Method of manufacturing wiring board

A manufacturing method and wiring substrate technology, applied in the manufacture of printed circuits, removal of conductive materials by chemical/electrolytic methods, reinforcement of conductive patterns, etc., can solve problems such as the risk of damage to electrical insulation and complicated manufacturing processes, and achieve manufacturing Simple process and good electrical insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

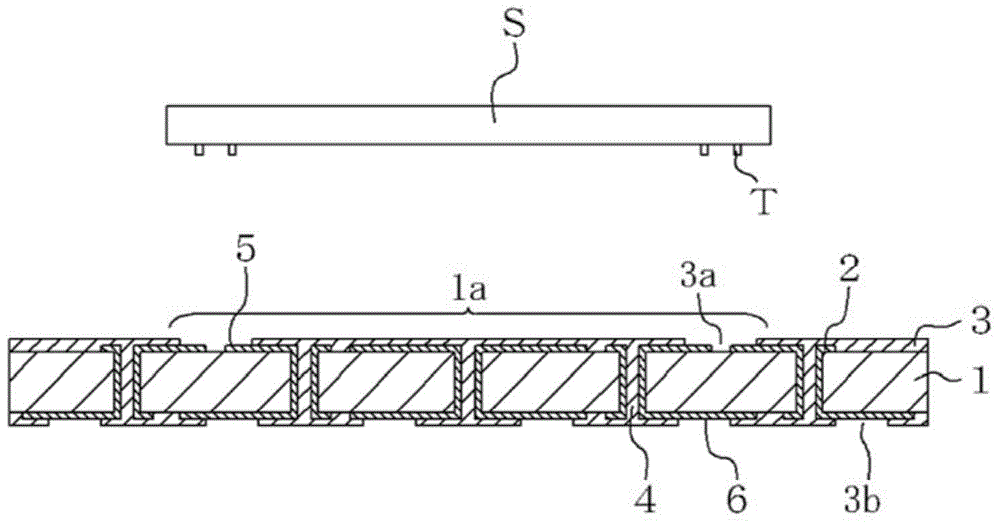

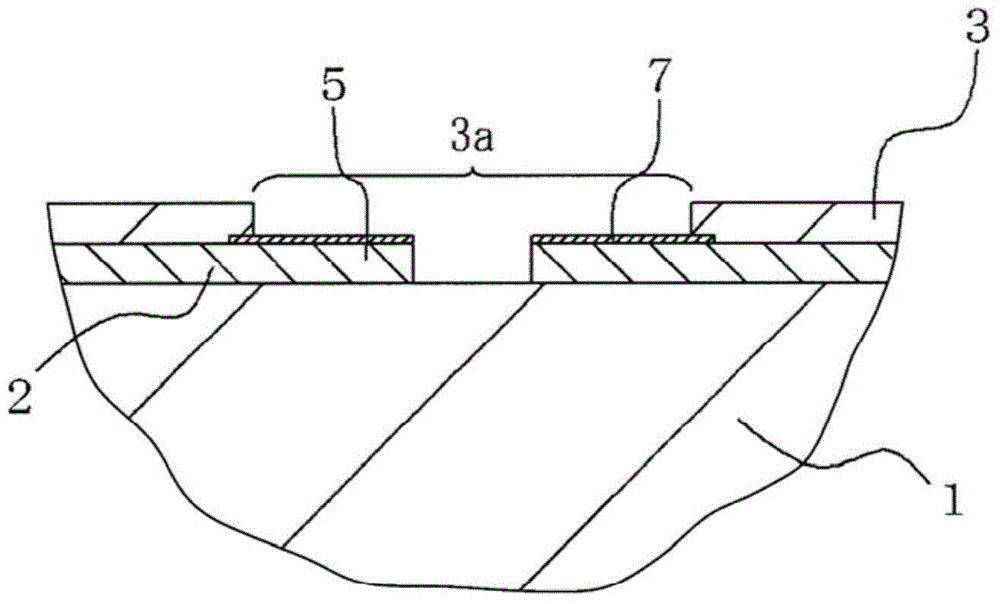

[0054] Next, the method of manufacturing the wiring board of the present invention will be explained based on the drawings. figure 1 It is a schematic cross-sectional view showing an example of a wiring board manufactured by the method of the present invention. figure 2 Yes figure 1 A schematic top view of the wiring board shown. image 3 Yes figure 1 An enlarged cross-sectional view of the main part of the wiring board shown.

[0055] The wiring board includes an insulating substrate 1, a wiring conductor 2, and a solder resist layer 3. in figure 2 In the figure, a dotted line indicates the portion covered by the solder resist layer 3 in the wiring conductor 2 on the upper surface of the insulating substrate 1.

[0056] The insulating substrate 1 is made of a resin-based electrical insulating material that heats a single-layer or multiple-layer insulating layer. The insulating layer is obtained by impregnating a glass cloth base material with a thermosetting resin such as epo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com