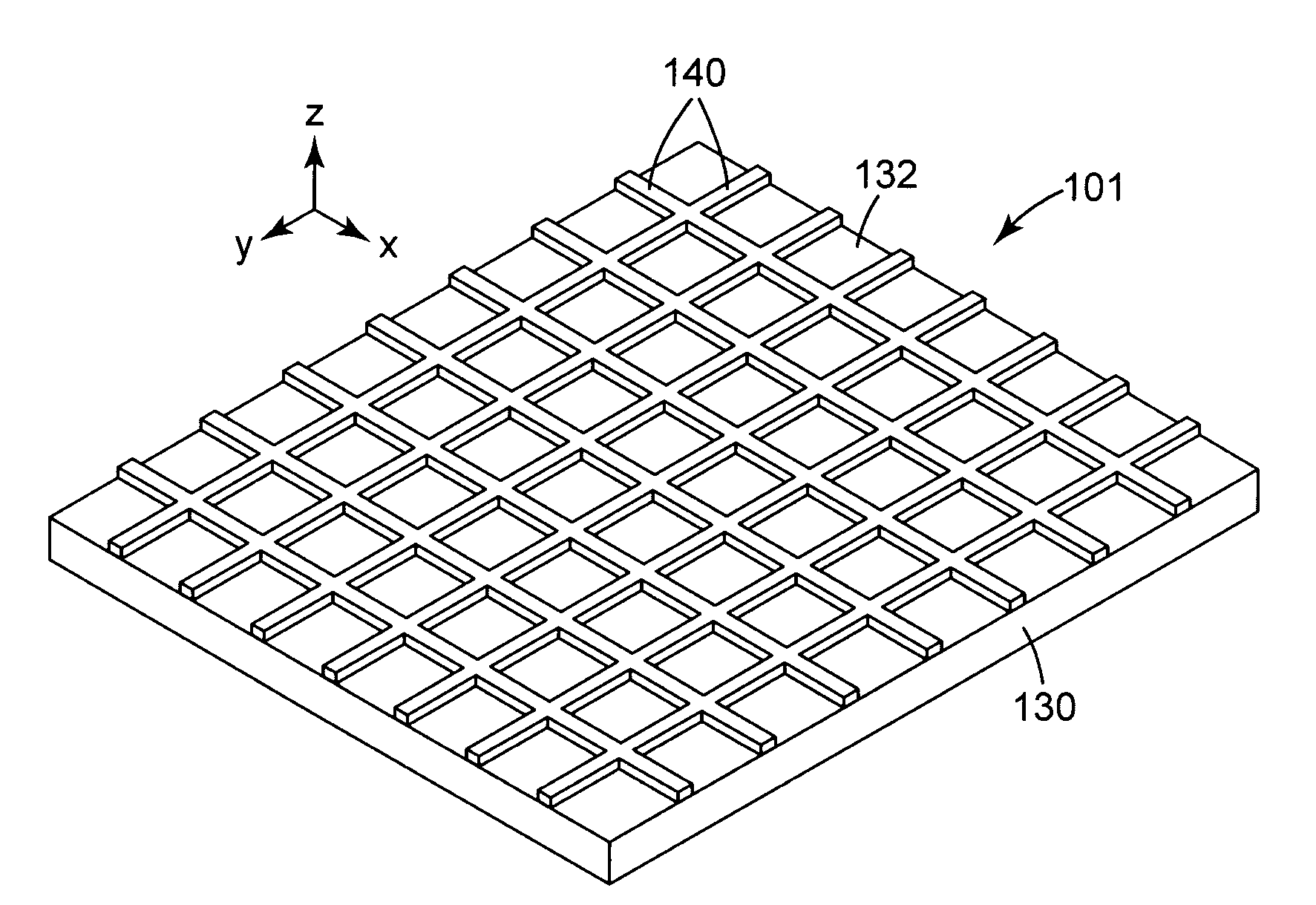

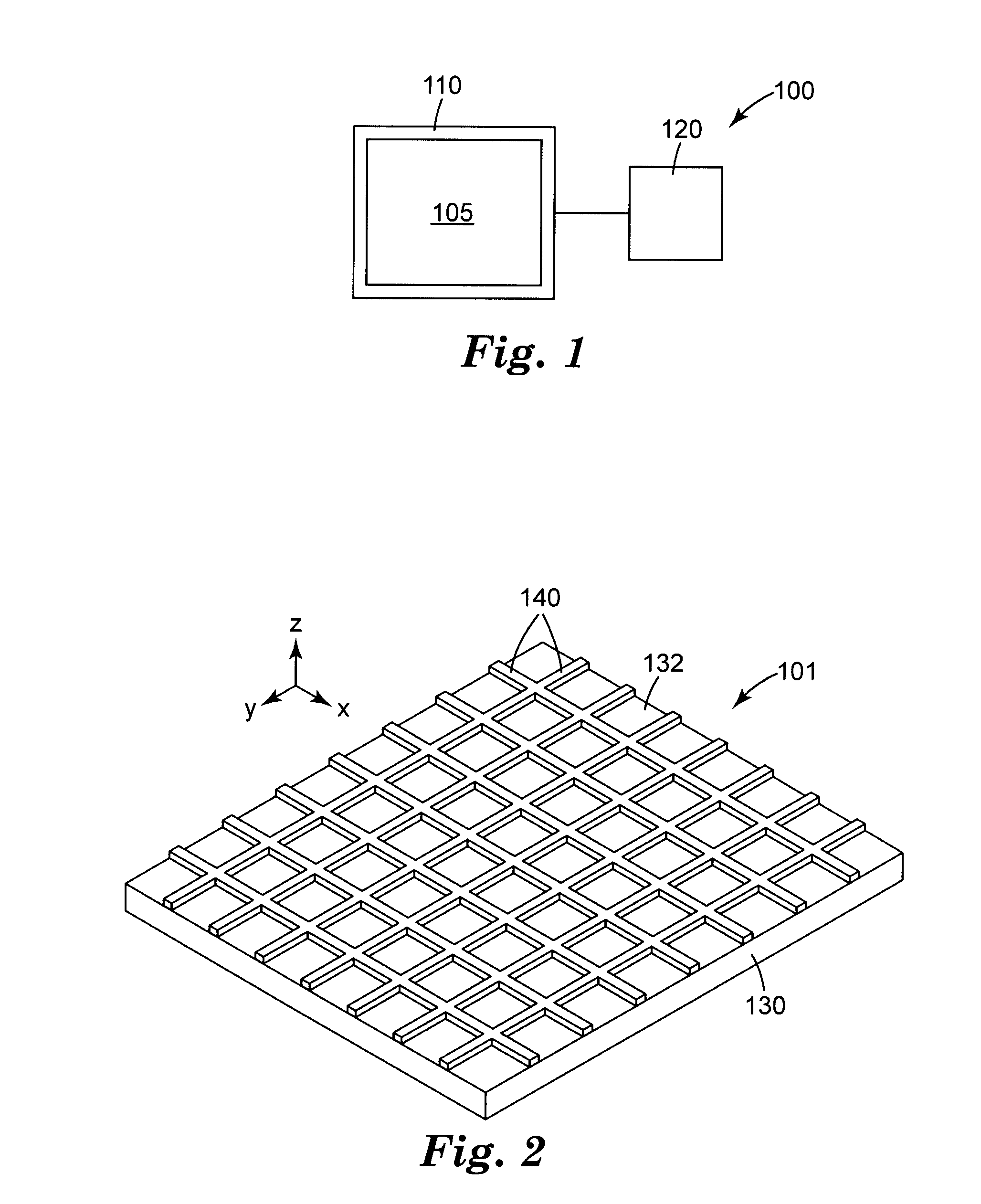

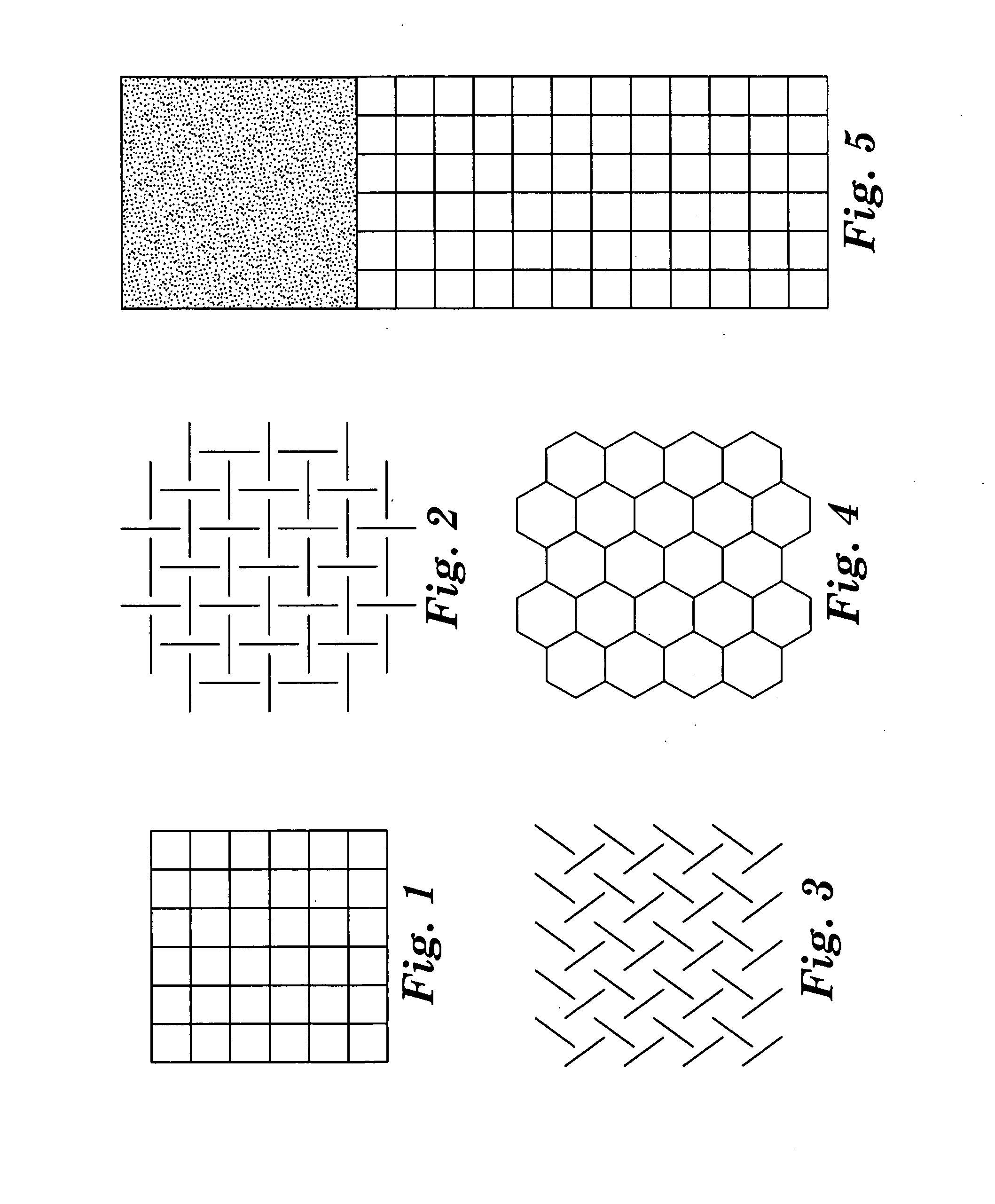

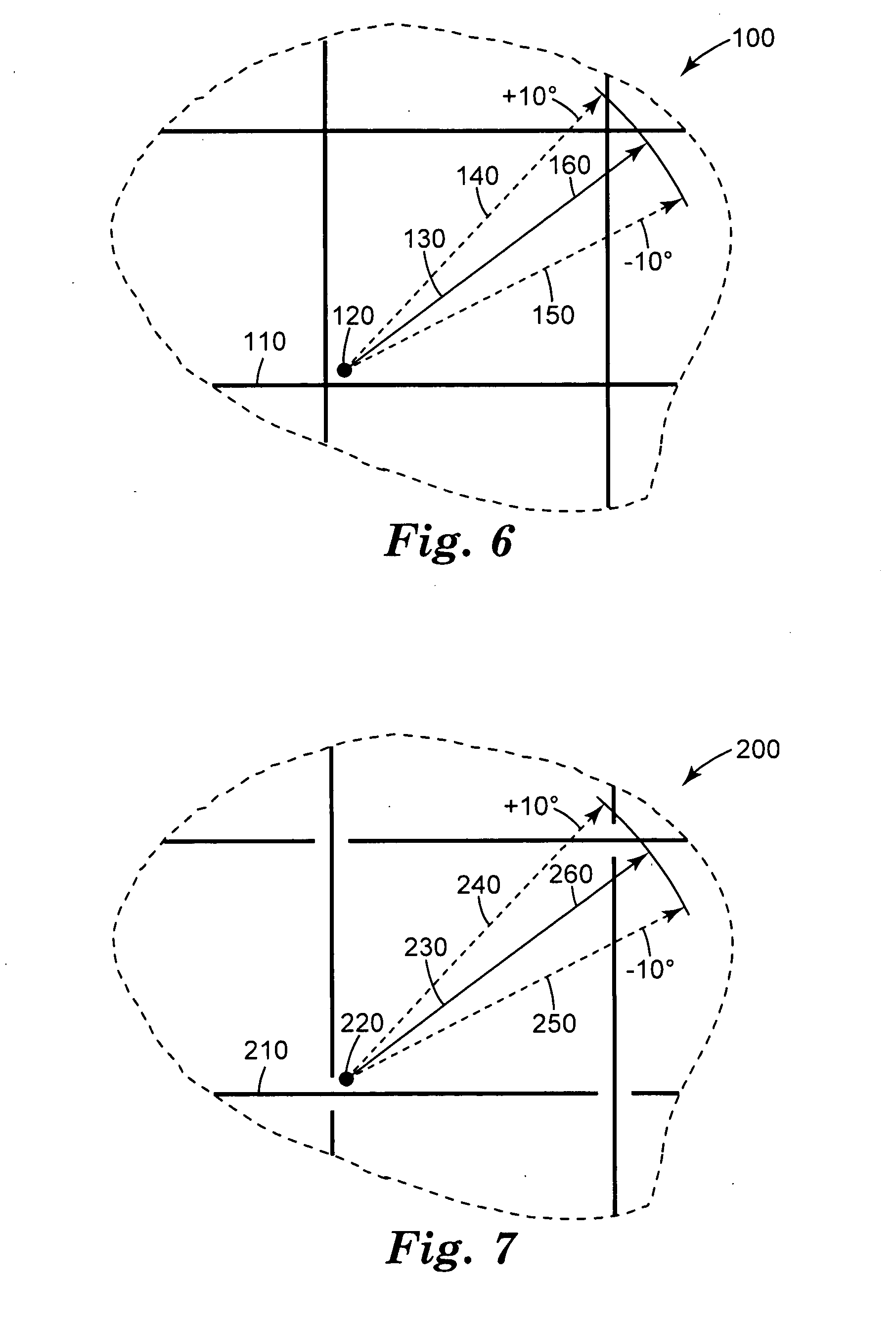

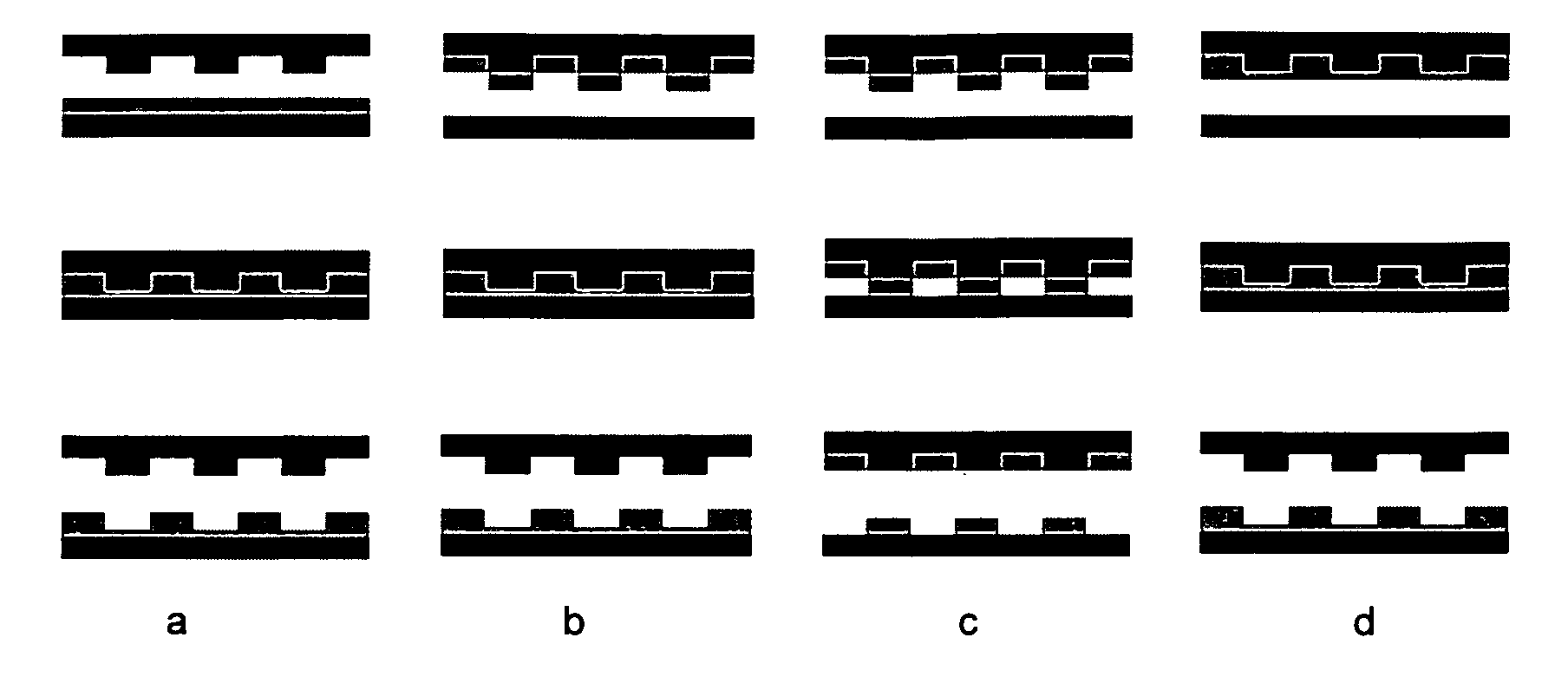

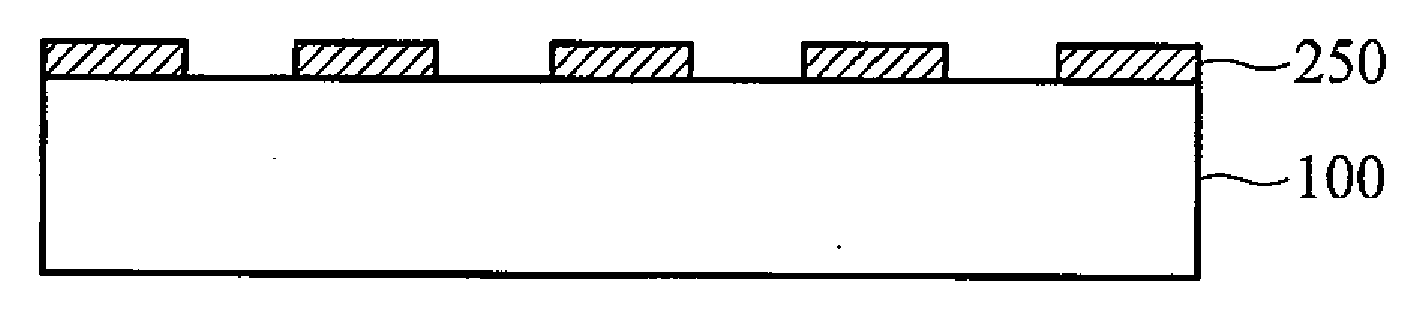

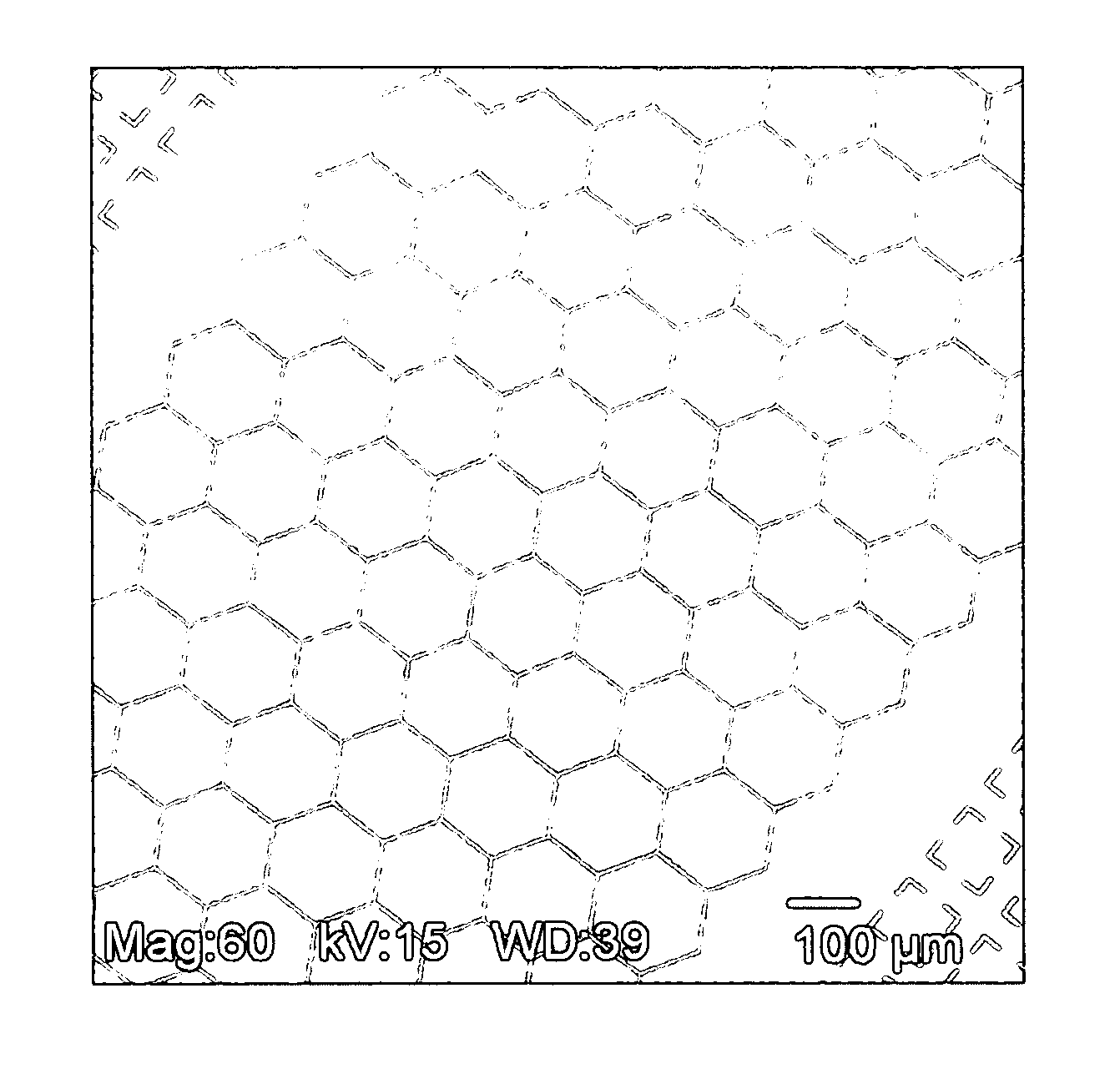

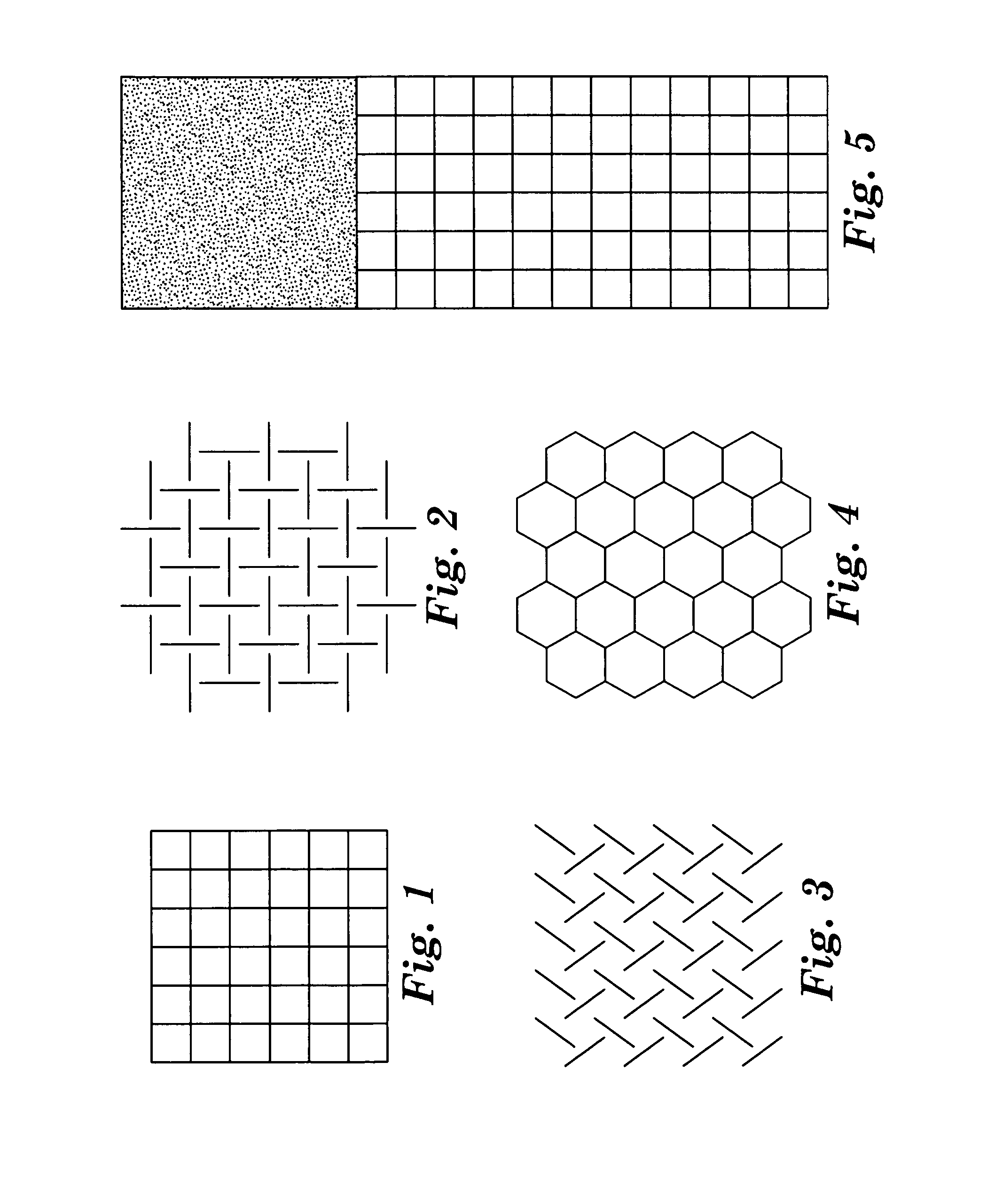

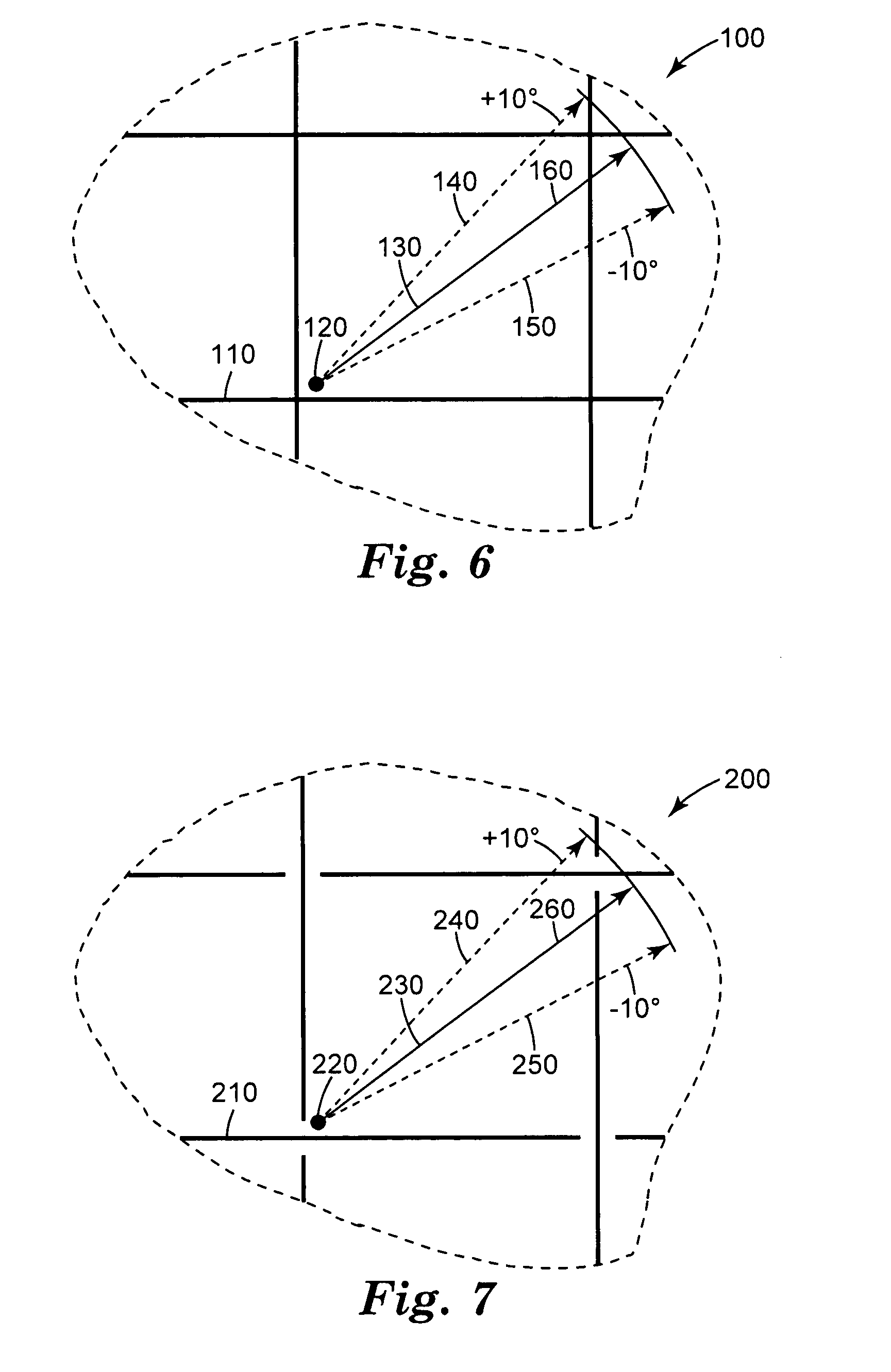

A touch screen sensor includes a visible light transparent substrate and an electrically conductive micropattern disposed on or in the visible light transparent substrate. The micropattern includes a first region micropattern within a touch sensing area and a second region micropattern. The first region micropattern has a first sheet resistance value in a first direction, is visible light transparent, and has at least 90% open area. The second region micropattern has a second sheet resistance value in the first direction. The first sheet resistance value is different from the second sheet resistance value.

Owner:3M INNOVATIVE PROPERTIES CO

Patterned coating method employing polymeric coatings

Patterned articles can be prepared by applying a release polymer to a substrate in a desired pattern, applying a substrate-adherent polymer over the pattern and substrate, and mechanically removing the substrate-adherent polymer from the pattern without requiring solvent. Suitable mechanical removal methods include applying adhesive tape to the substrate-adherent polymer and peeling the tape and substrate-adherent polymer away from the pattern, and abrading the substrate-adherent polymer from the pattern using impact media.

