Printed circuit board manufacturing method

A technology of printed circuit boards and manufacturing methods, which is applied in the fields of printed circuit manufacturing, method of using/removing circuit masks, printed circuits, etc., can solve the problems of reducing enterprise profits, high production material costs, high scrap rate, etc., and achieve reduction Effects of production cost, shortened production time, and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

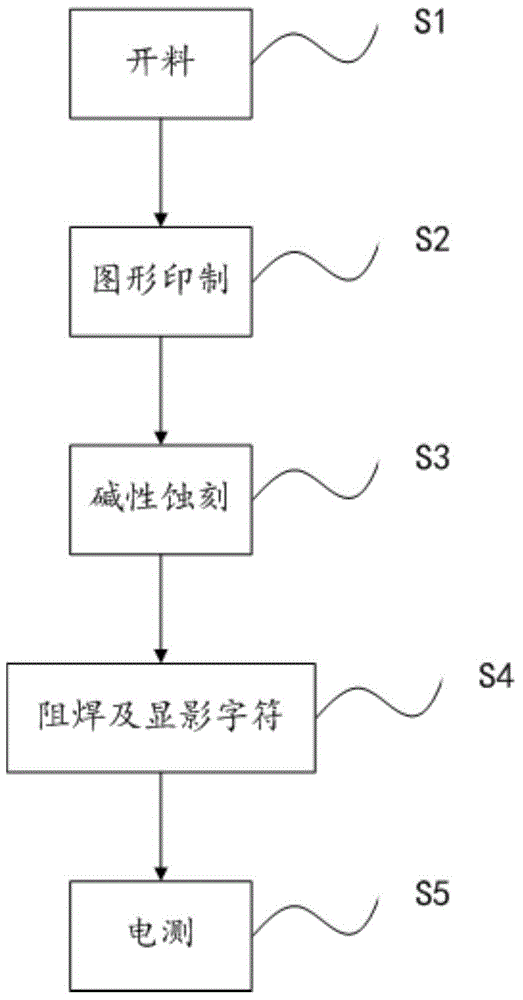

[0054] like figure 1 Shown, a kind of manufacturing method of printed circuit board comprises the following steps:

[0055] S1 cutting to form a jigsaw panel, which includes an inner substrate and copper foil attached to the upper and lower surfaces of the inner substrate;

[0056] S2 graphic printing;

[0057] S3 alkaline etching;

[0058] S4 solder mask and developing characters;

[0059] S5 electric test.

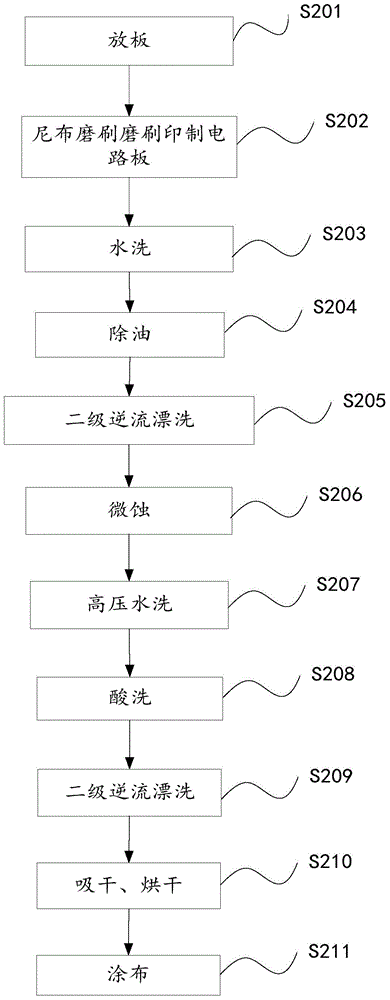

[0060] In the step S2, a wet film is used for graphic printing. like figure 2 As shown, the graphic printing steps described in the step S2 are specifically as follows:

[0061] S201, put the board.

[0062] S202 Nylon brushing is used to grind printed circuit boards. The nylon brush wheel rotates clockwise to form friction with the board surface to roughen and clean the surface of the printed circuit board. In this embodiment, the density of the nylon brush wheel is 800 mesh, the friction range formed by the nylon brush wheel and the printed circuit board is 8mm-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com