Electric motor

An electric motor and brush technology, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of large motor casing, difficult to install noise reduction components, interference, etc., and achieve miniaturization and prevent components from interfering. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

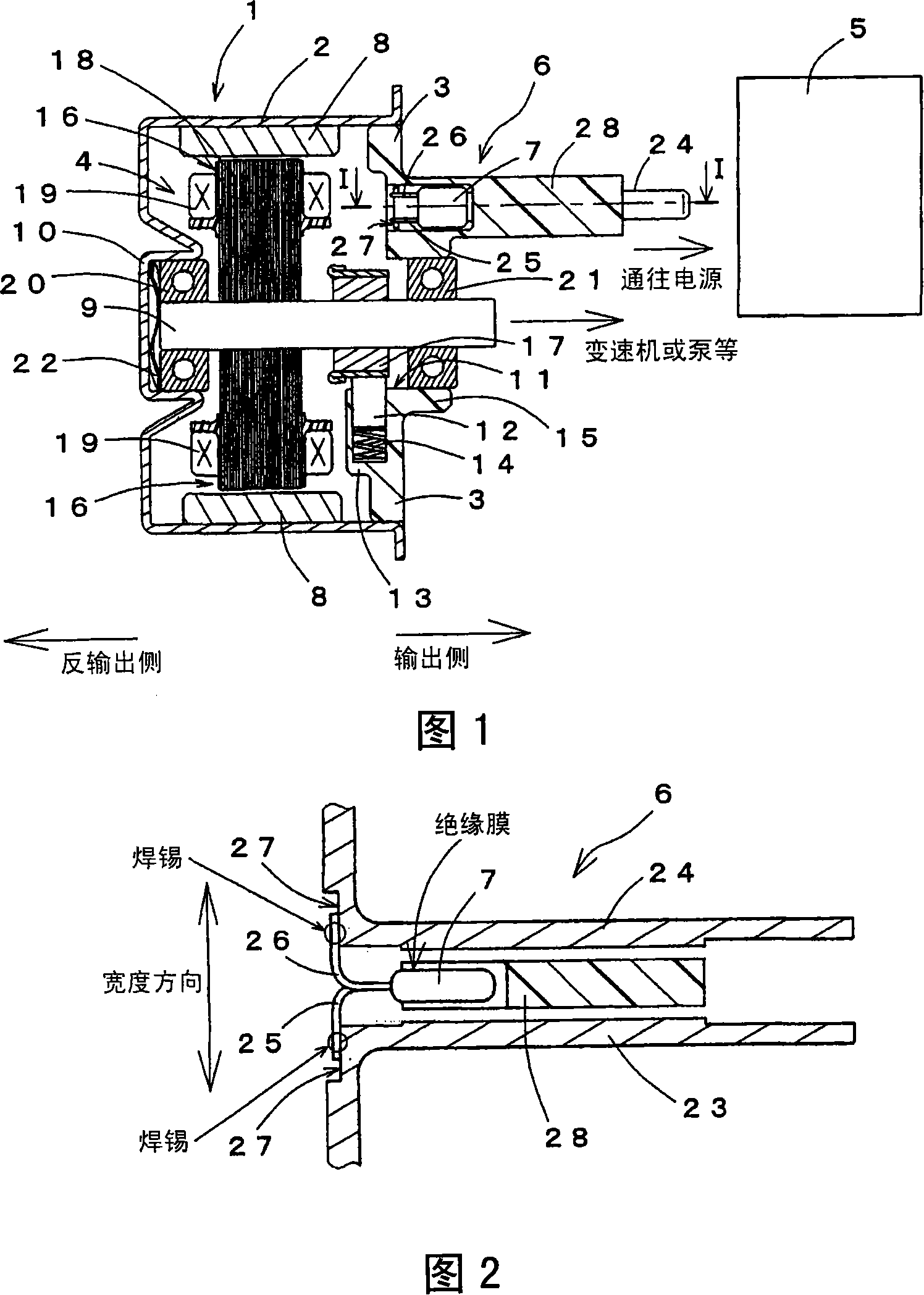

[0021] Hereinafter, a DC electric motor 1 used for automobile parts and the like according to the present invention will be described in detail with reference to FIGS. 1 and 2 .

[0022] FIG. 1 is a sectional view of an electric motor 1 related to the present invention. The electric motor 1 has a substantially bottomed cylindrical motor case 2 opened on the output side, a plate-shaped bottom plate 3 formed to close the opening of the motor case 2 , and a hollow space formed by the motor case 2 and the bottom plate 3 . The rotor 4 within the section, the power supply connector 6 formed on the output side from the power supply 5 to supply power to the rotor 4, and the capacitor 7 (noise reduction element) for noise reduction.

[0023] The motor case 2 is made of metal, and a plurality of magnets 8 are fixed to its inner peripheral surface at equal intervals along the circumferential direction. In addition, a bearing holding portion 10 is integrally formed on the motor housing 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com