Owner:3M INNOVATIVE PROPERTIES CO

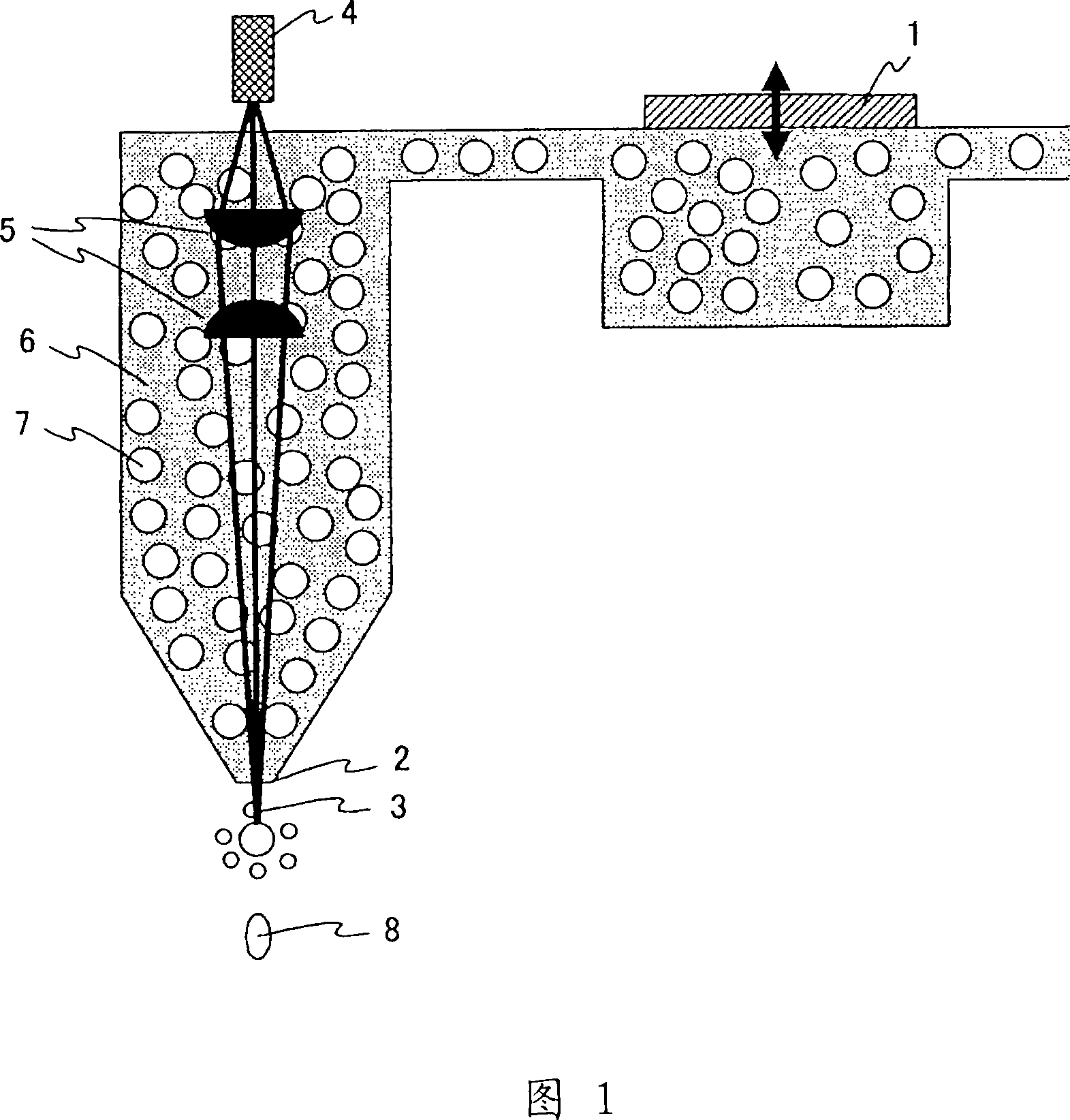

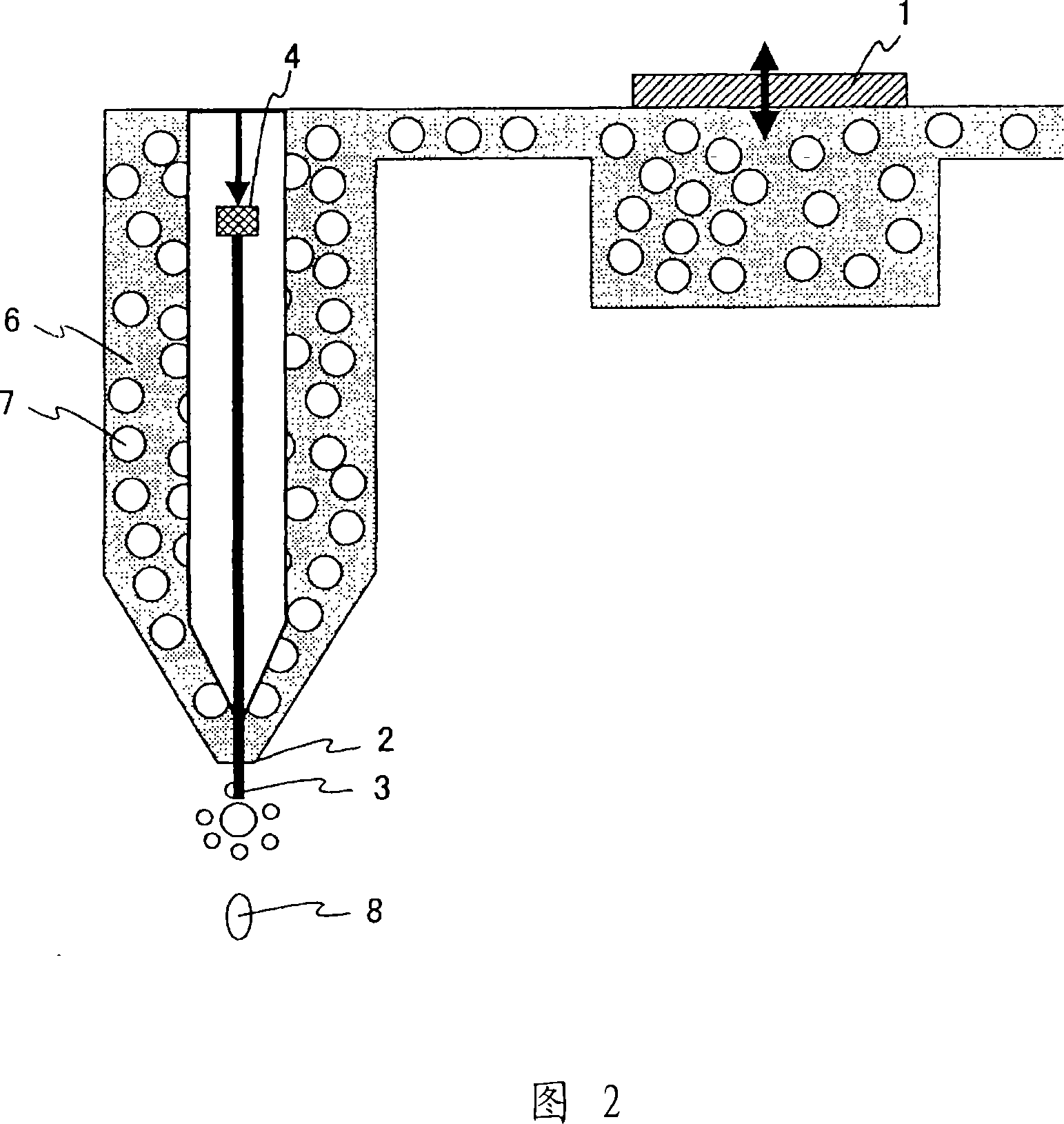

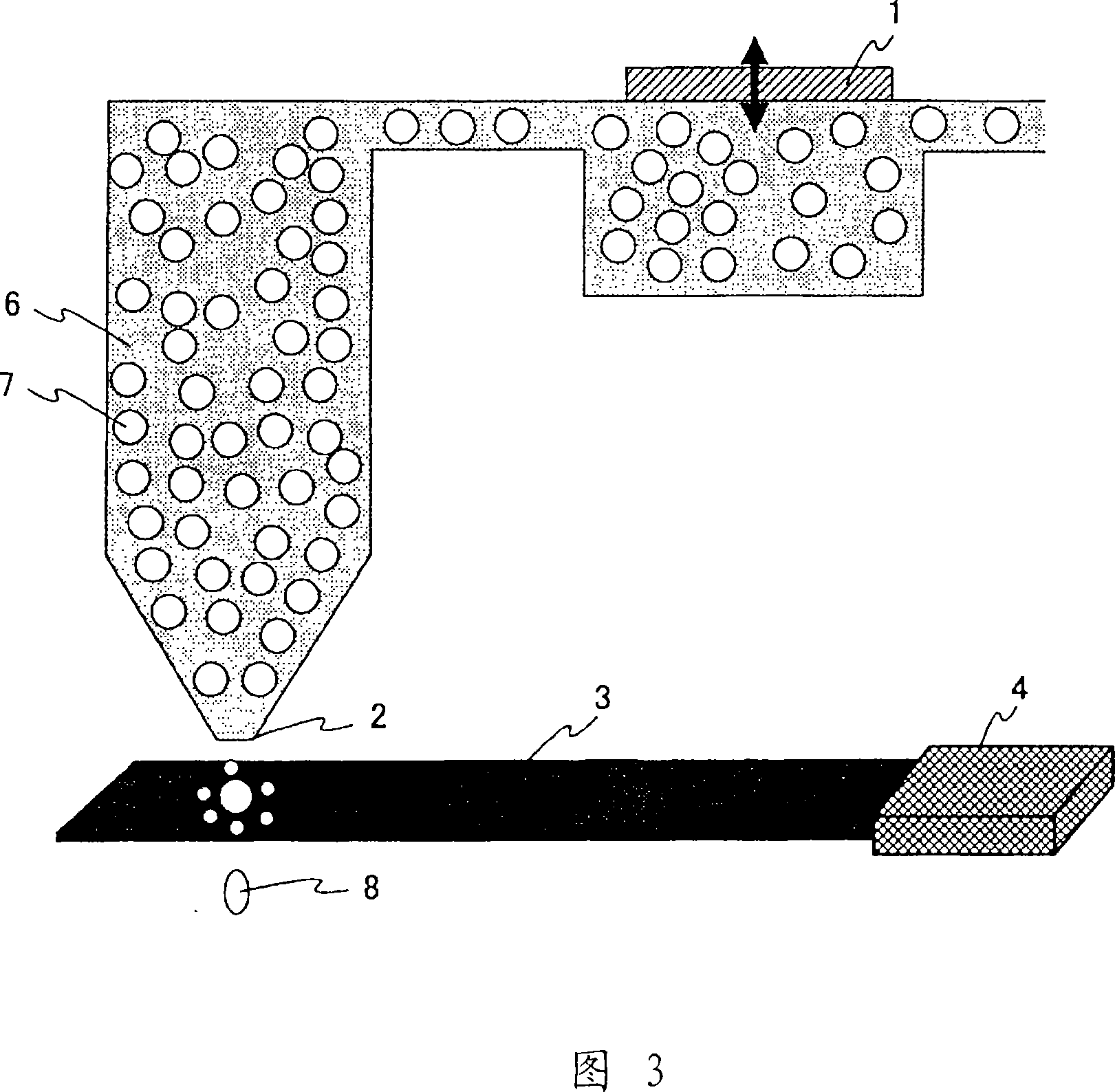

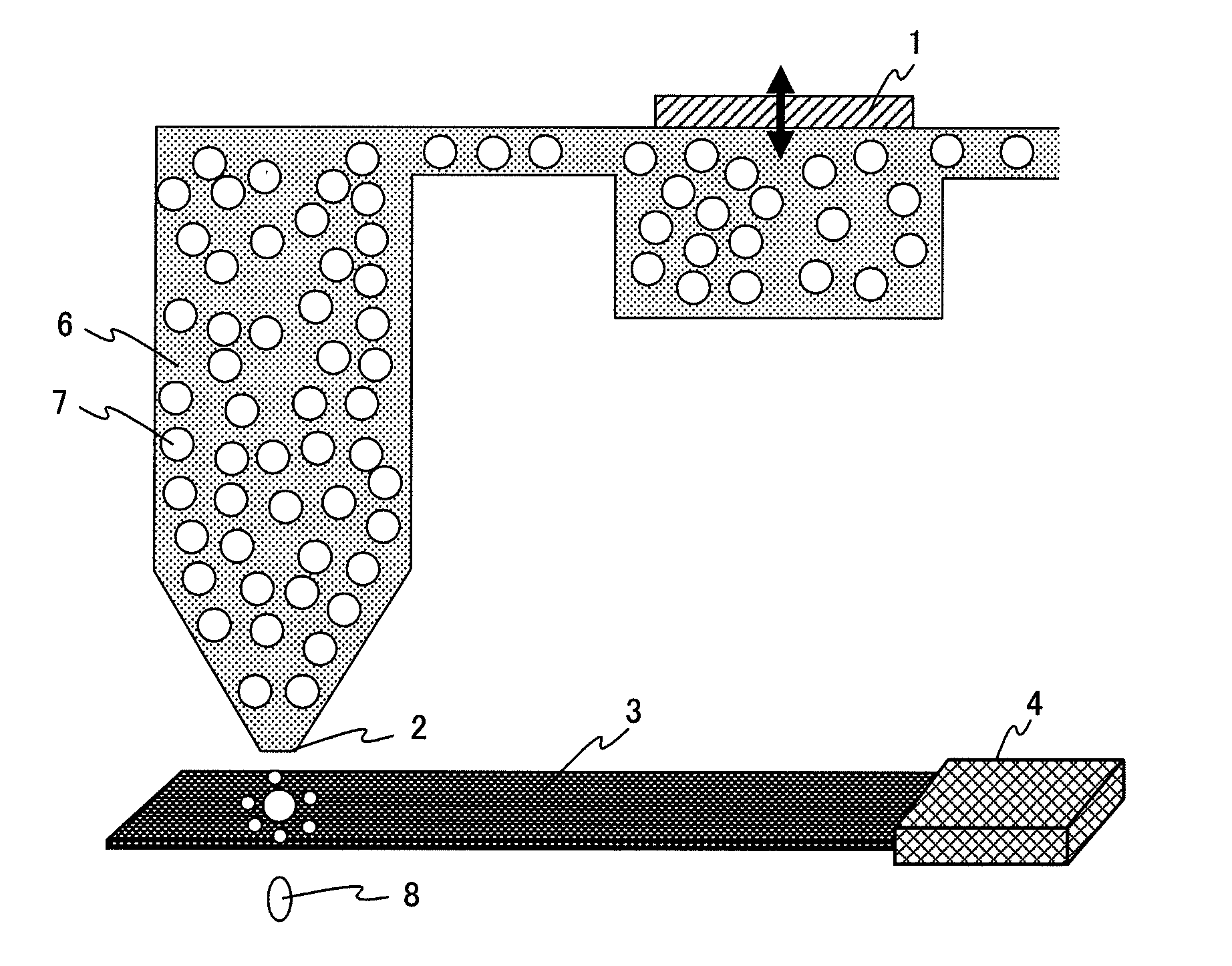

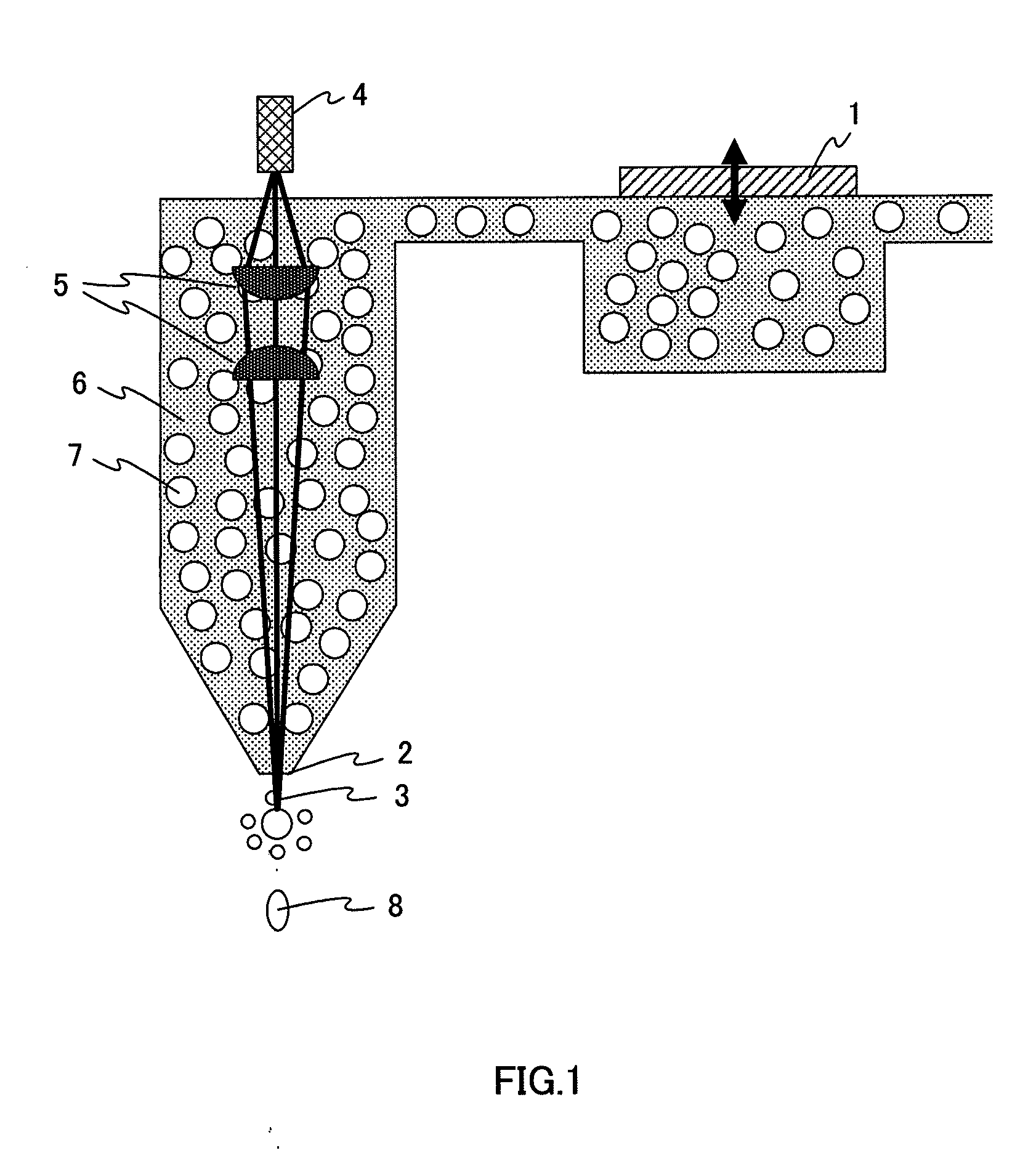

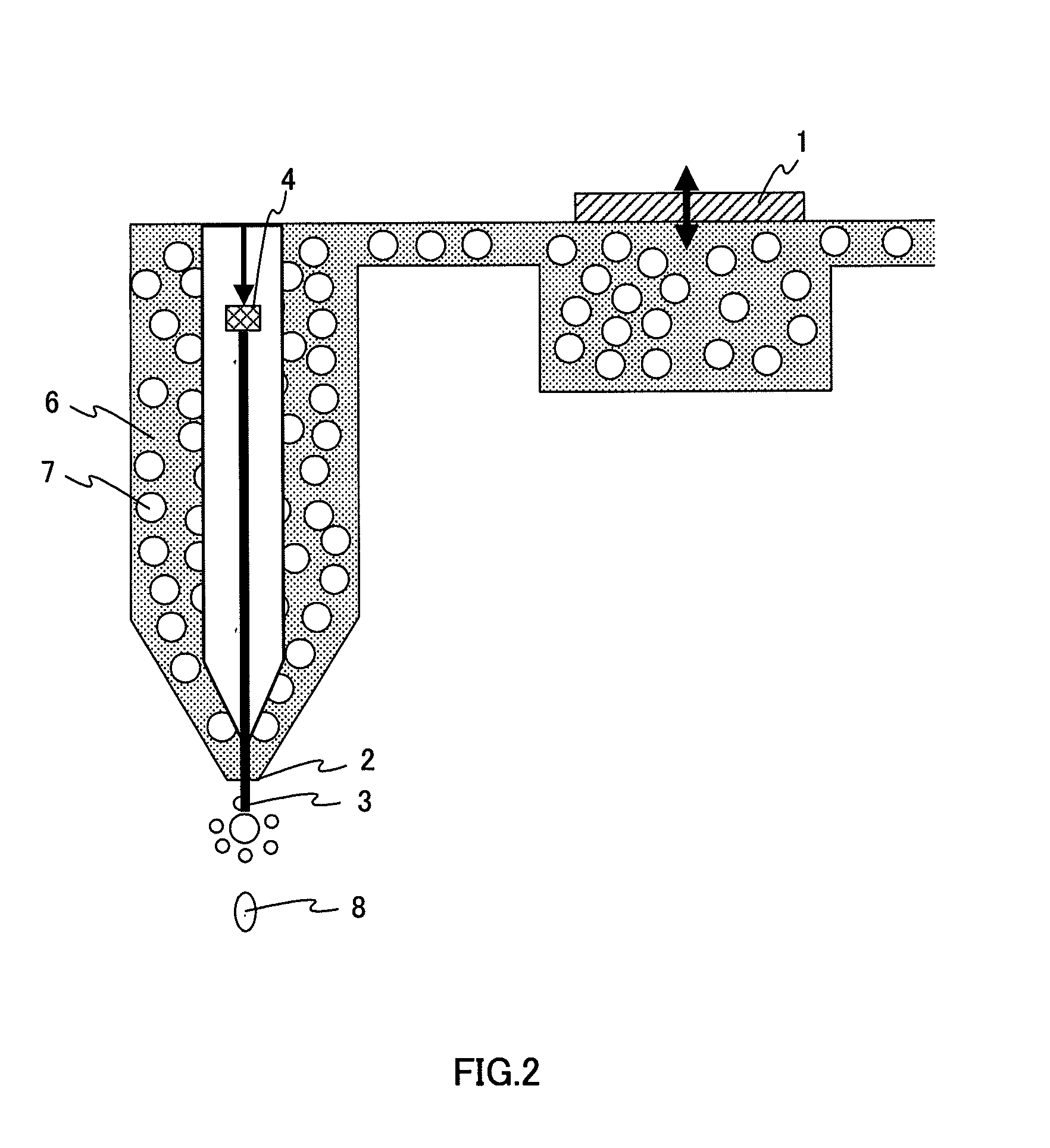

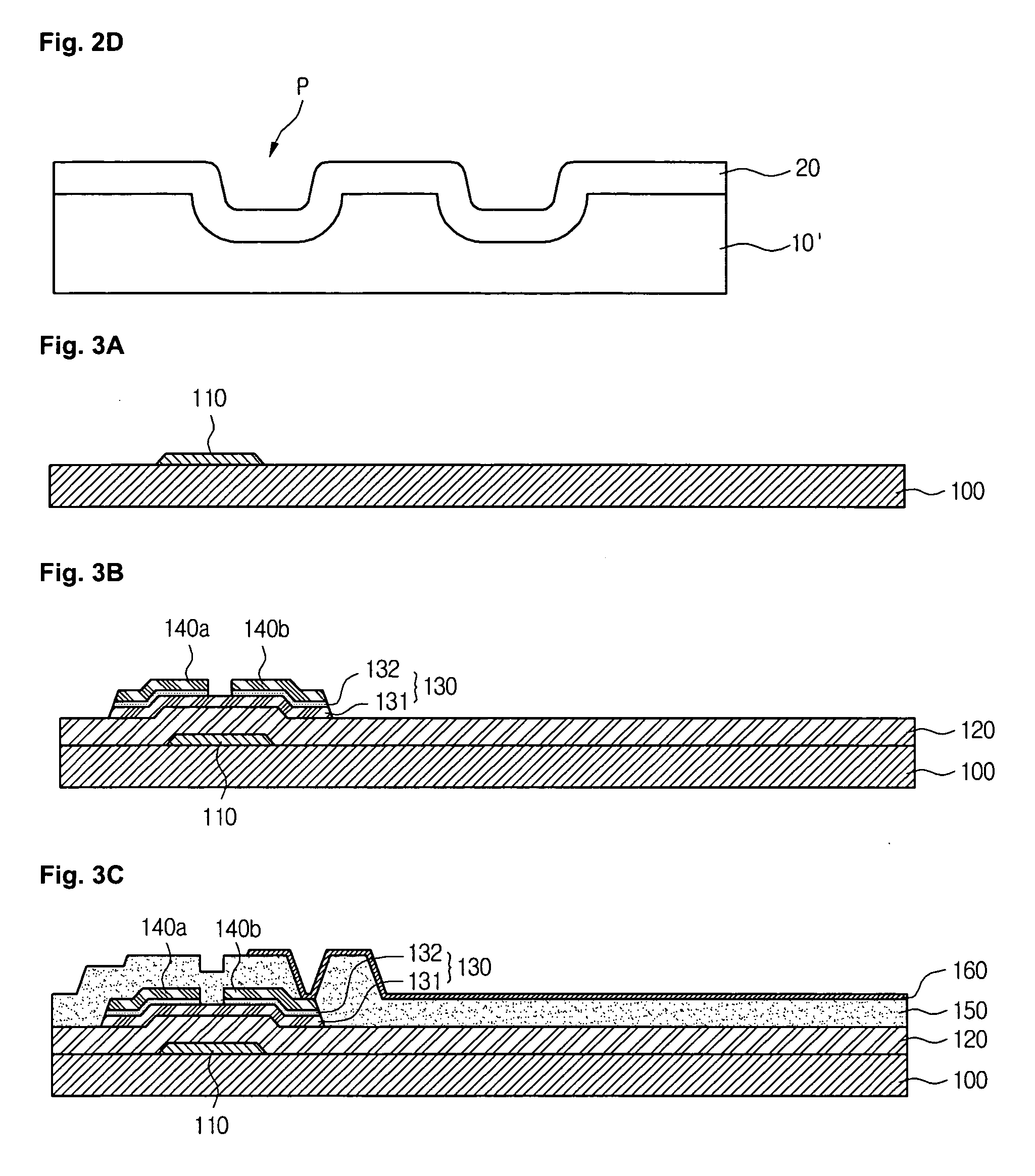

Method and apparatus for producing three-dimensional structure

ActiveCN101111362AEasy to manufactureMaterial nanotechnologySequential/parallel process reactionsPolymer scienceSolvent

The present invention aims to produce a three-dimensional structure having a high aspect ratio by using inkjet printing techniques or the like. Specifically, a three-dimensional structure is produced by ejecting a liquid drop of a solution, which contains a solvent and polymer particles dispersed in the solvent while having a viscosity of not more than 100 cps, from a nozzle onto a substrate; then evaporating the solvent and melting the polymer particles by irradiating the liquid drop with light; and then depositing the molten polymer particles on the substrate. The present invention can be applied to production of biochips and the like.

Owner:PANASONIC CORP

Laser resist transfer for microfabrication of electronic devices

A method for forming a resist pattern on a substrate (18) places a donor element (12) having a layer of thermoresist material proximate the substrate. A gap is maintained such that the surface of the layer of thermoresist material is spaced apart from the surface of the substrate by a number of spacing elements. Thermal energy is directed toward the donor element (12) according to the resist pattern, whereby a portion of thermoresist material is transferred from the donor element (12) across the gap by ablative transfer and is deposited onto the substrate (18) forming the resist pattern.

Owner:EASTMAN KODAK CO

Method and apparatus for producing three-dimensional structure

InactiveUS20090014916A1Easy to adaptHigh viscosityMaterial nanotechnologySequential/parallel process reactionsPolymer scienceSolvent

The present invention aims to produce a three-dimensional structure having a high aspect ratio by using inkjet printing techniques or the like. Specifically, a three-dimensional structure is produced by ejecting a liquid drop of a solution, which contains a solvent and polymer particles dispersed in the solvent while having a viscosity of not more than 100 cps, from a nozzle onto a substrate; then evaporating the solvent and melting the polymer particles by irradiating the liquid drop with light; and then depositing the molten polymer particles on the substrate. The present invention can be applied to production of biochips and the like.

Owner:PANASONIC CORP

Film applying apparatus

InactiveUS6136142ASmall rangeSecure bondingMechanical working/deformationLamination ancillary operationsSheet filmEngineering

A film applying apparatus is provided with preparatory bonding rolls, laminating rolls, a laminated film wound out from a film roll and a substrate conveyed by a substrate conveying device. The laminated film passes between these rolls and pressure bonding is performed. The diameter of the preparatory bonding rolls is made smaller than the diameter of the laminating rolls. The range of the elastically deformed area at the roll surface where the grasping of the substrate and the laminated film by the preparatory bonding rolls is begun, is made small, thereby limiting the range and reducing the generated amount of air holding or the like.

Owner:SOMAR CORP

Method for fabricating conductive pattern on flexible substrate and protective ink used therein

The invention discloses a method for fabricating a conductive pattern on a flexible substrate. A flexible substrate having a conductive layer thereon is provided. A protective ink is screen printed on the conductive layer, wherein a portion of the conductive layer is exposed through the protective ink. The exposed portion of the conductive layer is removed by etching using the protective ink as a mask. The protective ink is then removed, thus providing a conductive pattern with a minimum line width of not greater than 150 μm. The invention also discloses a composition for the protective ink.

Owner:IND TECH RES INST

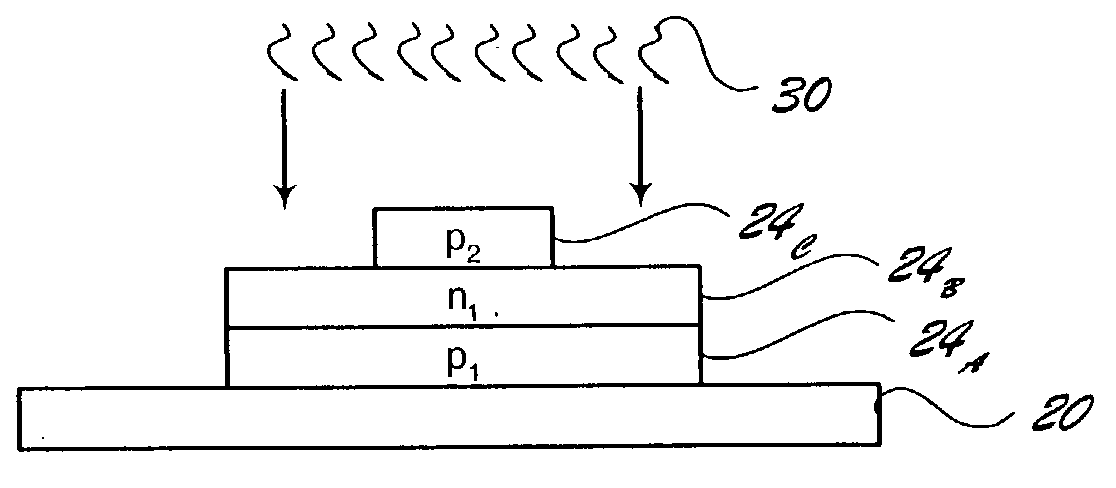

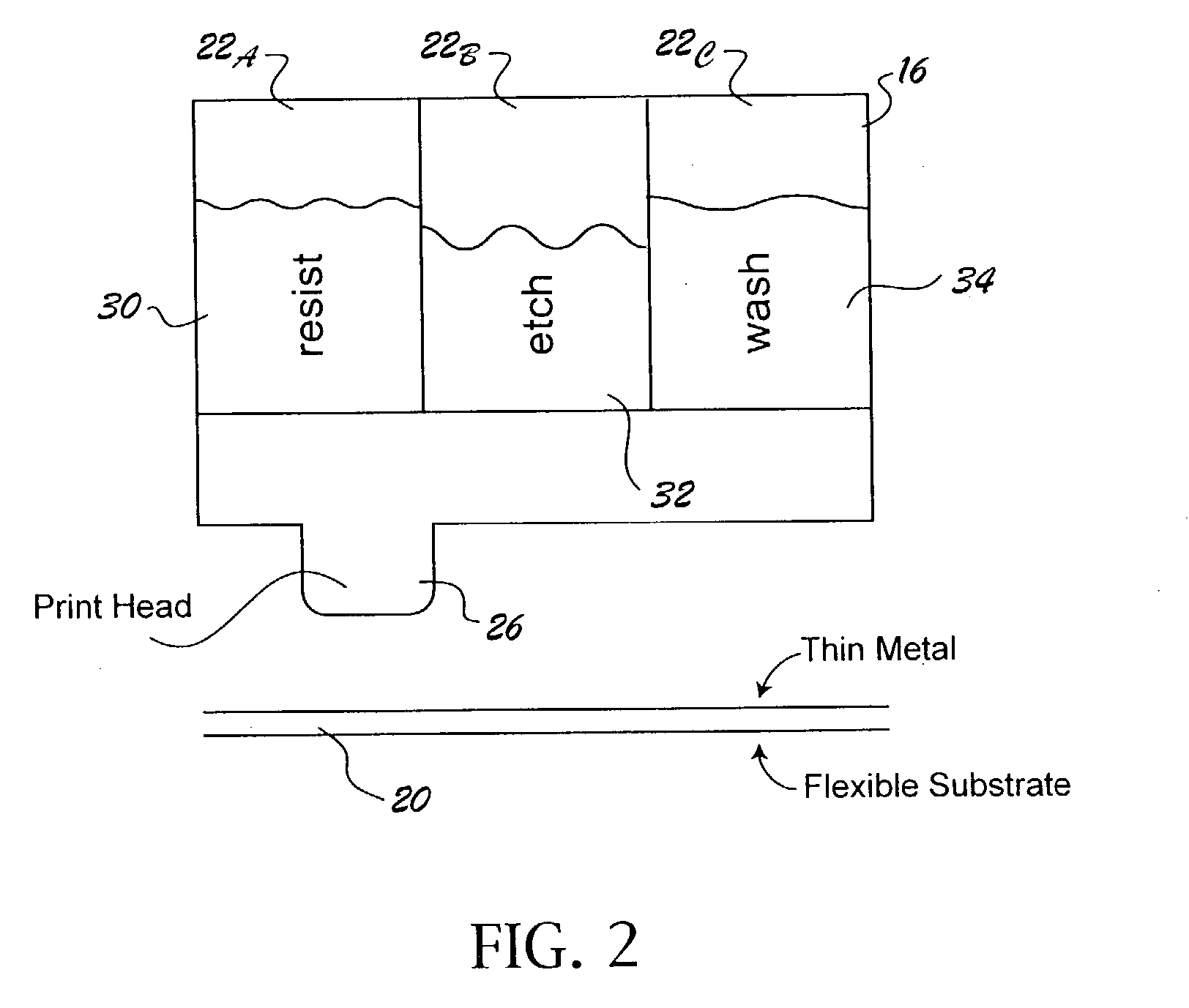

Conductive component manufacturing process employing an ink jet printer

InactiveUS20040077112A1Reduce expensesImprove connection densitySemiconductor/solid-state device manufacturingConductive pattern formationPrinted circuit boardSemiconductor

The present invention relates to conductive components manufacturing processes employing conventional direct transfer printers to make components such as printer circuit boards and semiconductors, by way of non-limiting example. The process disclosed allow for the production of customized conductive components, particularly prototype components, utilizing in a convenient, cost effective manner.

Owner:HEWLETT PACKARD DEV CO LP

Curable composition, film, and method of producing film

ActiveUS20160160003A1Fast filling speedGood release effectImpression capsDecorative surface effectsOrganic chemistryPolymerization

Provided is a curable composition, including a polymerization initiator; a polymerizable compound; and an internal addition type release agent having a hydrophilic functional group, in which the internal addition type release agent is prevented from being unevenly distributed in a gas-liquid interface of the curable composition.

Owner:CANON KK

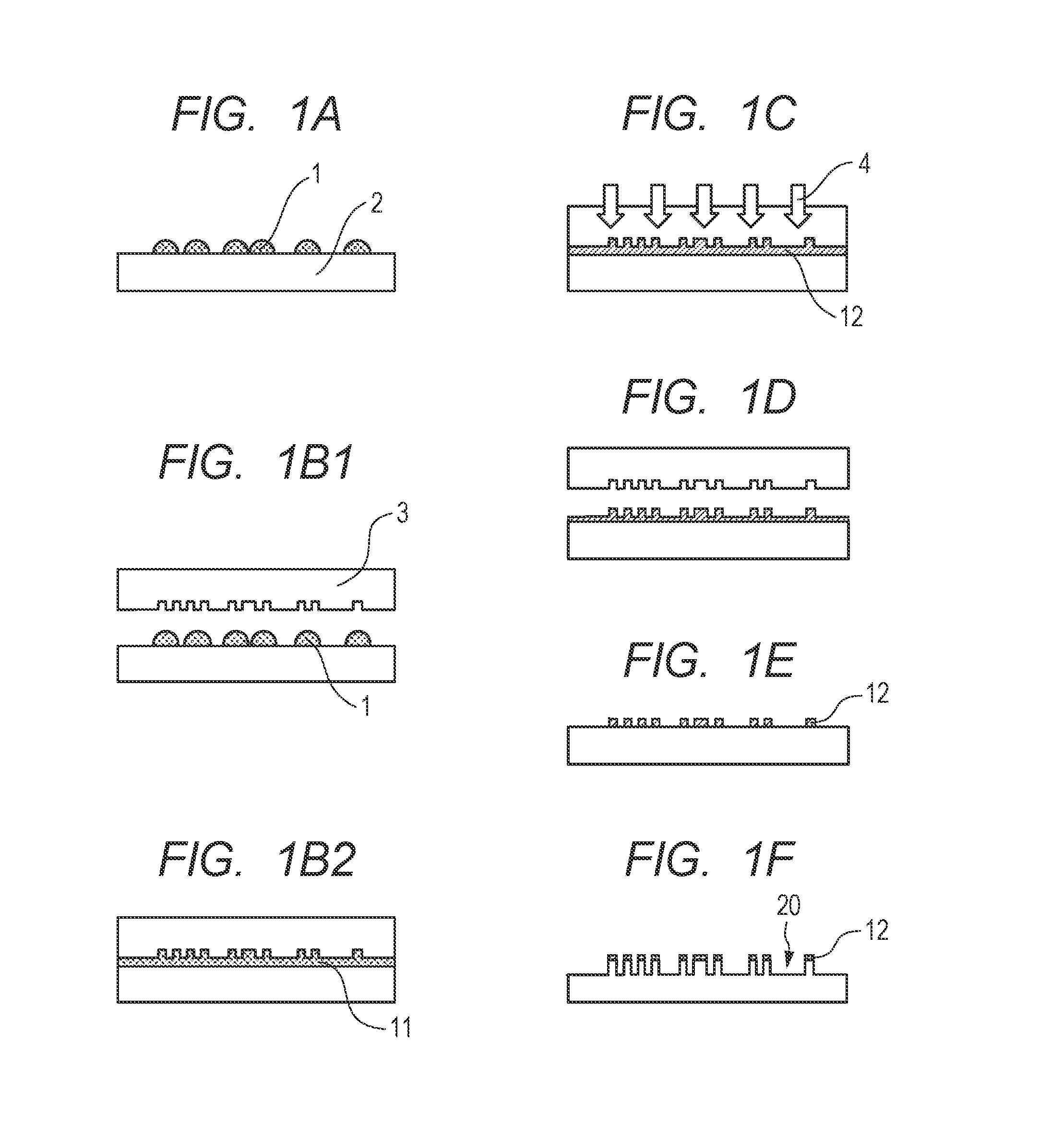

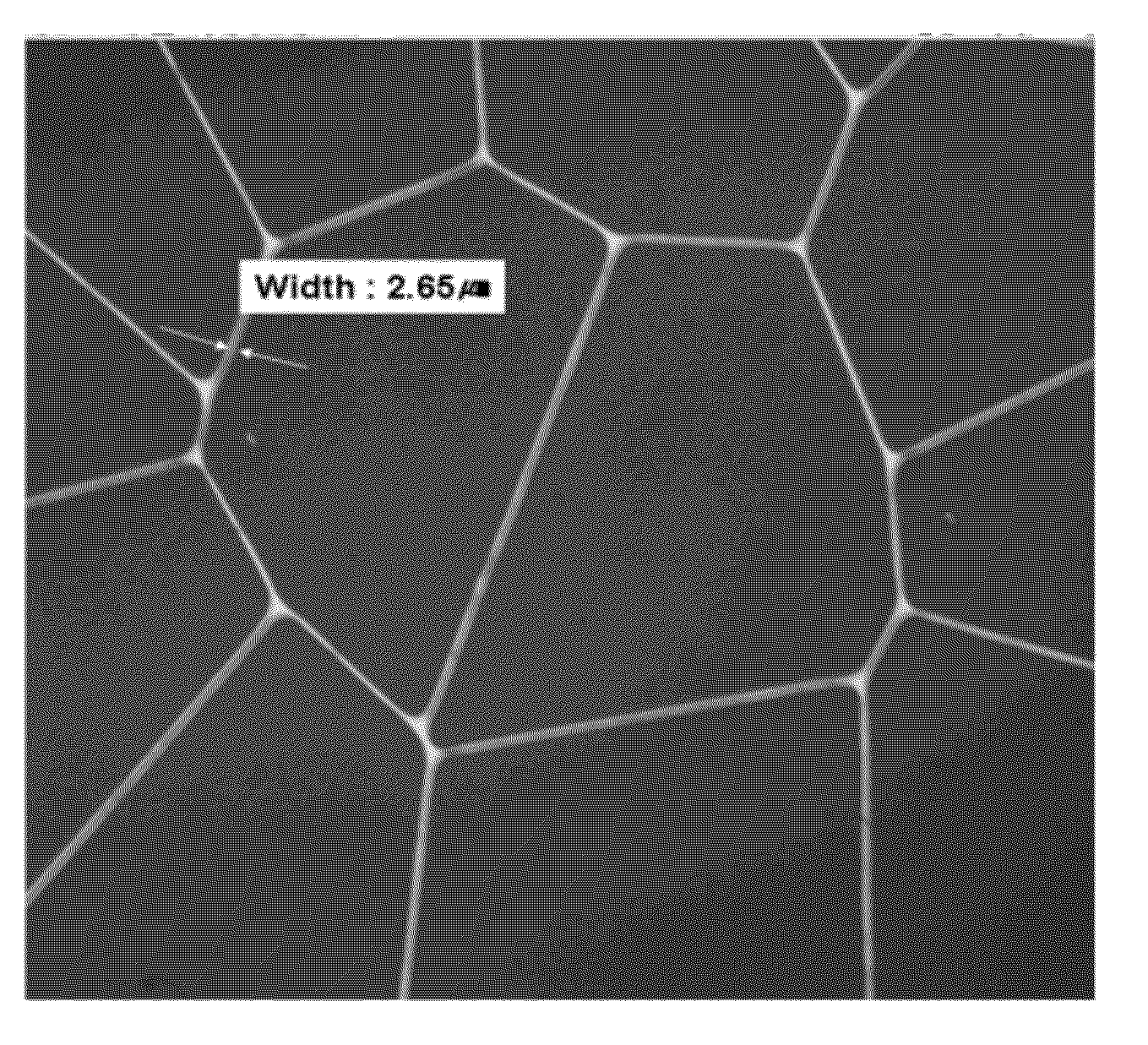

Conductive pattern and manufacturing method thereof

ActiveUS20120031647A1Thin line widthEasy to implementDual purpose resistPhotosensitive material processingResistElectrically conductive

The present invention provides a method for manufacturing a conductive pattern, comprising the steps of: a) forming a conductive film on a substrate; b) forming an etching resist pattern on the conductive film; and c) forming a conductive pattern having a smaller line width than a width of the etching resist pattern by over-etching the conductive film by using the etching resist pattern, and a conductive pattern manufactured by using the same. According to the exemplary embodiment of the present invention, it is possible to effectively and economically provide a conductive pattern having a ultrafine line width.

Owner:LG CHEM LTD

Inkjet printer

InactiveUS20050024424A1Smooth dischargeHigh viscosityTypewritersConductive pattern formationResistComputer printing

An inkjet printer which can be used for printing a resist pattern on a printed circuit board when wiring patterns are to be formed on the board. The inkjet printer has a liquid ejecting head which comprises: a liquid chamber filled with liquid and connected to a liquid storage tank; a capillary nozzle connected to the liquid chamber; a discharge unit for acting on the liquid filled in the liquid chamber to eject the liquid through an outlet of the capillary nozzle toward an object to be printed; and a negative pressure generating unit for applying a negative pressure in a direction in which the liquid is ejected from the outlet of the capillary nozzle. Due to the application of negative pressure, a liquid having a viscosity higher than that of a general ink can be ejected.

Owner:SHINKO ELECTRIC IND CO LTD

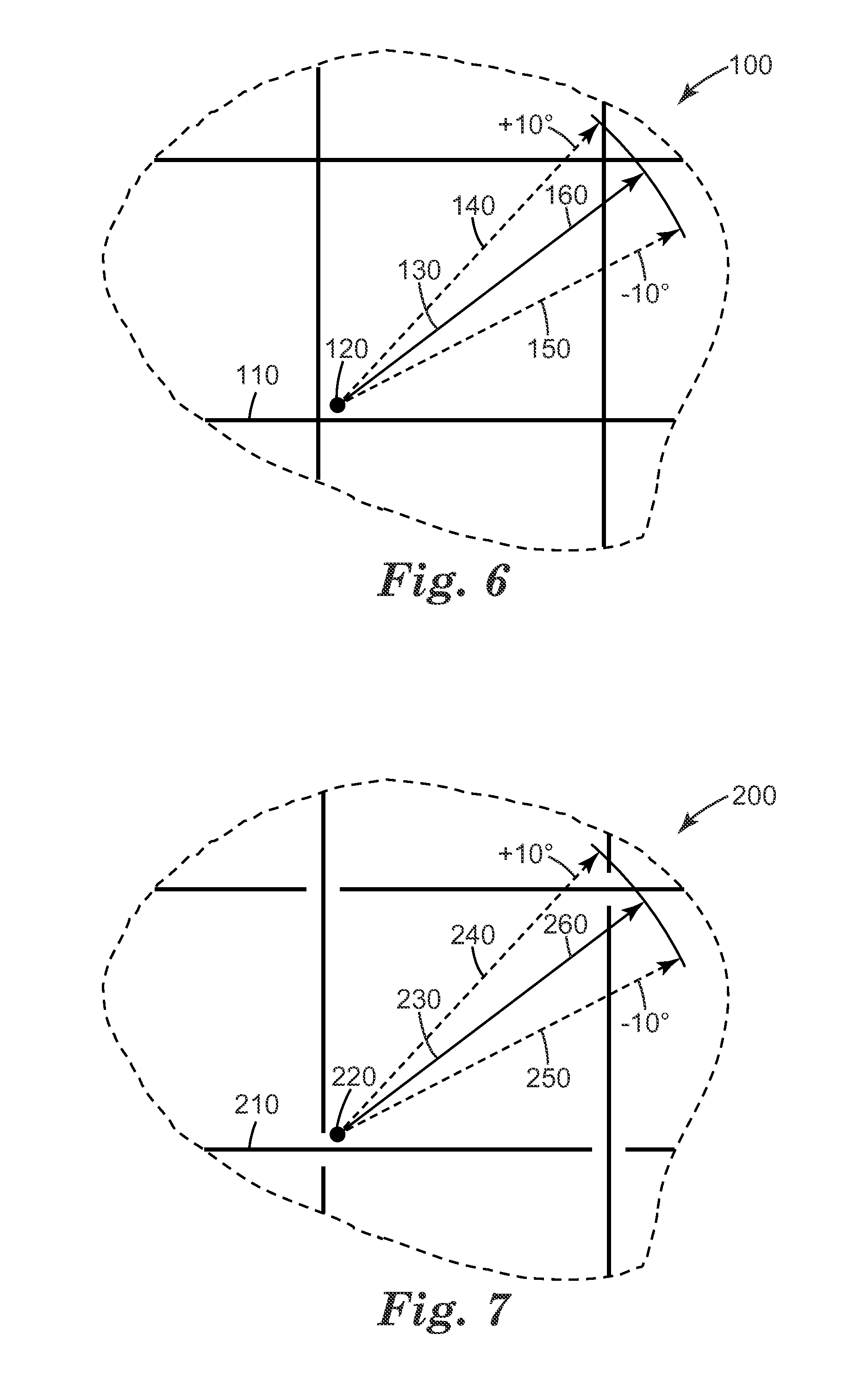

Methods of patterning a conductor on a substrate

InactiveUS8425792B2Decorative surface effectsNanoinformaticsElectrical conductorSelf-assembled monolayer

A method of patterning a conductor on a substrate includes providing an inked elastomeric stamp inked with self-assembled monolayer-forming molecules and having a relief pattern with raised features. Then the raised features of the inked stamp contact a metal-coated visible light transparent substrate. Then the metal is etched to form an electrically conductive micropattern corresponding to the raised features of the inked stamp on the visible light transparent substrate.

Owner:3M INNOVATIVE PROPERTIES CO

UV curable powder suitable for use as a photoresist

InactiveUS20030170568A1High resolutionMaximum sensitivityPhotosensitive materialsSemiconductor/solid-state device manufacturingPhotoinitiatorPhotoresist

The invention relates to a radiation curable powder photoresist composition comprising the components A a polymer, B a reactive compound having unsaturated groups and C a free radical photoinitiator, wherein the powder photoresist composition is soluble in a developer and wherein the powder photoresist composition has a Tg between 40 and 120° C.

Owner:DSM IP ASSETS BV

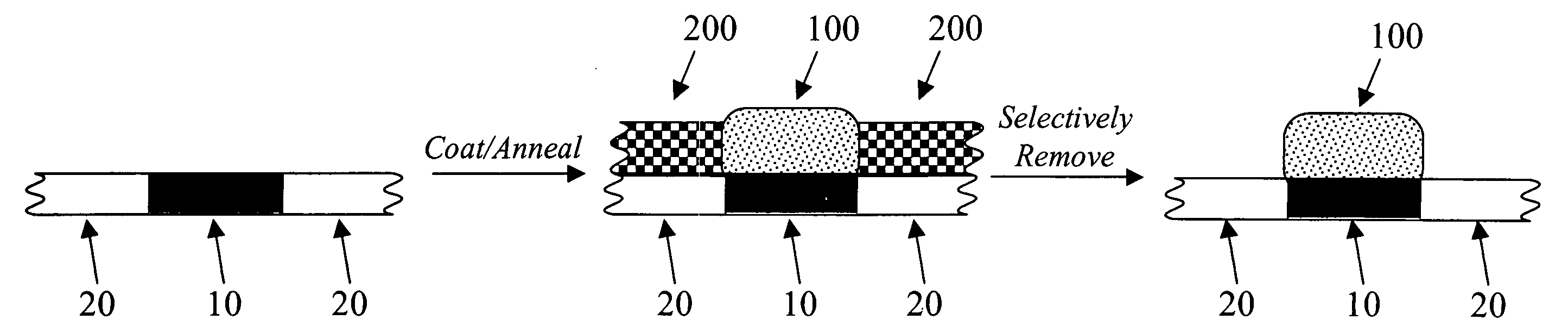

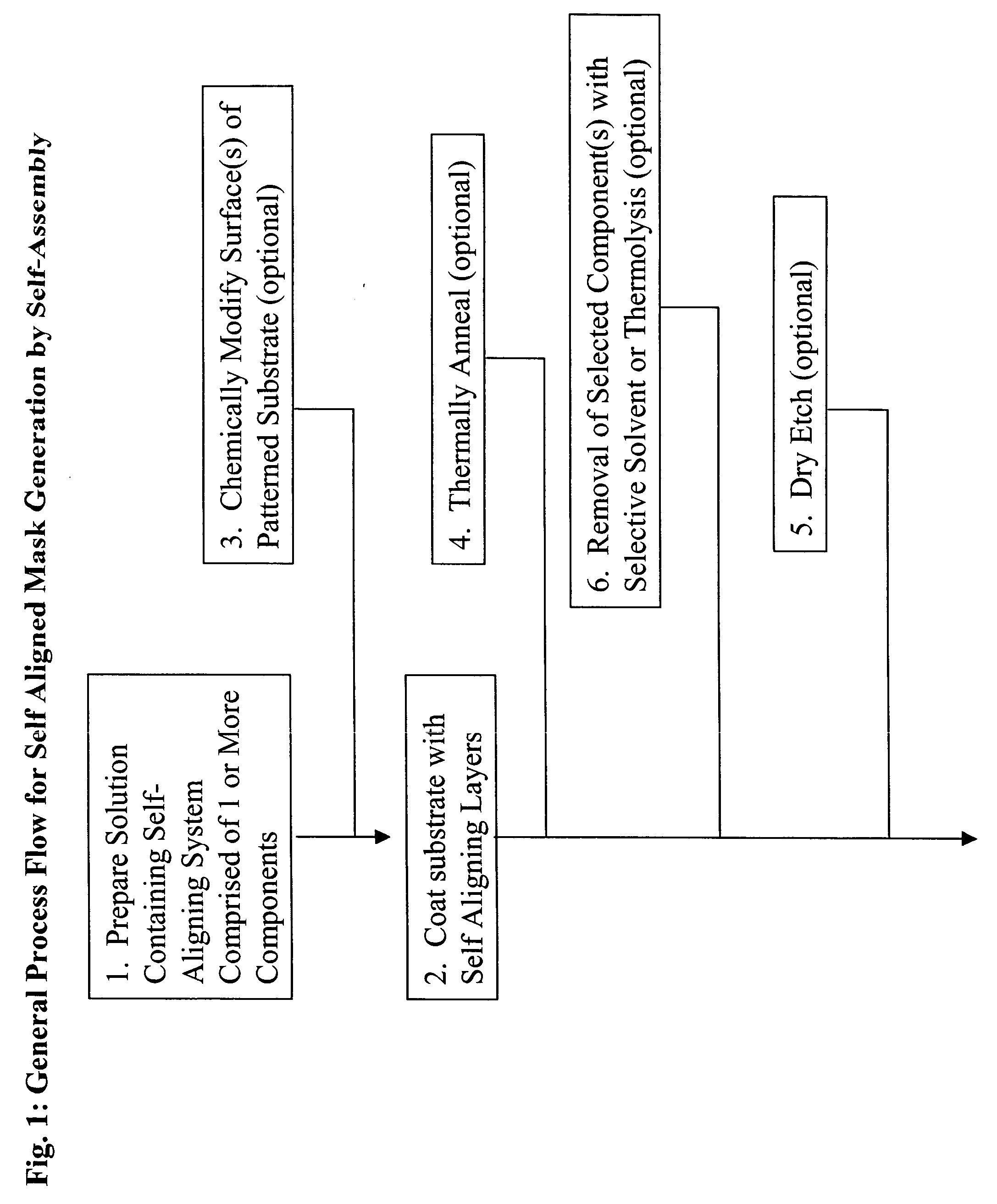

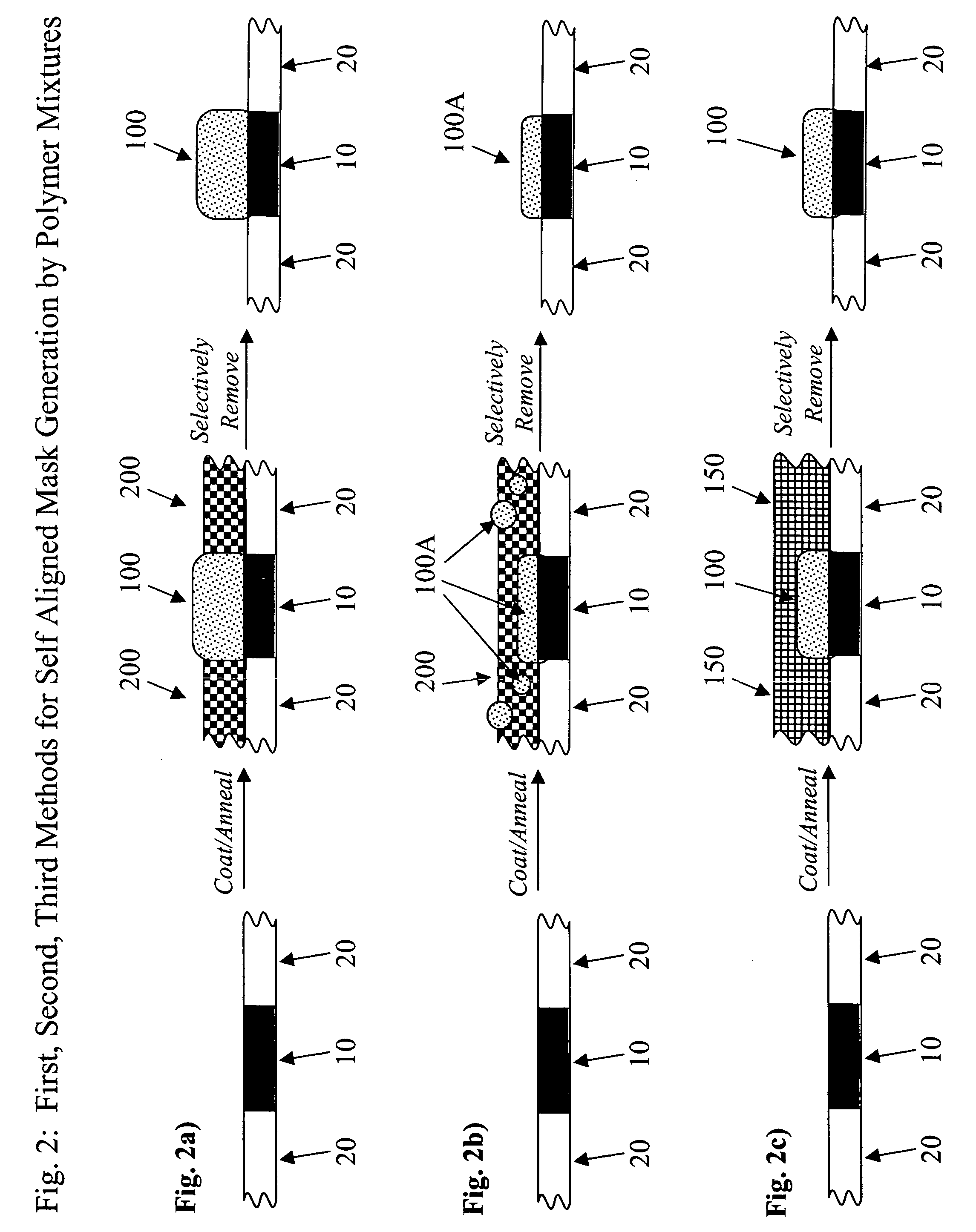

Nonlithographic method to produce self-aligned mask, articles produced by same and compositions for same

InactiveUS20050233597A1Simple and robustSpeed maximizationLayered productsSemiconductor/solid-state device manufacturingDielectricAtomic composition

Owner:GLOBALFOUNDRIES INC

Methods of patterning a conductor on a substrate

InactiveUS20130277330A1NanoinformaticsPhotomechanical apparatusElectrical conductorSelf-assembled monolayer

A method of patterning a conductor on a substrate includes providing an inked elastomeric stamp inked with self-assembled monolayer-forming molecules and having a relief pattern with raised features. Then the raised features of the inked stamp contact a metal-coated visible light transparent substrate. Then the metal is etched to form an electrically conductive micropattern corresponding to the raised features of the inked stamp on the visible light transparent substrate.

Owner:3M INNOVATIVE PROPERTIES CO

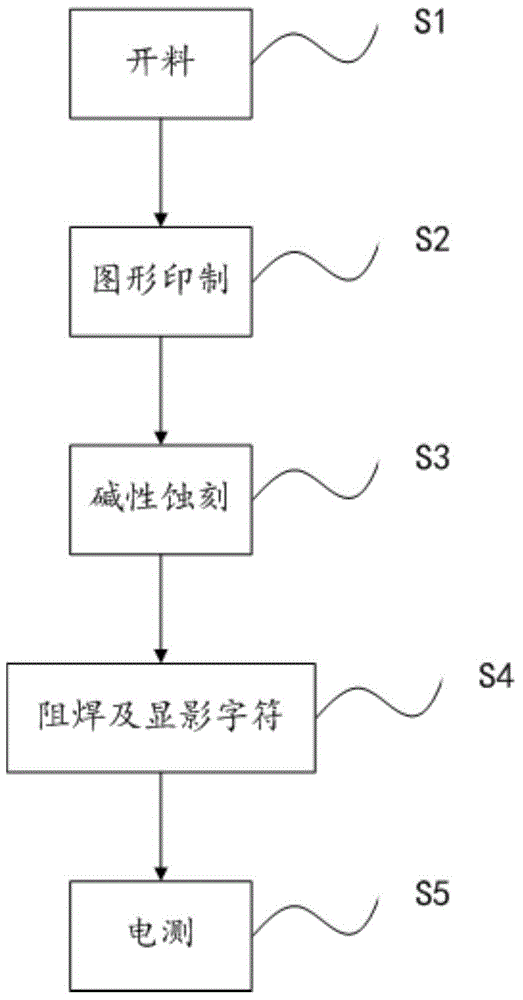

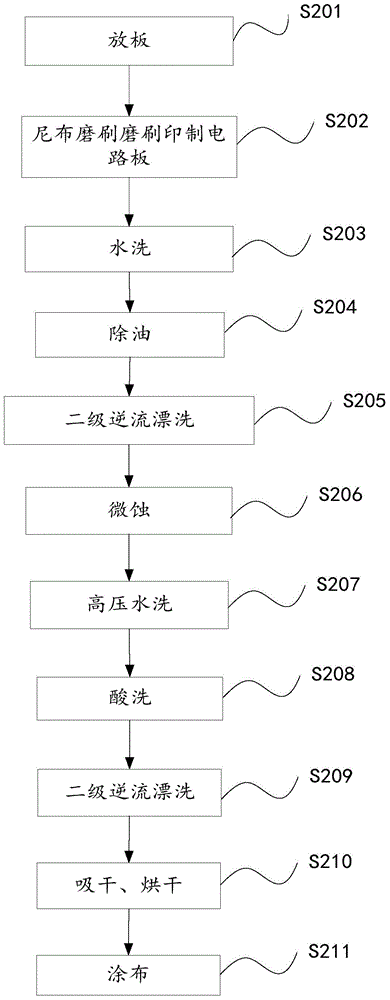

Printed circuit board manufacturing method

ActiveCN104619122ASimple processShorten production timeConductive material chemical/electrolytical removalNon-metallic protective coating applicationScreen printingElectricity

The invention relates to a printed circuit board manufacturing method which includes the steps: S1 cutting to form a jointed board comprising an inner base board and copper foils attached to the upper surface and the lower surface of the inner base board; S2 printing graphics by the aid of a wet film; S3 performing alkaline etching; S4 performing resistance welding and developing characters; S5 performing electric test. A green oil exposure developing character mode replaces a screen printing character mode in the prior art, the process is simpler, production time is greatly shortened, and production cost is reduced. Besides, compared with a dry film mode in the prior art, the graphics are printed by the aid of the wet film without trans-department coordinative operation, production cost is reduced, and production cycle is shortened.

Owner:HUIZHOU XINGZHIGUANG TECH

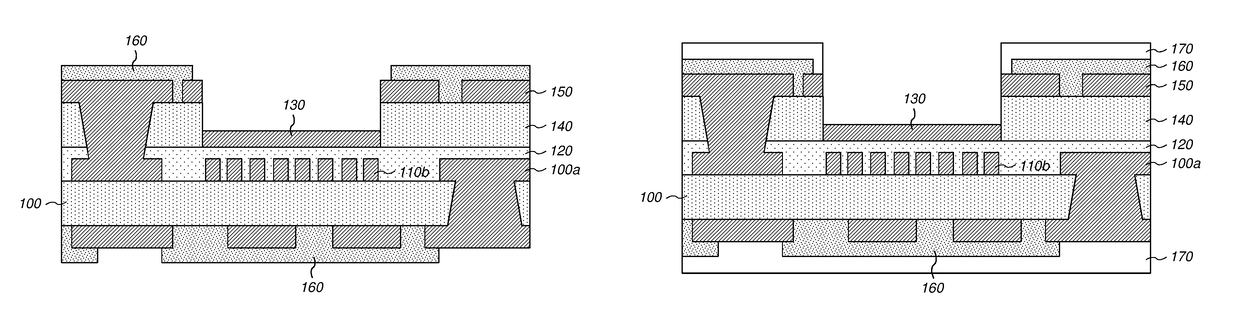

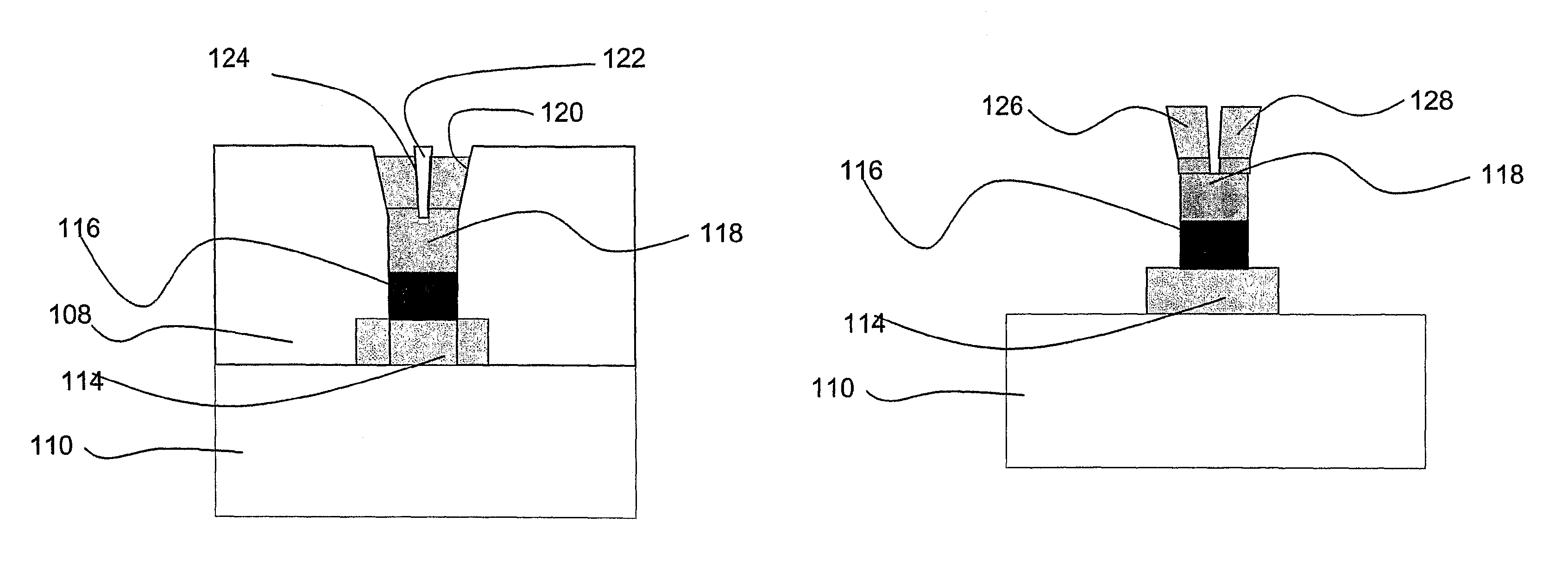

Method of manufacturing printed circuit board

ActiveUS10103113B2Improve integration densityReduce manufacturing costPrinted circuit assemblingSemiconductor/solid-state device detailsEngineeringLaser damage

A step of forming bump pads on the surface of the substrate corresponding to the cavity region, and covering the whole surface with a second insulating layer, forming a copper barrier on the surface of a second insulating layer corresponding to the cavity region for protection of the second insulating layer, forming a third insulating layer, and forming a copper layer for electrical circuit. A mask is formed on the copper later of the external circuit so that only the cavity region is exposed. The cavity is formed by laser-drilling only the surface-exposed area of the third insulating layer. The bottom copper layer protects the second insulating layer and bump pads underneath from laser damages. The copper barrier is removed by chemical etch after the laser drill. The second insulating layer with the bottom surface exposed will be removed via sand blast process, exposing the bump pads fabricated.

Owner:DAEDUCK ELECTRONICS

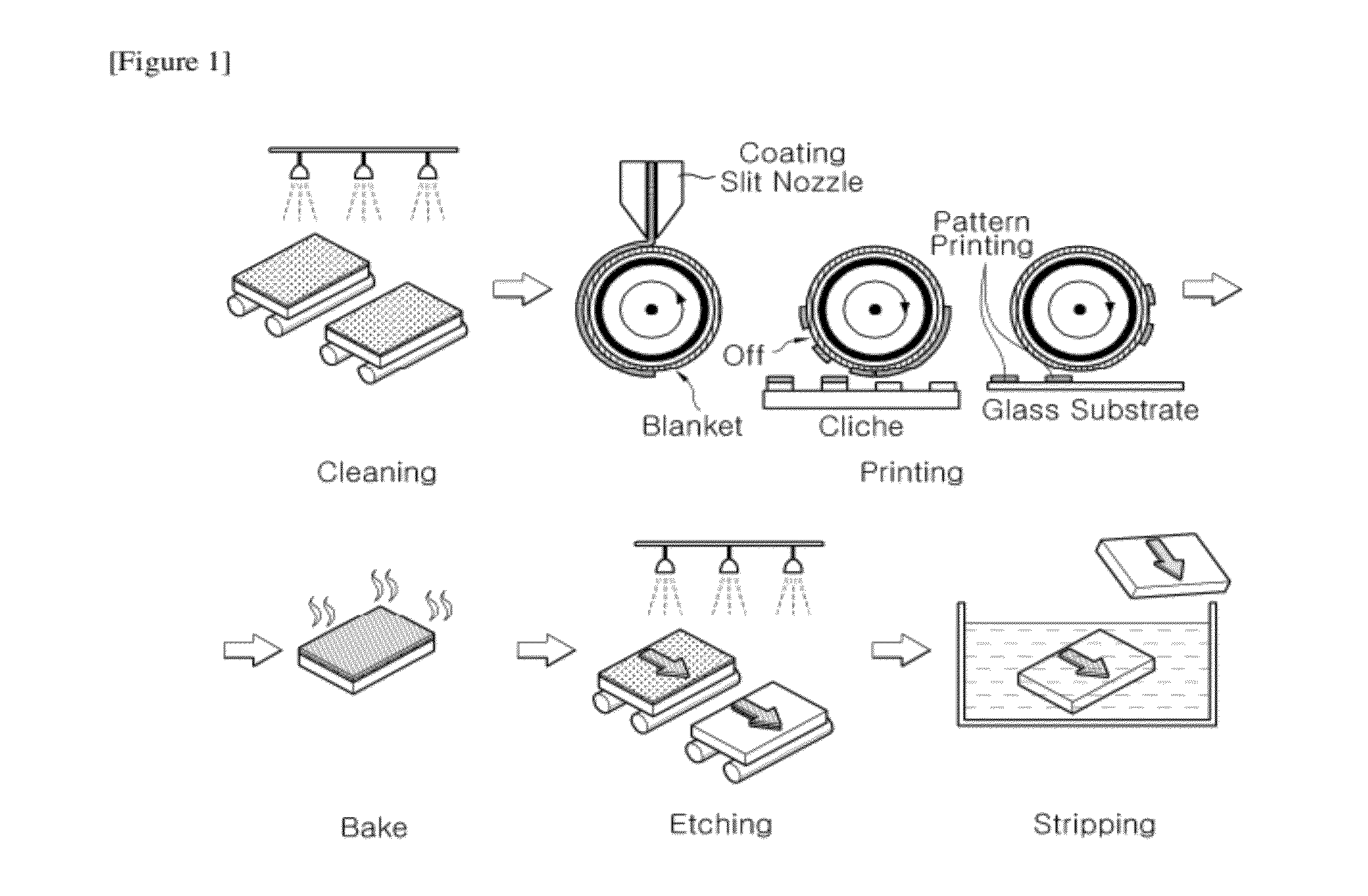

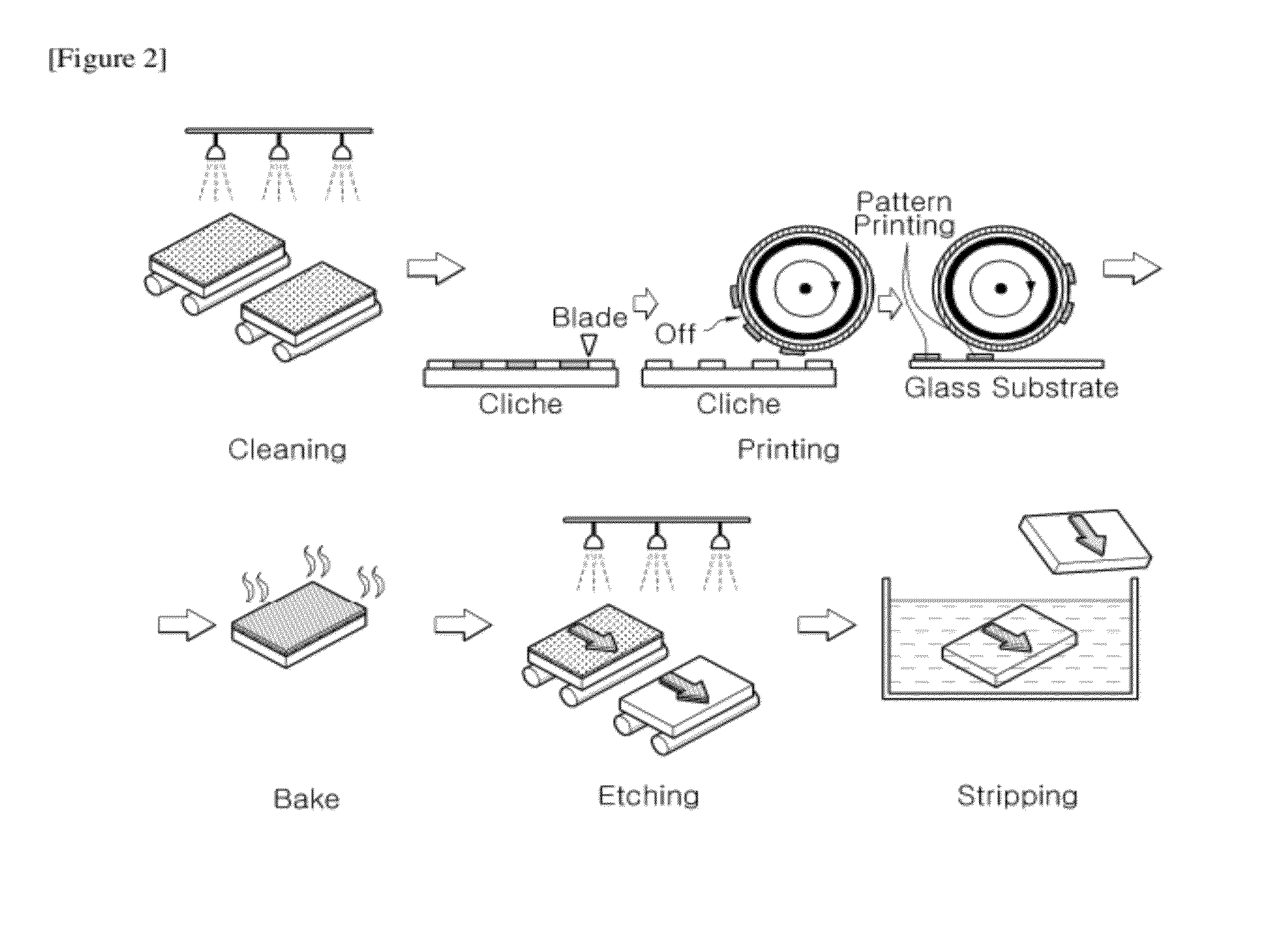

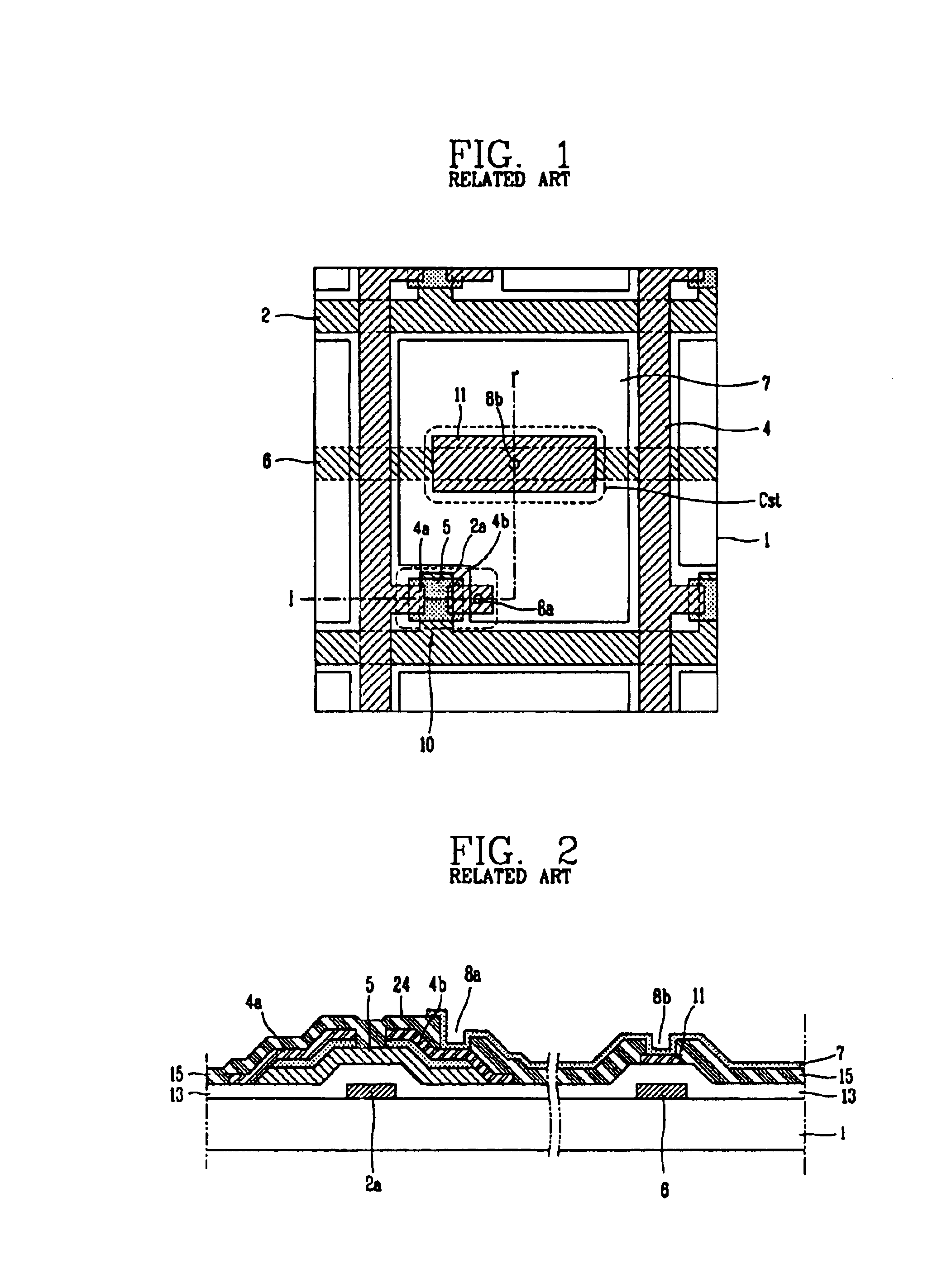

Method for forming pattern using printing process

A method for forming a pattern using a printing process is disclosed in the present invention. The method includes forming a resist layer on a substrate having an etching layer thereon, locating a master having a convex pattern over the substrate, pressing the master against the substrate until the convex pattern of the master directly contacts the etching layer, and removing a portion of the resist layer to expose a surface over the substrate, the removed portion of the resist layer having a width substantially the same as the convex portion of the master.

Owner:LG DISPLAY CO LTD

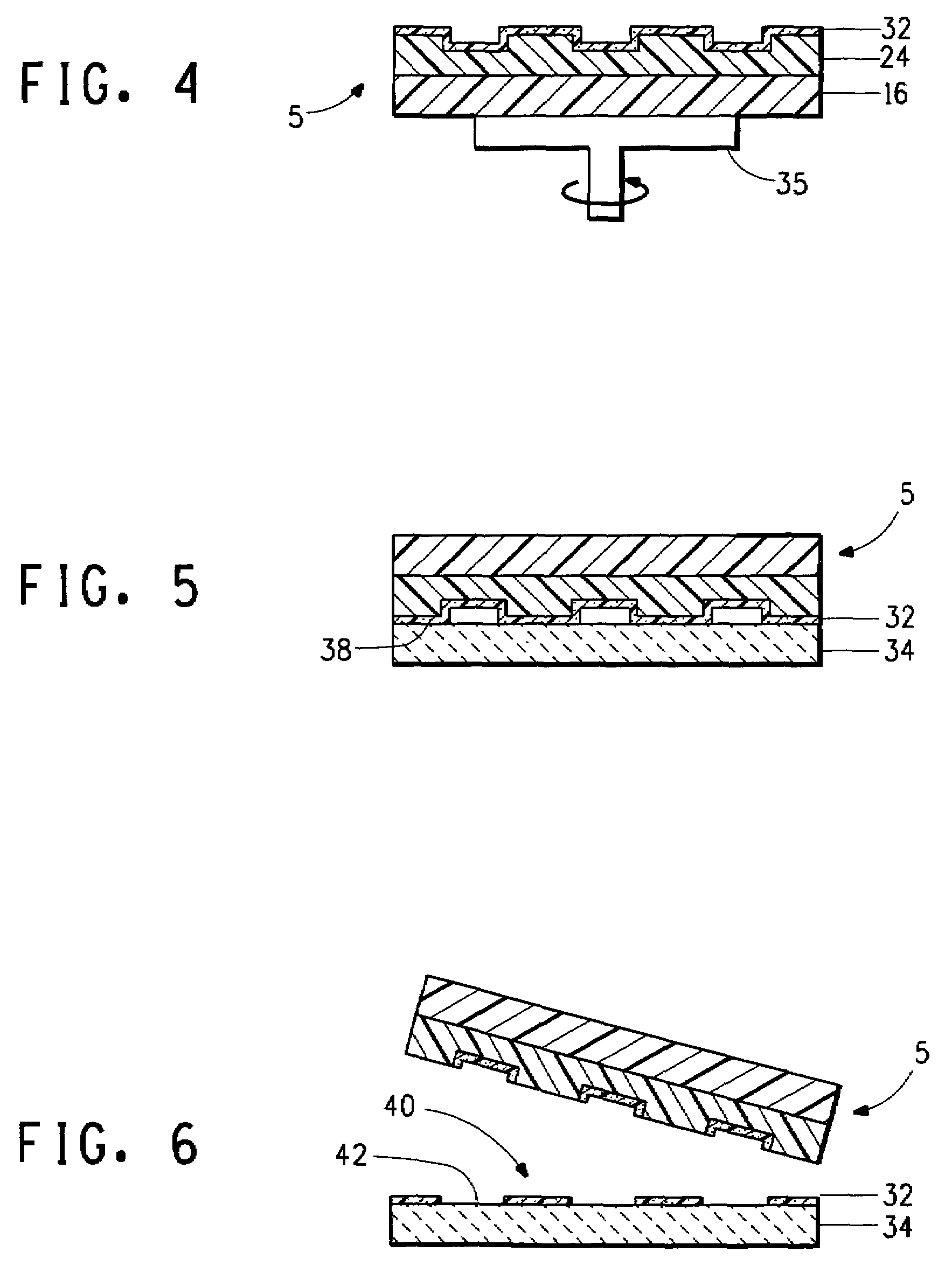

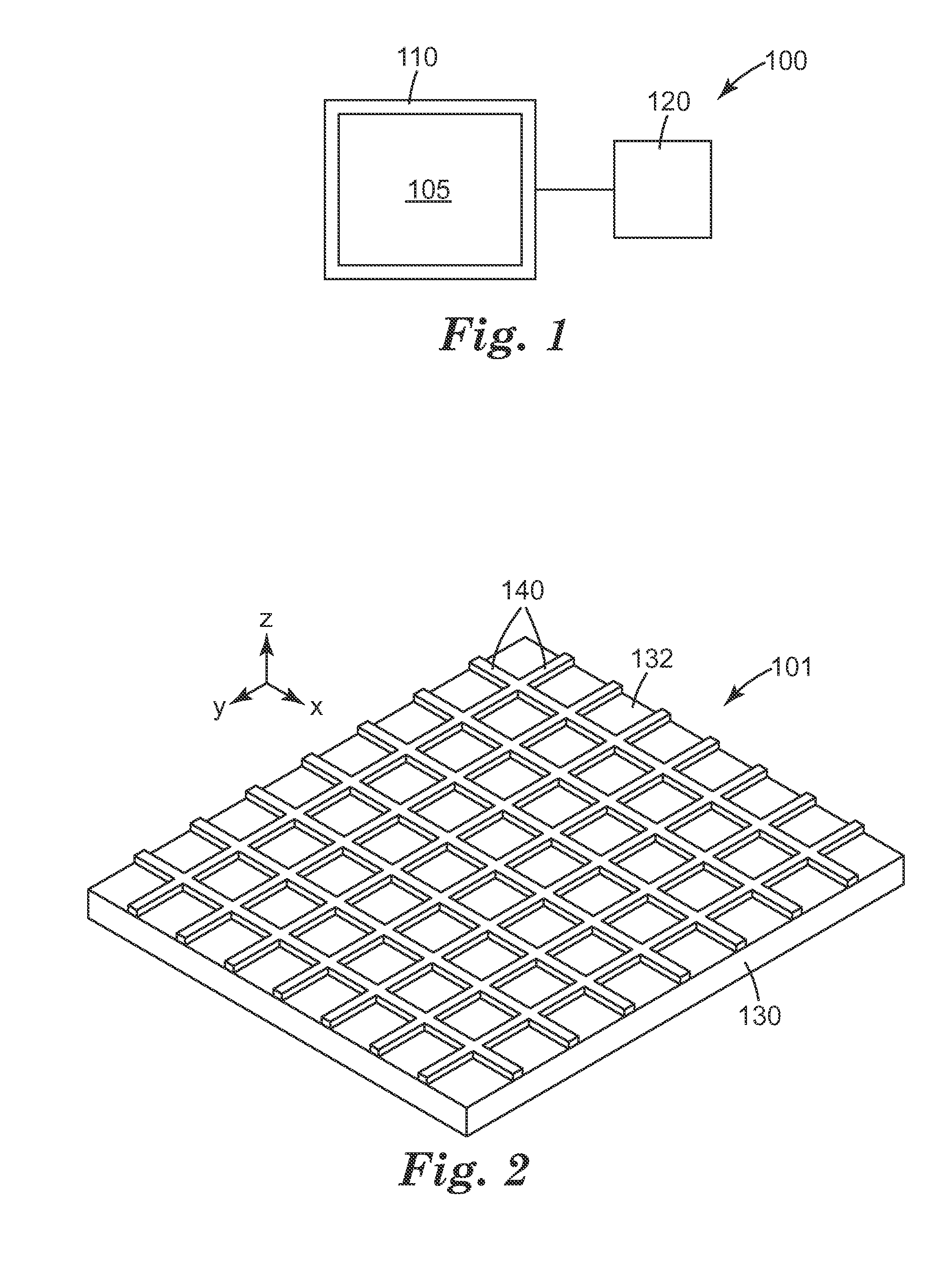

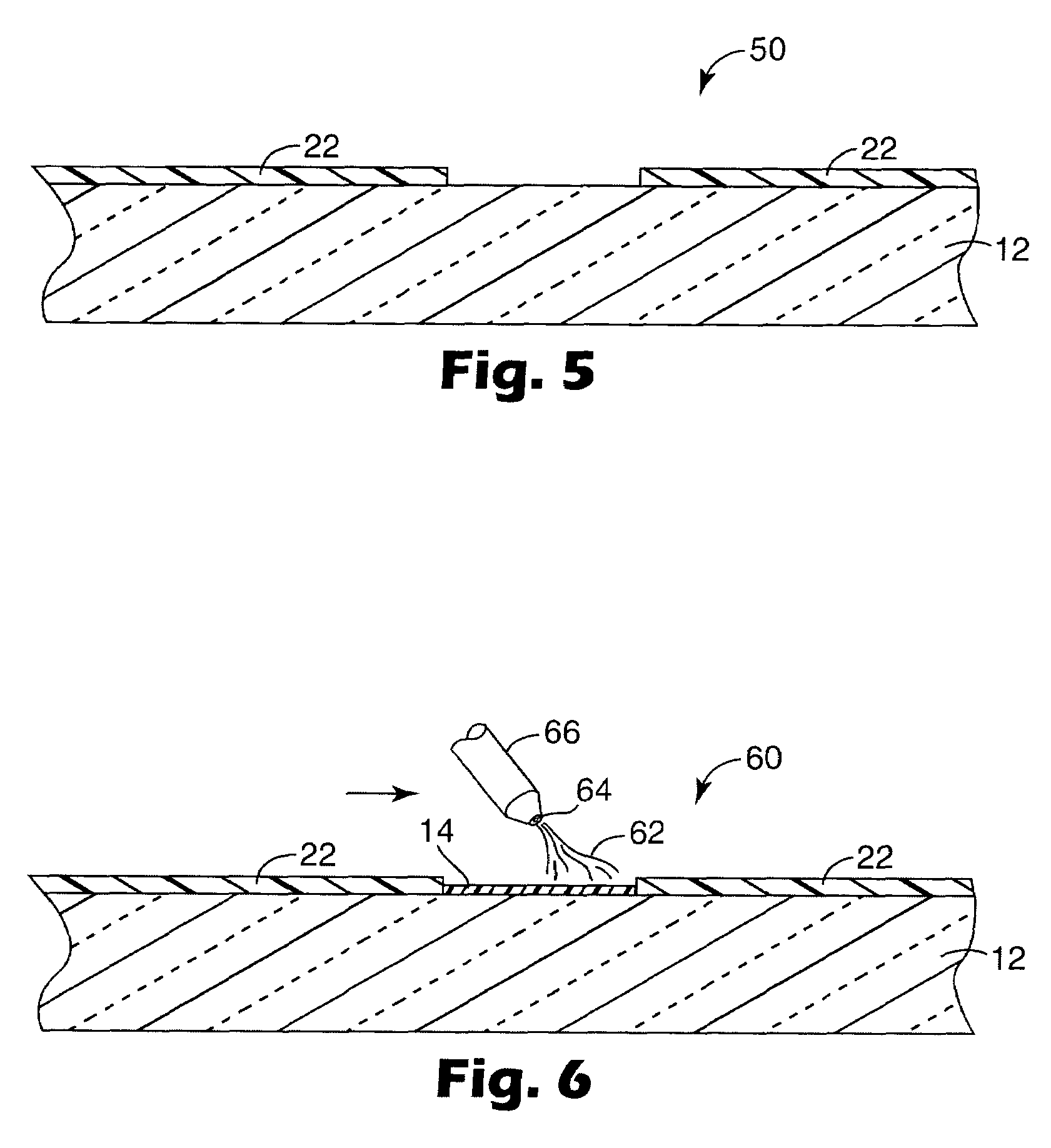

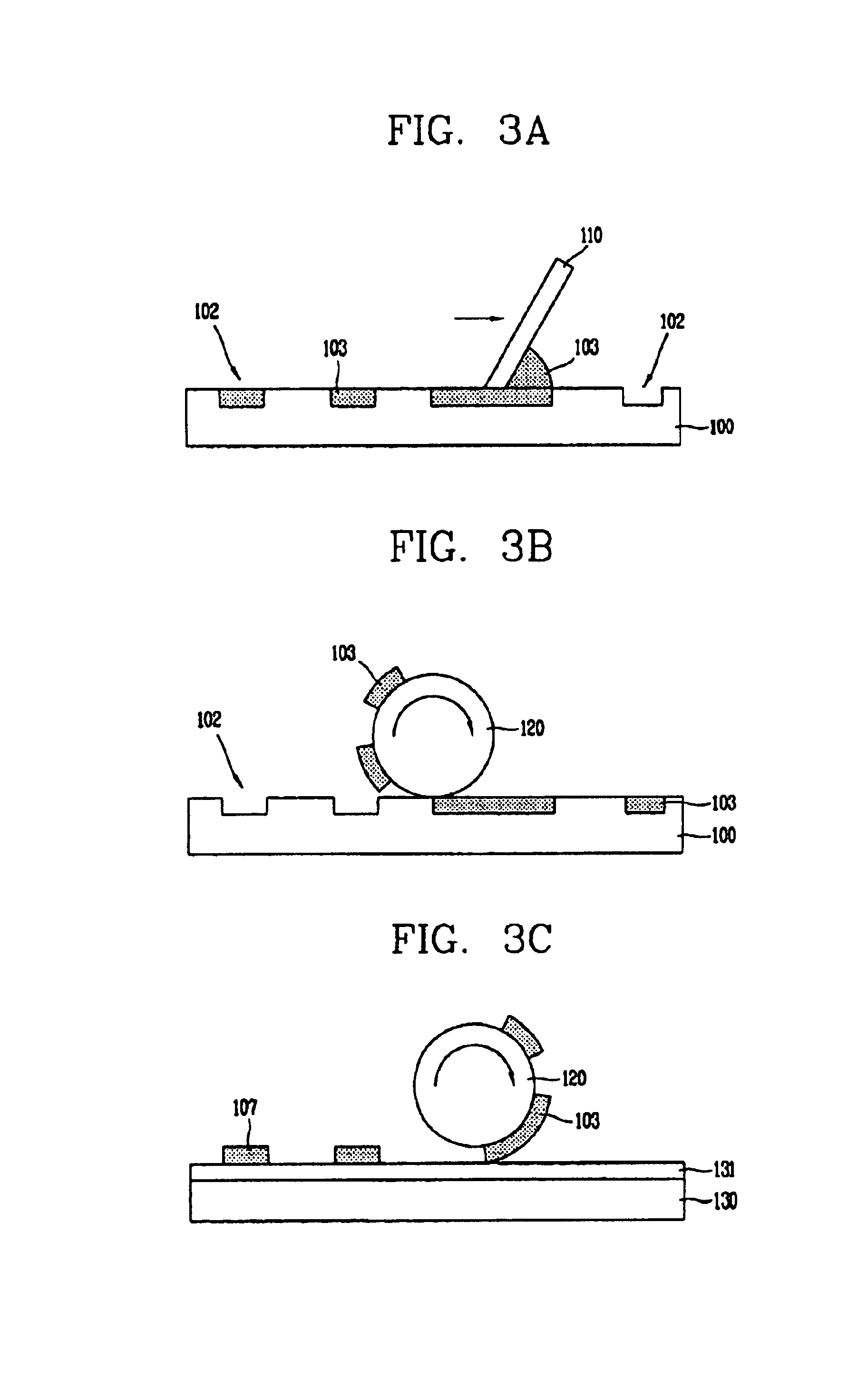

Methods and apparatus for the manufacture of microstructures

InactiveUS8124325B2Solve the lack of densityEase peelable removalTransistorLiquid surface applicatorsScale structureSemiconductor

A method of manufacturing microstructures is disclosed, the method comprising a applying a mask to substrate; forming a pattern in the mask; processing the substrate according to the pattern; and mechanically removing the mask from the substrate. A polymer mask is disclosed for manufacturing micro scale structure, the polymer mask comprising a thin, preferably ultra thin flexible film. A method of manufacturing an integrated circuit is disclosed, the method comprising forming a plurality of isolated semiconductor devices on a common substrate; and connecting some of the devices. Apparatus for manufacturing microstructures is disclosed comprising: a mechanism for coating a mass substrate to create a structure; a mechanism for removing a mask from the substrate; and processing apparatus. A thin film transistor is disclosed comprising drain source and gate electrodes, the drain and source electrode being separated by a semiconductor, and the gate electrode being separated from the semiconductor by an insulator, comprising a bandgap alignment layer disposed between a semiconductor and the insulator.

Owner:3T TECH

Ceramic substrate and manufacturing method therefor

ActiveUS20200315003A1Increase the areaImprove conductivityTransfer patterningSemiconductor/solid-state device detailsUltimate tensile strengthCeramic substrate

A ceramic substrate is provided in which an inclined protrusion is formed on boundary surface of a metal layer bonded to a ceramic base so as to increase bonding strength; and a manufacturing method therefor. The inclined protrusion may include: a tapered protrusion and a multi-stepped protrusion formed on the boundary surface of the metal layer according to an interval between the metal layer bonded to the ceramic base and a neighboring metal layer, wherein a multi-stepped protrusion having an inclination angle within a predetermined angle range with respect to the ceramic base may be formed on the boundary surface of the metal layer where stress is concentrated, such as the short edge, apex, corner, and the like, and a tapered protrusion may be formed on a remaining portion of the boundary surface of the metal layer.

Owner:AMOSENSE

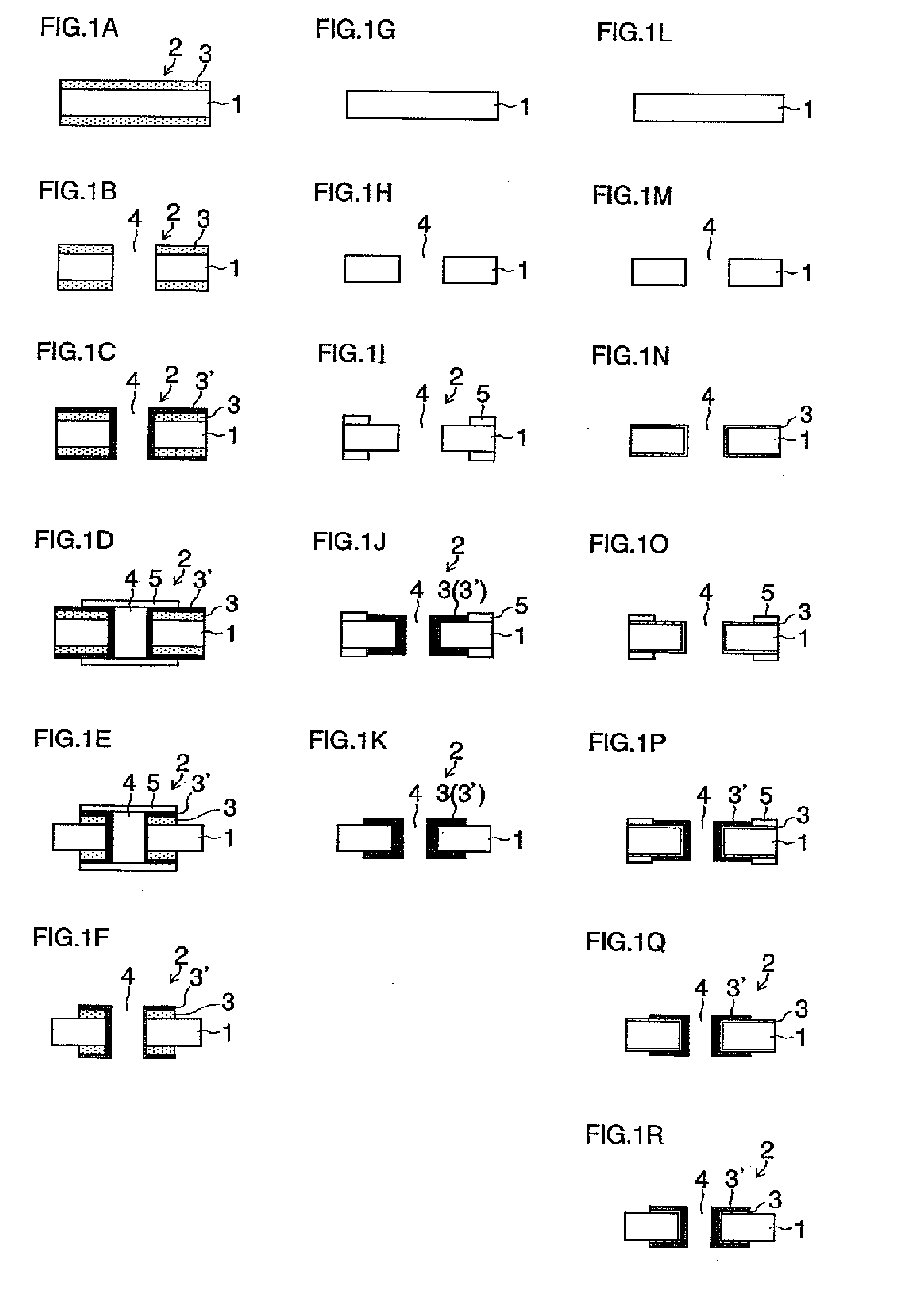

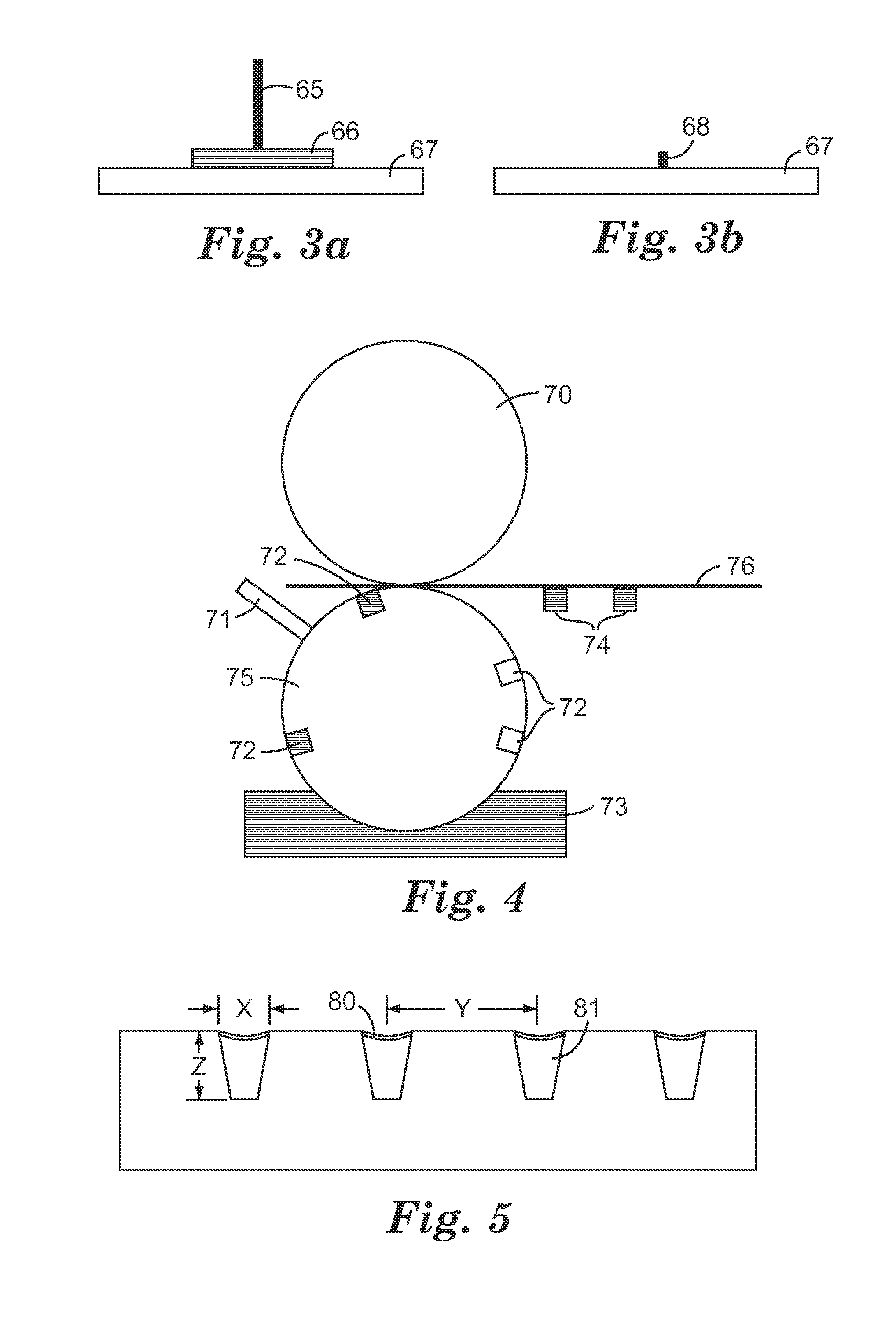

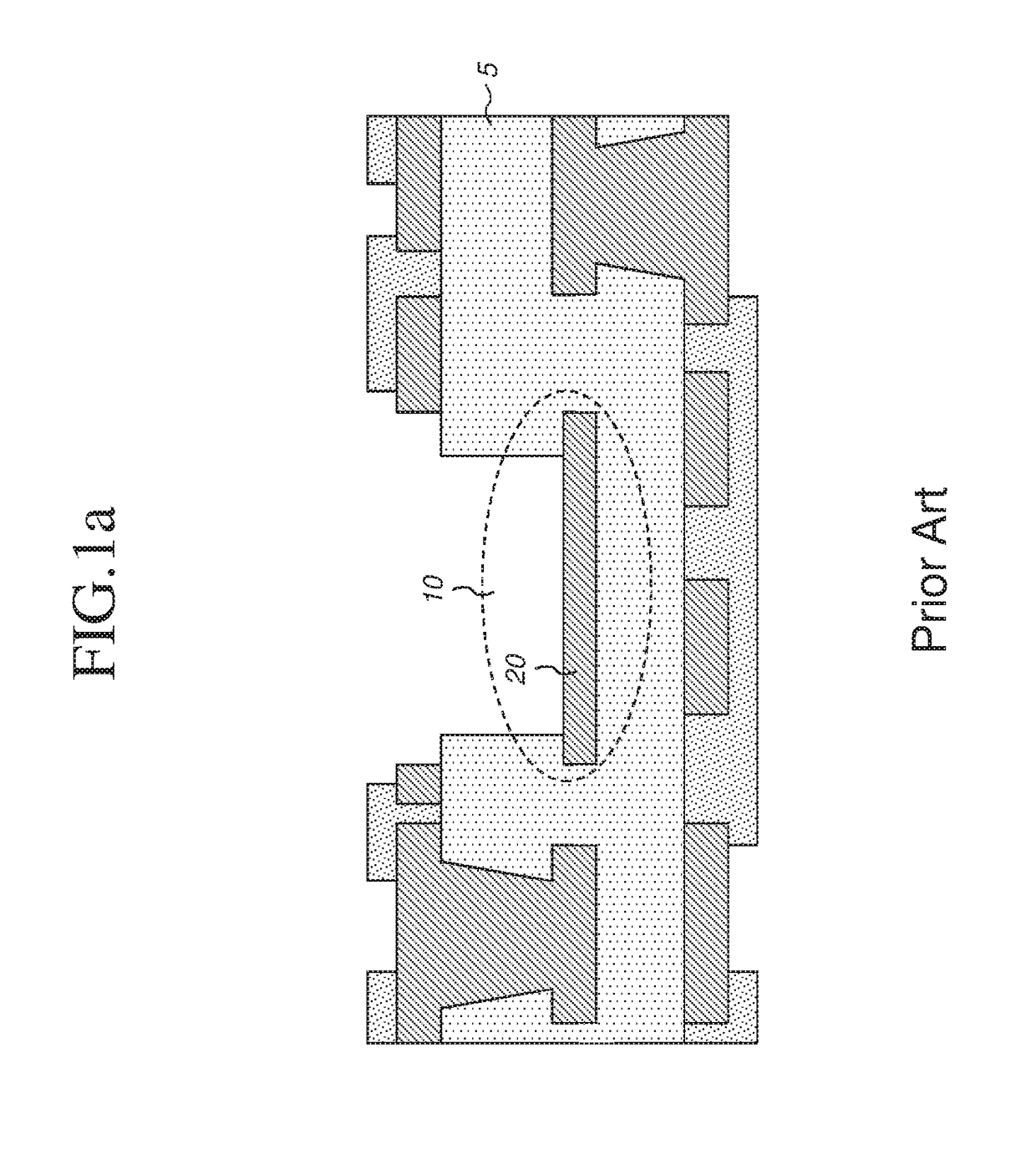

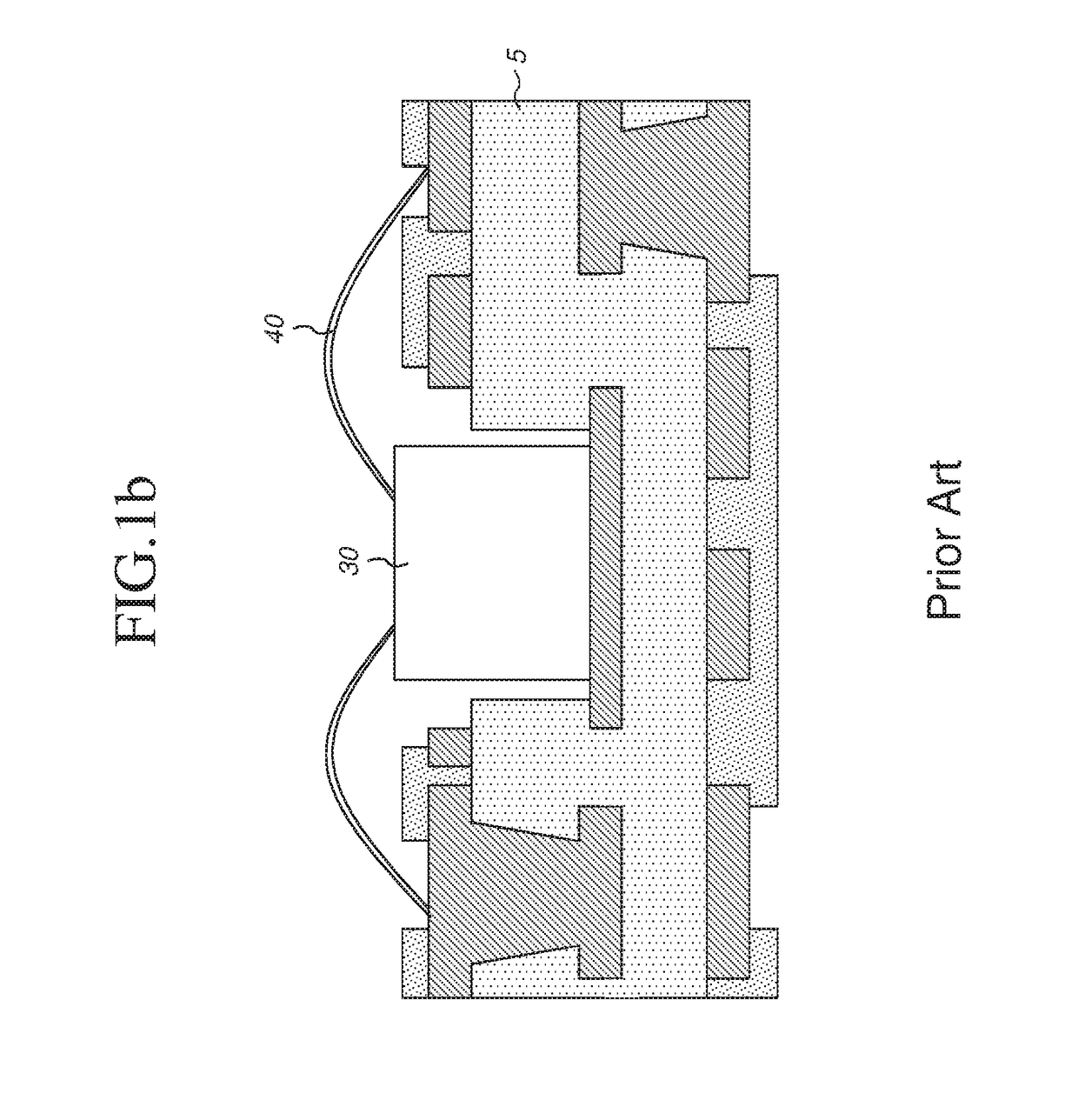

Printing plate, method of fabricating the same, and method of fabricating flat panel display using the same

ActiveUS20070048667A1Improve accuracyHigh precision formingNanoinformaticsSolid-state devicesResistDisplay device

A method of fabricating a printing plate includes: preparing a substrate; forming a metal layer on an entire surface of the substrate; forming a resist pattern on the metal layer, the resist pattern having a fine pattern exposing a portion of the metal layer; wet etching the exposed metal layer, and removing the resist pattern to form a metal layer pattern exposing a portion of the substrate; wet etching the exposed substrate, and removing the metal layer pattern to form a recessed pattern; and forming a compensation layer on an entire surface of the substrate where the recessed pattern is formed.

Owner:LG DISPLAY CO LTD

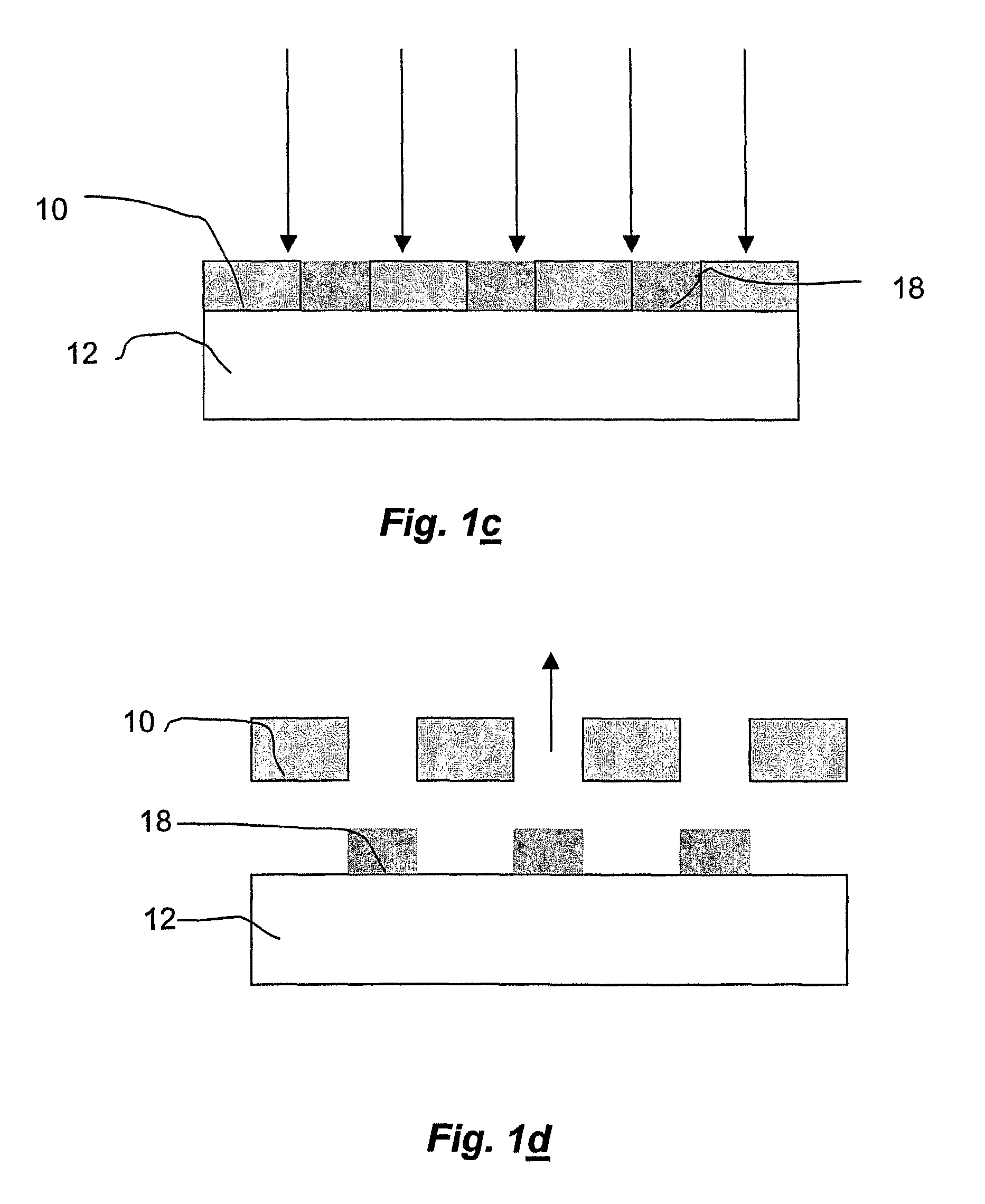

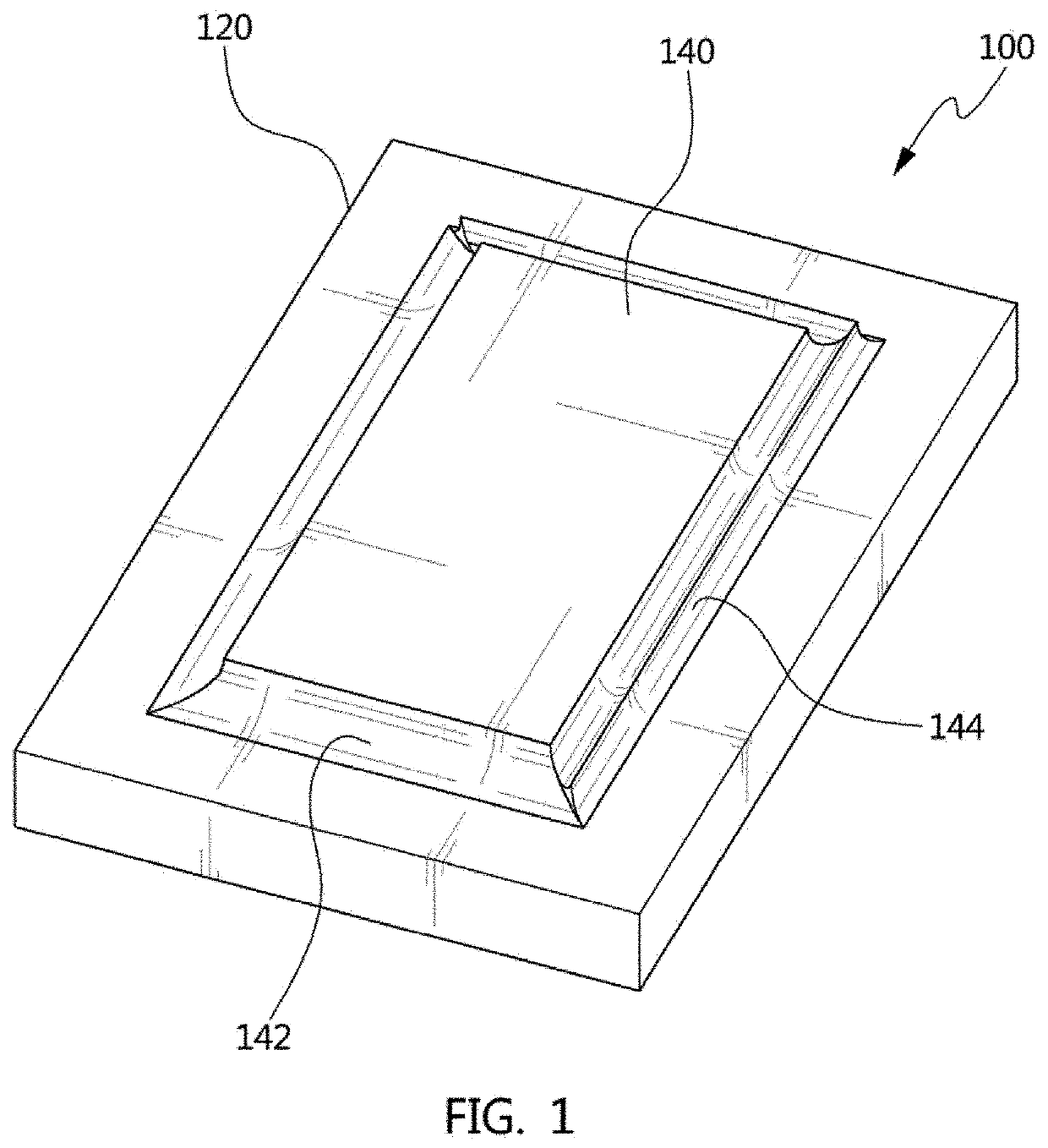

Masking substrates for application of protective coatings

ActiveUS20140192464A1Aesthetically pleasingLiquid surface applicatorsCircuit arrangements on support structuresMaterials scienceCoating

A method for applying a protective coating to selected portions of a substrate is disclosed. The method includes applying a mask to or forming a mask on at least one portion of the substrate that is not to be covered with the protective coating. The mask may be selectively formed by applying a flowable material to the substrate. Alternatively, the mask may be formed from a preformed film. With the mask in place, the protective coating may be applied to the substrate and the mask. A portion of the protective coating that overlies the mask may be delineated from other portions of the protective coating; for example, by cutting, weakening or removing material from the protective coating at locations at or adjacent to the perimeter of the mask. The portion of the protective coating that overlies the mask, and the mask, may then be removed from the substrate.

Owner:HZO INC

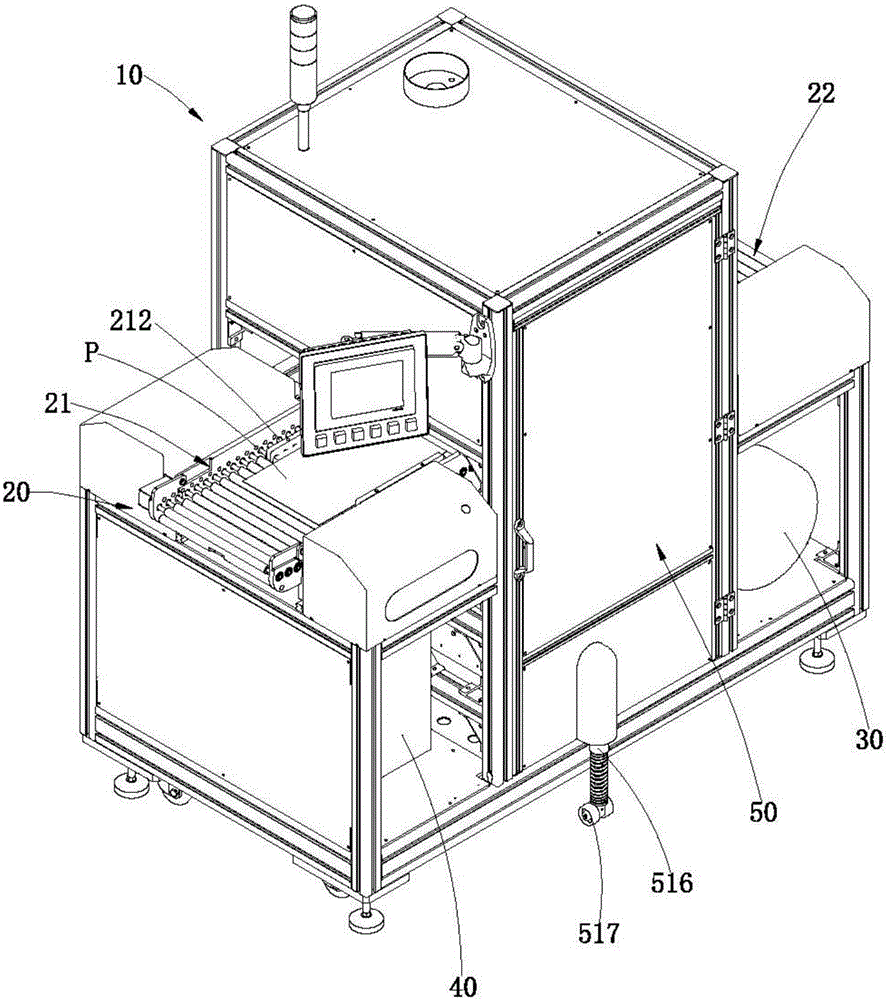

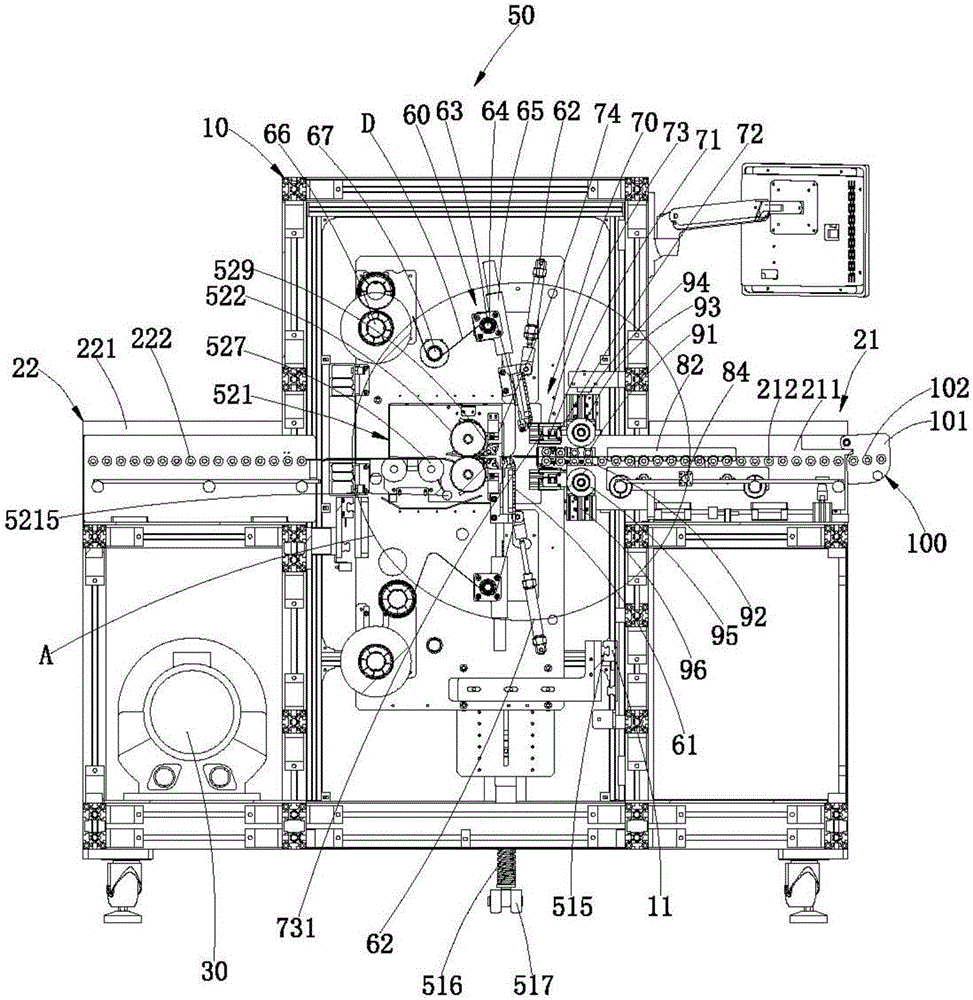

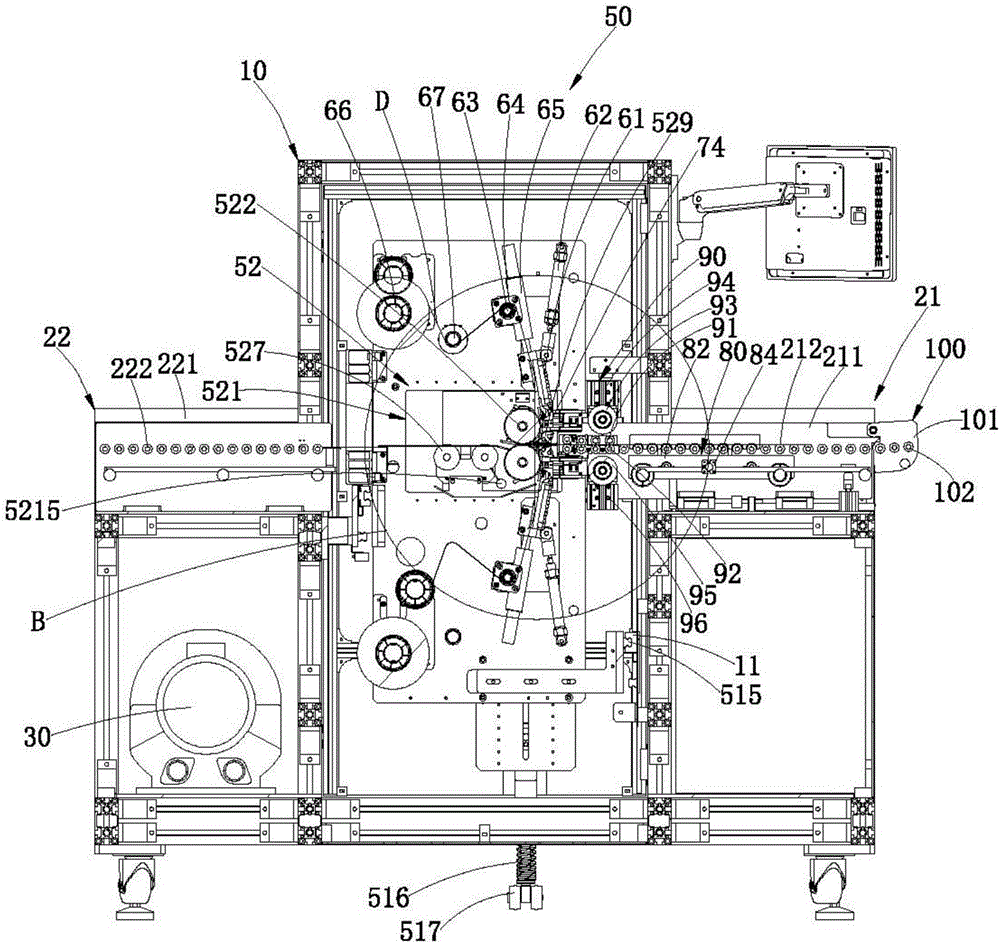

Film mounting machine

ActiveCN106304650AImprove yield rateAvoid Overlapping FilmsCircuit masks application/removalEngineeringElectrical and Electronics engineering

The present invention relates to the field of automated equipment, and more particularly to a film mounting machine. The machine is used for mounting a dry film on a printed board, and comprises a machine frame, a transmitting device installed on the machine frame to transmit a printed board, a film mounting module in sliding connection with the machine frame and to have the dry film attached on the surface of the printed board and a control device for controlling the electric components of the transmitting device and the film mounting module to work. In the invention, the film mounting machine can drive the film pressing roll of a film pressing driving device to move in the direction of a printed board so as to press tightly the printed board with a pre-attached dry film. This replaces the traditional method in which a flexible printed board is transmitted under the film pressing roll, and ensures that when the film pressing roll presses tightly a printed board, the problem of film overlapping and bending caused by the breakage of the printed board during transmission can be avoided. The machine can be especially suitable for mounting film on flexible printed boards, and raises the qualification rate of film mounting on the flexible printed boards. In addition, the film mounting process is completely automatic, which saves manpower and cost and increases production efficiency.

Owner:GUANGDONG SOWOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com